Patents

Literature

30results about How to "Granular concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

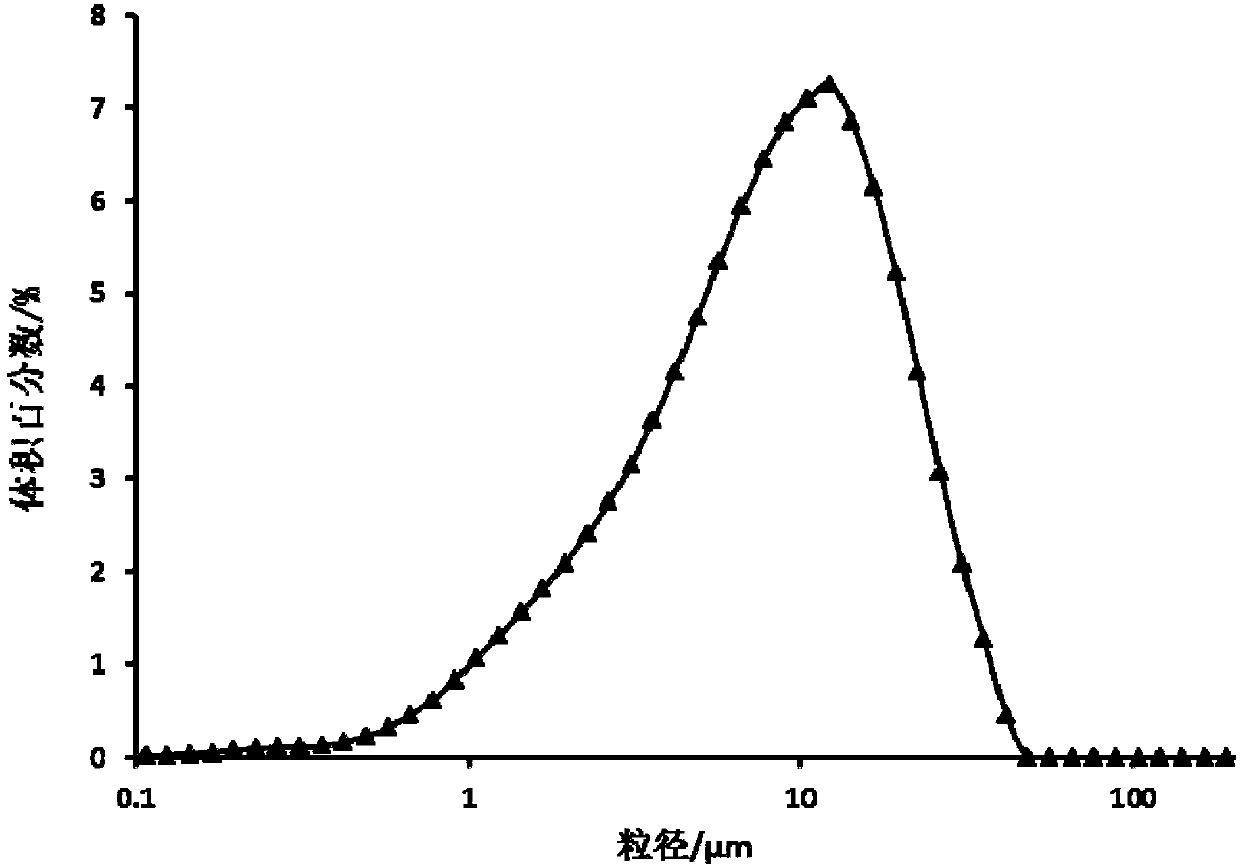

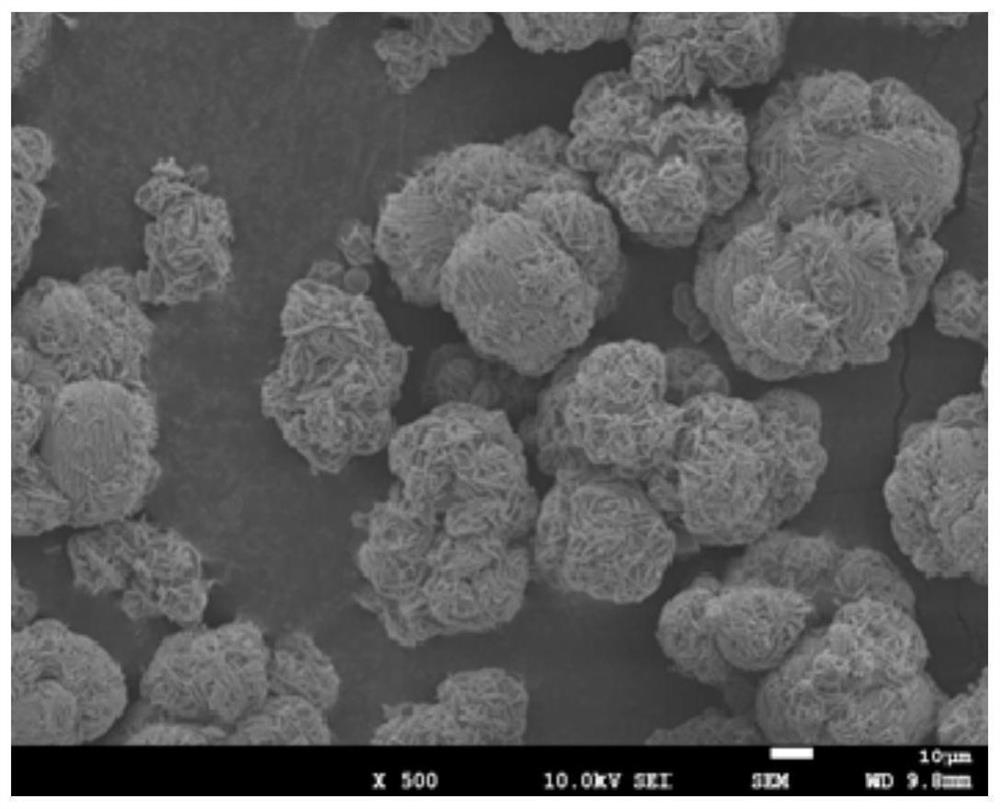

Method for preparing solid catalyst in olefin polymerization catalyst

ActiveCN101054424AProduct quality is easy to controlHigh particle sphericityContinuous/uninterruptedPolymer science

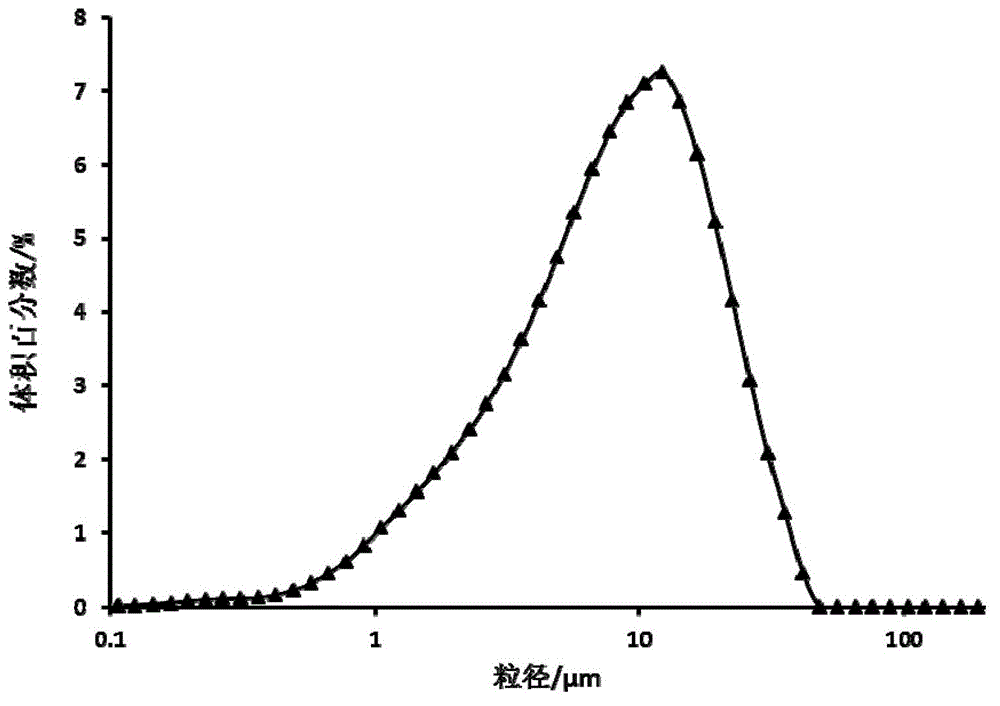

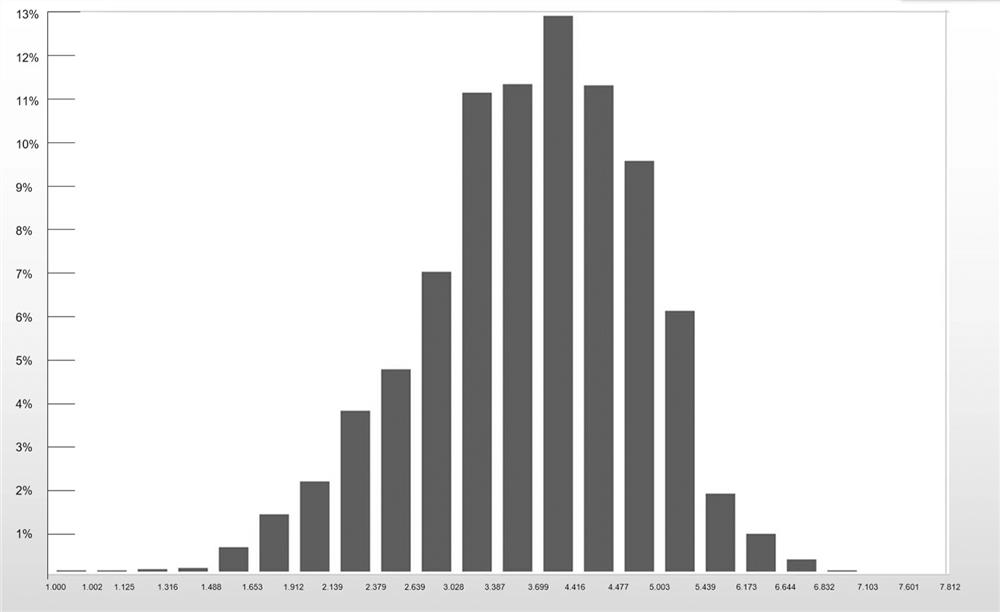

The invention provides a preparation method of solid catalyst used in olefinic polymerization catalyst, the method synthetizes the solid catalyst of olefinic polymerization continuously by magnesium powder, simplifies the technology of preparing magnesium compounds solid firstly then preparing the solid catalyst of olefinic polymerization, reduces quantity of equipment needed in industrialization, has advantages of simple technics, easy operation, low industrializing installation cost, low production cost, easy controlled product quality. The ball solid catalyst of olefinic polymerization which D(50) is in range of 10-80 mum is produced through the method of the invention, the catalyst has particle sphericity height L / W<1.4 (L expresses the longest axle of the particle, W is the minimum axle of the particle), has advantages of high polymerization activity, hydrogen regulating sensibility, high isotacticity of the polymer, centralized particle-size distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

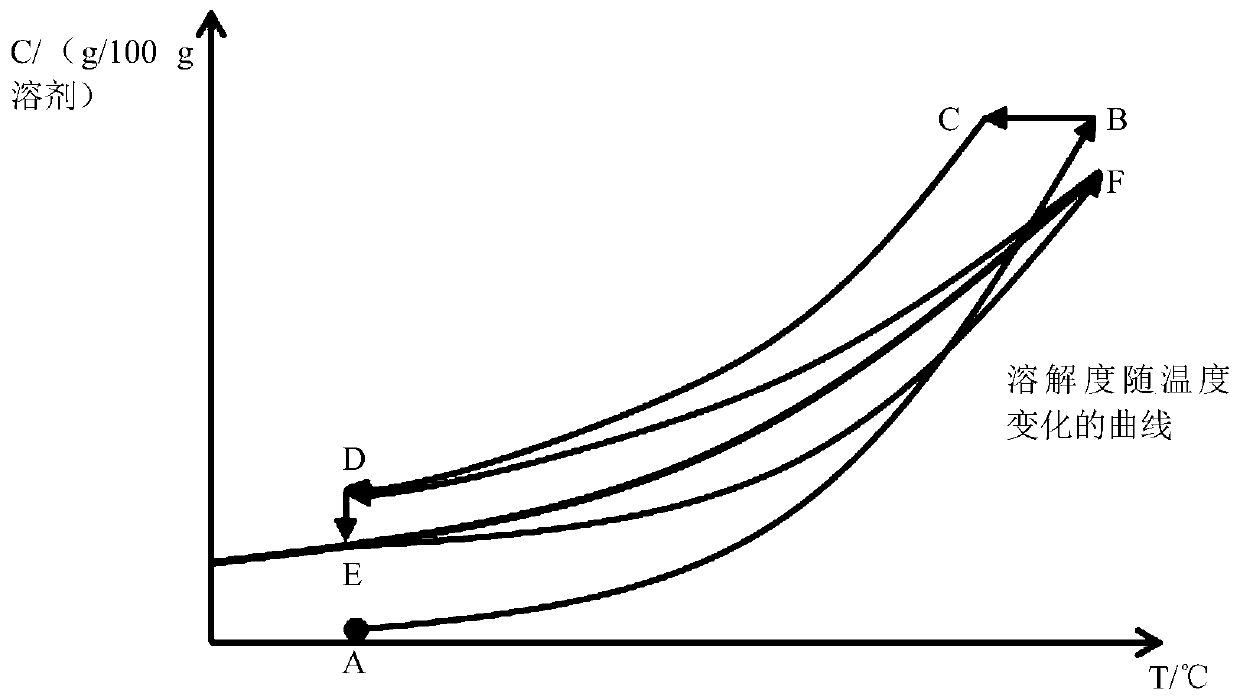

Xylitol refining crystallization process

InactiveCN1736970AQuality improvementHigh yieldHydroxy compound separation/purificationCrystallization temperatureNucleation

The invention relates to refine crystallization method for xylitol. Wherein, conveying the xylitol solution with mass concentration of 85-92% into crystallizer with original temperature of 65-85Deg; cooling and crystallizing; adding crystal seed to control refine crystallizing nucleation at temperature of 55-70Deg, holding for 15-60min; controlling cooling rate between 1Deg / hr-10Deg / hr during the process; the crystallization temperature is 30-45Deg, and the operation time is less than ten hours; centrifugal separating, cleaning, drying for 1-8h at temperature of 40-80Deg, finally, one obtains the product.

