Production technique for high grade high-yield synthetic diamond fine - micro-fine particle diamond

A technology of artificial diamond and production process, which is applied in the field of production technology of high-quality and high-yield production of fine-fine-grained artificial diamond, and achieves the effect of feasible process, concentrated particle size and fine particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

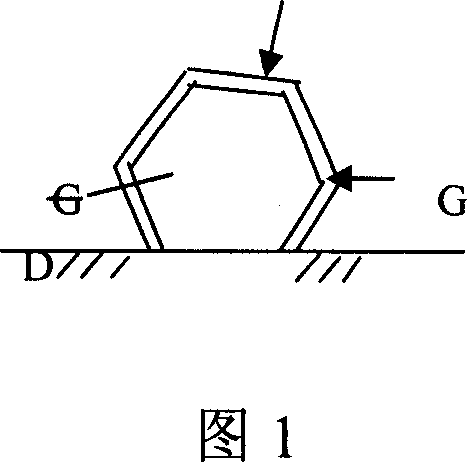

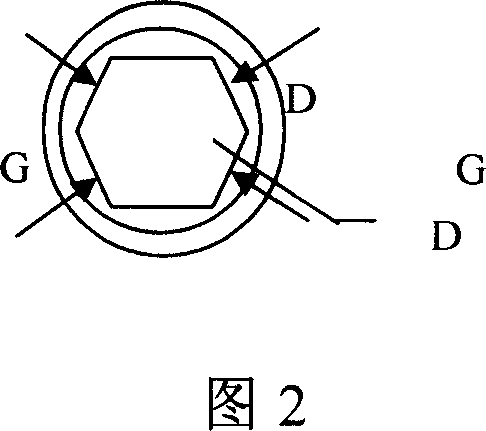

Method used

Image

Examples

Embodiment 1

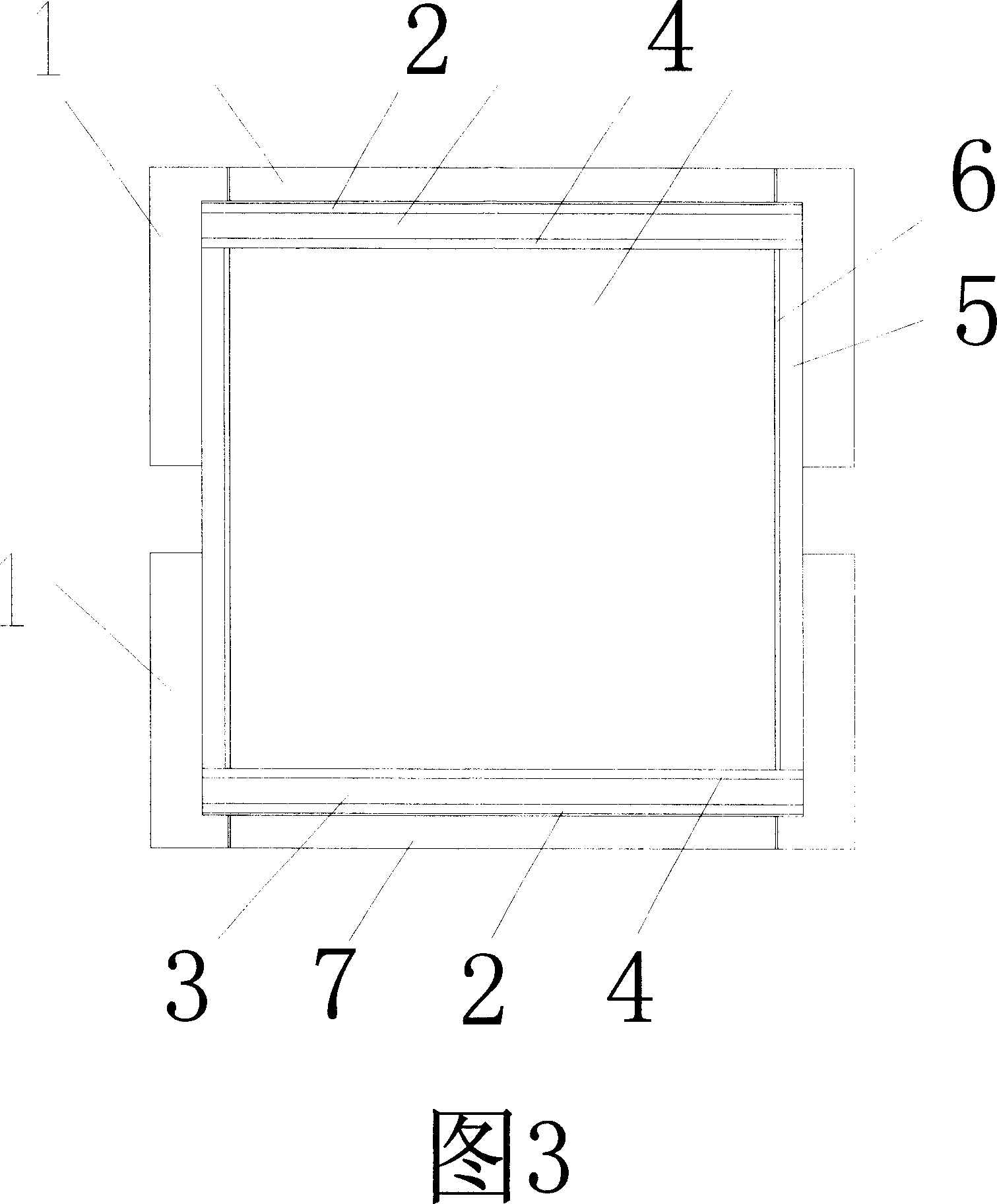

[0033] 1. Press: QYDS series 6×22MN six-sided top press produced by Hunan Changde Qiyi Machinery Factory, which has Chinese characteristics and is a pocket-bottom hinged press with a cylinder diameter of Φ520mm;

[0034] 2. Control system: JY-ZIC artificial diamond press electric control system produced by Changsha Shuangquan Automation Co., Ltd., with pressure accuracy of 0.01MPa and temperature accuracy (expressed in current) of 3A;

[0035] 3. Pyrophyllite block: 59×59×59mm 3 (two-section type);

[0036] 4. Dolomite liner: Φ 外 48mm×Φ 内38mm;

[0037] 5. Cavity: Φ38mm;

[0038] 6. Graphite column: Φ38mm×32mm

[0039] 7. Synthesis process:

[0040] Synthetic pressure: the original synthesis pressure: P (generally 95-98MPa) the actual synthesis pressure is 2-10% lower than the original synthesis pressure;

[0041] Suspension pressure: 80-92% of the synthetic pressure, the difference between the two suspension pressures is 0.10-0.15MPa;

[0042] Pause time: 120-180S;

...

Embodiment 2

[0049] 1. Press: QYDS series 6×22MN six-sided top press produced by Hunan Changde Qiyi Machinery Factory, which has Chinese characteristics and is a pocket-bottom hinged press with a cylinder diameter of Φ520mm;

