Patents

Literature

257results about How to "Lower yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

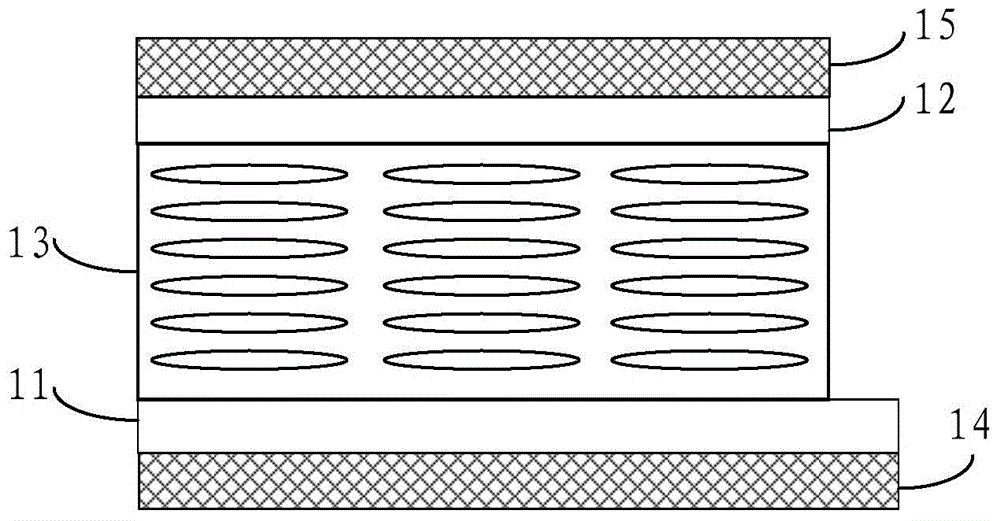

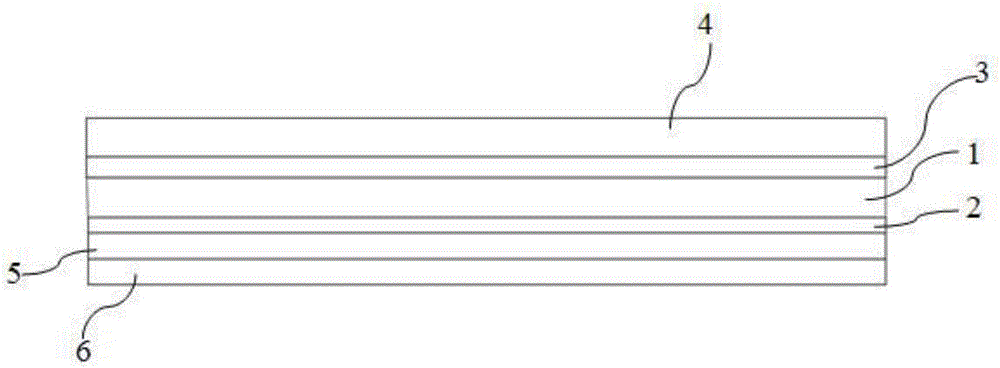

Formation method of lithium ion battery

ActiveCN105406129AConsistent thicknessReduce scrapFinal product manufactureSecondary cells charging/dischargingVacuum pumpingPower flow

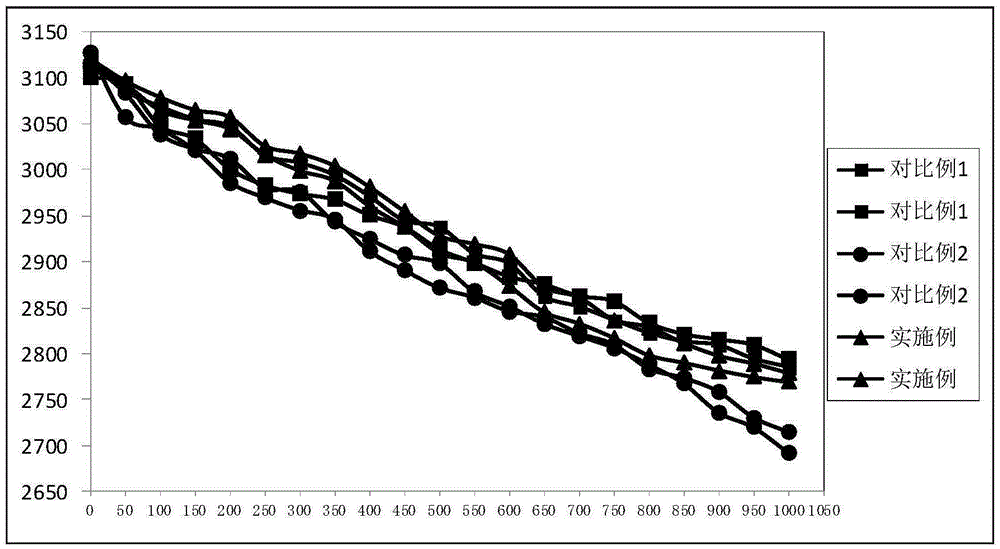

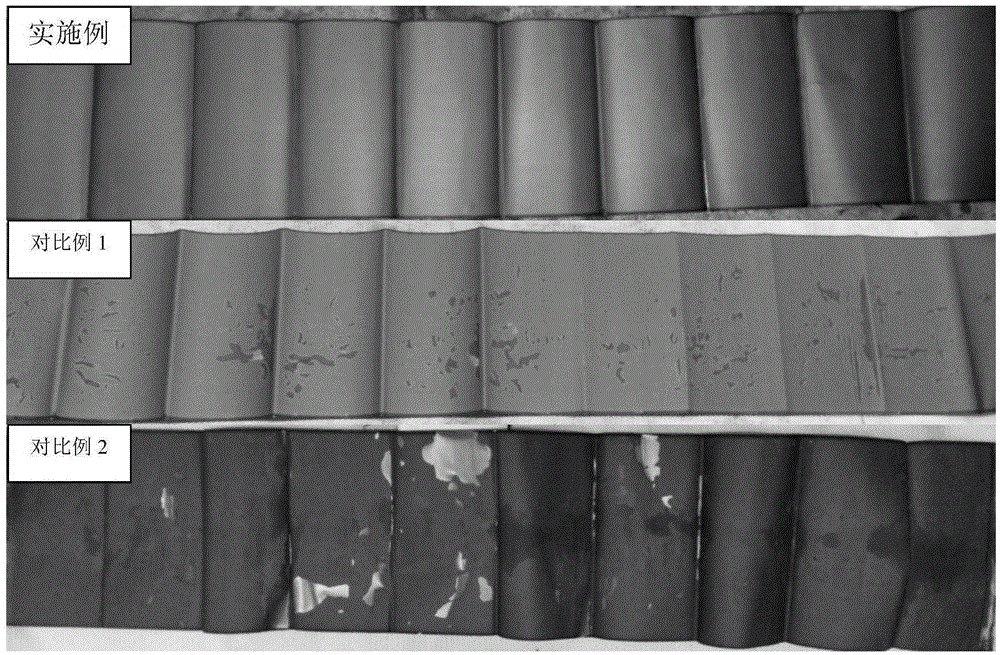

A formation method of a lithium ion battery comprises the following steps of placing an aged battery in a formation device for formation in a high-temperature pressurized environment, charging by using 0.1-0.5CmA current during charging until to a cut-off voltage of 3.7V, and then charging by using 0.5-2.0CmA current until to a cut-off voltage of 4.0V; increasing the temperature and keeping the pressure unchanged, and carrying out heat preservation and pressure maintaining on the battery; reducing the temperature and the pressure, and cooling the battery; and carrying out vacuum pumping and secondary sealing on the battery subjected to cooling finish, and completing formation. According to the formation method, a battery core is placed in a high temperature and certain pressure condition for large-current charging formation, the processing time is shortened, and the production efficiency is improved; moreover, the contact of an operator to the lithium battery core is reduced, and the cost problems caused by poor appearance, damage and the like are reduced; and the consistencies on the thickness, the capacity and pole piece interface states of the battery are higher, and the cycle ability is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

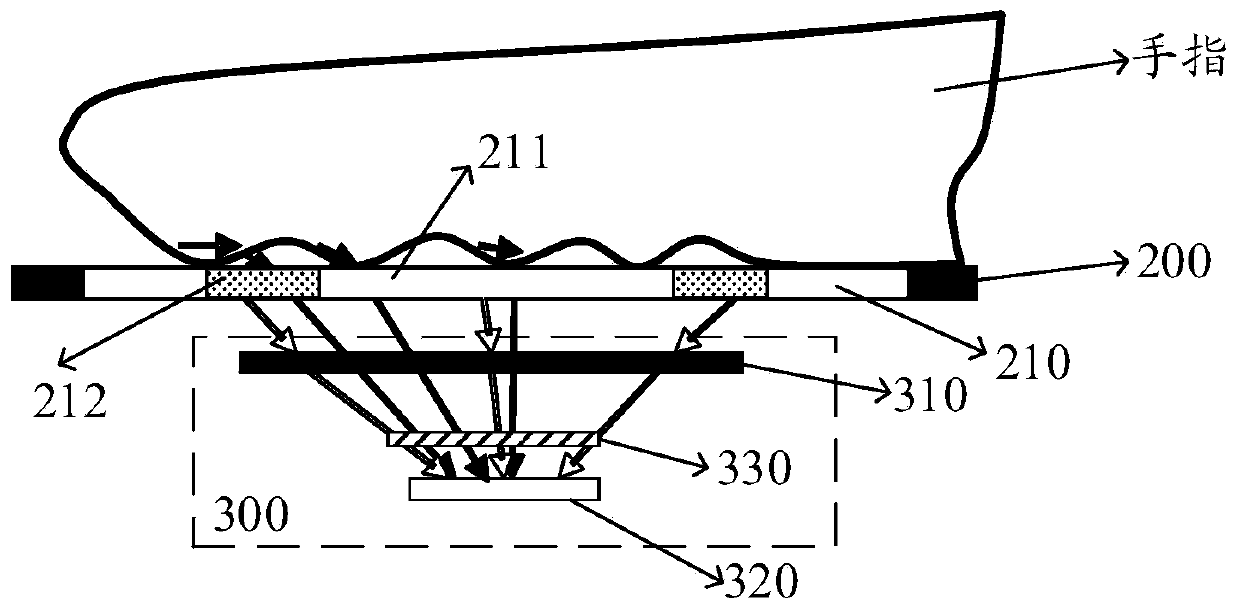

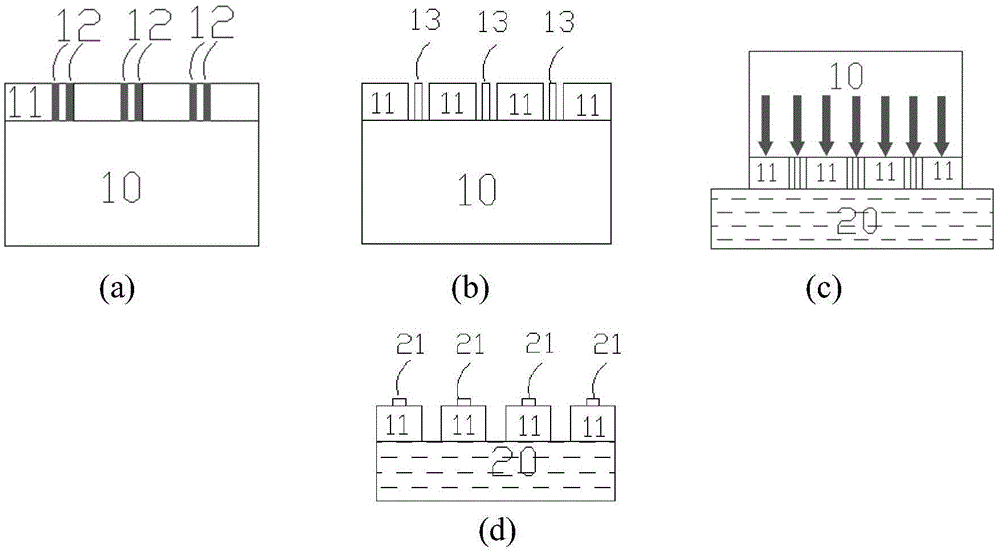

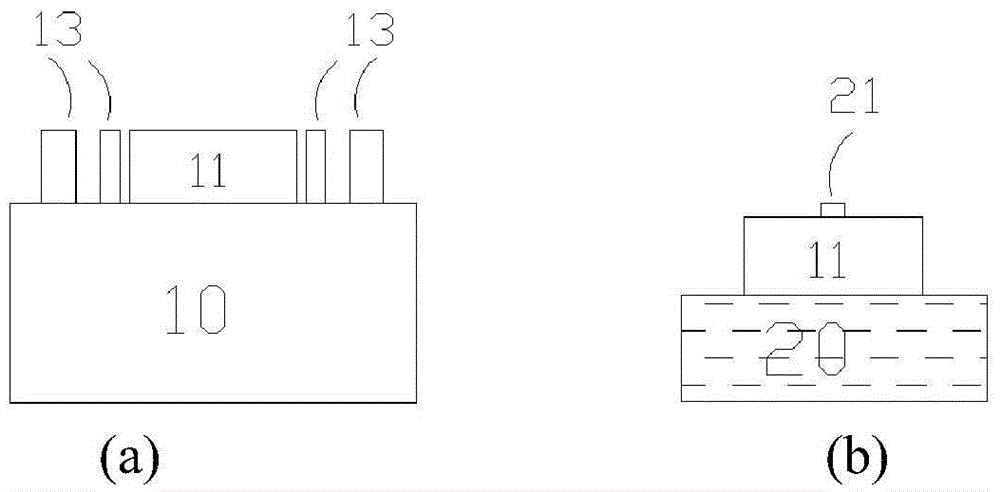

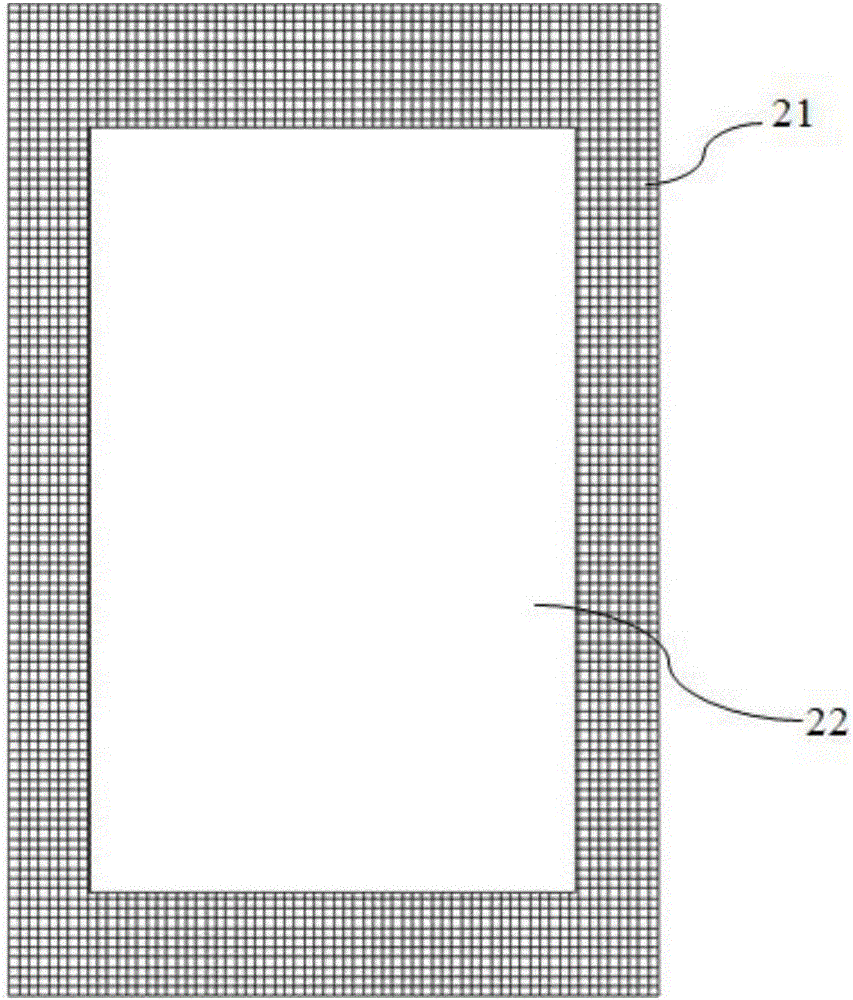

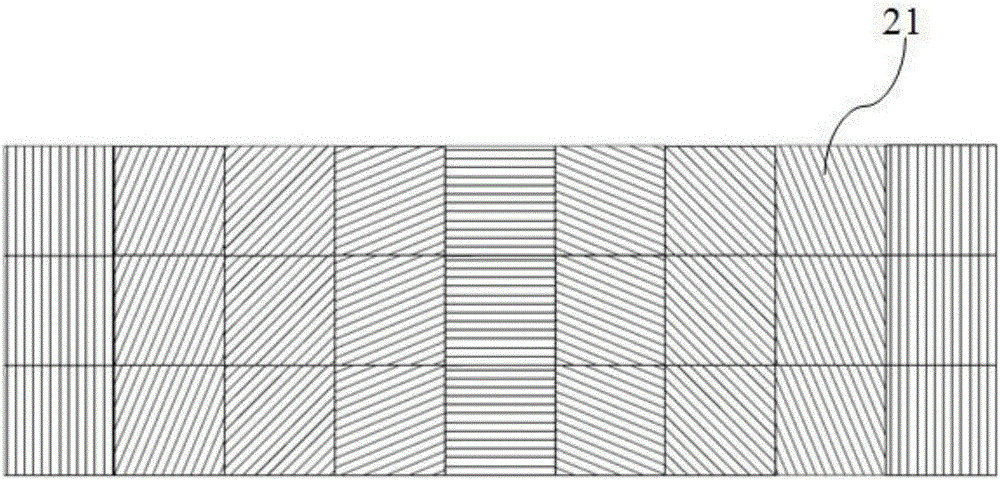

Method, device and electronic device for fingerprint identification and anti-counterfeiting

PendingCN110582780ASolve the problem that various forms of false fingerprints cannot be preventedImprove experiencePrint image acquisitionMonochromatic colorSecurity authentication