Owner:TIANJIN UNIV +1

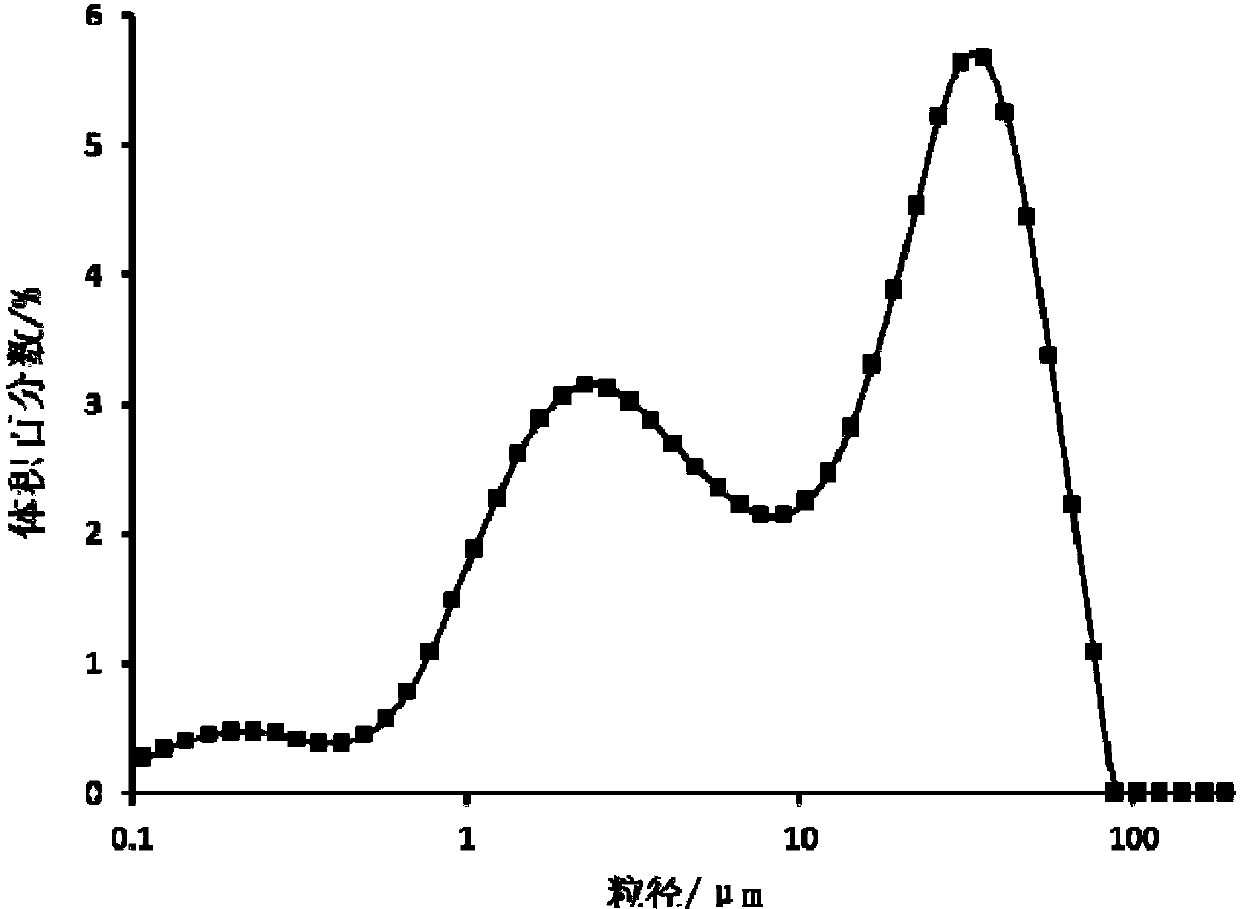

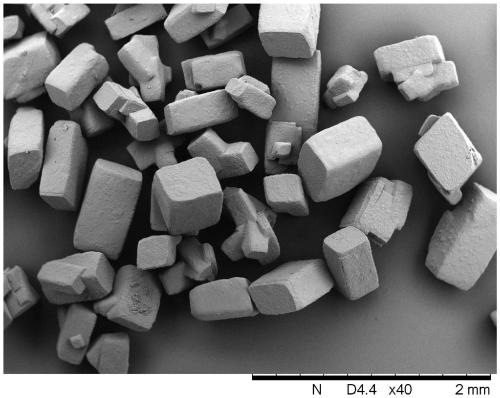

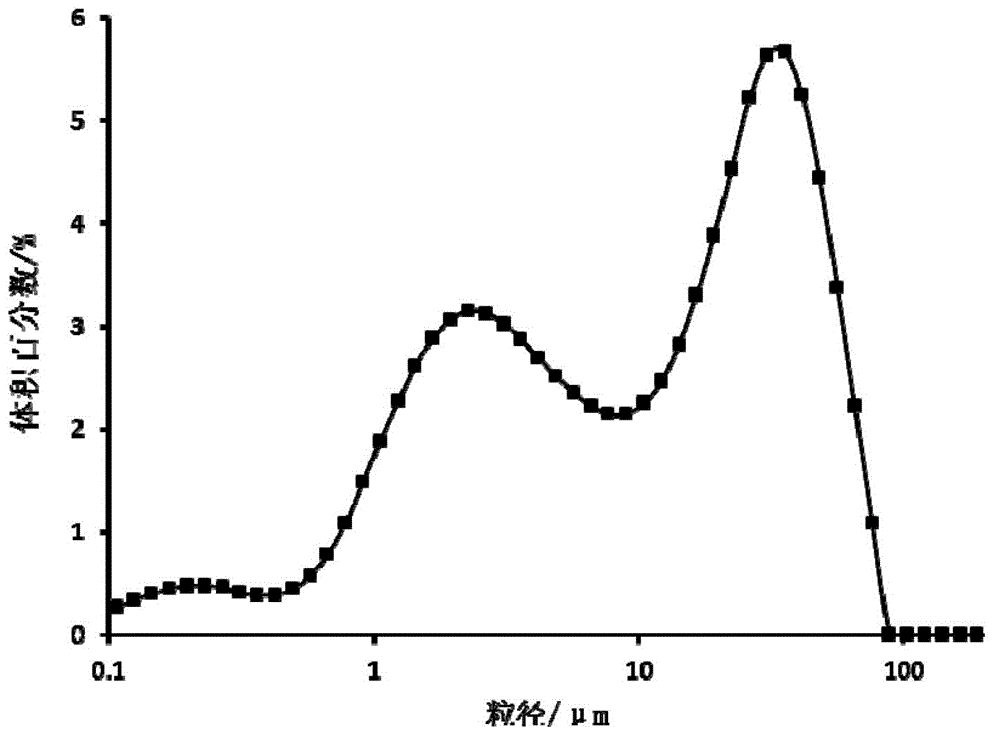

Preparation method of cefotaxime sodium crystal

ActiveCN103275101APrevent gelGranular concentrationOrganic chemistrySodium acetateSodium acetrizoate

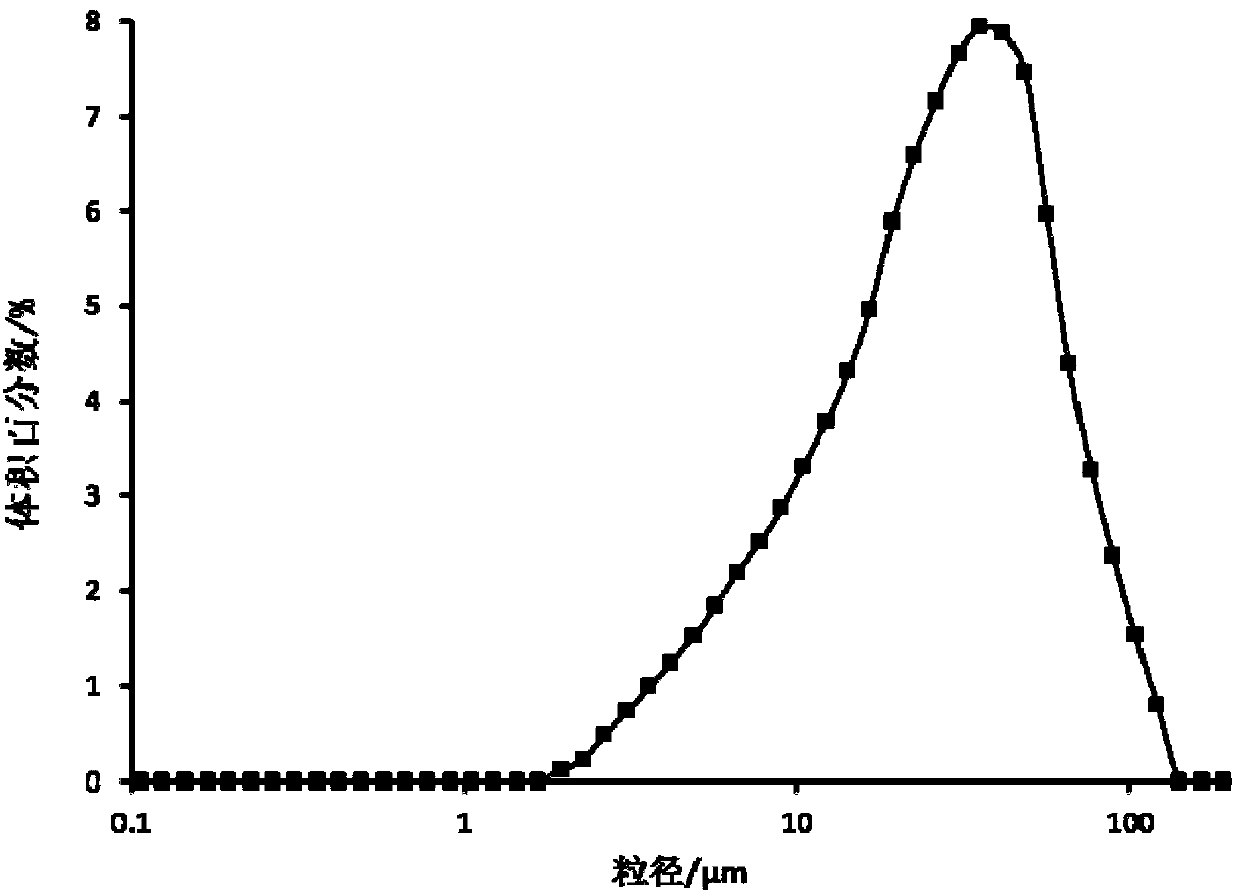

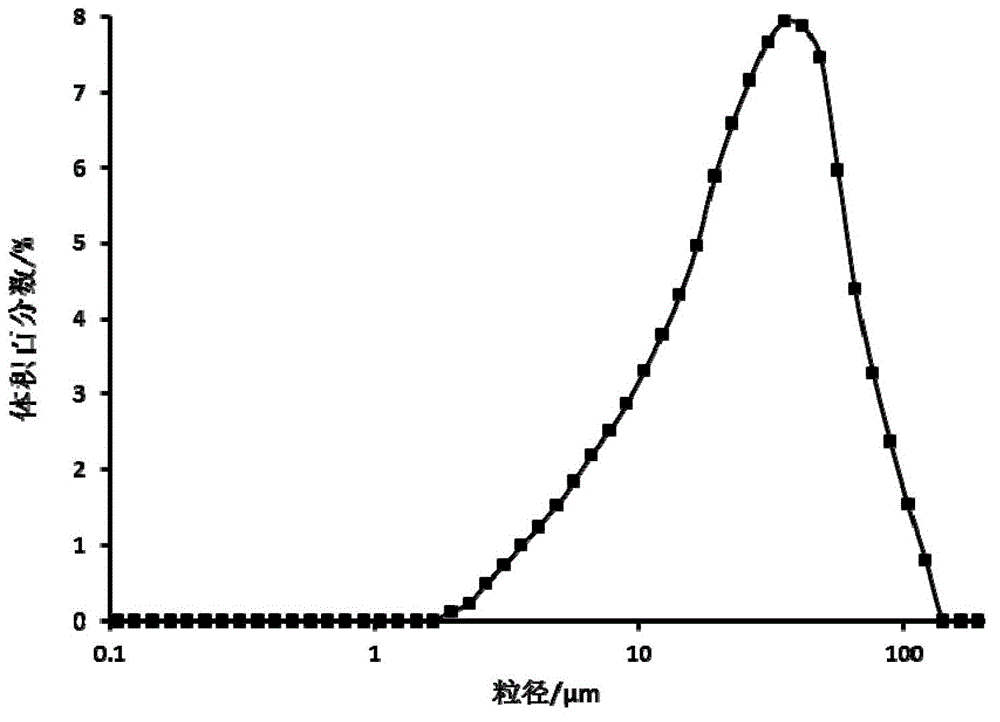

The invention relates to a preparation method of a cefotaxime sodium crystal. The preparation method comprises the following steps of: dissolving sodium acetate in a mixed solvent of organic solvent and water below 10-40 DEG C, wherein the volume fraction of organic solvent in the mixed solvent is 30-70%; adding cefotaxime acid, and stirring until the cefotaxime acid reacts in the solution; adding a cefotaxime sodium crystal in the solution, then adding elution agents with a feeding time of 2-8 hours, cooling to 5 DEG C below zero to 5 DEG C; and filtering, washing and drying a crystal slurry to obtain the cefotaxime sodium crystal. By the preparation method, the phenomenon of gelatinization frequently seen in the crystallization process of the cefotaxime sodium crystal is avoided, the size distribution of the products is centralized and the major particle size is adjustable from 5mu m to 60my m, the liquidity of the product is good, the process yield is higher than 87%, and the product purity is higher than 95.5%.

Owner:TIANJIN UNIV

Production method for samarium cobalt alloy powder

ActiveCN103537684AReduce performanceUniform grain size distributionInorganic material magnetismRare-earth elementHydrogen atmosphere

The invention discloses a production method for samarium cobalt alloy powder. The production method for the samarium cobalt alloy powder comprises weighing samarium, cobalt, iron, copper, zirconium and heavy rare earth element metal salt in proportion, preparing a salt solution and a salt-mixture solution, adding a little acid or alkali to control a PH (Potential of Hydrogen) value to be between 4 and 9, simultaneously adding surface active agent and dispersing agent which account 1 to 5 % of the mass of the metal salt in the metal salt solution, performing spray drying at the temperature between 300 and 350 DEG C to produce composite powder precursor, performing low temperature calcine at the temperature between 200 and 300 DEG C, performing two-step restoring on the precursor under hydrogen atmosphere with the temperature between 400 to 800 DEG C, ball-milling the restored powder to obtain the samarium cobalt alloy powder. The samarium cobalt alloy powder produced through the production method has the advantages of being reasonable in powder size, uniform in crystal grain and component distribution, high in purity and low in oxygen content. The production method has the advantages of being simple in operation, low in energy consumption, high in production efficiency and suitable for continuous production.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

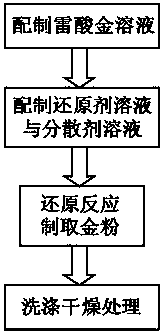

Preparation method of spherical superfine gold powder for electronic materials

The invention provides a preparation method of spherical superfine gold powder for electronic materials. The preparation method includes the following steps: a), preparing a fulminic acid gold solution, b), preparing a reductant solution and a dispersant solution, c), preparing the gold powder through a reduction reaction and d), washing and drying the gold powder. The preparation method is simple and reasonable, the spherical superfine gold powder prepared according to the method has the advantages of high dispersibility, centralized granularity, small specific surface area and high tap density, and conductor paste made of the superfine gold powder has excellent electric conductivity and sintering characteristic and compact sintered membrane layers.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

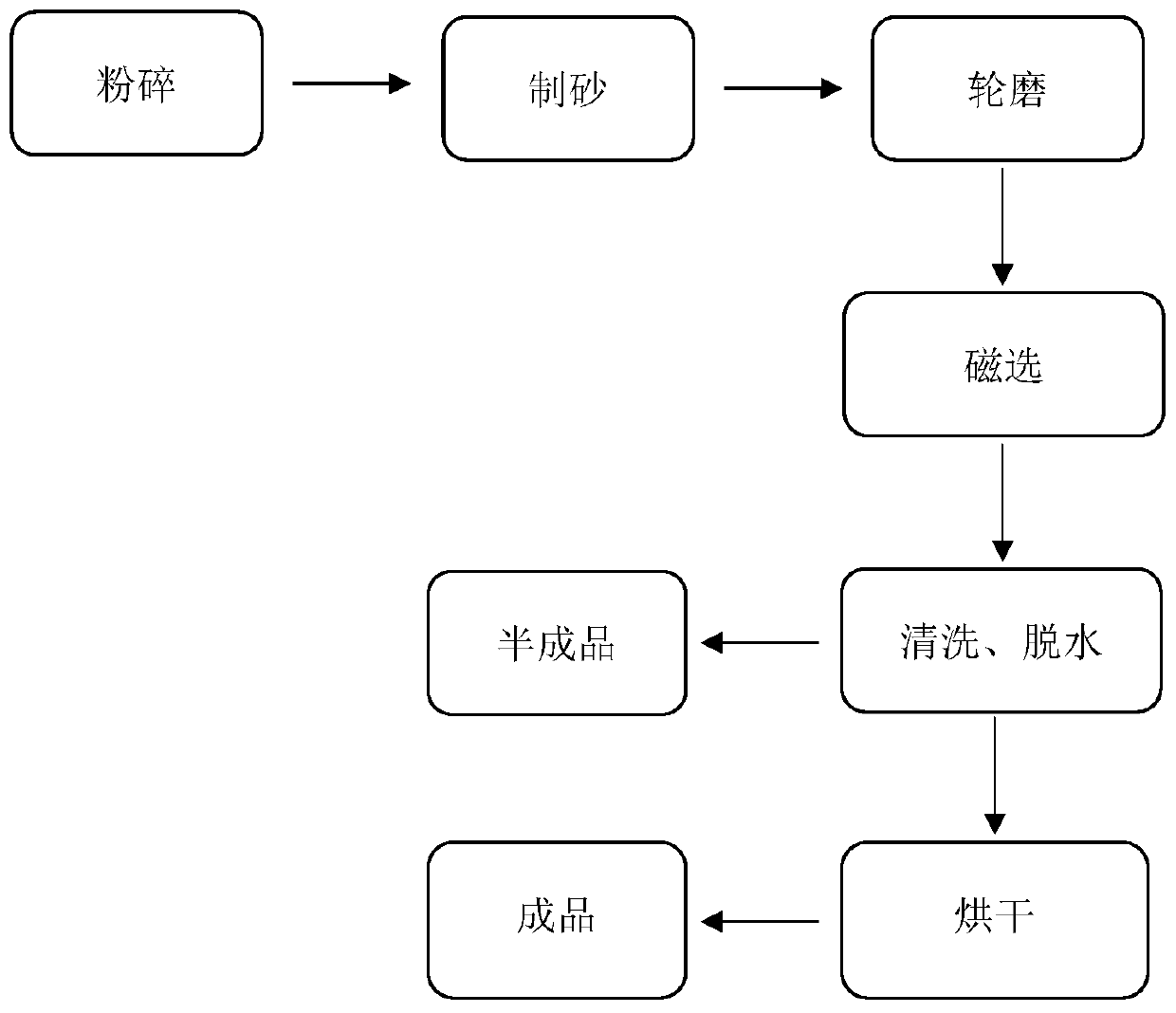

Silica sand preparation process

The invention relates to the technical field of silica sand, and discloses a silica sand preparation process, which comprises: 1) crushing: crushing cleaned raw ore to obtain a crushed material with aparticle size of less than 10 mm; 2) sand making: adding the crushed material obtained in the step 1) into a sand making machine, carrying out sand making, screening through a 40-70 mesh sieve afterthe sand making, and carrying out mud removing treatment to obtain primary screened sand; 3) wheel grinding: adding the primary screened sand obtained in the step 2) into a wheel grinding machine, grinding, screening through a 8-10 mesh sieve after the grinding, and carrying out mud removing treatment to obtain screened powder sand; and 4) magnetic separation: adding the screened powder sand obtained in the step 3) into a magnetic separator, and carrying out magnetic separation to obtain magnetic separation sand. According to the invention, the preparation process is simple in operation flow,and improves the processing efficiency; and the silica sand prepared by the process is high in purity, centralized in granularity and high in grade, and meets the requirements of users on the physicaland chemical properties of high-purity and high-precision silica sand.

