Patents

Literature

50results about How to "No reduction in yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

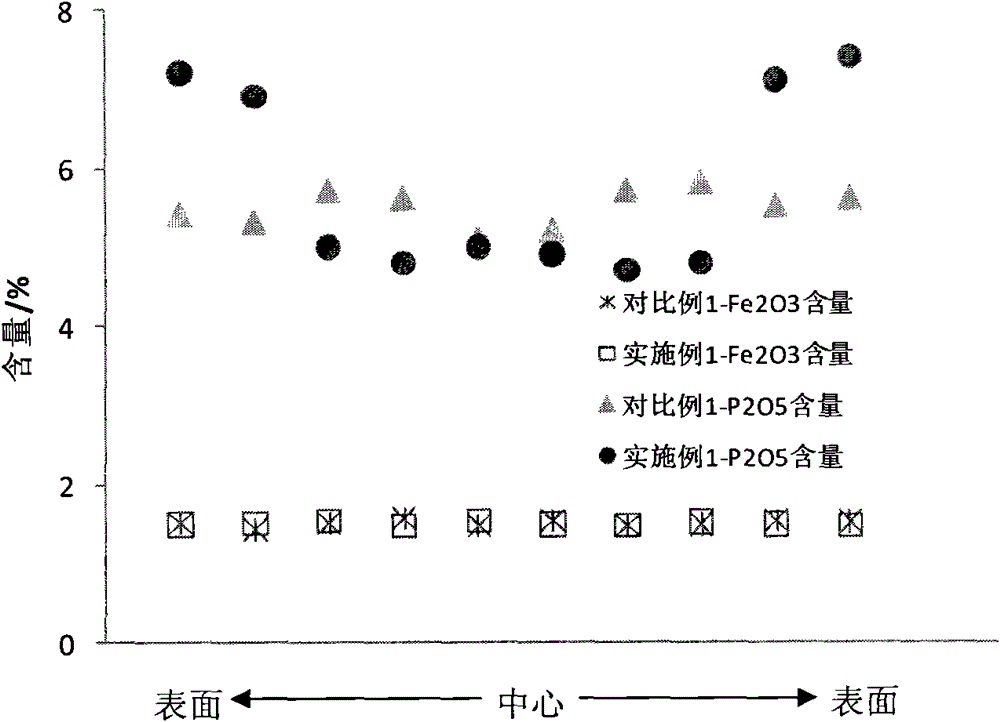

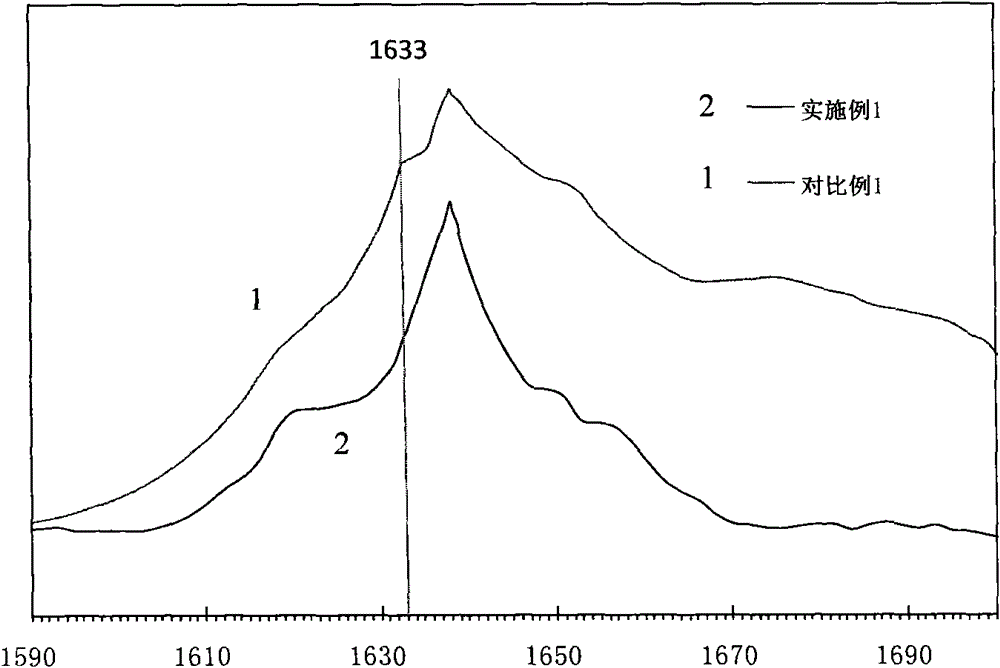

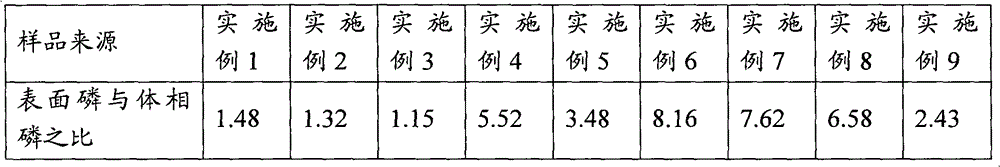

MFI structure molecular sieve containing phosphorus and transition metal as well as its preparation method

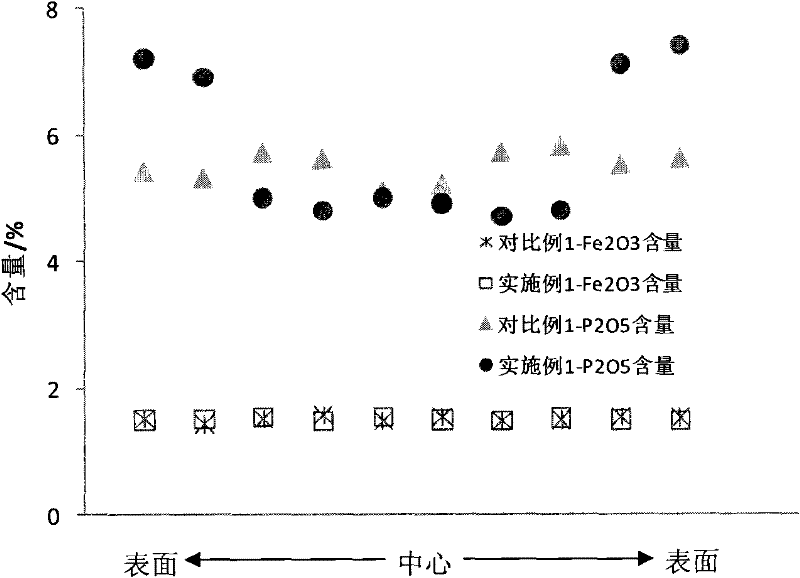

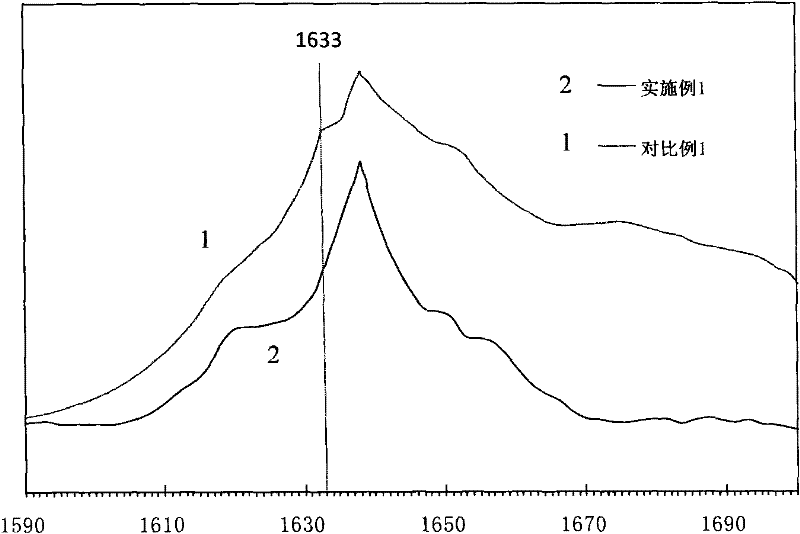

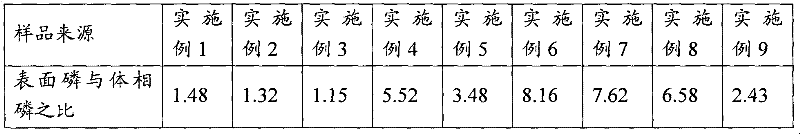

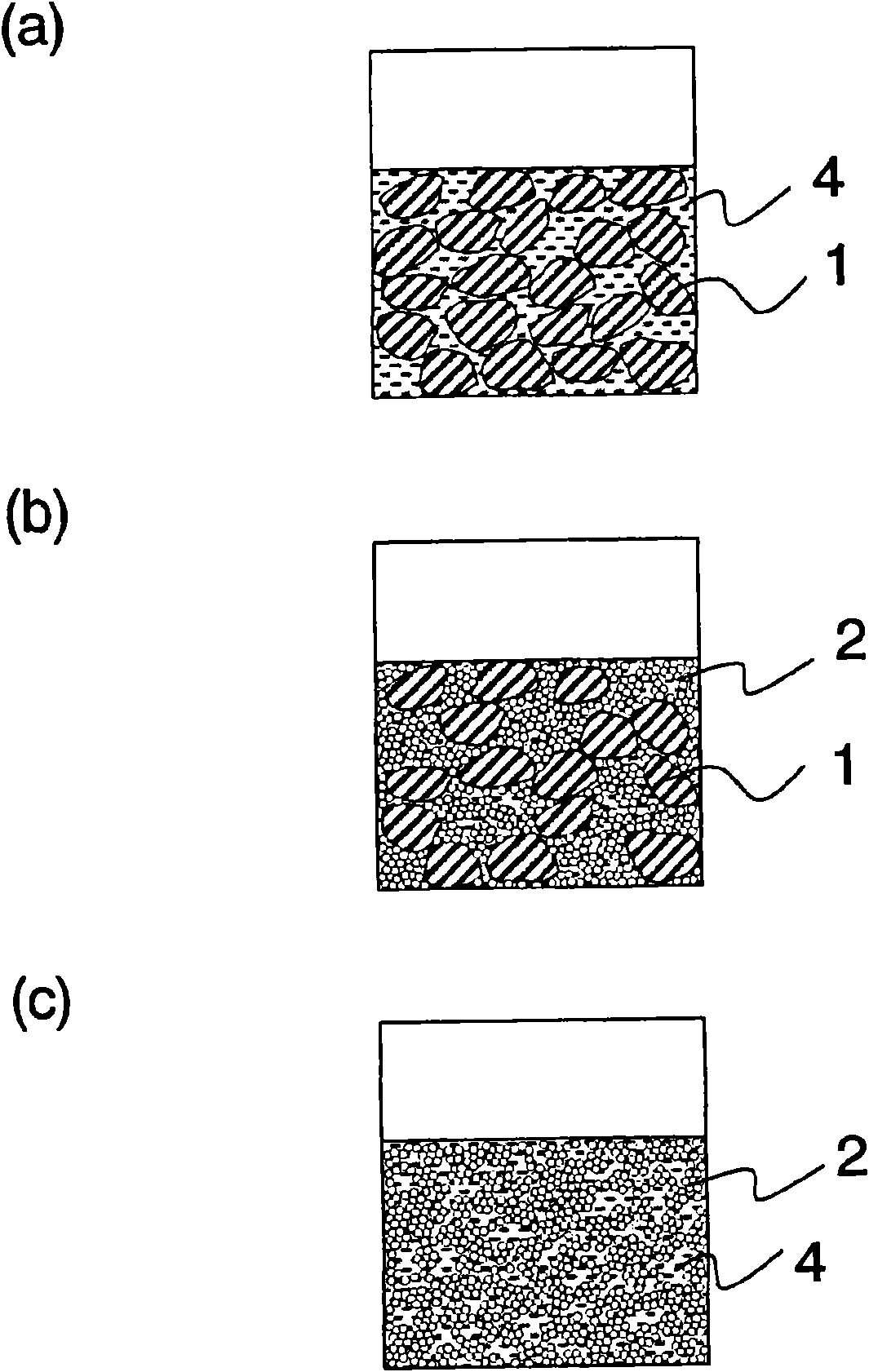

The invention relates to a MFI structure molecular sieve containing phosphorus and transition metal as well as its preparation method. The anhydrous chemical expression of the molecular sieve is (0-0.3) Na2O.(0.5-6) Al2O3.(1.3-10) P2O5.(0.7-15) MxOy.(70-97) SiO2, wherein M is selected from one or more of Fe, Co, Ni, Cu, Mn, Zn, Sn and Bi, x is expressed as atomicity of M, y is expressed as a number which satisfies the requirement of an oxidation state of M; No characteristic absorption peak is existed at 1633cm<-1> on infrared spectrum by molecular sieve trimethylpyridine adsorption. The preparation method comprises that phosphor and transition metal are introduced in molecular sieve with the MFI structure during ammonium exchanging, wherein the phosphor introduction is divided into two parts, a part of phosphor is introduced before introducing the transition metal or at the same time with transition metal introduction, the other part of the phosphor is introduced after the transitionmetal introduction. The provided molecular sieve is used for conversing hydrocarbon oil, the yield of dry gas and coke is low, and the yield of propylene and isobutene is high.

Owner:CHINA PETROLEUM & CHEM CORP

Process for preparing graphite surface anti oxidation coating material silicon carbide for nuclear reactor

InactiveCN1554802AReduce yieldNo reduction in yieldSolid/suspension decomposition chemical coatingNuclear reactor coreManufacturing technology

The present invention discloses the preparation process of antioxidant silicon carbide coating on the surface of graphite for nuclear reactor. The preparation process includes first coating polycarbosilane (PCS) solution on the surface of substrate to form PCS coating after volatizing solvent; and high temperature cracking the PCS coating in protecting gas containing Si while regulate cracking temperature and cracking atmosphere independently to realize required C / Si ratio in silicon carbide. Adding gas containing Si component into the cracking atmosphere can make cracked PCS to react with gas containing Si component to avoid free carbon in prepared SiC while maintaining the ceramic yield.

Owner:TSINGHUA UNIV

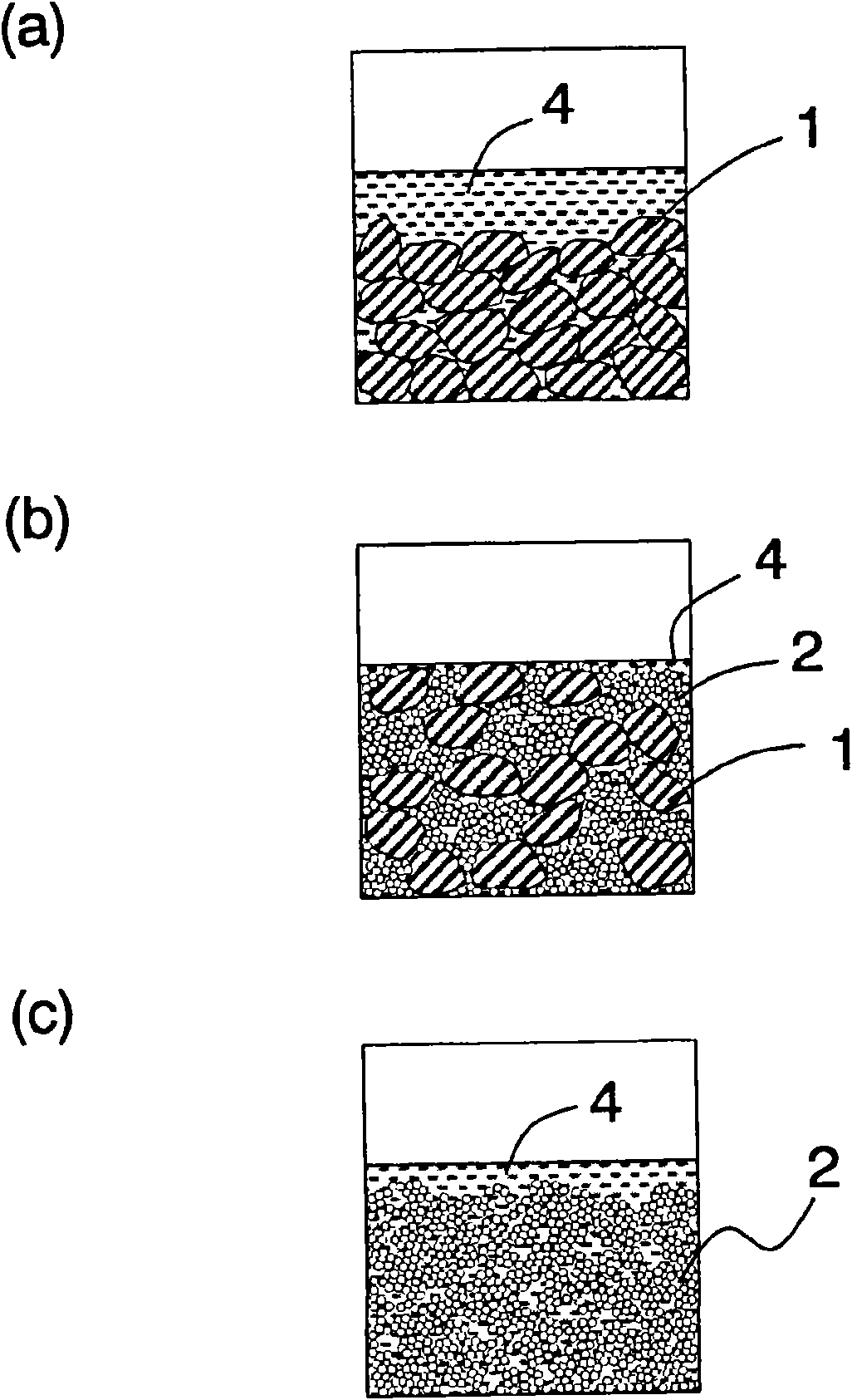

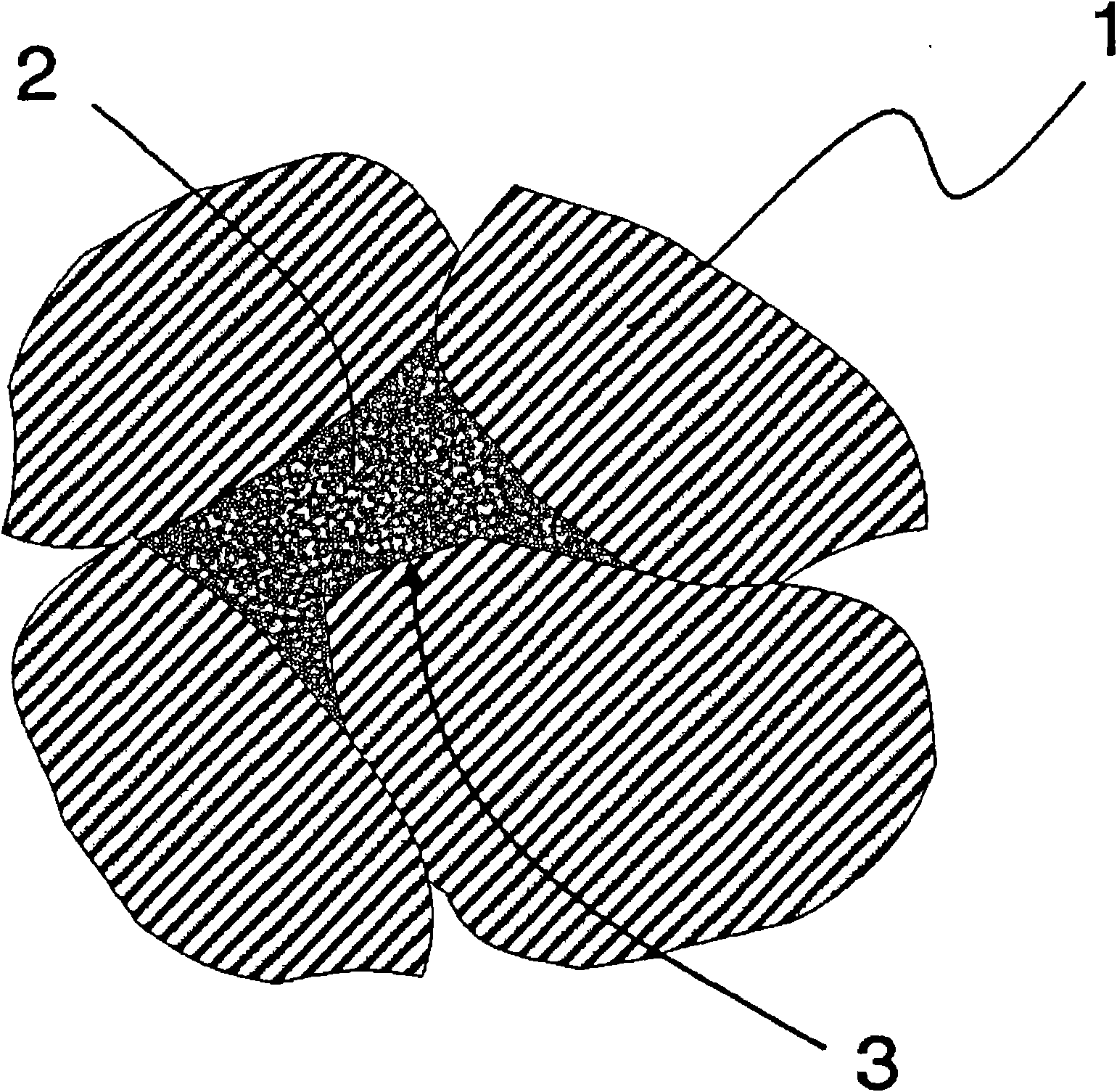

Coating liquid for formation of positive electrode for lithium rechargeable battery, positive electrode for lithium rechargeable battery, and lithium rechargeable battery

InactiveCN101611508AGood storage stabilityGood spreadabilityPositive electrodesNanotechnologyLithiumHigh density

This invention provides a coating liquid for the formation of a positive electrode for a lithium rechargeable battery. This coating liquid contains a large particle diameter active material having an average particle diameter of 1 to 20 [mu]m and a small particle diameter active material having an average particle diameter of 5 to 100 nm. The mixing ratio between the large particle diameter active material and the small particle diameter active material is 90 : 10 to 50 : 50 on a volume basis, and the average particle diameter ratio (the average particle diameter of the large particle diameter active material / the average particle diameter of the small particle diameter active material) is 50 to 500. The coating liquid has an excellent long-term storage stability and can realize high-density filling of the active material in the coating liquid. Accordingly, the preparation of a positive electrode using the coating liquid can realize the provision of a lithium rechargeable battery with a high energy density and a high capacity.

