Patents

Literature

33results about How to "Improved acid distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

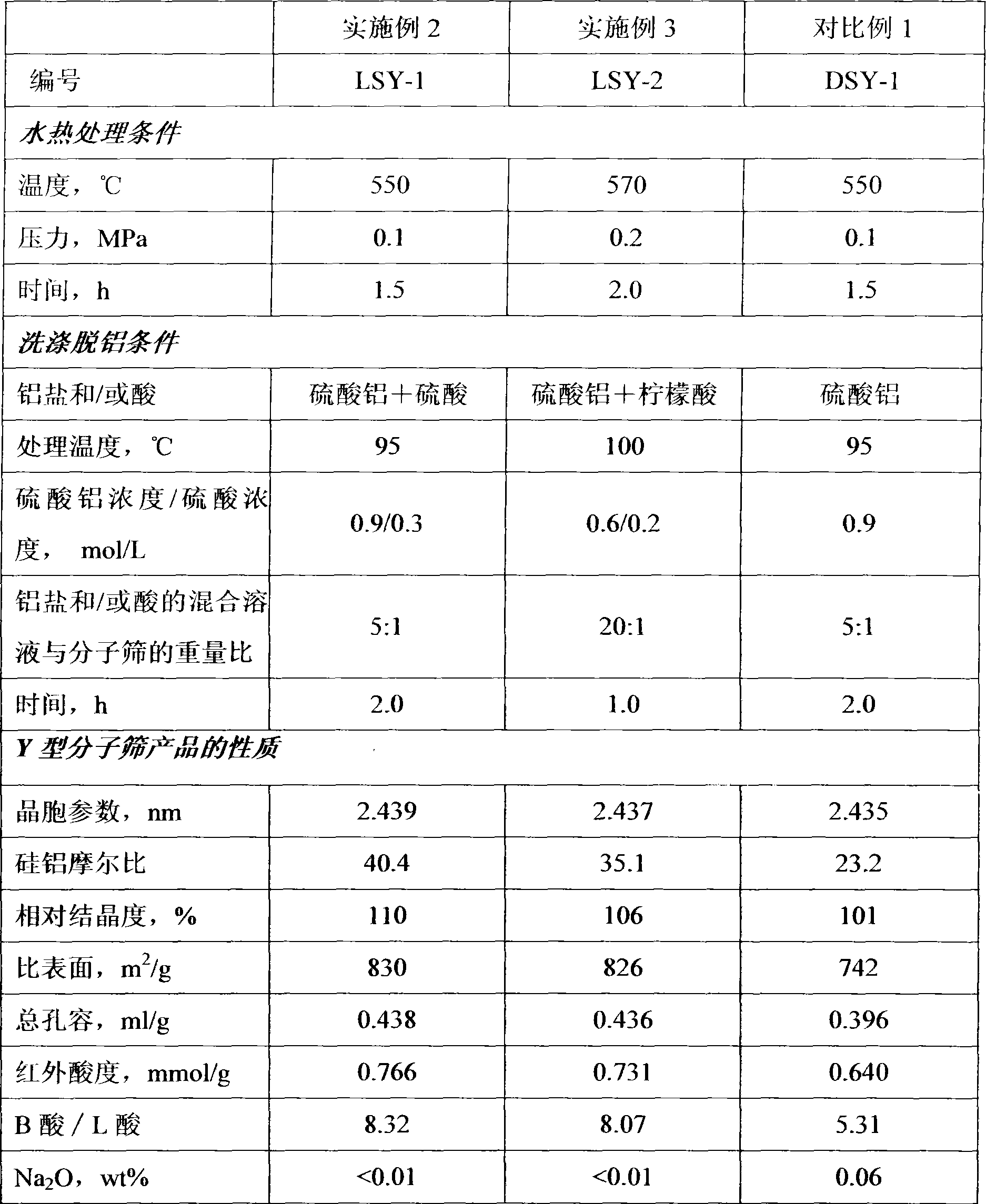

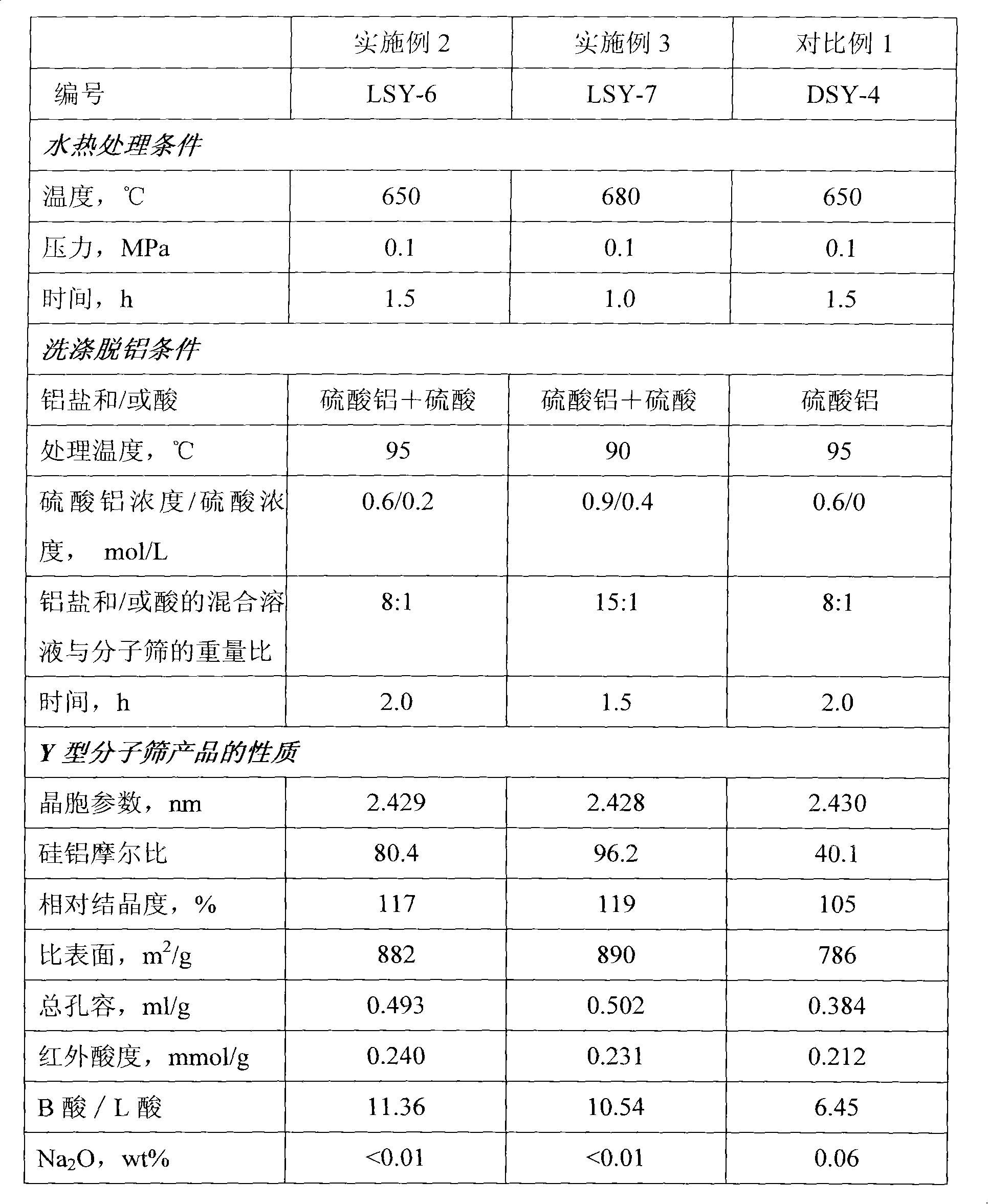

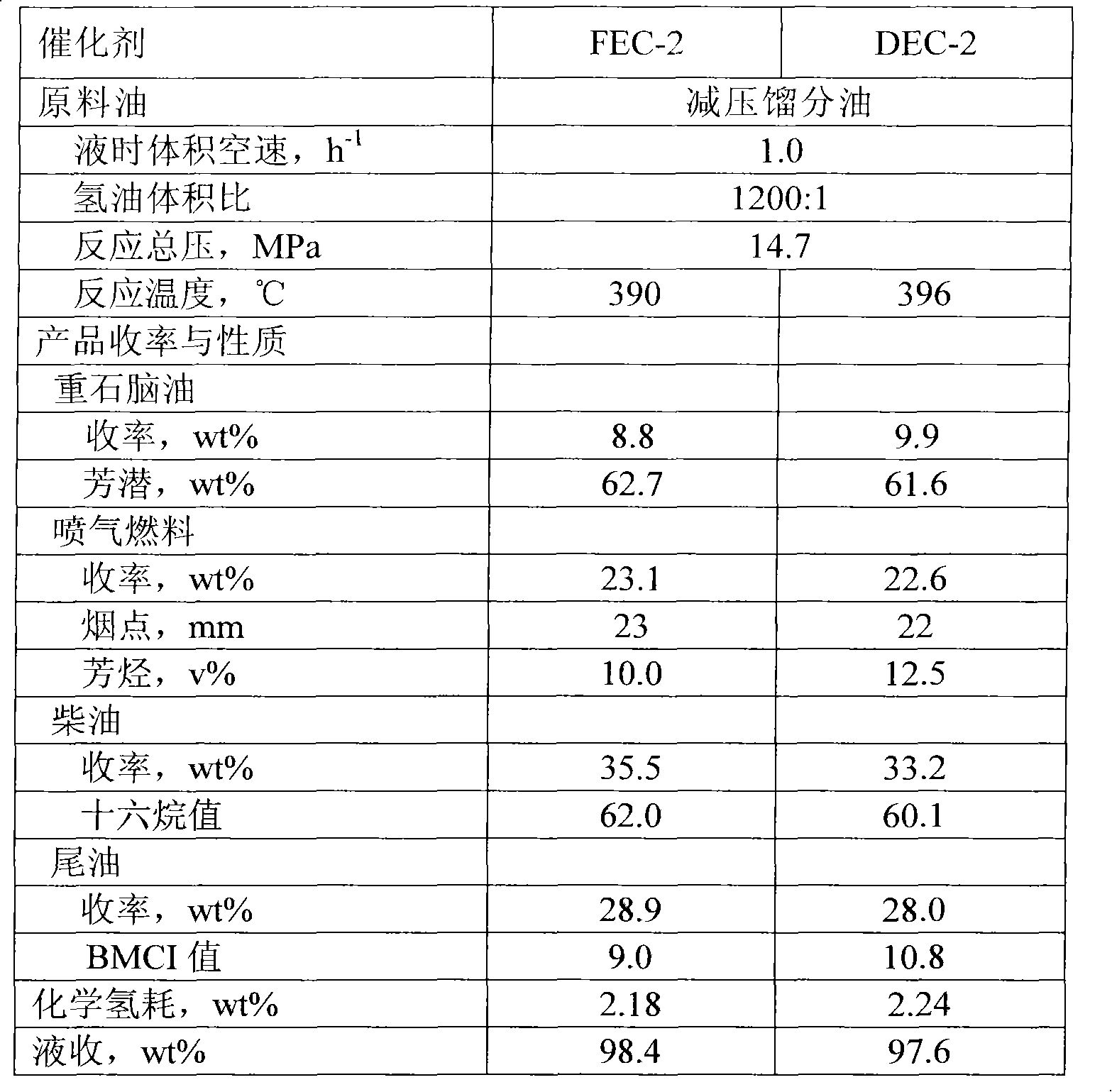

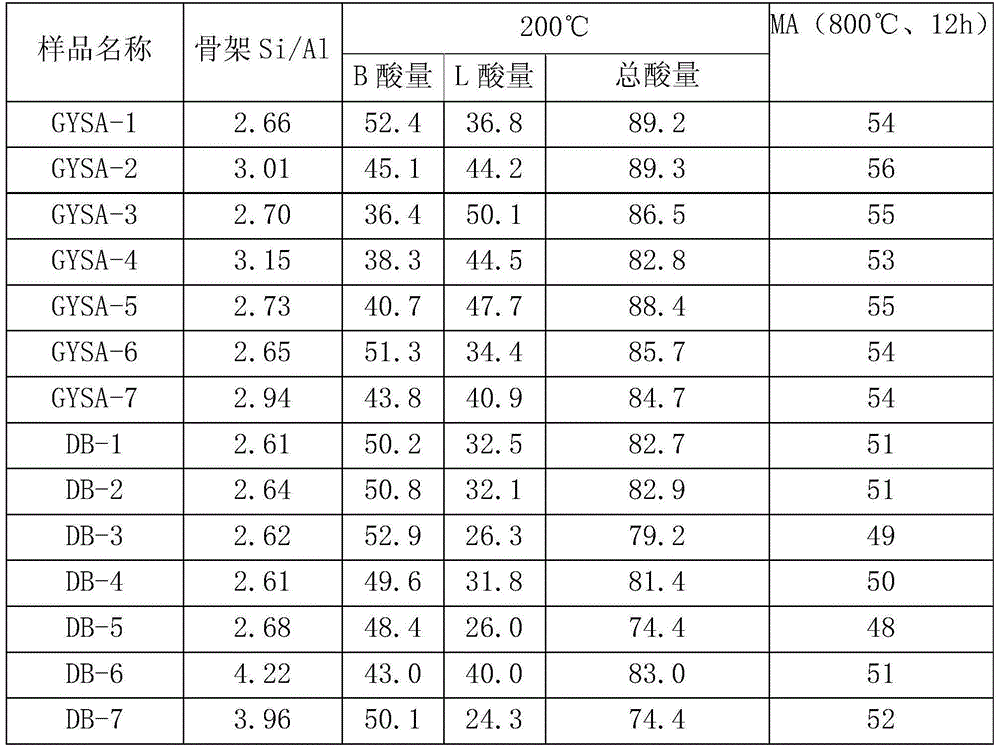

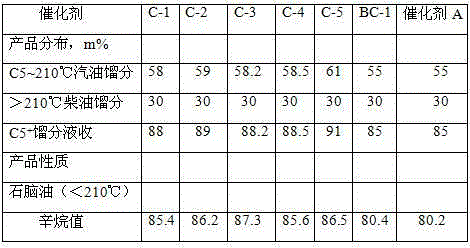

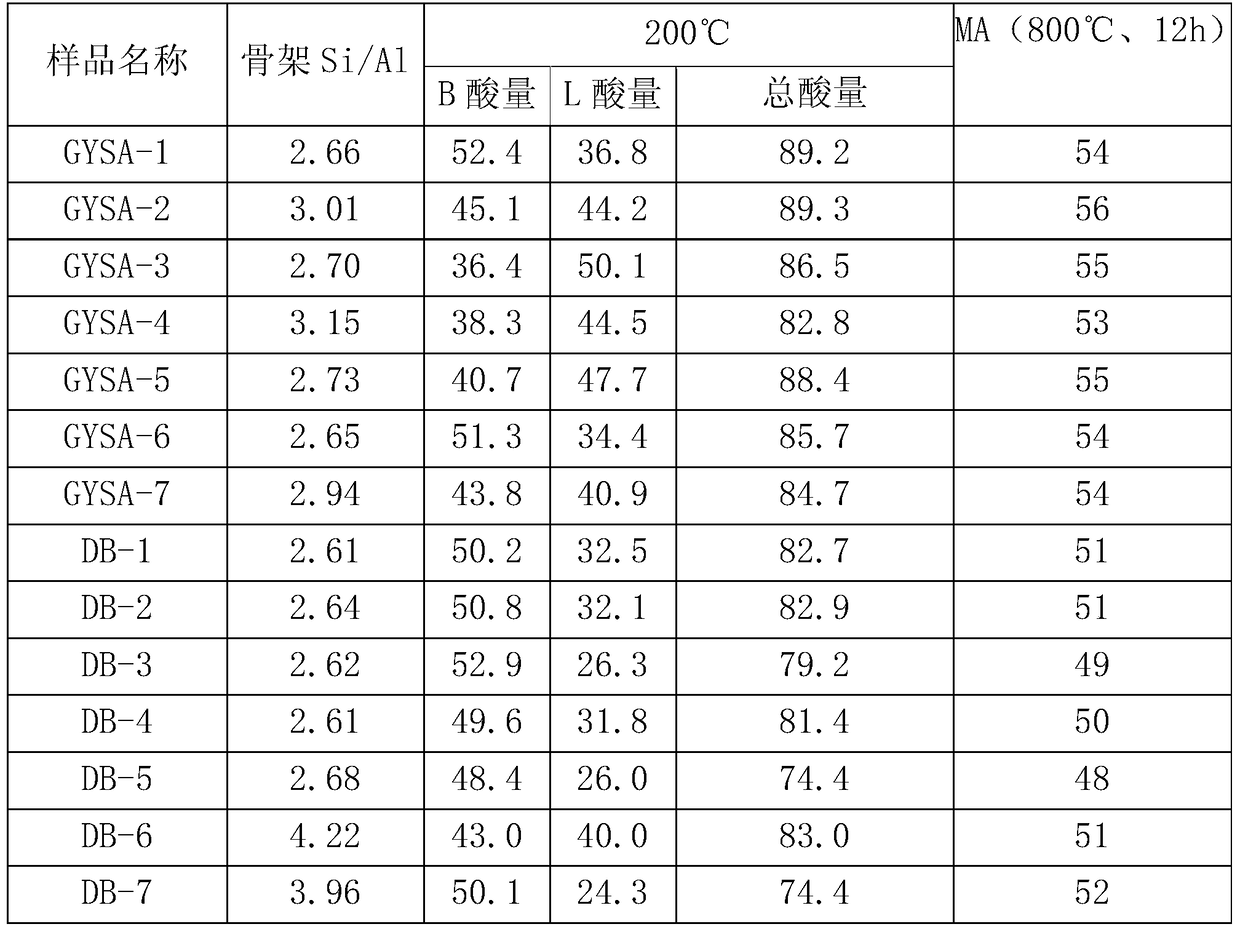