Owner:青川英华矿业有限公司

Production technique for high grade high-yield synthetic diamond fine - micro-fine particle diamond

InactiveCN101062471AGood crystal formGranular concentrationUltra-high pressure processesTemporary StoppingAdamite

The invention relates to an excellent high alloy man made diamond sand manufacturing, using powder catalyst and graphite dust compressed under super high pressure and temperature to synthesize diamond. The synthesized pressure is lowered 2-10% compared to common synthesized pressure, with requirement for temperature matching and regulation at the same time, temporary stopping pressure being 80-92% of the synthesized pressure, with a gap of 0. 10-0. 15MPa and time interval 120-180s and pressure maintaining time being 5-20s. The synthesized man made diamond grains are mainly 170 / 200, 200 / 230, 230 / 270, 270 / 325, with 325 / 400 and 400 / 500 even finer diamonds. It uses the alloy diamond powder catalyst and bar making process. It also designs a set of high temperature super pressure synthesis according to low temperature and low pressure for the special selection of temporary shut pressure. The newly established process realizes the good effect the product.

Owner:方啸虎 +1

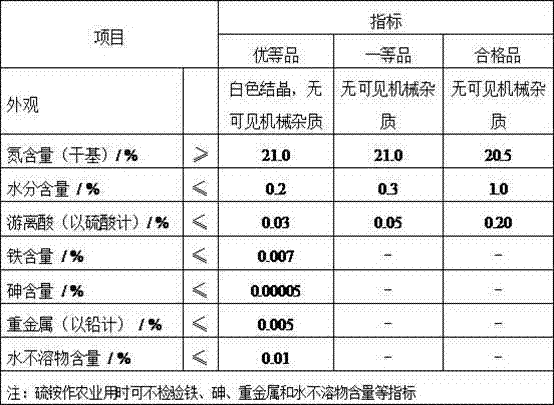

Method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate

InactiveCN103496714AImprove color levelReduced growth rateAmmonium sulfatesActivated carbonEngineering

The invention particularly relates to a method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate. According to the technical scheme, the method comprises the steps that the pH value of a coked coarse ammonium sulfate aqueous solution is adjusted through NaOH, activated carbon is further added, and the aqueous solution is filtered, so that a coked coarse ammonium sulfate crystallization mother solution is obtained; an acidity adjusting agent, a crystal habit modification agent and seed crystals are added to the mother solution and crystals are cultivated; finally, evaporative crystallization is conducted, so that ammonium sulfate crystals are obtained. The method for producing the industrial grade superior ammonium sulfate through the coked coarse ammonium sulfate has the advantages that the quality of a coked coarse ammonium sulfate product is remarkably improved, the particle size distribution of the ammonium sulfate product which is produced with the coked coarse ammonium sulfate serving as a raw material is concentrated, the average particle size is controllable, the surface is smooth, the purity is high, the liquidity is good, and the standard of an industrial grade superior product can be met.

Owner:WUHAN UNIV OF SCI & TECH

Xylitol refining crystallization process

InactiveCN1284755CQuality improvementHigh yieldHydroxy compound separation/purificationMonosaccharidesPhysical chemistrySlurry

The invention relates to a method for refining and crystallizing xylitol. The xylitol solution with a mass concentration of 85% to 92% is sent into a crystallizer, and the initial temperature of the raw material liquid is 65°C to 85°C, and then cooling and crystallization is carried out; at 55°C to 70 Add seed crystals at ℃ to control the nucleation of refined xylitol crystals, and grow crystals at a constant temperature for 15 to 60 minutes after adding seeds; the cooling rate of the entire refined crystallization process is controlled at 1°C / hr to 10°C / hr; the end point temperature of crystallization is 30°C ~45°C; the operation time of the crystallization process is less than 10 hours, the crystal slurry is centrifuged, washed, and dried at 40°C~80°C for 1~8 hours to obtain the crystal product. The invention greatly improves the quality of crystallization products and the yield of the process, is economical and practical, has short production cycle, and is especially suitable for applications in the fields of food and other fine chemicals. The particle size distribution of the xylitol crystal product obtained by the method is concentrated, the main particle size is adjustable from 150 μm to 1000 μm, the product crystal purity is greater than 99.5 percent, the fluidity is good, and the crystallization single-pass yield is more than 60 percent.

Owner:TIANJIN UNIV +1

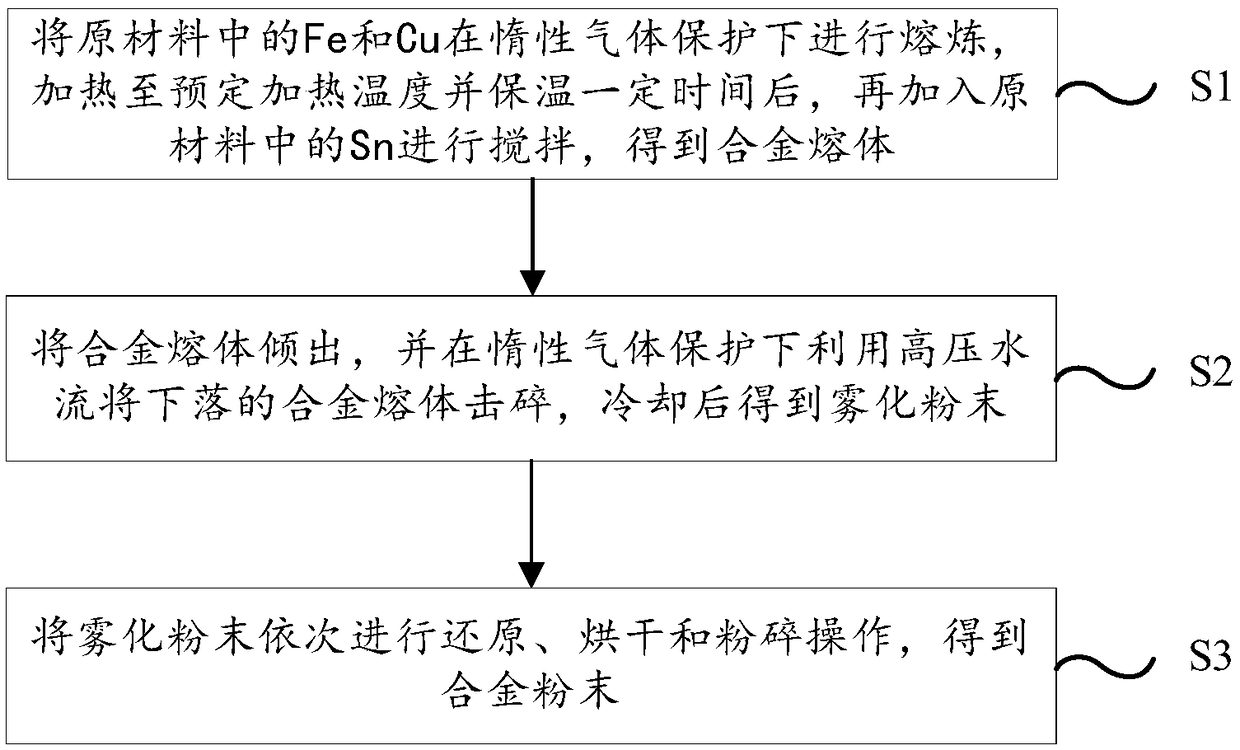

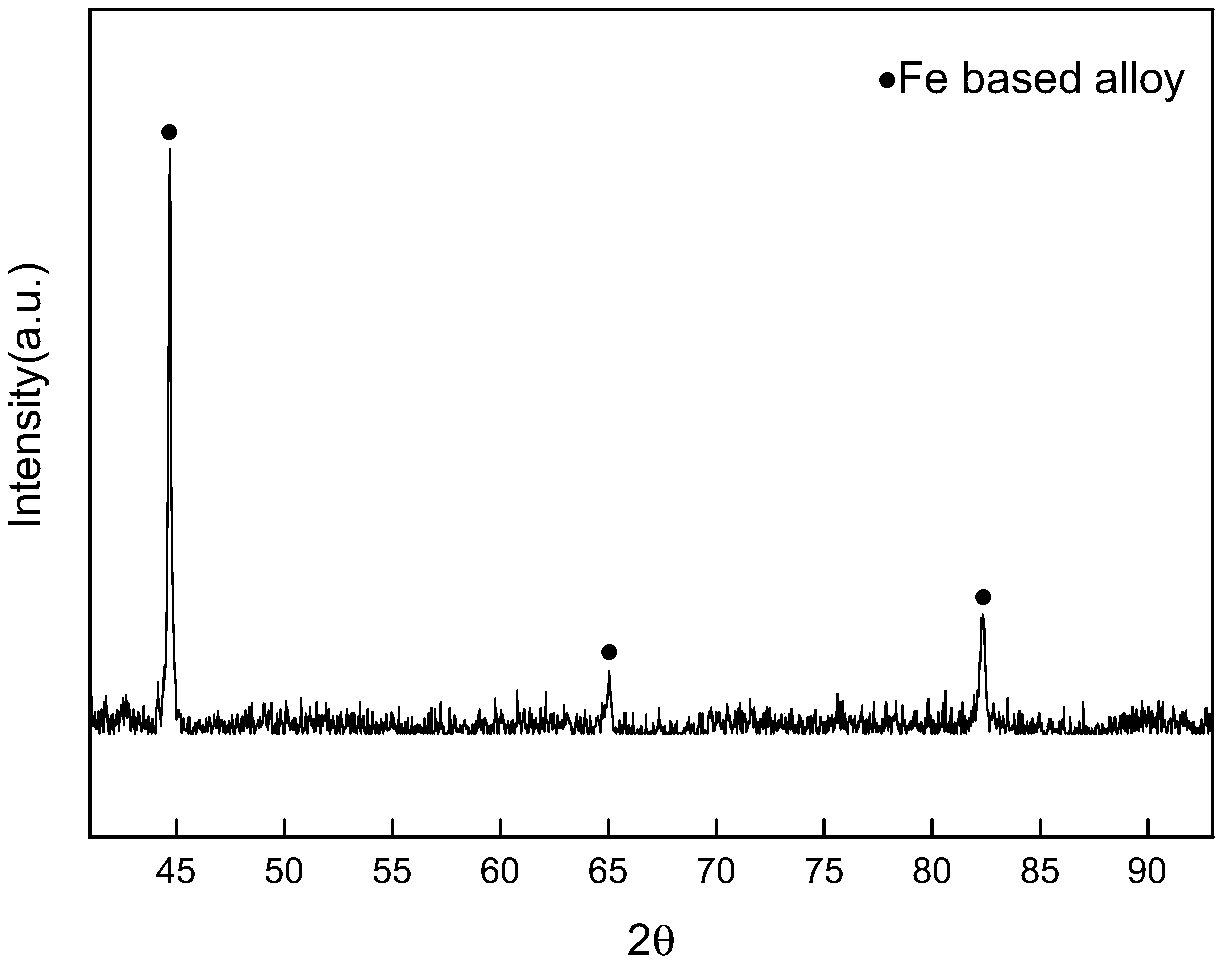

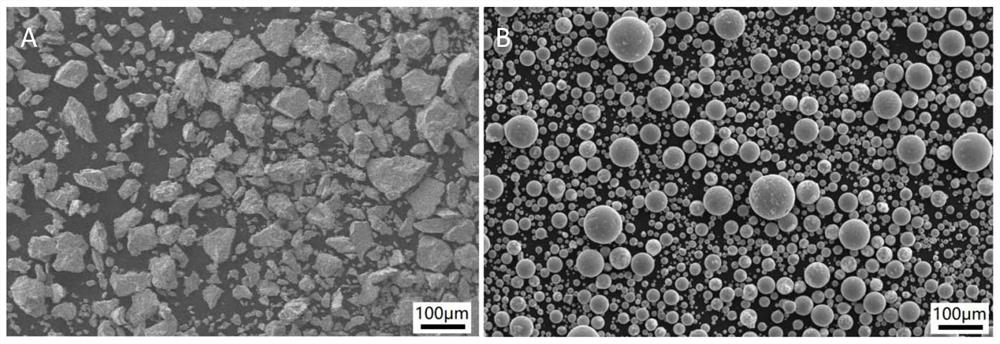

Alloy powder for mining exploration and collection tool, and preparation method of alloy powder

InactiveCN108637241AImprove mechanical propertiesSmall particle sizeTransportation and packagingMetal-working apparatusWater flowHigh pressure water

The invention provides alloy powder for a mining exploration and collection tool, and a preparation method of the alloy powder. The alloy powder comprises the following components of, by mass percentage, 68-86% of Fe, 13-25% of Cu, 1-7% of Sn, and the balance unavoidable impurities. The preparation method of the alloy powder comprises the following steps that the Fe and Cu in a raw material are smelted under inert gas shielding and are heated to scheduled heating temperature, heat preservation is carried out within a certain period of time, then the Sn in the raw material is added, stirring iscarried out, and an alloy molten mass is obtained; the alloy molten mass is poured, the falling alloy molten mass is crushed by a high-pressure water flow under the inert gas shielding, and atomizedpowder is obtained after cooling; and the atomized powder is sequentially subjected to reduction, drying and pulverizing operation, and the alloy powder is obtained. The categories of metal elements contained in the alloy powder prepared by the preparation method are less, the proportion is easy to control, the property is stable, components and structures of the alloy powder are more uniform, impurities are less, and the particle diameter is less, so that the material property of the alloy powder is more stable.

Owner:陕西铂锐钻探机具有限公司

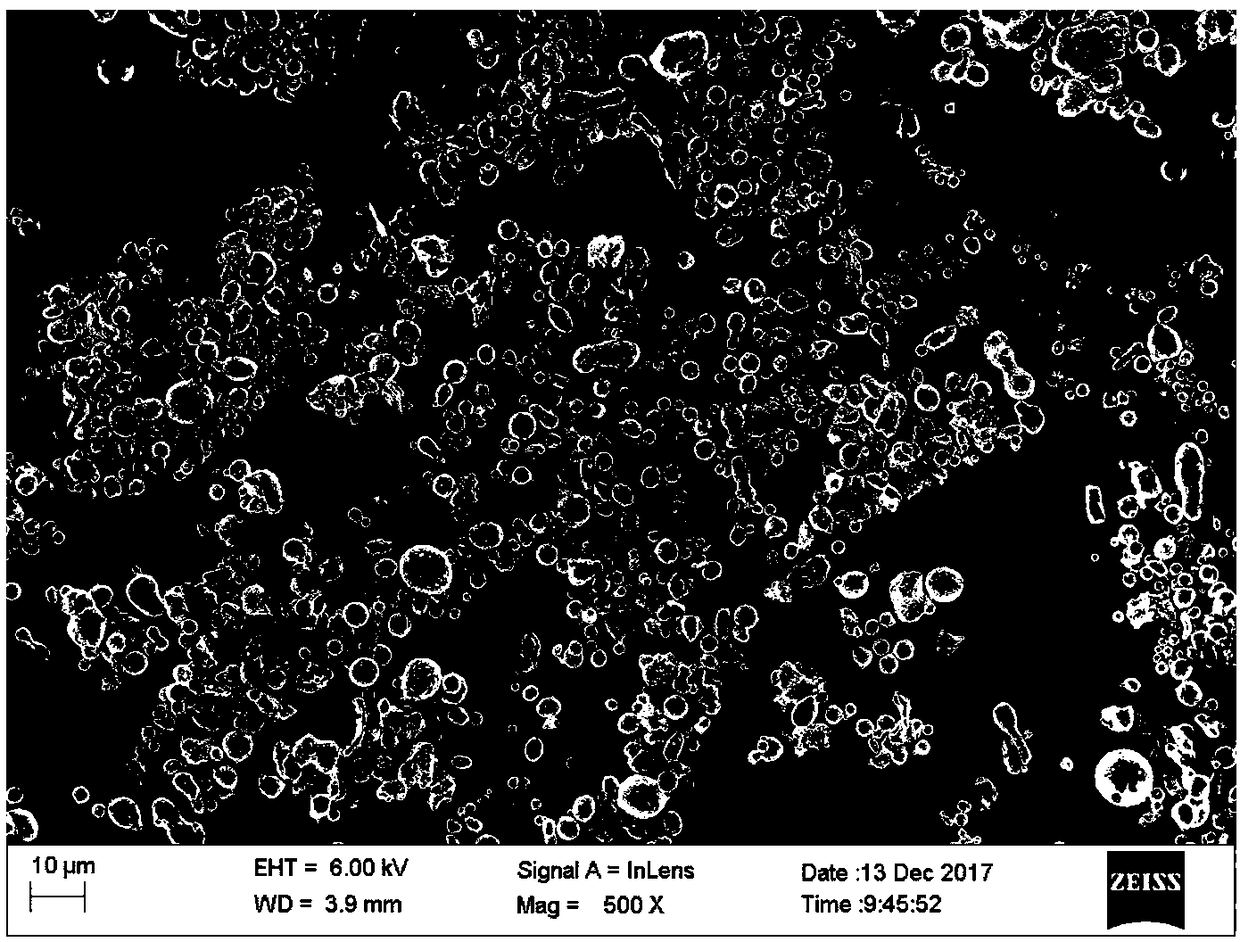

Production process and production device of ultrafine boron carbide micropowder

PendingCN108101059ASimple stepsReduce energy consumptionCarbon compoundsGrain treatmentsBoron carbideFilter press

Belonging to the technical field of boron carbide grinding, the invention in particular relates to a production process and production device of ultrafine boron carbide micropowder. The method includes the steps of: (1) crushing; (2) purification; (3) filter pressing; (4) drying; (5) dispersion; (6) grading; and (7) packaging. The production device includes a wet grinding machine, a first slurry pump, a slurry finished product tank, a second slurry pump, a slurry purification reaction tank, a filter press, a drying separation device and a vacuum packer that are communicated in order. Accordingto the invention, the process is simple, the production device is reasonable in design and easy to operate, the product cost is low, the dust production is small, the energy consumption is low, and the obtained boron carbide micropowder has high purity, finer grain size, a particle size of less than 0.5microm, large specific surface area, good fluidity, high stability and high sintering activity.