[0050] 2. Control system: JY-ZIC artificial diamond press electric control system produced by Changsha Shuangquan Automation Co., Ltd., with pressure accuracy of 0.01MPa and temperature accuracy (expressed in current) of 3A;

[0051] 3. Pyrophyllite block: 59×59×59mm 3 (two-section type);

[0052] 4. Dolomite liner: Φ 外 48mm×Φ 内 40mm;

[0053] 5. Cavity: Φ40mm;

[0054] 6. Graphite column: Φ40mm×34mm

[0055] 7. Synthesis process:

[0056] Synthetic pressure: the original synthetic pressure: P (generally 95-98MPa), the actual synthetic pressure is 2-10% lower than the original synthetic pressure;

[0057] Suspension pressure: 80-92% of the synthetic pressure, the difference between the two suspension pressures is 0.10-0.15MPa;

[0058] Pause time: 120-180S; ...

Embodiment 3

[0065] 1. Press: QYDS series 6×22MN six-sided top press produced by Hunan Changde Qiyi Machinery Factory, which has Chinese characteristics and is a pocket-bottom hinged press with a cylinder diameter of Φ520mm;

[0066] 2. Control system: JY-ZIC artificial diamond press electric control system produced by Changsha Shuangquan Automation Co., Ltd., with pressure accuracy of 0.01MPa and temperature accuracy (expressed in current) of 3A;

[0067] 3. Pyrophyllite block: 60×60×60mm 3 (two-section type);

[0068] 4. Dolomite liner: Φ 外 50mm×Φ 内 42mm;

[0069] 5. Cavity: Φ42mm;

[0070] 6. Graphite column: Φ42mm×35mm

[0071] 7. Synthesis process:

[0072] Synthetic pressure: the original synthetic pressure: P (generally 95-98MPa), the actual synthetic pressure is 2-10% lower than the original synthetic pressure;

[0073] Suspension pressure: 80-92% of the synthetic pressure, the difference between the two suspension pressures is 0.10-0.15MPa;

[0074] Pause time: 150-200S; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com