Method for reducing content of chlorinated derivative in isocyanate

A technology of isocyanate and derivatives, which is applied in the field of isocyanate, can solve the problems of prolonged reaction time, product loss, and prolonged production cycle, etc., and achieves the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

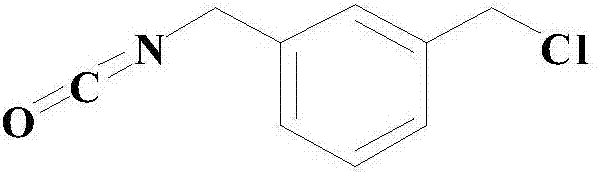

Image

Examples

Embodiment 1

[0029] A method for reducing the content of chlorinated derivatives in isocyanate, the concrete steps are:

[0030] (1) Take xylylene diisocyanate (the mass content of chlorinated derivative is 1%) 20g, add 40ml dichlorobenzene, then add 10ml acetone;

[0031] (2) Weigh 0.1g of potassium thiocyanate powder, add it to the above isocyanate solution, heat to 130°C, react for 5min, and cool to room temperature;

[0032] (3) Filtrate, remove the solvent, and collect the filtrate to obtain the crude or refined product of isocyanate with qualified content of chlorinated derivatives.

[0033] Chlorinated derivatives could not be detected by gas chromatography.

Embodiment 2

[0035] A method for reducing the content of chlorinated derivatives in isocyanate, the concrete steps are:

[0036] (1) Weigh 20 g of hexamethylene diisocyanate (the mass content of the chlorinated derivative is 1%), add 80 ml of toluene, and then add 15 ml of butanone;

[0037] (2) Weigh 0.2g of potassium thiocyanate powder, add it to the above isocyanate solution, heat to 30°C, react for 180min, and cool to room temperature;

[0038] (3) Filtrate, remove the solvent, and collect the filtrate to obtain the crude or refined product of isocyanate with qualified content of chlorinated derivatives.

[0039] Calculated by gas chromatography quantitative analysis, the mass content of chlorinated derivatives after treatment is reduced to 0.03%.

Embodiment 3

[0041] A method for reducing the content of chlorinated derivatives in isocyanate, the concrete steps are:

[0042] (1) Weigh 200 g of dicyclohexylmethane diisocyanate (the mass content of the chlorinated derivative is 5%), add 600 ml of chlorobenzene, and then add 150 ml of acetone;

[0043] (2) Weigh 11g of potassium thiocyanate powder, add it to the above isocyanate solution, heat to 80°C, react for 120min, and cool to room temperature;

[0044] (3) Filtrate, remove the solvent, and collect the filtrate to obtain the crude or refined product of isocyanate with qualified content of chlorinated derivatives.

[0045] Calculated by gas chromatography quantitative analysis, the mass content of the chlorinated derivatives after treatment was reduced to 0.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com