Owner:山东埃尔派粉体科技股份有限公司

High-purity tantalum rotating target material and preparation method thereof

InactiveCN113308671AHigh purityReduce oxygen contentMolten spray coatingTransportation and packagingSputteringHigh density

The invention discloses a high-purity tantalum rotating target material and a preparation method thereof. The preparation method comprises the steps that high-purity spherical tantalum powder is prepared through an induction plasma spheroidizing technology, then the high-purity spherical tantalum powder serves as a spraying raw material, a high-purity tantalum coating is prepared on the surface of a rotating substrate through a low-pressure plasma spraying technology, and the high-purity tantalum rotating target material is prepared. According to the method, the process difficulty is small, the method is not limited by the material and the size of the rotating substrate, the spraying applicability of the tantalum rotating target material is greatly improved, the thickness of the rotating target material can be easily and accurately controlled by adjusting the spraying time, a complex post-heat treatment process is avoided, the yield of the rotating target material is extremely high, and the manufacturing difficulty and the manufacturing cost of the rotating target material are reduced. The prepared high-purity tantalum rotating target material has the characteristics of high purity, low oxygen content, uniform and controllable coating thickness and high density, and is suitable for preparation and application of a high-purity tantalum sputtering film.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Method for preparing solid catalyst in olefin polymerization catalyst

ActiveCN100484970CProduct quality is easy to controlHigh particle sphericityContinuous/uninterruptedPolymer science

The invention provides a preparation method of solid catalyst used in olefinic polymerization catalyst, the method synthetizes the solid catalyst of olefinic polymerization continuously by magnesium powder, simplifies the technology of preparing magnesium compounds solid firstly then preparing the solid catalyst of olefinic polymerization, reduces quantity of equipment needed in industrialization, has advantages of simple technics, easy operation, low industrializing installation cost, low production cost, easy controlled product quality. The ball solid catalyst of olefinic polymerization which D(50) is in range of 10-80 mum is produced through the method of the invention, the catalyst has particle sphericity height L / W<1.4 (L expresses the longest axle of the particle, W is the minimum axle of the particle), has advantages of high polymerization activity, hydrogen regulating sensibility, high isotacticity of the polymer, centralized particle-size distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

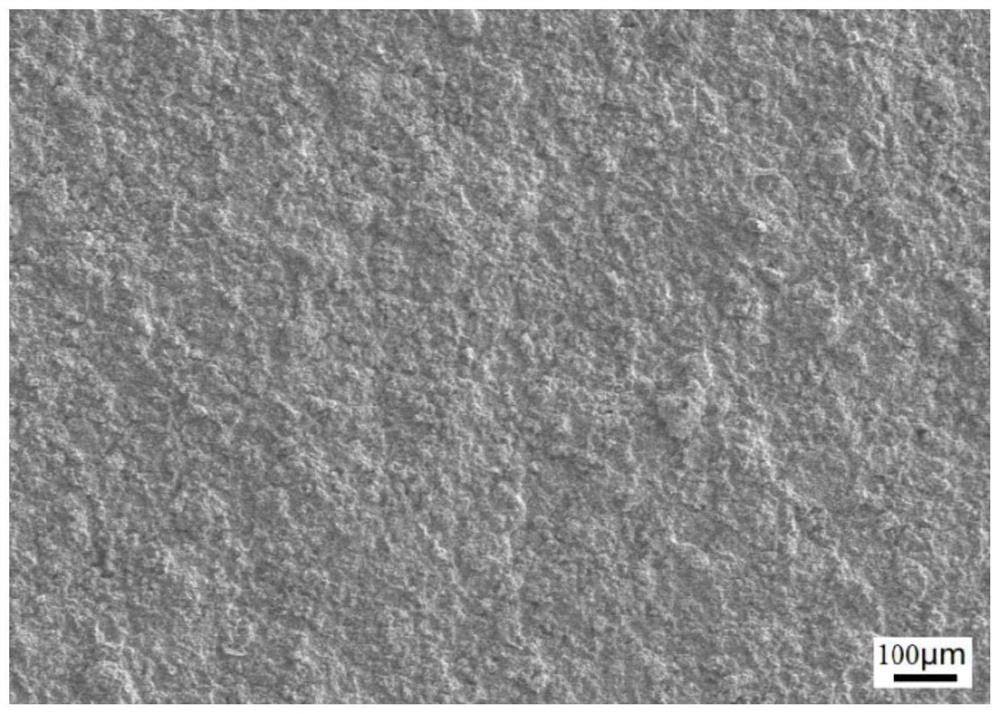

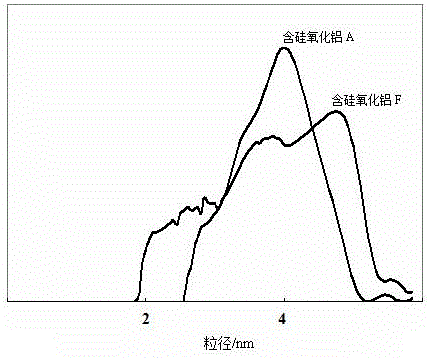

A kind of preparation method of silicon-containing alumina dry glue

ActiveCN103769232BConcentrated hole distributionIncrease acidityCatalyst carriersHydrocarbon oils treatmentPore distributionCombined method

The invention discloses a preparation method of an alumina dry glue containing silicon. The preparation method comprises the following steps: mixing original clay with a weak acid and a dispersant, then carrying out a hydrothermal treatment on the mixture so as to obtain modified clay; using an acidic solution containing aluminum and an alkaline solution containing aluminum to carry out a glue-forming reaction in the modified clay slurry by adopting a combined method of a pH swing method and a parallel-flow method, and after the glue-forming process, subjecting the glue-forming reaction product to processes of filtering, washing, and drying so as to obtain the alumina dry glue containing silicon. The alumina dry glue containing silicon has the advantages of uniform particle size, concentrated pore distribution, and proper acidity, and is especially suitable for being used to prepare a heavy oil or residual oil hydro-treatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

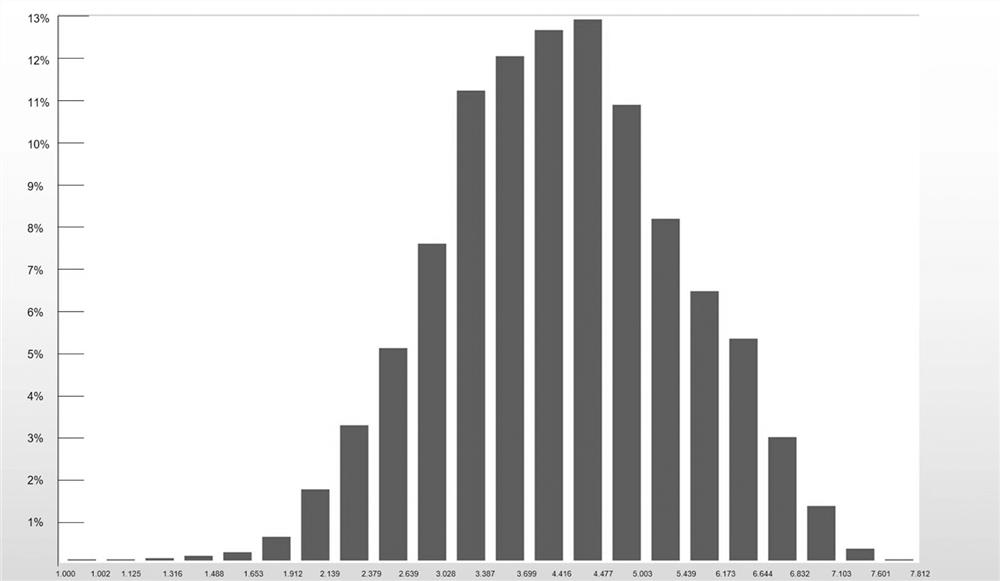

Method for preparing anhydrous betaine crystals with ultra-uniform granularity

ActiveCN111440081AChange the lamellar habitHigh bulk densityOrganic compound preparationOrganic chemistry methodsBetainePhysical chemistry

The invention relates to a method for preparing anhydrous betaine crystals with ultra-uniform granularity. An over-boiling explosion nucleation-cooling circulation method is adopted. The method comprises the steps: adding anhydrous betaine powder into a crystallizer, adding a solvent into the crystallizer, heating to completely dissolve the powder, and enabling the temperature of the solution to reach the boiling point of a crystallization system; rapidly cooling, and when crystal nucleuses are separated out of the crystallization system, adding a small amount of anhydrous betaine powder intothe crystallizer again to promote explosive separation of the crystal nucleuses from the crystallization system; continuously cooling the solution to room temperature; adding anhydrous betaine powderinto the crystallizer again, heating to dissolve the betaine powder until the temperature of the solution reaches the boiling point temperature of the crystallization system, and then cooling to roomtemperature; repeating the heating and cooling operations repeatedly until the mass of the crystal with 20-60 meshes is not lower than 99% of the total mass of the crystal; and cooling to the final temperature, filtering and washing the crystal, and drying to obtain the anhydrous betaine crystal product with ultra-uniform granularity.

Owner:TIANJIN UNIV +1

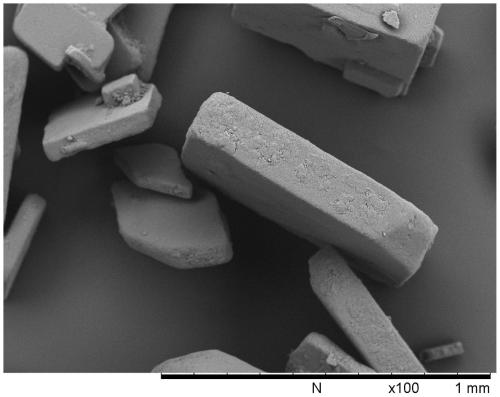

A kind of production method of single crystal corundum

ActiveCN104499051BInhibit growthSmall particle sizePolycrystalline material growthFrom frozen solutionsMass ratioSulfur

The invention relates to a single crystal corundum production method, which comprises the following steps: grinding alpha-alumina powder to a median particle size of 1-5mu, then adding an inhibitor, smelting at a temperature of 1500-1700 DEG C after mixing uniformly, keeping stand and cooling for 8-24h after melting fully, and hydrolyzing a mixture subjected to standing and cooling to obtain single crystal corundum, wherein the mass ratio of alpha-alumina powder to inhibitor is 6-25 to 1, and the inhibitor comprises the following components in percentage by mass: 1-3% of titanium oxide, 0-2% of iron oxide and 3-7% of sulfur. The single crystal corundum production method provided by the invention has the beneficial effects that the grain size of the generated single crystal corundum is controlled, and the yield is high.

Owner:SANXIANG ADVANCED MATERIALS

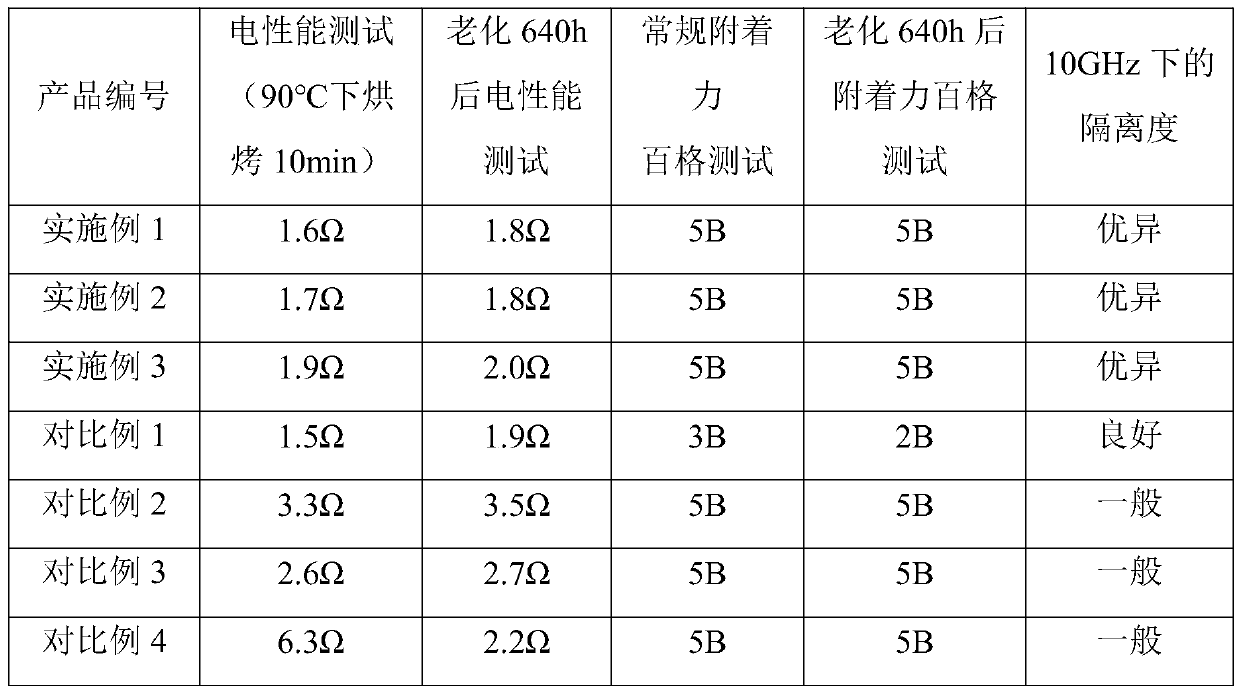

Electromagnetic shielding silver paste for communication equipment and preparation method thereof

PendingCN111587056AGood printabilityGood quick dryingMagnetic/electric field screeningInksSilver pasteMetal chelate

The invention provides electromagnetic shielding silver paste for communication equipment and a preparation method thereof. The electromagnetic shielding silver paste is prepared from, by mass percent, 45%-60% of silver powder A, 5%-15% of silver powder B, 0.1%-2% of metal chelate and 20%-48% of organic carriers; and both the silver powder A and the silver powder B are silver powder which is low in bulk density, very concentrated in particle size and moderate in burning loss. The flake powder with low bulk density is very good in electrical property, the silver powder with very concentrated granularity has the advantages in dispersity, leveling property and uniformity; and the prepared silver paste is stable in performance in the long-time printing process. The metal chelate is a Schiff base titanium hydride metal chelate, so that the quick-drying performance of the low-temperature silver paste can be improved. The electromagnetic shielding silver paste prepared through mutual cooperation of the components not only has excellent printing performance and can meet low-temperature curing, but also has excellent quick-drying performance, and is stable in adhesive force and good in shielding effect in subsequent environmental testing.

Owner:湖南省国银新材料有限公司

A kind of recovery method of silicon carbide micropowder

The invention discloses a method for recovering carbonized silica powder, which belongs to the technical field of silicon carbide production. The method solves the problems of large pollution, little production power, low product content and high refinement content in the prior art can be solved. The method comprises the following steps: calcining a recovered material, mixing the calcined raw material and water as well as mixing slurry, introducing the material into a cyclone for rotational flowing; fully stirring the slurry after rotational flowing, beating the material into an acid bubble barrel, adding sulfuric acid for immersion and using a vacuum filtration filter for depickling; fully stirring the depickled slurry, adding sodium hydroxide for alkali washing and impurity removal, then using the vacuum filtration filter for dealkalization to obtain the dealkalized slurry; using a pump for beating the slurry after alkali washing into a moisture feeding barrel, stirring fully the material and beating the material to a taper grading overflow barrel for waterpower grading to obtain a product; respectively dehydrating and drying the product according to the models; placing the dried product into a feed mixer for batch mixing, uniformly granulating the material, and respectively sieving the product. The method can be used for recovering the carbonized silica powder.