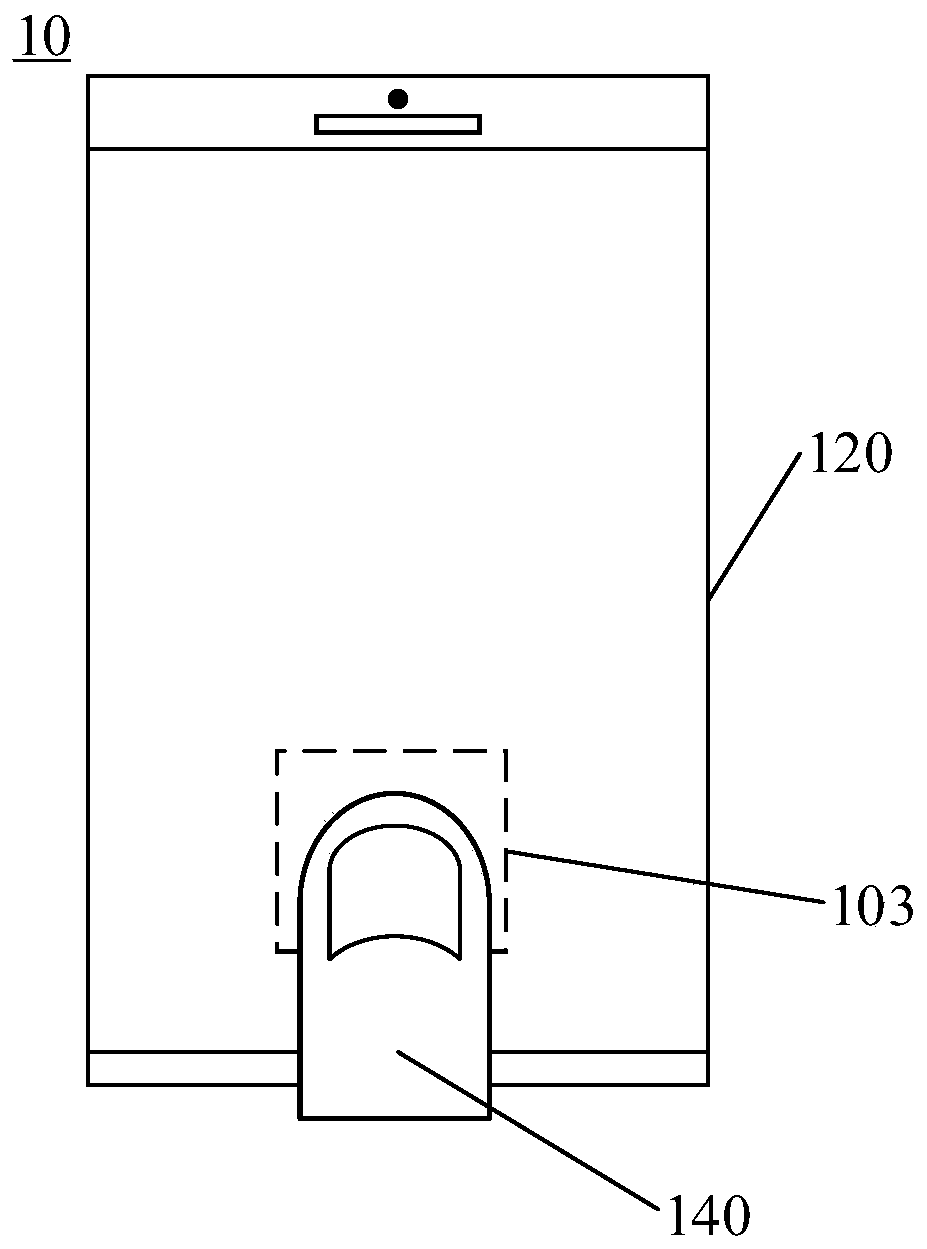

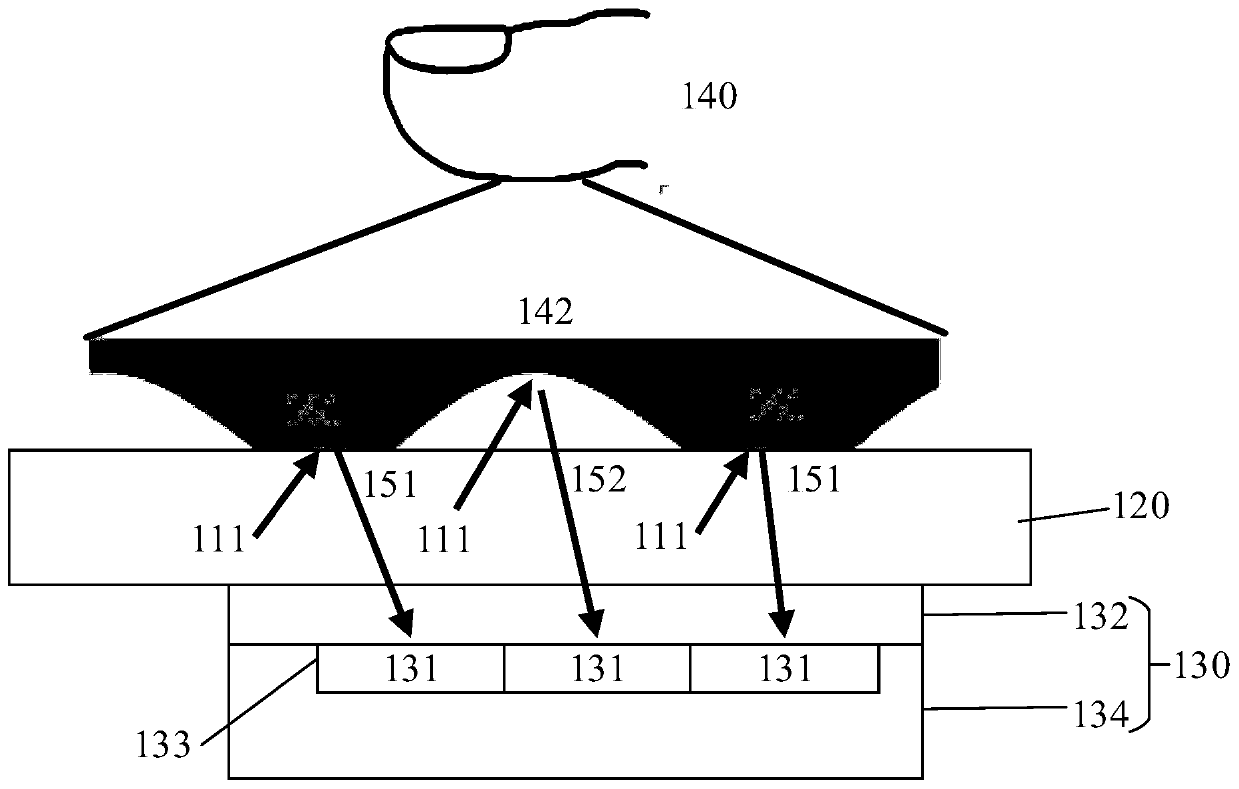

Embodiments of the present application relate to fingerprint identification and anti-counterfeiting methods, devices and electronic equipment. The fingerprint identification device is arranged under the display screen of the electronic device, and the fingerprint detection area of the display screen includes a central area and a surrounding area that do not overlap with each other. The fingerprint identification device includes: an optical path guiding structure for guiding the return optical signal sensor, the return light signal is the light signal returned after the light emitted by the light-emitting display pixels in the fingerprint detection area irradiates the finger, the light-emitting display pixels in the central area emit monochromatic light to illuminate the finger, and the light-emitting display pixels in the surrounding area emit a variety of colors of light that are spatially spaced apart to irradiate the finger; the optical sensor is used to receive the light signal passing through the light path guiding structure to obtain the fingerprint image of the finger, and the central part of the fingerprint image corresponding to the central area is used for For fingerprint identification, the surrounding part corresponding to the surrounding area in the fingerprint image is used for fingerprint anti-counterfeiting authentication.

Owner:SHENZHEN GOODIX TECH CO LTD

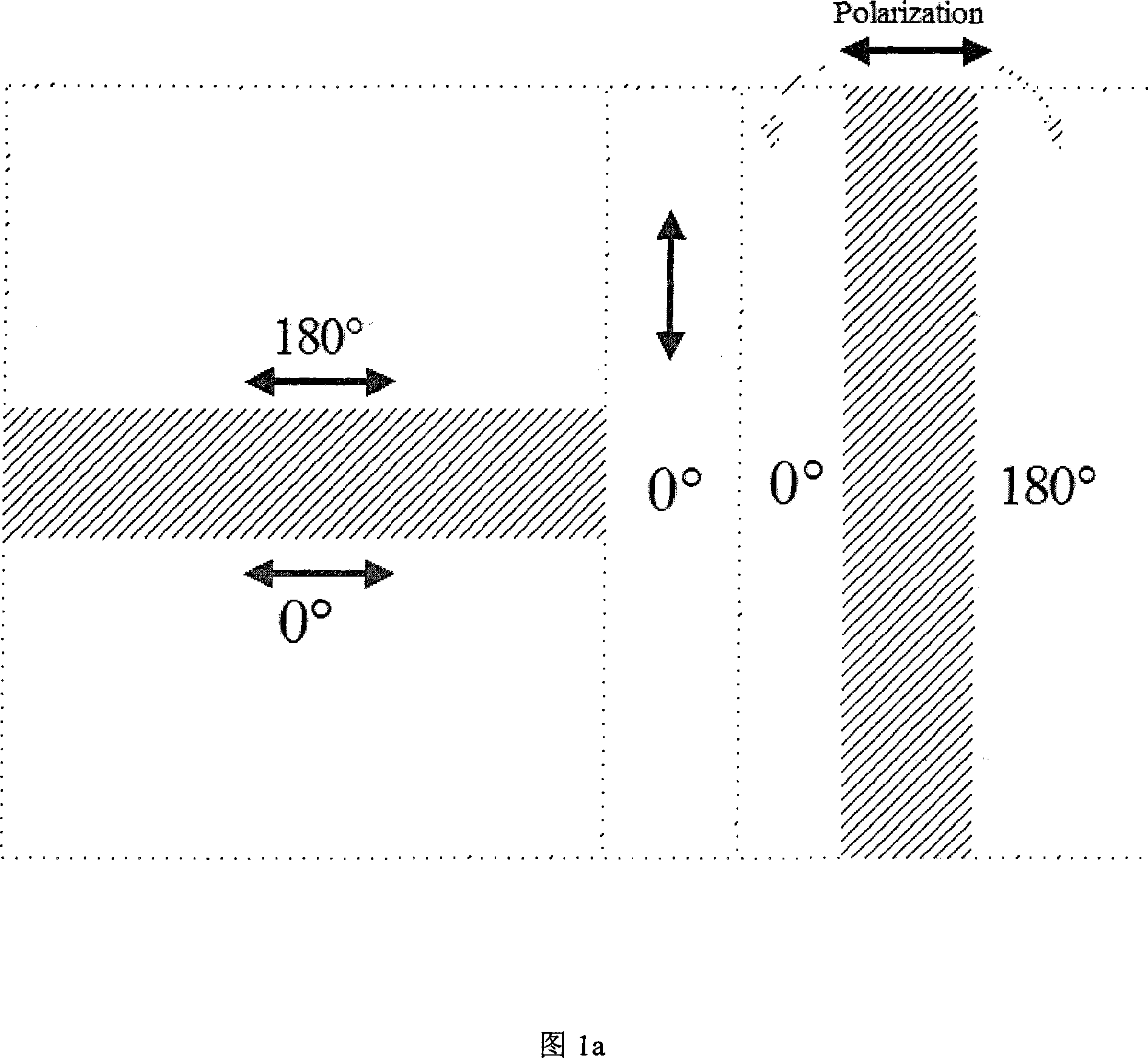

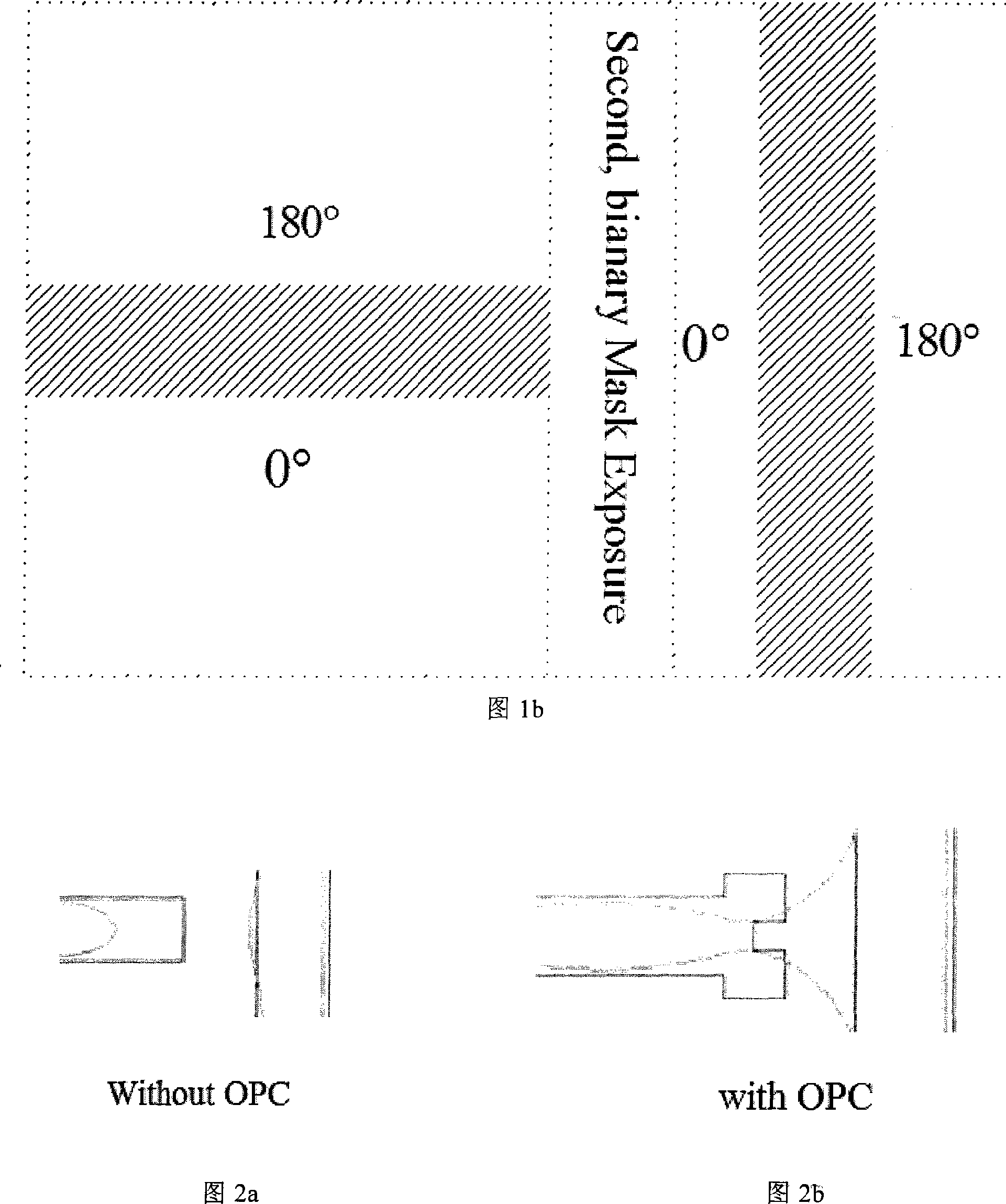

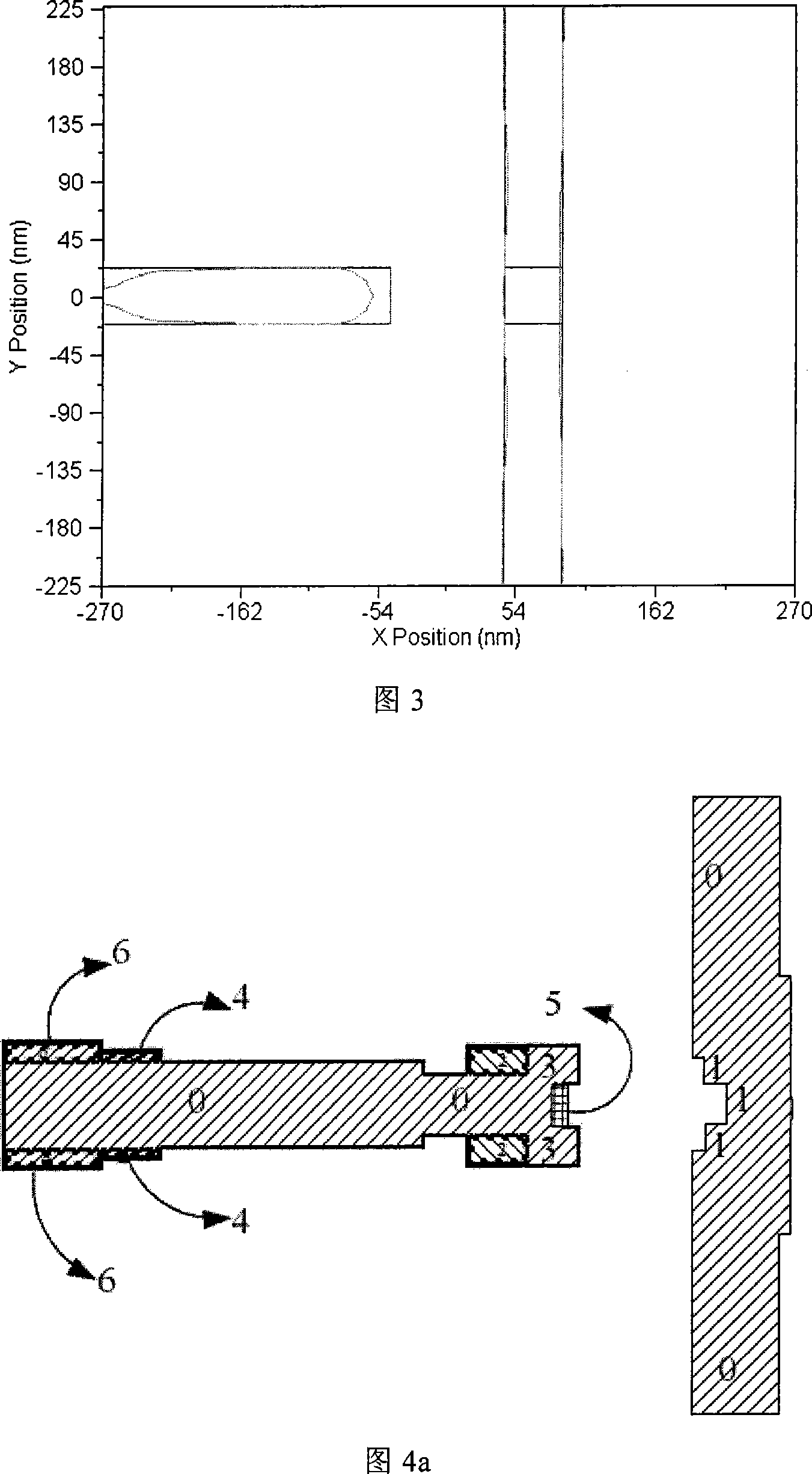

Photoetching system mask proximity effect correction method

InactiveCN101144976AImprove fidelityImprove image contrastOriginals for photomechanical treatmentPhase shiftedButt joint

A mask proximity effect correction method for a lithography system. First, find out the distortion of the final pattern on the silicon wafer compared with the mask design pattern, and correct it according to the proximity effect at the corresponding position of the mask pattern according to the position of the distorted pattern. The method to pre-segment and add the mask graphics: add serifs at the junction of X and Y graphics, and add non-transparent proximity effect correction graphics with 180-degree phase shift on both sides of the serifs, together Constitute the preliminary framework of phase-shift proximity effect correction; then observe the exposure result after adding phase-shift proximity effect correction through lithography simulation method, and according to the exposure result, use simulation software to measure the error between the exposure result and the expected pattern, according to This error adjusts the size, transmittance and other related parameters of the phase-shift proximity effect correction on the reticle until the error between the developed pattern on the silicon wafer and the original design pattern of the reticle is less than the allowable limit of ±10% deviation in industrial lithography .

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

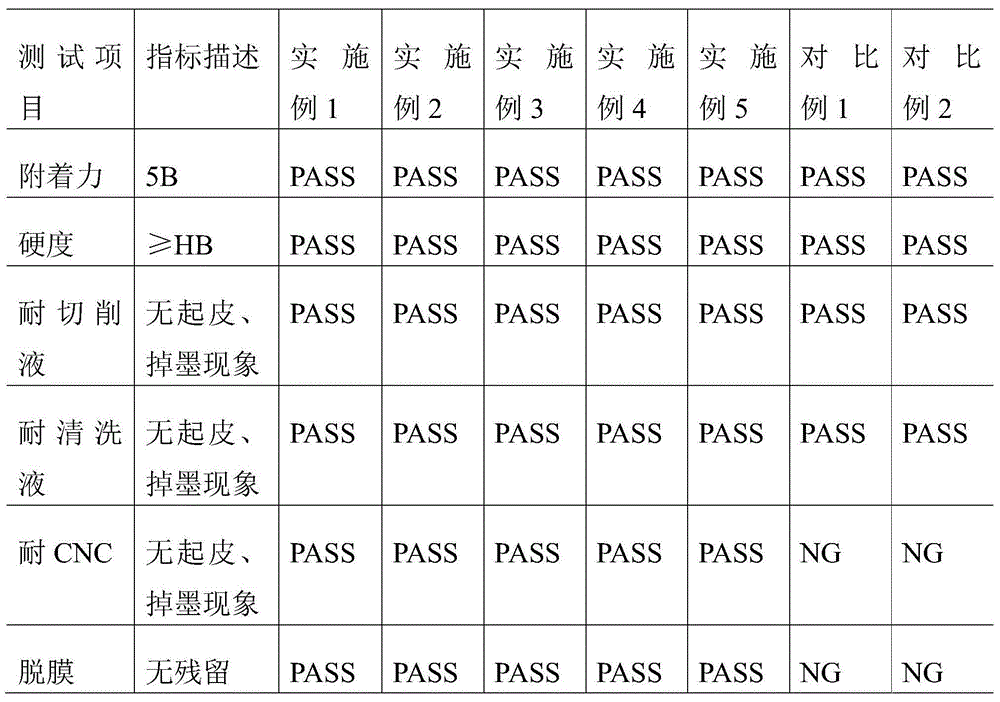

Ultraviolet curing full-shielding protection printing ink

The invention provides an ultraviolet curing full-shielding protection printing ink, by taking total weight of a printing ink composition as a reference, the ultraviolet curing anti-sandblasting shielding protection printing ink comprises the following components by weight percentage: 40-70% of low polymer, 0.5-25% of active monomer, 3-5 parts of initiator and 15-30% of filling material; wherein the low polymer is acrylate resin derived from ester long-chain polyhydric alcohols. The printing ink has the advantages of simple operation, high efficiency, CNC resistance, scratch resistance, easy stripping, no residues after film-stripping, and no base material corrosion; is suitable for metal base material and plastic cement base material, and is especially suitable for a metal and plastic cement-embedded composite base material.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