Owner:PANASONIC CORP

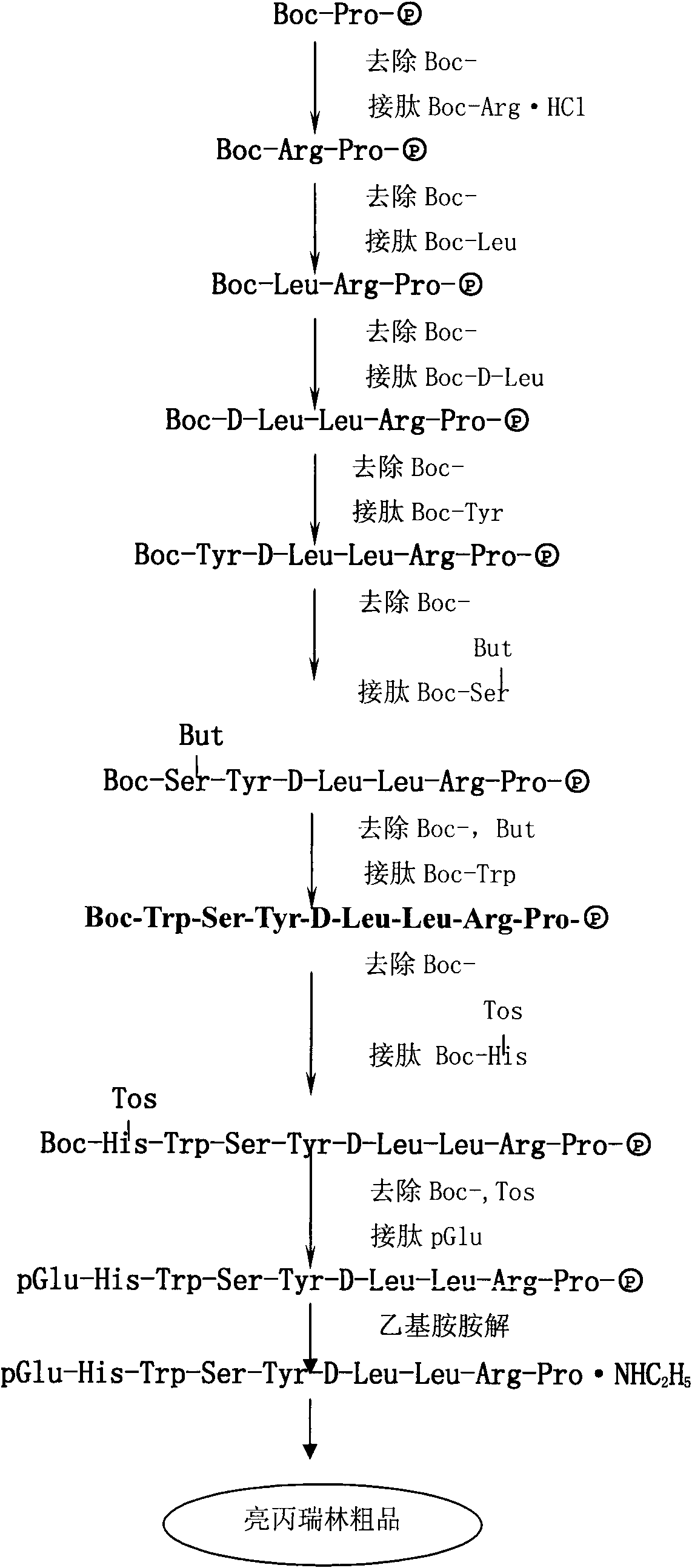

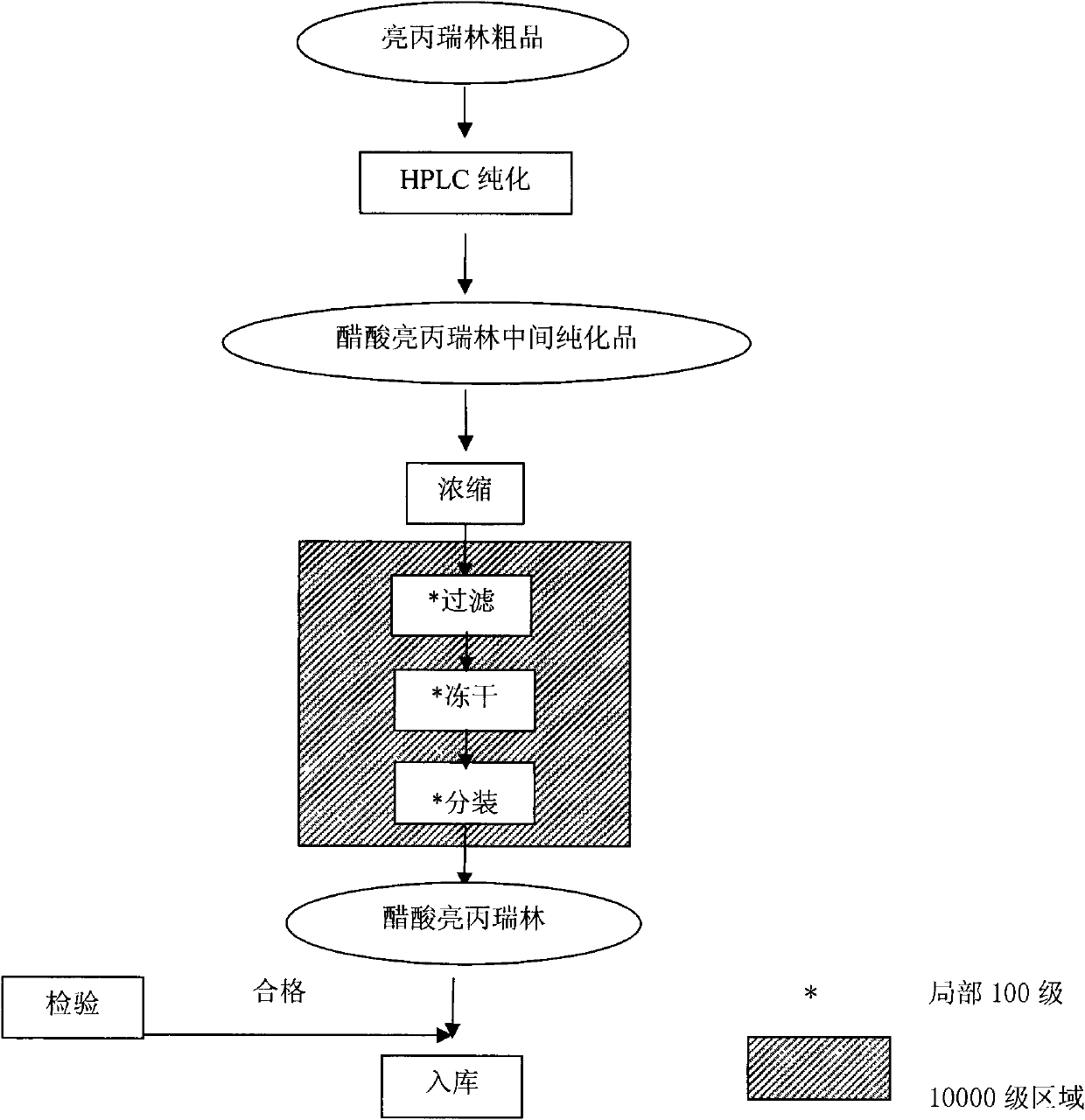

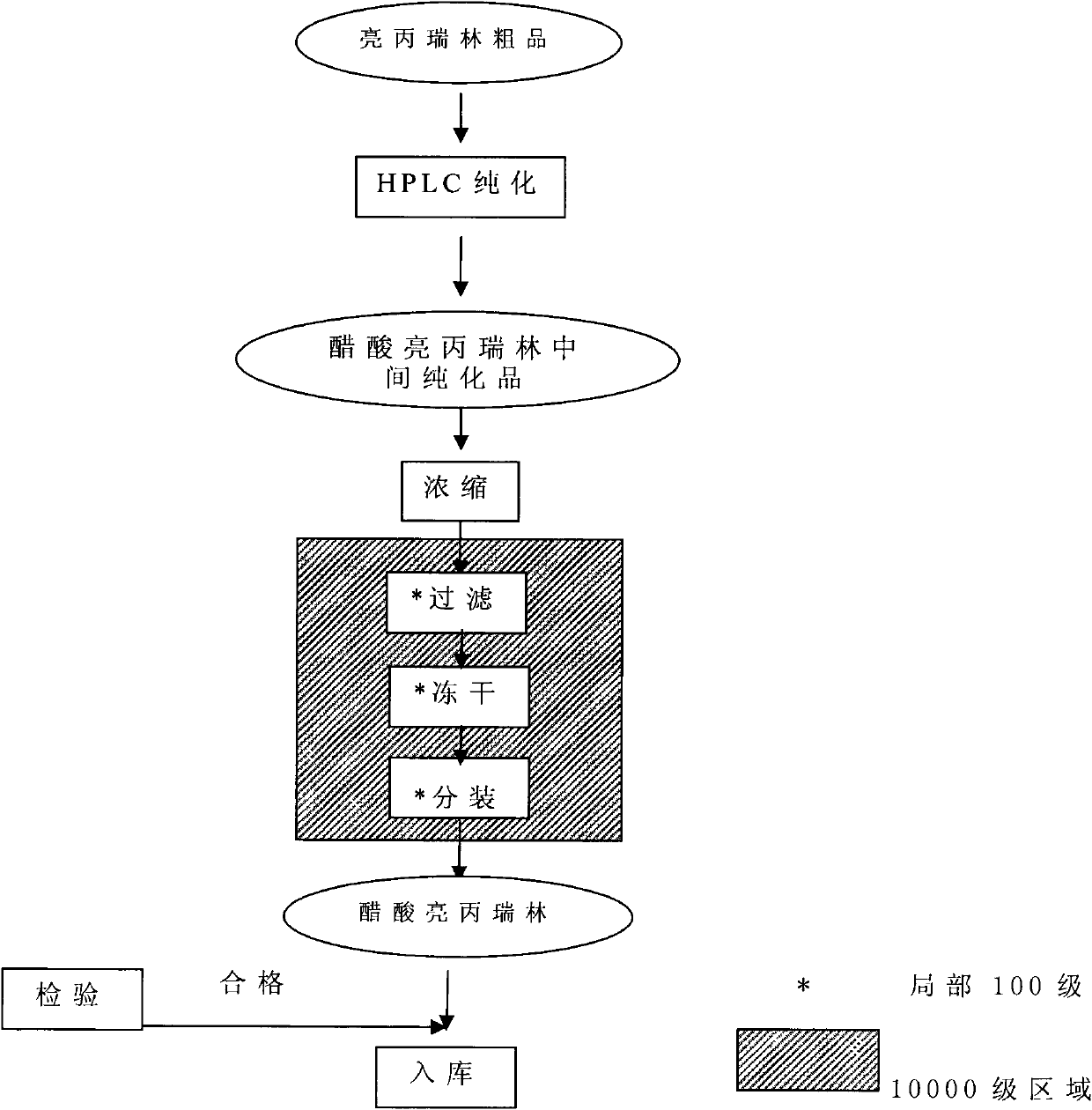

Method for preparing leuprorelin acetate, product and application

ActiveCN102464702AAvoid pollutionImprove securityPeptide/protein ingredientsLuteinising hormone-releasing hormoneSolid phasesChemistry

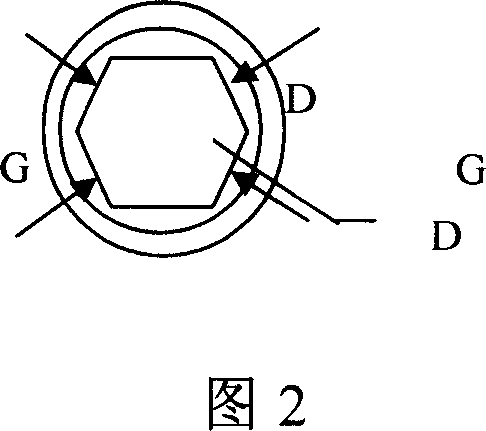

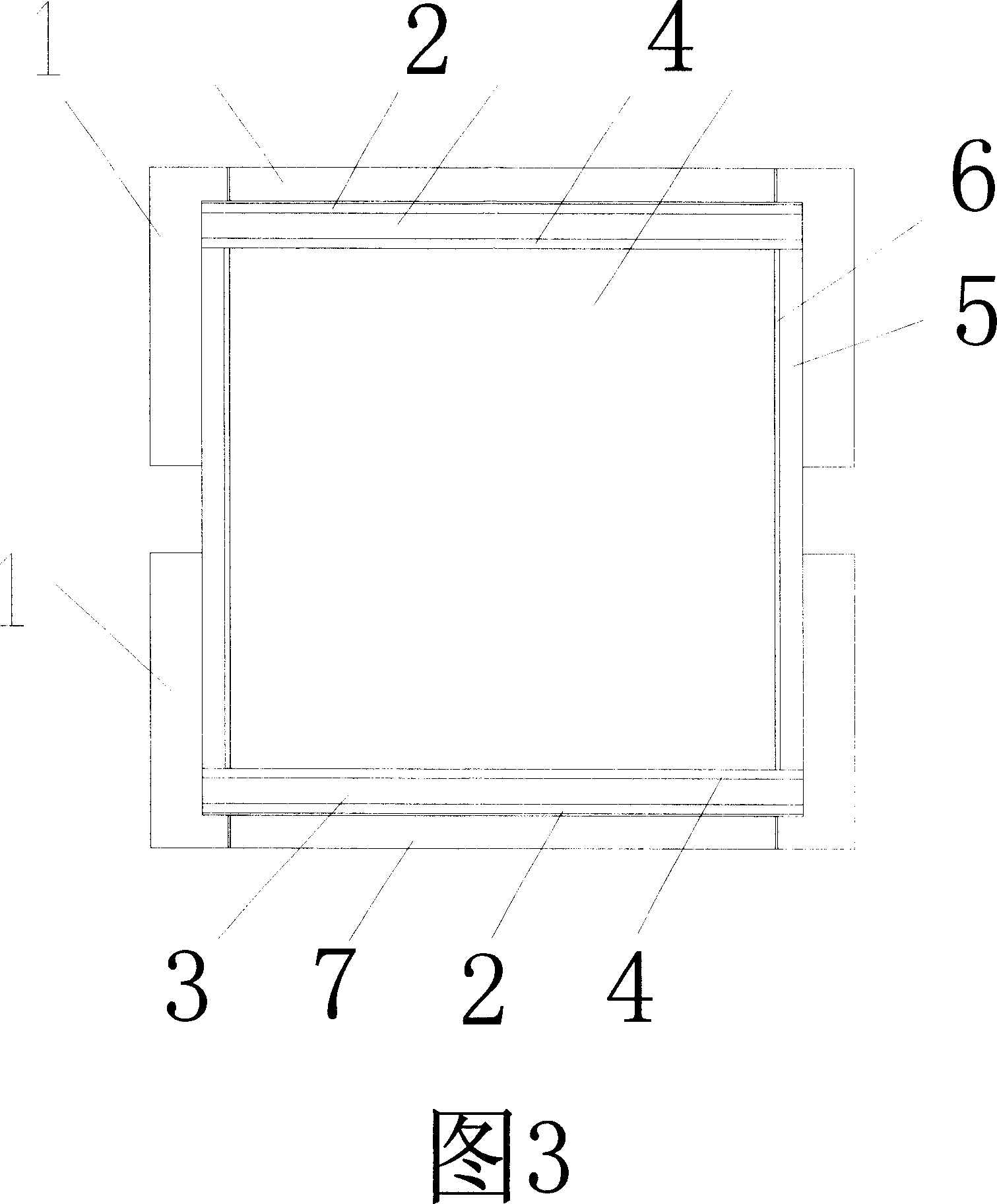

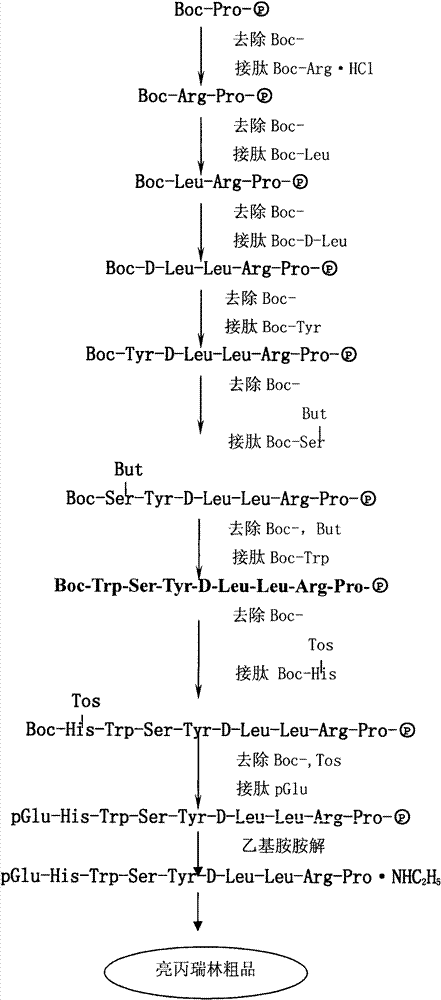

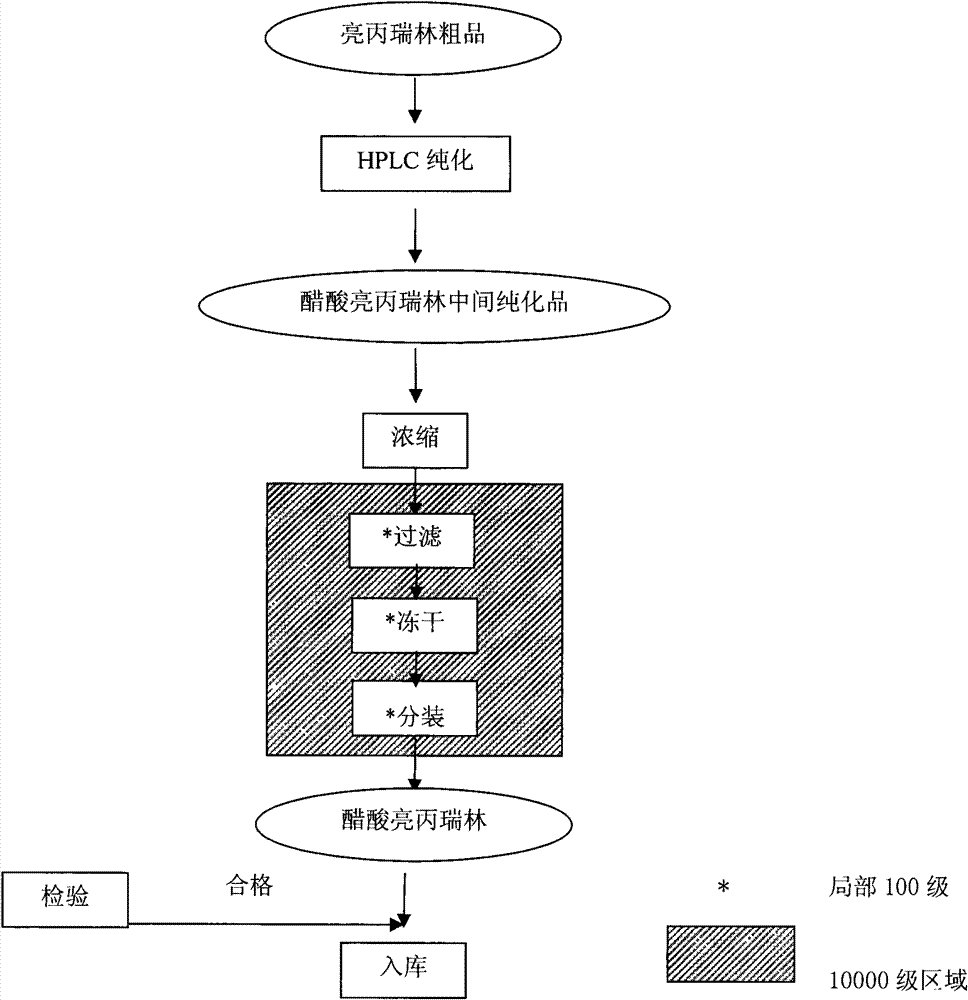

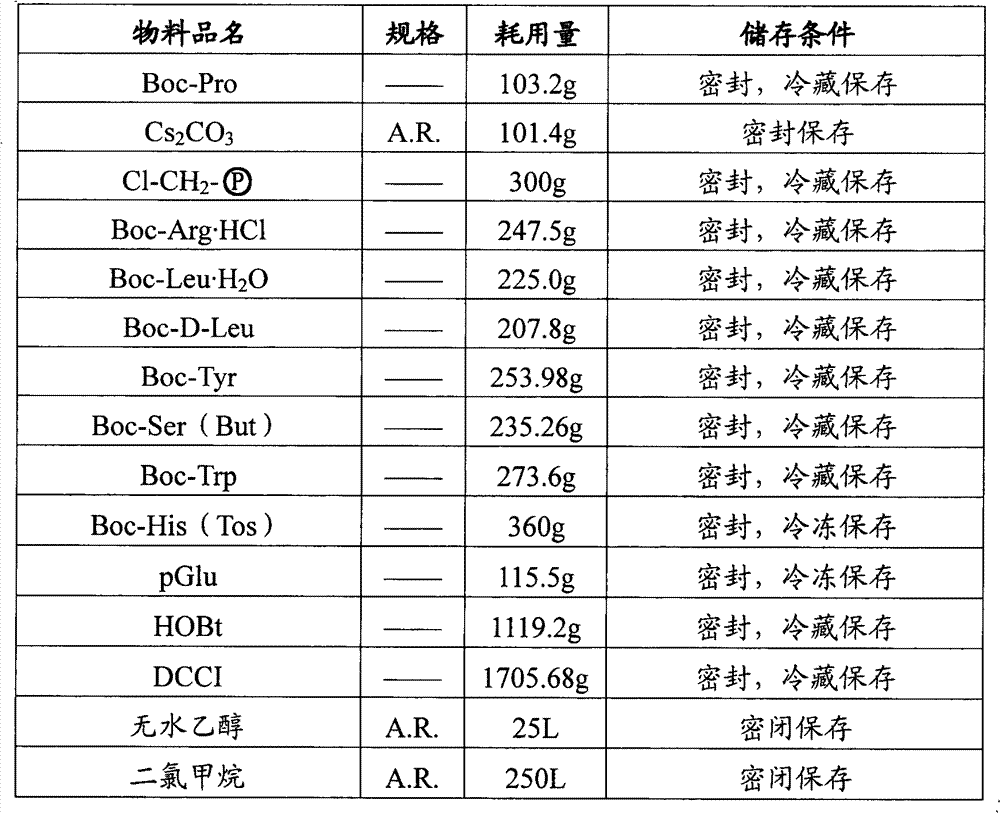

The invention provides a method for preparing leuprorelin acetate. The method comprises the following steps of: Boc-Pro-(p)preparation-solid phase peptide connection-aminolysis-HPLC (High Performance Liquid Chromatography) purification-concentration-filtering and drying, wherein in the solid-phase peptide connection step, obtaining a leuprorelin nonapeptide resin by preparing raw materials and connecting dipeptide, tripeptide, tetrapeptide, pentapeptide, hexapeptide, heptapeptide, octapeptide and nonapeptide. According to the preparation method provided by the invention, the leuprorelin acetate with higher purity and yield can be obtained, the preparation process has little pollution to environments and the safety of the product is high.