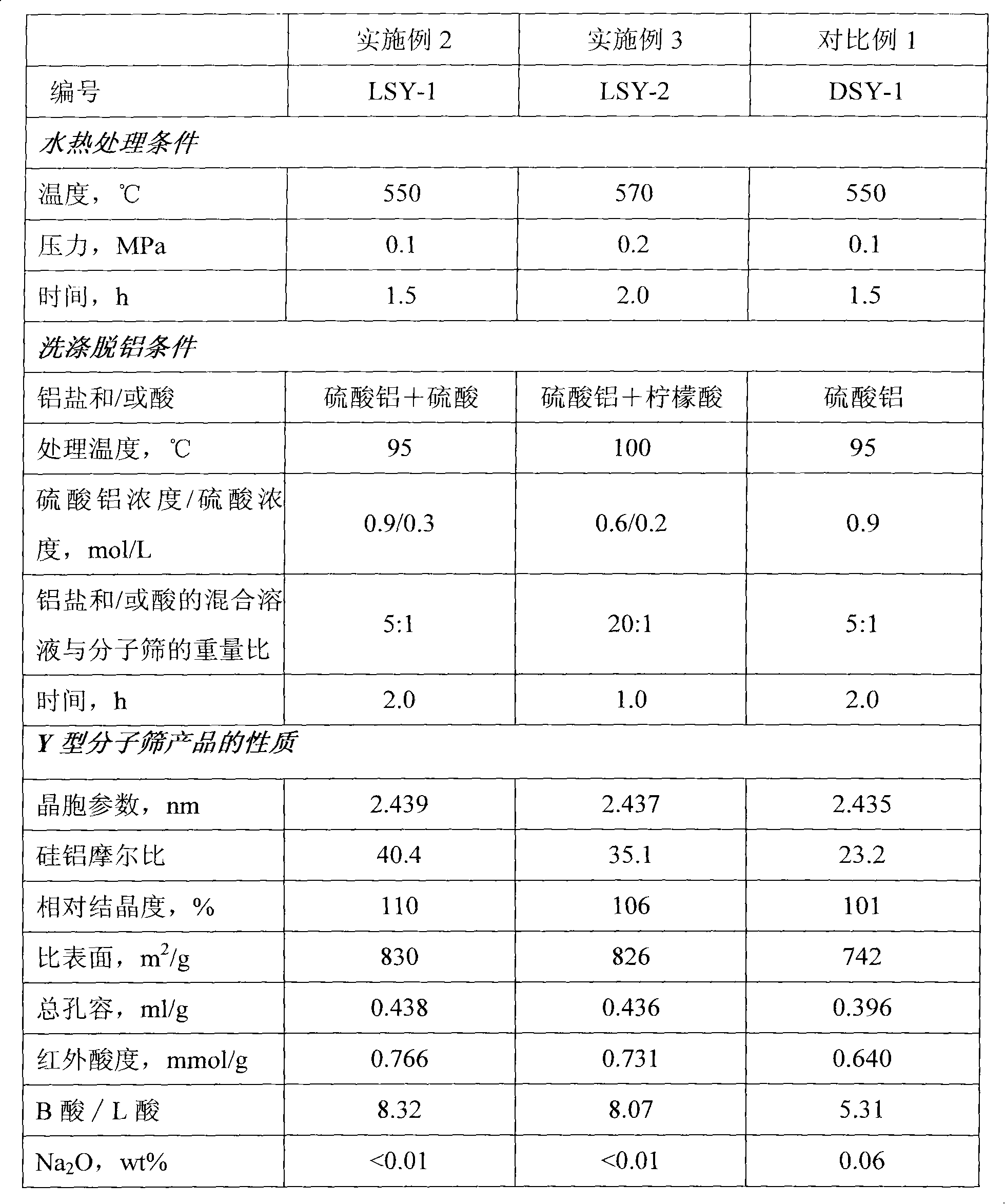

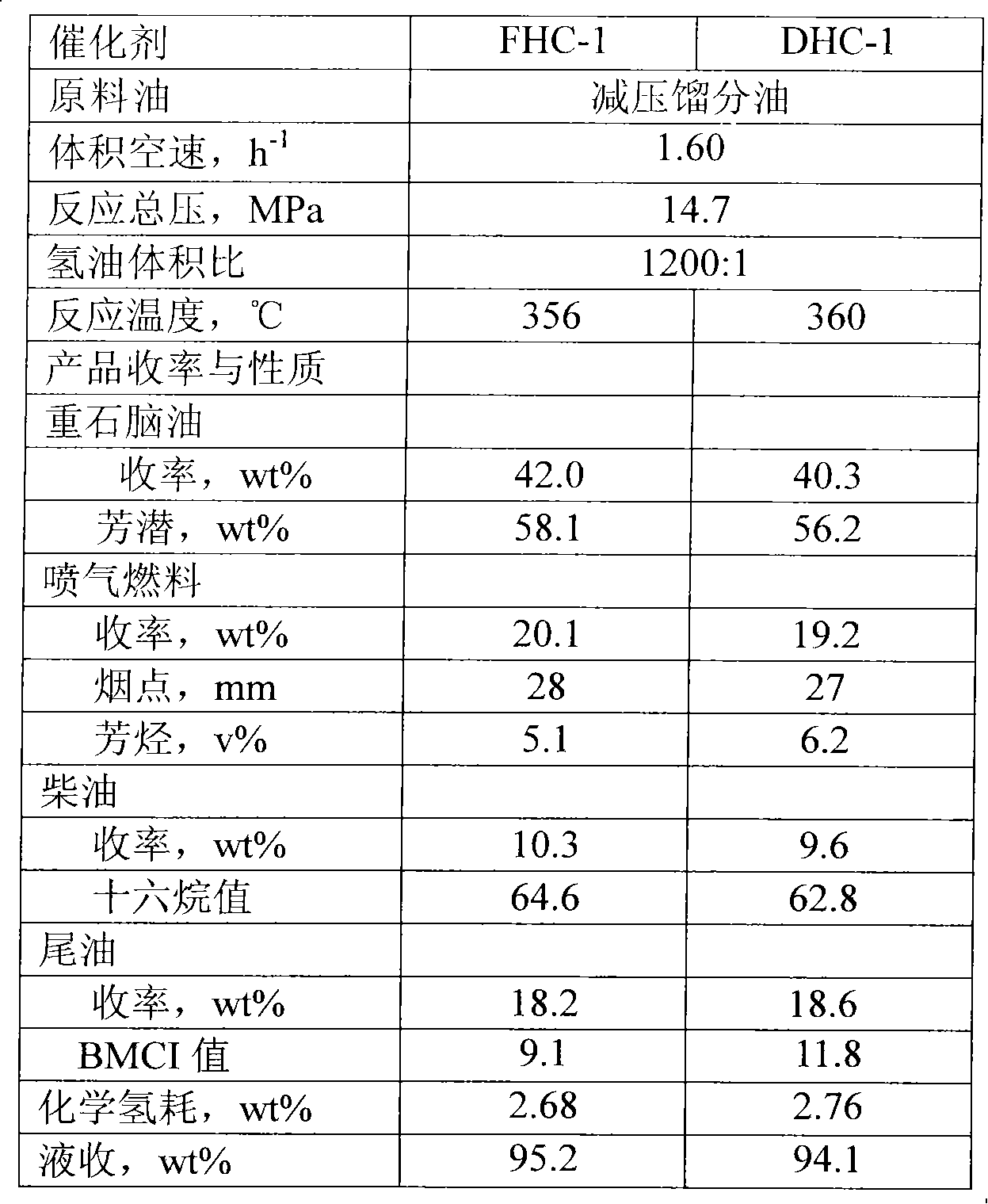

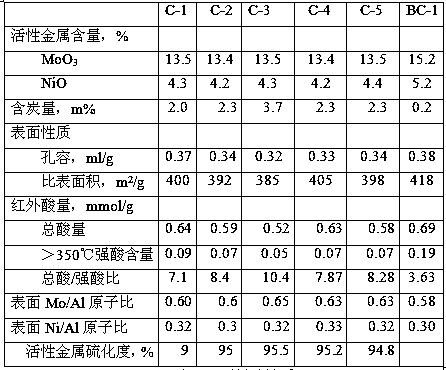

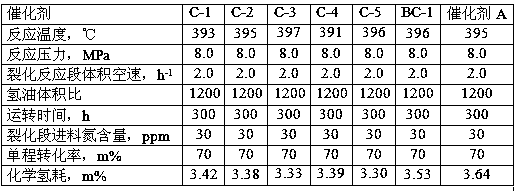

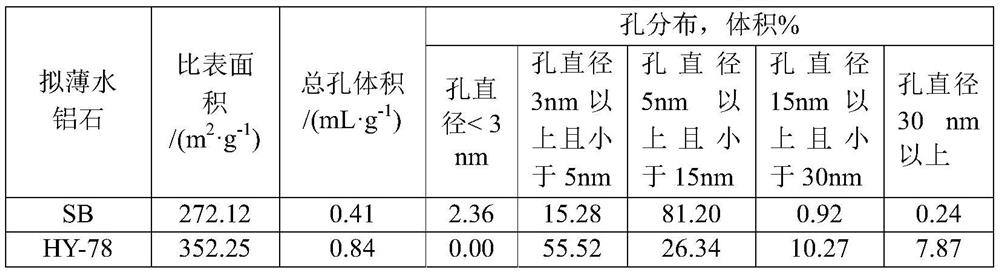

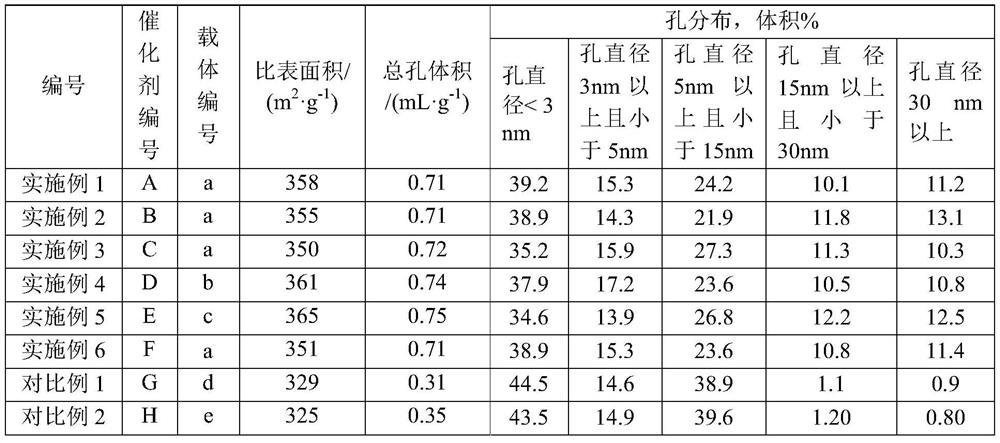

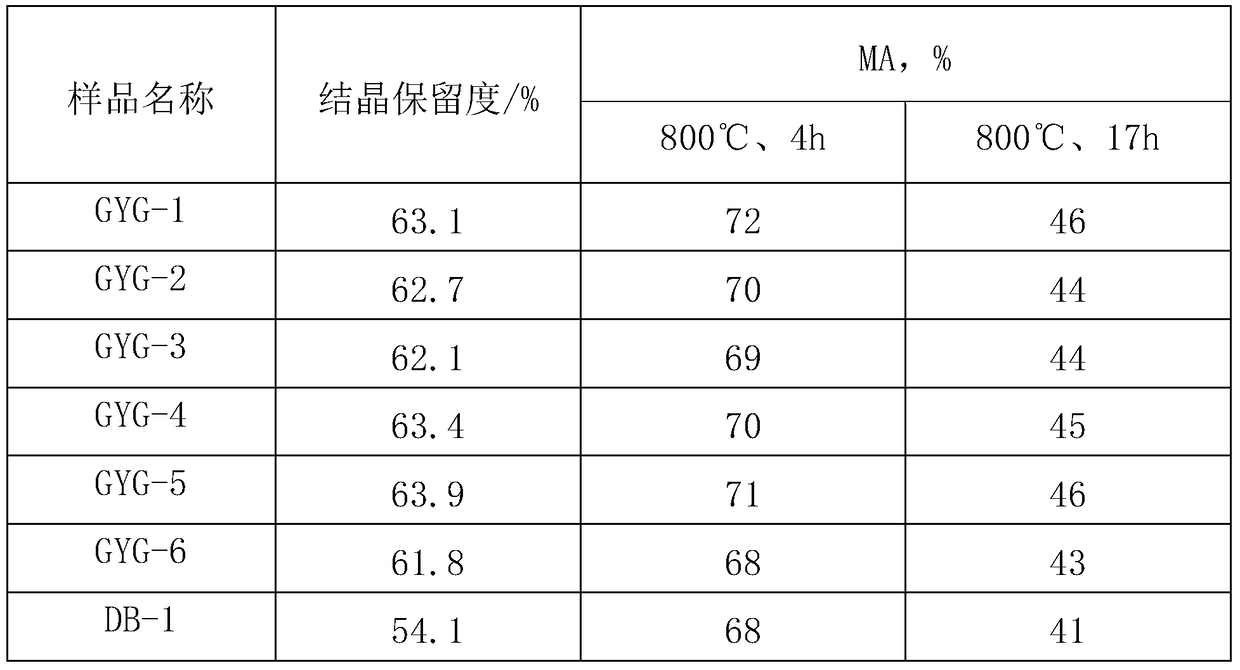

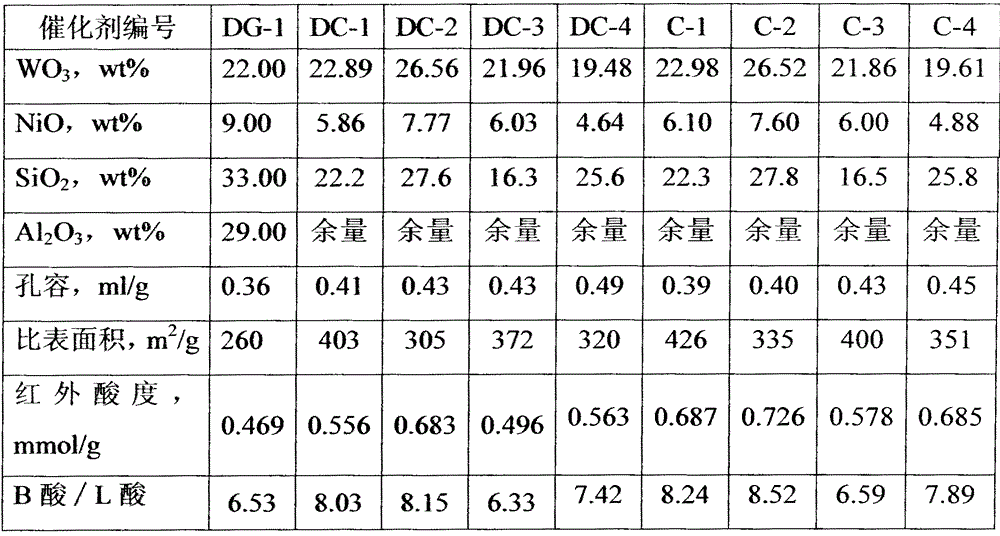

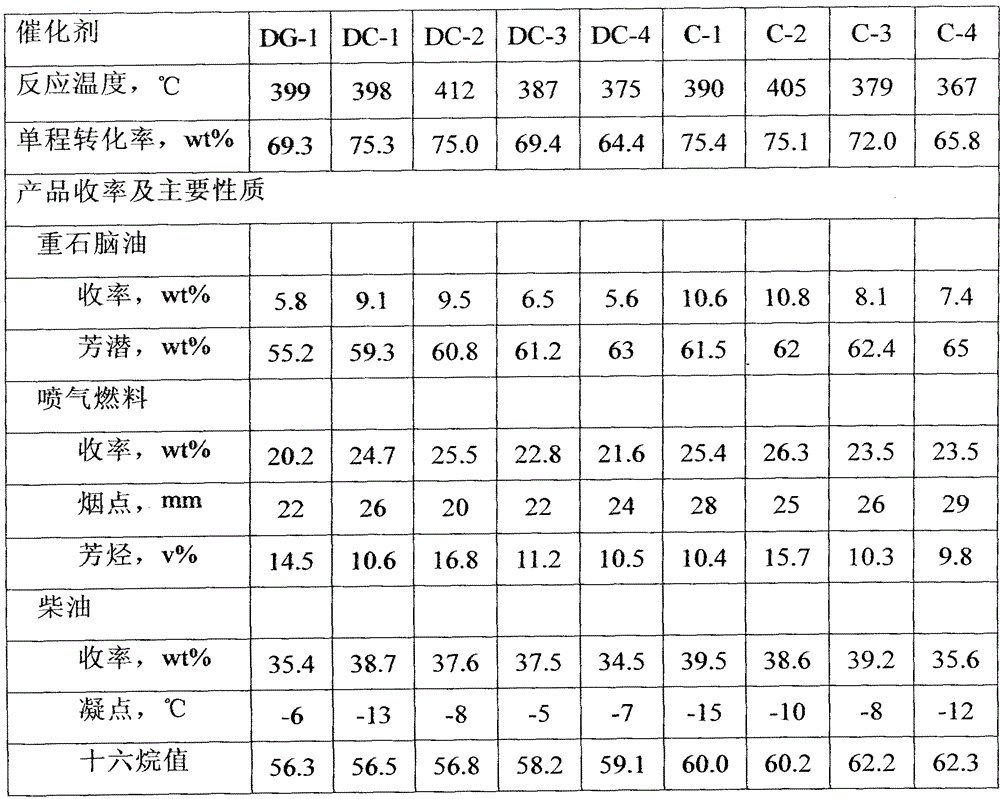