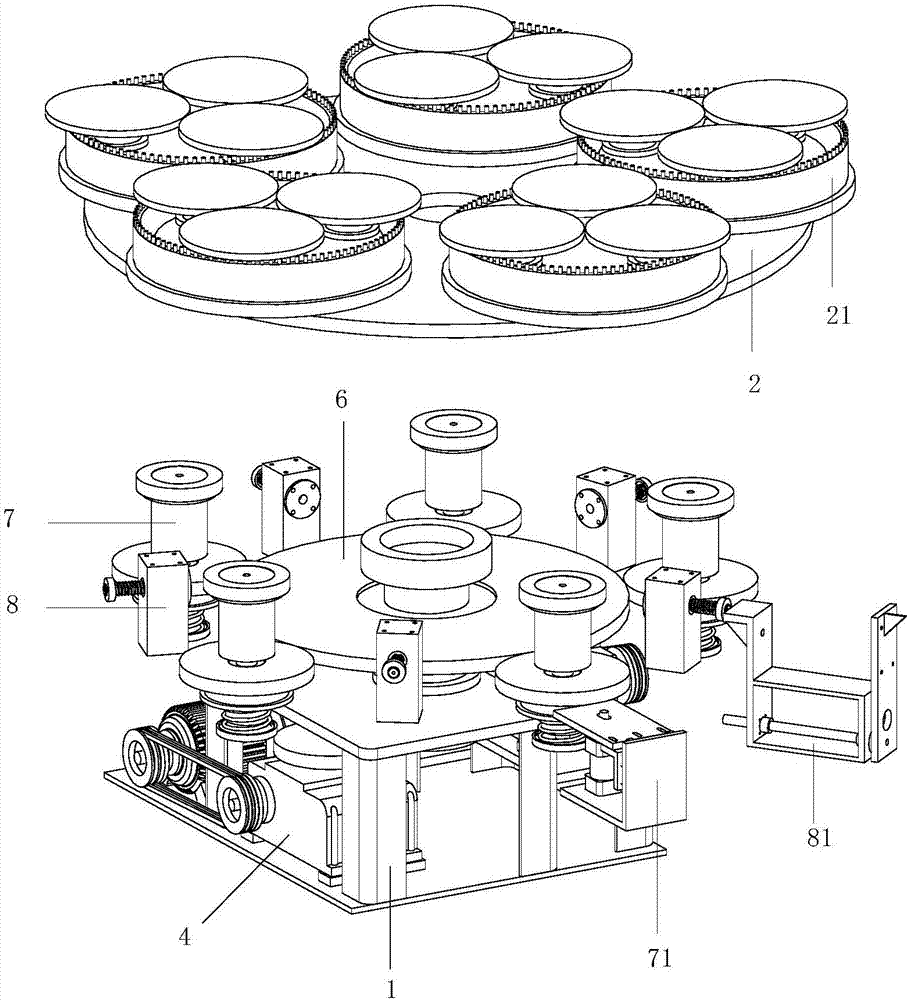

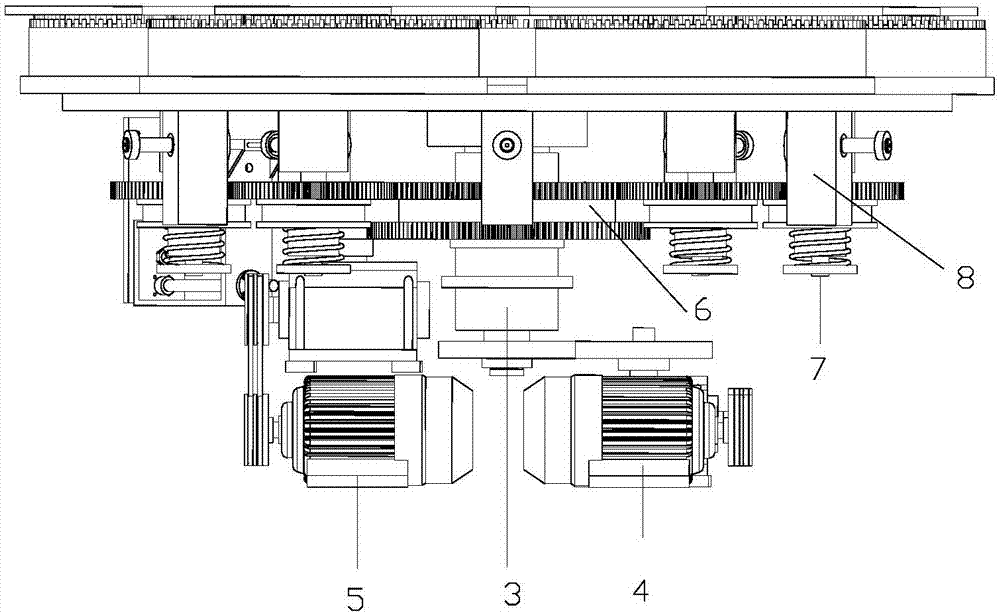

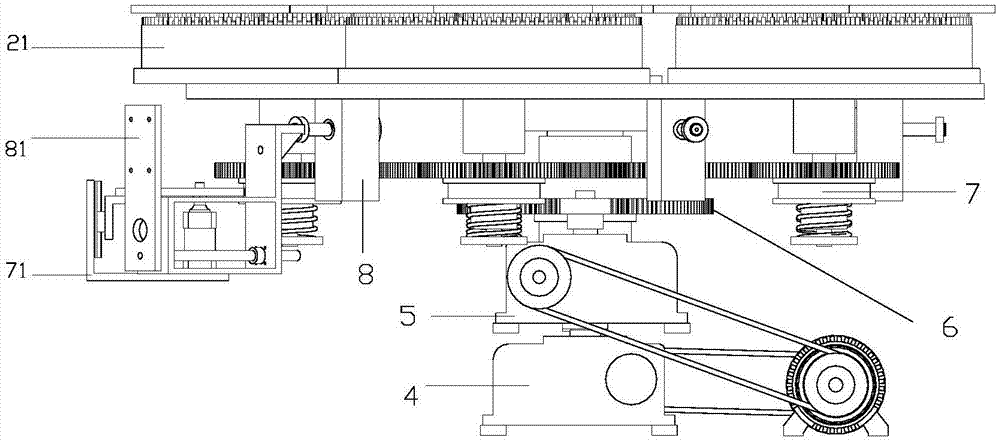

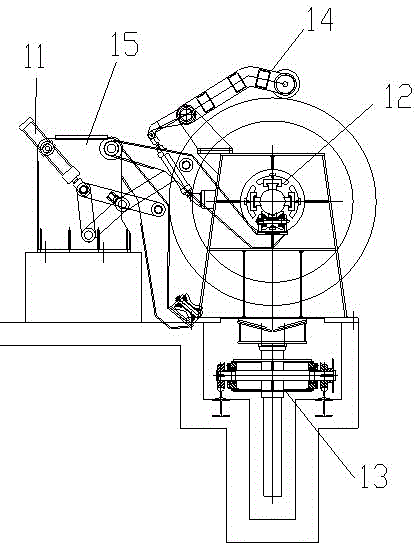

Intelligent multi-work-section hook face polishing machine

ActiveCN107322452AIncrease the number ofImprove processing efficiencyPolishing machinesGrinding drivesEngineeringMachining

The invention discloses an intelligent multi-work-section hook face polishing machine. The intelligent multi-work-section hook face polishing machine comprises a work disc, a first transmission assembly, a second transmission assembly and a plurality of rotation stop control devices. The first transmission assembly is arranged at the bottom of the work disc and drives the work disc to rotate around the axis of the work disc. A plurality of self-rotation assemblies are arranged on the periphery of the upper surface of the work disc. The second transmission assembly penetrates the work disc and is connected with the self-rotation assemblies, and the second transmission assembly drives the self-rotation assemblies to rotate around the axes of the self-rotation assemblies. The multiple rotation stop control devices are arranged on the second transmission assembly and control the target self-rotation assembly to stop rotating. According to the intelligent multi-work-section hook face polishing machine, through the manner of self-rotation and revolution, multi-level rotation and simultaneous multi-work-section machining of products are achieved. When workpieces are matched, the intelligent multi-work-section hook face polishing machine can firmly adsorb the workpieces, stop control can be conducted on the target self-rotation assembly without influencing machining of other self-rotation assemblies, and the workpiece machining efficiency is improved.

Owner:SHENZHEN XIKEO IND CO LTD

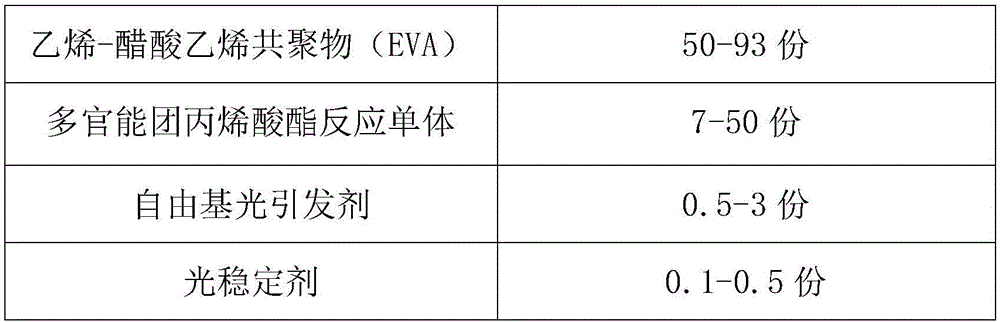

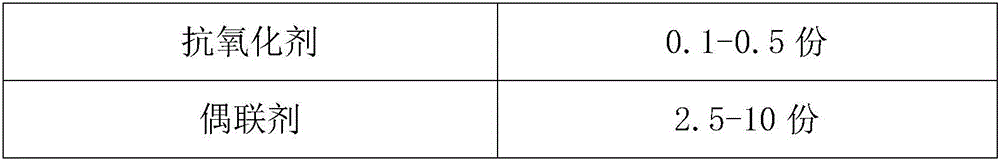

UV crosslinking and curing acrylic ester-modified EVA optical adhesive film and preparation method thereof

InactiveCN106147633ASimple processImprove Lamination Production EfficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesWeather resistanceWater vapor

The invention provides a UV crosslinking and curing acrylate modified EVA optical adhesive film and a preparation method thereof. The EVA optical adhesive film is prepared from the following raw materials in parts by weight: 50-93 parts of ethylene-vinyl acetate copolymer, 7-50 parts of multifunctional acrylate reactive monomer, 0.5-3 parts of free radical photoinitiator, photostable 0.1-0.5 part of anti-oxidant, 0.1-0.5 part of antioxidant, 2.5-10 part of coupling agent. The EVA optical adhesive film not only has the characteristics of simple lamination process, can be reworked, improves production efficiency, reduces defective rate and production cost, but also has excellent mechanical properties, water vapor barrier properties, heat resistance and stability, and other weather resistance.

Owner:SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

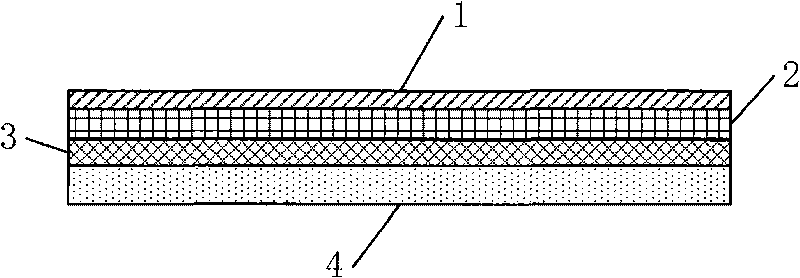

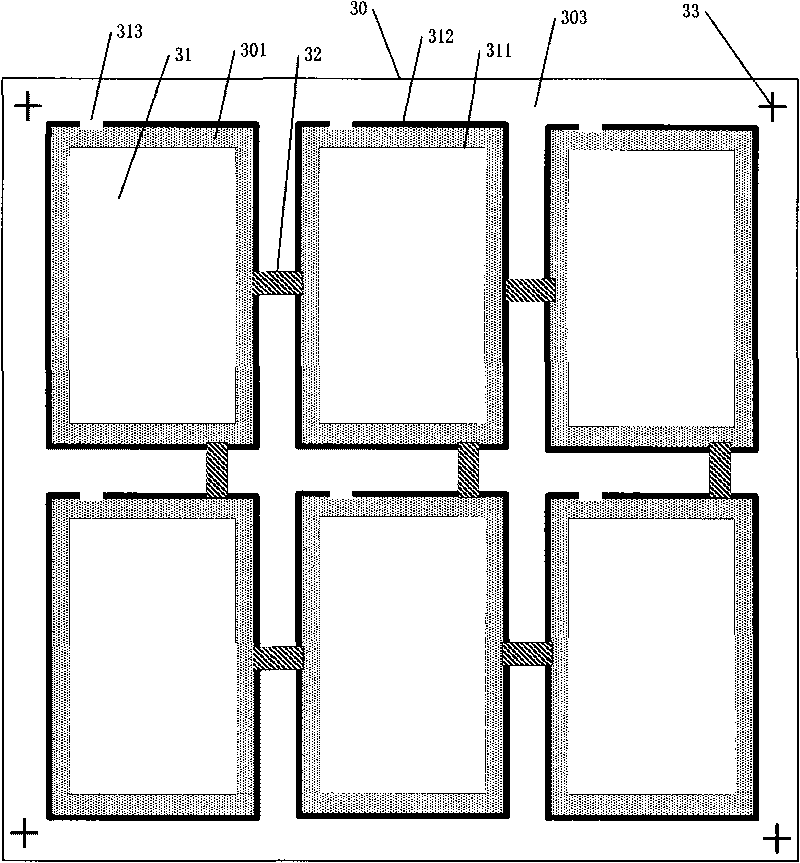

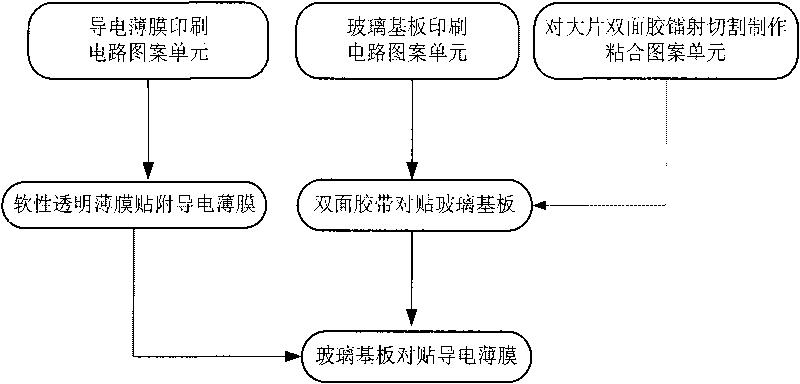

Improved sticking touch control panel body and manufacture method thereof

ActiveCN101719034AImprove efficiencySave man hoursInput/output processes for data processingThin membraneIndustrial engineering

The invention discloses an improved sticking touch control panel body and a manufacture method thereof, belonging to the technical field of sticking procedures for manufacturing touch control panel bodies. Release paper is rapidly torn at one step by adopting a large double sticky tape as a sticking medium and mounting a plurality of sticking pattern units formed by connecting sections, and the surface of a semi-finished product after all touch control panel bodies are cut and a soft transparent film are integrally moulded; and the great improvement of productivity, manufacture efficiency and quality qualified rate is realized in the most important sticking procedure.

Owner:牧东光电科技有限公司

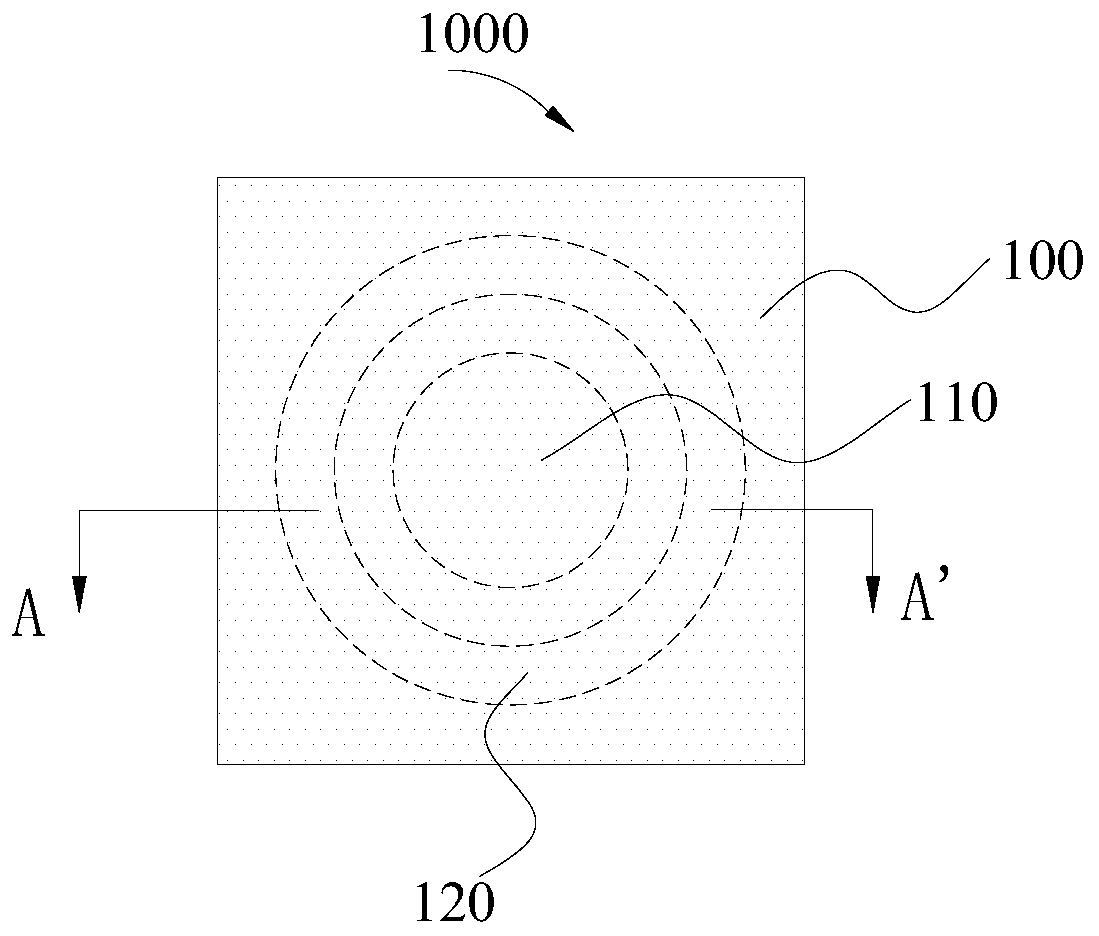

Camera lens and preparation method thereof, camera assembly and electronic equipment

InactiveCN110719393ADoes not affect shootingAvoid light transmissionTelevision system detailsColor television detailsCamera lensEngineering

The invention discloses a camera lens and a preparation method thereof, a camera assembly and electronic equipment. Specifically, the invention provides a camera lens, which comprises: a substrate, wherein the substrate is provided with a window area and a texture area arranged around the window area; an appearance membrane which is attached to one side of the base plate and comprises; a substrateprovided with a first hollowed-out area, wherein the orthographic projection of the first hollowed-out area on the base plate covers the window area; a texture layer, wherein the texture layer is arranged on one side of the substrate, and the orthographic projection of the texture layer on the substrate at least covers the texture area; and a coating layer, wherein the coating layer is arranged on one side, far away from the substrate, of the texture layer. Therefore, the bonding strength between the appearance diaphragm and the substrate is relatively high, the texture effect of the camera lens is flashing, the texture layer is not easy to fall off, the appearance effect is good, the product yield is relatively high, and the production cost is relatively low.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

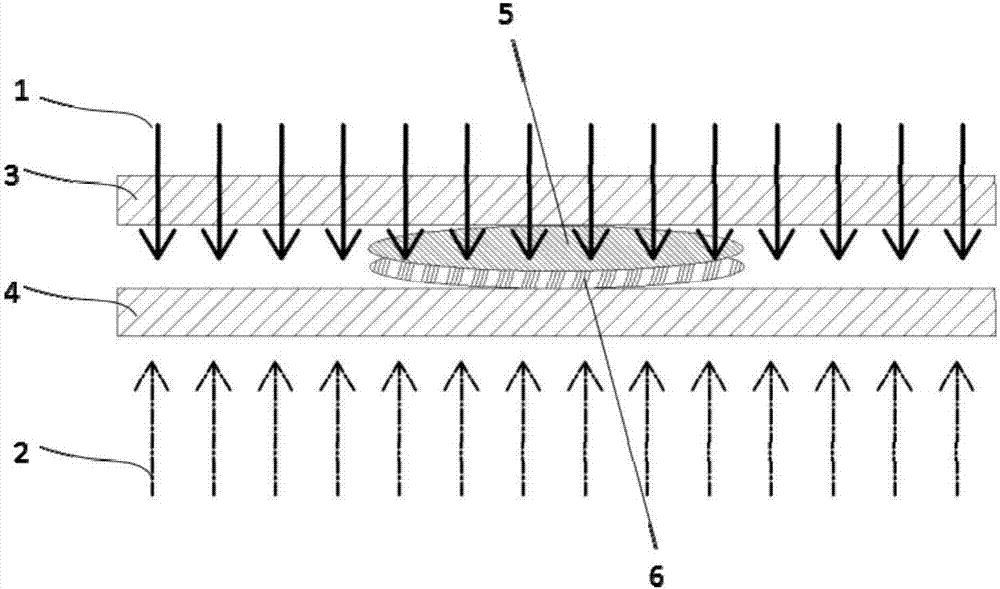

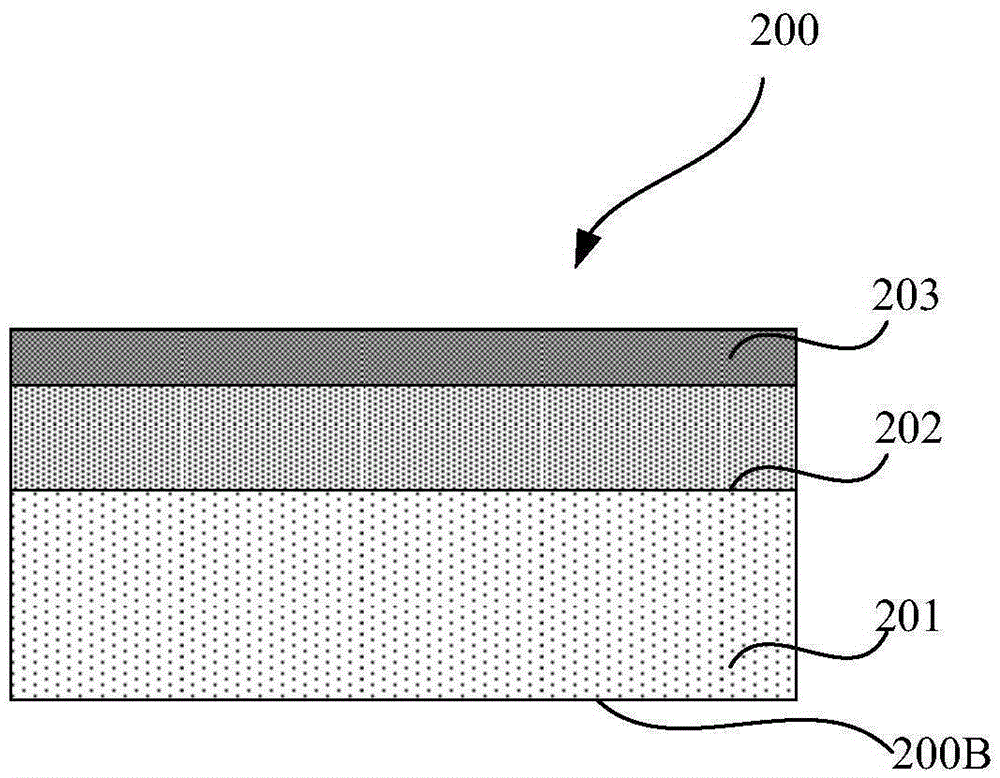

Method for improving hybrid bonding strength of wafers

InactiveCN107993927AHigh strengthLower yieldSemiconductor/solid-state device manufacturingUltimate tensile strengthBonding strength

The invention discloses a method for improving the hybrid bonding strength of wafers. The method is characterized by comprising the steps of providing wafers which need to be bonded; and aligning bonding interfaces of the wafers and carrying out a bonding technology and a thermal annealing technology on the wafers, wherein the wafers are subjected to hot pressing in the process of the bonding technology, and the wafers are further pressurized in the process of the thermal annealing technology. After the method disclosed by the invention is used, the hybrid bonding strength can be effectively improved, and the caused product yield loss and hidden danger of scrapping are reduced.