Owner:上海丽珠制药有限公司

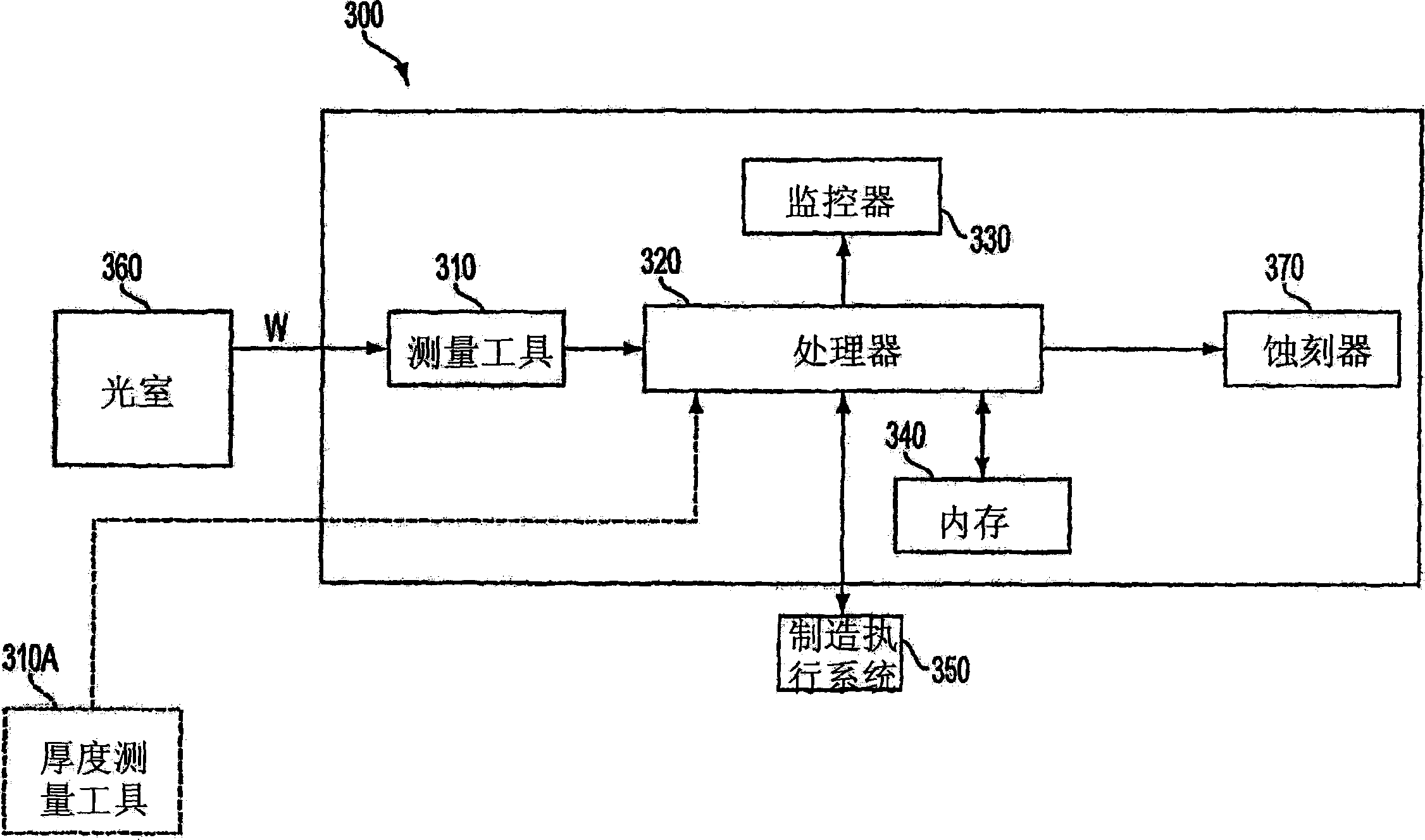

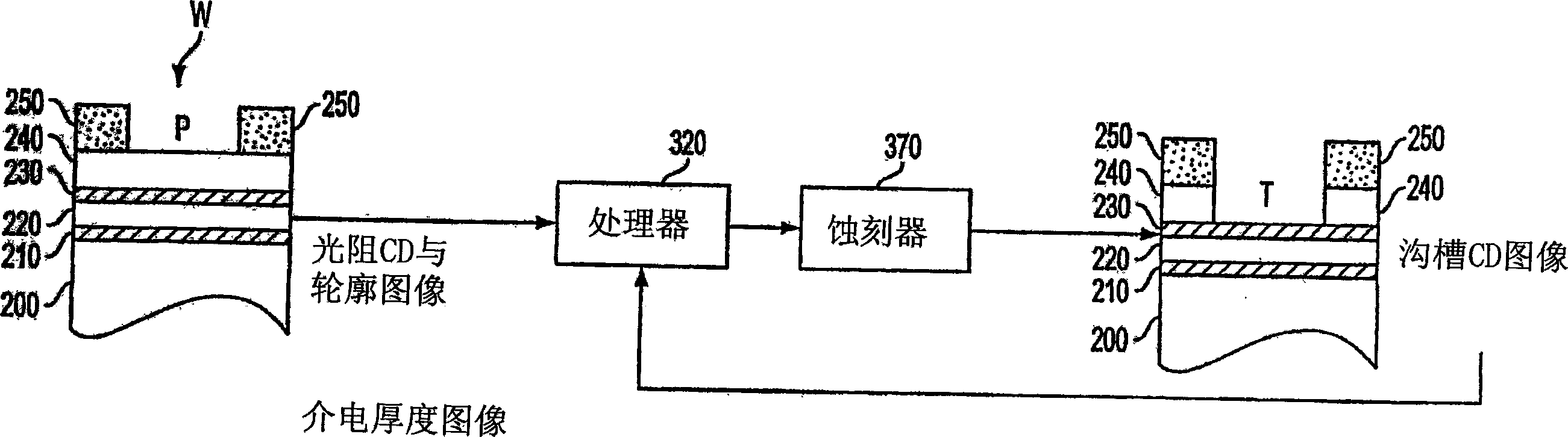

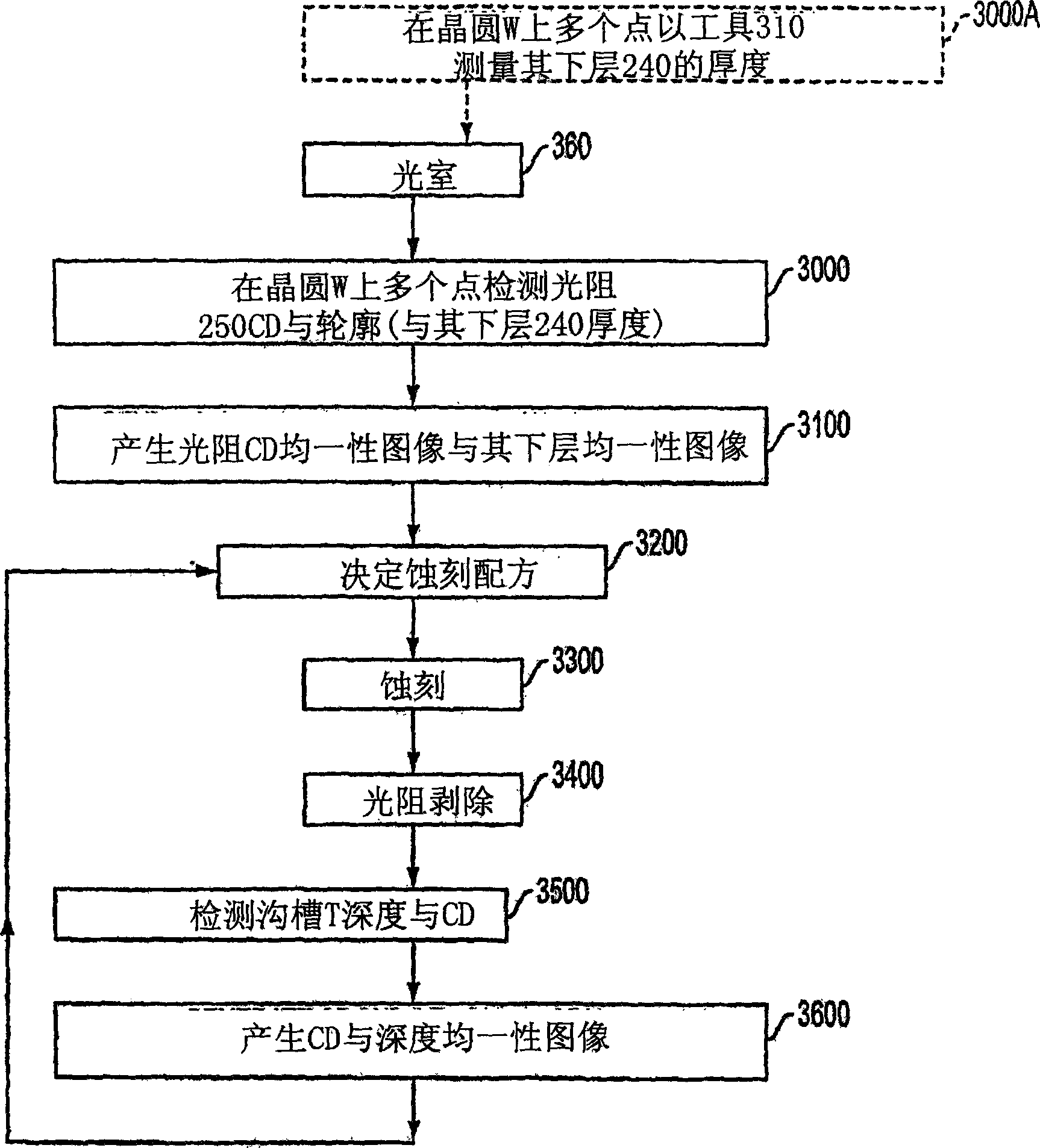

Method and apparatus employing integrated metrology for improved dielectric etch efficiency

InactiveCN1711632AReduced CD ChangesNo reduction in yieldSemiconductor/solid-state device testing/measurementSolid-state devicesMetrologyAtmospheric air

The present invention provides a method and equipment for processing semiconductor wafers to reduce dimensional changes. It measures the CD and profile of the photoresist mask and the thickness of the underlying layer at multiple points on the wafer and feeds back such information to adjust the following A process (eg, etch process) of the inspected wafer to be processed. After this processing step, the dimensions of the features formed by the process, such as the CD and depth of the trenches, are measured at multiple points on the wafer and this information is fed back to the processing tool to adjust the process for the next wafer , further reducing size variations. In some embodiments, CD, profiling, thickness and depth measurements, etch processing and post-etch cleaning are performed in a single module in a controlled environment. All transfer and processing steps implemented by this module are carried out in a clean environment, thereby avoiding exposure of the wafer to the atmosphere and avoiding possible contamination between steps to increase yield.

Owner:APPLIED MATERIALS INC

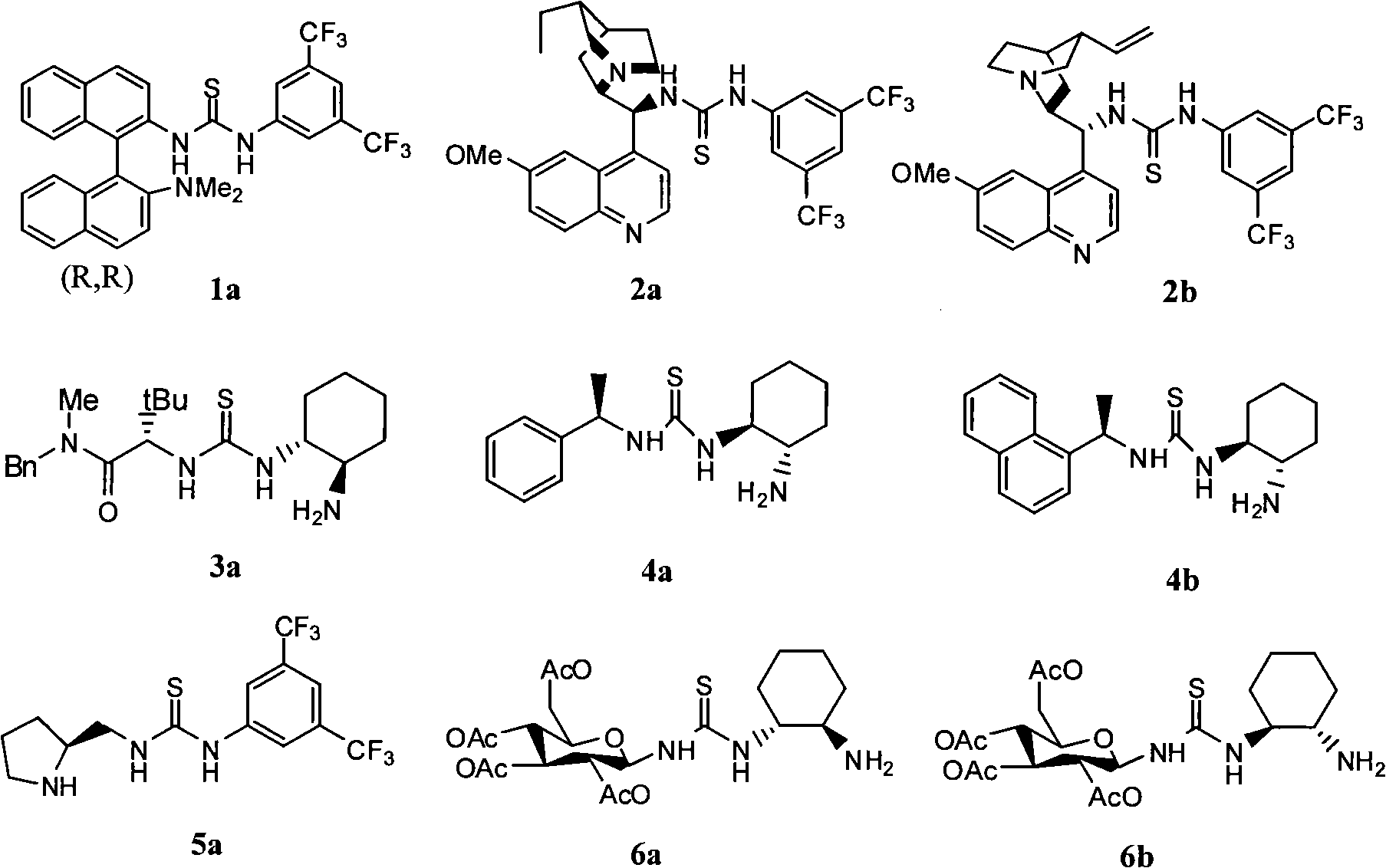

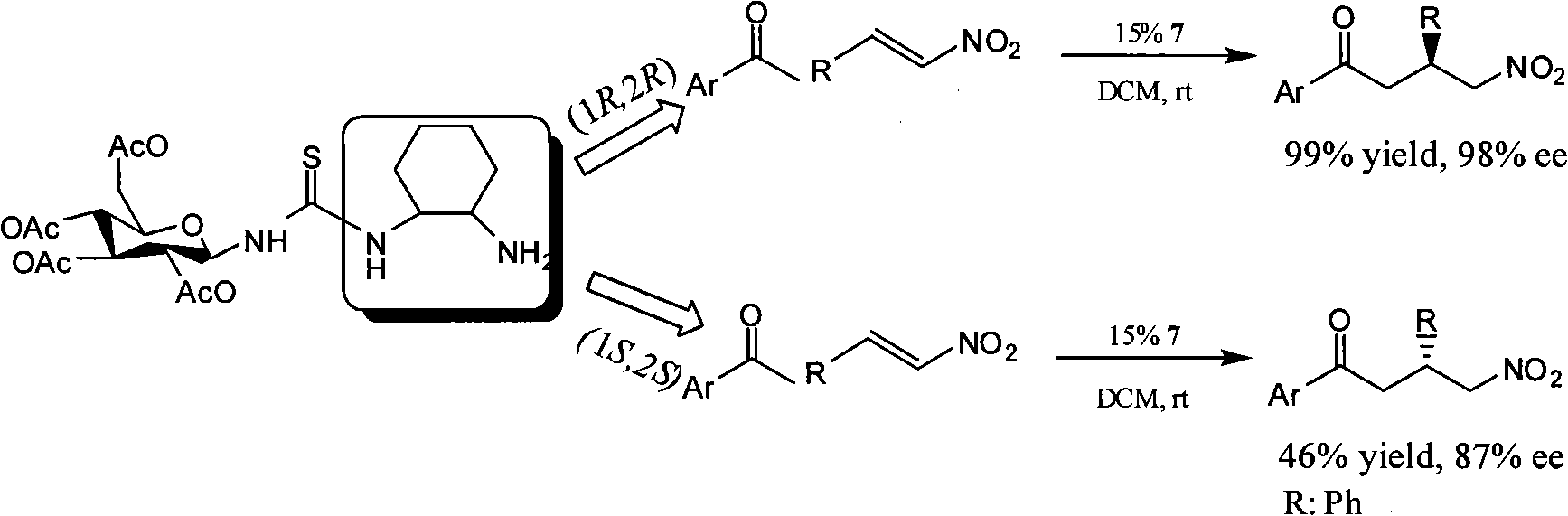

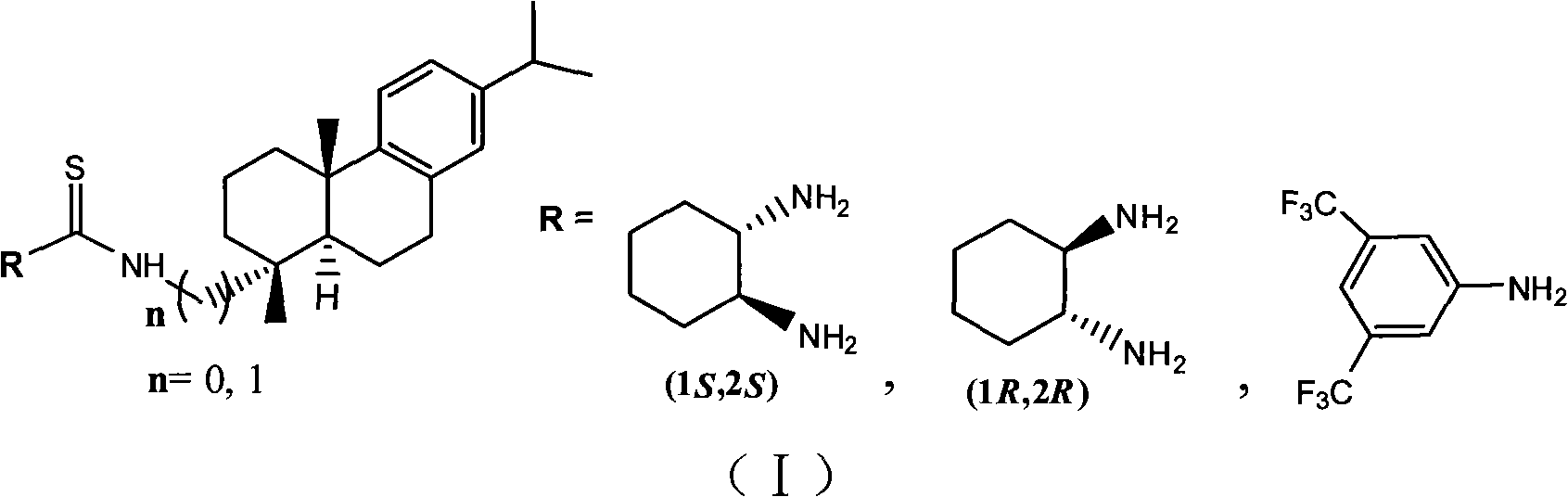

Application of dehydroabietylamine thiourea catalyst in synthesizing chiral compound with high-antipodism both-hand control

InactiveCN101318146AEasy to separateEasy recyclingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEnantiomerThiourea

The invention discloses an application of a dehydroabietylamine-chiral thiourea catalyst in both-hands synthesizing gamma-nitro-aromatic ketones and gamma-nitro-aromatic mixed ketones chiral compounds in a high enantiomer. The invention successfully utilizes the chiral source of the nature to synthesize a noveldehydroabietylamine-chiral thiourea catalyst with high catalytic activity. The catalyst has low price, is easy to decorate and prepare, is simple in treatment, can be separated or recycled from the products, can be reutilized and extends the limited range of known thiourea catalyst. The invention realizes that the same catalyst in the same reaction system can generate high optical pure target product with different configurations by high-efficiency and high-activity asymmetric catalysis. The method has simple operation, uses no metal reagent and has less environmental pollution. The reaction condition is mild and the reaction can be carried out in air rather than the strict anhydrous and oxygen-free conditions.

Owner:LANZHOU UNIVERSITY

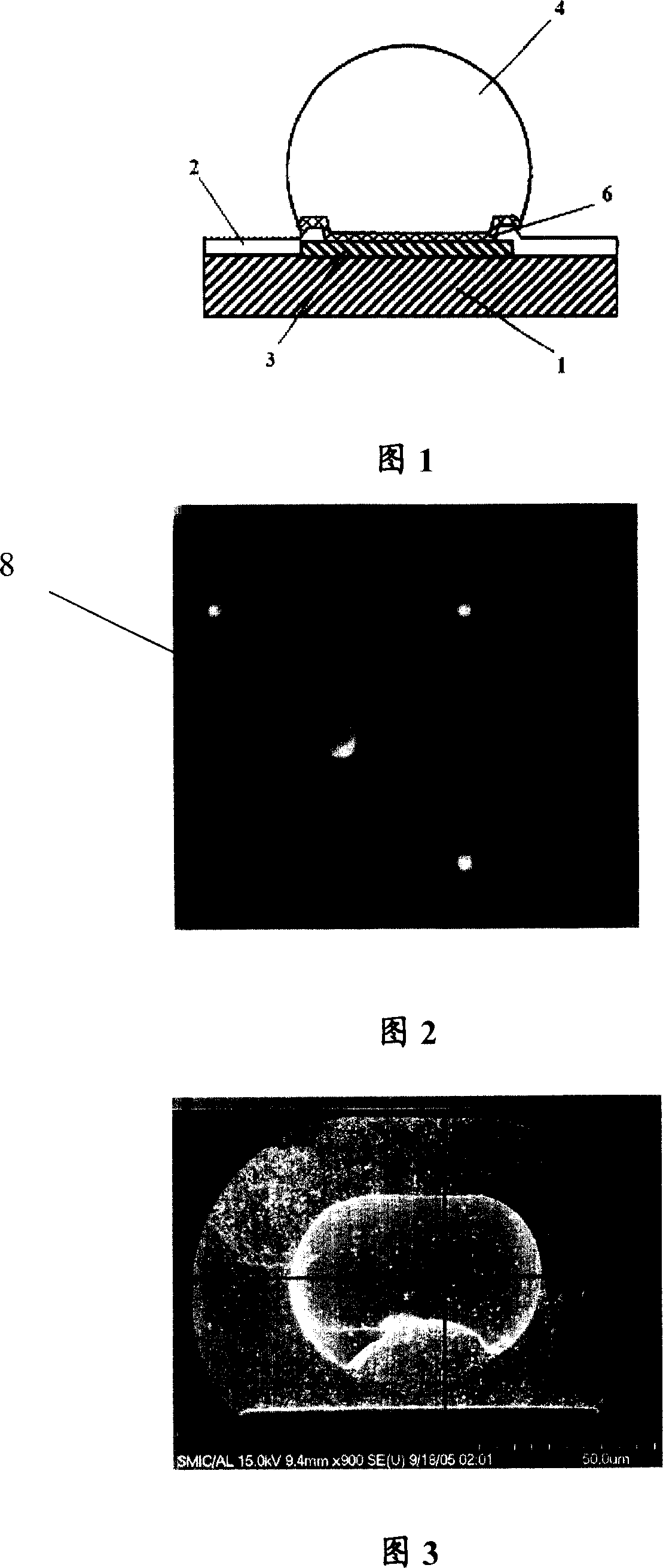

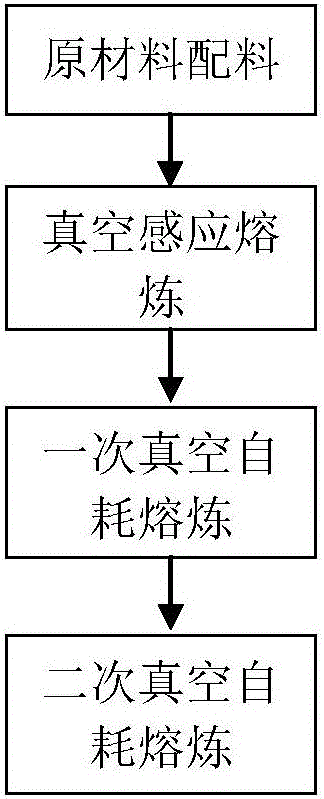

Method for making lead and tin alloy protruding point

InactiveCN101123196AImprove welding effectAvoid the phenomenon of air bubblesSolid-state devicesSemiconductor/solid-state device manufacturingAlloyPhotoresist

The present invention provides a pewter bump manufacturing method comprising the following steps: to deposit an under bump metal layer on wafer; to form a photoresist layer on the under bump metal layer, and to form a photoresist opening by exposure and develop; to form a transitional pewter layer on the under bump metal layer located at the photoresist opening; to electroplate a wiping solder on the transitional pewter layer; to remove the photoresist and the under bump metal layer; to backflow the wiping solder to form pewter bump. The process of forming the transitional pewter layer is of an electroplating process, the electric current density is 0.1A / dm2 to 1A / dm2, and the time is 1-5 minutes. The density of the formed transitional pewter layer is 0.2um to 4um. The method of the present invention avoids bubble formation in pewter bump solder in electroplating process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

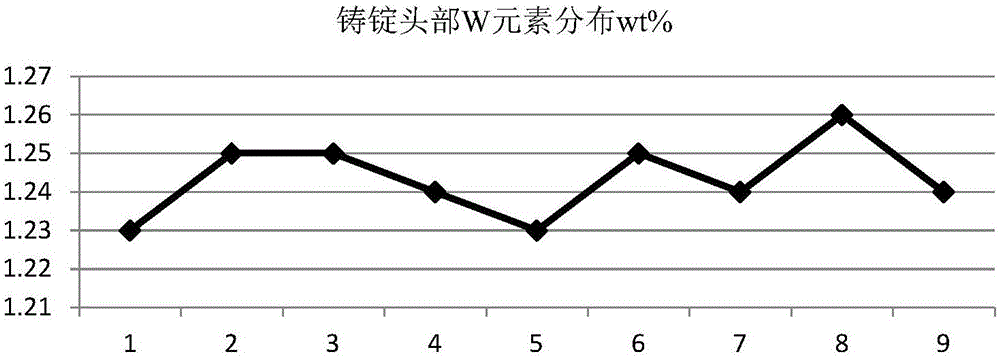

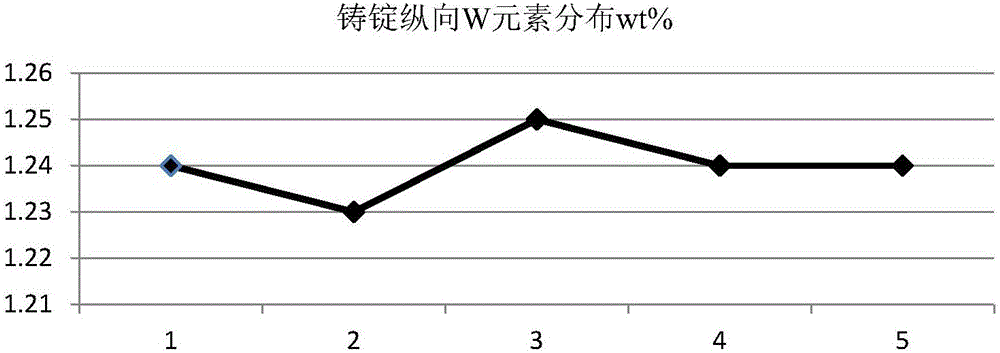

Method for improving component uniformity of W elements in GH4720Li alloy

The invention discloses a method for improving the component uniformity of W elements in GH4720Li alloy. Pure metallic W is replaced with nickel-tungsten intermediate alloy, a smelting mode with vacuum induction smelting and two times of vacuum consumable smelting is adopted, and low-smelting-speed controlled smelting is adopted for the second time of vacuum consumable smelting. On the premise that the yield of cast ingots is not decreased, the W elements in the cast ingots are distributed more uniformly. The problem of component difference in all positions of the cast ingots due to nonuniform distribution of the W elements, and accordingly the forging process of the alloy is influenced is solved, and the method has important functions on improving the component uniformity of the W elements and the performance uniformity of forge pieces.