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

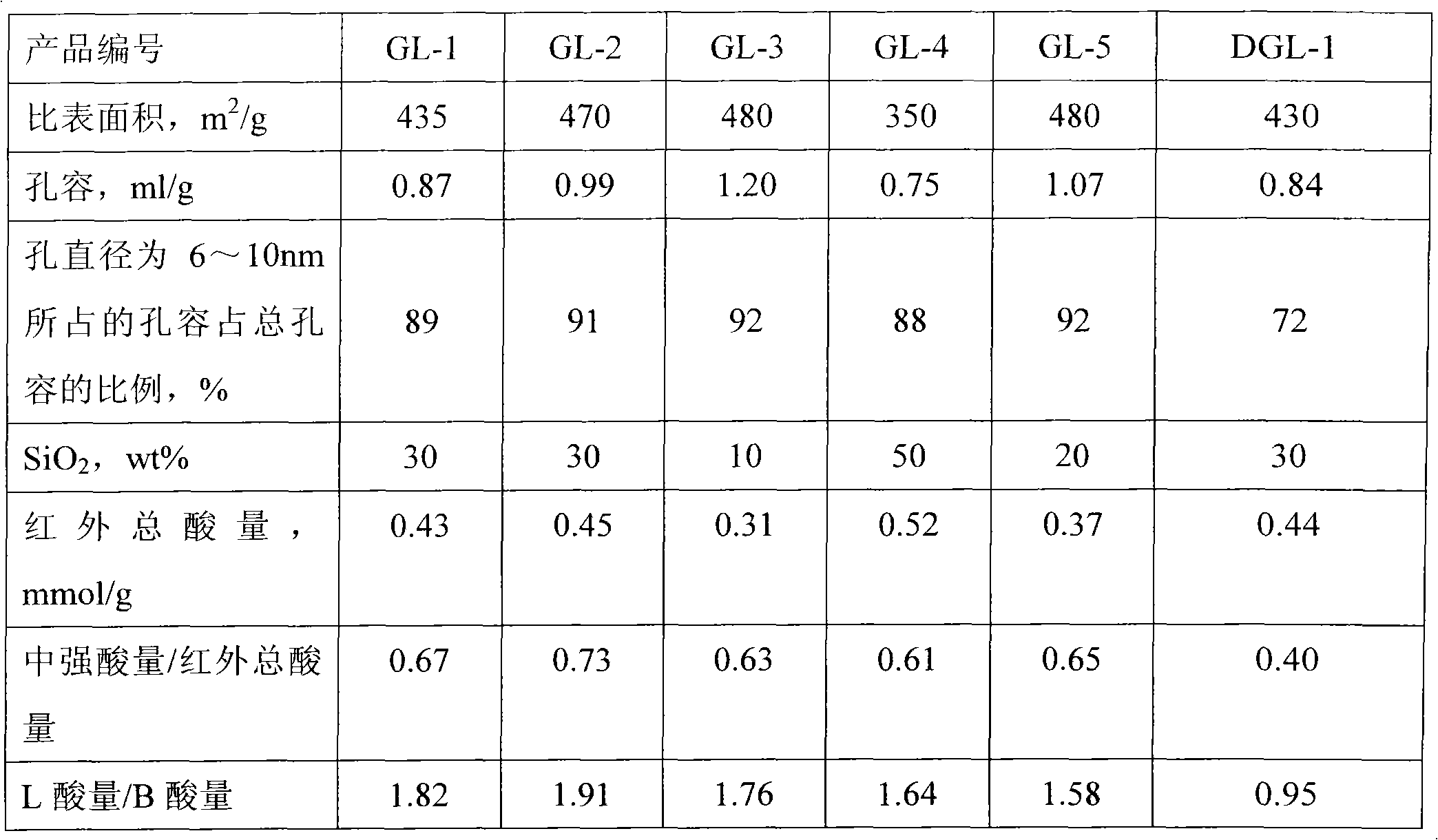

Amorphous silicon aluminium and preparation method thereof

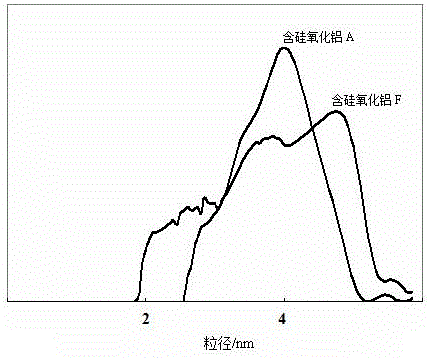

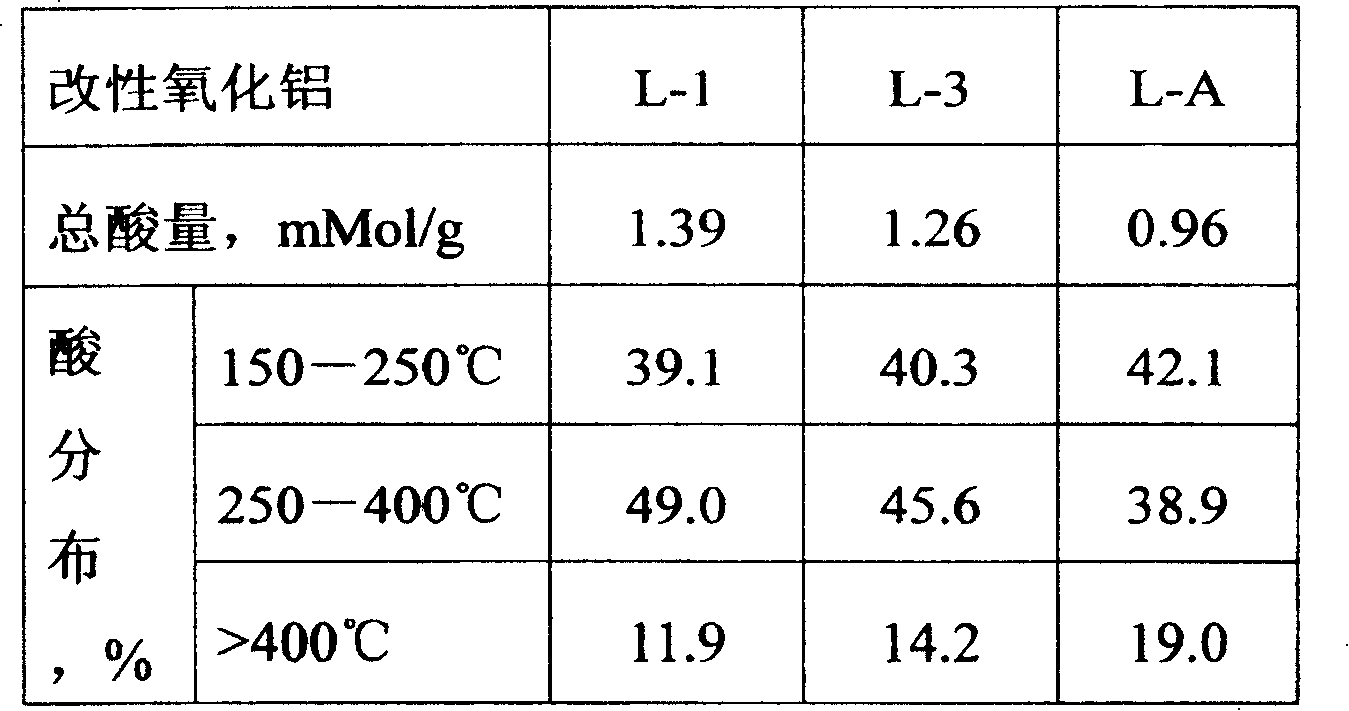

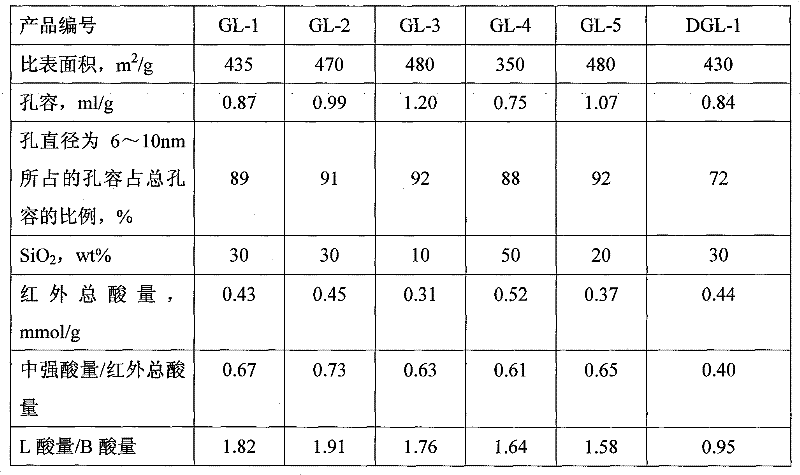

ActiveCN102039197ASimple processEasy to controlCatalyst carriersCatalytic crackingPore distributionStrong acids