Owner:YANGTZE MEMORY TECH CO LTD

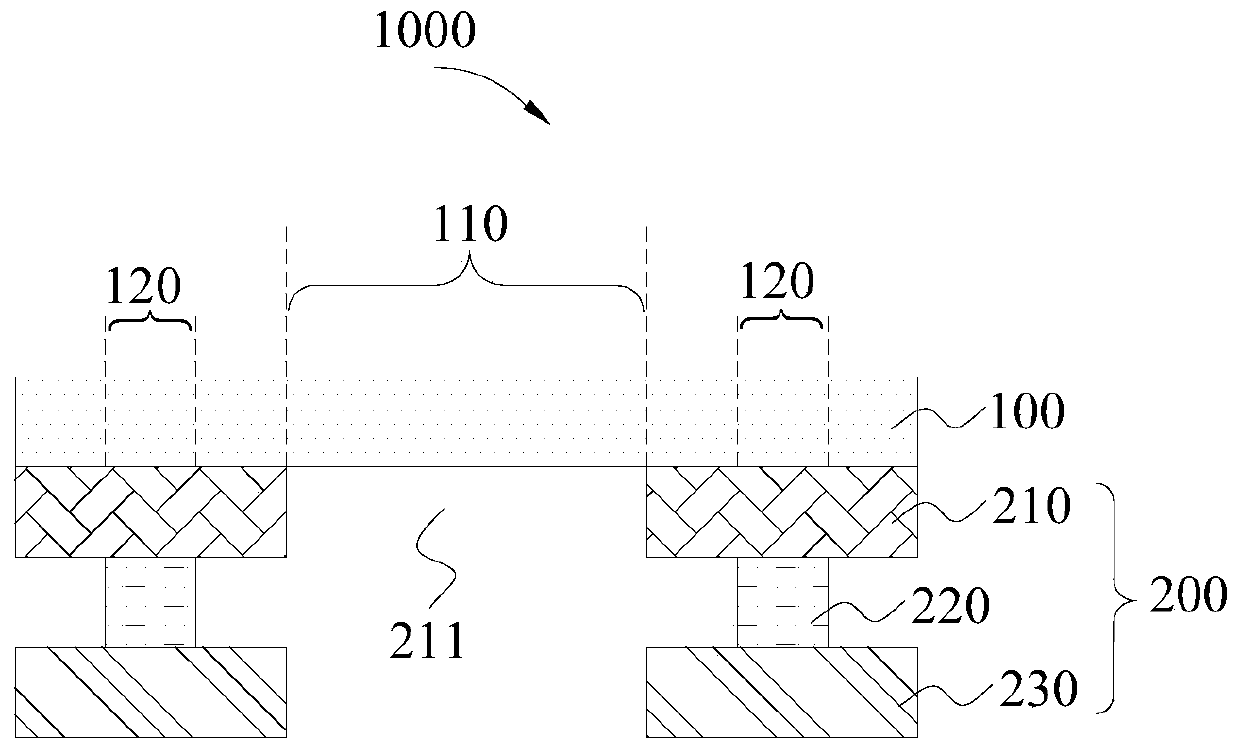

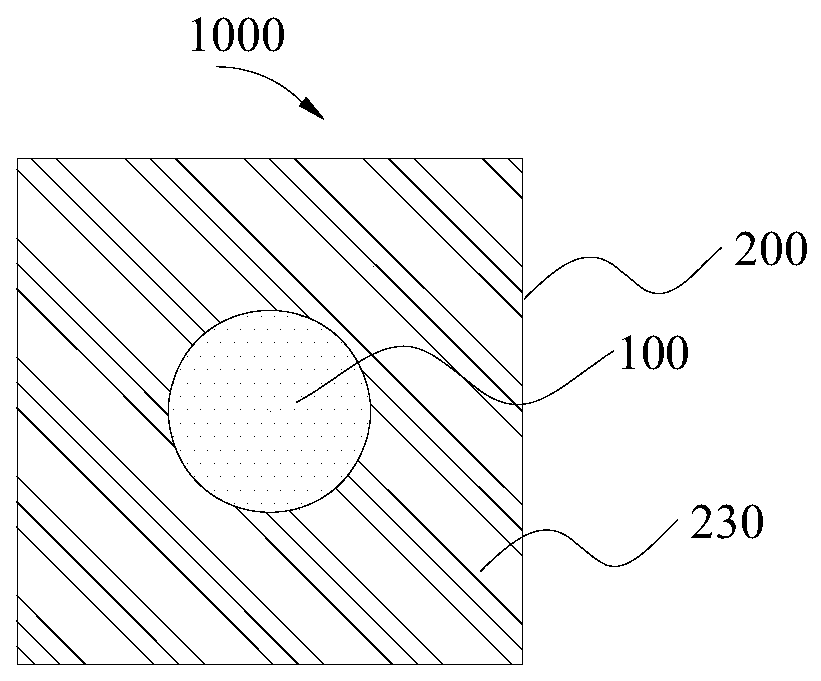

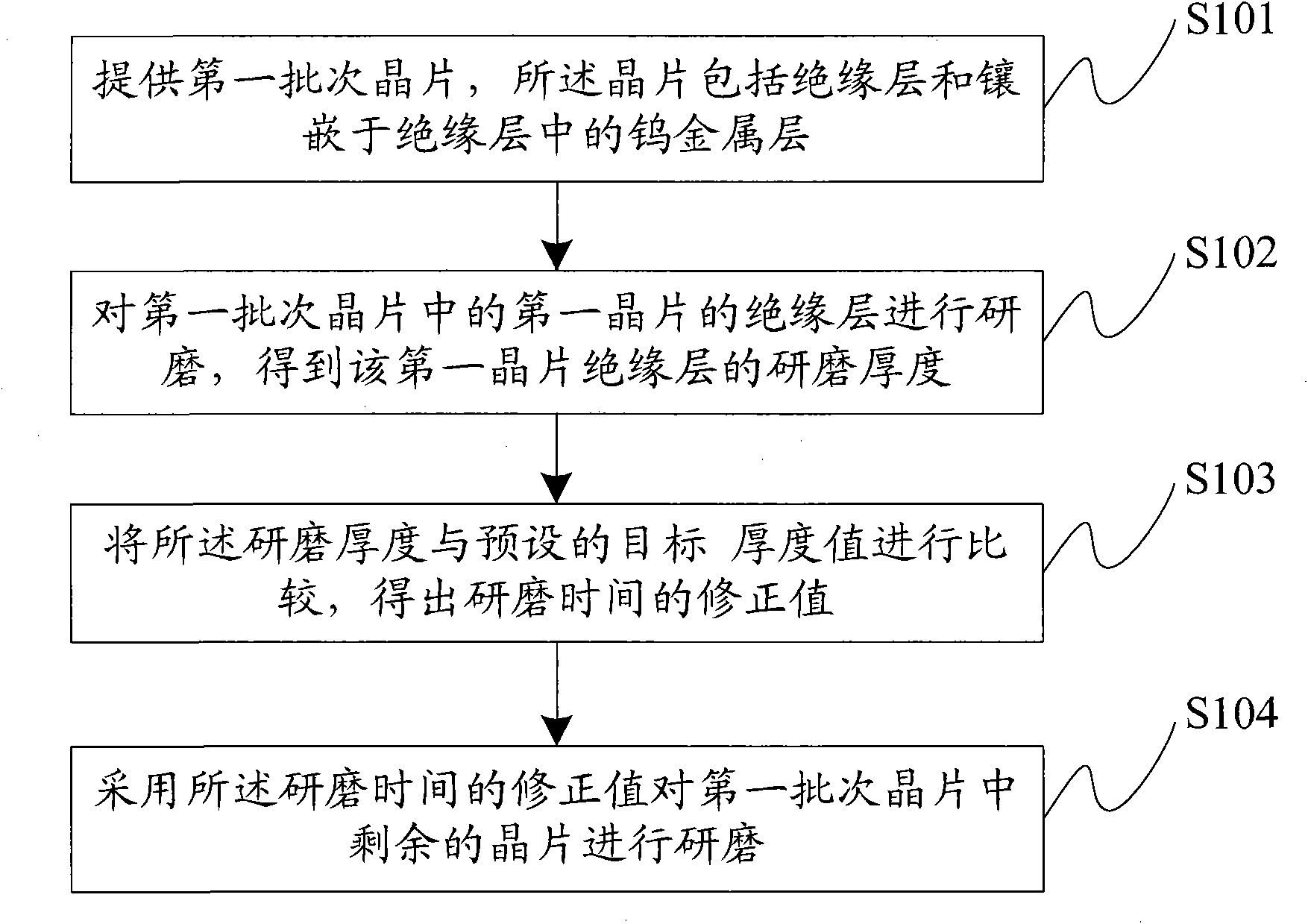

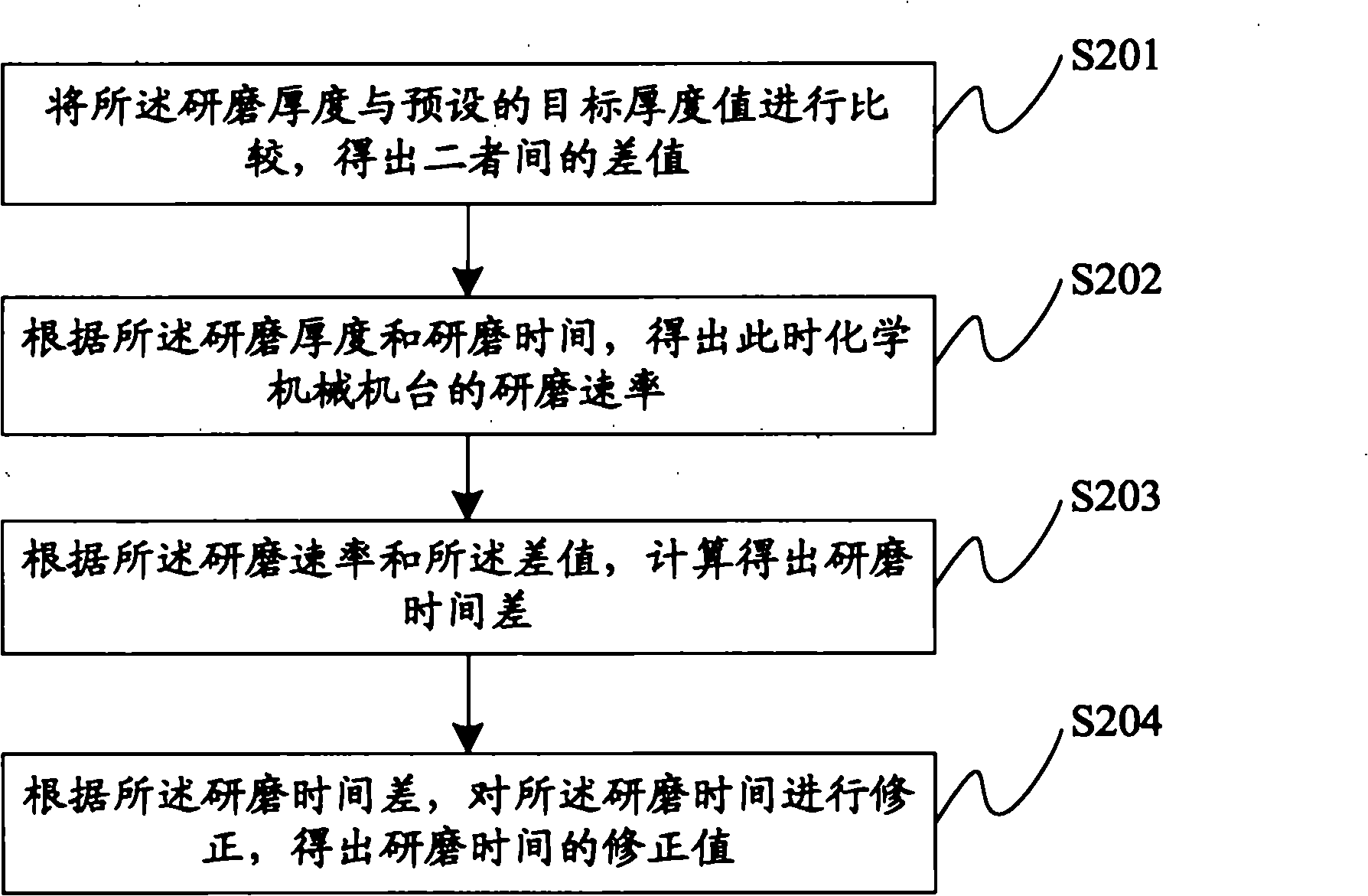

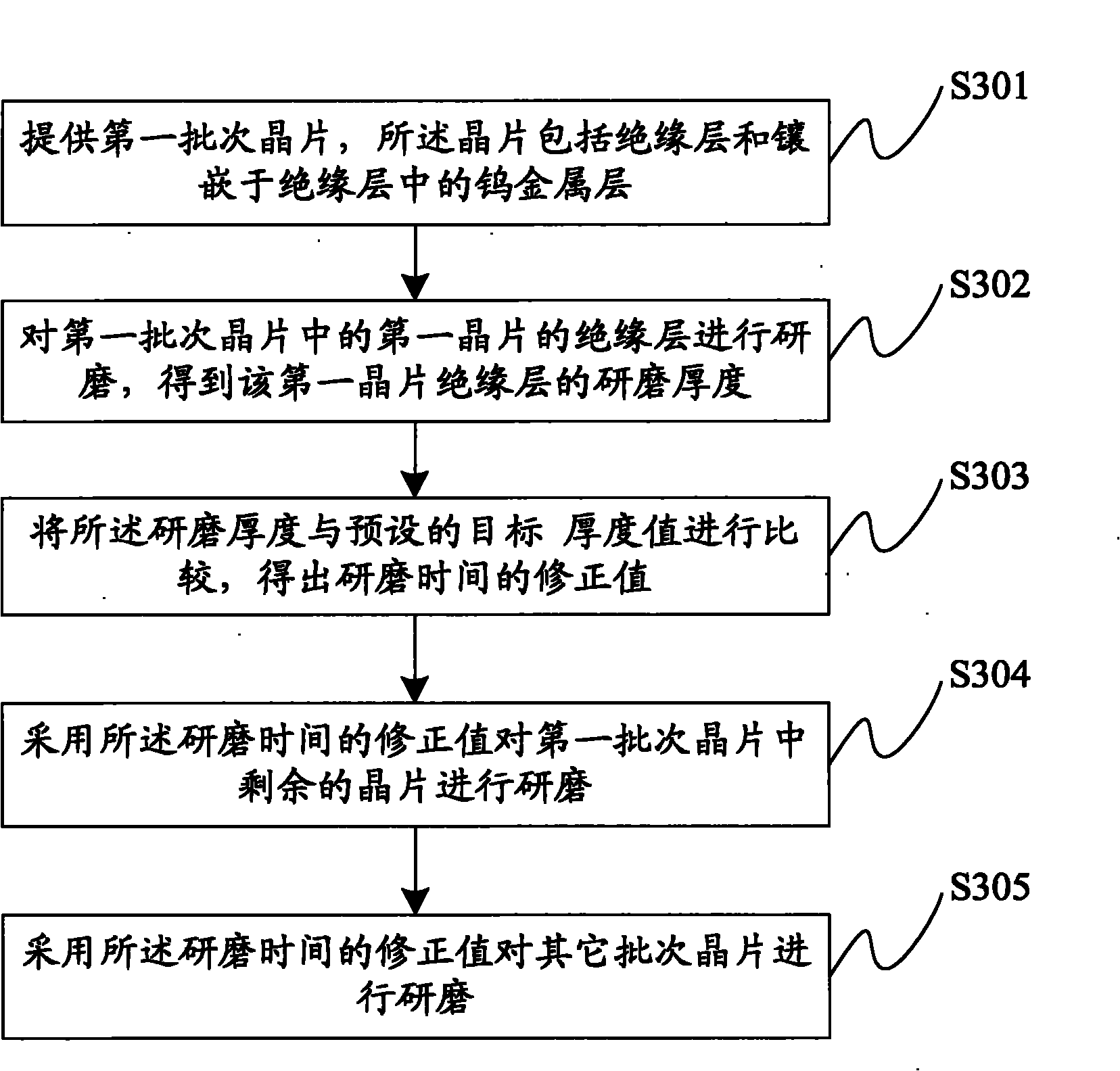

Chemical mechanical grinding method and chemical mechanical grinding system

InactiveCN102380815AReduce electricityLower yieldFinal product manufactureSemiconductor/solid-state device manufacturingSilicon oxideRejection rate

Embodiments of the invention provide a chemical mechanical grinding method and a chemical mechanical grinding system. The invention is used for chemically and mechanically grinding a silicon oxide insulating layer when tungsten is chemically and mechanically ground. The method comprises the steps of: providing a first batch of wafers, wherein each wafer comprises an insulating layer and a tungsten metal layer embedded in the insulating layer; grinding the insulating layer of a first wafer in the first batch of wafers to obtain the grinding thickness of the insulating layer of the first wafer; comparing the grinding thickness with a preset target thickness value so as to obtain a corrected value of the grinding time; and grinding the residual wafers in the first batch of wafers by adopting the corrected value of the grinding time. The embodiments introduce a time feedback mechanism to correct the grinding time of each batch of the products so as to lead the grinding thickness of each batch of the products to reach the target thickness value, thus the situation that electrical property and the yield of a chip are reduced as the difference value between the grinding thickness and the target thickness valve is overlarge is prevented, and the probability of the rejection rate is reduced.

