A method for improving the stability of Y-type molecular sieves

A molecular sieve and stability technology, applied in the direction of crystalline aluminosilicate zeolite, fauhhedral crystalline aluminosilicate zeolite, etc., can solve the problems of cracking activity and selectivity, acid content reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

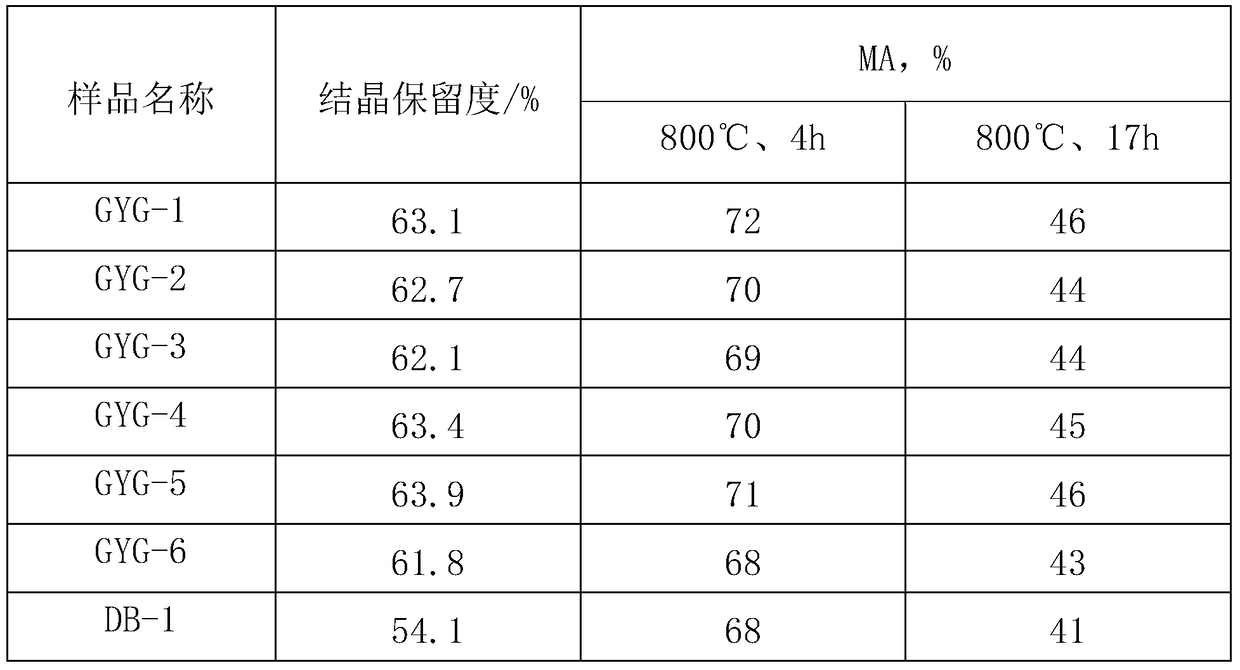

Examples

Embodiment 1

[0017] Take by weighing 20g (dry basis) industrial NaY molecular sieve (Na 2 O 12.9%, crystallinity 89%, Sinopec Changling Catalyst Factory) in a beaker, add deionized water for beating, add 140g glycerol after shearing evenly, heat up to 100 ° C for 10 hours, after cooling to room temperature, add 24g TPAOH solution (mass fraction 25wt%), then 110mL aluminum sulfate solution (Al 2 o 3 Content 90g / L) and appropriate amount of ammoniacal liquor (mass fraction 25wt%) are added in the above-mentioned slurry simultaneously, and the adjustment slurry pH value is 9.0, then 10mL water glass solution (SiO 2 content 250g / L, modulus 3.3) was added thereto, and the temperature was raised to 70°C for aging for 2 hours. The above slurry was crystallized at 110°C for 20 hours, and the obtained product was filtered, washed and dried, and then calcined at 600°C for 4 hours to obtain the molecular sieve of the present invention. Recorded as GYG-1.

Embodiment 2

[0019] Weigh 20g NaY molecular sieve (dry basis) in a beaker, add deionized water to make a slurry, add 80g glycerol after shearing evenly, heat up to 150°C for 5 hours, after cooling to room temperature, add 32g TMAOH solution (mass fraction 25wt% ), then 67mL of aluminum sulfate solution and ammonia water were added to the slurry at room temperature, and the pH value of the slurry was adjusted to 10.0, and then 10mL of water glass solution was added therein, and the temperature was raised to 60°C for aging for 2 hours. The above slurry was crystallized at 100°C for 10 hours, and the obtained product was filtered, washed and dried, and then calcined at 650°C for 2 hours to obtain the molecular sieve of the present invention. Recorded as GYG-2.

Embodiment 3

[0021] Weigh 20g NaY molecular sieve (dry basis) in a beaker, add deionized water for beating, shear evenly, add 200g propylene glycol, heat up to 170°C for 8 hours, cool to room temperature, add 30g TPAOH solution and 18gTEAOH solution (mass fraction 25wt %), then aluminum sulfate solution and sodium metaaluminate solution (Al 2 o 3 Content 190g / L) and flow into the above slurry, and adjust the pH value of the slurry to 8.0, then add 17mL water glass solution, and age at 50°C for 2 hours. The above slurry was crystallized at 120°C for 10 hours, and the obtained product was filtered, washed and dried, and then calcined at 550°C for 6 hours to obtain the molecular sieve of the present invention. Recorded as GYG-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com