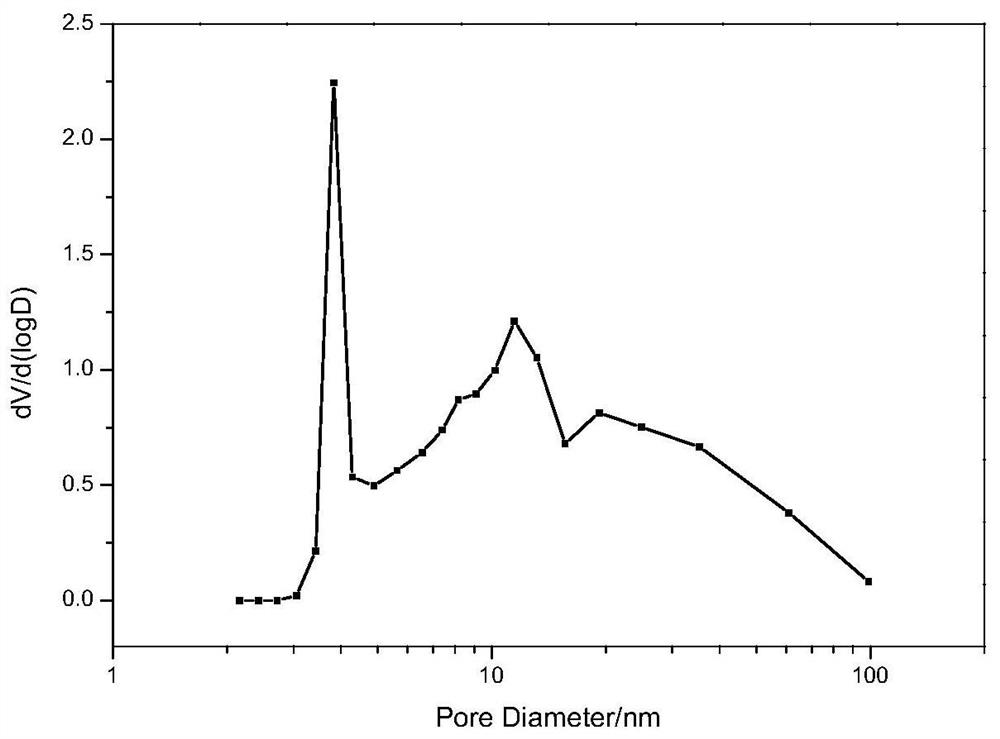

The invention discloses an amorphous silicon aluminium and a preparation method thereof. In the invention, hydro-thermal treatment is carried out on amorphous silicon aluminium obtained by a carbonization method, so that the amorphous silicon aluminium has higher specific surface area and bigger pore volume, the pore distribution is more intensive, and the pore volume the pore diameter of which is 6-10nm accounts for 80-95% of the total pore volume; meanwhile, the acid distribution of the amorphous silicon aluminium is improved; the amount of moderately strong acid and L acid is improved to effectively prevent raw material modules from excessively cracking, which is favourable for improving the selectivity of a target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

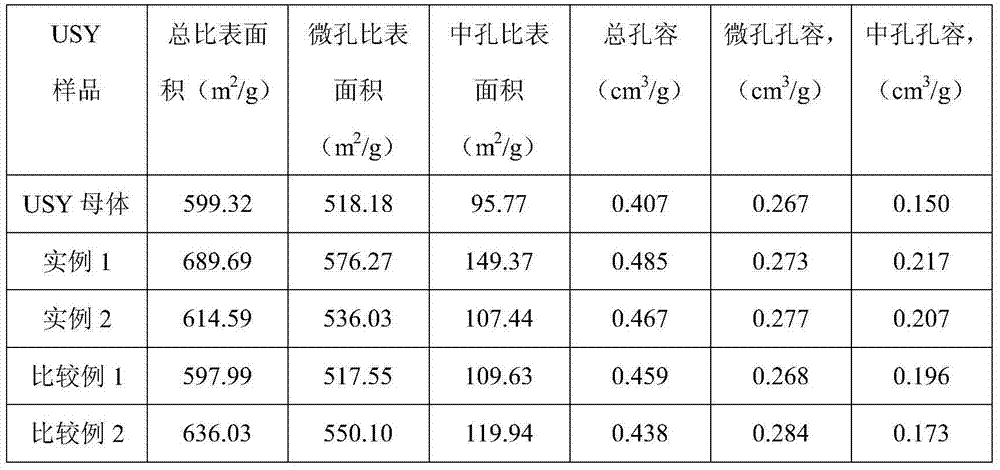

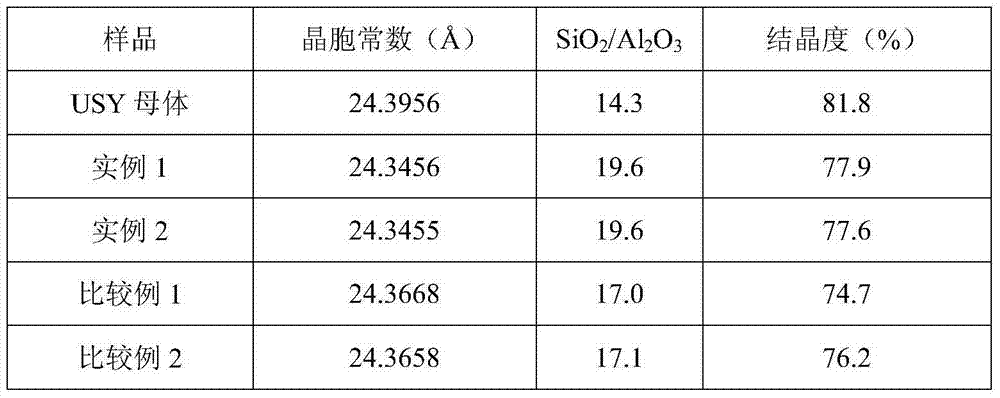

Combined modification method for mesopore USY molecular sieve

InactiveCN103936024AHigh crystallinityHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

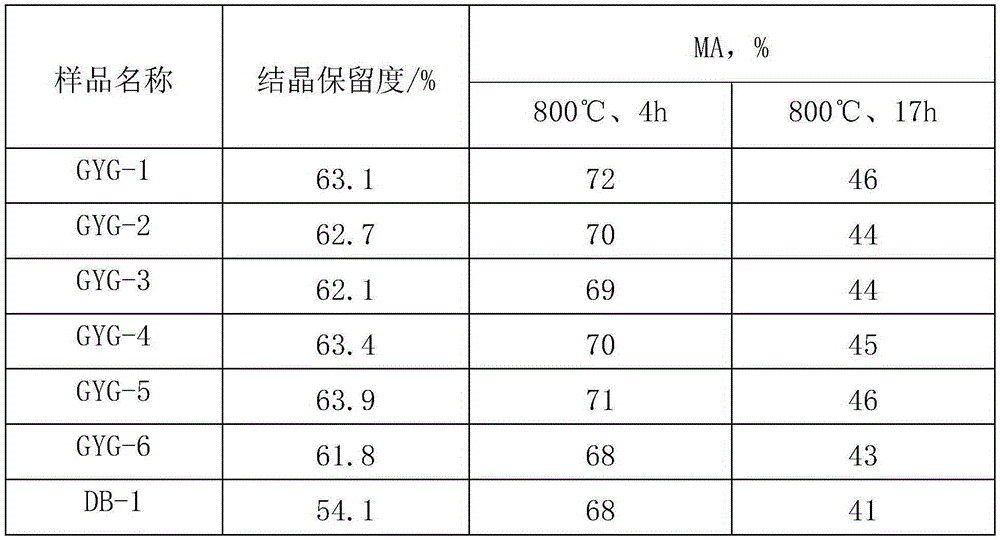

The invention relates to a modification method for a USY molecular sieve and in particular relates to a combined modification method for a mesopore USY molecular sieve. The combined modification method for the mesopore USY molecular sieve comprises that raw materials such as a USY material, an organic acid solution and an inorganic salt solution are measured in ratio, stirring in a closed reactor is carried out, temperature is increased to 90 DEG C, an organic acid-inorganic salt combined dealumination reaction is carried out for 8 hours; reactants are washed at room temperature, and suction filtration is carried out until the surface of USY is neutral; and drying is carried out at constant temperature of 110 DEG C for 16 hours, so that the USY molecular sieve product is obtained. The combined modification method for the mesopore USY molecular sieve has the advantages that a mixed aqueous solution of organic acid and inorganic salt is adopted for treating the USY type molecular sieve, so that high crystallinity of the molecular sieve can be maintained, silica-alumina ratio of the molecular sieve is increased, lattice constant is reduced, specific surface of the molecular sieve is increased, and acidity and acid distribution of the molecular sieve are improved; and more secondary holes are formed through dealumination, so that components with larger molecular diameter can easily enter into pore passages of the molecular sieve or get close to the surface of the molecular sieve, and conversion efficiency of hydrogen cracking can be improved.

Owner:PETROCHINA CO LTD +1

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320BHigh ratio of silicon to aluminumIncrease acidityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348BHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN101380589BHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

