Preparation method of hydrocracking catalyst

A hydrocracking and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problem of substandard gasoline product quality, loss of catalyst activity and reaction performance, reaction conversion rate, product distribution and product quality. Quality decline and other problems, to achieve good active metal dispersion, reasonable acid strength distribution characteristics, shorten the initial activity stability time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

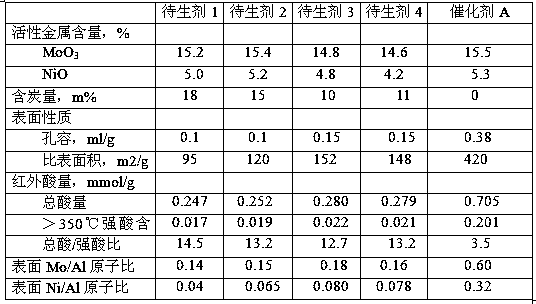

Embodiment 1

[0031] Low temperature decarburization process:

[0032] (1) Take the hydrocracking A standby agent 1 after the operation of an industrial catalytic diesel hydroconversion unit and place it in the regeneration furnace;

[0033] (2) Introduce an oxygen / nitrogen mixed gas with an oxygen content of 1% into the regeneration furnace, control the gas / agent ratio to 4000, and at the same time, raise the temperature to 380°C at a heating rate of 25°C / h, and obtain Example 1 after 4 hours of constant temperature roasting Decarbonization catalyst, code T-1;

Embodiment 2

[0035] (1) Take the hydrocracking A standby agent 2 after the operation of an industrial catalytic diesel hydroconversion unit and place it in the regeneration furnace;

[0036] (2) Introduce an oxygen / nitrogen mixed gas with an oxygen content of 3% into the regenerating furnace, control the gas / agent ratio to 1500, at the same time, raise the temperature to 350°C at a heating rate of 25°C / h, and obtain Example 2 after constant temperature roasting for 10 hours Decarbonization catalyst, code T-2

Embodiment 3

[0038] (1) Take the hydrocracking A standby agent 3 after the operation of an industrial catalytic diesel hydroconversion unit and place it in the regeneration furnace;

[0039] (2) Introduce oxygen / CO with an oxygen content of 3% into the regeneration furnace 2 Gas mixed gas, the gas / agent ratio is controlled to 1500, at the same time, the temperature is raised to 300°C at a heating rate of 25°C / h, and the decarbonization catalyst of Example 3 is obtained after constant temperature roasting for 15 hours, and the code is T-3;

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com