Catalyst for producing aromatics from methanol and its preparation method and application

A methanol preparation and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low xylene selectivity, improve reaction adaptability, improve acid distribution, and improve selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

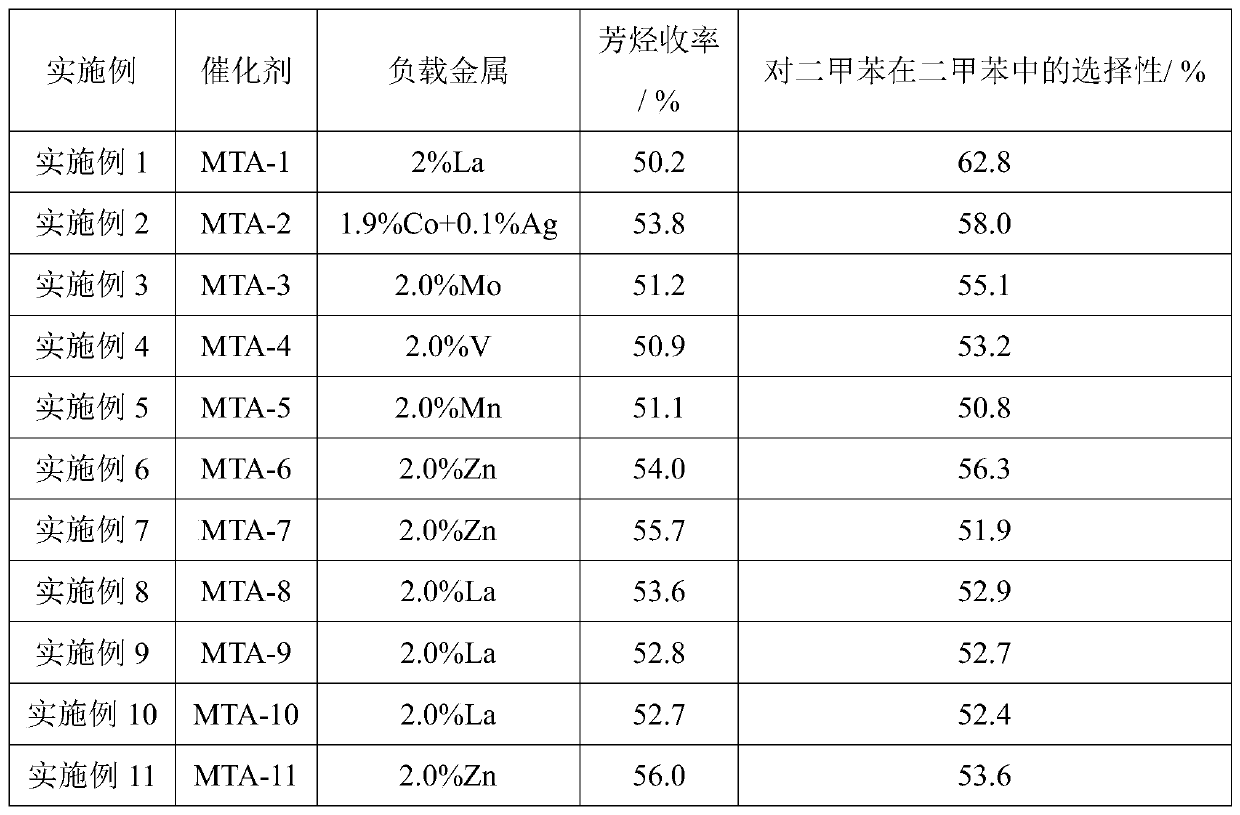

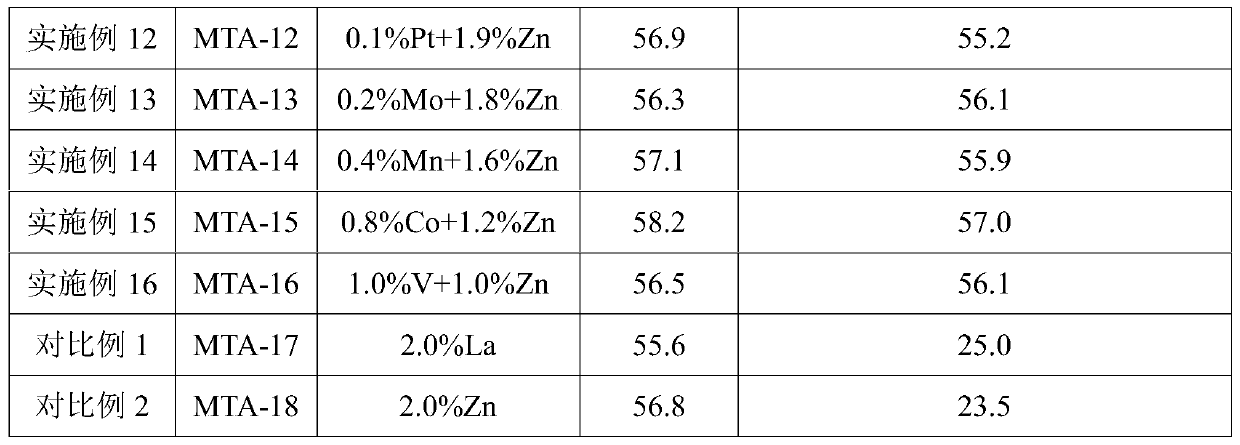

Examples

Embodiment 1

[0020] (1) under stirring condition, 14.7g pseudo-boehmite, 16.6g orthophosphoric acid (85%), 5g silica sol (40%) and 60g water are mixed to obtain mixed solution;

[0021] (2) Weigh 20g of hydrogen-type ZSM-5 molecular sieve and add it to the above mixture, stir for 2 hours, heat to 50°C and evaporate to dryness;

[0022] (3) Mix 5g of tetraethylammonium hydroxide, 10g of triethylamine and 35g of water evenly, and add 20g of the solid obtained in step (2), mix evenly, and then transfer to an autogenous pressure crystallization kettle for crystallization at 180°C for 48h ;

[0023] (4) After the crystallization is completed, the crystallization solution is taken out, washed with water, dried, and calcined at 550°C for 4 hours to obtain a core-shell type ZSM-5@SAPO-34 composite molecular sieve;

[0024] (5) Weigh 20g of the above-mentioned core-shell type ZSM-5@SAPO-34 composite molecular sieve, mix it with 20g of pseudoboehmite and 1.0g of turnip powder, weigh an appropriate ...

Embodiment 2

[0027](1) 7.5g pseudo-boehmite, 9g orthophosphoric acid (85%), 2.5g silica sol (40%) and 60g water are mixed uniformly to obtain a mixed solution under stirring conditions;

[0028] (2) Weigh 20g of ZSM-5 molecular sieve and add it to the above mixture, stir for 4 hours, heat to 90°C and evaporate to dryness;