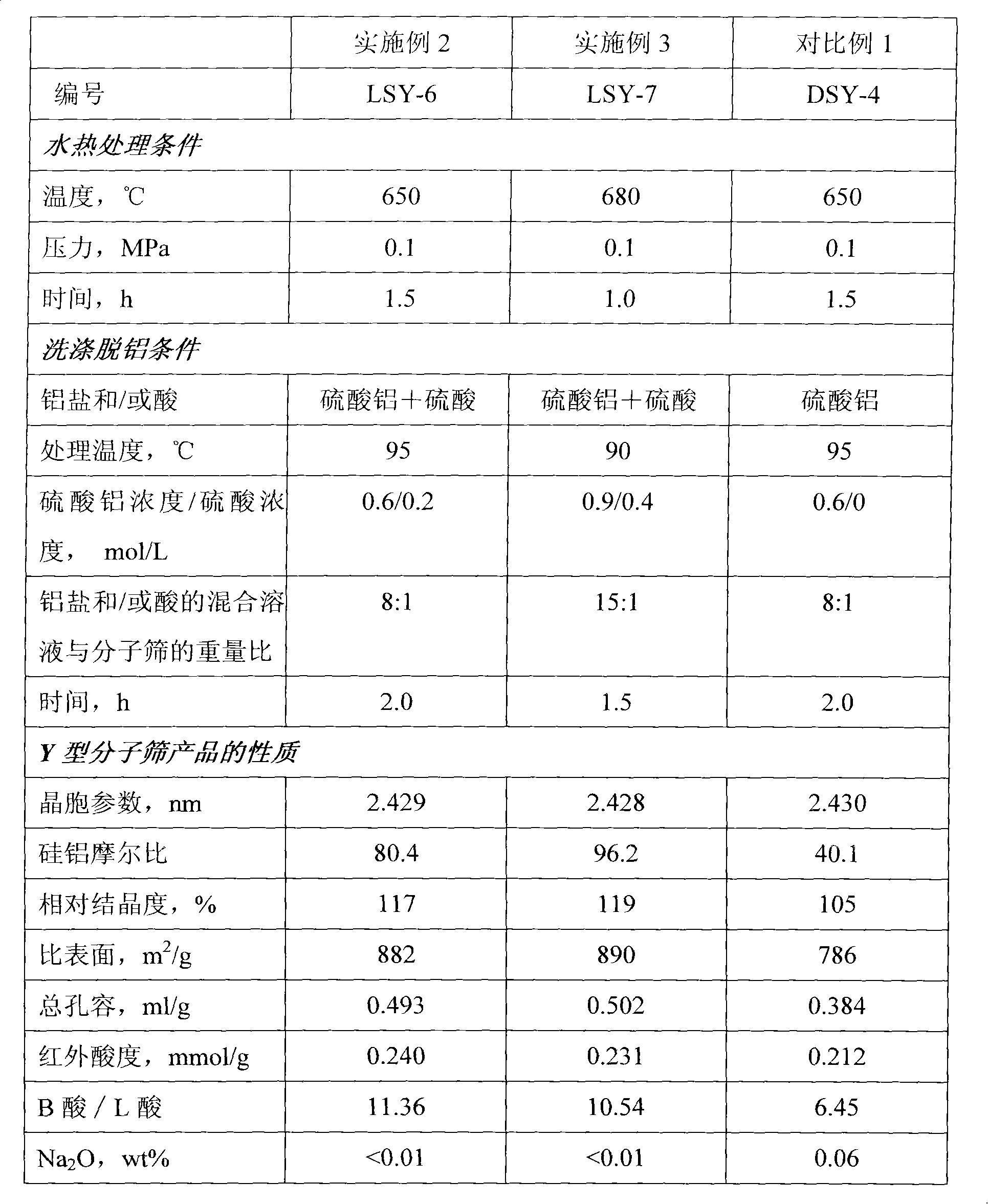

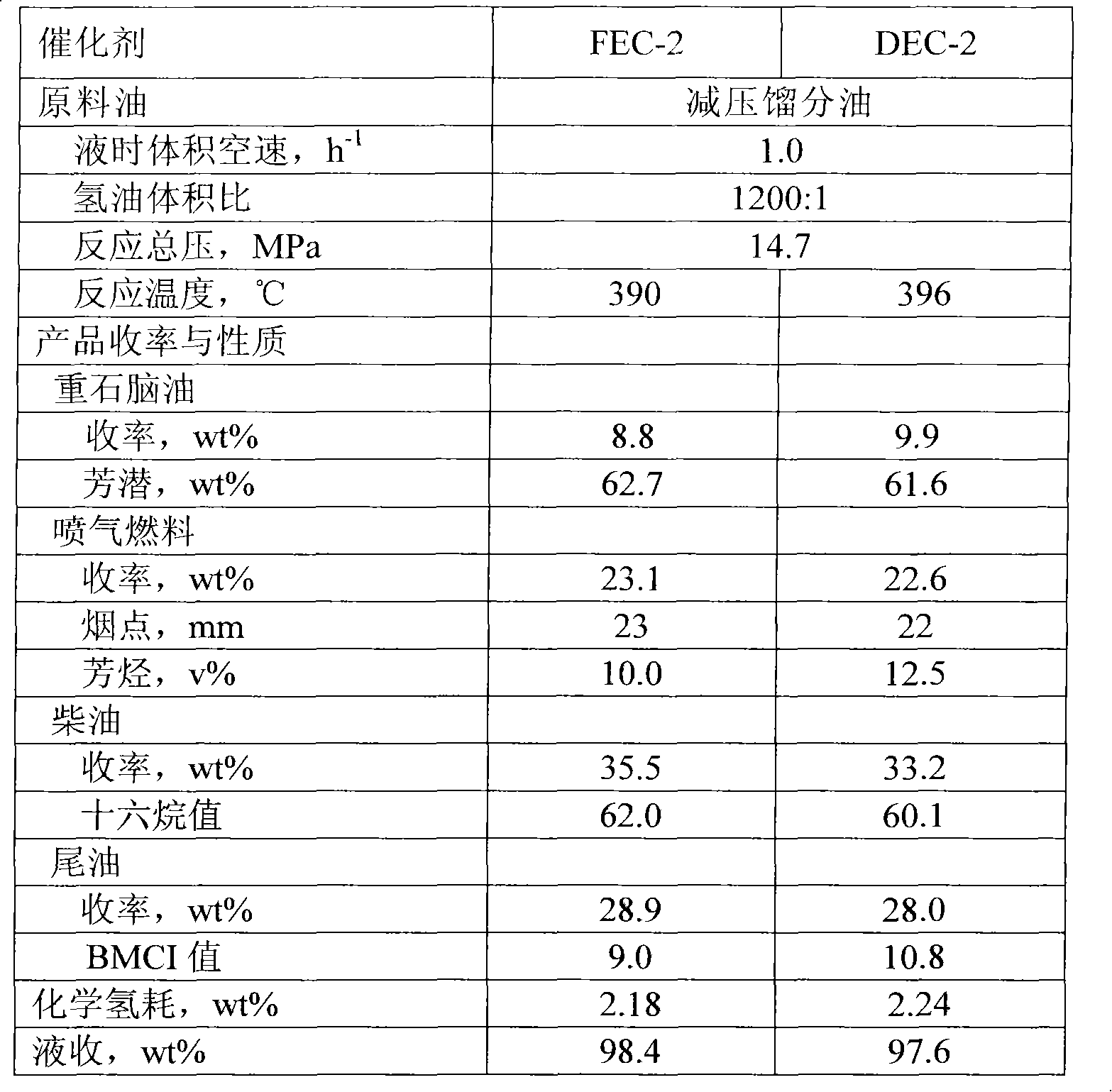

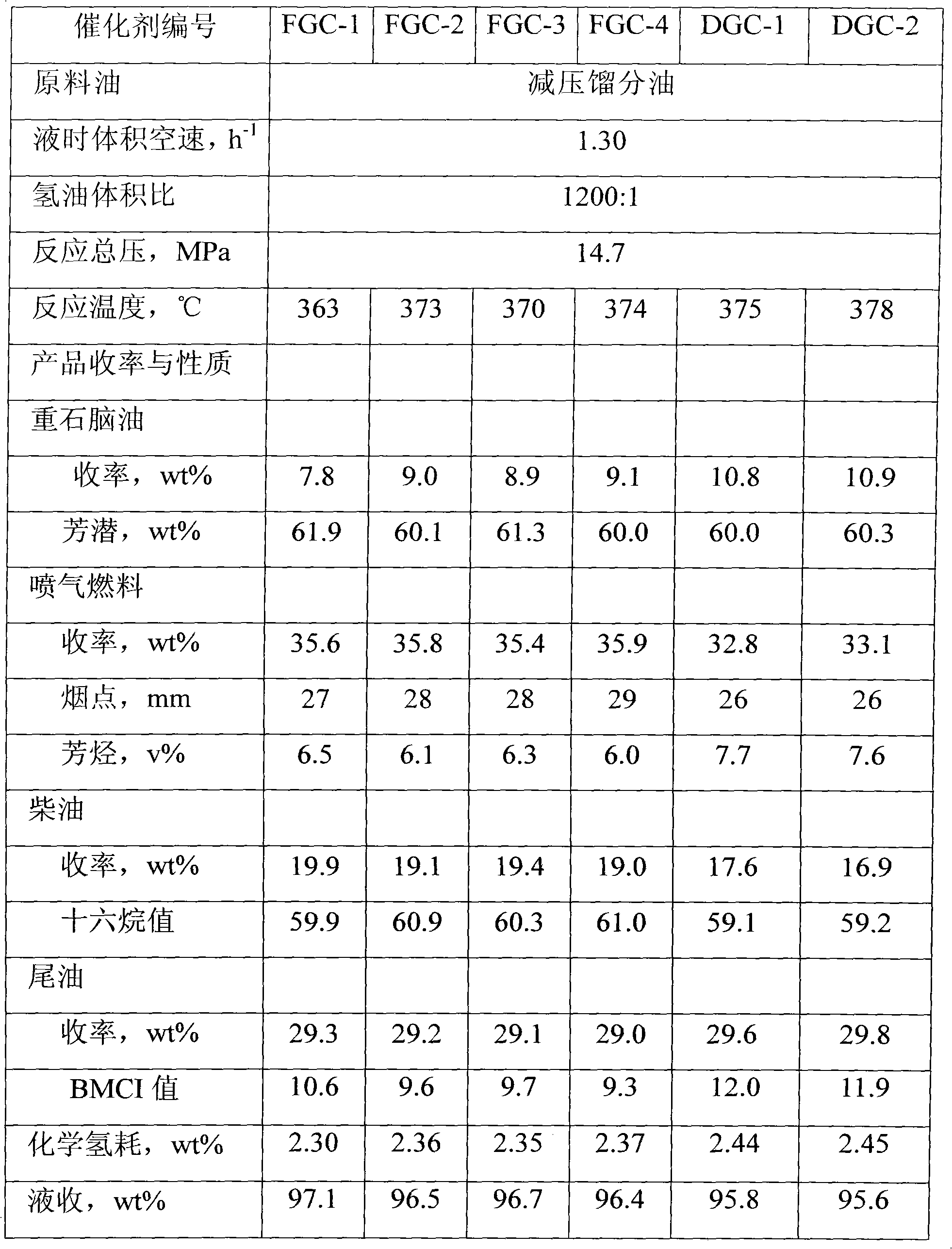

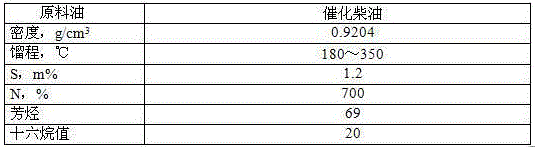

The present invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method for Y-type molecular sieve

ActiveCN106466618AHigh yieldHigh ratio of silicon to aluminumMolecular sieve catalystsMolecular sieveAlcohol

A modification method for a Y-type molecular sieve includes the steps of: a) adding water to NaY molecular sieve to pulp the molecular sieve, and adding polyhydroxy alcohol to the molecular sieve according to the alcohol-to-sieve ratio of 1-20:1, and treating the mixture at 80-200 DEG C to prepare slurry A; b) mixing the slurry A with organic alkali to prepare slurry B according to the alkali-to-sieve ratio of 0.1-1:1, and successively adding an aluminum source and a silicon source and aging the mixture to obtain slurry C, wherein the mass ratio of the aluminum source, on the basis of Al2O3, to the NaY molecular sieve is 0.1-1:1, the mass ratio of the silicon source, on the basis of SiO2, to the aluminum source, on the basis of Al2O3, is 0.1-0.5:1, and the silicon source is added after the aluminum source is fully and uniformly mixed with the slurry B; and c) performing hydrothermal crystallization to the slurry C in a sealed reaction kettle and collecting a product. The method can increase the silicon-aluminum ratio of framework of the molecular sieve and improve distribution of acidity, and meanwhile, ensures that the molecular sieve has better hydrothermal structural stability and excellent heavy oil conversion performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst for moderate oil and preparation thereof

ActiveCN101450319BHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAmorphous silicon

The invention discloses a high-activity and high and medium oil type hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieves, amorphous silicon aluminum and alumina, wherein the modified Y molecular sieves have high crystallinity, large silicon aluminum ratio and proper total acid amount and acid distribution, and are obtained by treating Y molecular sieves after hydro-thermal treatment by a mixed aqueous solution of aluminum salts and an acid. The hydrocracking catalyst has high activity and good intermediate distillate oil selectivity and product quality, and is particularly suitable for hydrocracking technology for producing intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

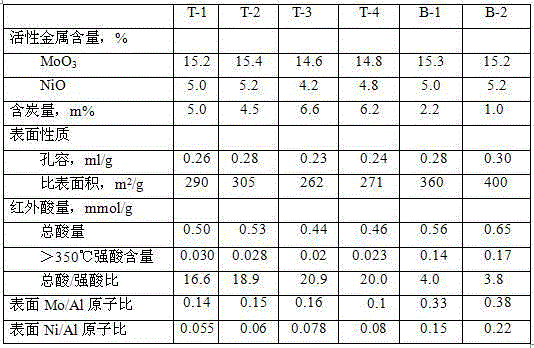

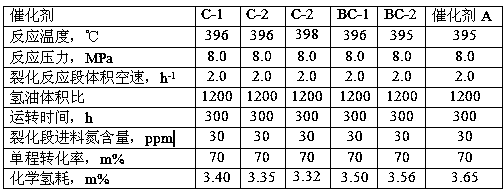

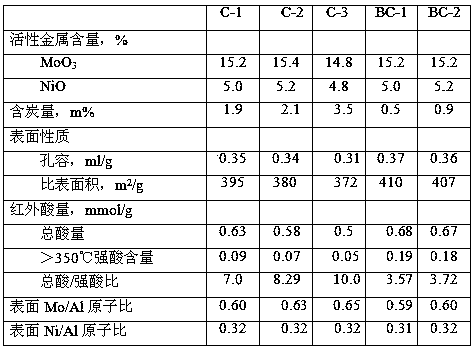

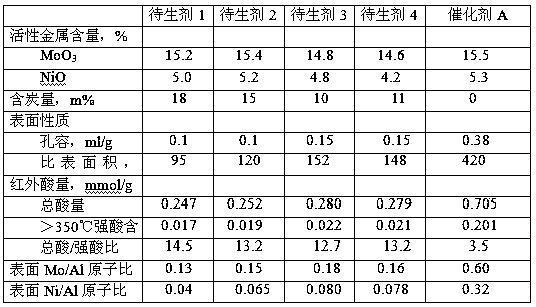

Preparation method of hydrocracking catalyst

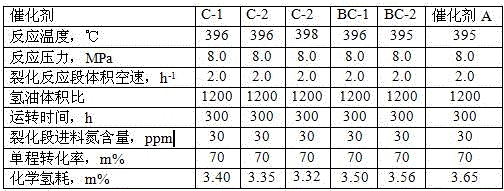

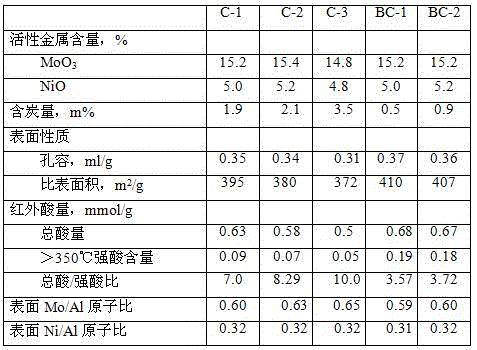

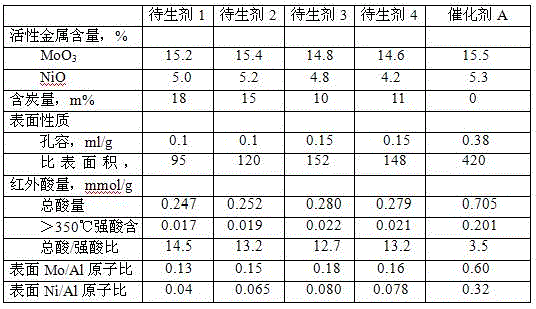

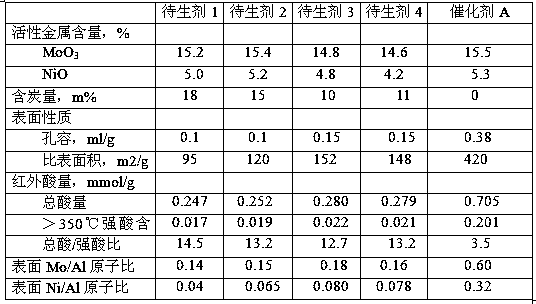

ActiveCN106669788AHigh degree of retentionImproved acid distributionMolecular sieve catalystsCatalyst activation/preparationVulcanizationAcid strength

The invention discloses a preparation method of a hydrocracking catalyst. The preparation method comprises the following steps: (1) roasting a hydrocracking catalyst inactivated in a catalytic diesel oil hydrogenation conversion process in an oxygen-containing atmosphere till the decarburization rate is 40-80 percent to obtain a decarbonization catalyst; (2) grinding the decarbonization catalyst obtained in the step (1) and sieving for later use; (3) mixing sieved power obtained in the step (2) as a raw material with a hydrocracking catalyst carrier material and a hydrogenated active metal precursor in proportion, adding a peptizing agent and an auxiliary extrusion agent, rolling, extruding and performing high-temperature and high-pressure treatment in an H2S atmosphere to obtain the hydrocracking catalyst. A hydrocracking catalyst regeneration agent is mixed in the preparation process of a fresh catalyst, and in the preparation process, and the vulcanization is completed at the same time. The catalyst has the characteristic of being more reasonable in acid strength distribution, is good in active metal dispersibility and is applied to the catalytic diesel oil hydrogenation conversion process; the initial settling time and the start-up time of the device catalyst are shortened, so that the inactivation rate of the catalyst is reduced, and the catalyst operating cycle is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving stability of Y-type molecular sieve

ActiveCN106608641AImprove the stability of hydrothermal structureImprove activity stabilityFaujasite aluminosilicate zeoliteMolecular sieveAlcohol

The invention provides a treating method for improving the stability of a Y-type molecular sieve. The method comprises the following steps: mixing a NaY molecular sieve with polyhydroxy alcohol according to an alcohol-sieve mass ratio of (1-20): 1 and carrying out treatment at 80 to 200 DEG C; then uniformly mixing the NaY molecular sieve with organic base according to a base-sieve mass ratio of (0.1-1): 1; adding an aluminum source and inorganic base and controlling the pH value of system to be 8 to 11; then adding a silicon source and carrying out aging; and subjecting aged slurry to crystallization and recovering a product; wherein a mass ratio of the aluminum source, in terms of Al2O3, to the molecular sieve is (0.1-1): 1, and a mass ratio of the silicon source, in terms of SiO2, to the molecular sieve is (0.1-1): 1. The method can effectively improve the hydro-thermal structural stability and hydro-thermal activity stability of the molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