Owner:西部超导材料科技股份有限公司

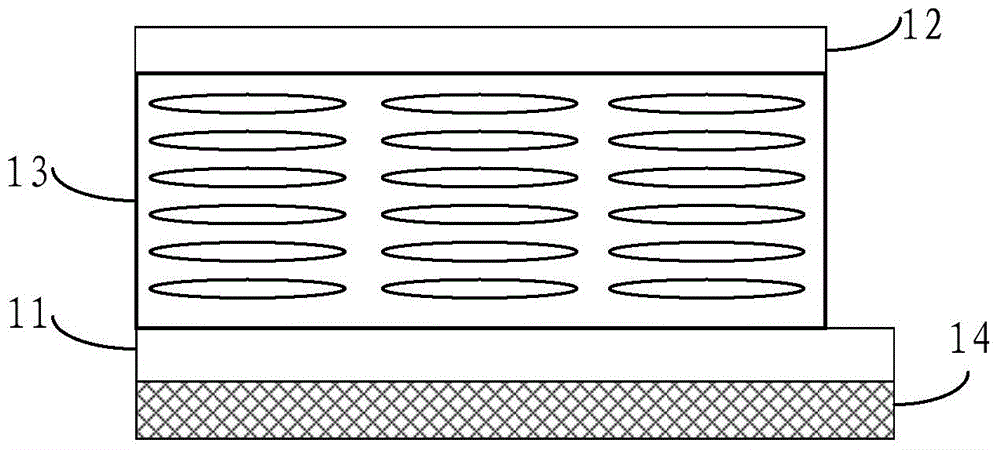

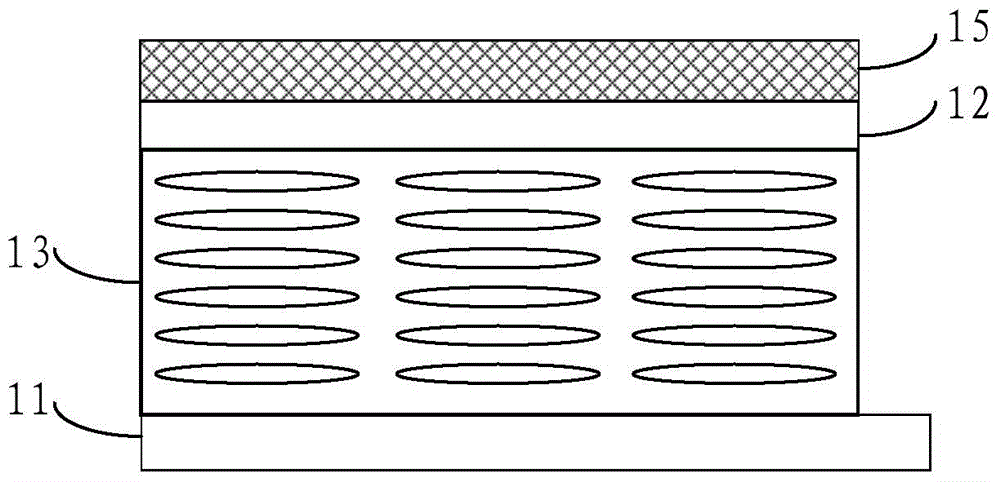

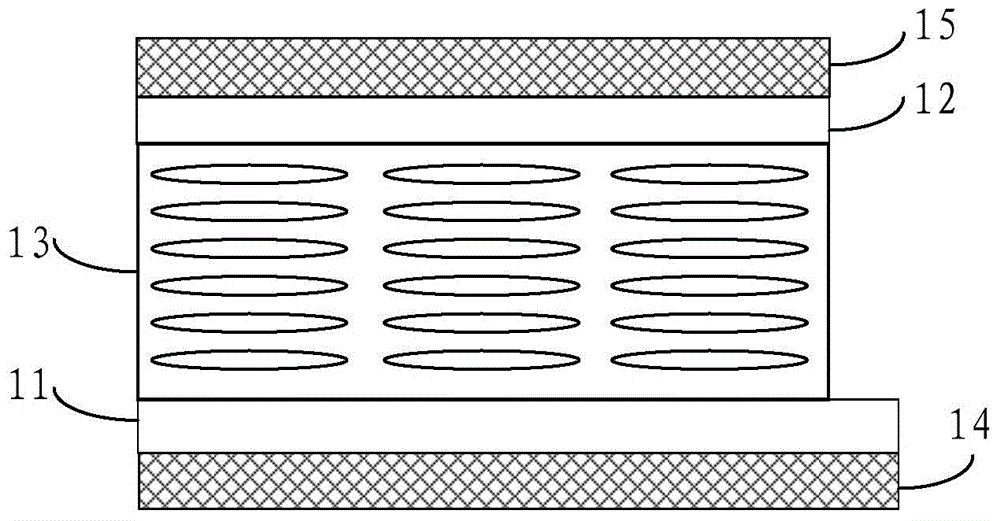

Curved surface display panel, manufacturing method and display device

ActiveCN105044987ALower yieldDoes not aggravate light leakageNon-linear opticsSurface displayLiquid-crystal display

The embodiment of the invention provides a curved surface display panel, a manufacturing method and a display device, and relates to the technical field of displays. The problem that a substrate is prone to being broken is solved while the curved surface display panel is used for reducing or avoiding light leakage of a curved surface display, and therefore the defect rate in the production technology can be reduced. The curved surface display panel comprises an array substrate, a cassette aligning substrate, a liquid crystal layer located between the array substrate and the cassette aligning substrate and a first 0-0 double refraction layer located at the side, far away from the liquid crystal layer, of the array substrate and / or a second 0-0 double refraction layer located at the side, far away from the liquid crystal layer, of the cassette aligning substrate. The curved surface display panel is used for manufacturing the displays.

Owner:BOE TECH GRP CO LTD

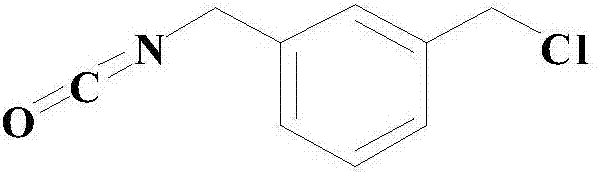

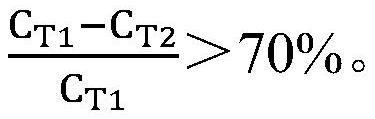

Method for reducing content of chlorinated derivative in isocyanate

ActiveCN107382777ALow yieldLow impurity contentIsocyanic acid derivatives purification/separationPreparation by isocyanic acid-halide reactionChloral derivativeCyanate compound

The invention belongs to the technical field of isocyanate and especially relates to a method for reducing content of chlorinated derivative in isocyanate and increasing the quality of isocyanate. The method disclosed according to the invention reduces the content of chlorinated derivative in isocyanate in the manner of enabling cyanate or thiocyanate to react with crude or fine product of isocyanate and then simply performing post-processing. The method can be used for removing more than 90% of chlorinated derivative from isocyanate and realizing the impurity content of the chlorinated derivative below 0.1%, is simple in operation and is easy for industrial application. Besides, the isocyanate treated according to the method is capable of improving the anti-ageing property of a downstream macromolecule product thereof due to the reduced content of the chlorinated derivative.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

MFI structure molecular sieve containing phosphorus and transition metal as well as its preparation method

The invention relates to a MFI structure molecular sieve containing phosphorus and transition metal as well as its preparation method. The anhydrous chemical expression of the molecular sieve is (0-0.3) Na2O.(0.5-6) Al2O3.(1.3-10) P2O5.(0.7-15) MxOy.(70-97) SiO2, wherein M is selected from one or more of Fe, Co, Ni, Cu, Mn, Zn, Sn and Bi, x is expressed as atomicity of M, y is expressed as a number which satisfies the requirement of an oxidation state of M; No characteristic absorption peak is existed at 1633cm<-1> on infrared spectrum by molecular sieve trimethylpyridine adsorption. The preparation method comprises that phosphor and transition metal are introduced in molecular sieve with the MFI structure during ammonium exchanging, wherein the phosphor introduction is divided into two parts, a part of phosphor is introduced before introducing the transition metal or at the same time with transition metal introduction, the other part of the phosphor is introduced after the transitionmetal introduction. The provided molecular sieve is used for conversing hydrocarbon oil, the yield of dry gas and coke is low, and the yield of propylene and isobutene is high.

Owner:CHINA PETROLEUM & CHEM CORP

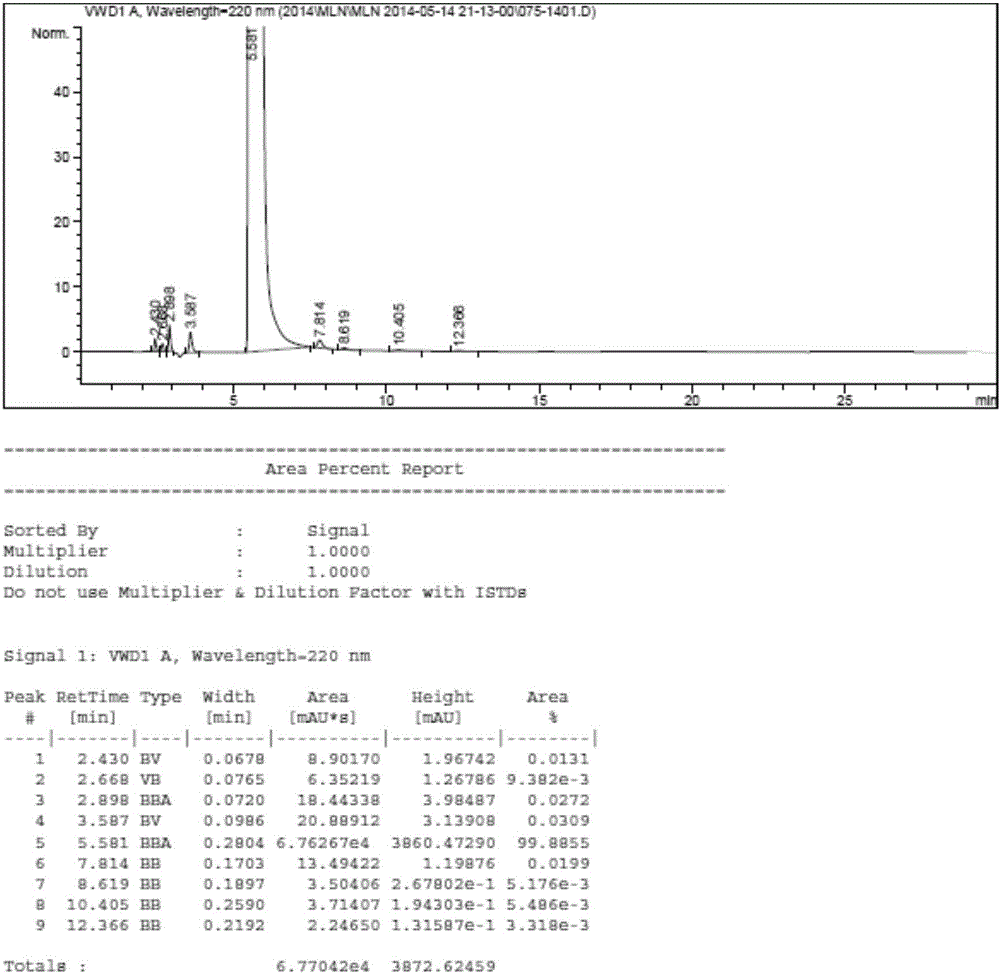

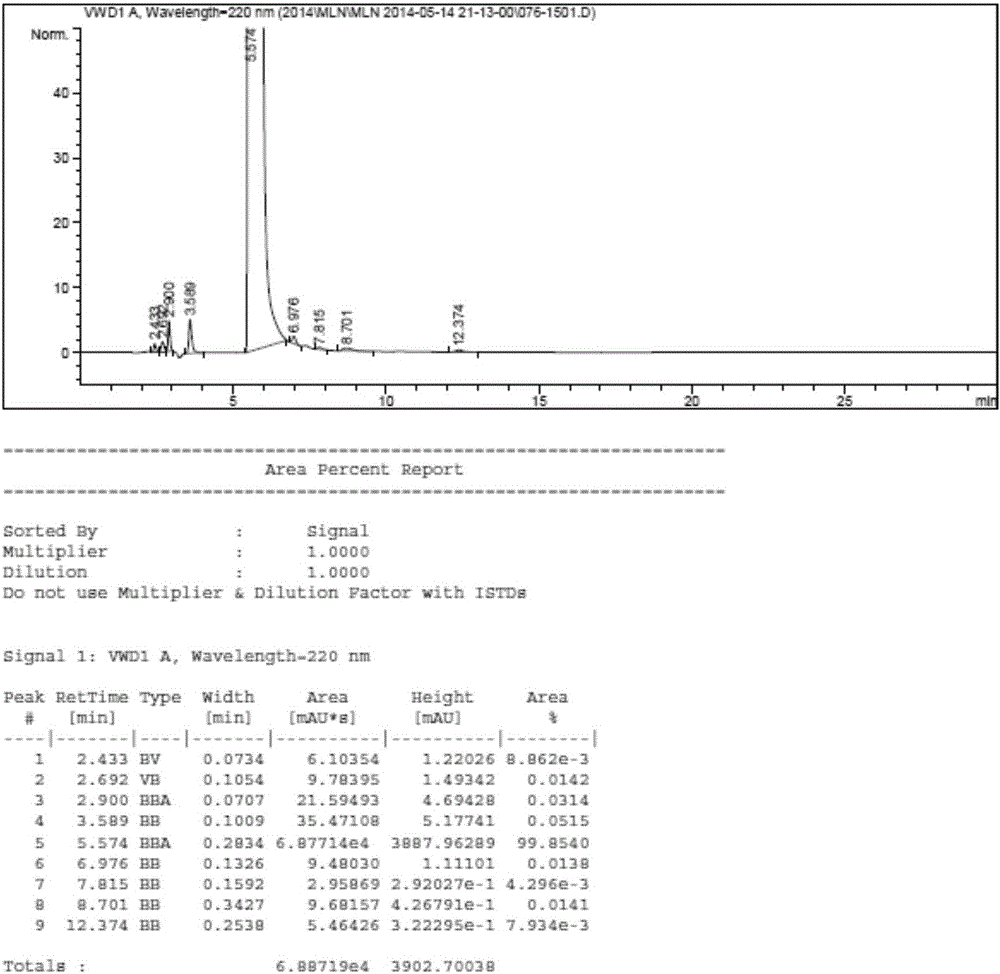

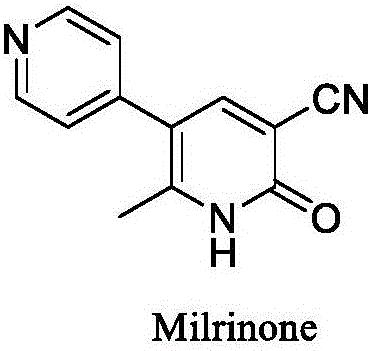

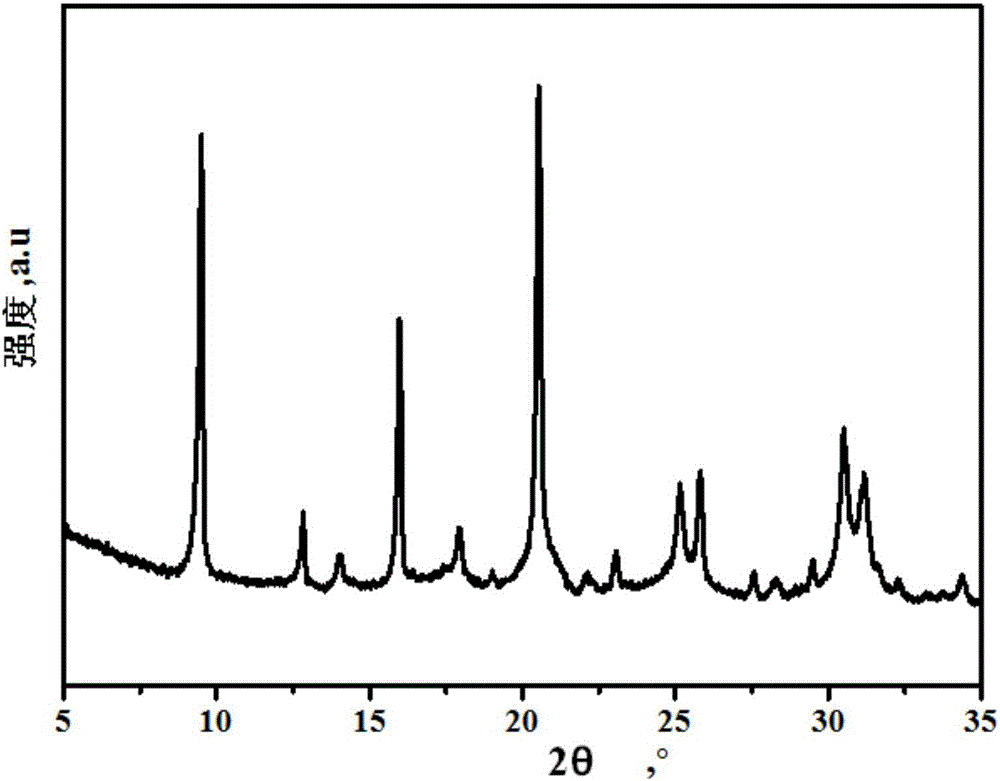

Method for preparing milrinone

The invention provides a method for preparing milrinone, wherein the method comprises the following steps: with 4-methyl pyridine (SM) as a raw material, in ethyl acetate, generating 1-(4-pyridyl)-2-acetone (represented by the formula I); then under action of triethyl orthoformate, acetic acid and acetic anhydride, generating 1-ethoxy-2-(4-pyridyl)vinyl methyl ketone (represented by the formula II); and finally, under an alkaline condition, carrying out a reaction of 1-ethoxy-2-(4-pyridyl)vinyl methyl ketone with cyanoacetamide to generate milrinone. The method has the advantages of simple and efficient operation, mild reaction conditions, strong safety, easy control and relatively high yield, and is suitable for industrialized production.

Owner:JIANGSU HAICI BIOLOGICAL PHARMA CO LTD OF YANGTZE RIVER PHARMA GRP

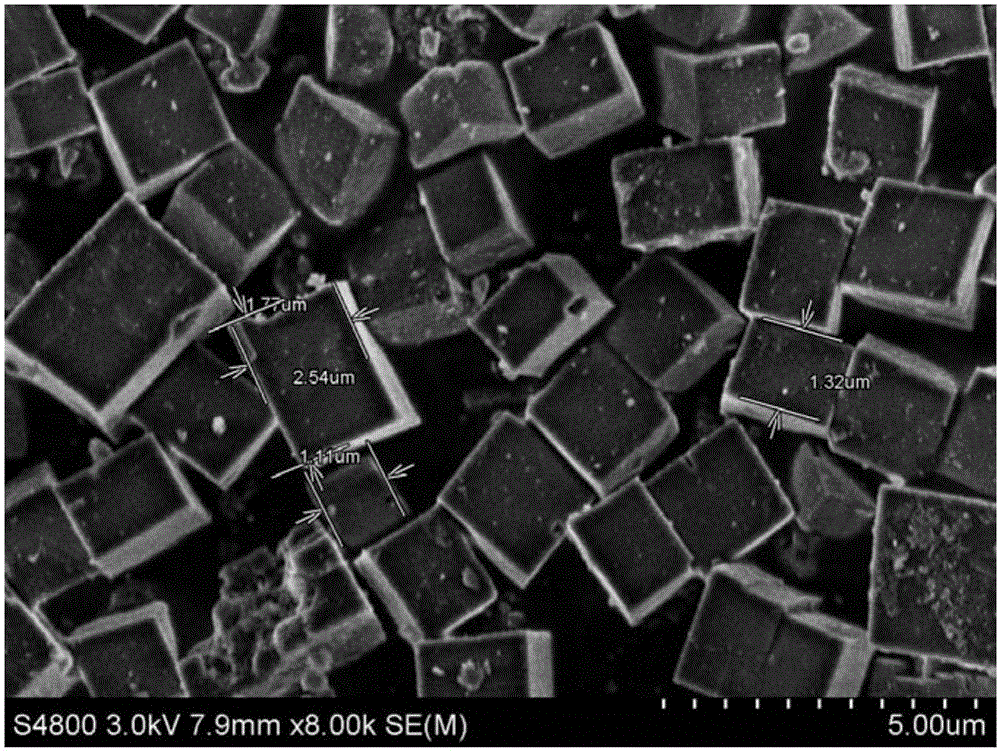

Low-silicon SAPO-34 molecular sieve as well as preparation method and application thereof

InactiveCN106513036AObvious advantagesMeet crystallinityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCrystallinity

The invention provides a low-silicon SAPO-34 molecular sieve as well as a preparation method and an application thereof. The preparation method of the low-silicon SAPO-34 molecular sieve comprises steps as follows: (1), guiding lyogel is prepared from a silicon source, an aluminum source, a phosphorus source, a seed crystal, a template agent and water through stirring and mixing at the temperature of 0-20 DEG C, and a seed crystal guiding liquid is prepared after the guiding lyogel is subjected to hydrothermal crystallization; (2), initial gel of the SAPO-34 molecular sieve is prepared from the silicon source, the aluminum source, the phosphorus source, the seed crystal guiding liquid, the template agent and water through stirring and mixing at the temperature of 0-20 DEG C; the initial gel of the SAPO-34 molecular sieve is subjected to low-temperature hydrothermal crystallization and high-temperature hydrothermal crystallization sequentially and then is subjected to aftertreatment, and the low-silicon SAPO-34 molecular sieve is prepared. According to the method, an inexpensive template agent can be used less or even cannot be used, and a product meeting requirements for crystallinity and purity is obtained without prolonging of crystallization time, and the preparation method of the low-silicon SAPO-34 molecular sieve is suitable for large-scale industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

