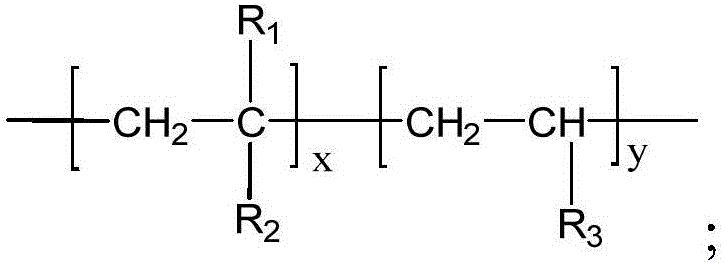

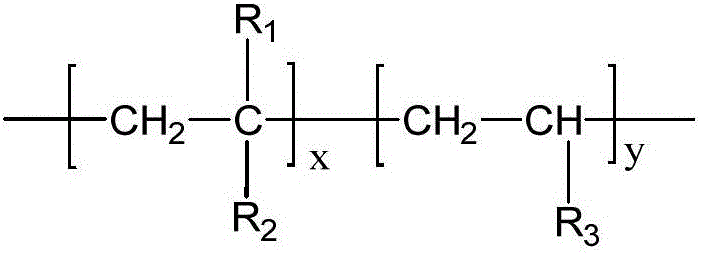

Water-based fluorosilicone acrylic resin and preparation method thereof

A technology of acrylic resin and water-based fluorosilicone, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., and can solve the problems of low utilization rate of fluorine and silicon monomers, increased gel rate, monomer Difficult emulsification and other problems, to achieve the effect of improving applicability, good film forming, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

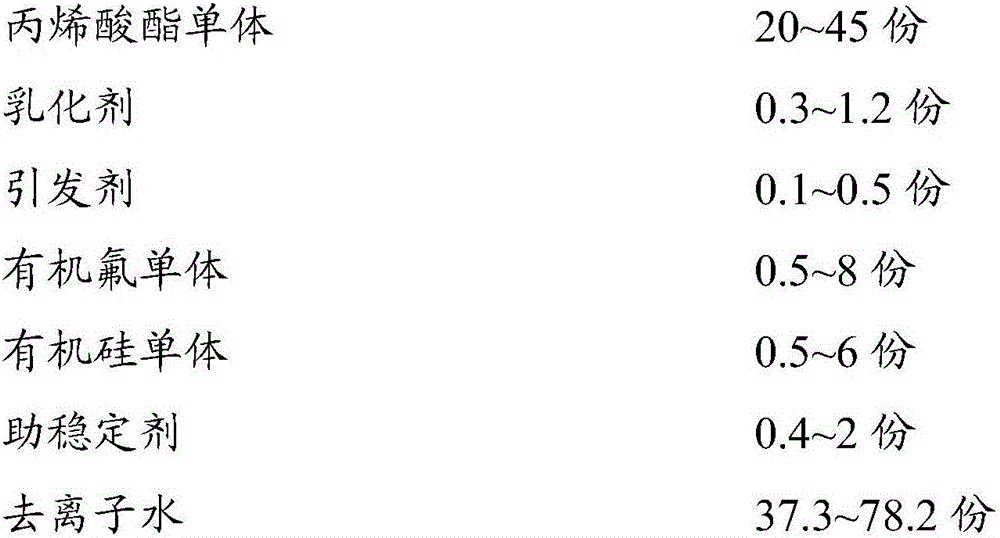

[0039] A kind of preparation method of above-mentioned water-based fluorosilicone acrylic resin, is characterized in that, comprises the following steps:

[0040] Mix the acrylate monomer, organofluorine monomer, organosilicon monomer, initiator and co-stabilizer uniformly to obtain a mixed solution;

[0041] Dissolve the emulsifier in deionized water, add the mixture dropwise while stirring, stir evenly, and ultrasonically emulsify for 5 to 15 minutes to obtain a monomer fine emulsion;

[0042] Oxygen in the single-system emulsion is removed, the temperature is raised to 65-85° C. while stirring, kept for 3-6 hours, cooled to room temperature, discharged, and filtered.

[0043] The principle of the present invention is: the microemulsion of the monomer is obtained by ultrasonic fine emulsification, so that the monomer droplet becomes the main place where the polymerization reaction takes place, the monomer does not need to migrate from the droplet to the micelle, and the orga...

Embodiment 1

[0046] 1.8g acrylic acid, 5.0g hydroxyethyl acrylate, 30.0g methyl methacrylate, 22.0g butyl acrylate, 8.0g dodecafluoroheptyl methacrylate, 4.0g vinyl-terminated silicone oil, 0.3g azobis Isobutyronitrile (AIBN) and 2.0g n-hexadecane are mixed uniformly to obtain a mixed solution for use;

[0047] Dissolve 1.4g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate in 100.0g of deionized water, add the above mixture dropwise while stirring, and after stirring evenly, emulsify for 10min with an ultrasonic cell pulverizer to obtain a monomer miniemulsion ;

[0048] Transfer the monomer fine emulsion into a four-necked flask equipped with a stirrer, a condenser, a nitrogen conduit, and a dropping funnel. After purging nitrogen to remove oxygen, the temperature was raised to 75°C while stirring, and the temperature was kept for 6 hours. After the reaction, it was lowered to Discharge at room temperature and filter with a 200-mesh sieve.

[0049] The water-based fluorosil...

Embodiment 2

[0051] 1.8g acrylic acid, 5.0g hydroxyethyl acrylate, 30.0g methyl methacrylate, 20.0g butyl methacrylate, 10.0g dodecafluoroheptyl methacrylate, 4.0g vinyl-terminated silicone oil, 0.3g AIBN and 2.0g n-hexadecane are mixed uniformly to obtain a mixed solution for use;

[0052] Dissolve 1.0g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate and 0.4g of sodium lauryl sulfate in 100.0g of deionized water, add the above mixture dropwise while stirring, and after stirring evenly, use ultrasonic cell crushing Machine emulsification for 10 minutes to obtain monomer fine emulsion;

[0053] Transfer the monomer fine emulsion into a four-necked flask equipped with a stirrer, a condenser, a nitrogen conduit and a dropping funnel. After purging nitrogen to remove oxygen, heat up to 75°C while stirring, keep the temperature for 6 hours, and drop to Discharge at room temperature and filter with a 200-mesh sieve.

[0054] The water-based fluorosilicone acrylic resin emulsion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com