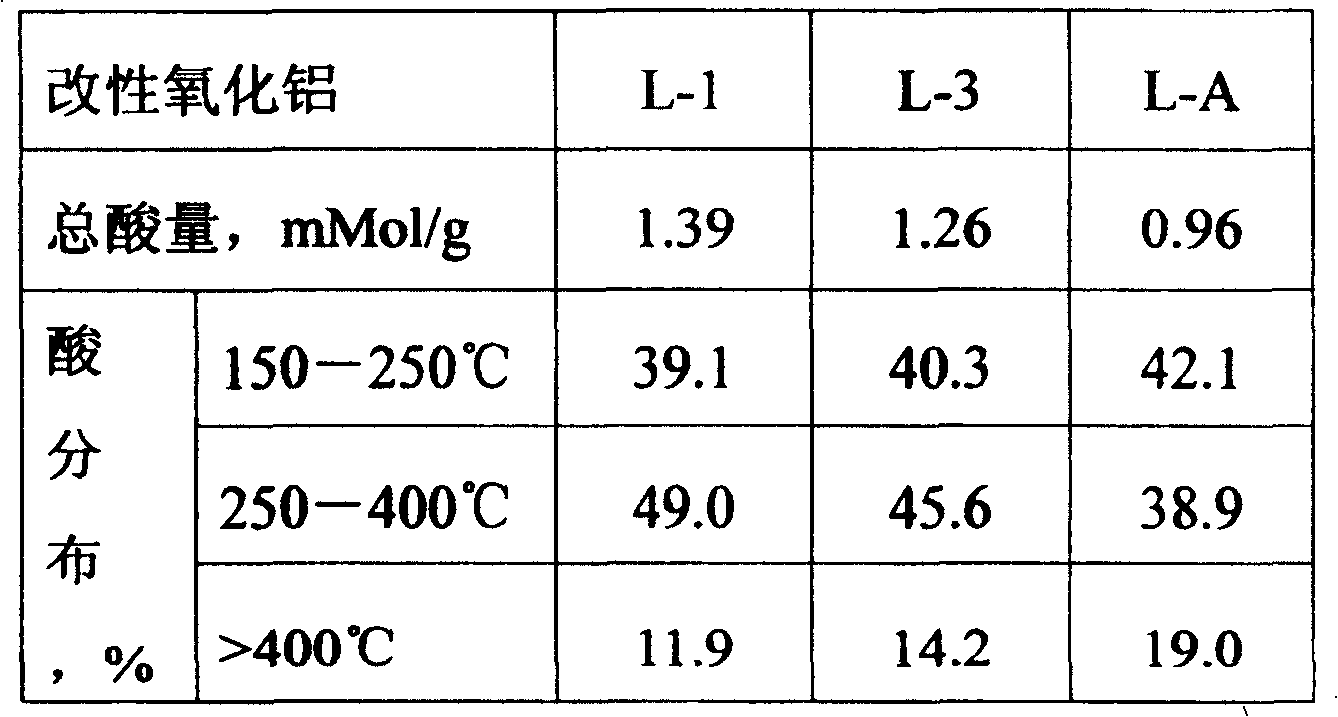

A kind of preparation method of silicon-containing alumina dry glue

ActiveCN103769232BConcentrated hole distributionIncrease acidityCatalyst carriersHydrocarbon oils treatmentPore distributionCombined method

The invention discloses a preparation method of an alumina dry glue containing silicon. The preparation method comprises the following steps: mixing original clay with a weak acid and a dispersant, then carrying out a hydrothermal treatment on the mixture so as to obtain modified clay; using an acidic solution containing aluminum and an alkaline solution containing aluminum to carry out a glue-forming reaction in the modified clay slurry by adopting a combined method of a pH swing method and a parallel-flow method, and after the glue-forming process, subjecting the glue-forming reaction product to processes of filtering, washing, and drying so as to obtain the alumina dry glue containing silicon. The alumina dry glue containing silicon has the advantages of uniform particle size, concentrated pore distribution, and proper acidity, and is especially suitable for being used to prepare a heavy oil or residual oil hydro-treatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst for catalyzing diesel hydrocracking

ActiveCN106669789AAcid improvementHigh degree of retentionMolecular sieve catalystsHydrocarbon oil crackingDistribution characteristicAcid strength

The invention discloses a method for preparing a catalyst for catalyzing diesel hydrocracking. The method comprises the following steps: (1) roasting a hydrocracking catalyst inactivated in a diesel hydro-conversion catalyzing process in an oxygen-containing atmosphere until a decarburization rate is 40-80% so as to obtain a decarburization catalyst; (2) grinding the decarburization catalyst obtained in the step (1) so as to obtain decarburization catalyst powder, and screening the powder for later use; (3) mixing the screened powder obtained in the step (2), a hydrocracking catalyst carrier material and a hydrogenation activity metal precursor, adding dilute nitric acid solution and sesbania powder, rolling, extruding, performing high-temperature treatment in an inert atmosphere, so as to obtain the catalyst for catalyzing diesel hydrocracking. The catalyst prepared by the invention has reasonable acid strength distribution characteristics and good active metal dispersion and is applied to the diesel hydro-conversion catalyzing process, so that the initial activity stabilization time of the device catalyst is shortened, the on-stream time is shortened, the catalyst inactivation rate is reduced, and the catalyst running period is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst as well as preparation method and application thereof

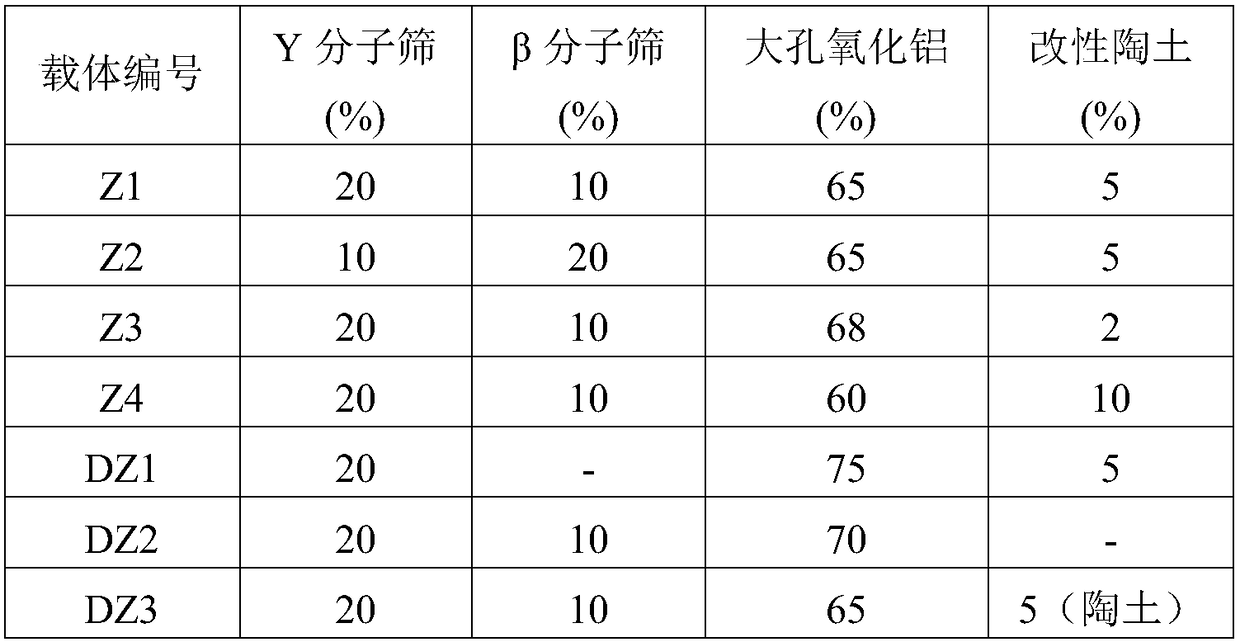

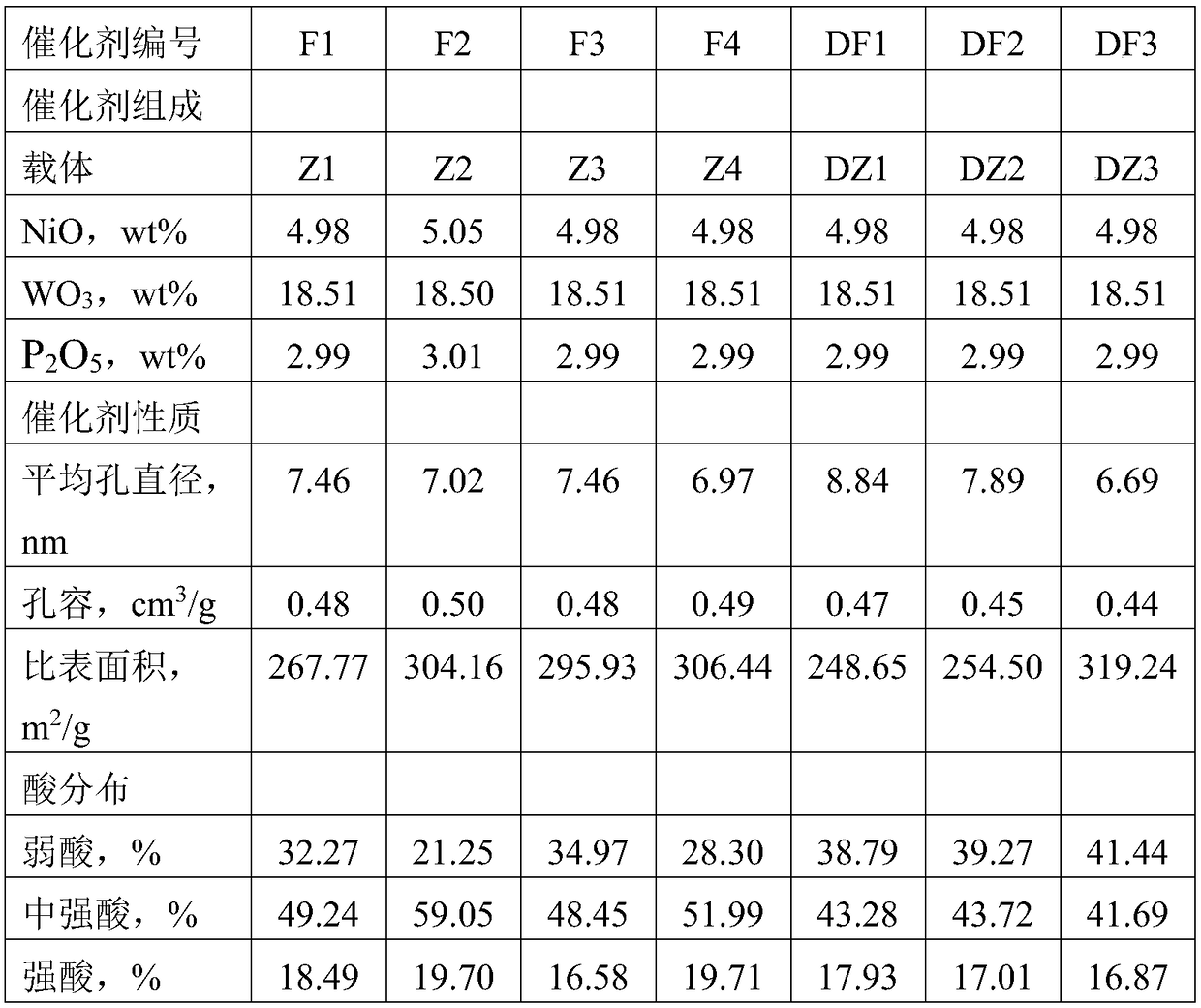

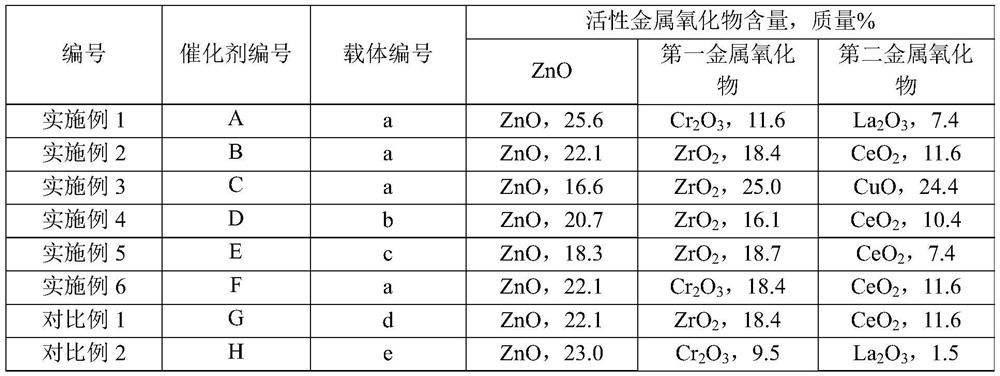

ActiveCN108714433AHigh selectivityGood activity and stabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveActive ingredient