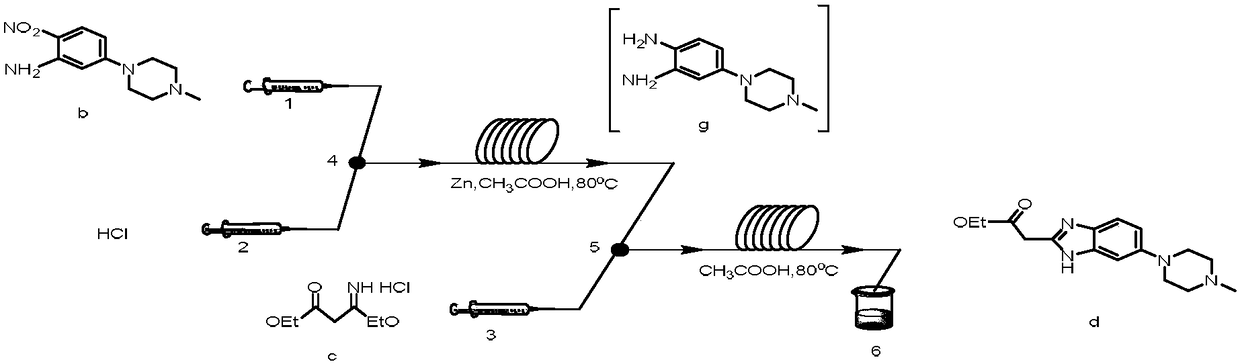

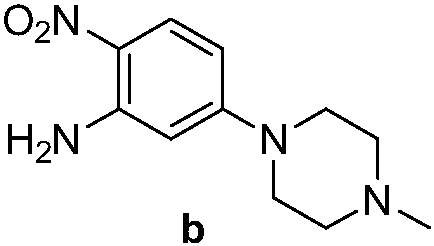

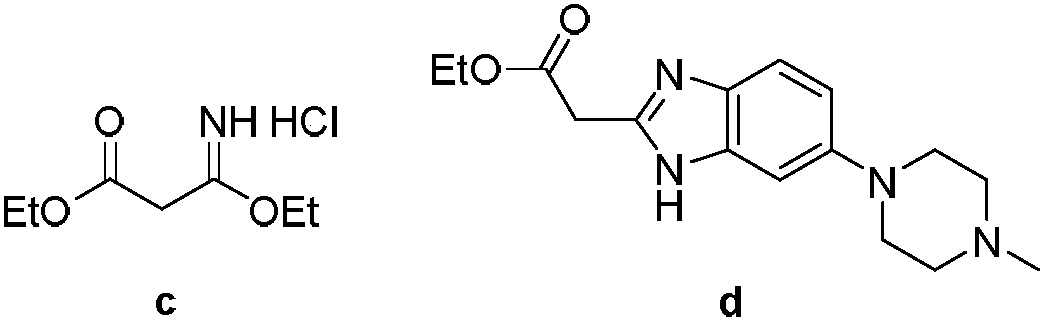

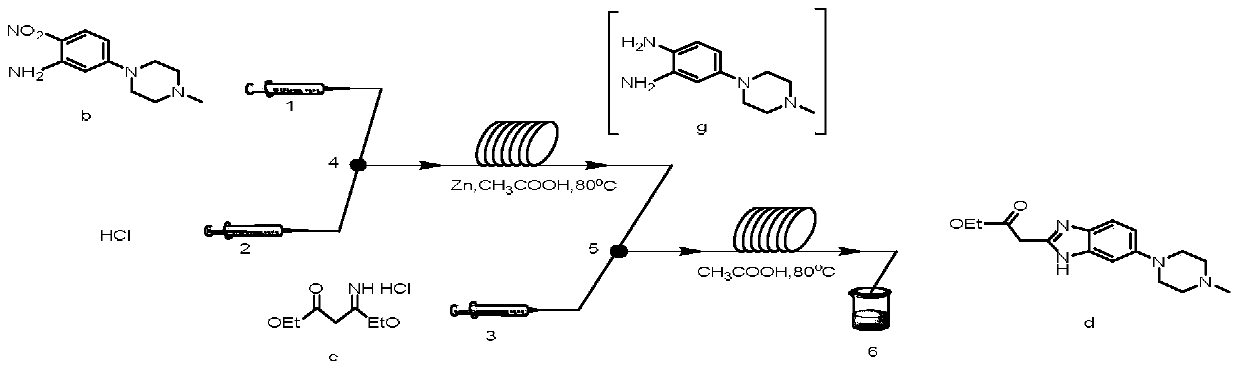

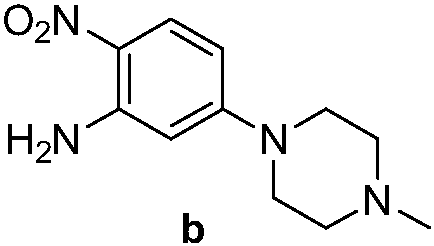

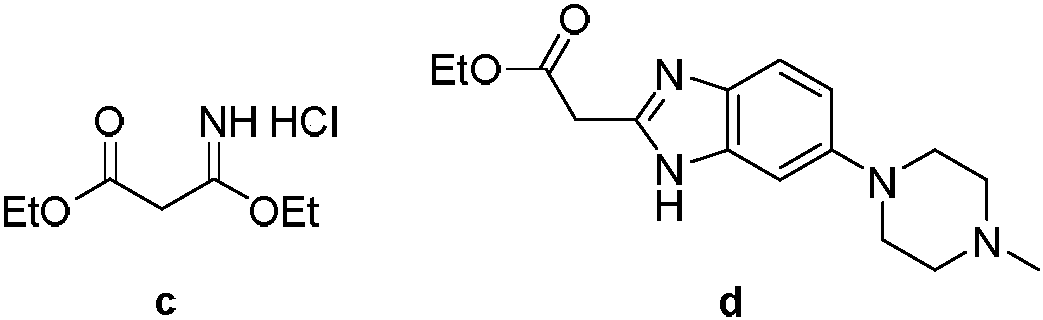

Method for preparing dovitinib intermediate with microchannel reaction device

The invention discloses a method for preparing a dovitinib intermediate with a microchannel reaction device. The method comprises the following steps: (1) dissolving hydrochloric acid in ethanol to form a mixed solution, and enabling the mixed solution and an ethanol solution of 5-(4-methylpiperazin-1-yl)-2-nitroaniline to flow into a first microstructural reactor in the microchannel reaction device filled with zinc powder simultaneously and respectively for a reaction to obtain a reaction effluent; (2) enabling the reaction effluent in step (1) and an ethanol solution of ethyl-beta-imino-beta-ethoxypropionate to flow into a second microstructural reactor in the microchannel reaction device simultaneously and respectively for a reaction to obtain ethyl-2-(6-(4- methylpiperazin-1-yl) benzimidazol-2-yl) ethyl acetate, namely, the dovitinib intermediate. The method has the advantages that few side reactions are produced, yield is high, technological steps are simplified, production cost is low, and the industrial standard of profit maximization is met better.

Owner:NANJING UNIV OF TECH

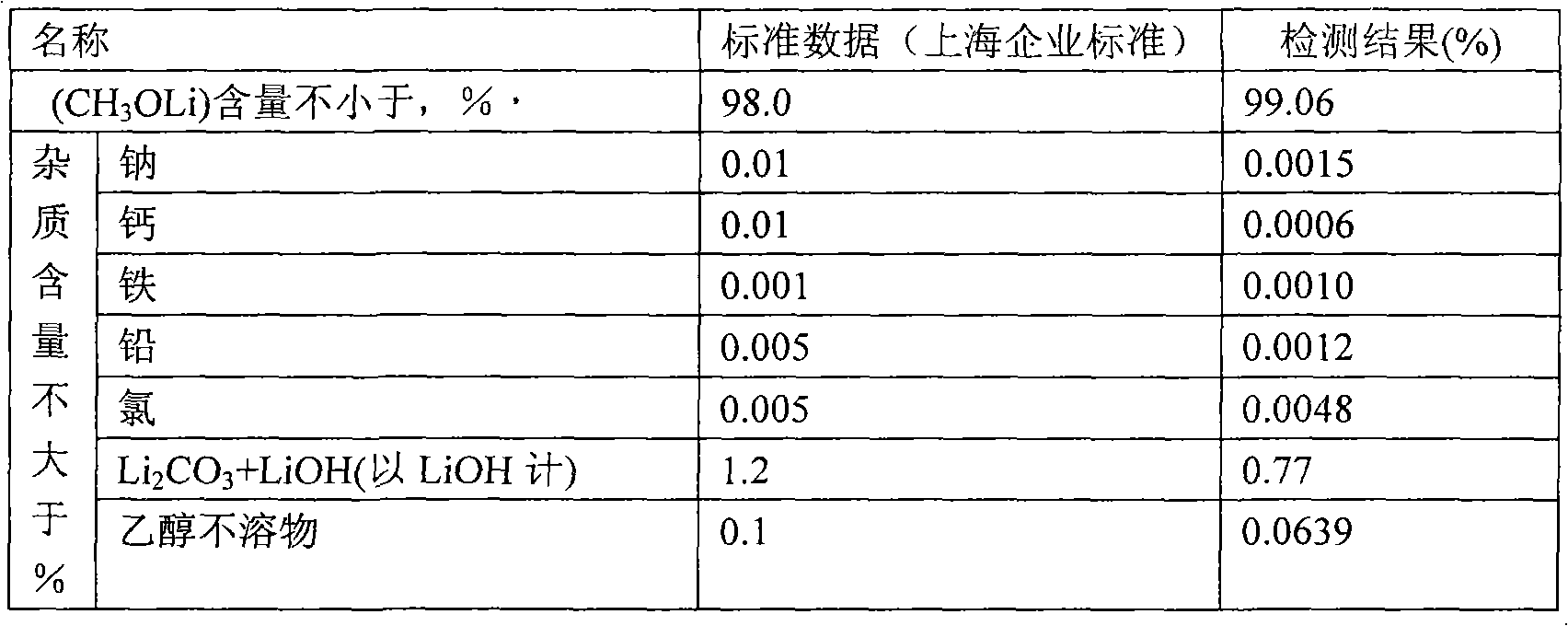

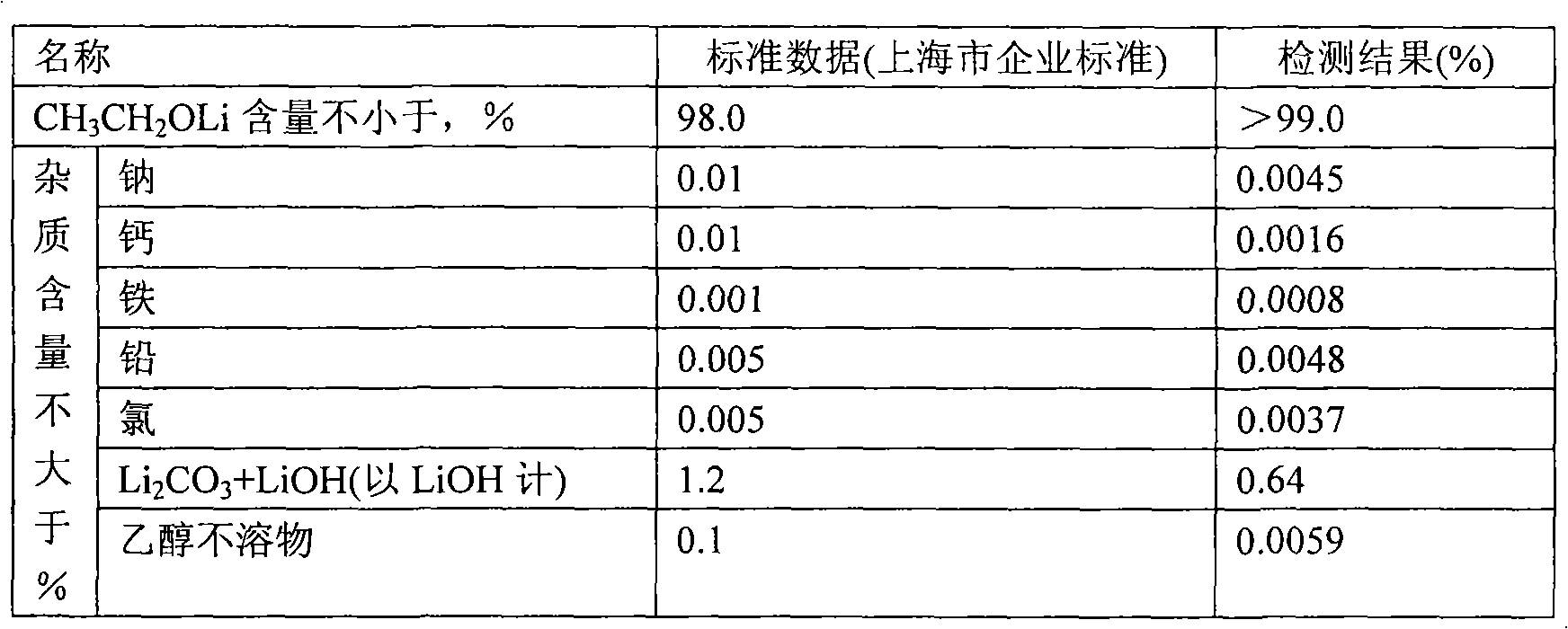

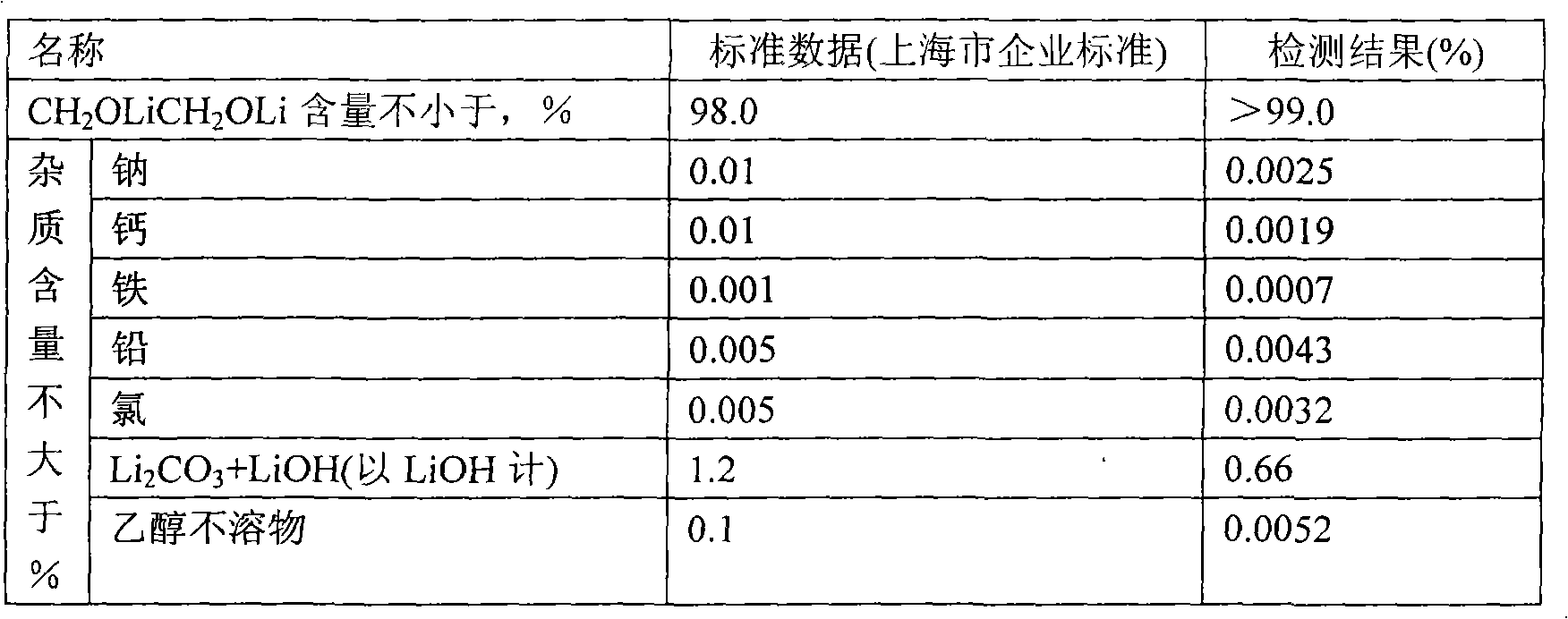

Method for preparing lithium alkoxide

InactiveCN102030611AGuaranteed purityNo reduction in yieldPreparation of metal alcoholatesDisplacement reactionsOrganic solvent

The invention discloses a method for preparing lithium alkoxide, which comprises the following steps of: dissolving lithium tert-butoxide or lithium isopropoxide in an organic solvent, adding methanol, ethanol or ethylene glycol for reacting, collecting a solid matter in a reaction product, and drying to obtain the lithium alkoxide. In the method, the lithium tert-butoxide or lithium isopropoxide with strong alkalinity is taken as a raw material, so that metallic lithium is prevented from being subjected to side reaction with water, oxygen and nitrogen in air and causing low quality of a product, and the purity of the product is ensured while the yield is not reduced; and the lithium tert-butoxide or lithium isopropoxide is dissolved in tetrahydrofuran, the methanol (ethanol or ethylene glycol and the like) is added at normal temperature, and displacement reaction is completely performed with full stirring, so that reaction at normal temperature and normal pressure is performed, and potential safety hazard is reduced.

Owner:SHANGHAI CHINA LITHIUM INDAL

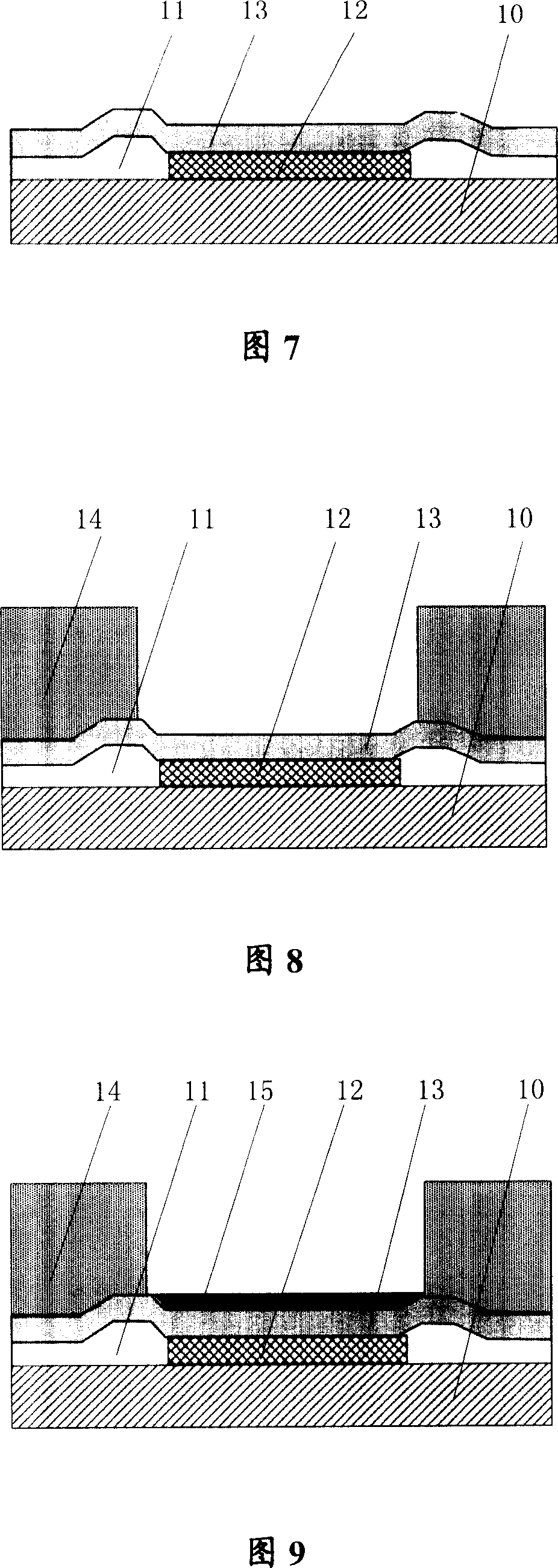

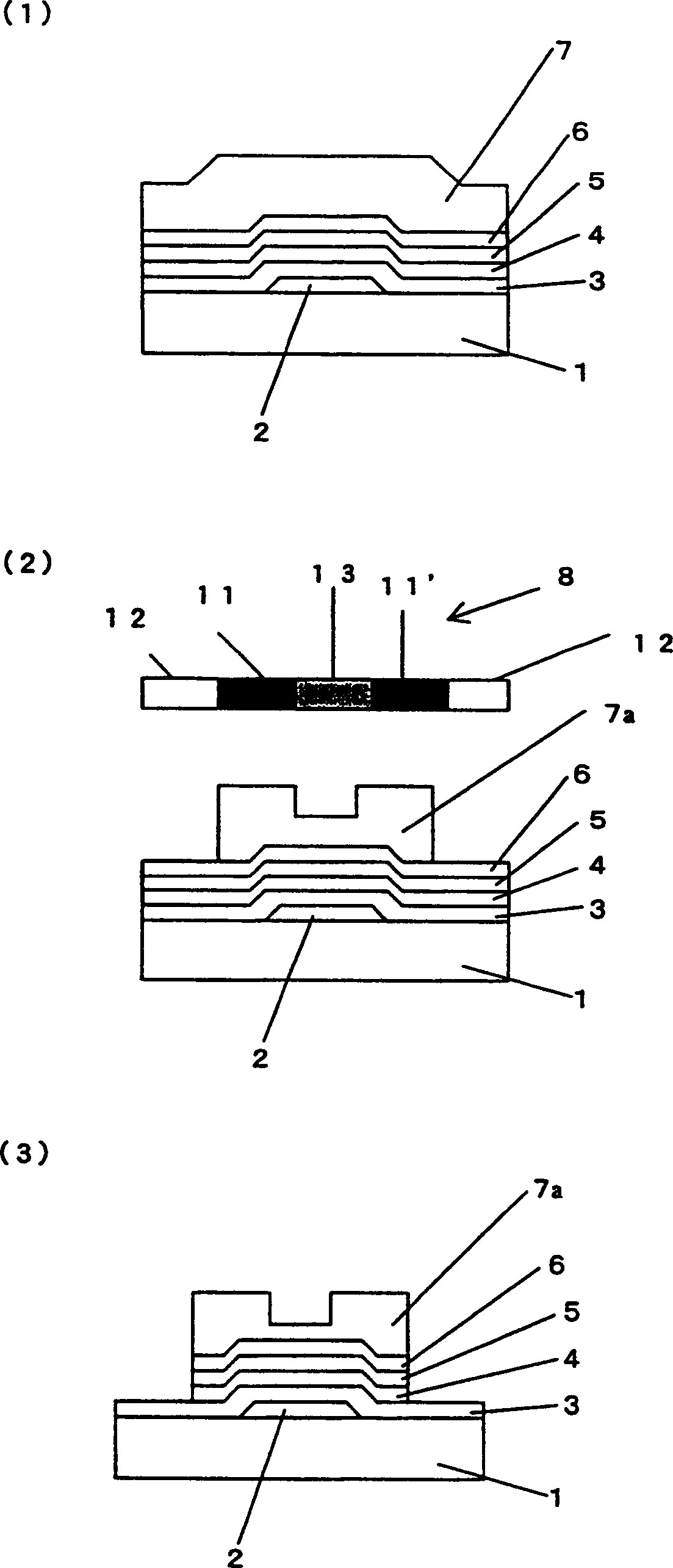

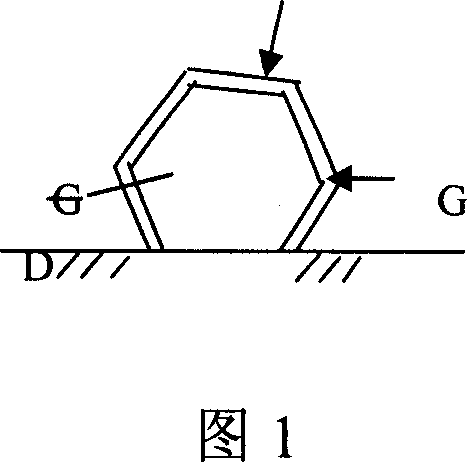

Defect examining method of gray mask and mfg. method thereof

InactiveCN1534365ANo reduction in yieldTransistorSemiconductor/solid-state device manufacturingComputer scienceTransistor

PURPOSE: A method for testing defects of a gray tone mask and a method for fabricating a gray tone mask are provided to prevent the generation of defects of a TFT substrate such as the short between a source and a drain, without decreasing the yield of the gray tone mask production. CONSTITUTION: A method for testing defects of a gray tone mask includes a step of extracting a reject of a mask having black and / or white defect of defect level beyond a predetermined allowance range. In the allowance range, a defect threshold value of the white defect is larger than that of the black defect. A gray tone part(13) is an area formed with a shield pattern(13a) below an exposure threshold value of light when using the gray tone mask. The gray tone part is a pattern corresponding to a channel part of a TFT substrate.