Owner:CSMC TECH FAB1 +1

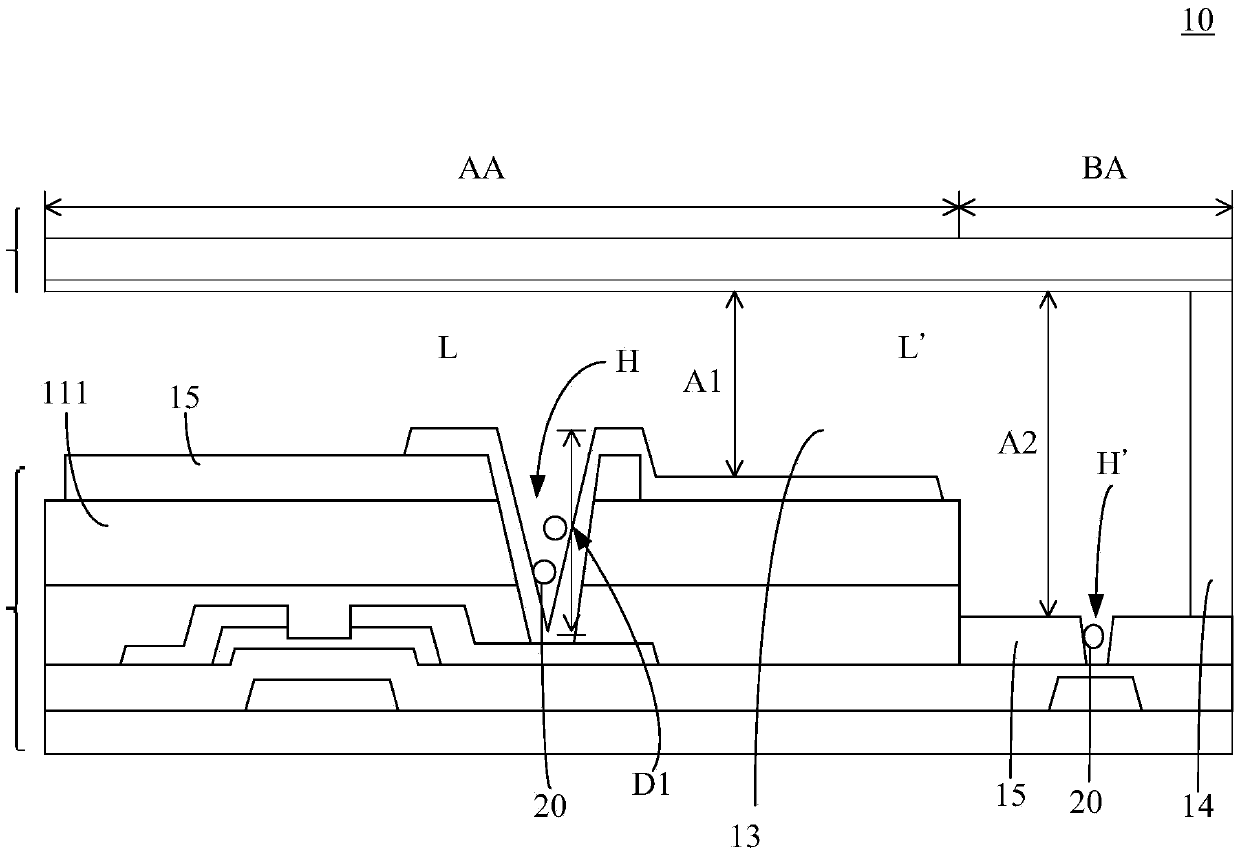

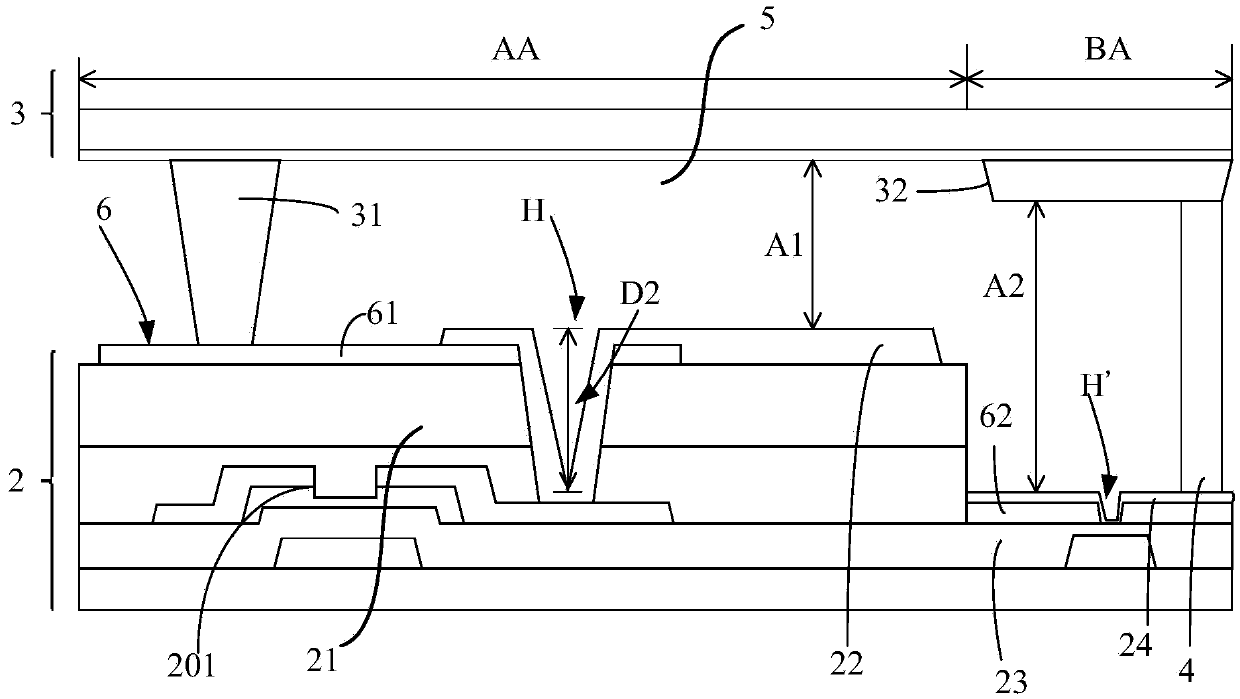

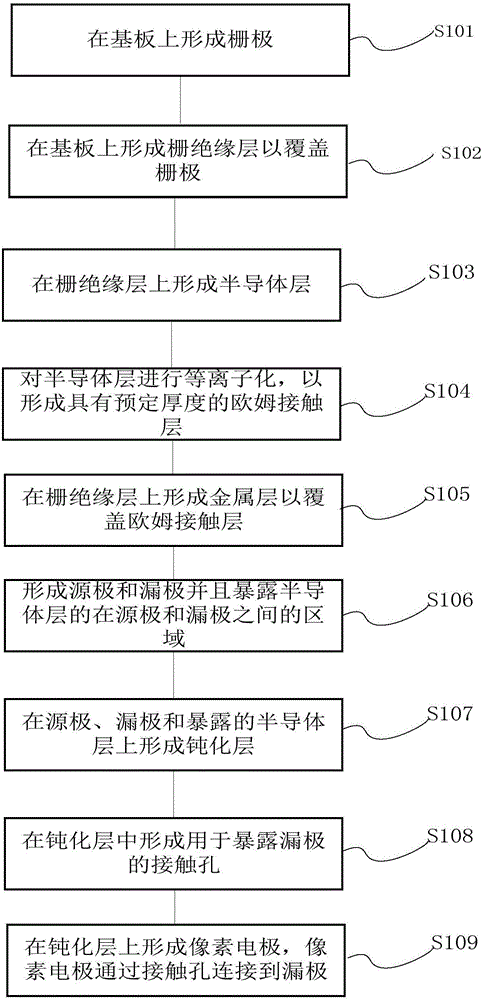

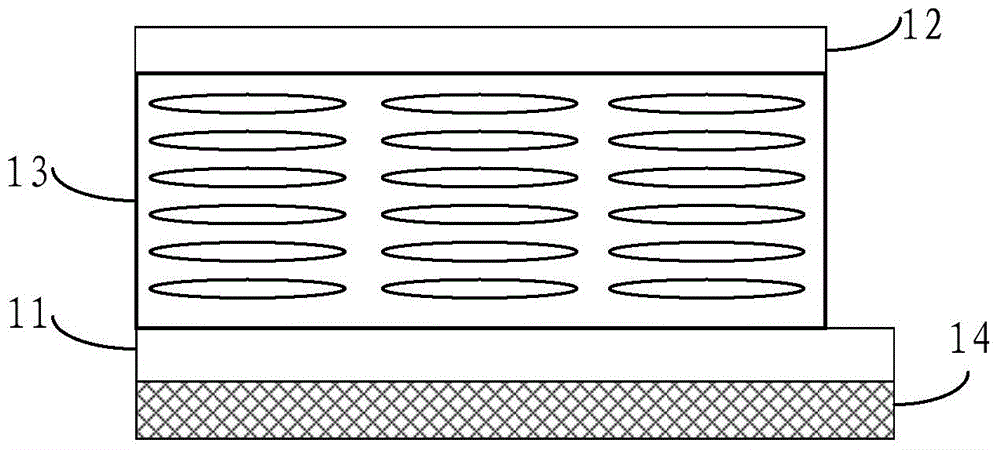

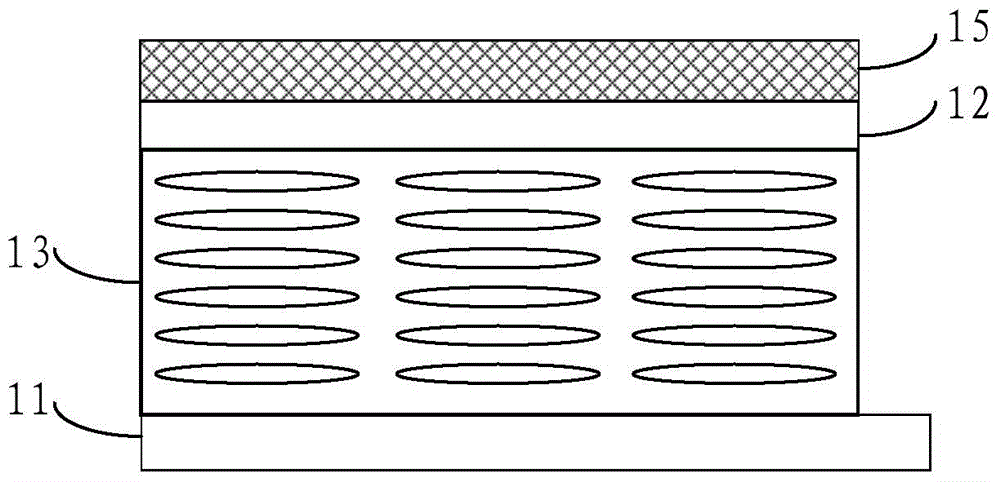

Liquid crystal display panel

ActiveCN105372866ALower yieldReduce quality problemsNon-linear opticsLiquid-crystal displayActive component

The invention discloses a liquid crystal display panel comprising an array substrate, an opposite substrate, frame sealant, a liquid crystal layer, and a black matrix layer. The array substrate has a display area and a non-display area, and the display area includes multiple active components and a color photoresist layer. The opposite substrate is arranged above the array substrate. The frame sealant is arranged between the array substrate and the opposite substrate, and surrounds the non-display area. The liquid crystal layer is configured between the array substrate and the opposite substrate. The black matrix layer is arranged on the array substrate, and is distributed corresponding to the display area and the non-display area. The liquid crystal display panel is characterized in that at least the black matrix layer distributed in the non-display area has a thickness smaller than or equal to 2 microns. Thus, the thickness of the black matrix layer is reduced, the depth of the via on the array substrate is reduced, and bubbling in the via is prevented.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

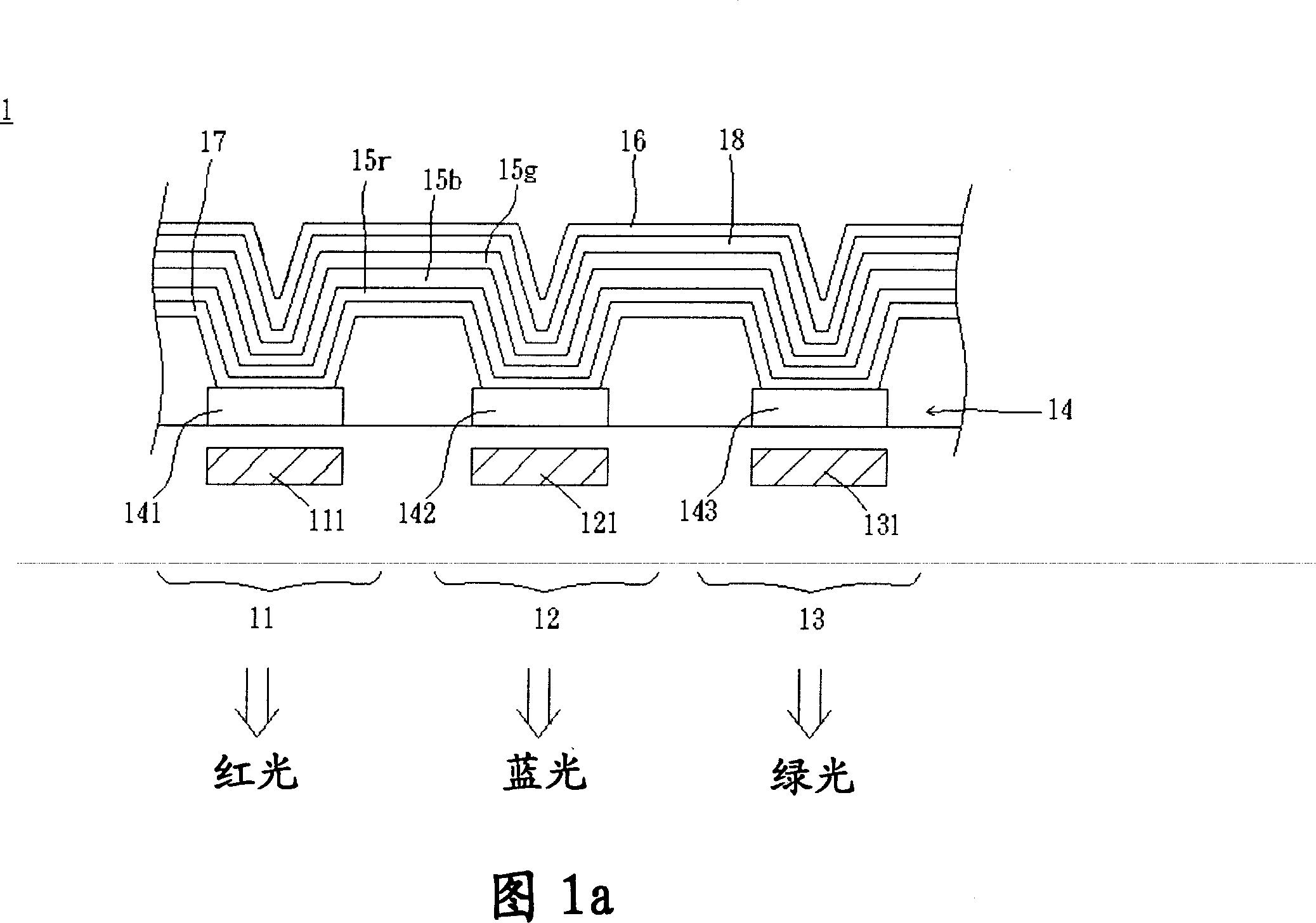

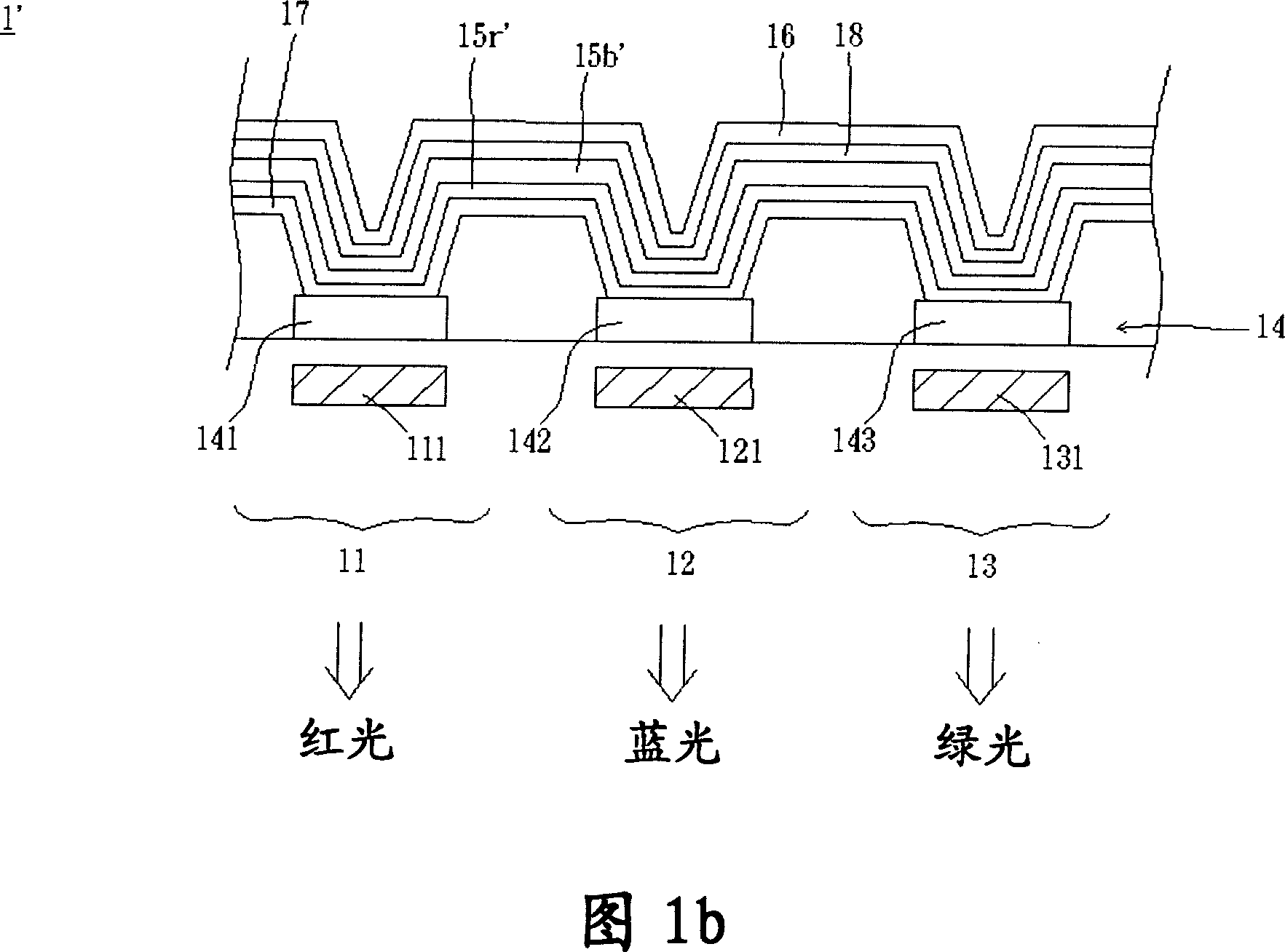

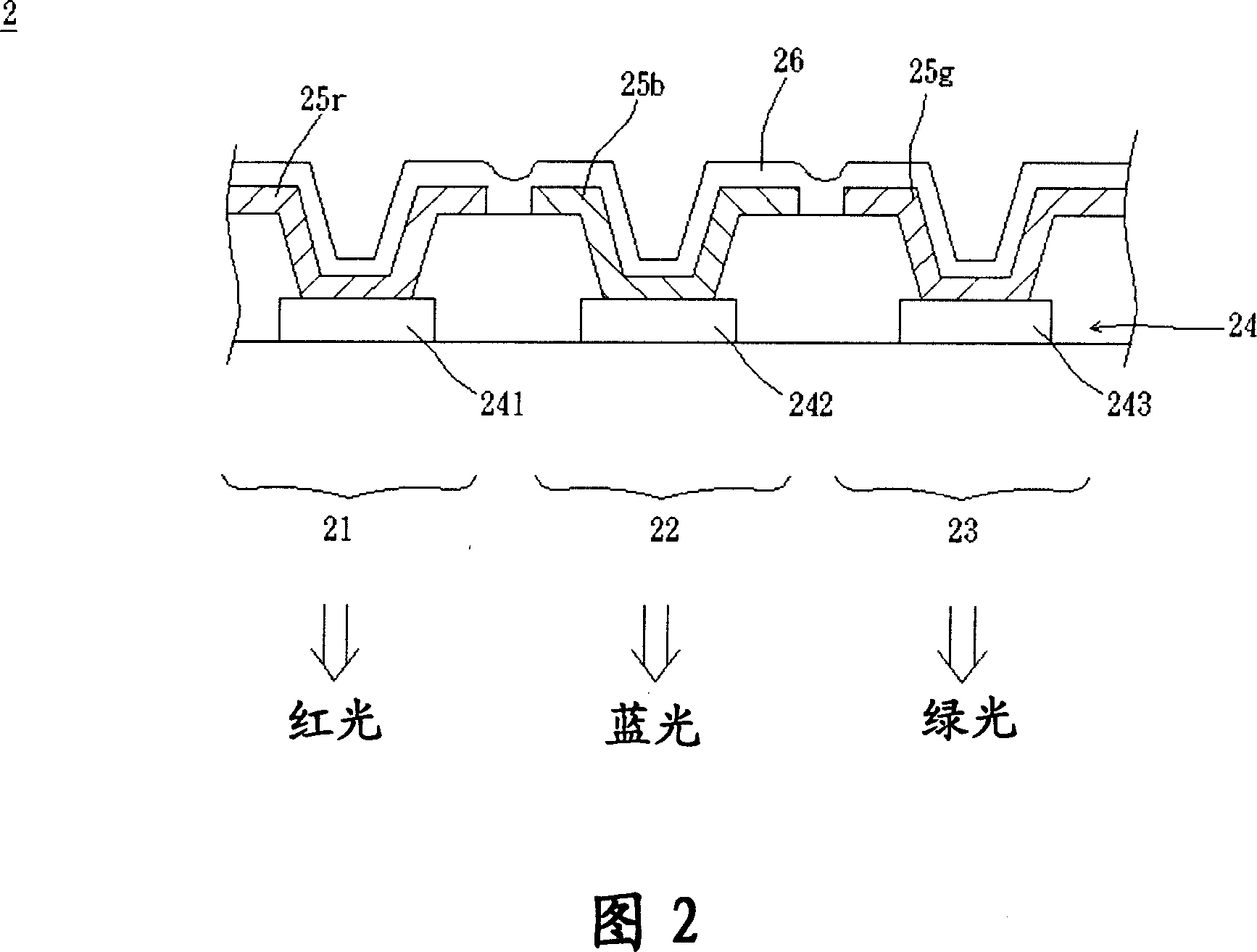

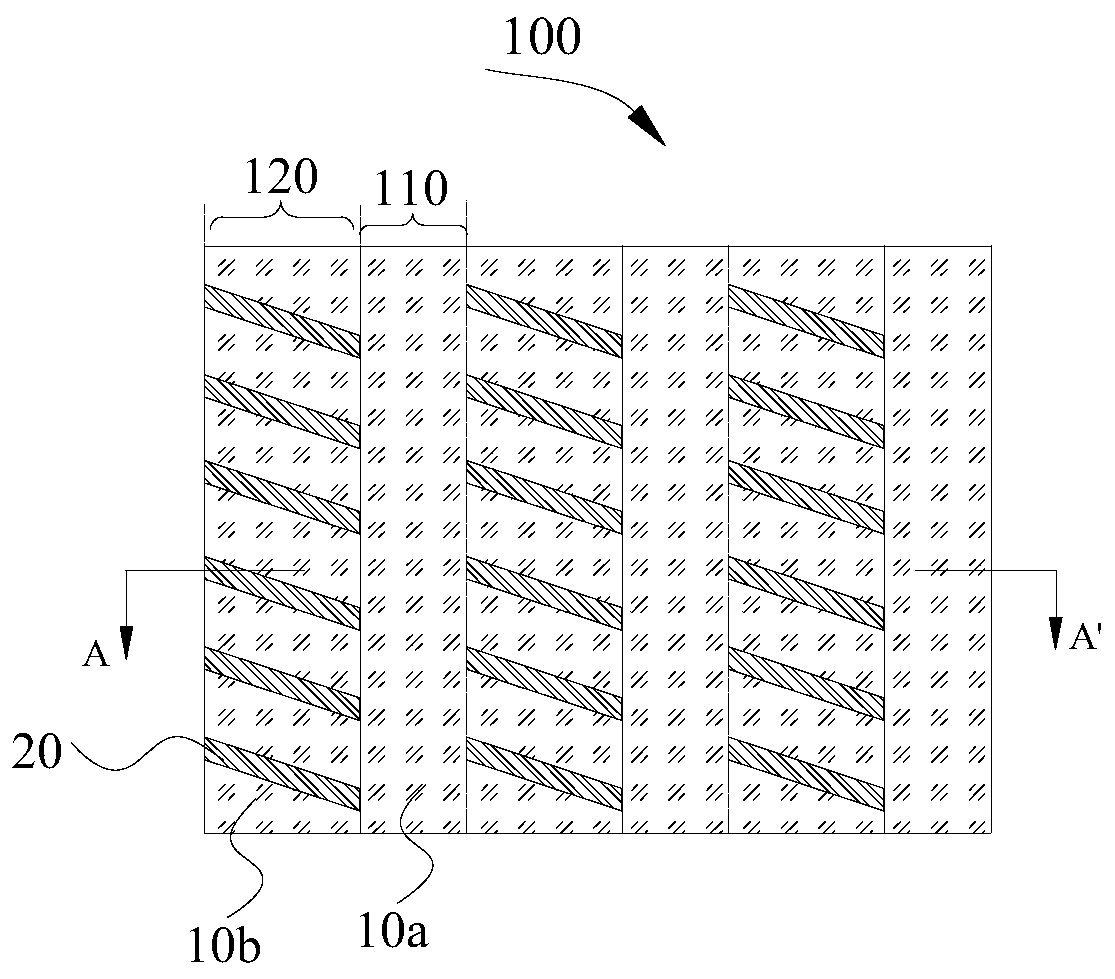

Display image system

InactiveCN101083275AImprove yieldImprove performanceSolid-state devicesSemiconductor devicesOptoelectronicsImage system

The invention relates to a video display system, comprising plural pixels, each having first, second and third organic light-emitting component and comprising a first electrode layer, a first organic light-emitting layer, a second organic light-emitting layer, a second electrode layer and a filtering component, where the first organic light-emitting layer is arranged on the first electrode layer and inside the first and second organic light-emitting components; the second organic light-emitting layer is arranged on the first electrode layer, and inside the second and third organic light-emitting components, so as to make the first and second organic light-emitting layers overlap in the second organic light-emitting component; the second electrode layer is arranged on the first organic light-emitting layer and the second one; the filtering component is arranged in the second organic light-emitting component.