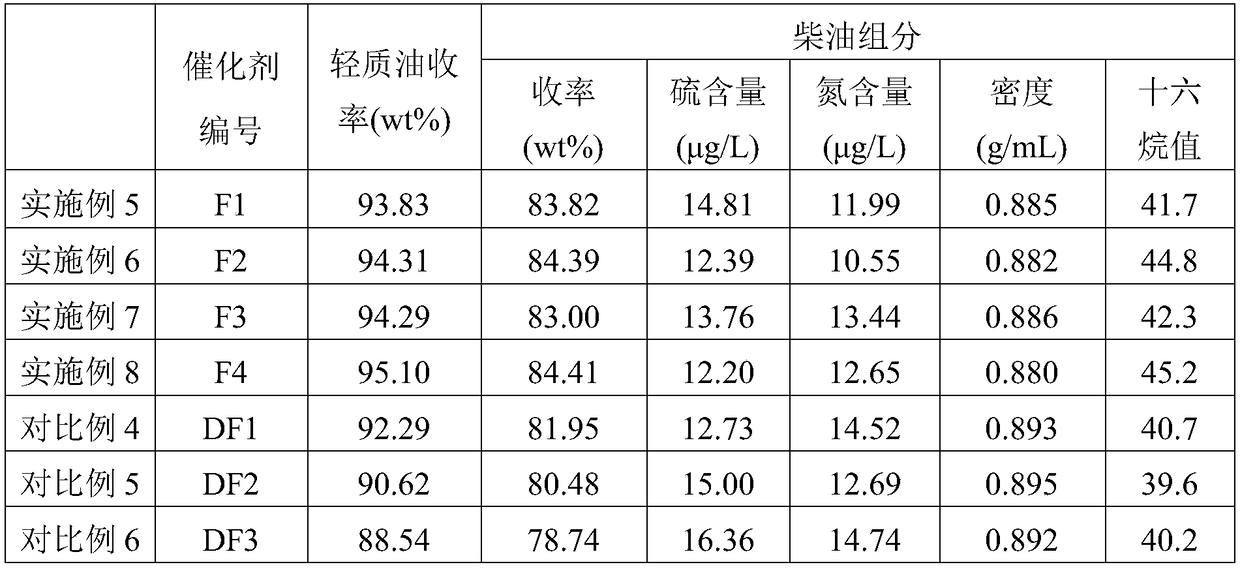

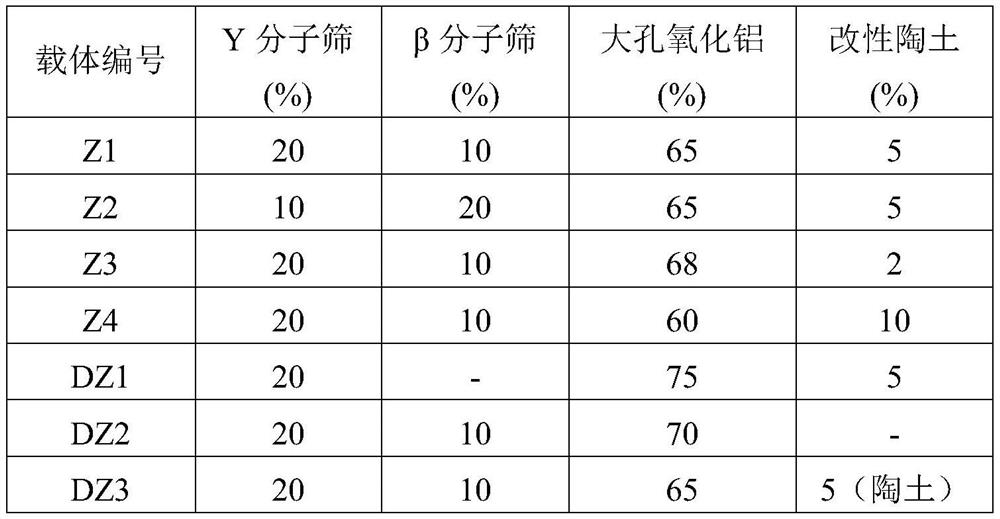

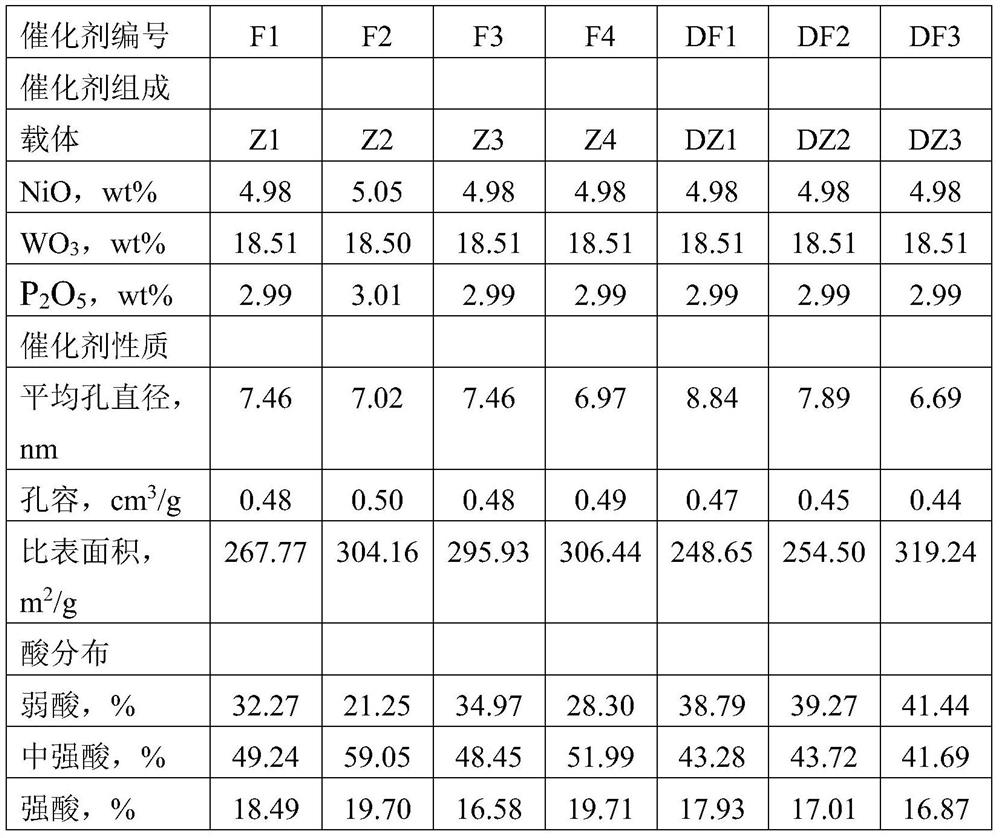

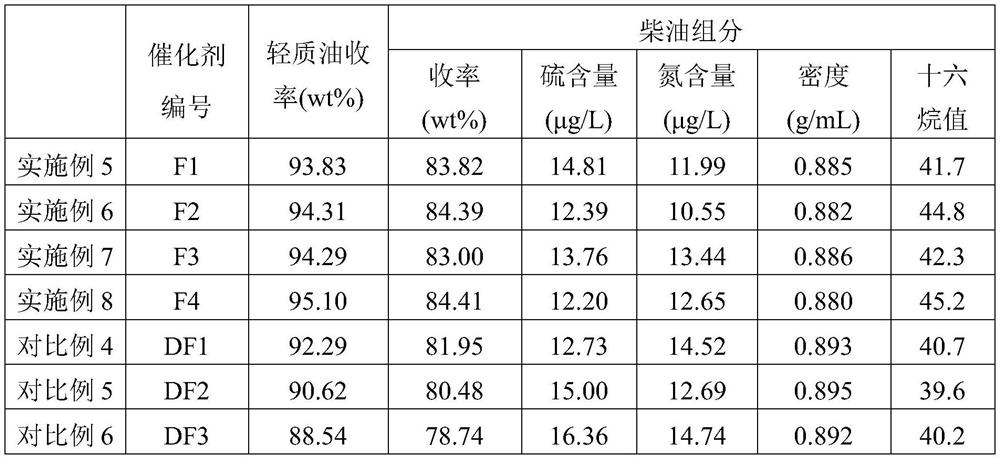

The invention discloses a hydrocracking catalyst as well as a preparation method and the application thereof. The hydrocracking catalyst comprises a carrier, active ingredients and aids, wherein the carrier comprises the following components in percentage by weight: 2-30% of a Y molecular sieve, 2-30% of a beta molecular sieve, 50-70% of porous alumina and 1-12% of modified clay. The hydrocrackingcatalyst disclosed by the invention is applied to high temperature coal tar hydrogenation for preparing diesel components, and has the advantages of high selectivity, high activity, high stability, high light oil yield, high diesel yield, excellent quality and the like.

Owner:BEIJING GAOXIN LIHUA TECH CO LTD +2

A kind of hydrocracking catalyst and its preparation method and application

ActiveCN108714433BHigh selectivityGood activity and stabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst as well as a preparation method and the application thereof. The hydrocracking catalyst comprises a carrier, active ingredients and aids, wherein the carrier comprises the following components in percentage by weight: 2-30% of a Y molecular sieve, 2-30% of a beta molecular sieve, 50-70% of porous alumina and 1-12% of modified clay. The hydrocrackingcatalyst disclosed by the invention is applied to high temperature coal tar hydrogenation for preparing diesel components, and has the advantages of high selectivity, high activity, high stability, high light oil yield, high diesel yield, excellent quality and the like.

Owner:BEIJING GAOXIN LIHUA TECH CO LTD +2

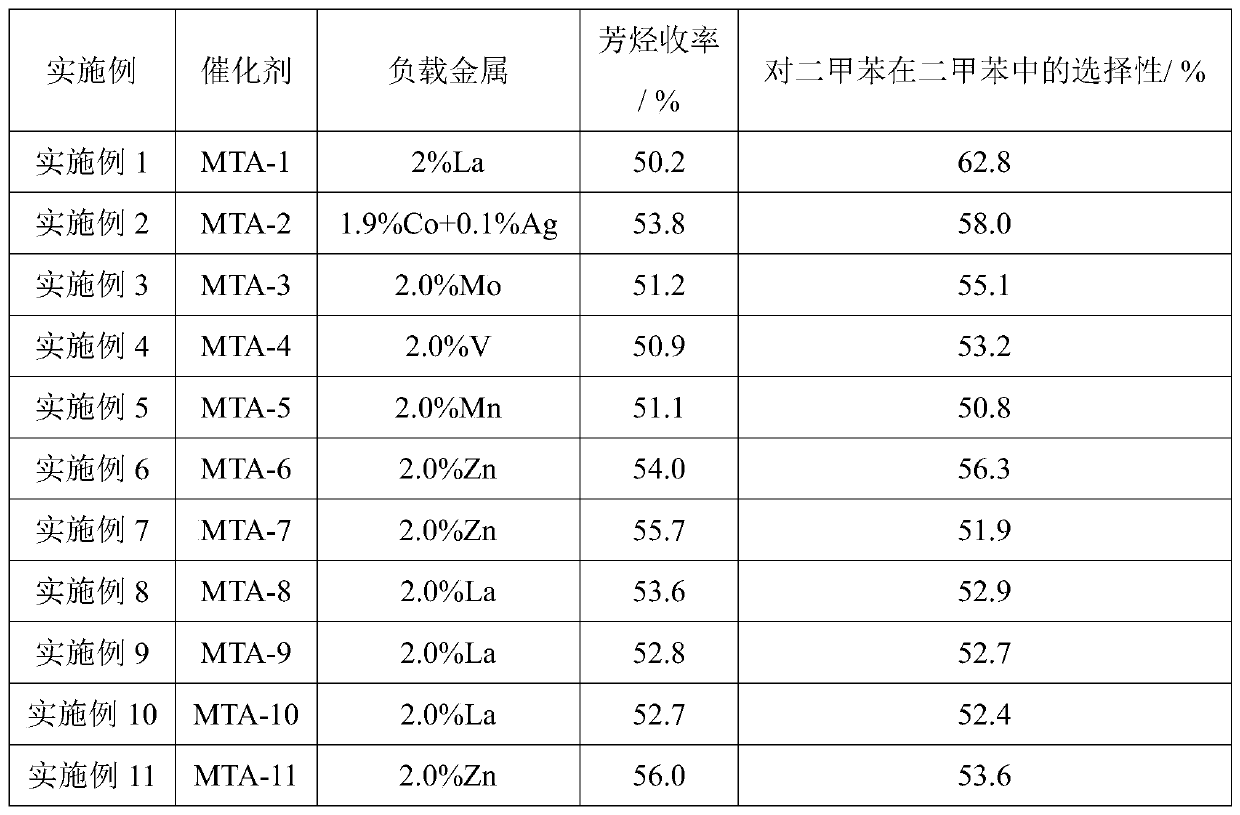

Catalyst for producing aromatics from methanol and its preparation method and application

ActiveCN106607088BImproved acid distributionImprove adaptabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsXylyleneMolecular sieve

Owner:CHINA PETROLEUM & CHEM CORP +1

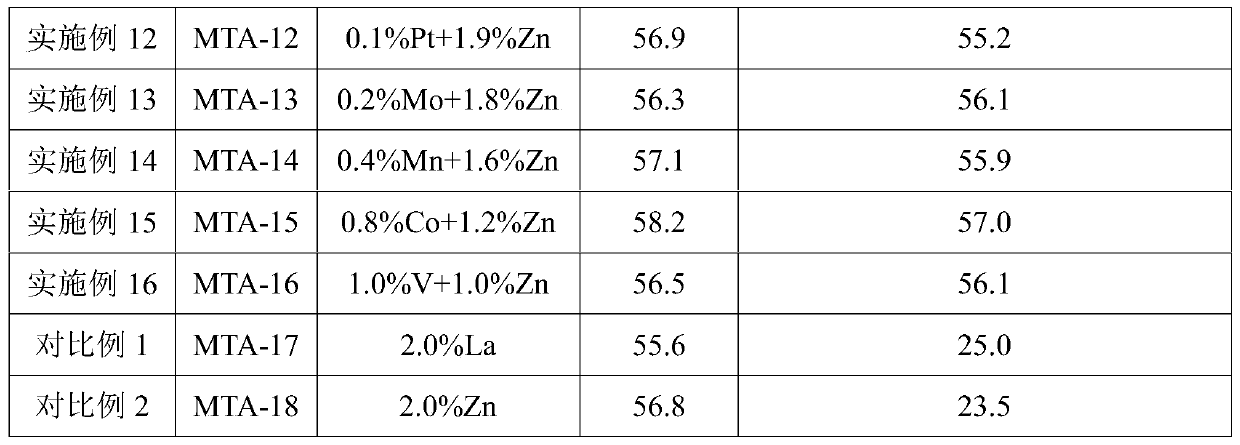

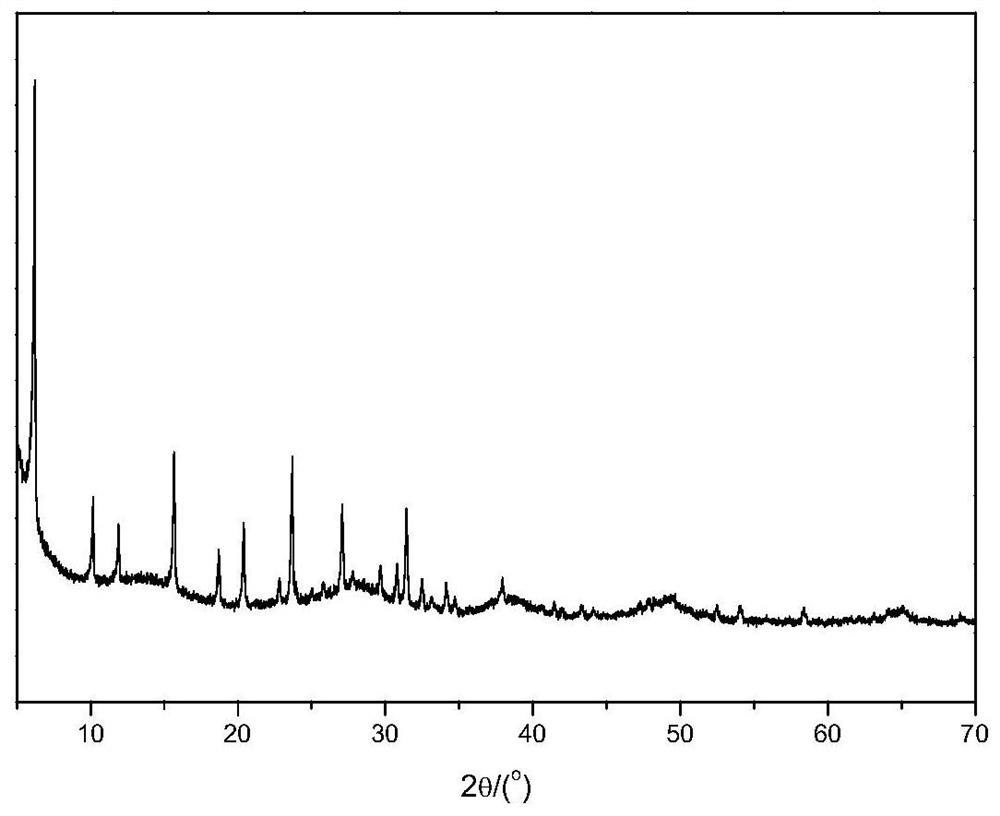

Preparation method of multi-metal modified composite material

ActiveCN111744528AImproved acid distributionImprove responseCatalytic crackingMolecular sieve catalystsPore distributionAmorphous phase