Owner:HOYA CORP

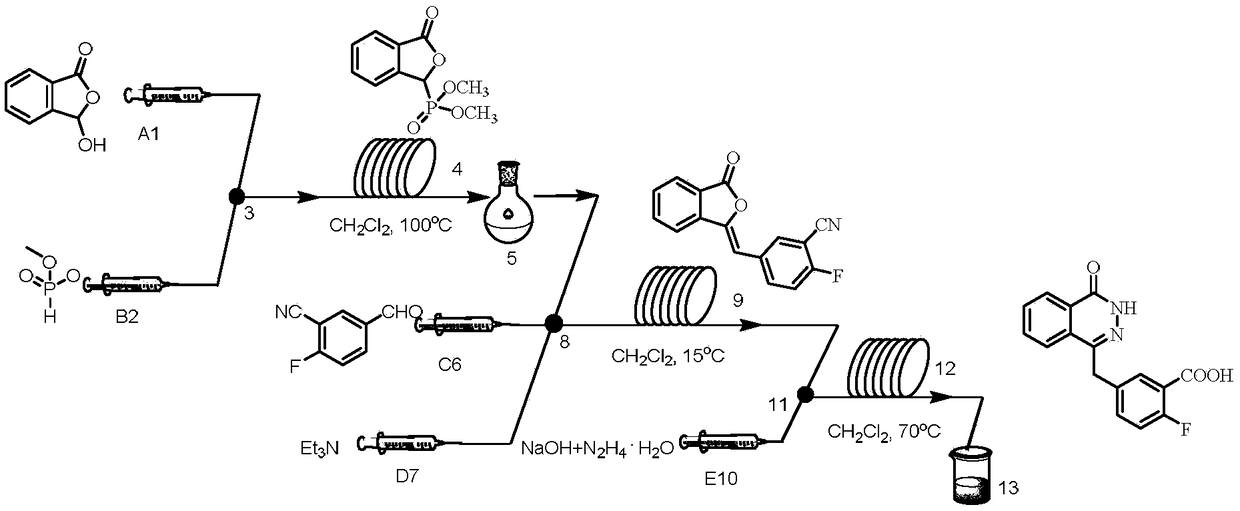

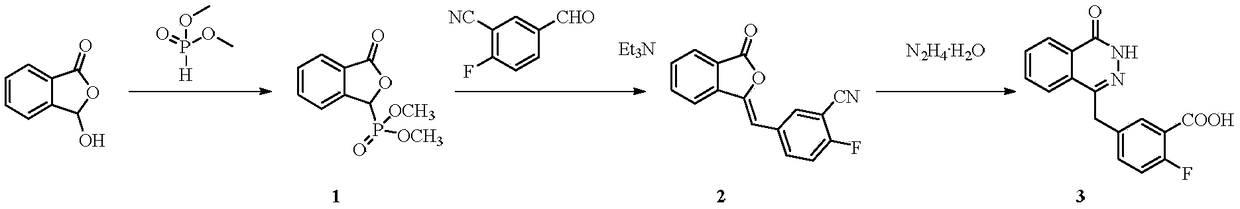

Method for continuously preparing Olaparib intermediate by microchannel modular reaction device

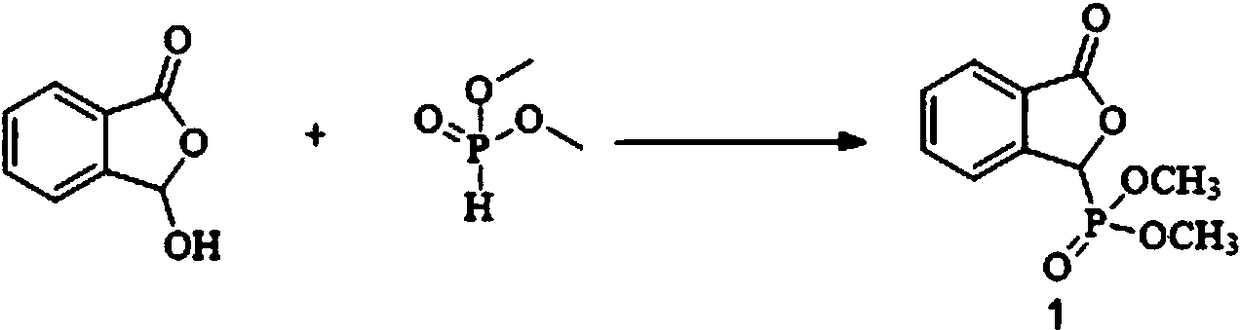

The invention discloses a method for continuously preparing an olaparib intermediate by a microchannel modular reaction device. The method comprises the following steps: performing reaction on a dichloromethane solution of 3-hydroxyisobenzofuran-1(3H)-ketone and a dichloromethane solution of dimethyl phosphate in a first microreactor, and performing liquid separation to obtain effluent of (3-oxo-1,3-dihydroisobenzyfuran-1-yl)dimethyl phosphate; performing reaction on the effluent, a dichloromethane solution of 2-fluorine-5-formyl benzene nitrile and a dichloromethane solution of triethylaminein a second microreactor to generate reaction liquid of 2-fluorine-5-(3-oxo-3H-isobenzofuran-1-yl methylene)benzyl cyanide; and performing reaction on the reaction liquid and a homogenous mixed solution which is obtained by stirring an ethanol solution of sodium hydroxide and hydrazine hydrate in a third microreactor and treating the effluent to obtain the olaparib intermediate 2-fluorine-5-[(4-oxo-3,4-dihydrodiazene-1-yl-)methyl]benzoic acid.

Owner:NANJING UNIV OF TECH

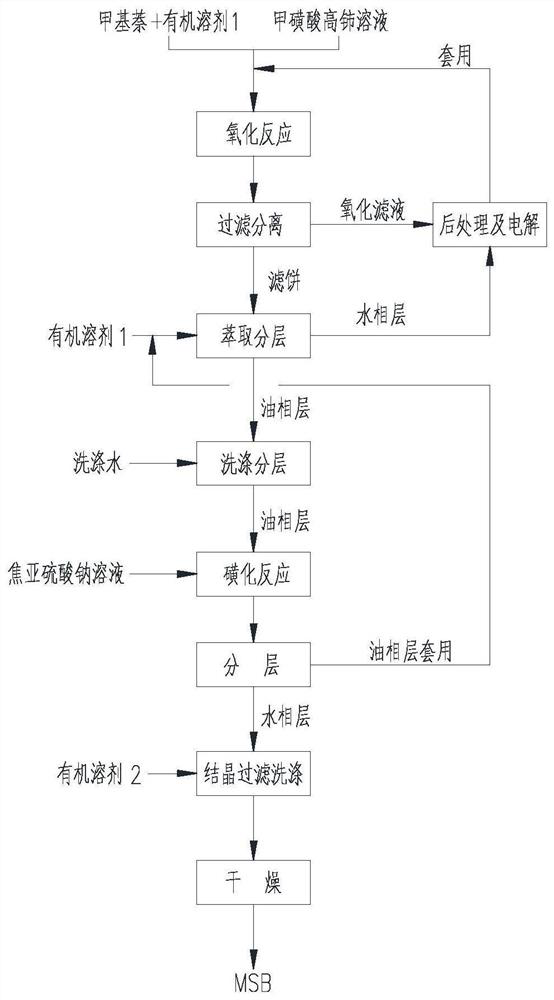

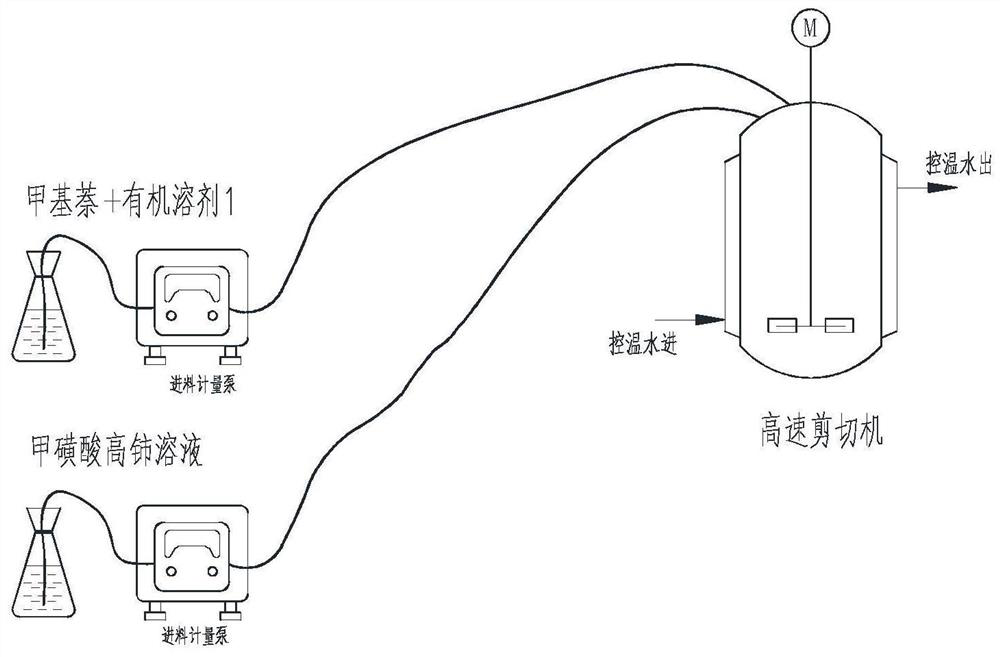

Method for preparing beta-menadione and derivative menadione sodium bisulfate of beta-menadione by taking Ce < 4 + > as oxidant

PendingCN111892490AReduce usageSolve the problem of foamingQuinone preparation by oxidationQuinone separation/purificationSodium bisulfateOil phase

The invention relates to a method for preparing beta-menadione by using Ce < 4 + > as an oxidant, which comprises the following steps: step 1, preparing an electrolyzed ceric methanesulfonate solution, and dissolving beta-methylnaphthalene in a first organic solvent to obtain a beta-methylnaphthalene organic solution; step 2, adding a part of the ceric methanesulfonate solution into a reaction kettle as a priming solution; 3, carrying out a three times of constant temperature reaction, and 4, after the reaction is finished, filtering to obtain a beta-menadione filter cake; layering a filtrateto obtain an organic solvent oil phase layer and a cerium methanesulfonate water phase layer; and 5, extracting the beta-menadione filter cake with a first organic solvent, filtering, and layering thefiltrate to obtain a beta-menadione organic solution oil phase layer and a cerous methanesulfonate water phase layer. According to the method, a high-speed shearing emulsifying machine is adopted inthe oxidation process to strengthen mass transfer, so that the use of an emulsifying agent is avoided, and the problems of foam, electrolytic efficiency and long-term cyclic utilization enrichment inthe oxidation residual liquid aftertreatment and electrolysis process are solved.

Owner:BROTHER ENTERPRISES HLDG CO LTD

Production technique for high grade high-yield synthetic diamond fine - micro-fine particle diamond

InactiveCN101062471AGood crystal formGranular concentrationUltra-high pressure processesTemporary StoppingAdamite

The invention relates to an excellent high alloy man made diamond sand manufacturing, using powder catalyst and graphite dust compressed under super high pressure and temperature to synthesize diamond. The synthesized pressure is lowered 2-10% compared to common synthesized pressure, with requirement for temperature matching and regulation at the same time, temporary stopping pressure being 80-92% of the synthesized pressure, with a gap of 0. 10-0. 15MPa and time interval 120-180s and pressure maintaining time being 5-20s. The synthesized man made diamond grains are mainly 170 / 200, 200 / 230, 230 / 270, 270 / 325, with 325 / 400 and 400 / 500 even finer diamonds. It uses the alloy diamond powder catalyst and bar making process. It also designs a set of high temperature super pressure synthesis according to low temperature and low pressure for the special selection of temporary shut pressure. The newly established process realizes the good effect the product.

Owner:方啸虎 +1

Method for preparing leuprorelin acetate, product and application

ActiveCN102464702BAvoid pollutionImprove securityLuteinising hormone-releasing hormoneDipeptideAminolysis

The invention provides a method for preparing leuprorelin acetate. The method comprises the following steps of: Boc-Pro-(p)preparation-solid phase peptide connection-aminolysis-HPLC (High Performance Liquid Chromatography) purification-concentration-filtering and drying, wherein in the solid-phase peptide connection step, obtaining a leuprorelin nonapeptide resin by preparing raw materials and connecting dipeptide, tripeptide, tetrapeptide, pentapeptide, hexapeptide, heptapeptide, octapeptide and nonapeptide. According to the preparation method provided by the invention, the leuprorelin acetate with higher purity and yield can be obtained, the preparation process has little pollution to environments and the safety of the product is high.

Owner:上海丽珠制药有限公司

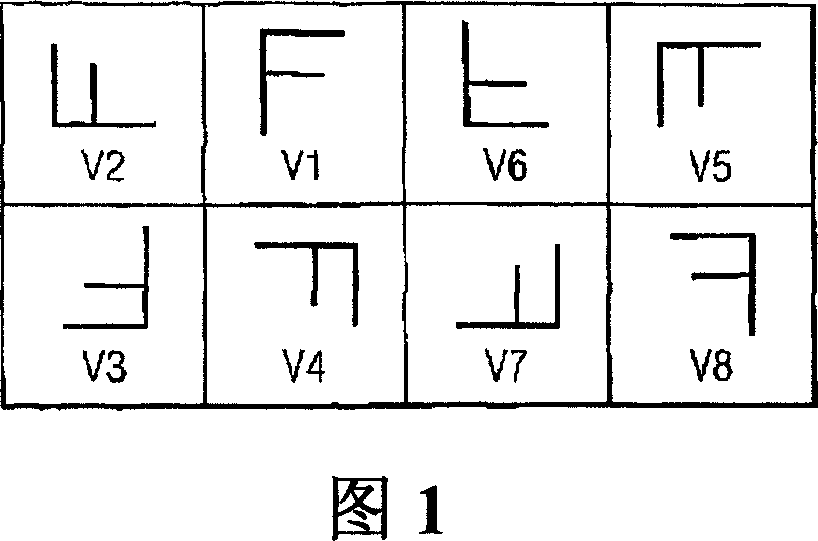

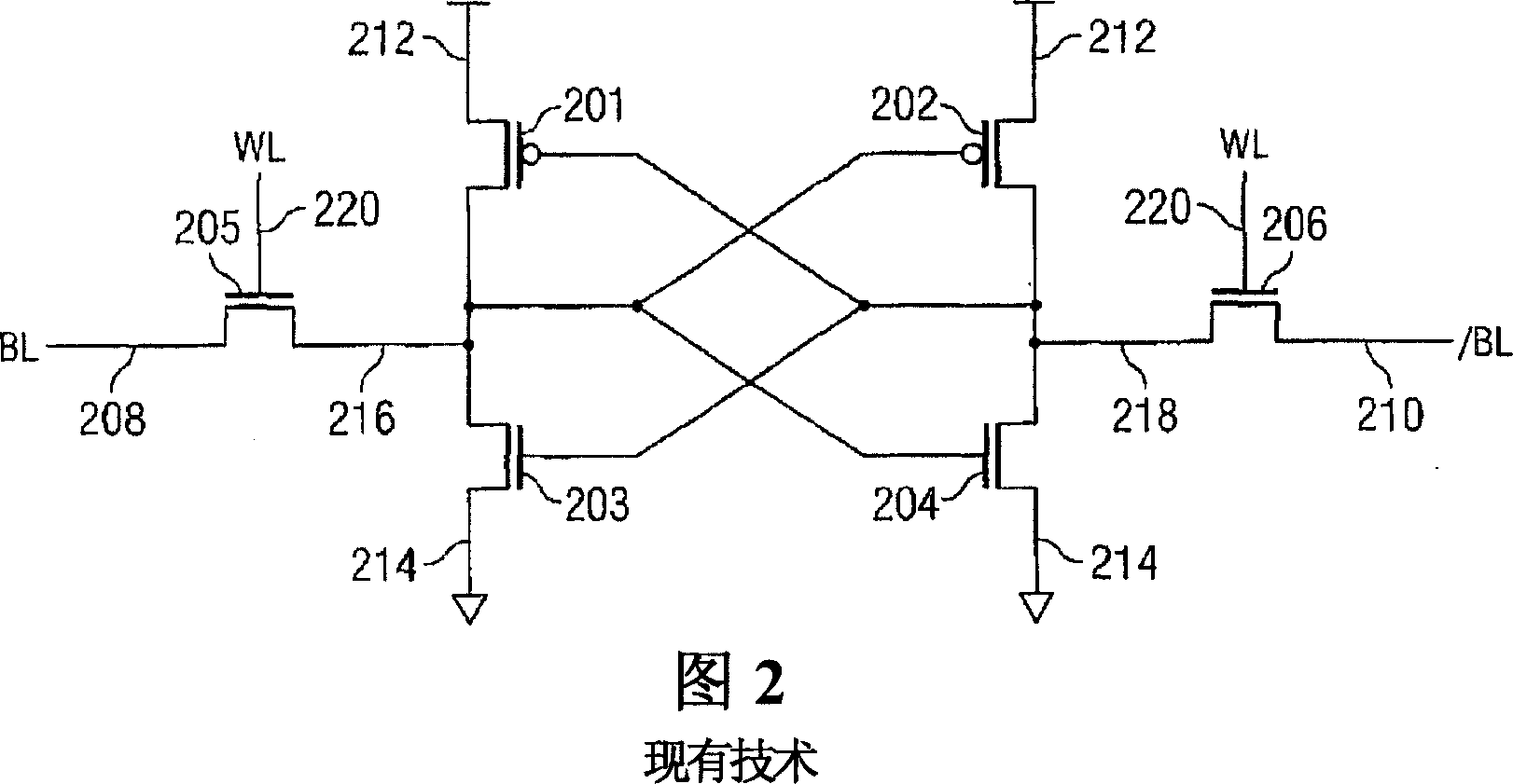

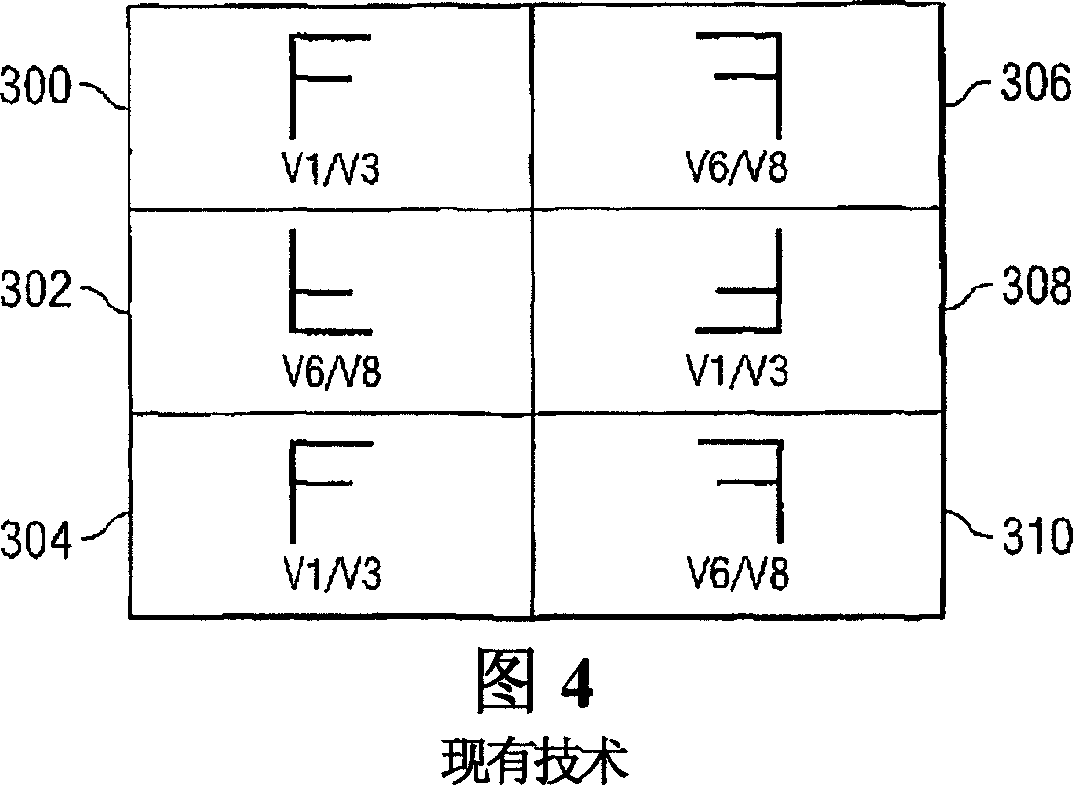

Staggered memory cell array

InactiveCN1961376ASmall sizeIncrease critical distanceTransistorSolid-state devicesOffset distanceMemory array