Owner:INNOLUX CORP

Texture transferring female die, plate and preparation method thereof, shell and electronic equipment

ActiveCN111016415ALower yieldIncrease production costTransfer printingOrnamental structuresEngineeringTexture transfer

The invention discloses a texture transferring female die, a plate and a preparation method thereof, a shell and electronic equipment, and particularly provides a texture transferring female die. A first texture area and a second texture area which are alternately arranged at an interval are arranged on the texture transferring female die. The texture transferring female die comprises a first texture and a second texture. The texture shapes of the first texture and the second texture are not completely identical, the first texture is located in the first texture area and part of the second texture area, and the second texture is located in the second texture area. The first texture and the second texture in the second texture area are arranged at an interval. Thus, a texture transferring sub-die formed by the texture transferring female die can form the effect that multiple kinds of textures are combined and overlaid through a one-time UV transferring process, a texture layer with a rich texture combined and overlaid effect can be easily and conveniently prepared through the texture transferring female die, the preparation process is simple, and the production cost can be reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

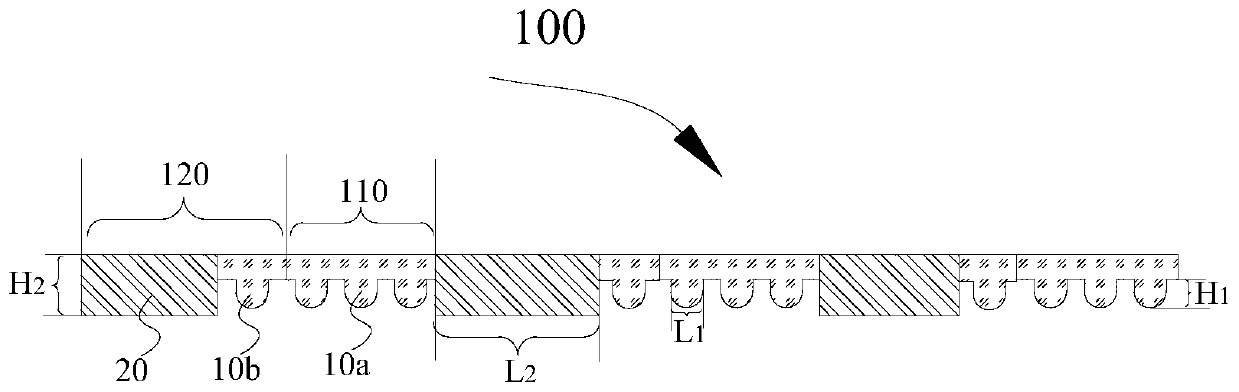

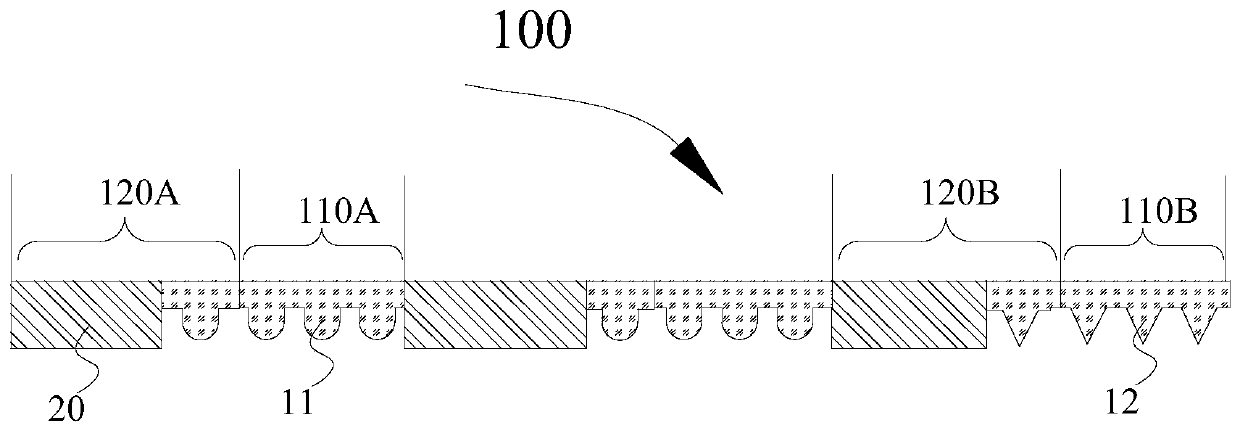

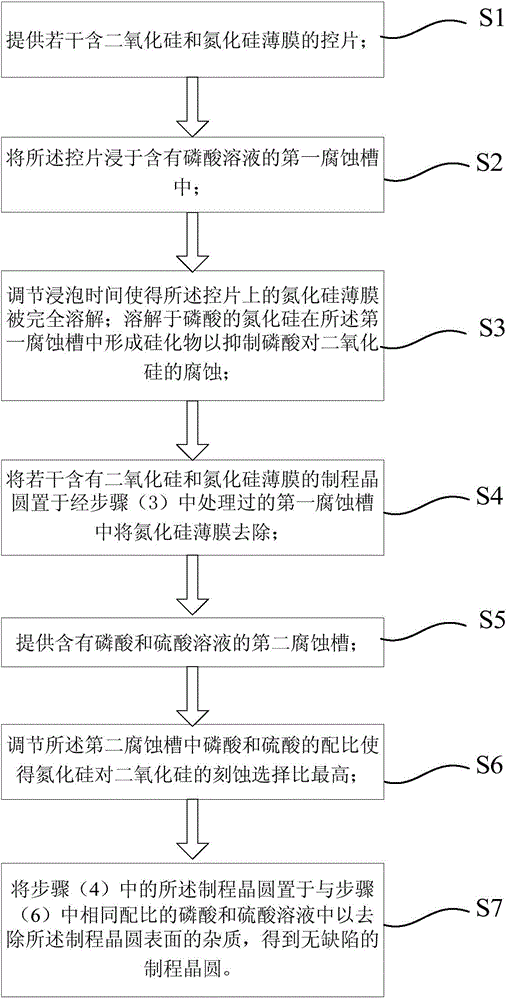

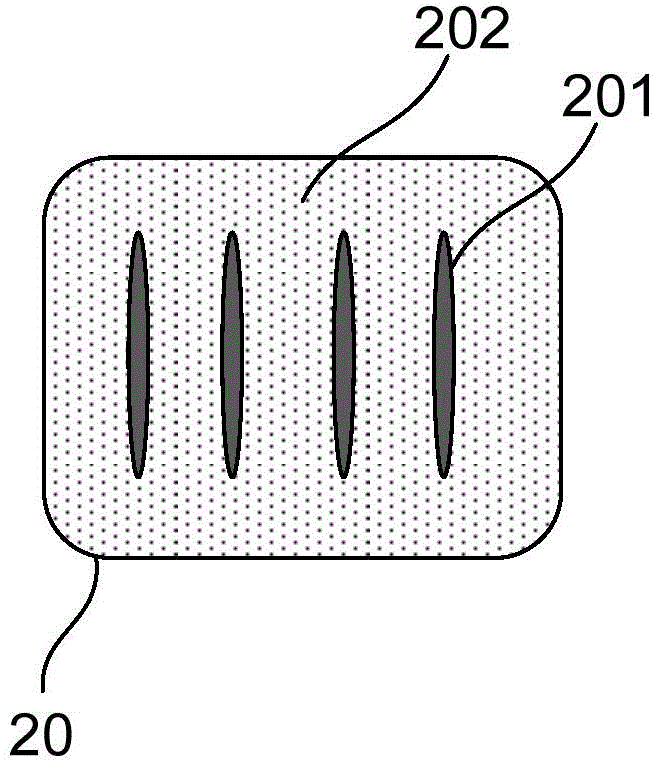

Method for eliminating wafer surface defect in wet etching

ActiveCN105575762AReduce manufacturing costLower yieldSemiconductor/solid-state device manufacturingSalicideEtching

The invention provides a method for eliminating a wafer surface defect in wet etching. A control wafer is used for replacing a processing wafer to manufacture a proper silicide-contained phosphoric acid solution, thereby reducing the production cost. A silicon nitride film of the control wafer reacts with the phosphoric acid solution to generate the silicide for inhibiting silicon dioxide corrosion, so that a problem of sound filed cost increasing because of adding the silicide into the phosphoric acid solution independently can be effectively solved. Impurities attached to the surface of the control wafer after silicon nitride corrosion are removed by using a mixed solution with phosphoric acid and sulfuric acid in a proper ratio; and impurities on the surface of the processing wafer are also removed by using a mixed solution with phosphoric acid and sulfuric acid in a same proper ratio, so that the product yield is effectively reduced under the circumstance that no defect exist on the wafer surface.

Owner:SEMICON MFG INT (SHANGHAI) CORP

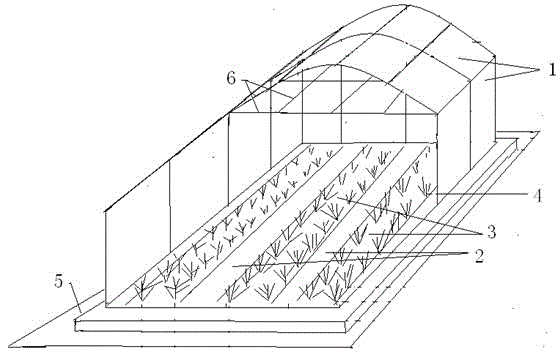

Breeding method and device for young tussah

InactiveCN102715135AReduce lossesSolve the problem that the silkworm reduction rate remains high in the young silkworm stageAnimal husbandryHabitSeedbed

The invention discloses a breeding method and a breeding device for young tussah. A greenhouse is built, hatching tree seedlings are planted in the greenhouse, and a hatching seedling bed is formed; after the fixed planting of the hatching tree seedlings, the hatching tree seedlings are bred into low-trunk tree forms, and 5 to 6 branches are left for each strain; graine is loaded into a kraft paper bag for hastening the hatching of silkworms, after the breakthrough of young silkworms, an opening of the kraft paper bag is opened, after the silkworm head tree climbing completion, the paper bag is removed, and the hatching is completed; the temperature in the greenhouse is maintained at 16 DEG C to 28 DEG C; the young silkworms are fed to 2 to 3 days at the molting of primary sleeping silkworms, and the silkworm heads are moved to a field silkworm plant for breeding outside cages before 9 o'clock in the morning or after 17 o'clock in the afternoon in sunny days. The young tussah is bred through adopting a mode of building three-dimensional breeding environment in rooms, the harm to the young tussah caused by natural environment and natural enemy can be effectively prevented, the labor work for picking and storing oak leaves is also avoided, the ventilation three-dimensional breeding environment is provided, the natural attributives of upward climbing habit, scattering habit and the like of the tussah are met, the disease rate of the silkworm body is reduced, the management requirement is reduced, the disease prevention difficulty and the cost are reduced.

Owner:GUIZHOU SERICULTURE RES INST GUIZHOU PEPPER RES INST

Vertically structured LED chip preparation method

InactiveCN105655452AImprove yieldImprove appearance yieldSemiconductor devicesOhmic contactEngineering

The invention discloses a vertically structured LED chip preparation method. The method comprises the steps of 1) obtaining an LED epitaxial layer of an LED structure on a heterogeneous substrate according to the epitaxial growth method; 2) forming multiple interlaced grooves on the upper surface of the LED epitaxial layer through the laser machining process so as to form a cylindrically surrounded gallium nitride high-pressure gas release sacrificial region; 3) successively preparing an ohmic contact layer and a first bonding material layer on the LED epitaxial layer, and preparing a second bonding material layer on a bonding substrate; 4) bonding the first bonding material layer on the LED epitaxial layer and the second bonding material layer on the bonding substrate together, and removing the heterogeneous substrate through the laser lift-off process; 5) etching the lifted-off LED epitaxial layer onto an N-GaN surface, removing the gallium nitride material outside the cylindrically surrounded gallium nitride high-pressure gas release sacrificial region and the effective region of the LED epitaxial layer based on the wet etching technology, and finally completing the preparation of a passivation layer and an N electrode. In this way, a vertically structured LED chip can be obtained.

Owner:XI AN JIAOTONG UNIV

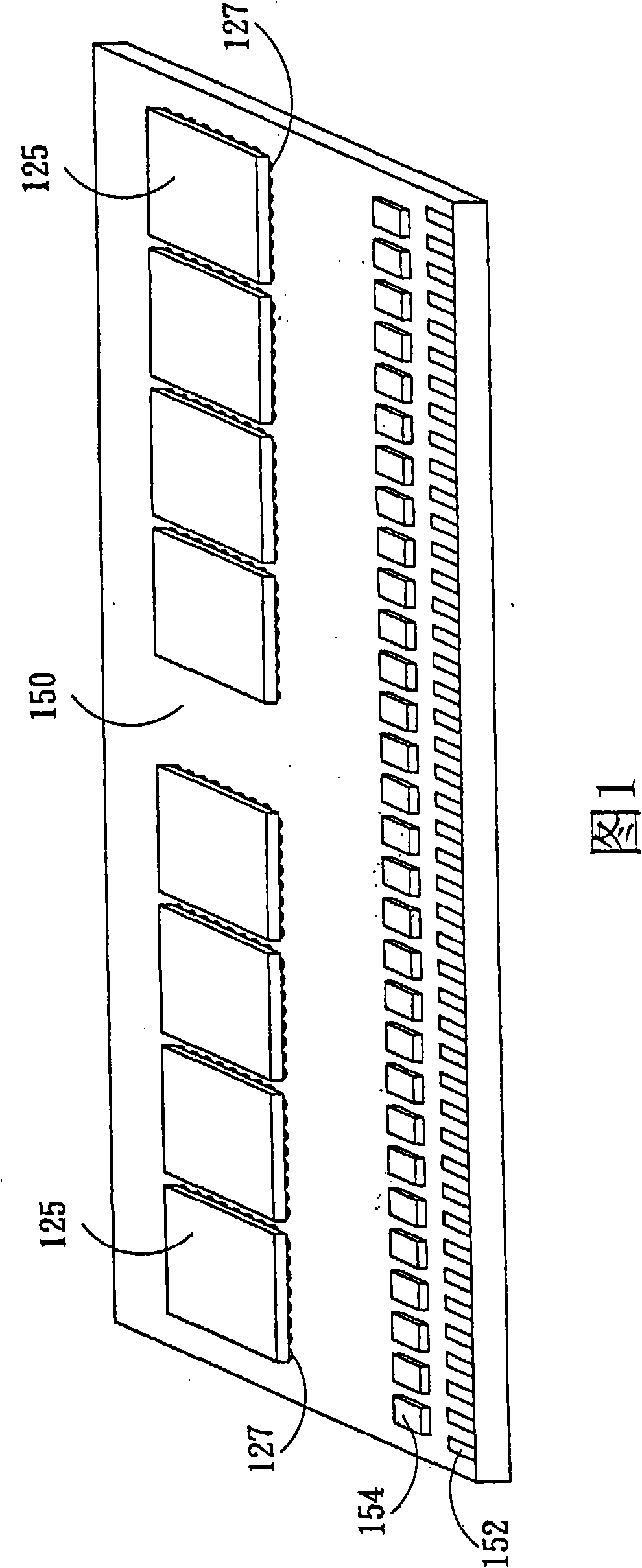

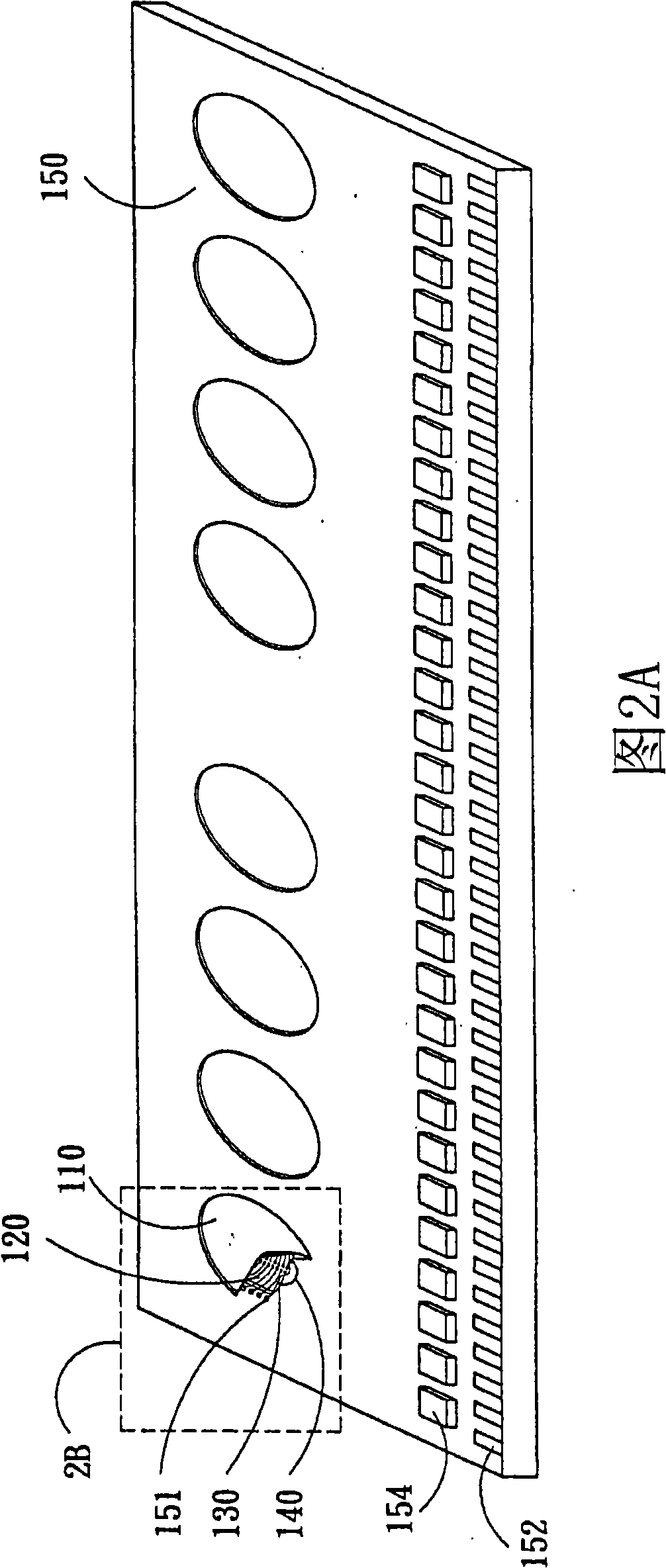

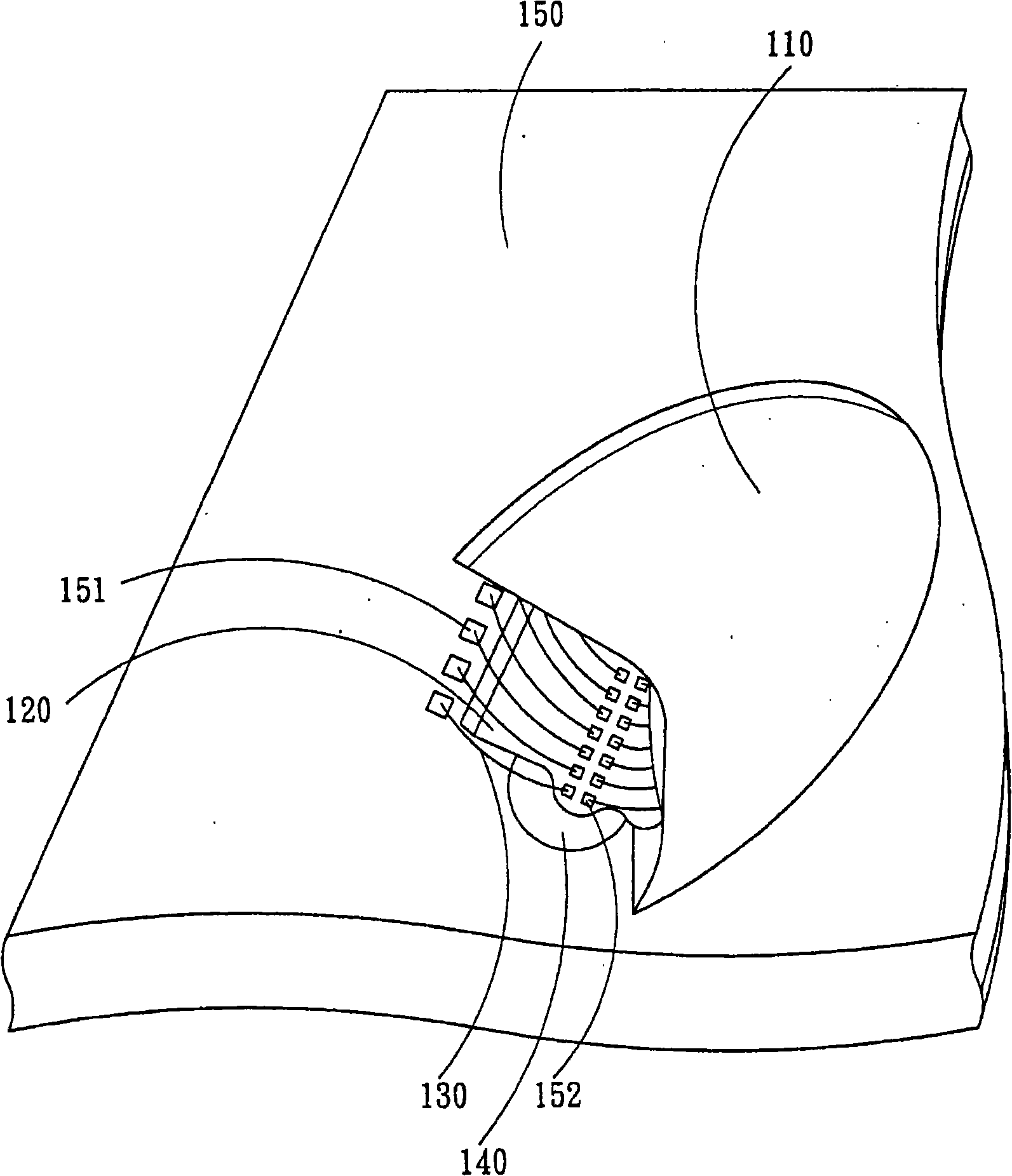

Memory module encapsulation construction and encapsulation method thereof

InactiveCN101359653AImprove reliabilityReduce the amount of sealantPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringMemory module

The invention relates to a memory module enclosure and an encapsulation method. A die, surrounding a chip, is arranged on a carrier plate to limit the flow and distribution range of fluid sealant and to equalize the thicknesses of the areas covered by the fluid sealant so as to avoid that pull to the enclosure is uneven after the fluid sealant in all the areas is solidified, thus preventing the enclosure from deforming due to uneven pull and improving the reliability of the enclosure. The invention uses the die to protect the leads during the fabrication process of the enclosure, thus preventing the leads from damages caused by collision.