Owner:LINSHUSNTIAN ABRASIVE +1

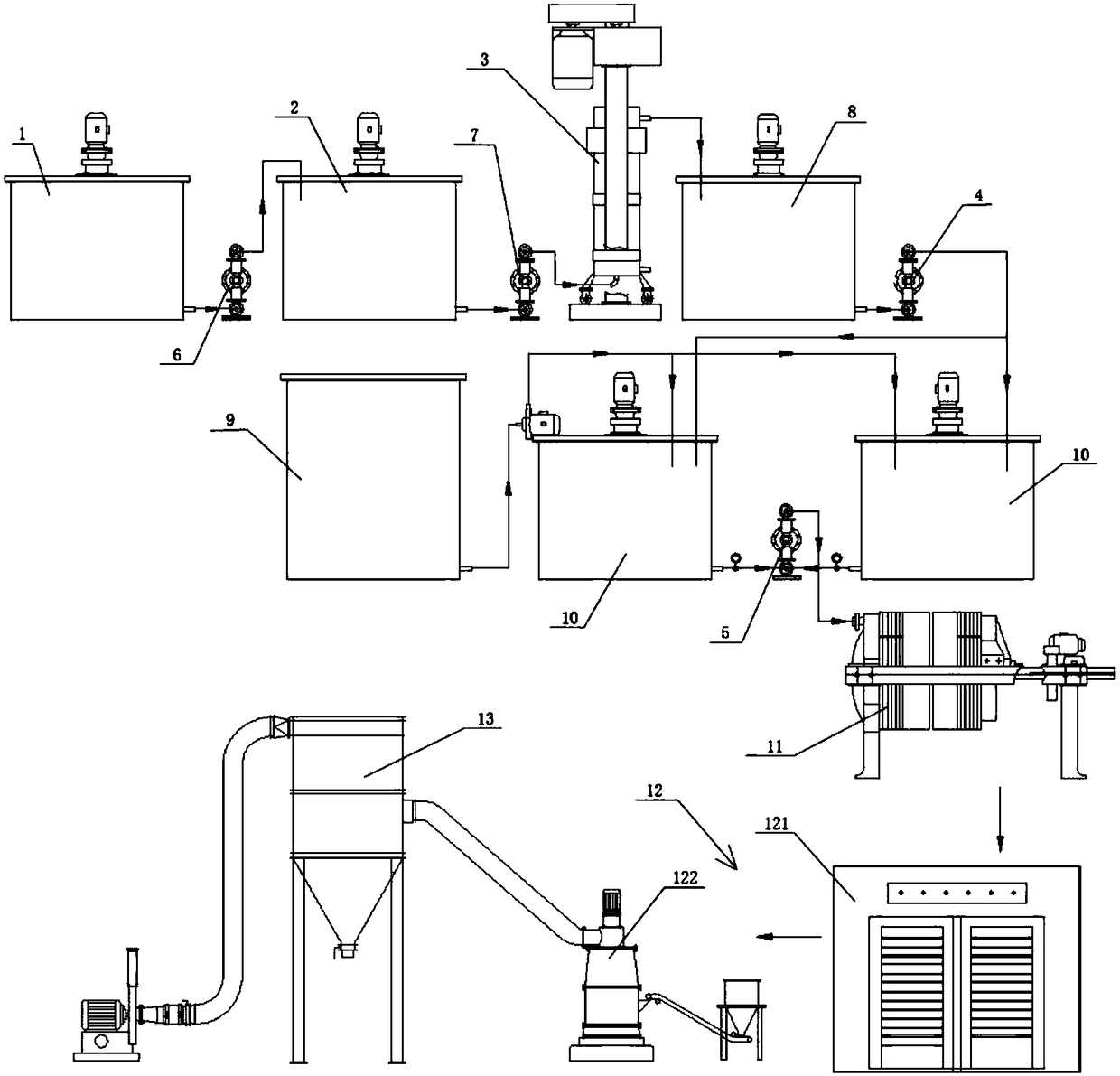

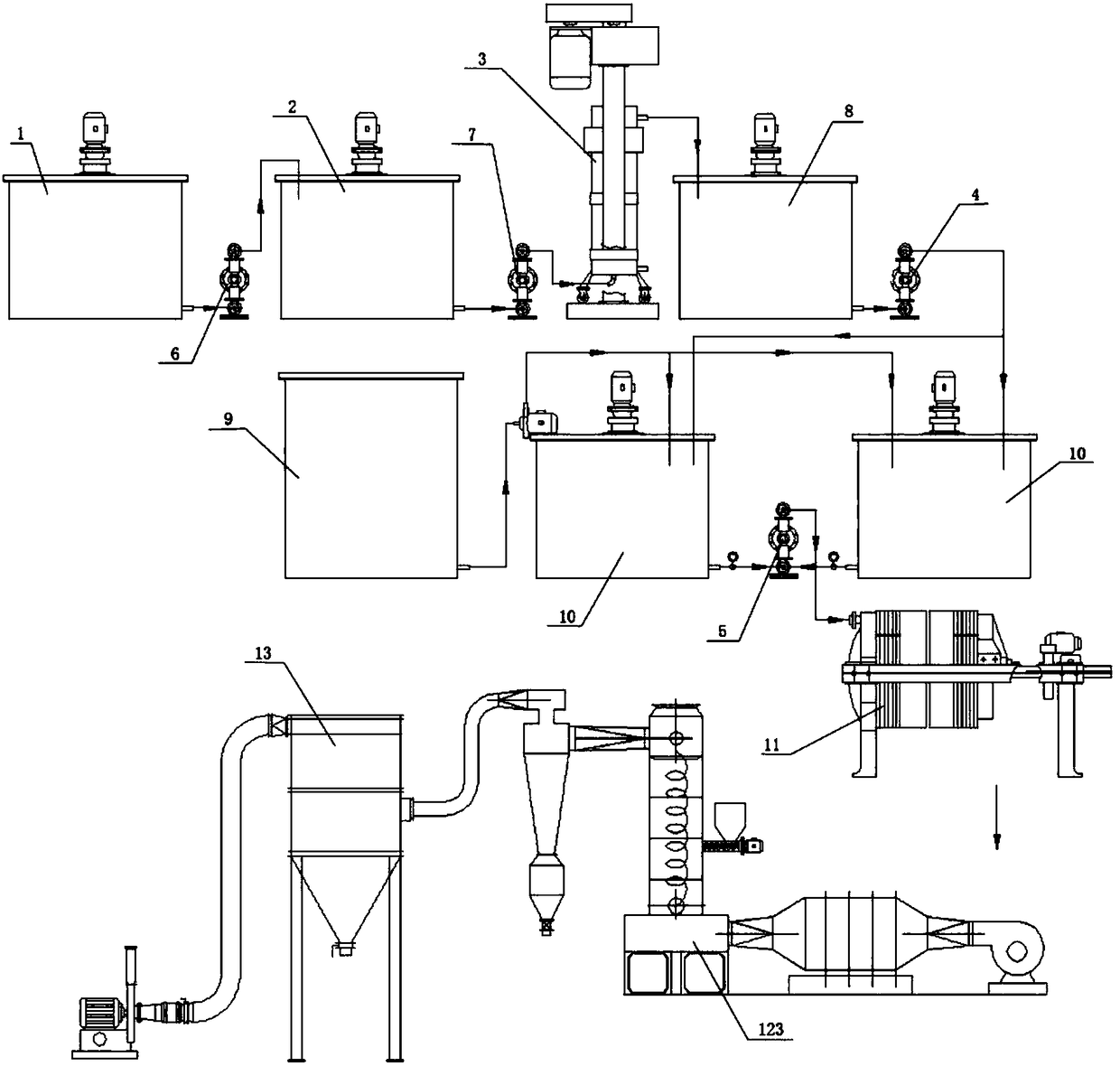

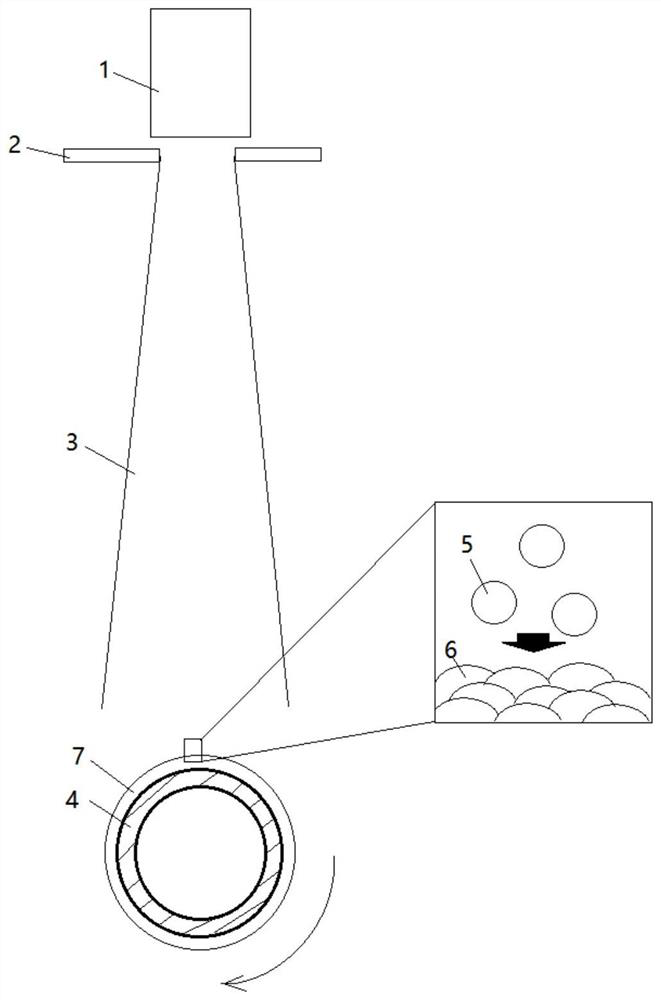

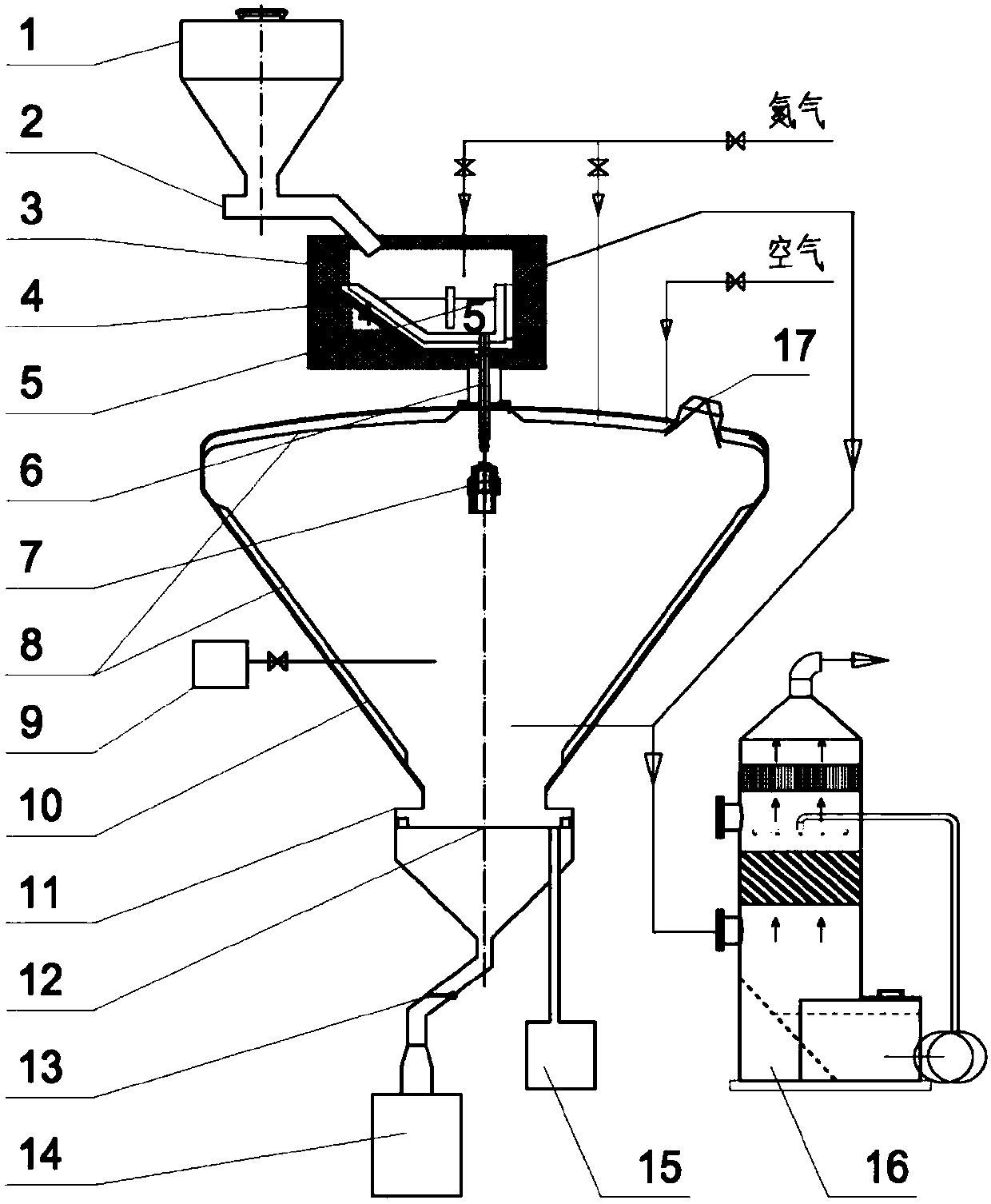

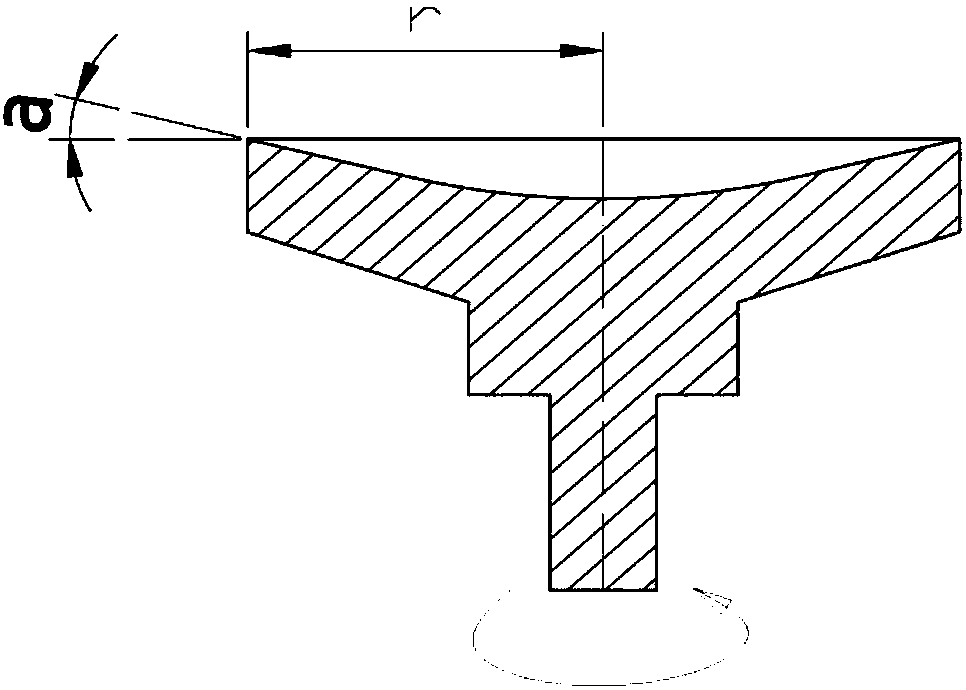

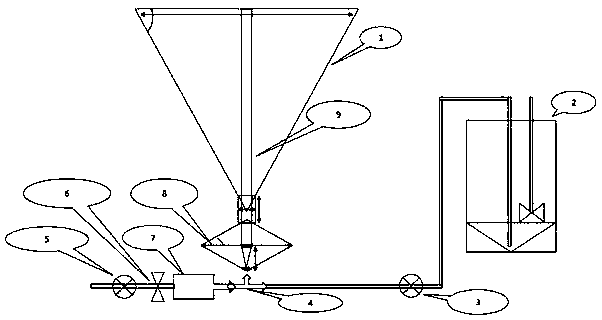

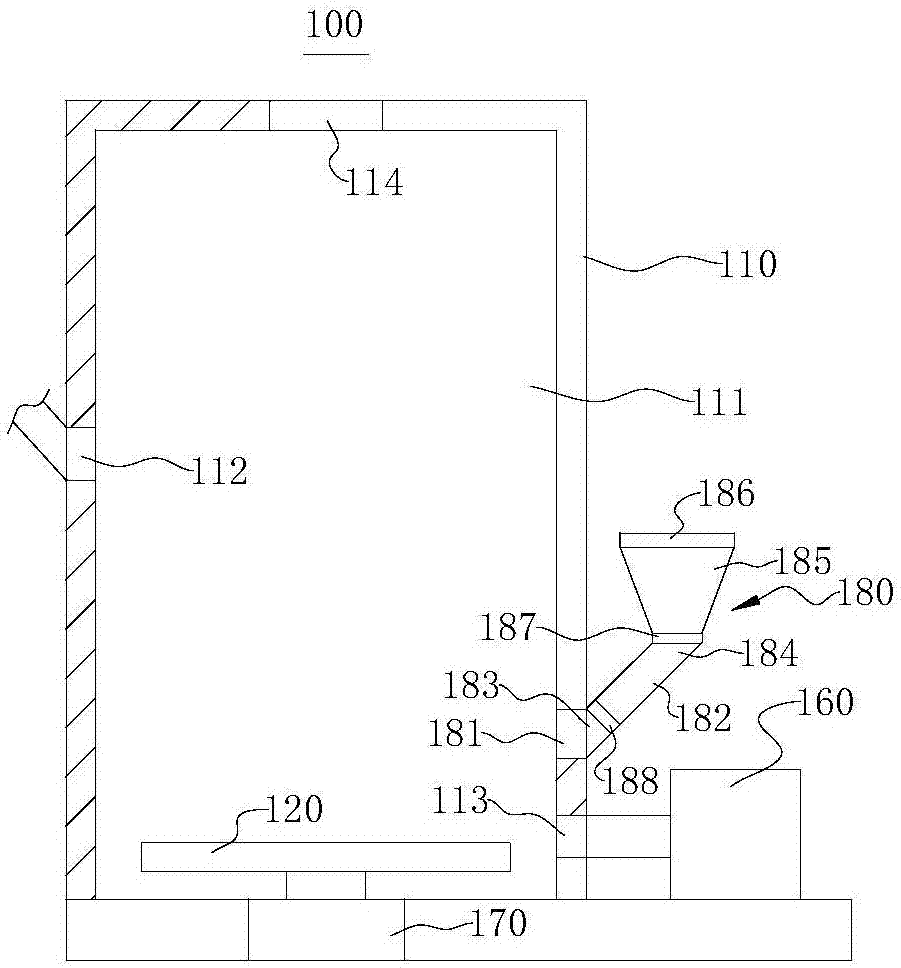

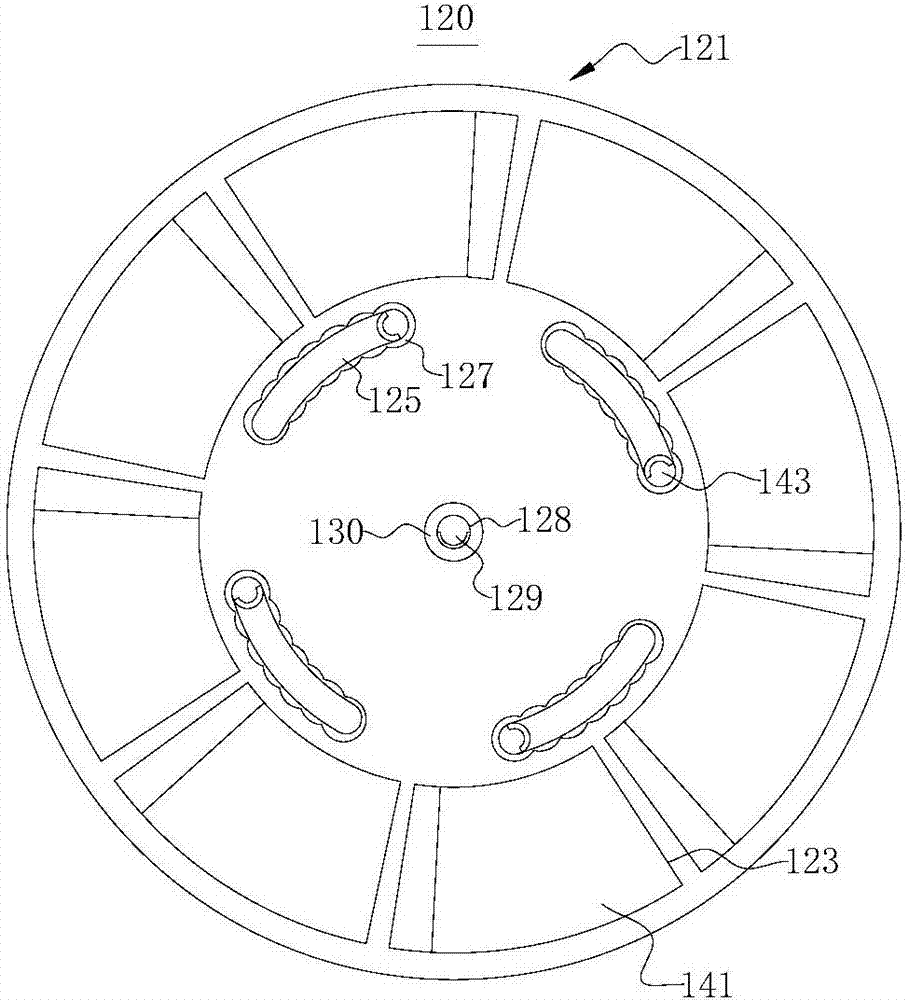

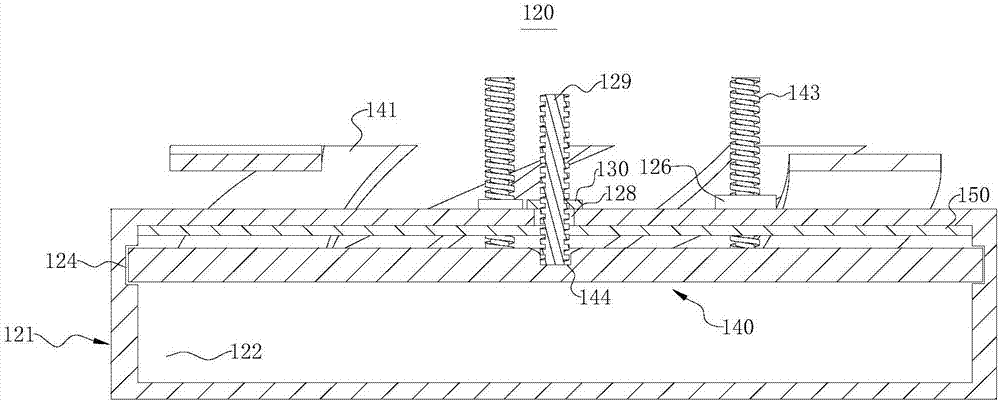

