Modified urethane acrylate copolymer, photoresist and preparation method of photoresist

A polyurethane acrylate and acrylate technology, applied in the field of photoresist, can solve problems such as poor heat resistance, and achieve the effects of strong chemical resistance, short production cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

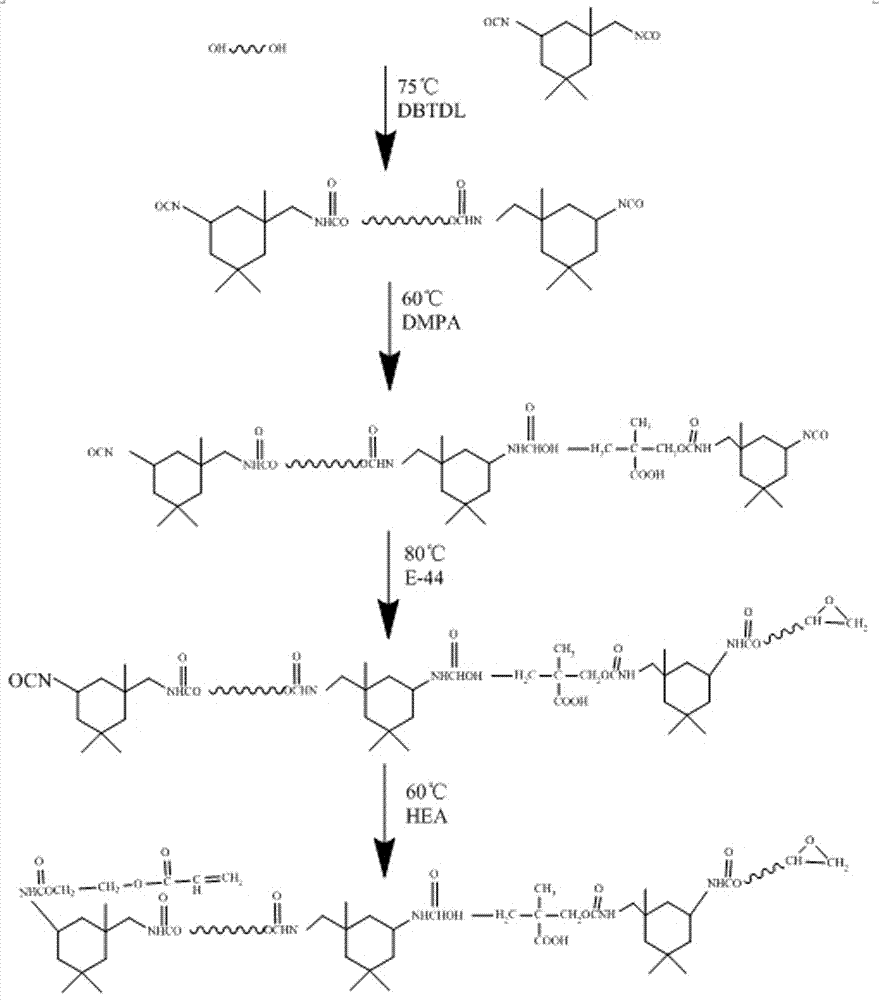

[0068] The preparation method of described modified polyurethane acrylate copolymer, comprises the steps:

[0069] Step 1: Preparation of polyurethane prepolymer: Add polyisocyanate and catalyst to the reaction equipment with thermometer, stirring paddle, and condenser tube, add polyether polyol dropwise at 60-90°C while stirring, and keep warm for reaction 1 ~3h, take a sample to measure the NCO content until it is close to the theoretical value;

[0070] Step 2: Chain extension: Dissolve the dried chain extender carboxyl diol in the solvent at 60-75°C, add it dropwise to the reaction equipment, react for 2-4 hours, and take samples to measure the NCO content until it is close to the theoretical value;

[0071] Step 3: Epoxy resin modification: heat up to 80-95°C, add epoxy resin, react for 2-4 hours, and take samples to measure the acid value;

[0072] Step 4: Capping of hydroxyl-containing acrylate: cooling down to 50-65° C., adding dropwise an appropriate amount of hydrox...

Embodiment 1

[0089] Preparation of modified polyurethane acrylate copolymer: add 33.6g HDI and 0.01g catalyst dibutyltin dilaurate in a four-necked flask equipped with condenser tube, stirring paddle and thermometer, and add 40.2g of dibutyltin dilaurate dropwise while stirring. Polyoxypropylene diol, heat preservation reaction at 75°C for 3h, and take a sample to measure the NCO group content during the reaction by the toluene-di-n-butylamine back titration method;

[0090] Then lower the temperature to 60°C, dissolve 6.65g of dried dimethylolpropionic acid in 60g of acetone, and add it dropwise into a four-neck flask, stir and react for 2h, and take samples to measure the NCO group content until it is close to the theoretical value of 2.11%;

[0091] Then heat up to 80°C, add 13.5g of epoxy resin E-44, continue to react for 3h, and measure the acid value;

[0092] Finally, the temperature was lowered to 60°C, and 15g of hydroxyethyl acrylate and 0.1g of polymerization inhibitor p-hydroxy...

Embodiment 2

[0096] The preparation of modified polyurethane acrylate copolymer: add 50.9g IPDI and 0.04g catalyst dibutyltin dilaurate in the four-necked flask that condensation tube, stirring paddle, thermometer are housed, while stirring, dropwise add 25g molecular weight is 1000 poly Oxypropylene glycol, heat preservation reaction at 75°C for 3h, and take a sample to measure the NCO group content during the reaction by the toluene-di-n-butylamine back titration method;

[0097] Then lower the temperature to 60°C, dissolve 3.1g of dried dimethylolpropionic acid in 10g of acetone, and add it dropwise into the flask, stir and react for 2h, and take samples to measure the NCO group content until it is close to the theoretical value of 2%;

[0098] Then heat up to 80°C, add 5.3g of epoxy resin E-44, continue to react for 3h, and measure the acid value;

[0099] Finally, the temperature was lowered to 60°C, and 10.7g of hydroxyethyl acrylate and 0.4g of polymerization inhibitor p-hydroxyanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com