Alumina dry glue containing silicon and boron and production thereof

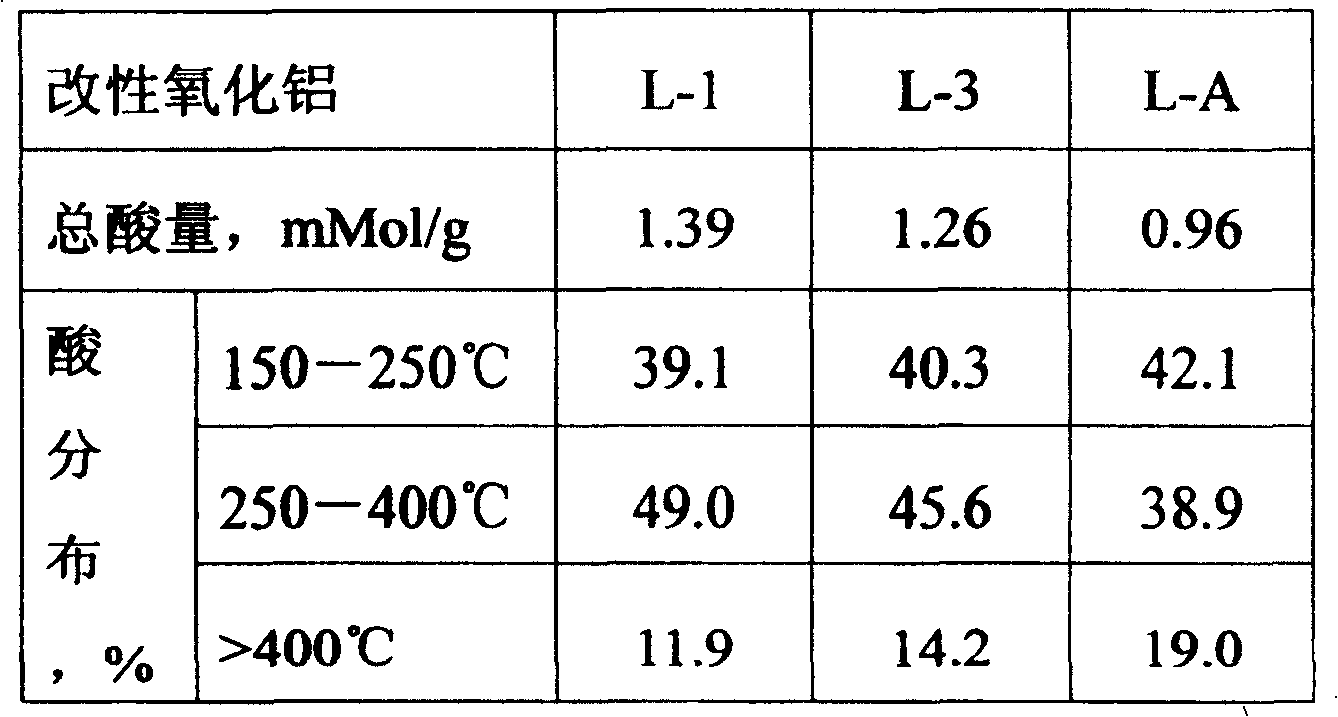

A technology of alumina dry gel and boron compound, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of affecting the physical and chemical properties of the final carrier, the small diameter of alumina gel pores, and insufficient Play its role and other issues to achieve the effect of increasing strength, large pore diameter, and improving acid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 1000ml of clean water into a container, raise the temperature to 65°C, add 3700ml of a solution containing 310g of aluminum chloride, and at the same time add 10g of NH 3 / 100ml of ammonia solution, the pH value is controlled at 8.2, the temperature is 62°C, and the feeding time is 60min.

[0038]After the feeding was stopped, the system was aged for 50 minutes under the above-mentioned pH value and temperature conditions, and 40 ml of a solution containing 4.8 g of sodium metasilicate was added, and the system was continued to age for 75 minutes under the above-mentioned pH value and temperature conditions. Filter and wash to Cl - / Al 2 o 3 <0.3wt%.

[0039] After the filter cake was beaten with clean water, 43g of boric acid was added, the temperature was controlled at 50°C, and the feeding time was 40min.

[0040] Filter and dry the filter cake at 130° C. for 8 hours, and crush it until the particle size is less than 180 mesh, accounting for more than 95 wt%,...

Embodiment 2

[0042] Add 1000ml of clean water into a container, heat up to 65°C, add 560g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O) solution 3700ml, adding concentration simultaneously is 10gNH 3 / 100ml of ammonia solution, the pH value is controlled at 7.6, the temperature is 60°C, and the feeding time is 80min.

[0043] After the feed was stopped, the system was aged for 25 minutes under the above pH and temperature conditions, and 100 ml of a solution containing 15.3 g of sodium metasilicate was added. The system continued to age for 75 minutes under the above pH and temperature conditions, filtered and washed to SO 4 2- / Al 2 o 3 <1.5wt%.

[0044] Dissolve 34.6g of boric acid in clean water, then add wet filter cake to make slurry, control the temperature at 55°C for 40min.

[0045] After filtering and drying the filter cake at 130° C. for 8 hours, it was crushed until the particle size was less than 180 mesh, accounting for more than 95 wt%, to obtain modified alumina dry ...

Embodiment 3

[0047] Add 1000ml of clean water into a container, heat up to 65°C, add 300g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O) solution 2000ml, adding 1011g concentration simultaneously is 15.0gAl 2 o 3 / 100ml of sodium metaaluminate solution, the pH value is controlled at 8.5, the temperature is 64°C, and the feeding time is 120min.

[0048] After the feed was stopped, the system was aged for 60 min under the above pH and temperature conditions, and 245 ml of a solution containing 32 g of sodium metasilicate was added. The system continued to age for 45 minutes under the above pH and temperature conditions, filtered and washed to SO 4 2- / Al 2 o 3 <1.5w%.

[0049] After the filter cake was beaten with clean water, 30 g of boric acid was added, and the temperature was controlled at 45° C. for 40 minutes.

[0050] After the filter cake was dried at 130°C for 8 hours, it was crushed until the particle size was less than 180 mesh, accounting for more than 95w%, to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com