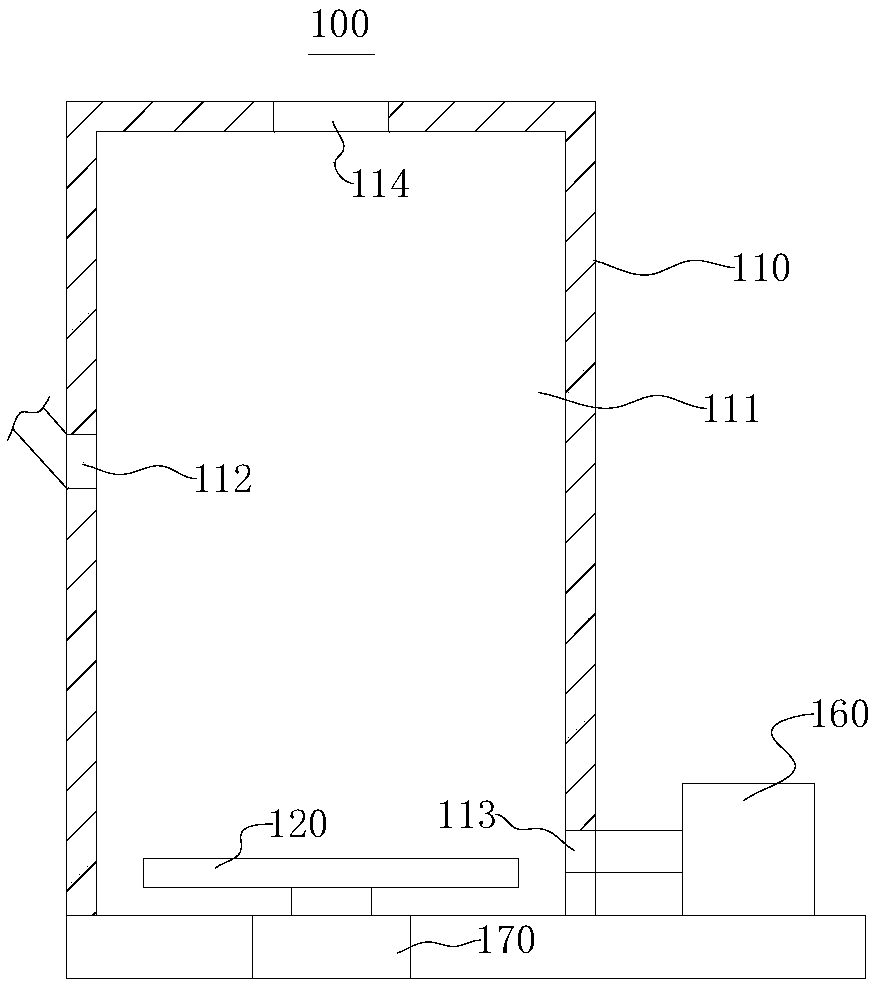

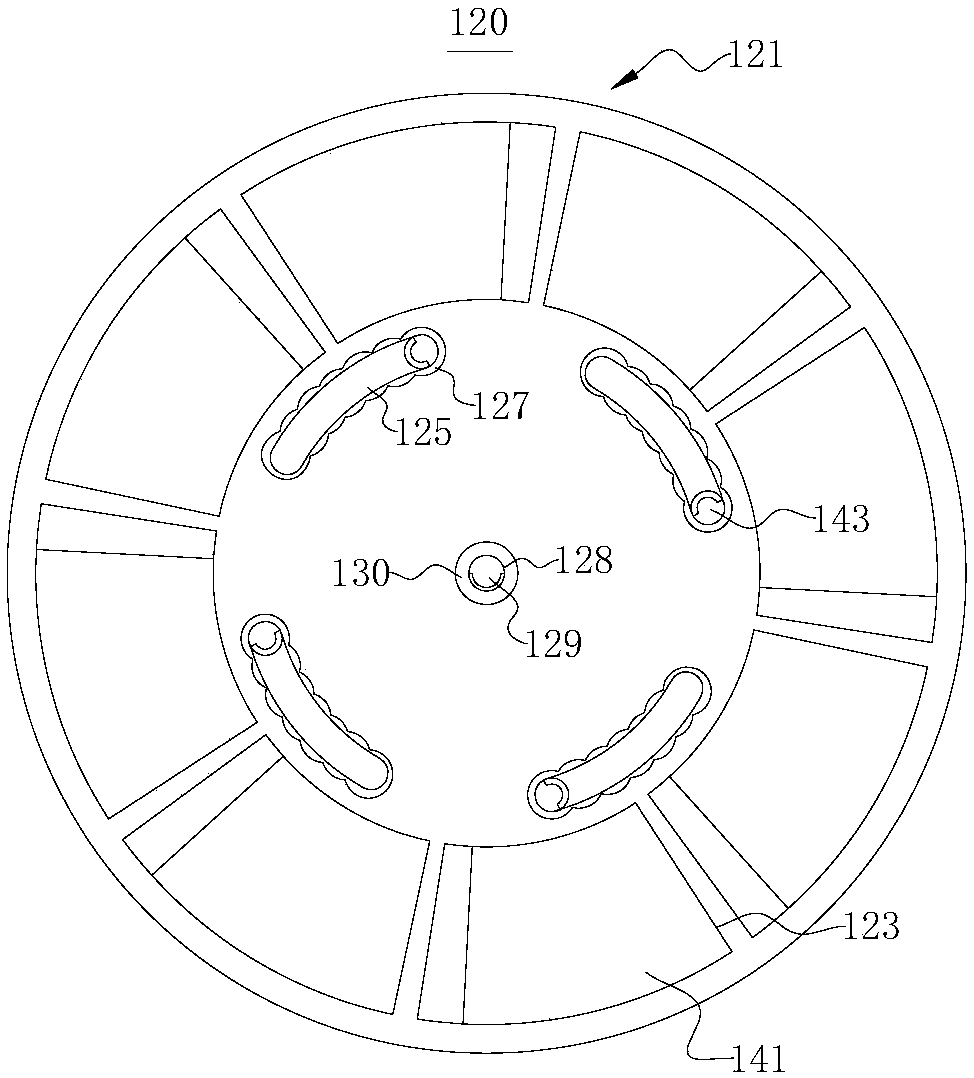

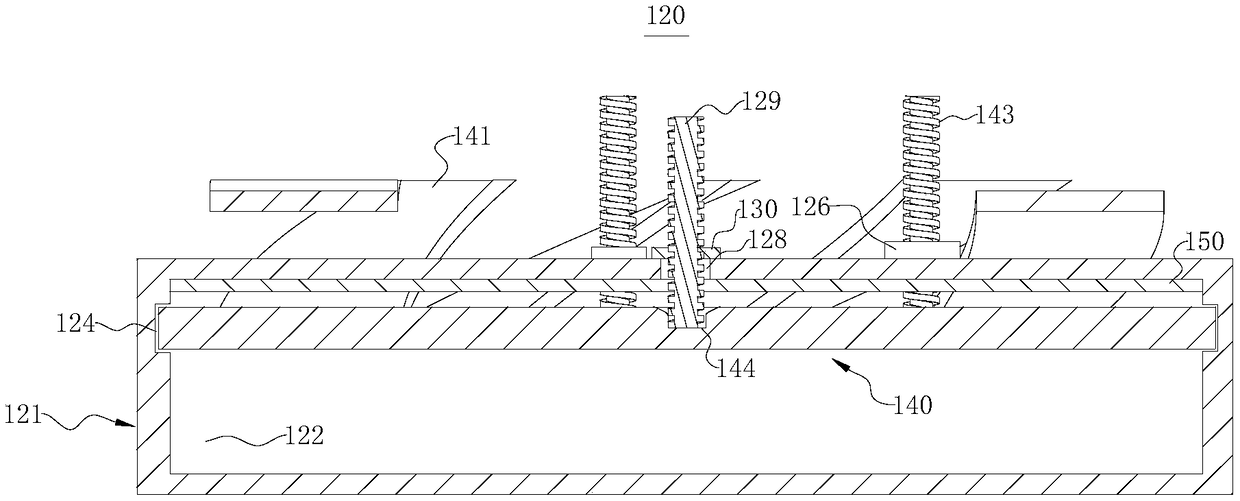

A melt atomization system and a highly active spherical cuprous chloride catalyst prepared by the system and its preparation method

ActiveCN105817178BImprove yieldReduce risk of leakageCatalyst activation/preparationGranulation by liquid drop formationDispersityGranularity

