A method for black tea vacuum pulse drying and aroma enhancement

A technology of vacuum drying and vacuum pulsation, which is applied in the direction of tea treatment before extraction, can solve the problems of smoky tea, prone to burnt edges and high temperature, and achieve the effect of mellow tea taste, fast extraction rate and improved taste quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Example 1 Selection of the parameter range of vacuum pulse drying

[0027] Control of pulsation time:

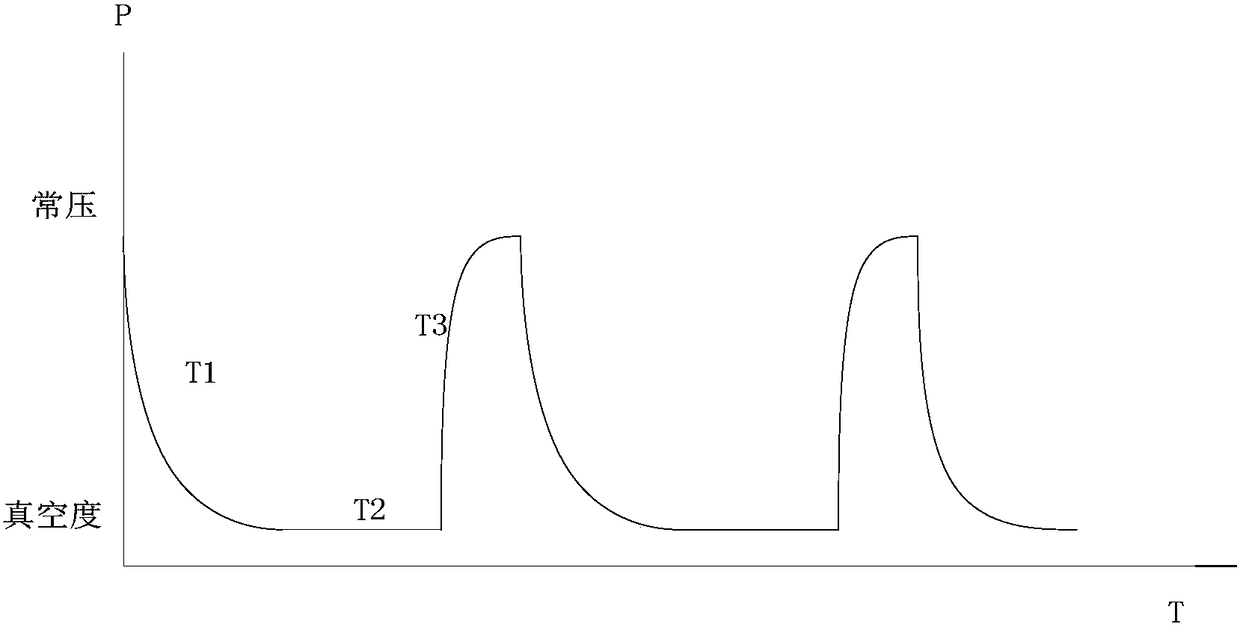

[0028] The vacuum degree is expressed by atmospheric pressure-absolute pressure. During the vacuum pulsation drying process, the pressure in the vacuum drying chamber changes like figure 1 Shown as follows: in each pulsation cycle, the time for vacuuming is 20s≤T1≤120s; the vacuum holding time is 0s≤T2≤120s; the time to restore normal pressure is 18s≤T3≤35s.

[0029] Control of vacuum pulse drying temperature:

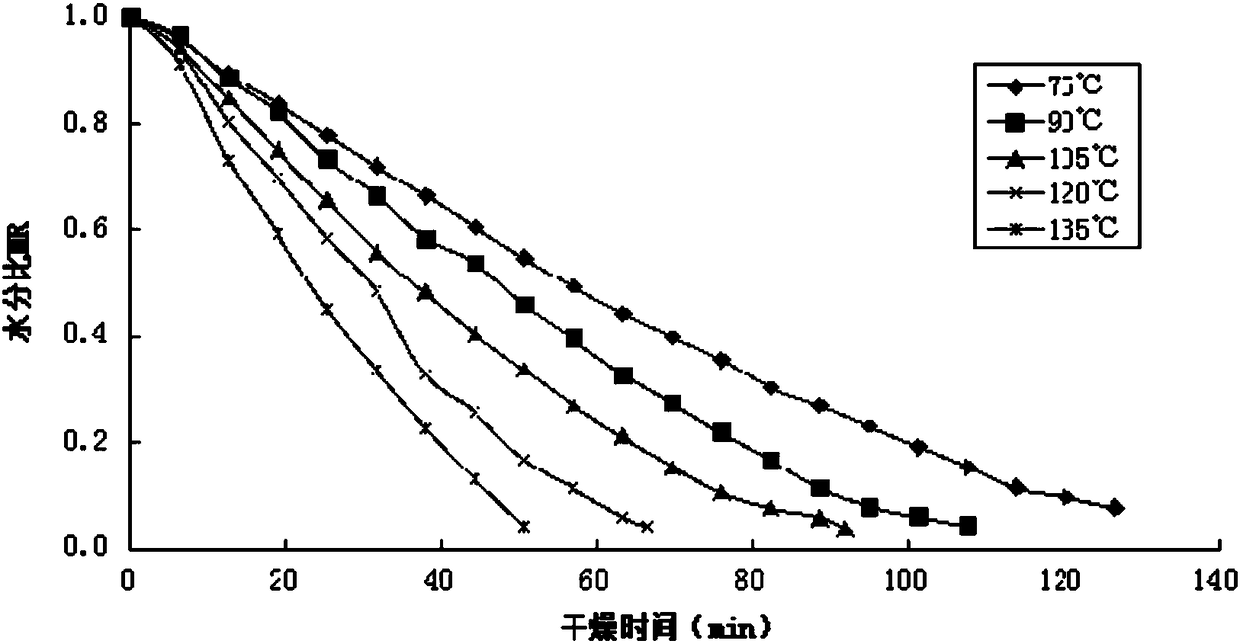

[0030] Set the vacuum degree to 95KPa and the vacuum pressure holding time of 2min to study the variation curve of the moisture ratio of the in-process product with the drying time at different temperatures (75, 90, 105, 120 and 135℃) of black tea fermented leaves using the pulse parameters. figure 2 . When the black tea fermented leaves were dried to a moisture content of 10%, the required cycles with increasing temperature were 116.67, 97.67, 80.83, 60.50 and 40.67...

Embodiment 2

[0046] Use the following steps to vacuum pulsate black tea to dry and increase aroma:

[0047] (1) Spread moderately fermented fermented leaves (55-60% water content;) on the partition in the vacuum drying chamber. The temperature of the drying chamber is 80°C and the vacuum degree is cyclically changed between 0-65KPa, each pulse Medium: Vacuum time T1≤60s, vacuum holding time T2≤120s, normal pressure recovery time T3≤60s.

[0048] When the drying process reaches 90 minutes, the moisture content of the tea leaves drops to about 12%.

[0049] (2) At this time, carry out the pulsating aromatization process, set the temperature of the vacuum drying chamber to 90°C, and continue the aromatization time for 2h, and the moisture of the tea will drop to about 5-7%;

[0050] In the pulsating aromatization process, the pressure of the vacuum drying chamber is adjusted by the pulsation adjustment of normal pressure holding-vacuuming-vacuum holding, and the vacuum degree is not less than 65KPa; ...

Embodiment 3

[0054] (1) Spread moderately fermented fermented leaves (with a water content of 55-60%;) on the partitions in the vacuum drying chamber. The temperature of the drying chamber is 80°C and the vacuum degree is cyclically changed between 0-95KPa, each pulse Medium: Vacuum time T1=120s, vacuum holding time T2=0s, normal pressure return time T3=35s.

[0055] When the drying process reaches 120 minutes, the moisture content of the tea leaves drops to about 12%.

[0056] (2) At this time, carry out the pulsating aromatization process, set the temperature of the vacuum drying chamber to 90°C, and continue the aromatization time for 2h, and the moisture of the tea will drop to about 5-7%;

[0057] In the pulsating aromatization process, the pressure of the vacuum drying chamber is adjusted by the pulsation adjustment of normal pressure holding-vacuuming-vacuum holding, and the vacuum degree is not less than 65KPa; the pulsation period is the same as step (1), which is beneficial to the heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com