The method for preparing cefotaxime sodium crystal

A technology for cefotaxime sodium and cefotaxime acid is applied in the field of preparation of cefotaxime sodium crystals, which can solve the problems of large seed crystal size, difficult to adjust crystal size, large supersaturation degree of cefotaxime sodium and the like, and achieve particle size distribution. Concentration, good fluidity, avoid gelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

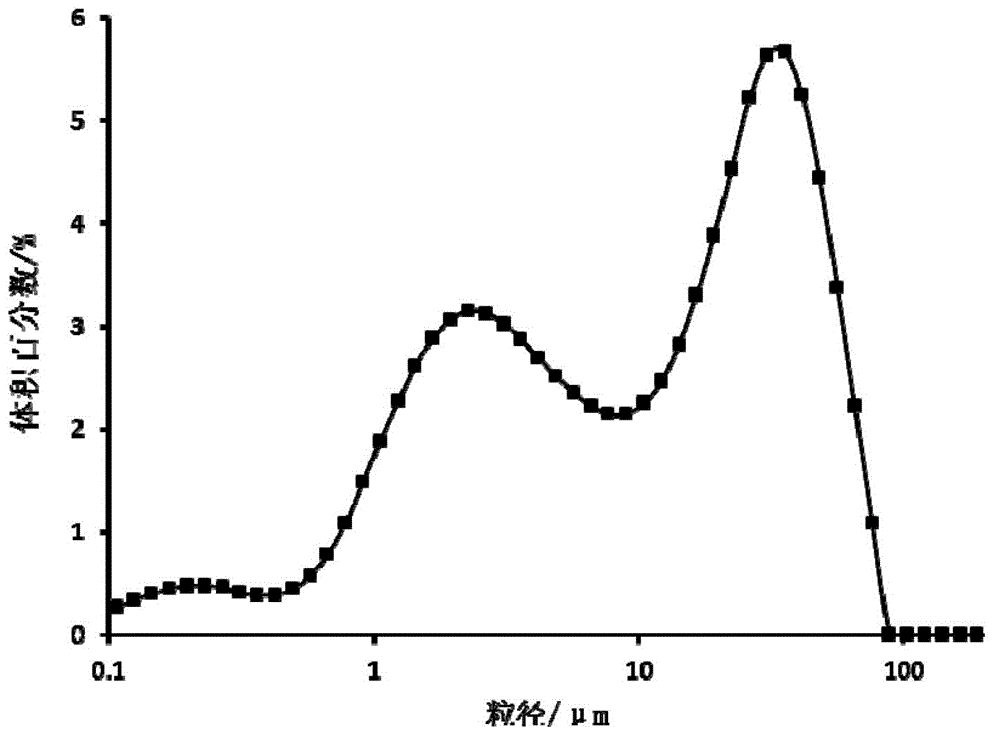

Image

Examples

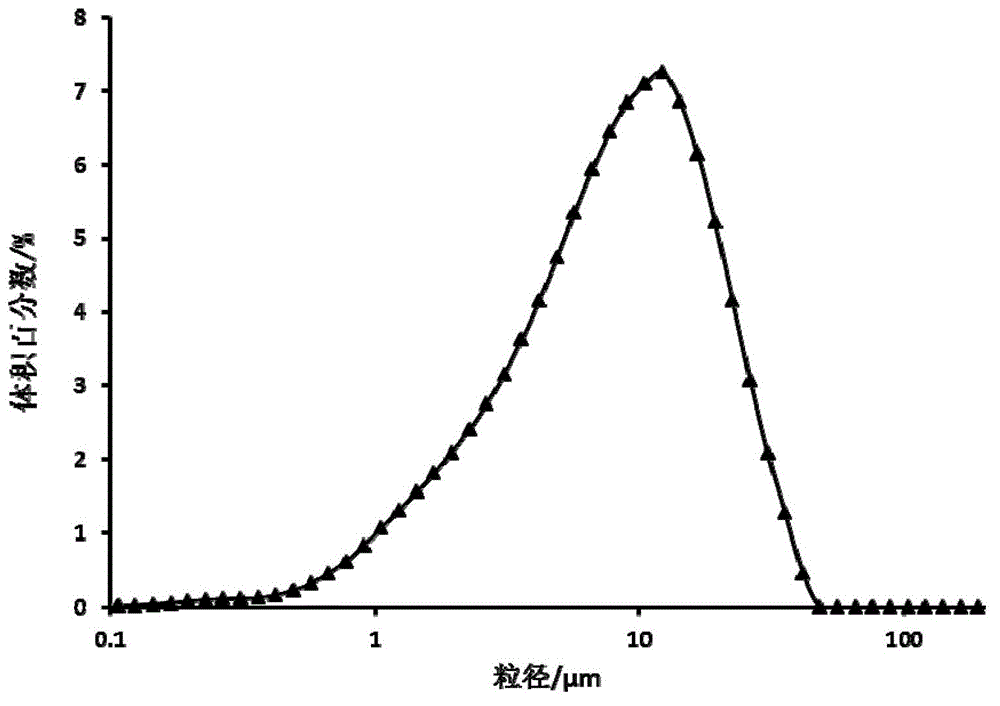

Embodiment 1

[0030] The temperature is 30°C, and 2.1 g of sodium acetate is dissolved in 30 mL of n-propanol-water mixed solvent with a volume fraction of n-propanol of 55%, to obtain a sodium acetate solution with a concentration of 0.07 g / mL; add 10 g of cefotaxime acid, Stir to react the cefotaxime acid in the solution to obtain a cefotaxime sodium solution; add 0.4 g of cefotaxime sodium seed crystals with a main particle size of 10 μm to the solution; add 240 mL of acetone, and the feeding time is 5 hours. After the feeding was completed, the temperature was lowered to 2°C. After the crystalline slurry was filtered, washed, and dried at 40° C. and a vacuum degree of 0.09 MPa for 20 hours, 9.29 g of cefotaxime sodium crystals were obtained.