Owner:HUIJIN ATOMIZING SCI

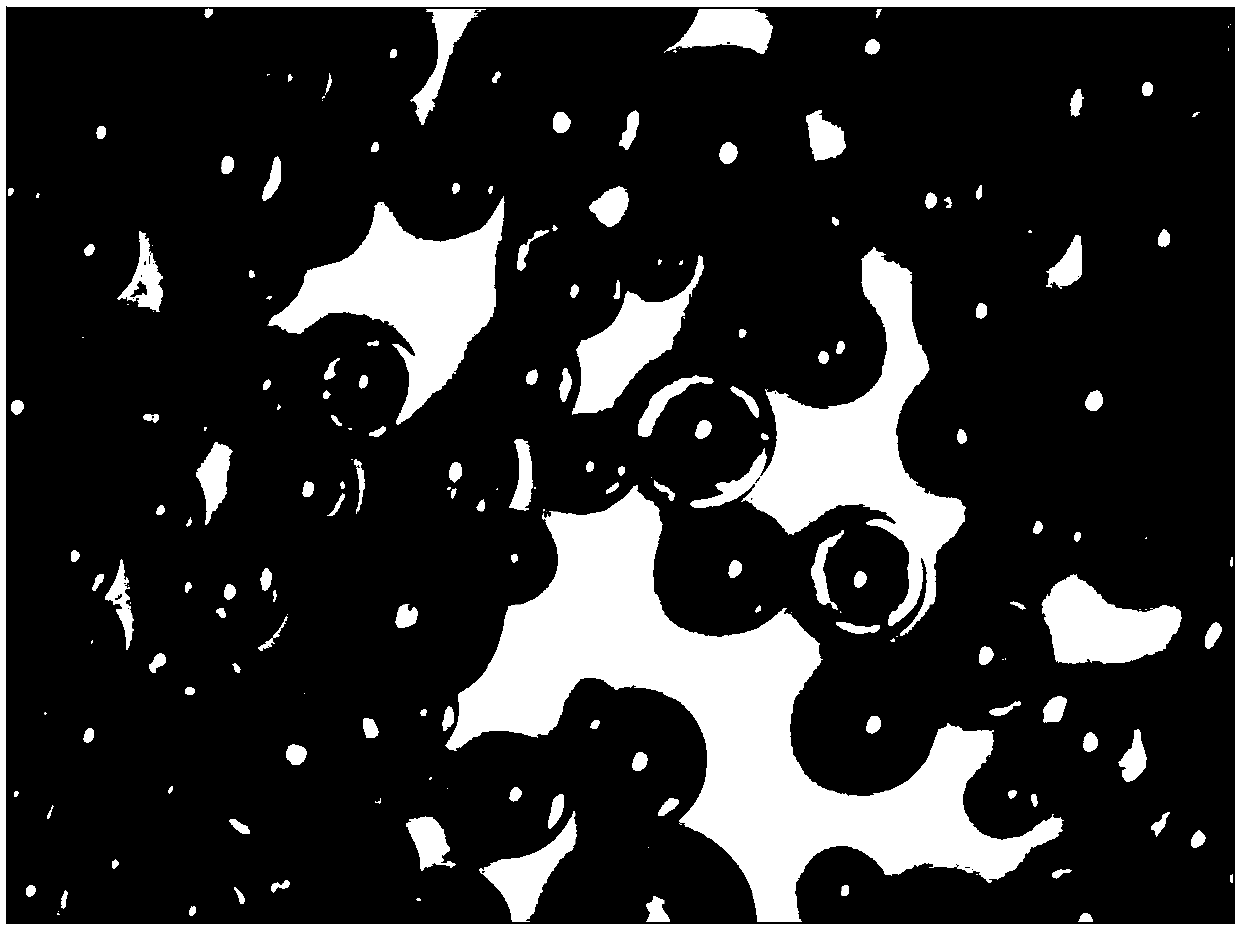

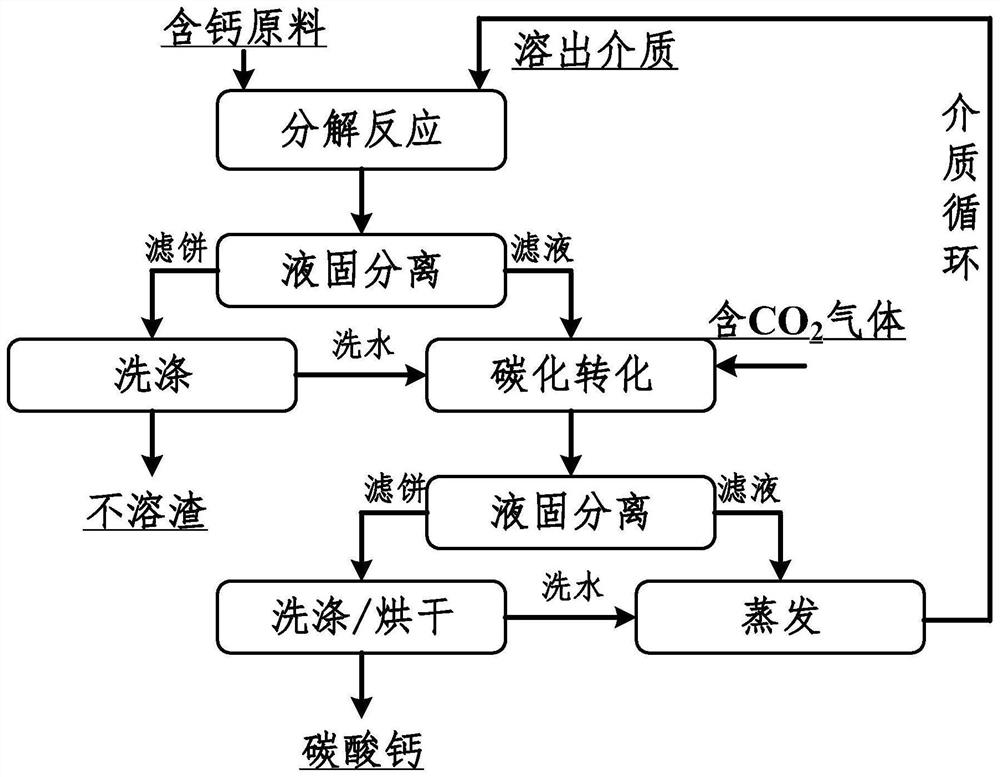

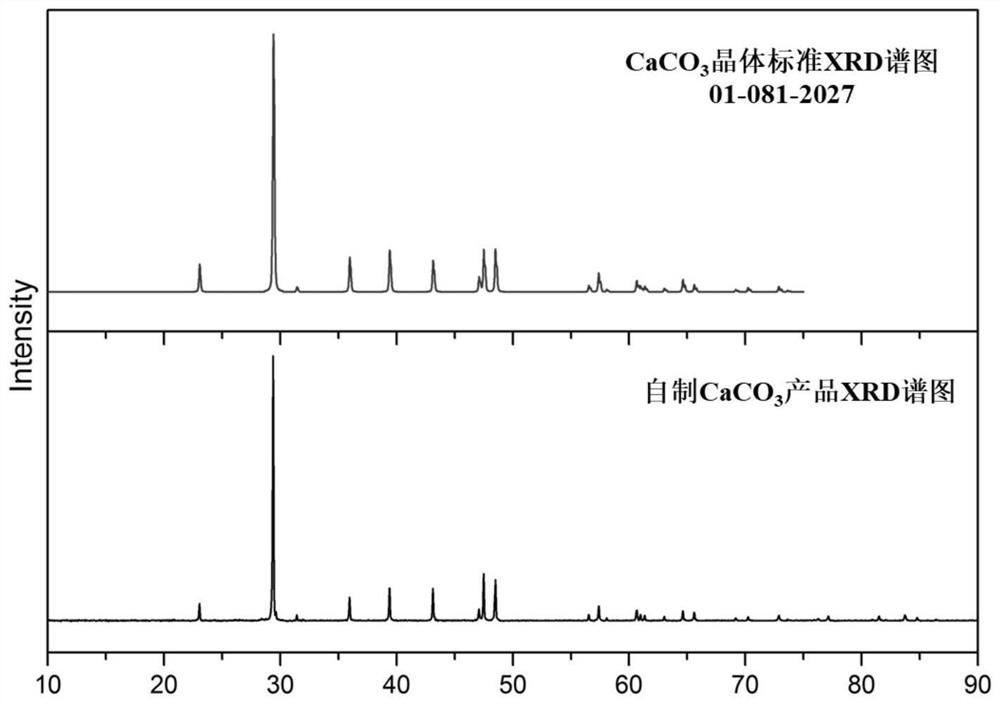

Calcium carbonate and preparation method thereof

ActiveCN113120935AShape is easy to controlGranularity controllableCalcium/strontium/barium carbonatesPhysical chemistryCarbonization

The invention relates to calcium carbonate and a preparation method thereof, and the preparation method comprises the following steps: (1) mixing a calcium-containing raw material with a dissolution medium, carrying out a decomposition reaction, and carrying out liquid-solid separation on the calcium-containing material liquid after the reaction to obtain a calcium-containing solution and insoluble slag; and (2) contacting the calcium-containing solution obtained in the step (1) with a gas containing carbon dioxide, carrying out a carbonization reaction, and carrying out liquid-solid separation on a carbonized material liquid obtained after the reaction to obtain calcium carbonate and a carbonized mother solution. The preparation method not only can realize controllable morphology, controllable granularity and controllable purity of artificially synthesized calcium carbonate, but also can realize efficient circulation of a medium. The purity of the calcium carbonate obtained by the preparation method is higher than 99%, the morphology is regular, and the granularity is uniform and adjustable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Production method for samarium cobalt alloy powder

ActiveCN103537684BReduce performanceUniform grain size distributionInorganic material magnetismRare-earth elementHydrogen atmosphere

The invention discloses a production method for samarium cobalt alloy powder. The production method for the samarium cobalt alloy powder comprises weighing samarium, cobalt, iron, copper, zirconium and heavy rare earth element metal salt in proportion, preparing a salt solution and a salt-mixture solution, adding a little acid or alkali to control a PH (Potential of Hydrogen) value to be between 4 and 9, simultaneously adding surface active agent and dispersing agent which account 1 to 5 % of the mass of the metal salt in the metal salt solution, performing spray drying at the temperature between 300 and 350 DEG C to produce composite powder precursor, performing low temperature calcine at the temperature between 200 and 300 DEG C, performing two-step restoring on the precursor under hydrogen atmosphere with the temperature between 400 to 800 DEG C, ball-milling the restored powder to obtain the samarium cobalt alloy powder. The samarium cobalt alloy powder produced through the production method has the advantages of being reasonable in powder size, uniform in crystal grain and component distribution, high in purity and low in oxygen content. The production method has the advantages of being simple in operation, low in energy consumption, high in production efficiency and suitable for continuous production.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

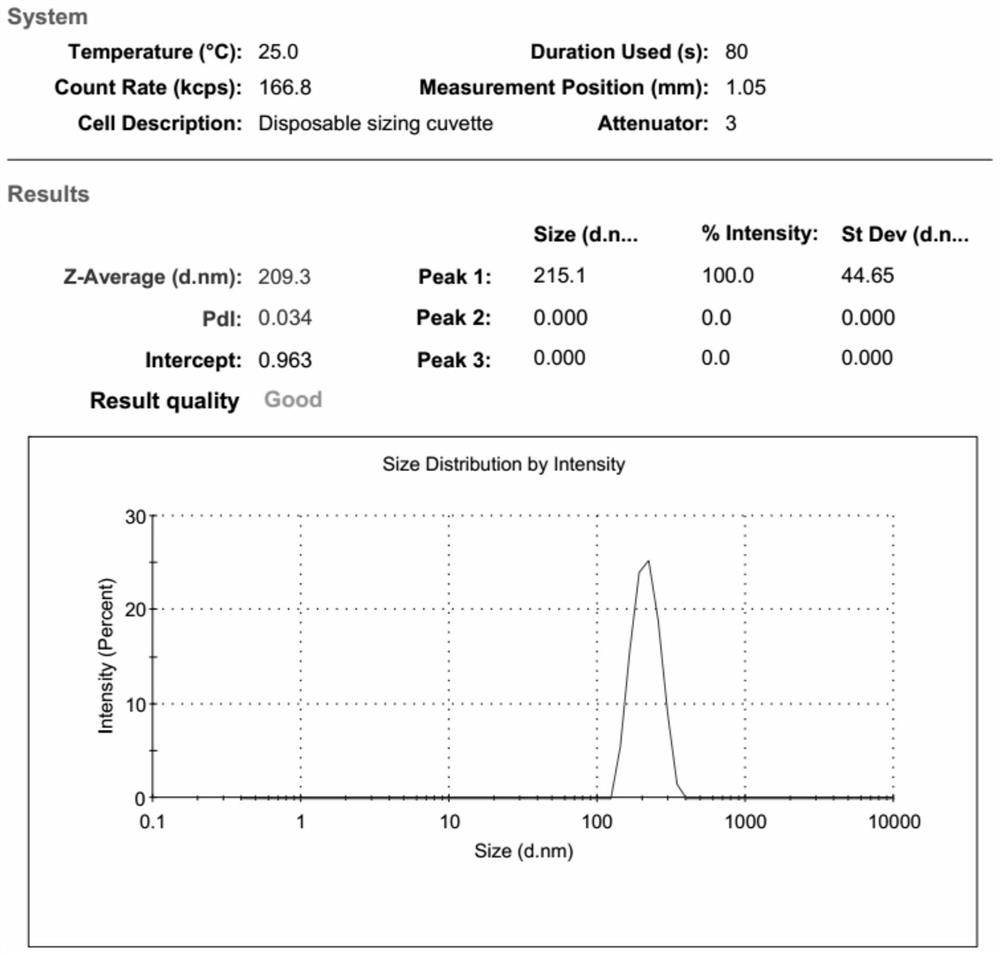

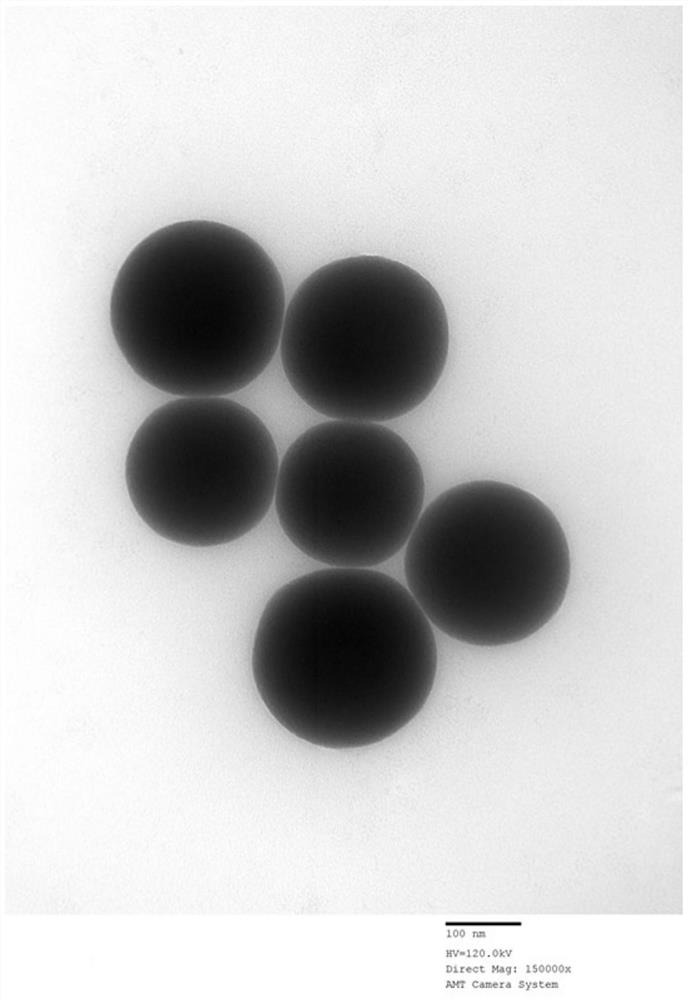

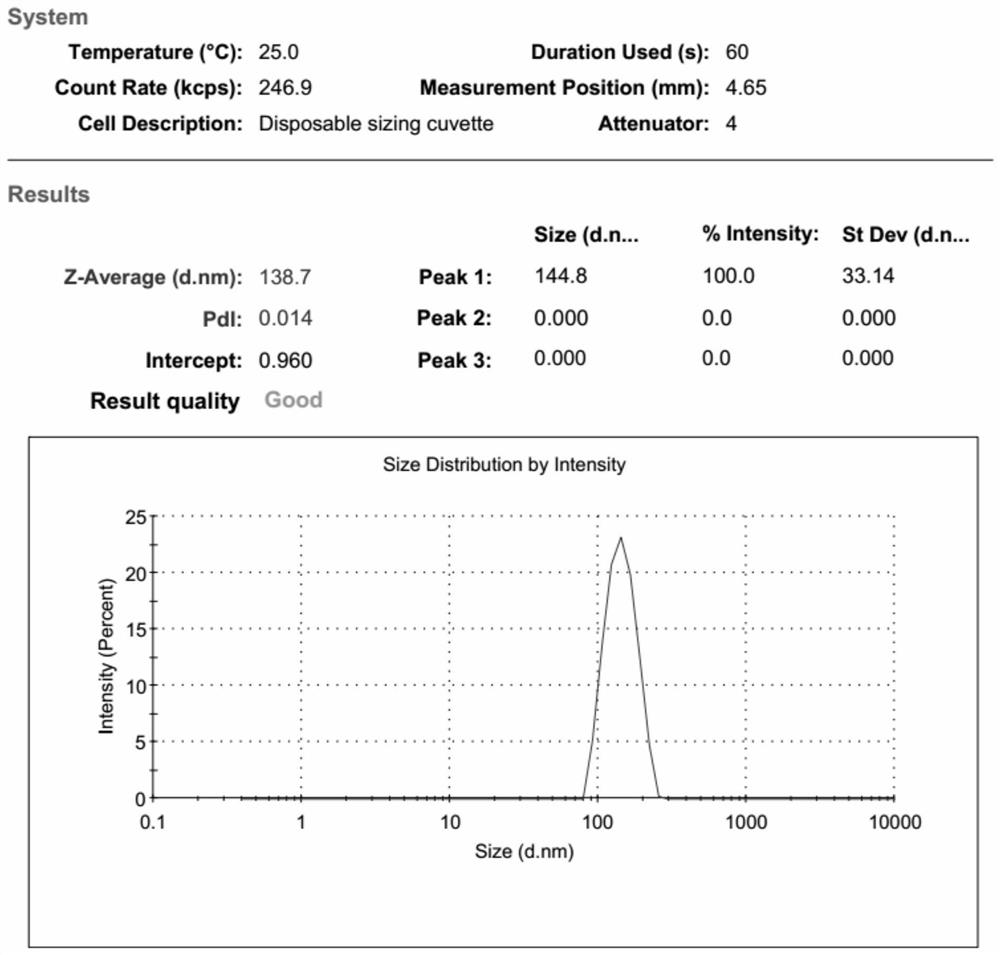

A method for continuous and controllable preparation of nano-silica spherical particles

The invention provides a method for continuously and controllably preparing nano-silica spherical particles, which comprises the following steps: using alcohol as a dispersant, organosilicon and silicate as a silicon source, and hydrolyzing under the action of an alkaline catalyst to obtain nano-dioxide Silicon spherical particles are then dried to obtain a solid product. The preparation process mainly includes: simultaneously introducing the silicon source solution and the catalyst into the microchannel mixer to strengthen the mixing, then heating to a certain temperature with high intensity, and after a certain time of aging reaction, the finished nano-silica products of different scales can be directly obtained. particles. The characteristics of the method of the invention are: high-purity silica particles with a particle size of 10-1000 nm, high sphericity, and a uniformity PDI range of 0.02-0.3 can be prepared, and the method of the invention has high efficiency, uniform product particles, and nano-scale. Controllable, high yield, easy to scale up and can realize continuous production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Device and method for diamond micro-powder overflowing grading treatment

InactiveCN108246486AReduce usageGranular concentrationWet separationParticle-size distributionUltrapure water

The invention discloses a device and method for diamond micro-powder overflowing grading treatment. The device for the diamond micro-powder overflowing grading treatment comprises a cooling-water machine, an ultrapure water machine, a homogenizing tank, a mechanical measuring pump, a counterbalance valve, a one-way valve, a pulse damper, an overflowing cone, a discotic dispenser, a diversion column and a feeding pump. The device for the diamond micro-powder overflowing grading treatment is characterized in that dispersed diamond turbid liquid in the homogenizing tank is transported into the overflowing cone by the feeding pump, pure water produced by the ultrapure water machine is controlled by the cooling-water machine under the constant temperature, and the diamond particles with different particle sizes are flowed out of the overflowing cone by controlling the flow of ultra-pure water entering the overflowing cone through the measuring pump, so that the fine grading of the diamond micro-powder is realized. According to the device for the diamond micro-powder overflowing grading treatment, rapid and accurate grading of the diamond micro-powder with the different particle sizes can be realized, the production cycle is shortened, and the particle size distribution is concentrated.

Owner:常熟华融太阳能新型材料有限公司

The method for preparing cefotaxime sodium crystal

The invention relates to a preparation method of a cefotaxime sodium crystal. The preparation method comprises the following steps of: dissolving sodium acetate in a mixed solvent of organic solvent and water below 10-40 DEG C, wherein the volume fraction of organic solvent in the mixed solvent is 30-70%; adding cefotaxime acid, and stirring until the cefotaxime acid reacts in the solution; adding a cefotaxime sodium crystal in the solution, then adding elution agents with a feeding time of 2-8 hours, cooling to 5 DEG C below zero to 5 DEG C; and filtering, washing and drying a crystal slurry to obtain the cefotaxime sodium crystal. By the preparation method, the phenomenon of gelatinization frequently seen in the crystallization process of the cefotaxime sodium crystal is avoided, the size distribution of the products is centralized and the major particle size is adjustable from 5mu m to 60my m, the liquidity of the product is good, the process yield is higher than 87%, and the product purity is higher than 95.5%.