The invention discloses a preparation method of a multi-metal modified composite material. The method comprises a process of modifying a porous material by rare earth and magnesium. The porous material has two structures which are an FAU crystalline phase structure and a pseudo-boehmite amorphous phase structure at the same time, ordered diffraction stripes of an FAU crystal part and a disorderedstructure of a pseudo-boehmite part exist, and the disordered structure is derived and grown along the edges of the ordered diffraction stripes, and the two structures are effectively combined together to form a microporous-mesoporous composite structure; a / b of a Raman spectrum is equal to 1.5-10, and probable pore distribution occurs at the wavelength of 3-4nm, 8-20nm and 18-40nm. The compositematerial prepared by the method contains microporous and mesoporous structures at the same time, the acid distribution is further improved through the modification effect of rare earth and magnesium,and the reaction performance is promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of catalytic diesel hydrocracking catalyst

ActiveCN106669789BAcid improvementHigh degree of retentionMolecular sieve catalystsHydrocarbon oil crackingDistribution characteristicAcid strength

The invention discloses a preparation method of a catalytic diesel hydrocracking catalyst, which includes the following contents: (1) roasting the deactivated hydrocracking catalyst in the catalytic diesel hydroconversion process in an oxygen-containing atmosphere until the decarbonization rate is 40 %~80% to obtain a decarburization catalyst; (2) pulverize the decarburization catalyst obtained in step (1) to obtain decarburization catalyst powder, and sieve the powder for later use; (3) pulverize the decarburization catalyst obtained in step (2) for later use; The sieved powder, hydrocracking catalyst carrier material and hydrogenation active metal precursor are mixed, and then dilute nitric acid solution and sesbania powder are added, followed by rolling, extrusion, and high-temperature treatment in an inert atmosphere to obtain a catalytic diesel hydrocracking catalyst. The catalyst prepared by the invention has more reasonable acid intensity distribution characteristics and good active metal dispersion, and is used in the catalytic diesel hydrogenation conversion process to shorten the initial activation and stabilization time of the device catalyst, shorten the start-up time, and reduce the catalyst deactivation The rate decreases and the catalyst operation cycle is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic process of ZSM-5 and MAPO-5 two-structure molecular sieve

InactiveCN100390058CImprove distributionImproved acid distributionMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesSynthesis methodsCatalytic decomposition

This invention relates to a method to synthesize ZSM-5 and MAPO-5 binary structure molecular sieves, which mainly adopts M heteroatom source, aluminium source, phosgene source, template reagent, ZSM-5 and deionized water as raw materials, and the mole ratio of MxOy, Al2O3, P2O5, R and H2O is (0.5~1.5) : (5~15) : (4~20) : (4~20) : (100~2000), where x and y represent the number of M and O atoms in the heteroatom source; R represents template reagent; ZSM-5 is original ZSM-5 powder and is taken at any ratio to the mixture. The raw materials are mixed at 10~95 deg. C, stirred to homogeneity and crystallized at 20~200 deg. C for 5~200 hours after aging. The product is recycled, filtered, washed, exchanged, dried and baked to obtain catalyst product. In the molecular sieves synthesized in this invention, MAPO-5 can be more equably distributed on the surface of ZSM-5, and this method has potential value in catalytic cracking, catalytic decomposition and hydrogenation cracking of heavy oil and some other fine chemical fields.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

A kind of modification method of Y-type molecular sieve

ActiveCN106466618BHigh yieldHigh ratio of silicon to aluminumMolecular sieve catalystsMolecular sieveAlcohol

A modification method for a Y-type molecular sieve includes the steps of: a) adding water to NaY molecular sieve to pulp the molecular sieve, and adding polyhydroxy alcohol to the molecular sieve according to the alcohol-to-sieve ratio of 1-20:1, and treating the mixture at 80-200 DEG C to prepare slurry A; b) mixing the slurry A with organic alkali to prepare slurry B according to the alkali-to-sieve ratio of 0.1-1:1, and successively adding an aluminum source and a silicon source and aging the mixture to obtain slurry C, wherein the mass ratio of the aluminum source, on the basis of Al2O3, to the NaY molecular sieve is 0.1-1:1, the mass ratio of the silicon source, on the basis of SiO2, to the aluminum source, on the basis of Al2O3, is 0.1-0.5:1, and the silicon source is added after the aluminum source is fully and uniformly mixed with the slurry B; and c) performing hydrothermal crystallization to the slurry C in a sealed reaction kettle and collecting a product. The method can increase the silicon-aluminum ratio of framework of the molecular sieve and improve distribution of acidity, and meanwhile, ensures that the molecular sieve has better hydrothermal structural stability and excellent heavy oil conversion performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055925AHigh ratio of silicon to aluminumLarge specific surface areaMolecular sieve catalystsCatalyst activation/preparationDispersityMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon and filling CO2 into the solution A; and preparing a sodium metaaluminate alkaline solution B, subjecting the solution B to react with the solution A into which CO2 is filled to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the hydrocracking catalyst composition prepared by the method is especially suitable for producing more high-quality naphtha, jet fuel and diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347BHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

The invention relates to a Y-type molecular sieve-containing hydrocracking catalyst carrier and a preparation method thereof. The carrier consists of a modified Y-type molecular sieve and alumina, wherein the Y-type molecular sieve is obtained by the treatment by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal treatment and has the properties of a specific surface of between 750 and 850m<2> / g, a total pore volume of between 0.35 and 0.48ml / g, a relative crystallinity of between 90 and 130 percent, a cell parameter of between 2.437 and 2.445nm, a silicon to aluminum molar ratio of between 15 and 70, an infrared acidity of between 0.5 and 1.0 mmol / g, a Bronsted acid to Lewis acid ratio of more than 7.0 and a sodium oxide content of less than or equal to 0.05 weight percent. The carrier can be used in the preparation of a hydrocracking catalyst, and the obtained catalyst has the characteristics of excellent catalytic activity, high heavy naphtha selectivity, high yield, high aromatic hydrocarbon potential content of the heavy naphtha and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN106669788BHigh degree of retentionImproved acid distributionMolecular sieve catalystsCatalyst activation/preparationVulcanizationAcid strength

The invention discloses a preparation method of a hydrocracking catalyst. The preparation method comprises the following steps: (1) roasting a hydrocracking catalyst inactivated in a catalytic diesel oil hydrogenation conversion process in an oxygen-containing atmosphere till the decarburization rate is 40-80 percent to obtain a decarbonization catalyst; (2) grinding the decarbonization catalyst obtained in the step (1) and sieving for later use; (3) mixing sieved power obtained in the step (2) as a raw material with a hydrocracking catalyst carrier material and a hydrogenated active metal precursor in proportion, adding a peptizing agent and an auxiliary extrusion agent, rolling, extruding and performing high-temperature and high-pressure treatment in an H2S atmosphere to obtain the hydrocracking catalyst. A hydrocracking catalyst regeneration agent is mixed in the preparation process of a fresh catalyst, and in the preparation process, and the vulcanization is completed at the same time. The catalyst has the characteristic of being more reasonable in acid strength distribution, is good in active metal dispersibility and is applied to the catalytic diesel oil hydrogenation conversion process; the initial settling time and the start-up time of the device catalyst are shortened, so that the inactivation rate of the catalyst is reduced, and the catalyst operating cycle is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Benzene and synthesis gas alkylation catalyst as well as preparation method and application thereof

PendingCN114433217AImprove pore structureImproved acid distributionMolecular sieve catalystsMolecular sieve catalystMolecular sieveBenzene

The invention relates to a benzene and synthesis gas alkylation catalyst and a preparation method and application thereof. The catalyst carrier adopts two composite molecular sieves, optimizes the pore structure and acid distribution of the catalyst, has the advantages of high catalytic activity and good selectivity, and adopts macroporous alumina as a binder to increase the specific surface area and pore volume of the catalyst, improve the mass transfer and heat transfer effects of the catalyst, and improve the catalytic activity of the catalyst. The conversion rate of benzene and the selectivity and yield of methylbenzene and C8 aromatic hydrocarbon are improved, and the preparation method is simple, sufficient in raw material source, low in cost, easy to operate and suitable for large-scale industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for improving the stability of Y-type molecular sieves

ActiveCN106608641BImprove the stability of hydrothermal structureImprove activity stabilityFaujasite aluminosilicate zeoliteMolecular sieveAlcohol

The invention provides a treating method for improving the stability of a Y-type molecular sieve. The method comprises the following steps: mixing a NaY molecular sieve with polyhydroxy alcohol according to an alcohol-sieve mass ratio of (1-20): 1 and carrying out treatment at 80 to 200 DEG C; then uniformly mixing the NaY molecular sieve with organic base according to a base-sieve mass ratio of (0.1-1): 1; adding an aluminum source and inorganic base and controlling the pH value of system to be 8 to 11; then adding a silicon source and carrying out aging; and subjecting aged slurry to crystallization and recovering a product; wherein a mass ratio of the aluminum source, in terms of Al2O3, to the molecular sieve is (0.1-1): 1, and a mass ratio of the silicon source, in terms of SiO2, to the molecular sieve is (0.1-1): 1. The method can effectively improve the hydro-thermal structural stability and hydro-thermal activity stability of the molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

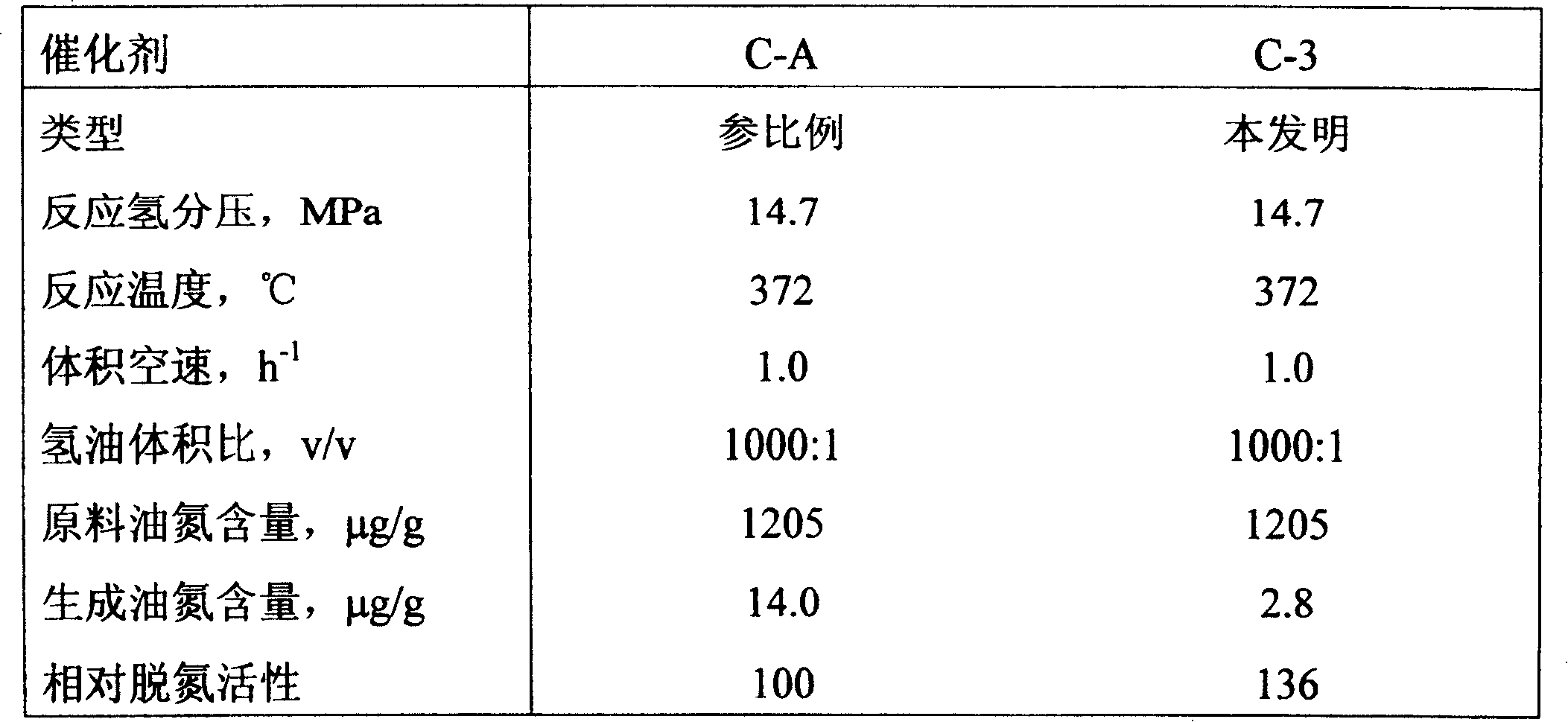

Silicon and boron contained alumina carrier and production thereof

A Si and B contained alumina carrier for the hydrogenating catalyst, especially the hydrodenitrifying catalyst, is prepared from macroreticular alumina and millipore alumina through continuously forming colloid while introducing Si and B step by step to disperse the most of Si and B on the surface of alumina.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN102451743BReduce roasting stepsEasy to manufactureMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a preparation method of a hydrogenation catalyst. According to the catalyst, a cracking molecular sieve, amorphous silica-alumina and alumina are used as carriers, and VIII and VIB metals are used as hydrogenation active components. The preparation process comprises the following steps of: mixing the cracking molecular sieve, amorphous silica-alumina and alumina for molding, drying, loading the active metals by an immersion method, drying and roasting to obtain the catalyst. In comparison with the routine immersion method, the method provided by the invention can be used to prepare the molded carriers without roasting, simplify time and energy, minimize strong interaction, help uniform distribution of the metals as well as performance of the metal activity, and avoid specific surface area loss caused by multi-step roasting. The catalyst prepared by the method is especially applicable to be used as a hydrogenation catalyst for high-yield high-quality heavy naphtha, aviation kerosene and diesel oil. By the adoption of the preparation method, activity and selectivity of the catalyst are raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amorphous silicon aluminium and preparation method thereof

ActiveCN102039197BSimple processEasy to controlCatalyst carriersCatalytic crackingPore distributionStrong acids

The invention discloses an amorphous silicon aluminium and a preparation method thereof. In the invention, hydro-thermal treatment is carried out on amorphous silicon aluminium obtained by a carbonization method, so that the amorphous silicon aluminium has higher specific surface area and bigger pore volume, the pore distribution is more intensive, and the pore volume the pore diameter of which is 6-10nm accounts for 80-95% of the total pore volume; meanwhile, the acid distribution of the amorphous silicon aluminium is improved; the amount of moderately strong acid and L acid is improved to effectively prevent raw material modules from excessively cracking, which is favourable for improving the selectivity of a target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alumina dry glue containing silicon and boron and production thereof

ActiveCN100421784CEvenly dispersedFully utilizePhysical/chemical process catalystsDispersityNitrogen

A dry alumina colloid containing Si and B is prepared through continuously forming colloid while adding Si and B assistants step by step for high and uniform dispersity of Si and B. It can be used as the carrier precursor of catalyst to improve the hydrogenation activity of catalyst, especially the hydrodenitrifying activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com