Combined modification method for mesopore USY molecular sieve

A molecular sieve and mesopore-rich technology, applied in the field of USY molecular sieve modification, can solve the problems of harsh modification conditions, expensive chemicals, unfavorable industrialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

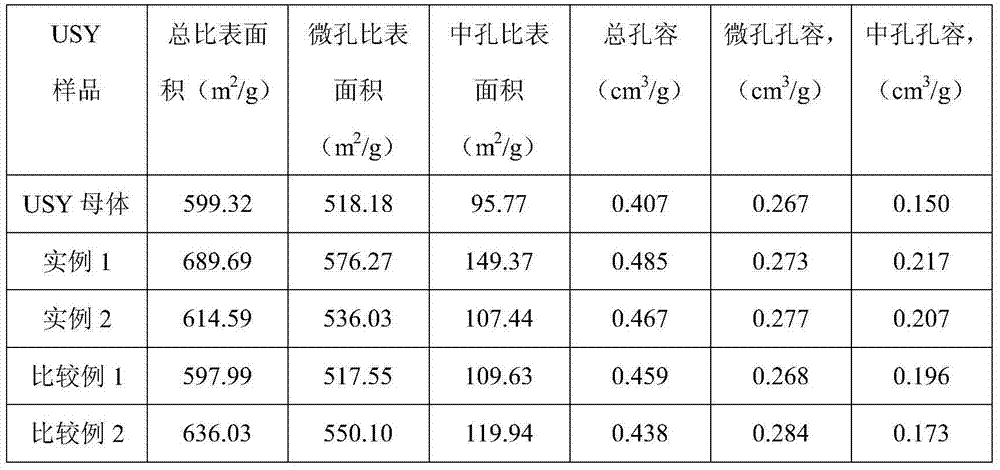

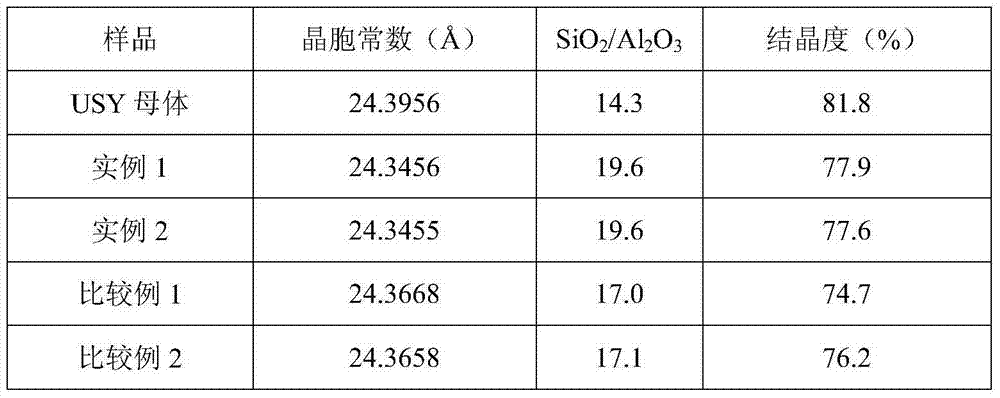

Embodiment 1

[0018] Weigh 12g of USY and pour it into a 250ml three-necked plastic flask; measure citric acid solution and ammonium fluoride solution according to the ratio; 40ml of 0.4mol / L citric acid solution and 80ml of 0.2mol / L ammonium fluoride solution. Stir at room temperature, set the water bath temperature of 90°C to react; after constant temperature reaction for 8 hours, wash and filter the product until the surface of the product is neutral; put it in an oven at 110°C, dry at constant temperature for 16 hours, and grind to obtain a modified sample.

Embodiment 2

[0020] Weigh 48g of USY and pour it into a 1L autoclave; according to the ratio, measure 160ml of citric acid solution with a concentration of 0.4mol / L and 320ml of an ammonium fluoride solution with a concentration of 0.2mol / L; stir, fill the kettle, and set the temperature of the inner kettle 90°C; after the temperature of the inner kettle reaches the set temperature, react at a constant temperature for 8 hours, wash and filter until the surface of the product is neutral; put it in an oven at 110°C, dry at a constant temperature for 16 hours, and grind to obtain a modified sample in a large kettle .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com