Owner:TIANJIN UNIV

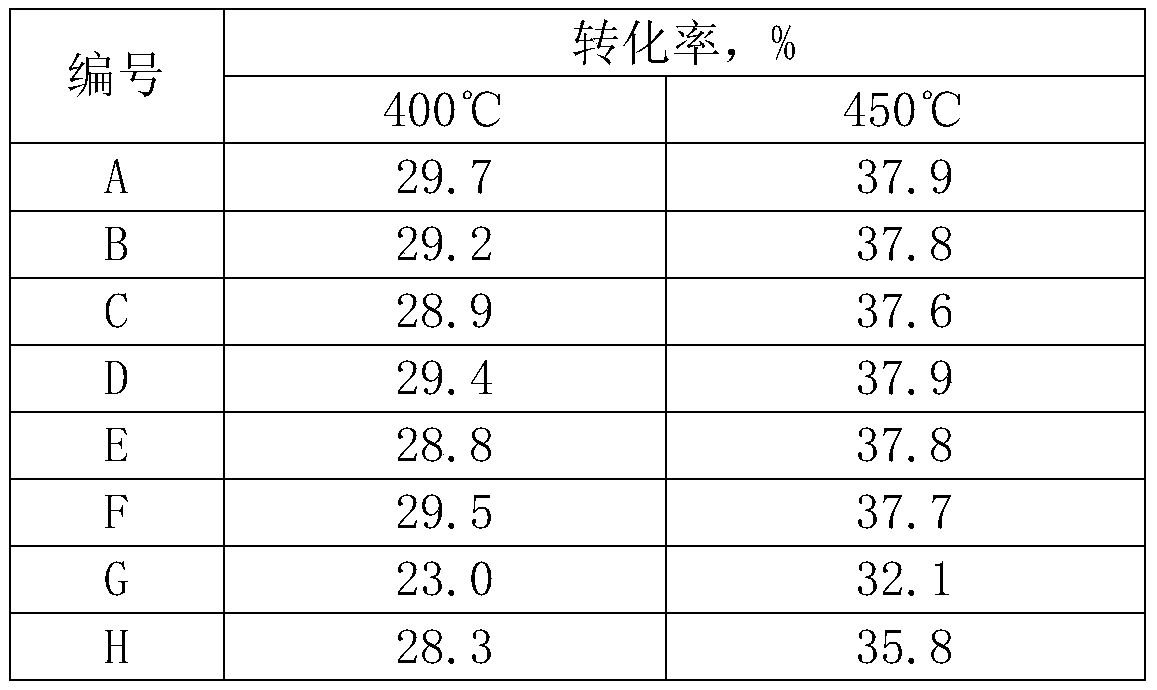

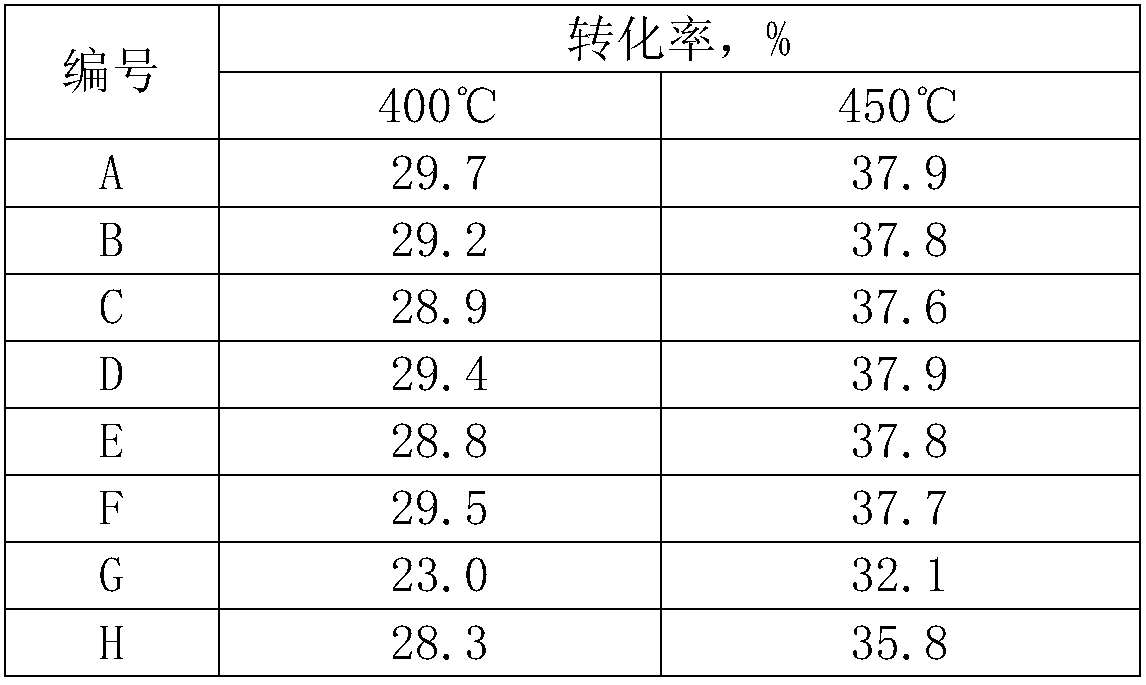

Catalyst for preparing trichlorosilane by hydrogenation of silicon tetrachloride and preparation method thereof

ActiveCN108283925BIncrease added valueReduce secondary pollutionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicon oxide

The invention provides a catalyst for hydrogenating silicon tetrachloride to prepare trichlorosilane and a preparation method thereof. A silicon source acidic solution containing silicon oxide is acidified, soluble salts of active components and additives are added, and then pseudo-thin The waste fine powder produced during the catalytic hydrogenation of diaspore and fluidized bed silicon tetrachloride is then added with a curing agent to form a slurry; the slurry is solidified and formed by spray drying, and then washed, dried, and roasted to form a catalyst. The trichlorosilane catalyst prepared by the present invention has round particle size, concentrated particle size distribution, large specific surface area and high active metal dispersion; the method of the present invention makes the fluidized bed silicon tetrachloride catalytic hydrogenation process The waste fine powder produced by the friction between silicon powder and the reactor, the friction between silicon powder and the silicon powder, and the friction between the silicon powder and the catalyst are made into the catalyst carrier, so that the waste fine powder can be reused, while increasing the added value of the waste fine powder, Reduce secondary pollution.

Owner:辽宁金易化工有限公司

Grinding fluid for processing silicon carbide wafer and preparation method of grinding fluid

ActiveCN114806502AEfficient removalGranular concentrationOther chemical processesSemiconductor/solid-state device manufacturingCarbide siliconWafering

The invention relates to a grinding fluid for silicon carbide wafer processing and a preparation method thereof, the grinding fluid comprises the following components by mass: 0.5-10 parts of diamond micro powder, 0.5-10 parts of a dispersant, 1-20 parts of a suspending agent and 50-98 parts of water; during preparation, the diamond micro-powder is taken into the dispersing agent and the suspending agent, water is added to form a two-phase mixture, the diamond micro-powder with coarse particles is separated and removed by utilizing the density difference of two-phase media through centrifugal separation, and the diamond micro-powder with more concentrated particle sizes is dispersed into the dispersing agent and the suspending agent, so that the grinding fluid for processing the silicon carbide wafer can be obtained. In the grinding fluid, the particle size of the diamond micro powder is more concentrated, and the number of coarse particles is far smaller than that of the diamond grinding fluid prepared by a traditional method, so that a silicon carbide wafer is effectively prevented from being scratched by large-particle diamonds.

Owner:河南创研新材料科技有限公司

Trichlorosilane catalyst prepared from silicon tetrachloride through hydrogenation and preparing method of trichlorosilane catalyst

ActiveCN108283925AIncrease added valueReduce secondary pollutionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDispersitySlurry

The invention provides a trichlorosilane catalyst prepared from silicon tetrachloride through hydrogenation and a preparing method of the trichlorosilane catalyst. The method includes the steps of conducting acidification treatment on a silicon source acidic solution containing silicon oxide, adding active components and soluble salt of aids, adding pseudo-boehmite and abandoned micropowder generated in the silicon tetrachloride catalytic hydrogenation process of a fluidized bed, adding a curing agent to prepare slurry, conducting solidification forming on the slurry by means of a spray dryingmode, and conducting washing, drying and calcinating to prepare the catalyst. The trichlorosilane catalyst prepared through the method is uniform in granularity and concentrated in grain size distribution, and has a large specific surface area and high reactive metal dispersity; by means of the method, the catalyst carrier is prepared from the abandoned micropowder generated by making the siliconpowder in the silicon tetrachloride catalytic hydrogenation process of the fluidized bed rub a reactor, making the silicon powder rub the silicon powder and making the silicon powder rub the catalyst, the abandoned micropowder is reused, and secondary pollution is reduced when the additional value of the abandoned micropowder is increased.

Owner:辽宁金易化工有限公司

Barite modifying and crushing assembly and production device

InactiveCN107377146ABroken fastImprove efficiencyGrain treatmentsPigment physical treatmentPropellerAir compressor

The invention discloses a barite modifying and crushing assembly and a production device, and belongs to the field of barite processing. The assembly comprises a crushing chamber, a rotating disc, an air compressor, a modifying agent hopper and a drive device. The crushing chamber is provided with a crushing cavity. An air inlet and a modifying agent feeding inlet are formed in the bottom end of the side wall of the crushing chamber. The air compressor communicates with the air inlet. The modifying agent hopper comprises a conveying tube connected with the modifying agent feeding inlet and a hopper body connected with the conveying tube. The hopper body is provided with a sealing cover. A first regulating valve is arranged between the hopper body and the conveying tube. A second regulating valve is arranged between the conveying tube and the modifying agent feeding inlet. The rotating disc is arranged at the bottom of the crushing cavity and comprises a disc body and a plurality of propeller blades. The disc body is rotationally connected with the drive device. The propeller blades are uniformly distributed at the top of the disc body. The device comprises a barite screening assembly and the barite modifying and crushing assembly. A discharging outlet communicating with the crushing cavity is formed in the top of the crushing chamber. The barite screening assembly is arranged at the discharging outlet. The crushing efficiency is high, modifying can be performed, the process is saved, the product particle diameter is small, the product purity is high, and equipment loss is small.

Owner:HONGXIN MINERAL IND

Barite crushing components and production equipment

The invention provides a barite crushing assembly and a production device, and belongs to the field of barite processing. The barite crushing assembly comprises a crushing chamber, a rotating disc, an air compressor and a driving device. The crushing chamber is provided with a crushing cavity. An air inlet communicating with the crushing cavity is formed in the bottom end of the crushing chamber, and the air compressor communicates with the air inlet. The rotating disc is arranged at the bottom of the crushing cavity and comprises a disc body and a plurality of spiral blades. The disc body is rotatably connected with the driving device, and the multiple spiral blades are evenly distributed at the top of the disc body. According to the barite crushing assembly, the barite crushing efficiency is high, the particle sizes of products are small, the purity of the products is high, and the loss of equipment is small. The production device comprises a barite screening assembly and the barite crushing assembly. A discharging port communicating with the crushing cavity is formed in the top of the crushing chamber, and the barite screening assembly is arranged at the discharging port. The crushing effect is good, the production efficiency is high, the particle sizes of the products are centralized, the service life of the production device is prolonged, and the cost is low.

Owner:HONGXIN MINERAL IND

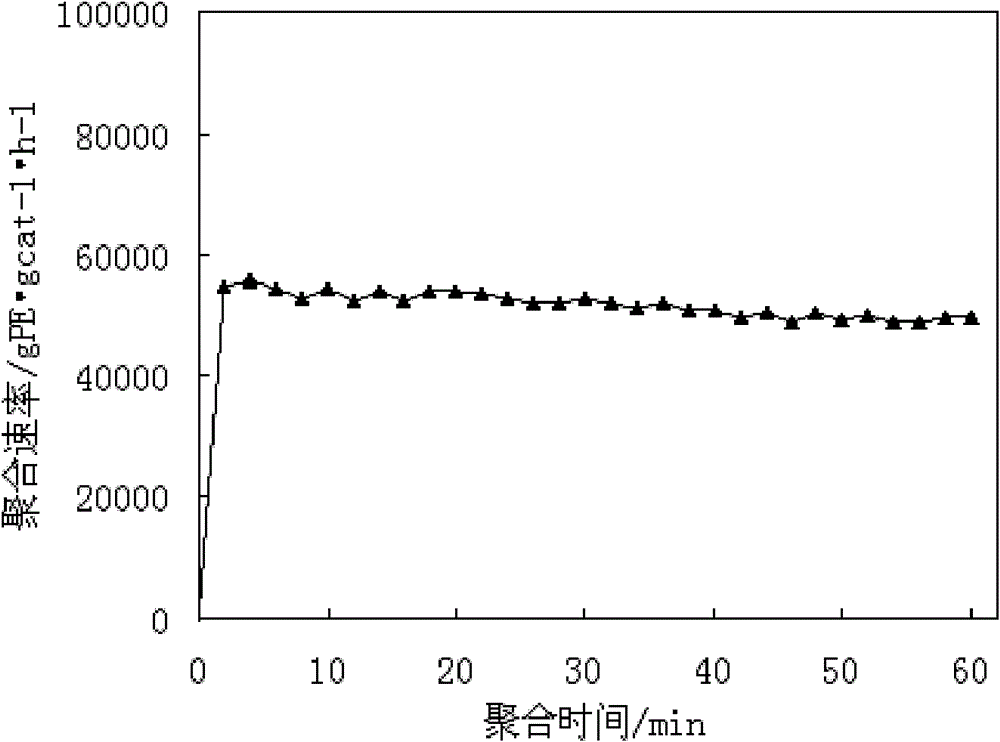

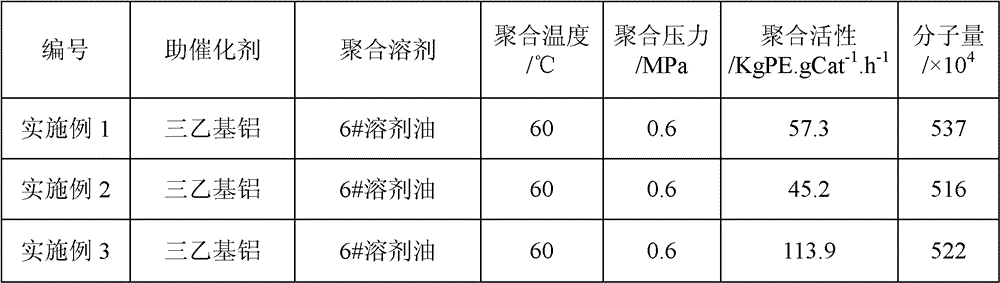

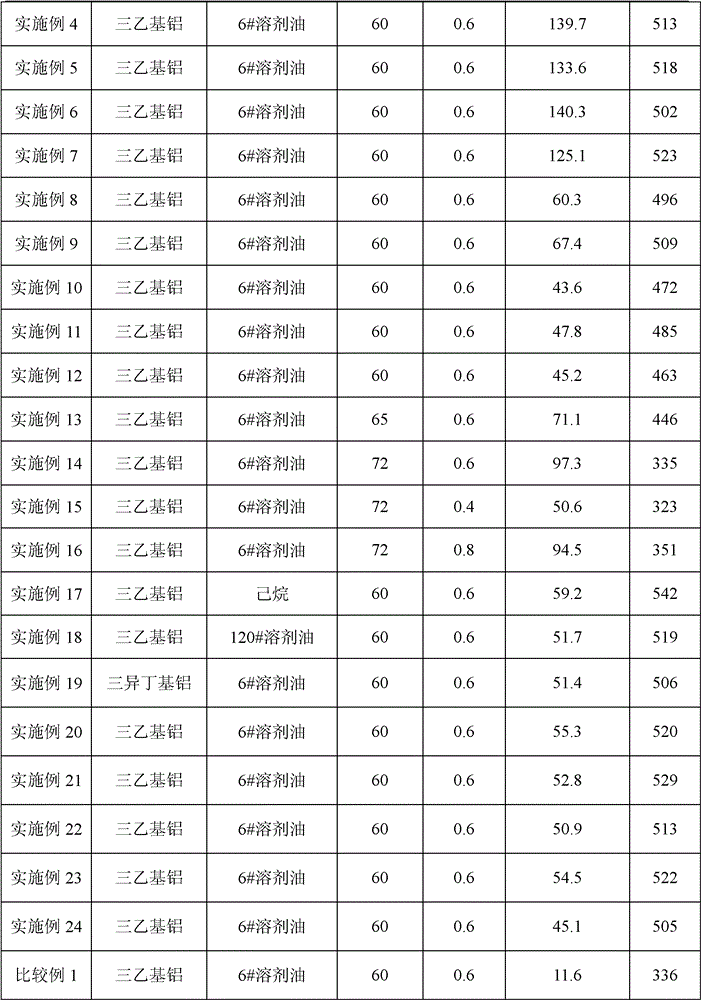

Ultra-high molecular weight polyethylene resin and preparation method thereof

The invention discloses an ultra-high molecular weight polyethylene resin and a preparation method thereof, particularly an ultra-high molecular weight polyethylene resin prepared by using an ultrasonic-treated supported titanium catalyst and a preparation method thereof, belonging to the technical field of high polymer materials. The preparation method comprises the following steps: by using an ultra-high molecular weight polyethylene catalyst as a main catalyst and alkyl aluminum as a cocatalyst, adding a polymerization solvent and an outer electron donor to carry out homopolymerization under non-hydrogen conditions by a slurry polymerization technique. The preparation method disclosed by the invention can easily implement industrialization, and has the advantages of favorable adjustability of technological conditions and high reaction kinetic stability of the catalyst. The ultra-high molecular weight polyethylene resin prepared by the method has the advantages of higher viscosity-average molecular weight and adjustable molecular weight, and effectively lowers the content of fine powder in resin granules.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com