Preparation method of multi-metal modified composite material

A composite material, multi-metal technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor cracking activity, high price, large steric hindrance effect, etc., and achieve reaction performance. The effect of promoting and improving acid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation process of the directing agent adopted in the embodiment is: 5700g water glass (Changling Catalyst Company provides, SiO 2 261g / L, modulus 3.31, density 1259g / L) is put into the beaker, add 4451g perbasic sodium metaaluminate (provided by Changling Catalyst Company, Al 2 o 3 39.9g / L, Na 2 O279.4g / L, density 1326g / L) and aged at 30°C for 18 hours, a molar ratio of 16.1Na 2 O: Al2 o 3 :15SiO2 2 :318.5H 2 O's directing agent.

[0041] In each example, the RE of the material 2 o 3 , MgO, Na 2 O, Al 2 o 3 , SiO 2 The content is determined by X-ray fluorescence method (see "Petrochemical Analysis Method (RIPP Experimental Method)", edited by Yang Cuiding, etc., Science Press, published in 1990).

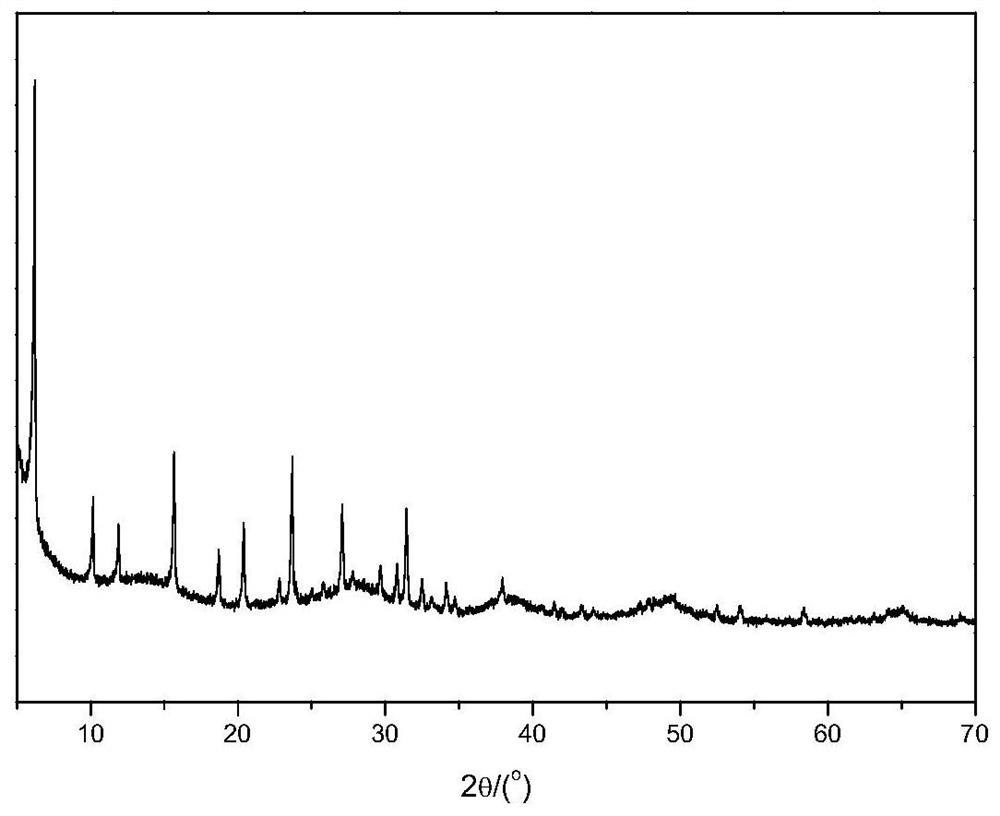

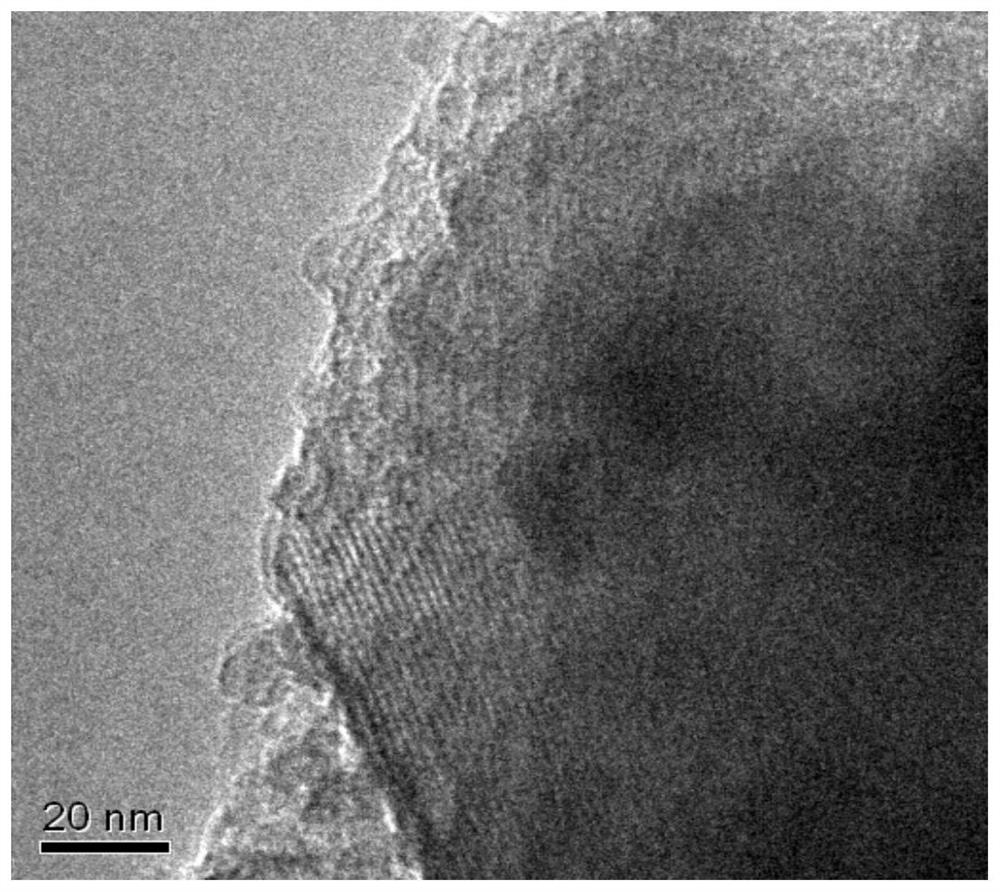

[0042] The phase, unit cell constant and crystallinity were determined by X-ray diffraction method. The crystallinity is determined according to the industry standards SH / T 0340-92 and SH / T 0339-92 of China Petroleum & Chemical Corporation, and the cry...

Embodiment 1

[0049] According to 8.5SiO 2 :Al 2 o 3 : 2.65Na 2 O: 210H 2 The molar ratio of NaY molecular sieve gel of O is mixed in sequence with water glass, aluminum sulfate, sodium metaaluminate, guiding agent and deionized water and stirred for 1 hour, wherein the mass ratio of guiding agent is 5%. , the gel was crystallized at 100° C. for 30 hours, and then the crystallized slurry was filtered and washed, and dried in an oven at 120° C. for 10 hours to obtain NaY molecular sieves.