Owner:TEXAS INSTR INC

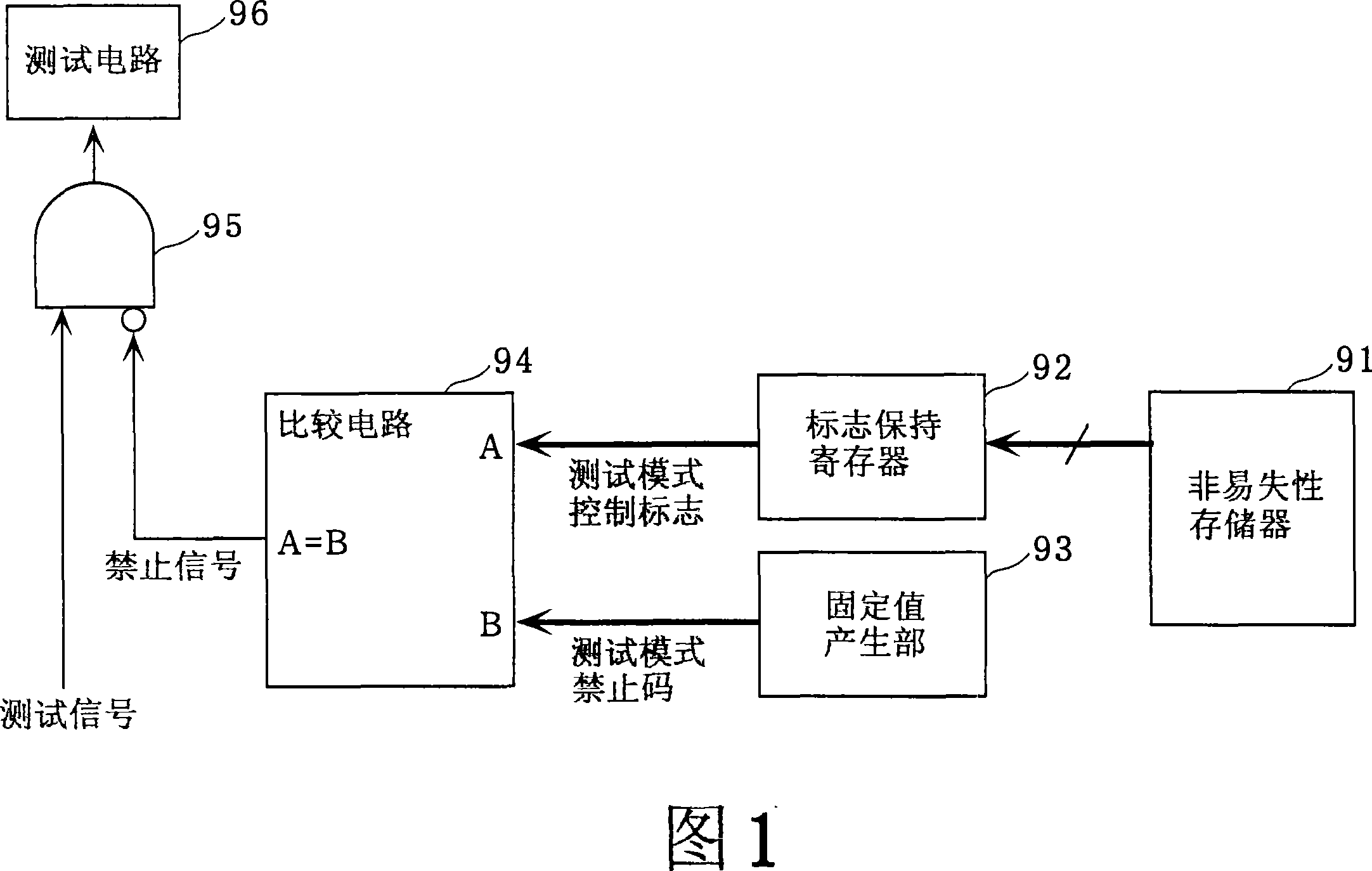

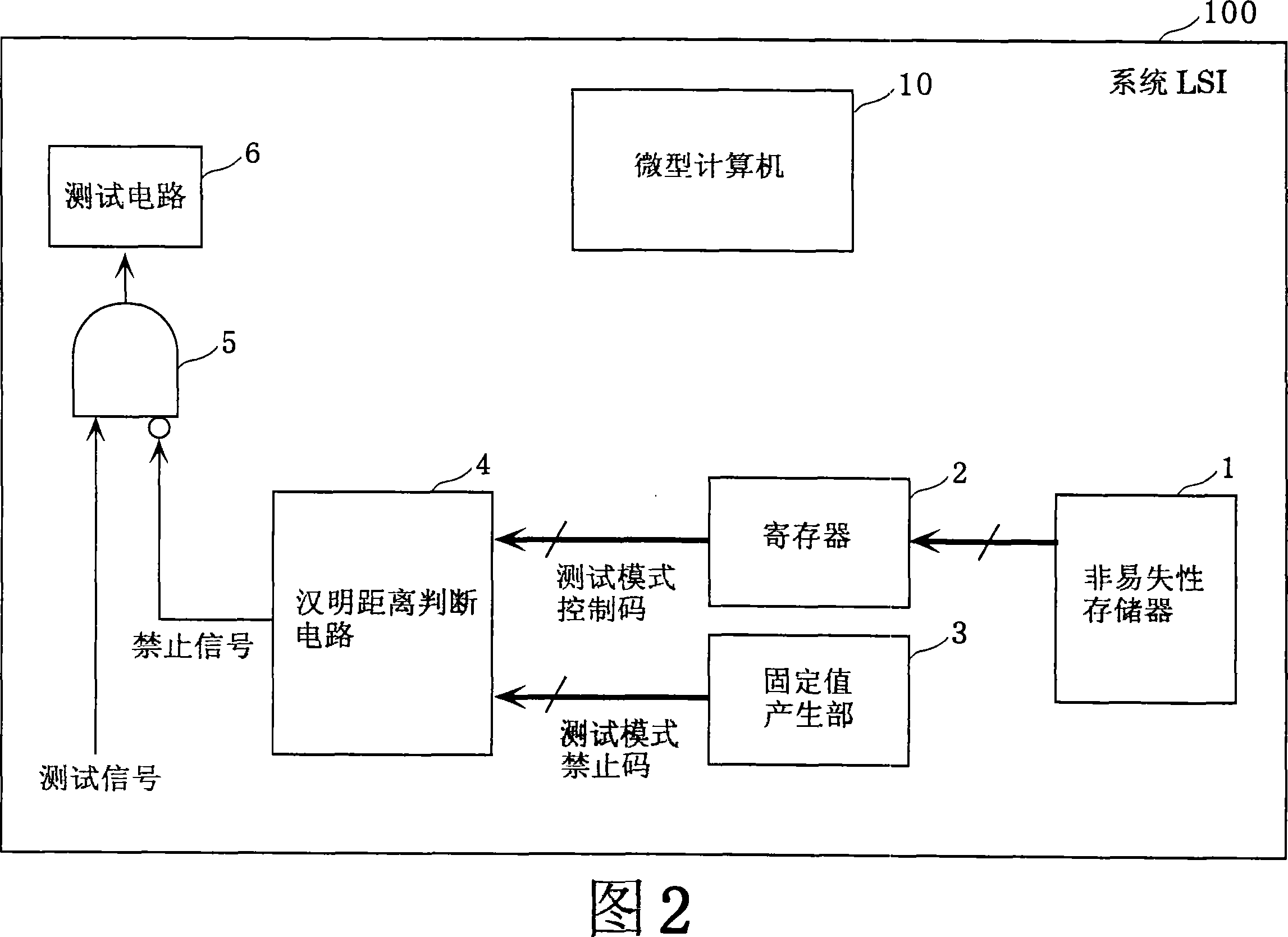

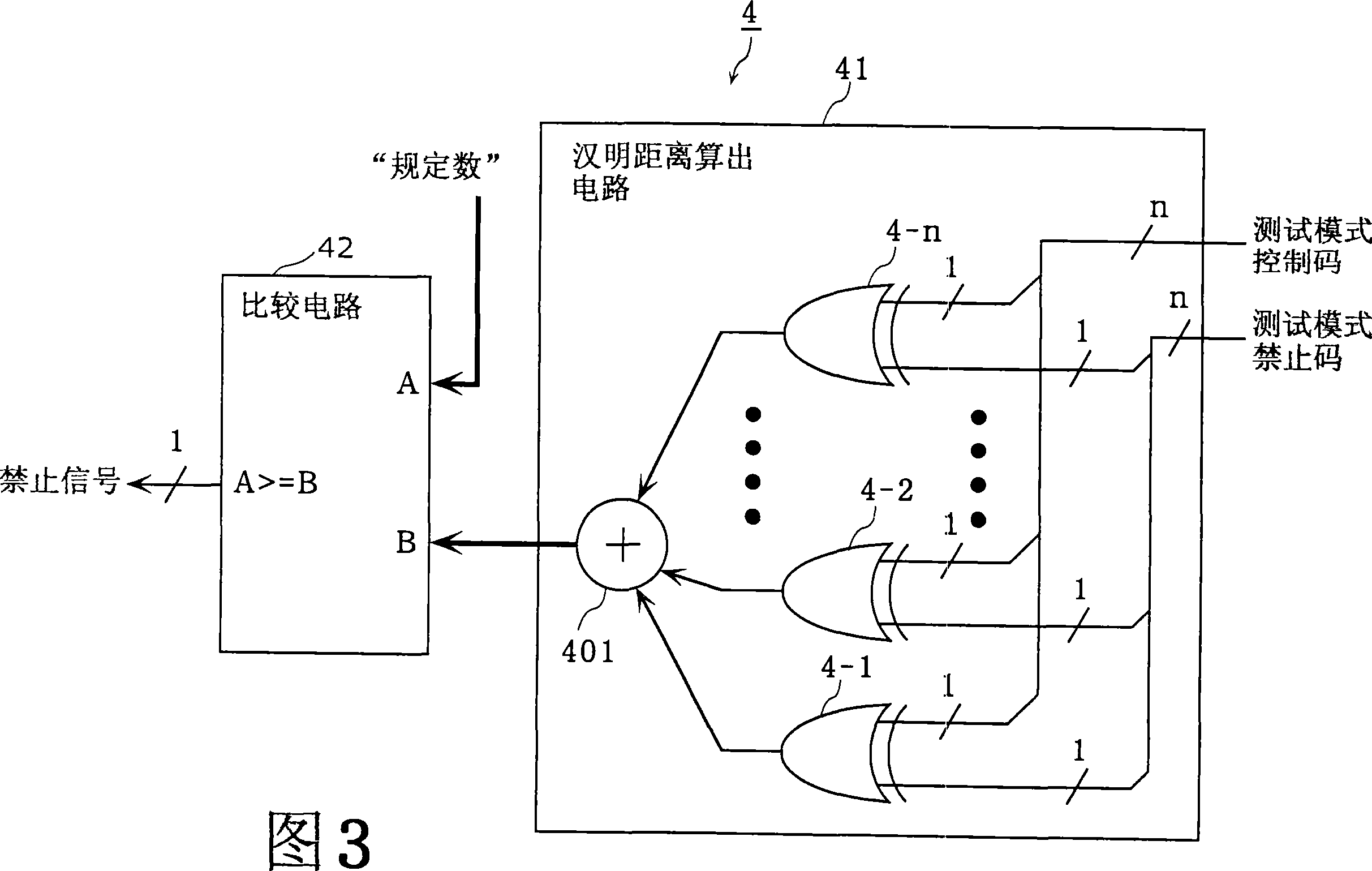

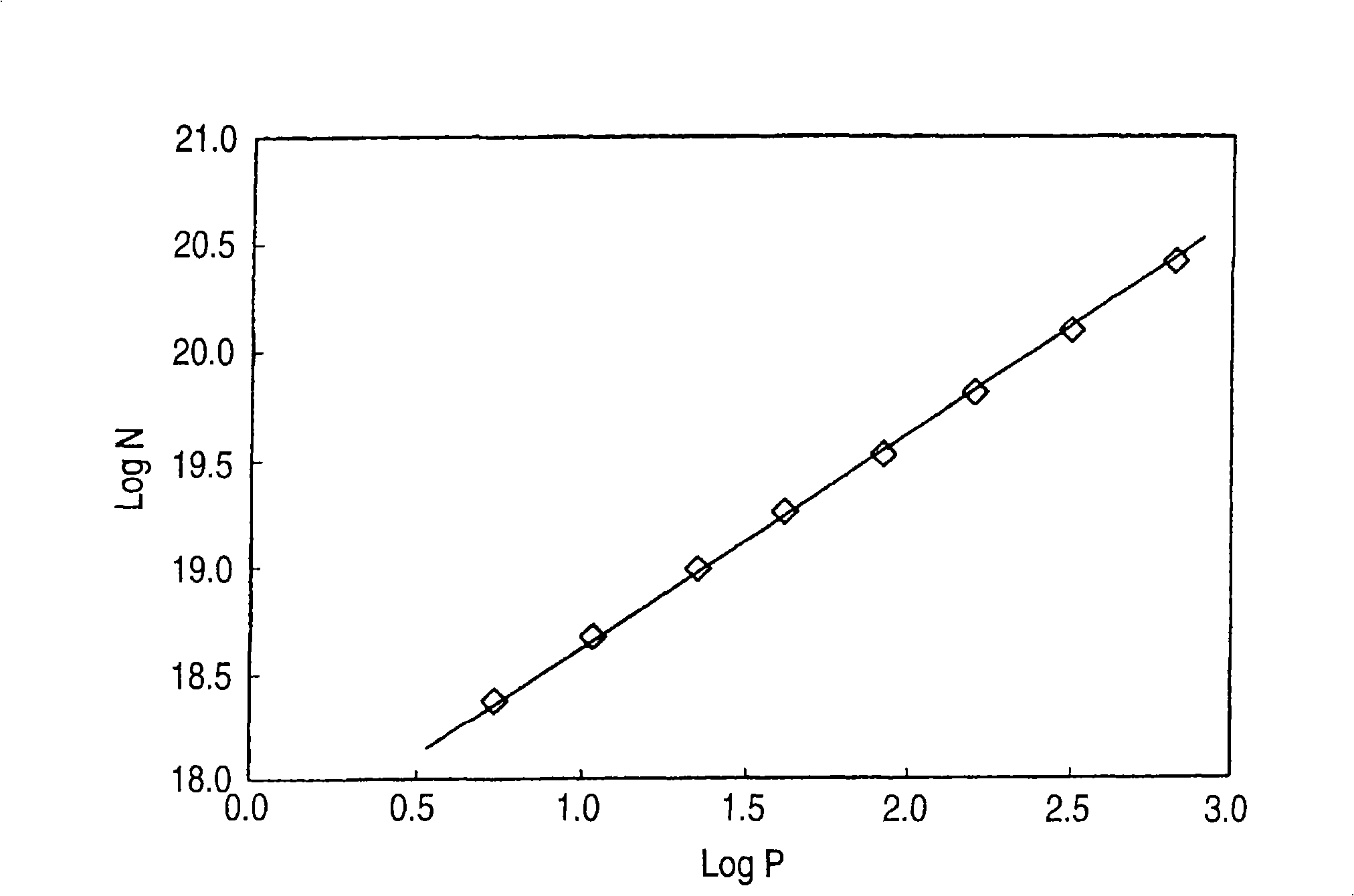

Semiconductor device and test mode control circuit

InactiveCN101253413APrevent leakagePrevent the situationElectronic circuit testingDecision circuitMode control

A semiconductor device is provided in which its security is fully ensured and its manufacturing yield is not lowered even if a data bit change occurs due to a malfunction or the like in the test mode control flag data stored in a nonvolatile memory. The semiconductor device comprises a nonvolatile memory (1) for storing a test mode control code into a predetermined address, a generator (3) for generating a fixed value indicating whether the test mode is disabled or enabled, and a Hamming distance decision circuit (4) for controlling the transfer to the test mode depending on whether the Hamming distance between the control code and the fixed value is less than or equal to a predetermined value or not.

Owner:PANASONIC CORP

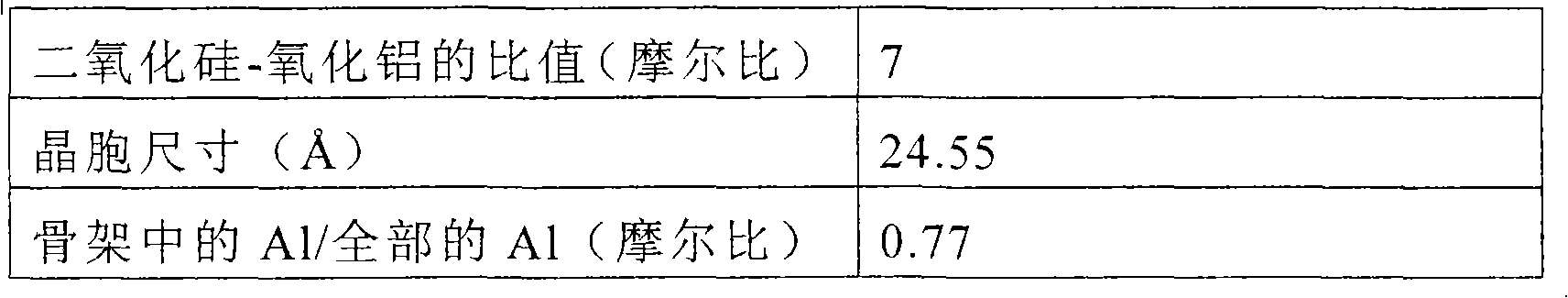

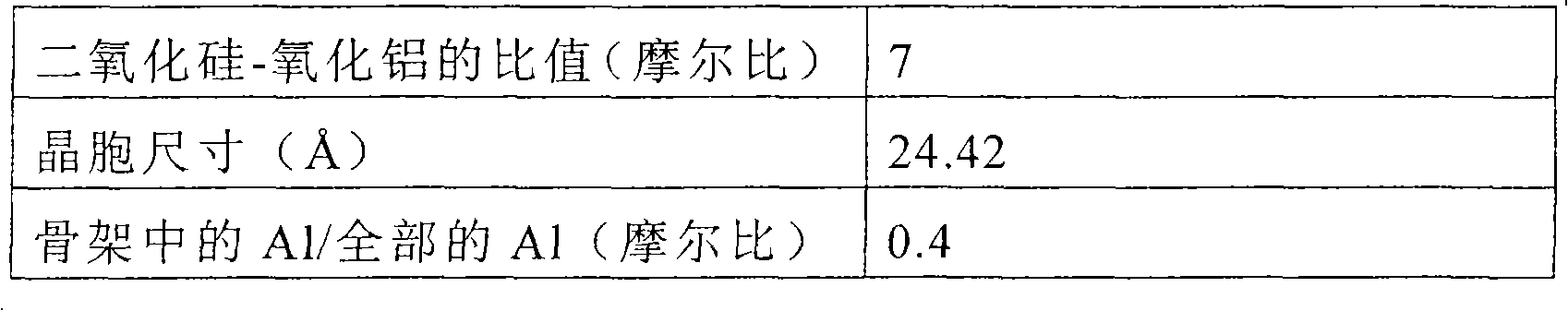

Cracking catalyst, process for preparation thereof, and process for catalytic cracking of hydrocarbon oil

InactiveCN101405078AIncrease lytic activityNo reduction in yieldCatalytic crackingMolecular sieve catalystsRare-earth elementClay minerals

The present invention provides a cracking catalyst which has high cracking activity and makes it possible to produce high-octane FCC gasoline through efficient progress without lowering the yield of gasoline; a process for the preparation of the catalyst; and a process for catalytic cracking of hydrocarbon oil with the same. A catalyst for catalytic cracking of hydrocarbon oil comprising a crystalline aluminosilicate having a predetermined composition, a binder, and clay mineral, which has contents of sodium and potassium in terms of oxides (Na2O and K2O) of 0.5% by mass or below, contents of rare earth metals in terms of oxides (RE2O3 wherein RE is a rare earth element) of 3.0% by mass or below, a mass ratio of [RE2O3 + Na2O + K2O] / [crystalline aluminosilicate] of 0.1 or below, and a xenon adsorption of at least 2.20OE0<20> molecules per g of the catalyst as determined at 25 DEG C and a xenon partial pressure of 650torr; a process for the preparation of the catalyst; and a process for catalytic cracking of hydrocarbon oil with the same.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

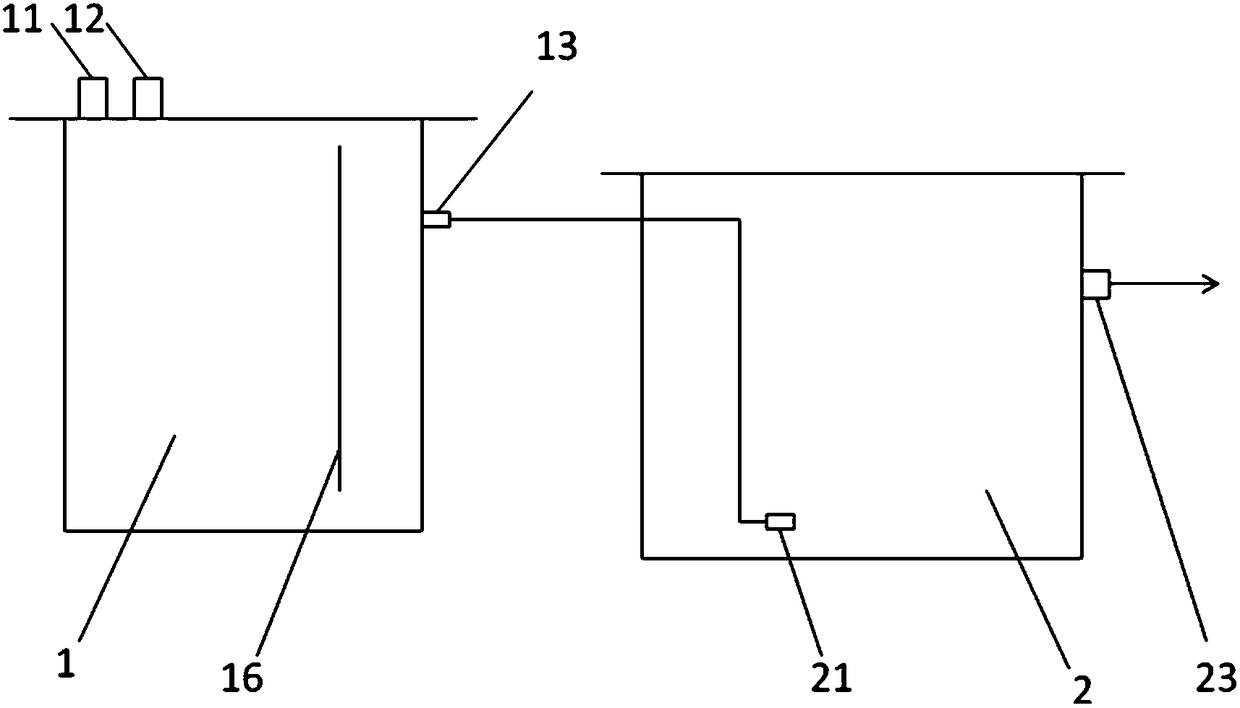

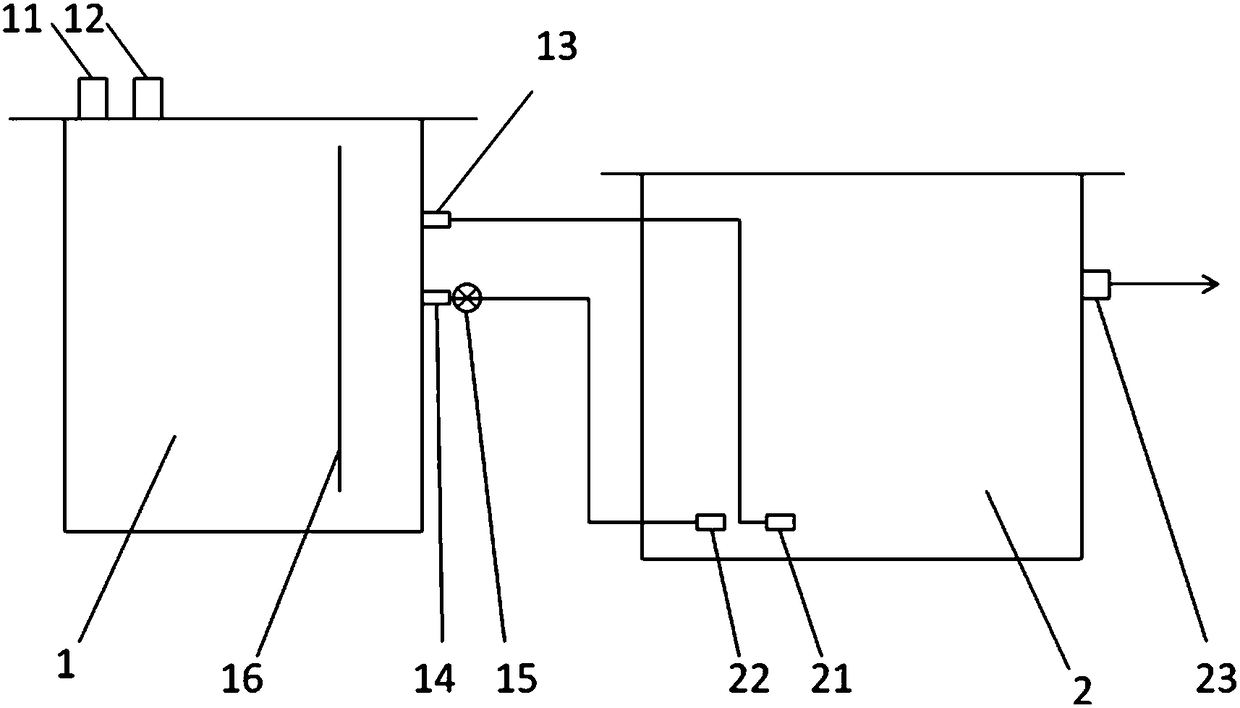

Sulfamic acid production apparatus and method

ActiveCN108147381AFully meet the dwell timeReduce the ratioAmidosulfonic acidChemical/physical/physico-chemical stationary reactorsInorganic SynthesesSulfamic acid

The invention belongs to the field of inorganic synthesis and particularly relates to a sulfamic acid production apparatus and method. In specific conjunction with the characteristics and demands of asulfamic acid production process, setting manner and position of a feeding pipe of the sulfamic acid production apparatus are re-designed and reformed in specific manner; key process indexes and parameters in the reaction process are strictly controlled, consumption ratio and quantity of fuming sulfuric acid are decreased at the premise of not reducing product production quality; therefore, the technical problem is solved that high production cost is caused due to high consumption of fuming sulfuric acid in the prior art.