[0029] (3) 5g of tetraethylammonium hydroxide, 10g of morphine and 35g of water were mixed uniformly, and 20g of the solid obtained in step (2) was added, mixed uniformly, and then transferred to an autogenous pressure crystallization kettle for crystallization at 160°C for 72h;

[0030] (4) After the crystallization is completed, the crystallization solution is taken out, washed with water, dried, and calcined at 500°C for 6 hours to obtain a core-shell type ZSM-5@SAPO-34 composite molecular sieve;

[0031] (5) Weigh 20g of the above-mentioned core-shell type ZSM-5@SAPO-34 composite molecular sieve, mix it with 20g of silica sol (40%wt), 1.0g of soluble starch, weigh a...

Embodiment 3-6

[0034] (1) under stirring condition, 15g pseudo-boehmite, 18g orthophosphoric acid (85%), 5g silica sol (40%) and 200g water are mixed to obtain mixed solution;

[0035] (2) Weigh 60g of ZSM-5 molecular sieve and add it to the above mixture, stir for 4 hours, heat to 100°C and evaporate to dryness;

[0036] (3) 20g tetraethylammonium hydroxide, 20g morphine, 20g triethylamine and 140g water are mixed homogeneously, and add the solid that 80g step (2) obtains, mix homogeneously, then transfer to 200 in autogenous pressure crystallization still ℃ crystallization 24h;

[0037] (4) After the crystallization is completed, the crystallization solution is taken out, washed with water, dried, and calcined at 600°C for 2 hours to obtain a core-shell type ZSM-5@SAPO-34 composite molecular sieve;

[0038] (5) Weigh 20g of the core-shell type ZSM-5@SAPO-34 composite molecular sieve prepared above in the example, mix it with 15g of pseudo-boehmite, 5g of fumed silica, and 1g of scallop po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com