A kind of preparation method of silicon-containing alumina dry glue

A technology of silica-alumina and dry glue, which is applied in the direction of chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve the problems of large proportion and unsuitable hydrogenation catalyst materials, and achieve acidity and acid distribution. Cost reduction Low, the effect of improving cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

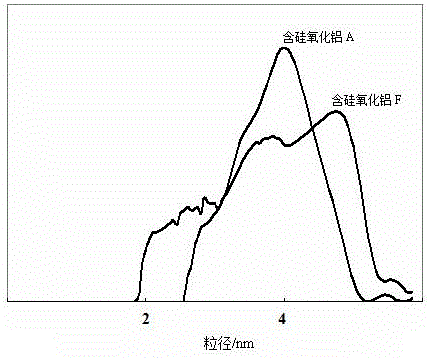

Image

Examples

Embodiment 1

[0033] Mix 200g of kaolin original soil with 2.0mol / L acetic acid 50mL and 50mL water-dissolved 20g polyethylene glycol solution, and perform modification treatment on the hydrothermal treatment device. The hydrothermal treatment temperature is 600℃, the treatment is 4h, and the hydrothermal treatment pressure is 0.25MPa. .

[0034] The concentration of sodium metaaluminate solution is 45gAl 2 O 3 / L total 1.6L, the concentration of aluminum sulfate solution is 20gAl 2 O 3 / L total 0.7L, ready to use.

[0035] Weigh 30g of modified kaolin, add 1L of distilled water to the gelatinization tank, the solid content in the slurry is 3wt%, and heat to 70°C. Add the prepared sodium metaaluminate solution to the modified kaolin slurry, adjust the pH to 9.0, after stabilizing for 5 minutes, add aluminum sulfate solution to adjust the pH to 3.0, after stabilizing for 5 minutes; swing like this 3 times, add sodium metaaluminate For the solution, adjust the pH of the slurry to 8.5, and then ad...

Embodiment 2

[0037] The other conditions were the same as in Example 1, except that the amount of modified kaolin was weighed and increased to 100g, the solid content in the slurry was 10wt%, and the organic pore expander alkylphenol and ethylene oxide condensate (OP- 10) 63mL (content 92g / L, calculated at 5wt% of silicon-containing alumina content) to prepare silicon-containing alumina B.

Embodiment 3

[0039] Other conditions are the same as in Example 1, except that the kaolin is replaced with halloysite, the hydrothermal treatment temperature is changed to 700° C., and the treatment time is 3 hours, to prepare silicon-containing alumina C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com