Owner:湖北丽康源化工有限公司

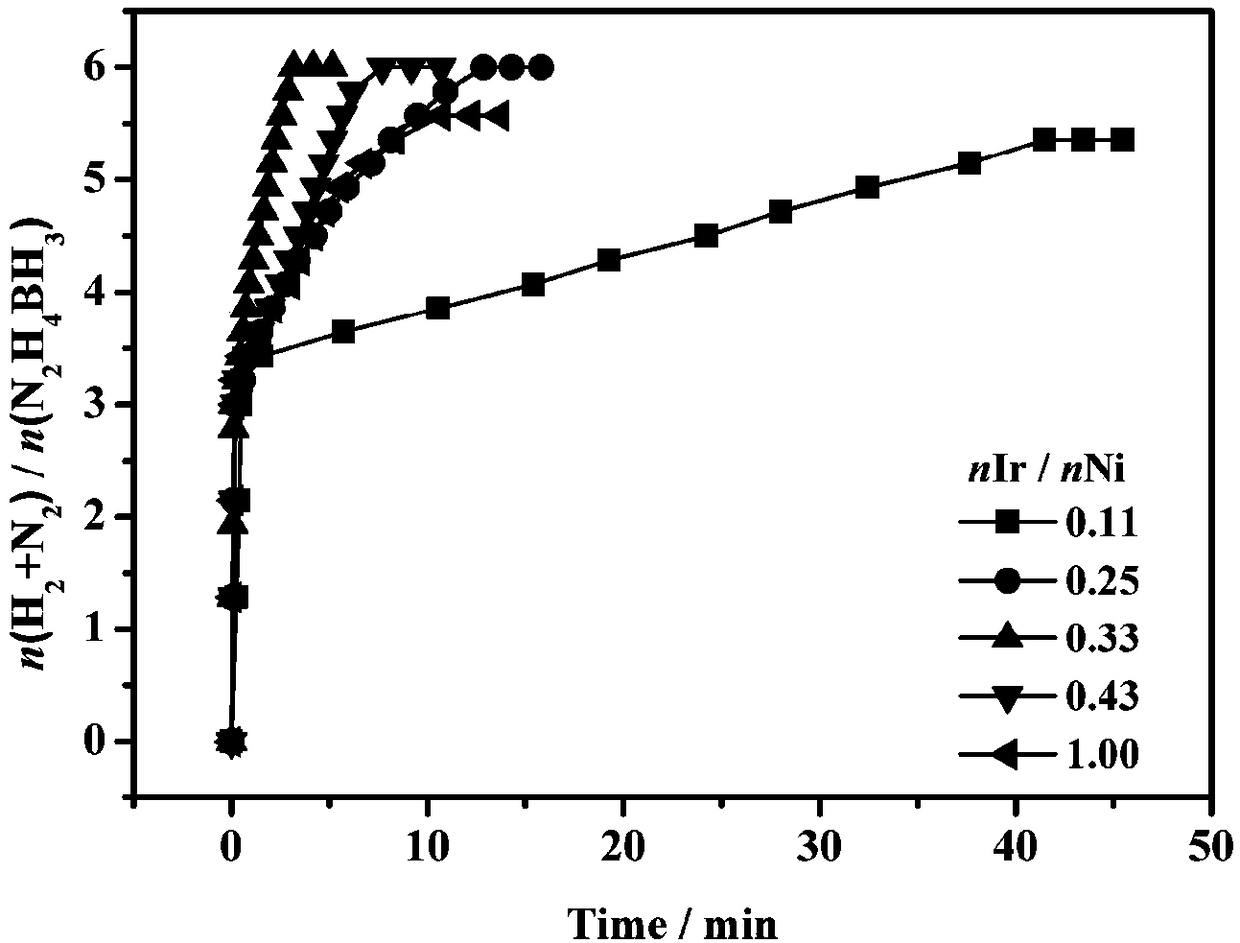

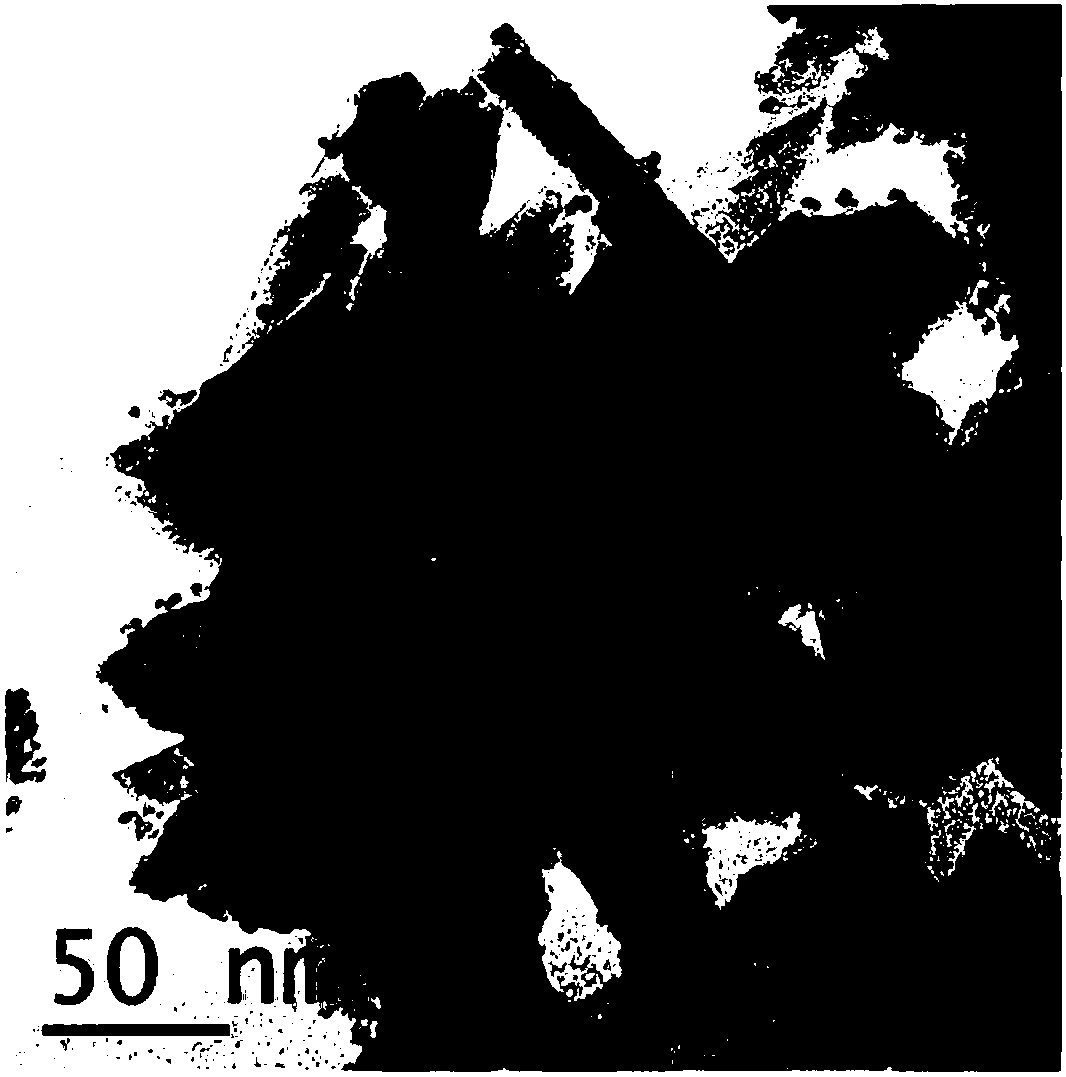

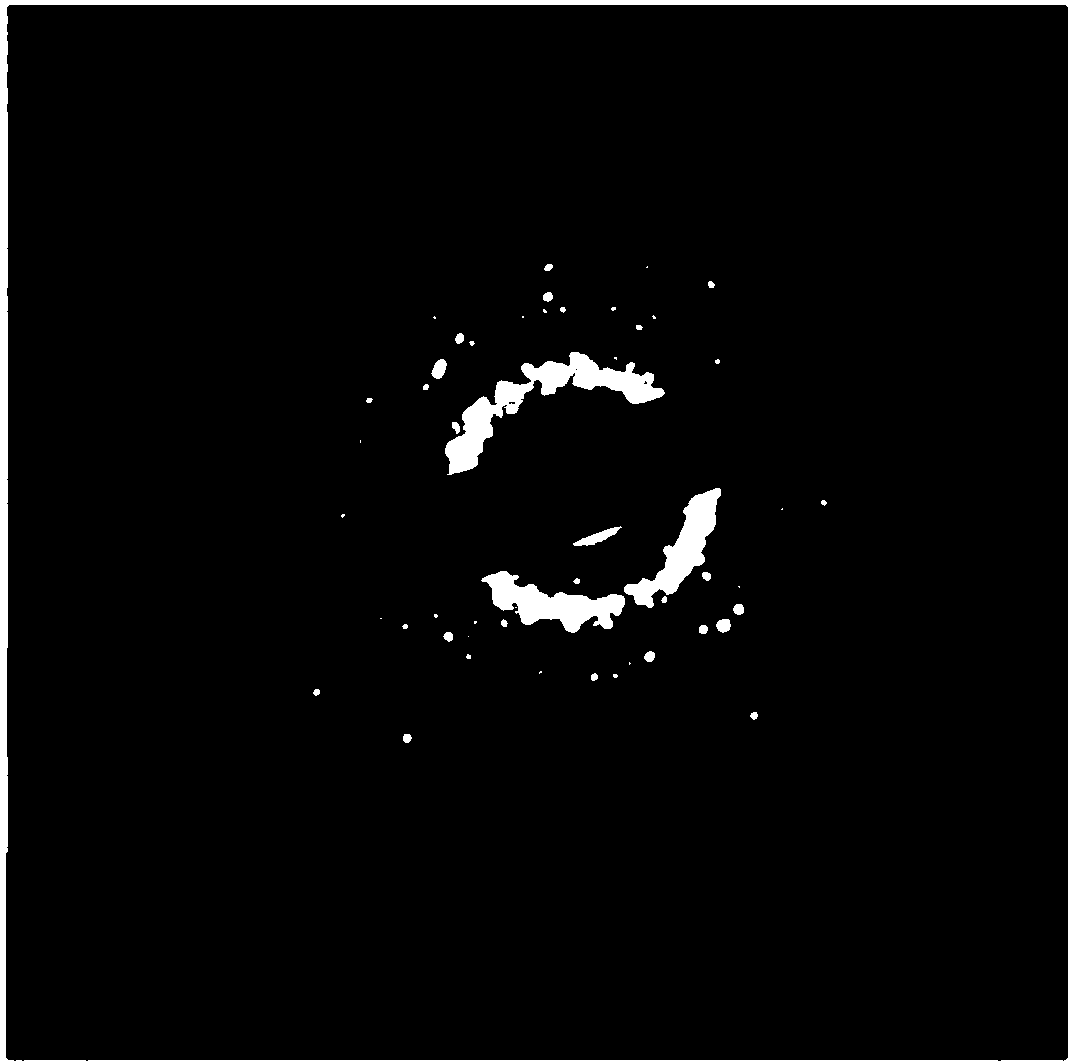

IrNi composite nano catalyst for catalyzing hydrazine borane to produce hydrogen and preparation method thereof

ActiveCN108525690AGood activity and stabilityImprove cycle stabilityPhysical/chemical process catalystsHydrogen productionNano catalystHydrazine compound

The invention provides a IrNi composite nano catalyst for catalyzing hydrazine borane to produce hydrogen and a preparation method thereof. The IrNi composite nano catalyst is prepared by using a soluble Ir source and a soluble Ni source as the metal precursors and La2O2CO3 as the supporter through a sodium hydroxide assisted co-reduction method under room temperature. The prepared IrNi compositenano catalyst has excellent catalytic performance on hydrogen production reaction using hydrazine borane and can efficiently catalyze the hydrazine borane to hydrolyze the boryl of the hydrazine borane and split the hydrazino of the hydrazine borane under 323K so as to achieve complete hydrogen production of the hydrazine borane, and the reaction transformation frequency (TOF) of the IrNi composite nano catalyst reaches up to 950 (mol H2mol metal<-1>h<-1>). The preparation method is simple to operate and promising in development prospect.

Owner:JIANGXI NORMAL UNIV

Catalyst for dewaxing lubricating oil base oil produced by Fischer-Tropsch synthetic wax and preparation method and application of catalyst

PendingCN112007692ALow cloud pointNo reduction in yieldMolecular sieve catalystsPetroleum wax recoveryMolecular sievePtru catalyst

The invention relates to the field of catalytic dewaxing, and discloses a catalyst for dewaxing lubricating oil base oil produced by Fischer-Tropsch synthesis wax and a preparation method and application of the catalyst. Based on the total weight of the catalyst, the catalyst comprises the following components in percentage by weight: 0.1-5% of a metal active component; 9%-90% of a modified molecular sieve; 8%-90% of aluminum oxide, wherein the metal active component is Pt and / or Ni; the modified molecular sieve is a product obtained after surface passivation-shrinkage treatment of an acidic molecular sieve, and the acidic molecular sieve is selected from at least one of a ZSM-5 molecular sieve, a ZSM-22 molecular sieve, a ZSM-48 molecular sieve, an SAPO-11 molecular sieve and a mercerizing molecular sieve. The acidic active site on the outer surface of the catalyst is passivated, and the micro-pore opening of the molecular sieve is finely adjusted so that the cloud point of the base oil product can be significantly reduced while the liquid yield is not reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

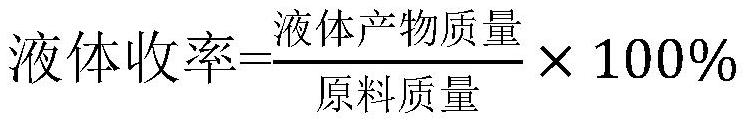

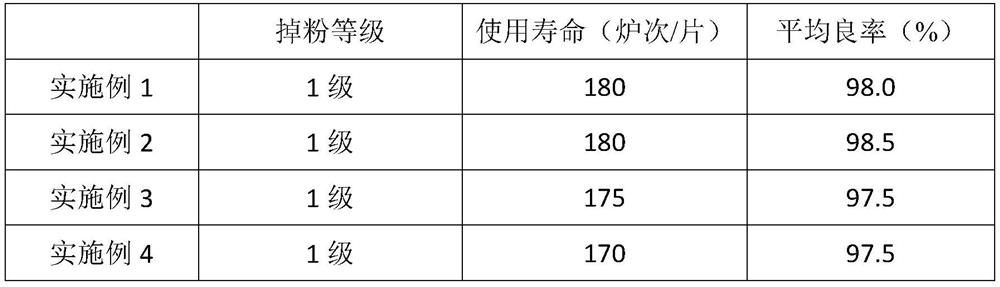

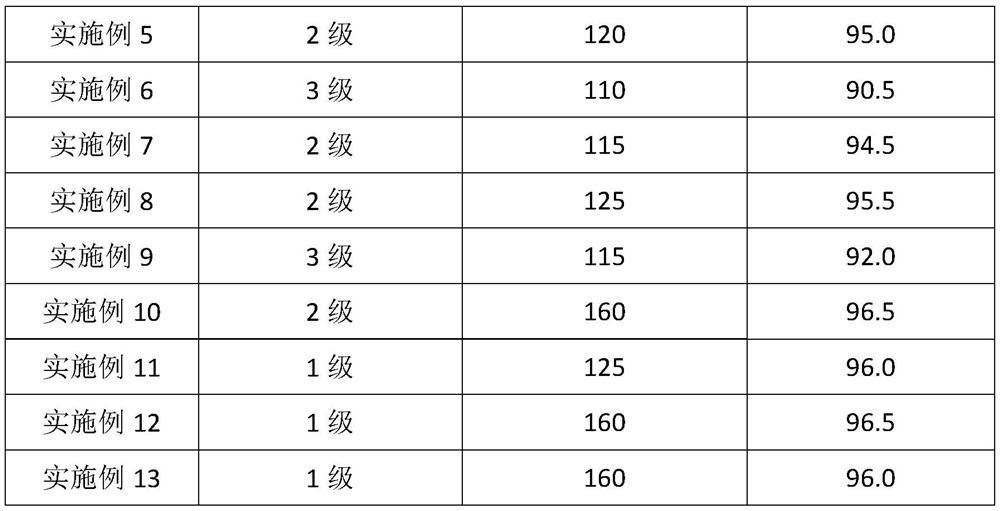

Adhesive for high-temperature photoelectric semiconductor material and preparation method thereof

ActiveCN111925752AHigh bonding strengthAvoid wastingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementSemiconductor materials

The invention relates to the technical field of semiconductor material processing, in particular to an adhesive for a high-temperature photoelectric semiconductor material and a preparation method thereof. The adhesive is prepared from the following raw materials in parts by weight: 25 to 50 parts of polyvinyl acetate emulsion, 40 to 60 parts of a filler, 0 to 1.0 part of a thickening agent, 1 to3.5 parts of a functional additive, 0.1 to 0.8 part of a dispersing agent, 0.1 to 0.8 part of a defoaming agent and 3 to 12 parts of a solvent. The adhesive has higher bonding strength on a stone milldisc; after the damaged part of the coating is brushed and repaired, the phenomenon of cracking or damage does not occur again after the coating is used for multiple times, the service life is remarkably prolonged and can be improved to 180 times per piece from 100 times per piece in the prior art, and the yield in semiconductor product production is not reduced after the coating is repaired.

Owner:林俊贤

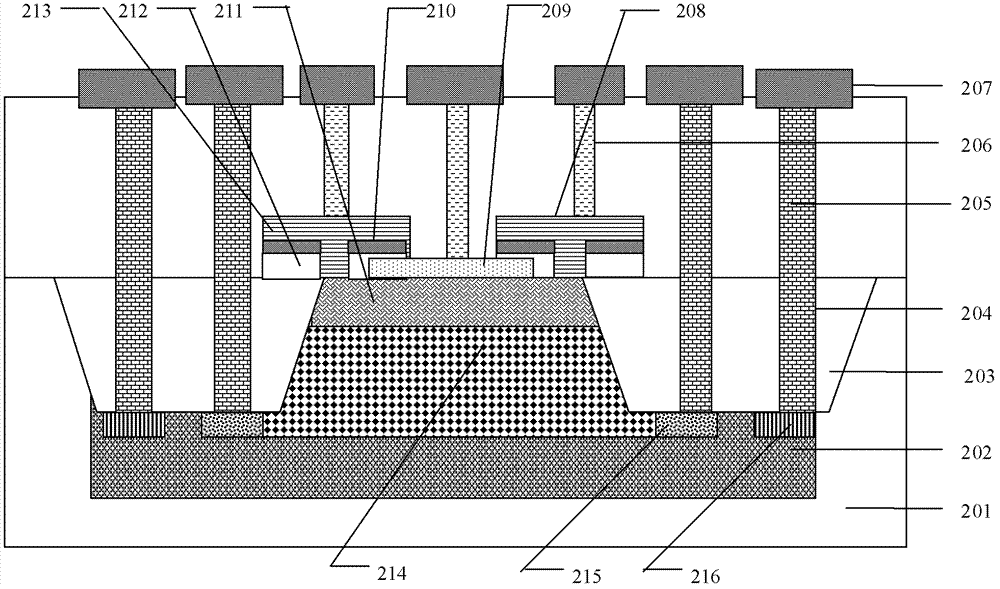

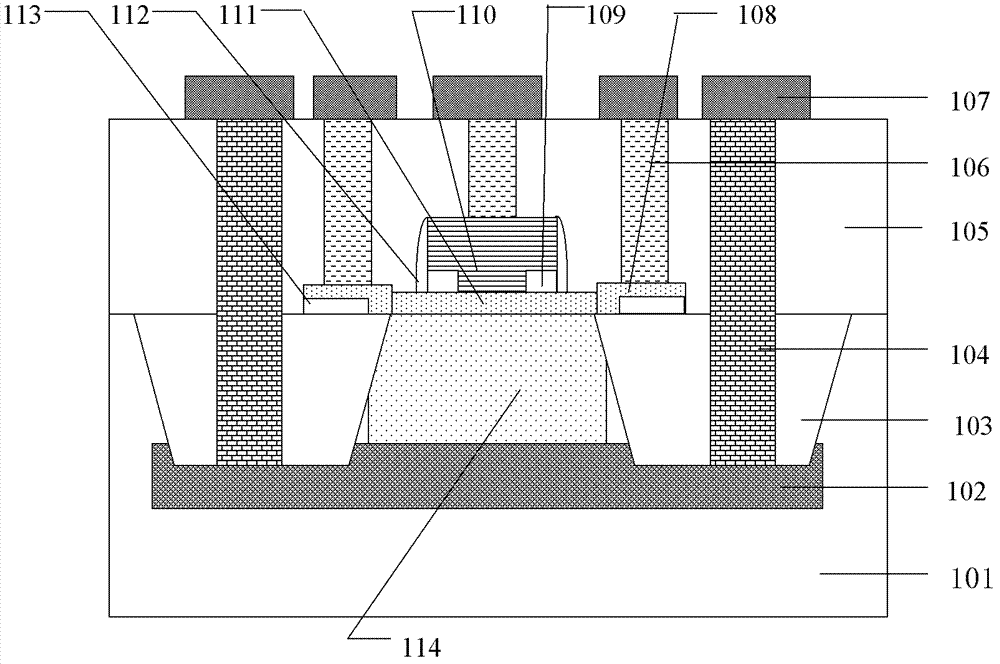

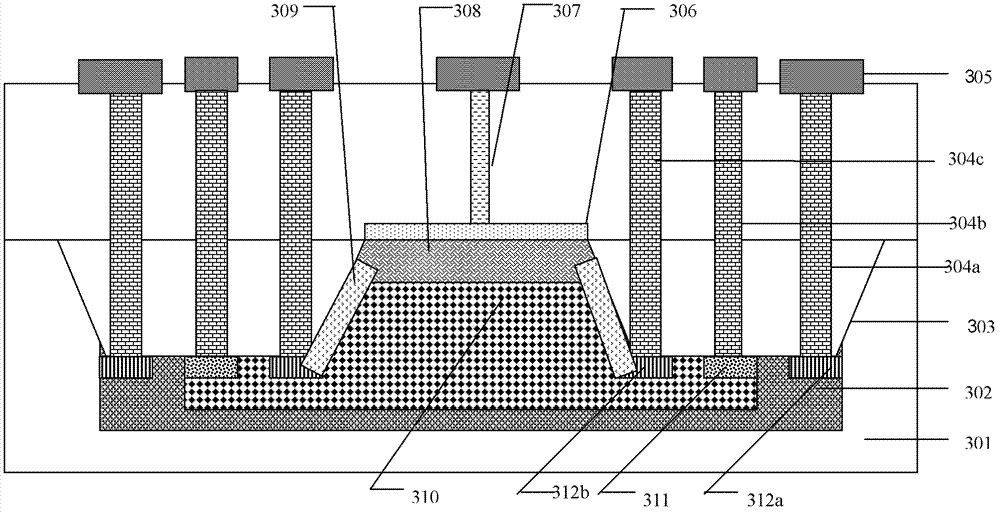

Positive-negative-positive transistor integrated with germanium-silicon hetero-junction negative-positive-negative transistor

The invention discloses a positive-negative-positive (PNP) transistor integrated with a germanium-silicon hetero-junction negative-positive-negative (NPN) transistor. A base area out-leading area is arranged on the lateral face of an active area to lead out a base area so that the fact that polycrystalline silicon is formed on the top portion of the active area to lead out the base area can be avoided, and therefore the integration of the PNP transistor and the germanium-silicon hetero-junction NPN transistor can be realized without changing the manufacturing process of the germanium-silicon hetero-junction NPN transistor, influences to the manufacturing of the germanium-silicon hetero-junction NPN transistor are prevented from being produced, and the facts that manufacturing cost of germanium-silicon hetero-junction NPN transistor is not increased and yield of the germanium-silicon hetero-junction NPN transistor is not reduced are guaranteed.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Production process of 1,3-bis(2,4-diaminophenoxy)propane hydrochloride

InactiveCN104292118ANo reduction in yieldOrganic compound preparationAmino-hyroxy compound preparationEnvironmental engineeringPropane

The invention discloses a production process of 1,3-bis(2,4-diaminophenoxy)propane hydrochloride; based on an original production process, new steps are added in the production process: adding tap water into a reaction pot, starting to stir, then adding a 1,3-bis(2,4-diaminophenoxy)propane hydrochloride condensation product, heating up, then adding liquid caustic soda drop by drop, controlling the temperature and stirring, after stirring is finished, discharging and carrying out suction filtration while being hot, rinsing with clear water, rinsing to a specified pH value, pumping water out and centrifuging, and then drying. The production process can remove impurities fully dissolved in water while the product is not dissolved in water, so the product yield is not decreased, and besides, the impurities required to be controlled are removed.

Owner:YIXING XINYU CHEM

A kind of method adopting microchannel reaction device to prepare dovitinib intermediate

The invention discloses a method for preparing a dovitinib intermediate with a microchannel reaction device. The method comprises the following steps: (1) dissolving hydrochloric acid in ethanol to form a mixed solution, and enabling the mixed solution and an ethanol solution of 5-(4-methylpiperazin-1-yl)-2-nitroaniline to flow into a first microstructural reactor in the microchannel reaction device filled with zinc powder simultaneously and respectively for a reaction to obtain a reaction effluent; (2) enabling the reaction effluent in step (1) and an ethanol solution of ethyl-beta-imino-beta-ethoxypropionate to flow into a second microstructural reactor in the microchannel reaction device simultaneously and respectively for a reaction to obtain ethyl-2-(6-(4- methylpiperazin-1-yl) benzimidazol-2-yl) ethyl acetate, namely, the dovitinib intermediate. The method has the advantages that few side reactions are produced, yield is high, technological steps are simplified, production cost is low, and the industrial standard of profit maximization is met better.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com