Owner:KUNSHAN HEISEI ELECTRONICS

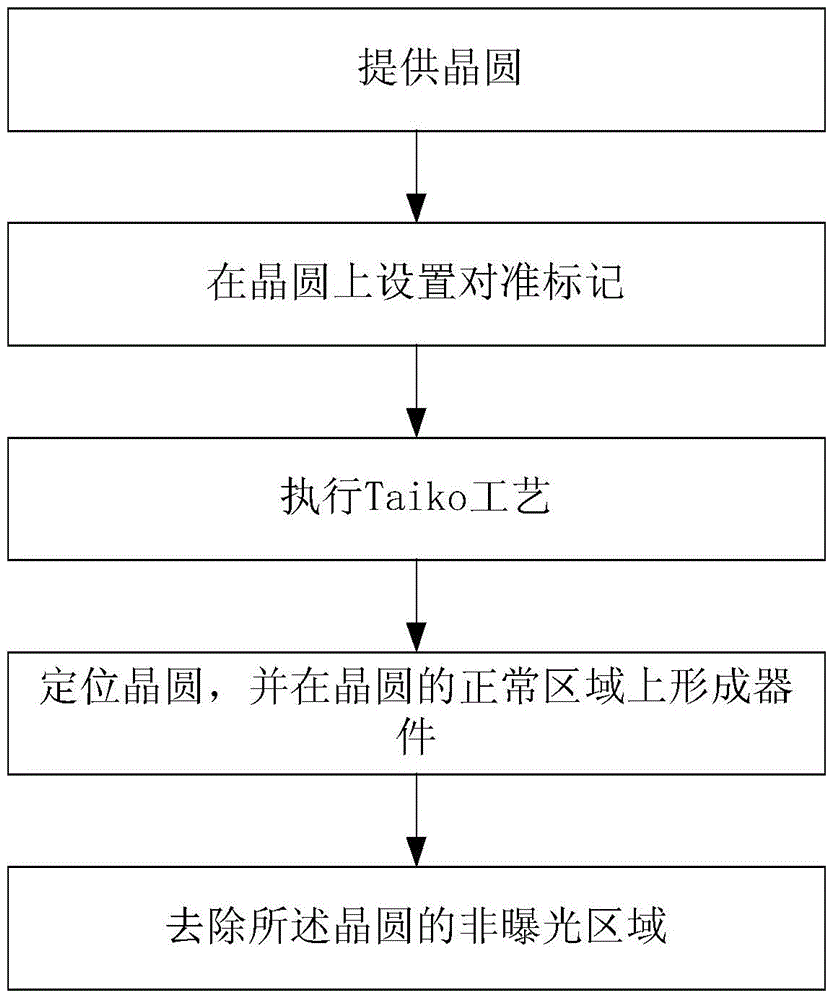

Wafer positioning method

InactiveCN104795317AForm to ensureLower the resistance valueSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

The invention discloses a wafer positioning method. The wafer positioning method includes providing a wafer comprising a normal area and a non-exposure area, and setting alignment marks on the normal area and the non-exposure area respectively; implementing Taiko process; positioning the wafer and forming a device on the normal area of the wafer. By means of the Taiko process, the peripheral edge of the wafer, namely the non-exposure area, should be reserved, and the normal area and the non-exposure area of the wafer are provided with alignment marks at the same time. When the Taiko process is performed, the normal area of the wafer is ground and thinned, the alignment marks of the normal area are ground and become shallow or disappear, and the alignment marks of the non-exposure area are still reserved. Therefore, the non-exposure area is provided with the alignment marks, resistance of the semiconductor power device of an automobile electronic product can be reduced, formation of a subsequent device can be ensured, and low yield of the semiconductor power device due to the fact that the wafer is hard to position is avoided.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

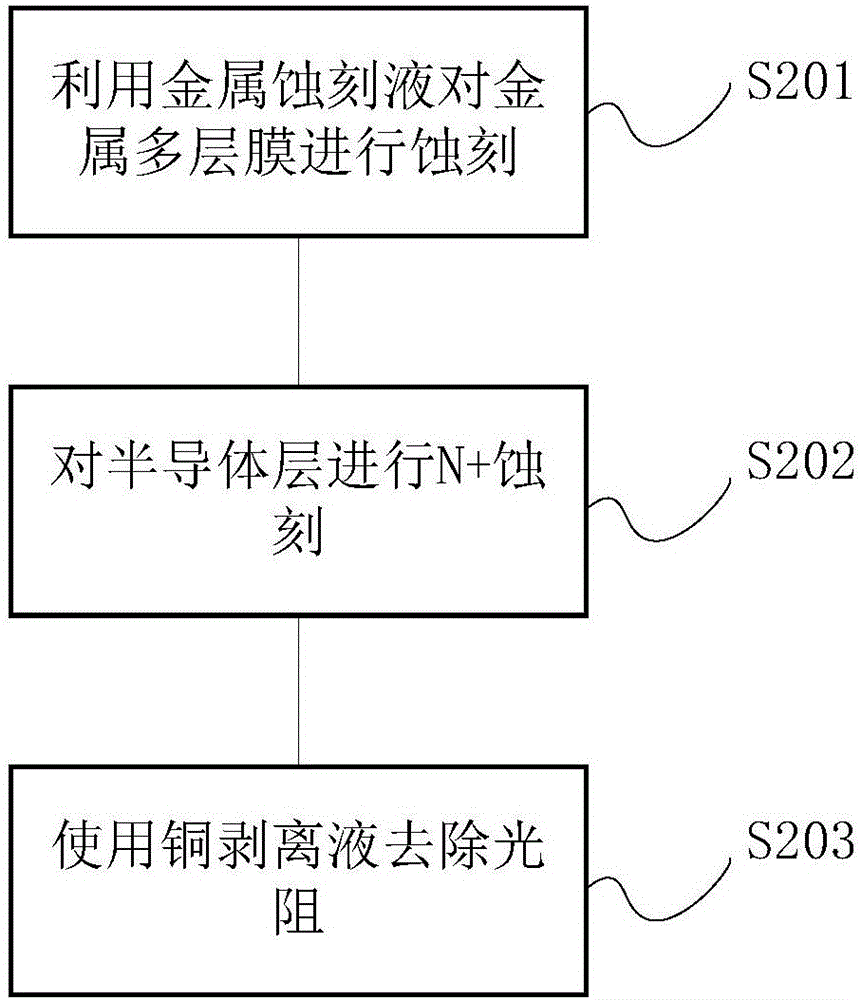

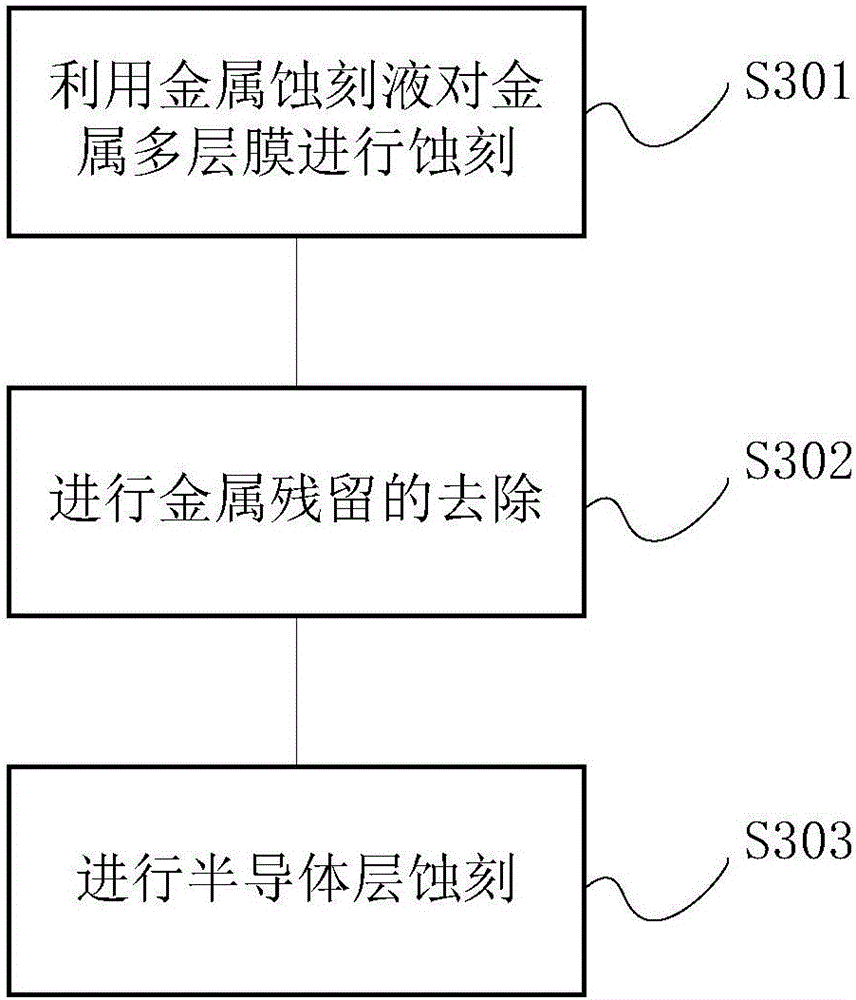

Lead process array etching method

InactiveCN106601596AImprove yieldLower yieldSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMaterials science

The invention discloses a lead process array etching method comprising the following steps: using a metal etching liquid to etch metal multilayer films; removing metal residuals; etching a semiconductor layer. The method can prevent metal residuals so as to solve N+ residual problems, and thus improving product yield rate.

Owner:HKC CORP LTD +1

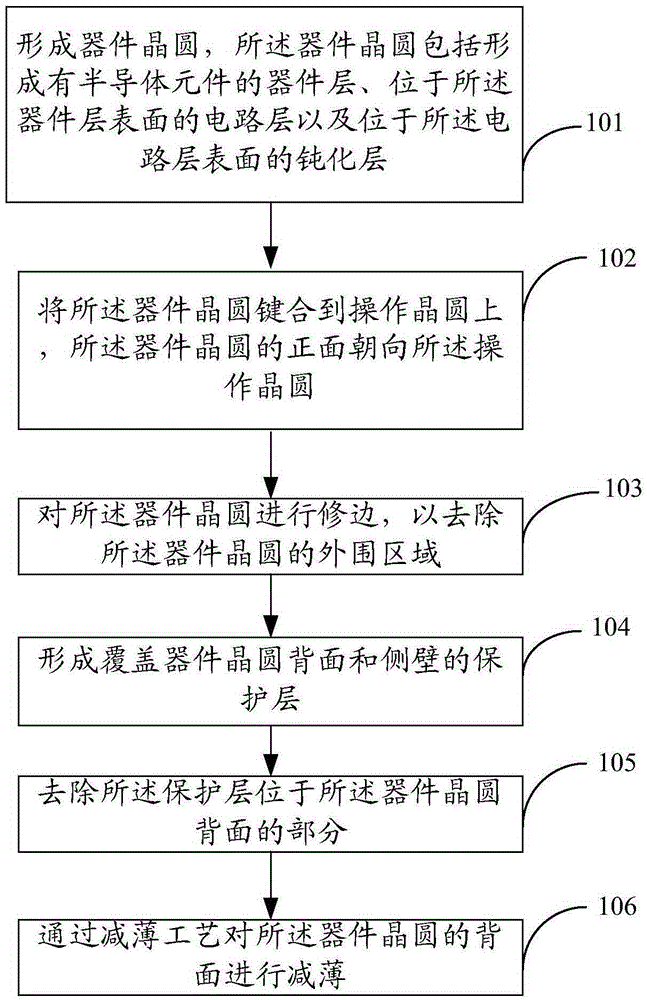

Semiconductor device and manufacturing method thereof, and electronic device

InactiveCN106571376AAvoid damageLower yieldSolid-state devicesRadiation controlled devicesPower semiconductor deviceEtching

The invention provides a semiconductor device and a manufacturing method thereof, and an electronic device. The manufacturing method comprises steps that a device wafer is formed, the device wafer comprises a device layer provided with a semiconductor element, a circuit layer arranged at a surface of the device layer, and a passivation layer arranged on the surface of the circuit layer, and the device wafer comprises a center region and a peripheral region surrounding the center region; an operation wafer is provided, the operation wafer is made to bond with the device wafer through the passivation layer, and a surface of the device wafer which is not bonded with the operation wafer is a back surface; the device wafer is trimmed so as to remove the peripheral region of the device wafer; a protection layer for covering a side wall of the circuit layer is formed; the back surface of the device wafer is thinned through the thinning process. Through the manufacturing method, the protection layer for covering the side wall of the circuit layer is formed, the wafer is prevented from being damaged by wet etching in a subsequent thinning process, and a yield rate is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

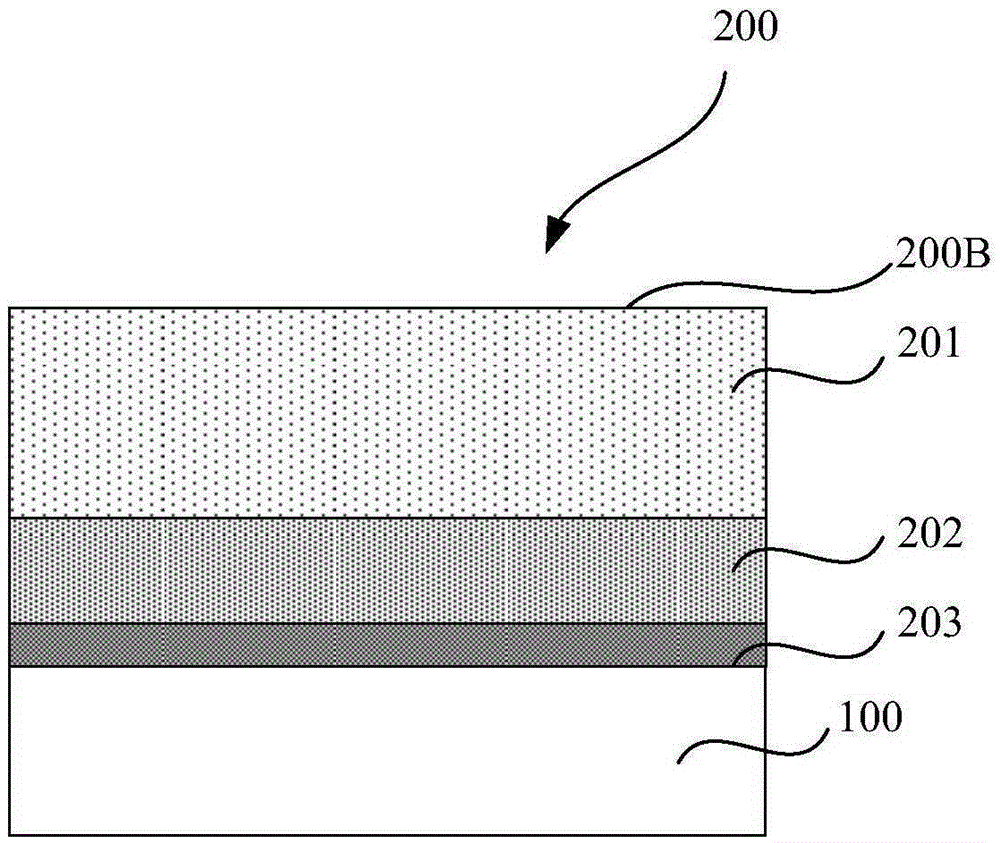

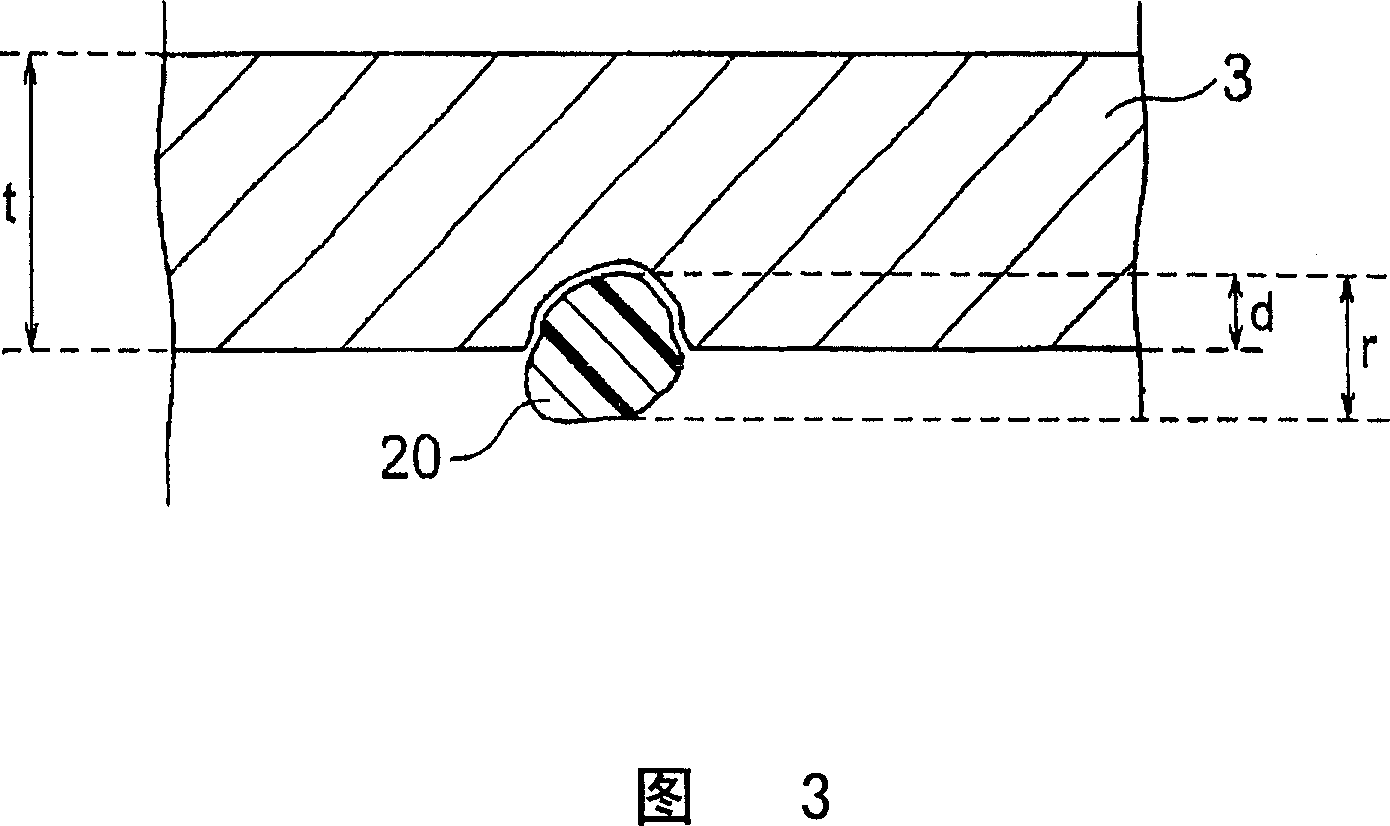

Production method of multilayer ceramic electronic device

ActiveCN1941233AAvoid crackingLower yieldFixed capacitor dielectricStacked capacitorsMetallurgyLow voltage

A method of manufacturing a laminated ceramic electronic component having a dielectric layer and an internal electrode layer, wherein the conductive paste for forming the internal electrode layer contains at least a first common material composed of conductive particles and ceramic powder, and a ceramic A second co-material composed of powder and having an average particle diameter larger than the above-mentioned first co-material; the average particle diameter of the above-mentioned first co-material is 1 / 20 to 1 / 2 of the average particle diameter of the above-mentioned conductor particles Size, the average particle diameter of the above-mentioned second co-material is a size of 1 / 10 to 1 / 2 of the average thickness of the above-mentioned internal electrode layer after sintering A method for manufacturing a multilayer ceramic electronic component of a conductive paste, the present invention provides A method of manufacturing multilayer ceramic electronic components such as multilayer ceramic capacitors capable of effectively suppressing the occurrence of cracks, reducing short-circuit failure rates and withstand voltage failure rates, and having high electrostatic capacitance.

Owner:TDK CORPARATION

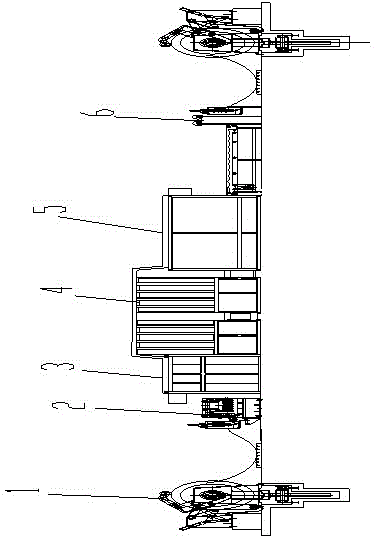

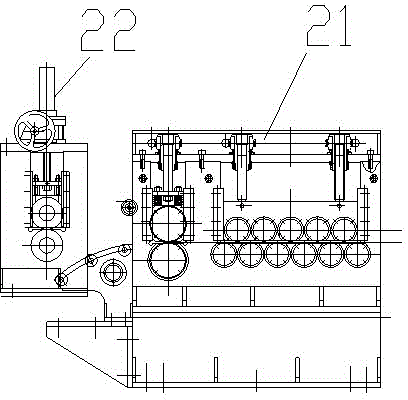

Grinding system and method for workpiece surface treatment

ActiveCN104625943AReduce labor costsLower yieldPolishing machinesGrinding drivesEconomic benefitsEngineering

The invention discloses a grinding system and method for workpiece surface treatment. The system comprises two groups of uncoiling components arranged on the left side and right side respectively, wherein a leveling tension bracket component, a rough grinding component, a polishing component, a cleaning component and a film tension bracket are arranged between the two groups of uncoiling components from left to right in sequence. Grinding is conducted by means of the system. By the adoption of the system and method, automation is achieved, labor cost is reduced, productivity in unit time is improved, economic benefits are remarkable, and output benefits are high.

Owner:佛山市美凌不锈钢有限公司

Semiconductor structure and fabricating method thereof

InactiveCN106684149APrevent mergeLower yieldSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringElectrical and Electronics engineering

A semiconductor structure includes a device region and a test region. In the device region, first fin spacers cover sidewalls of a first fin structure and have a first height, and a first epitaxy structure is disposed in the first fin structure, which a portion of the first epitaxy structure is above the first fin spacers and having a first width. In the test region, second fin spacers cover sidewalls of the second fin structure and have a second height, and the second height is greater than the first height. A second epitaxy structure is disposed in the second fin structure, and a portion of the second epitaxy structure is above the second fin spacers and having a second width, which the second width is less than the first width.