[0050] Add water to the obtained NaY molecular sieve dry powder again, stir evenly, then raise the temperature to 50°C, stir vigorously, and at the same time, add AlCl 3 Solution (concentration 60gAl 2 o 3 / L) and NaAlO 2 Solution (concentration 102gAl 2 o 3 / L) and flow into it, carry out contact reaction, and control the pH value of slurry system to be 8.5, after reacting certain hours, according to the total Al in aluminum chloride solution used and sodium metaaluminate solution 2 o 3 by wei...

Embodiment 2

[0056] According to the gel feeding molar ratio of NaY molecular sieve described in Example 1, water glass, directing agent, aluminum sulfate, sodium metaaluminate and required deionized water were mixed in sequence and stirred for 1 hour, wherein the directing agent The mass ratio was 6%. The gel was crystallized at 100° C. for 25 hours, and then the crystallized slurry was filtered and washed, and dried in an oven at 120° C. for 10 hours to obtain NaY molecular sieves.

[0057] The obtained NaY molecular sieve dry powder was re-added with water to make a slurry, stirred evenly and then heated to 40°C, under vigorous stirring, at the same time, the Al 2 (SO 4 ) 3 Solution (concentration 50gAl 2 o 3 / L) and NaAlO 2 Solution (concentration 102gAl 2 o 3 / L) and flow into it, carry out the contact reaction, and control the pH value of the slurry system to be 9.0, after reacting for a certain period of time, according to the total Al in the aluminum sulfate solution used and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com