Trichlorosilane catalyst prepared from silicon tetrachloride through hydrogenation and preparing method of trichlorosilane catalyst

A technology of silicon tetrachloride and trichlorosilane, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Loss of activity, affects catalyst activity, etc., to achieve the effect of increasing added value, improving activity, and improving catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 13.3g of water glass with a silicon oxide content of 30% in the preparation tank, start the stirring device, and then slowly add a concentration of 62% nitric acid solution, so that the pH of the acidified water glass solution is 2.5, mix it evenly and pour it into the preparation tank Add 12.5g of nickel nitrate hexahydrate, stir to dissolve and then add pore volume 1.109mL / g to the above solution, specific surface area is 363m 2 / g, dry base is 70% pseudo-boehmite 10g and 86g fine silica fume, add solidifying agent urea again after stirring evenly, add deionized water after treating that urea dissolves completely, make the silicon dioxide of slurry in the preparation tank, The sum concentration of alumina, fine silicon powder and nickel oxide is 33%, and it is kept as a slurry with certain fluidity.

[0035] The above-mentioned slurry with certain fluidity is spray-dried in the spray drying tower, the diameter of the nozzle is set to 0.6mm, the gas in the spray dr...

Embodiment 2

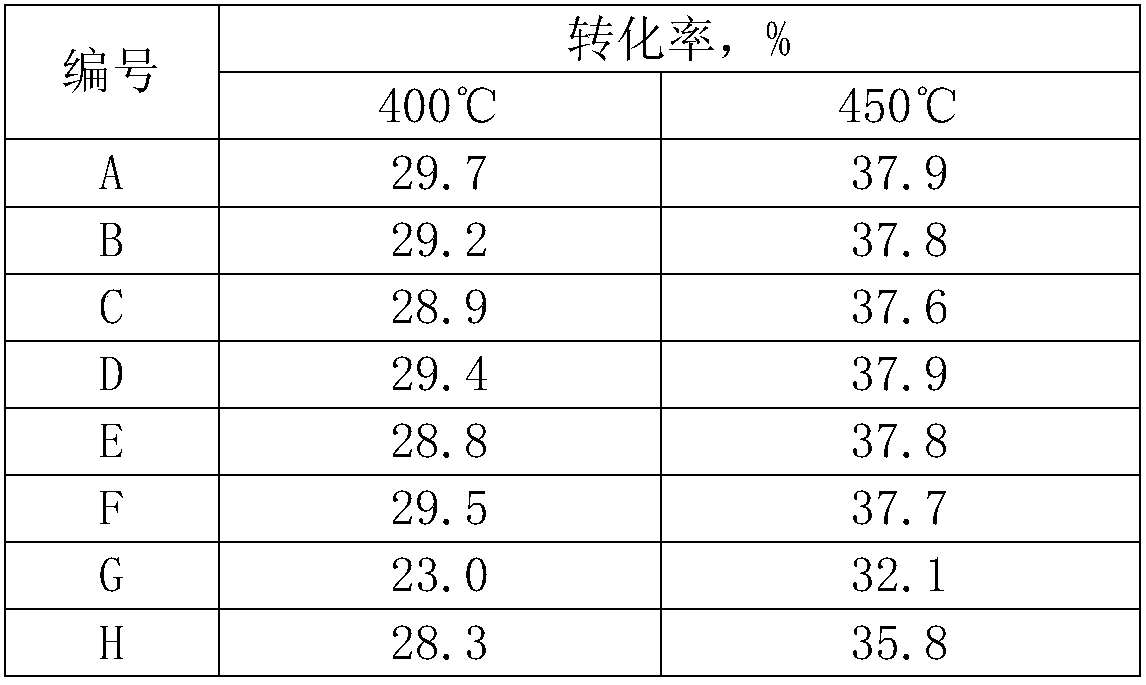

[0038] The preparation process was the same as in Example 1, except that the curing agent was changed to hexamethylenetetraammonium to prepare catalyst B of the present invention. The properties are shown in Table 1, and the evaluation results of the catalyst are shown in Table 2.

Embodiment 3

[0040] The preparation process was the same as in Example 1, except that the diameter of the nozzle was changed to 1.0 mm, and the drying temperature inside the spray drying tower was 150° C. to prepare catalyst C of the present invention. The properties are shown in Table 1, and the evaluation results of the catalyst are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com