[0031] The main particle size of the product is 12.2 μm, the product molar yield is 88.6%, and the product purity is 95.6%. The particle size distribution of the product is shown in figure 2 .

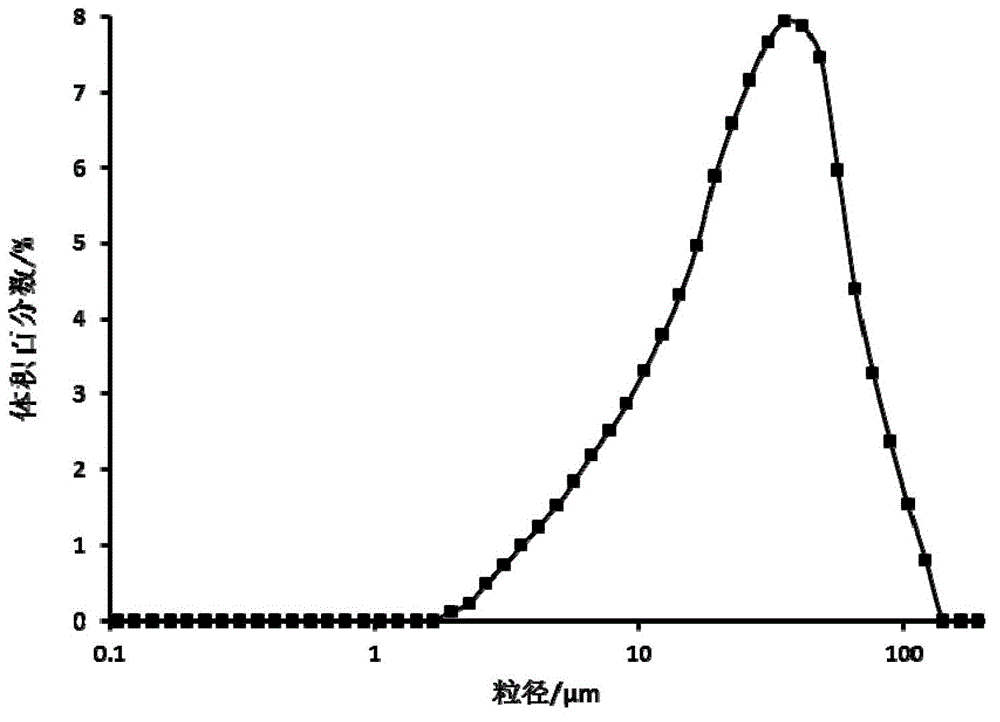

Embodiment 2

[0033] Temperature is 10 ℃, and 2.3g sodium acetate is dissolved in the ethanol-water mixed solvent 40mL that ethanol volume fraction is 70%, obtains the sodium acetate solution that concentration is 0.0575g / mL; Add cefotaxime acid 10g, stir to make cefotaxime The xamic acid was reacted in the solution to obtain a cefotaxime sodium solution; 5 mL of ethanol was added to the solution, and then 0.1 g of cefotaxime sodium seed crystals with a main particle size of 1 μm were added, and 400 mL of ethanol was added continuously for 3 hours. After feeding, the temperature was lowered to 0°C, and the crystal was grown for 2 hours. The crystal slurry was filtered, washed, and dried for 24 hours at 30° C. under a vacuum of 0.095 MPa to obtain 9.29 g of cefotaxime sodium crystals.

[0034] The main particle size of the product is 41.4μm, the molar yield of the product is 88.6%, and the product purity is 95.8%. For the particle size distribution of the product, see image 3 . The partic...

Embodiment 3

[0036]Temperature is 40 ℃, and 1.8g sodium acetate is dissolved in the methanol-water mixed solvent 30mL that methanol volume fraction is 50%, obtains the sodium acetate solution that concentration is 0.06g / mL; Add cefotaxime acid 10g, stir to make cefotaxime The xamic acid reacts in the solution to obtain a cefotaxime sodium solution; add 9 mL of acetone to the solution, then add 0.5 g of cefotaxime sodium seed crystals with a main particle size of 10 μm, and grow the crystals for 0.5 h; continue to add 270 mL of acetone, and the feeding time 8h. After feeding, the temperature was lowered to -5°C, and the crystal was grown for 1 hour. The crystal slurry was filtered, washed, and dried for 18 hours at 40° C. under a vacuum of 0.09 MPa to obtain 9.40 g of cefotaxime sodium crystals.

[0037] The main particle size of the product is 6.1 μm, the product molar yield is 89.7%, and the product purity is 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com