Owner:TAIWAN SEMICON MFG CO LTD

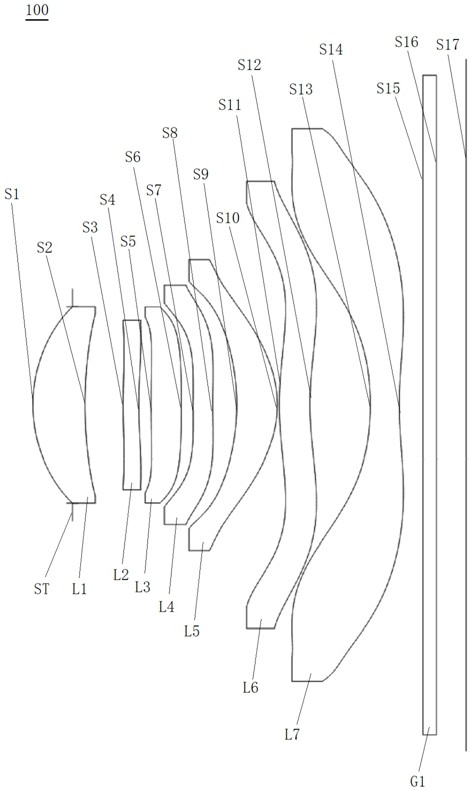

Optical lens and imaging equipment

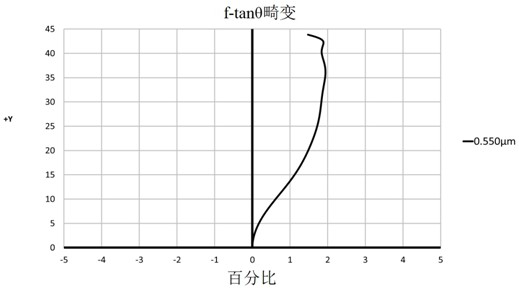

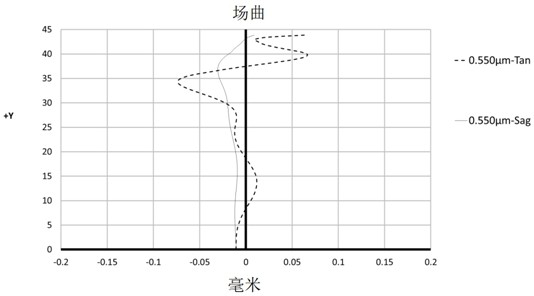

ActiveCN113721350AReduce thicknessGood light transmissionOptical elementsTarget surfaceOphthalmology

The invention discloses an optical lens and imaging equipment. The optical lens sequentially comprises a diaphragm, a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens and a seventh lens from an object side to an imaging surface along an optical axis; the first lens has positive focal power, the object side surface of the first lens is a convex surface, and the image side surface of the first lens is a concave surface; the second lens has negative focal power, the object side surface of the second lens is a convex surface near the optical axis, and the image side surface of the second lens is a concave surface near the optical axis; the third lens has positive focal power, and the object side surface of the third lens is a convex surface near the optical axis; the fourth lens has negative focal power, the object side surface of the fourth lens is a convex surface near the optical axis, and the image side surface of the fourth lens is a concave surface near the optical axis; the fifth lens has positive focal power, the object side surface of the fifth lens is a concave surface, and the image side surface of the fifth lens is a convex surface; the sixth lens has negative focal power; the seventh lens has negative focal power; and the first lens is a glass aspheric lens, and the other lenses are plastic aspheric lenses. The optical lens has the advantages of being large in aperture, large in imaging target surface, high in pixel, capable of meeting the requirement for grouping adjustability of the AA technology and high in yield.

Owner:JIANGXI LIANYI OPTICS CO LTD

Curved surface display panel, manufacturing method and display device

ActiveCN105044987ALower yieldDoes not aggravate light leakageNon-linear opticsSurface displayLiquid-crystal display

The embodiment of the invention provides a curved surface display panel, a manufacturing method and a display device, and relates to the technical field of displays. The problem that a substrate is prone to being broken is solved while the curved surface display panel is used for reducing or avoiding light leakage of a curved surface display, and therefore the defect rate in the production technology can be reduced. The curved surface display panel comprises an array substrate, a cassette aligning substrate, a liquid crystal layer located between the array substrate and the cassette aligning substrate and a first 0-0 double refraction layer located at the side, far away from the liquid crystal layer, of the array substrate and / or a second 0-0 double refraction layer located at the side, far away from the liquid crystal layer, of the cassette aligning substrate. The curved surface display panel is used for manufacturing the displays.

Owner:BOE TECH GRP CO LTD

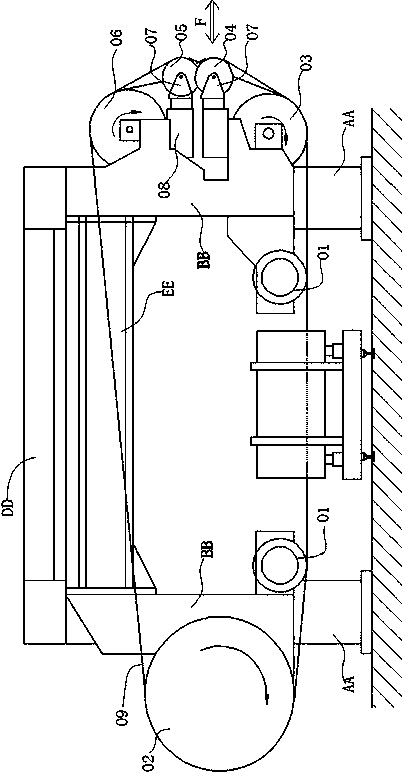

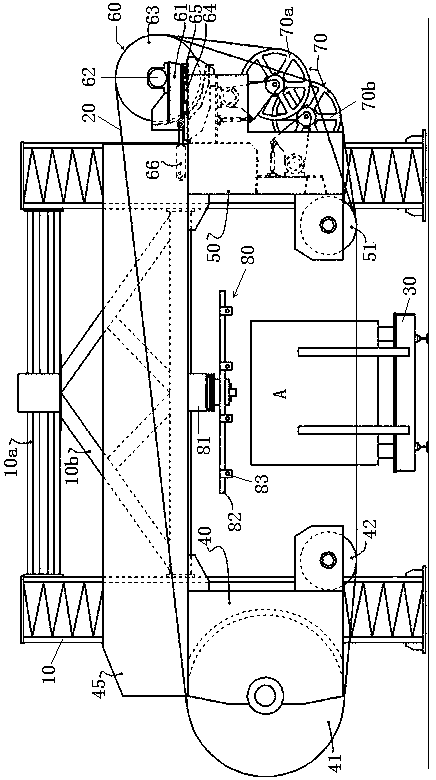

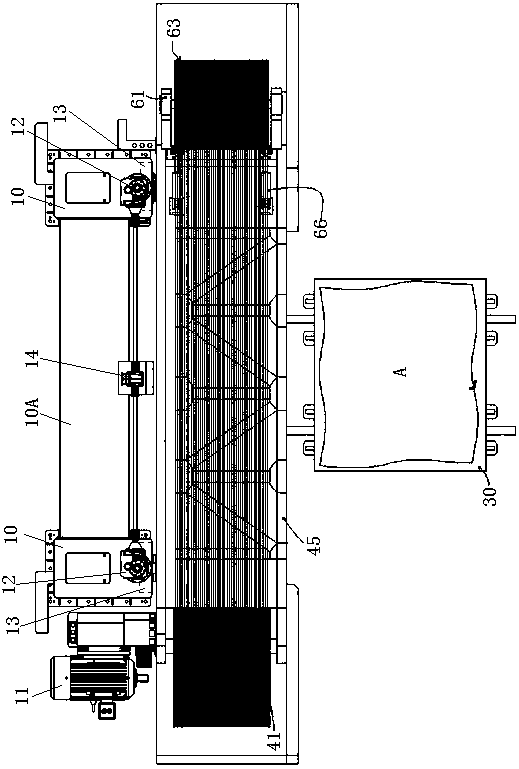

Multi-set-rope sawing machine and control method thereof

PendingCN108481571AEasy to change ropeLower yieldWorking accessoriesStone-like material working toolsWheel trainEngineering

The invention relates to a multi-set-rope sawing machine and a control method thereof. The multi-set-rope sawing machine comprises a gantry rack and a plurality of diamond string bead ropes. The lowerside of the gantry rack is provided with a trolley used for storing stone blocks and capable of longitudinally sliding. A first rack box and a second rack box which are connected through a truss andcan be lifted are arranged on the front portions of the two sides of the gantry rack correspondingly. The first rack box is internally provided with a main driving wheel. The upper portion of the second rack box is provided with a pre-tensioning wheel train assembly. The lower portion of the second rack box is provided with a micro-tensioning wheel train assembly for providing tensioning and supporting. Guiding wheels are further arranged on the inner sides of the lower portions of the first rack box and the second rack box correspondingly. The diamond string bead ropes are wound in wheel grooves corresponding to the main driving wheel, the pre-tensioning wheel train assembly, the micro-tensioning wheel train assembly and a guiding wheel set. The gantry rack is further provided with a water spraying cooling device. The multi-set-rope sawing machine is compact in structure, the purpose of stably cutting a plate can be achieved, and control is convenient.

Owner:FUJIAN XIAPU ZHONGYUAN MACHINERY

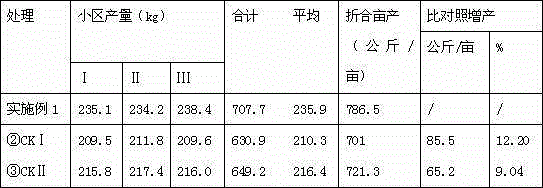

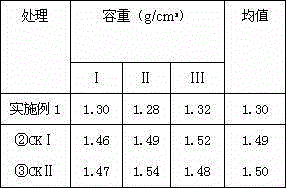

Preparing method for nutritional type water conserving and soil loosening compound fertilizer

The invention discloses a preparing method for nutritional type water conserving and soil loosening compound fertilizer. The method comprises the following steps that 1, compound enzyme liquid is prepared; 2, microelement is thrown into gamma-polyglutamic acid liquid to carry out a chelation reaction to prepare a pelleting bonding agent; 3, a pharmacy agent, an enzyme preparation and citric acid are selected, fermented and filtered in a pressing mode to obtain mycelium residues, the mycelium residues are thrown into a high-temperature and high-pressure wall breaking tank, saturated steam is introduced, and instant pressure reducing is carried out to enable mycelium cell walls to be broken to prepare a chitin and chitosan organic mixture; 4, the organic mixture obtained in the step three is dried and crushed to obtain a water conserving and soil loosening master batch, the master batch and inorganic nutrients are mixed and stirred uniformly, and thrown into a pelletizer, the pelleting bonding agent is sprayed into the mixture, and pelleting and screening are carried out to obtain the nutritional type water conserving and soil loosening compound fertilizer. The fertilizer has the advantages of being rich in nutrient and capable of reducing water loss and soil erosion, increasing soil moisture content, increasing soil bulk density, loosening soil, remarkably increasing the nutrient utilization rate, and promoting the agriculture yield and income increase.

Owner:QINGDAO LILIHUI BIOTECH

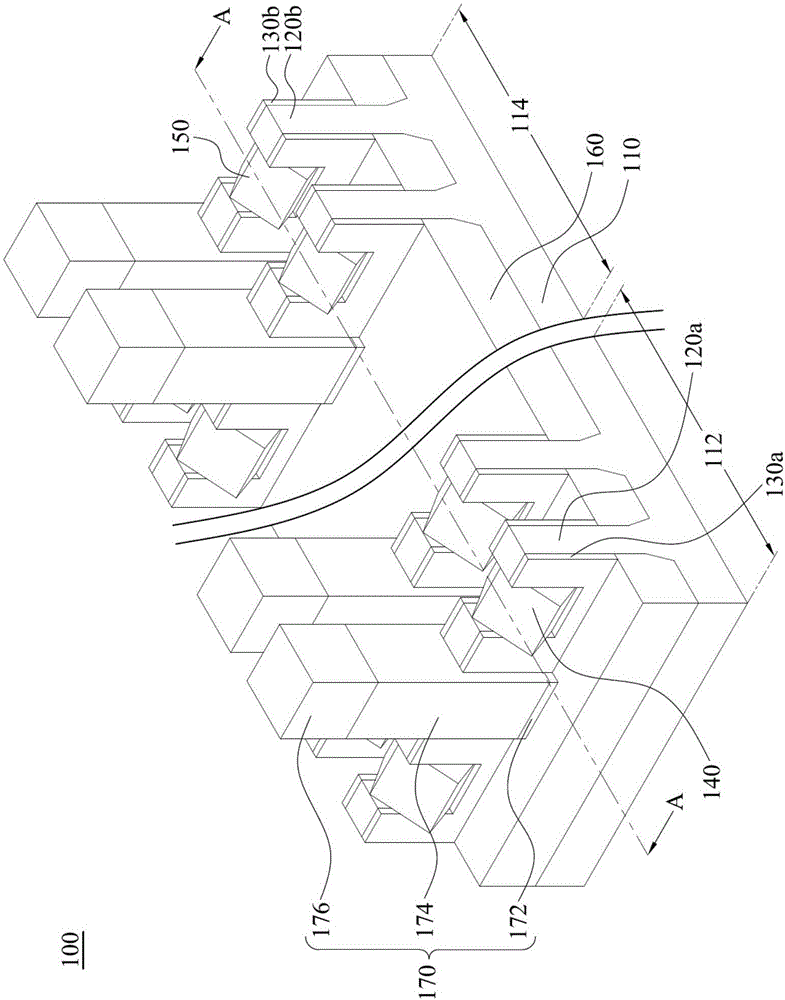

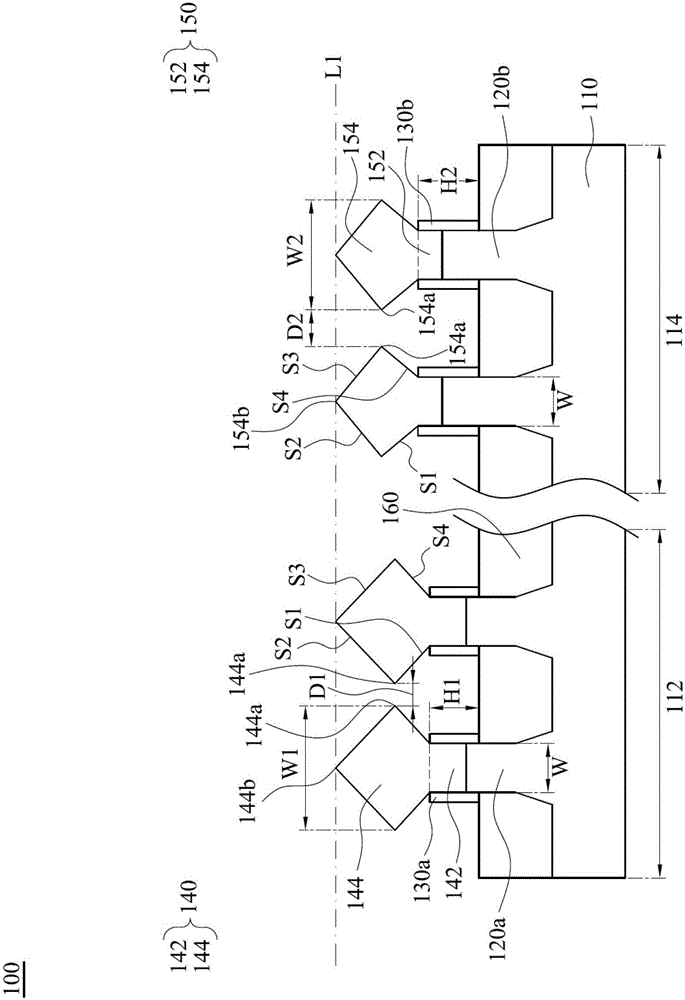

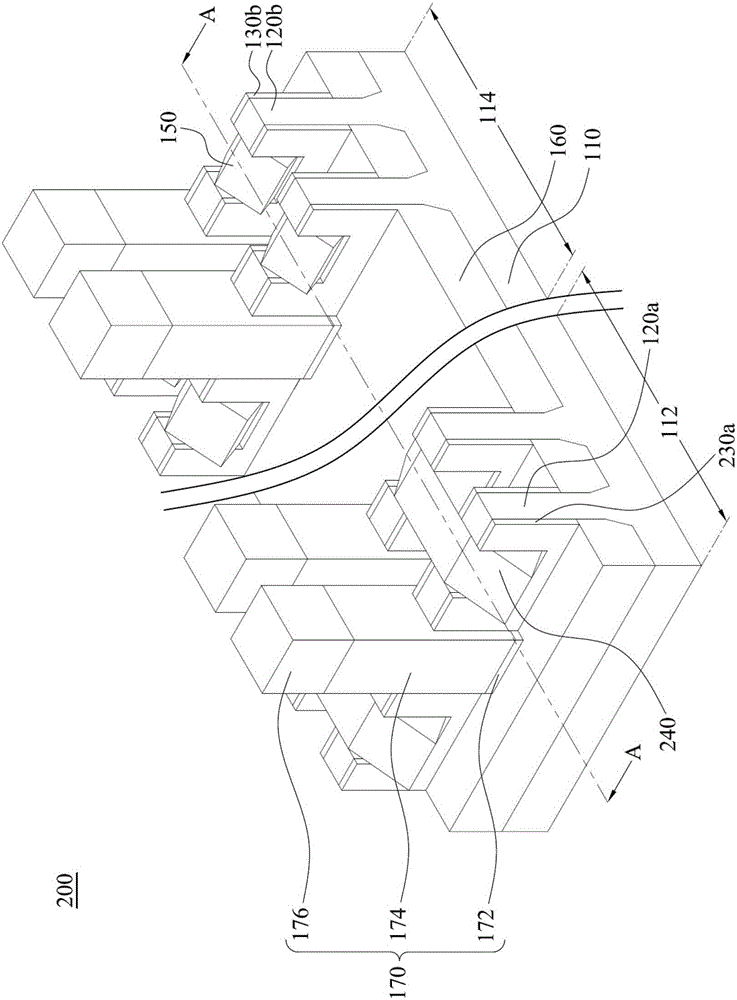

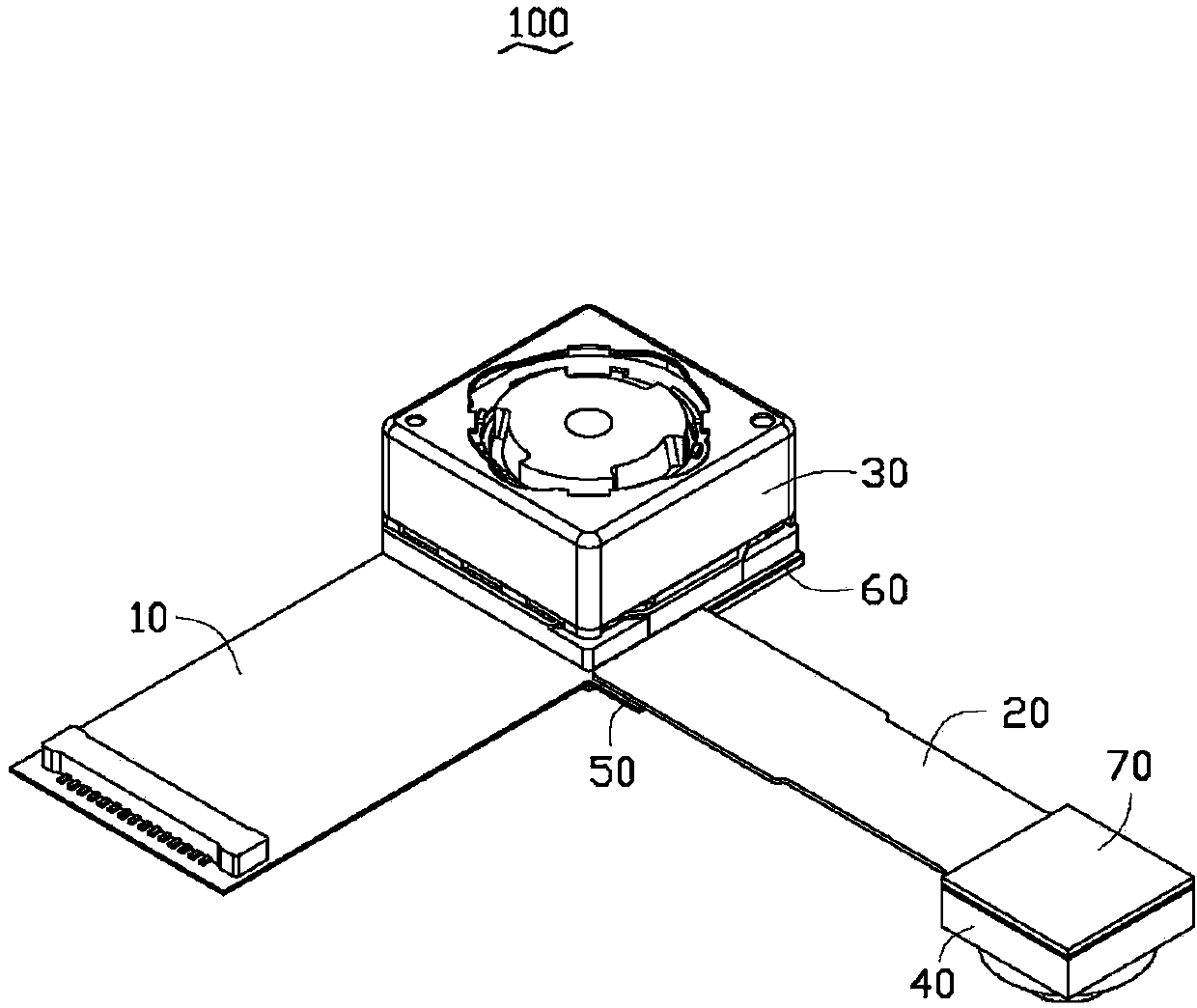

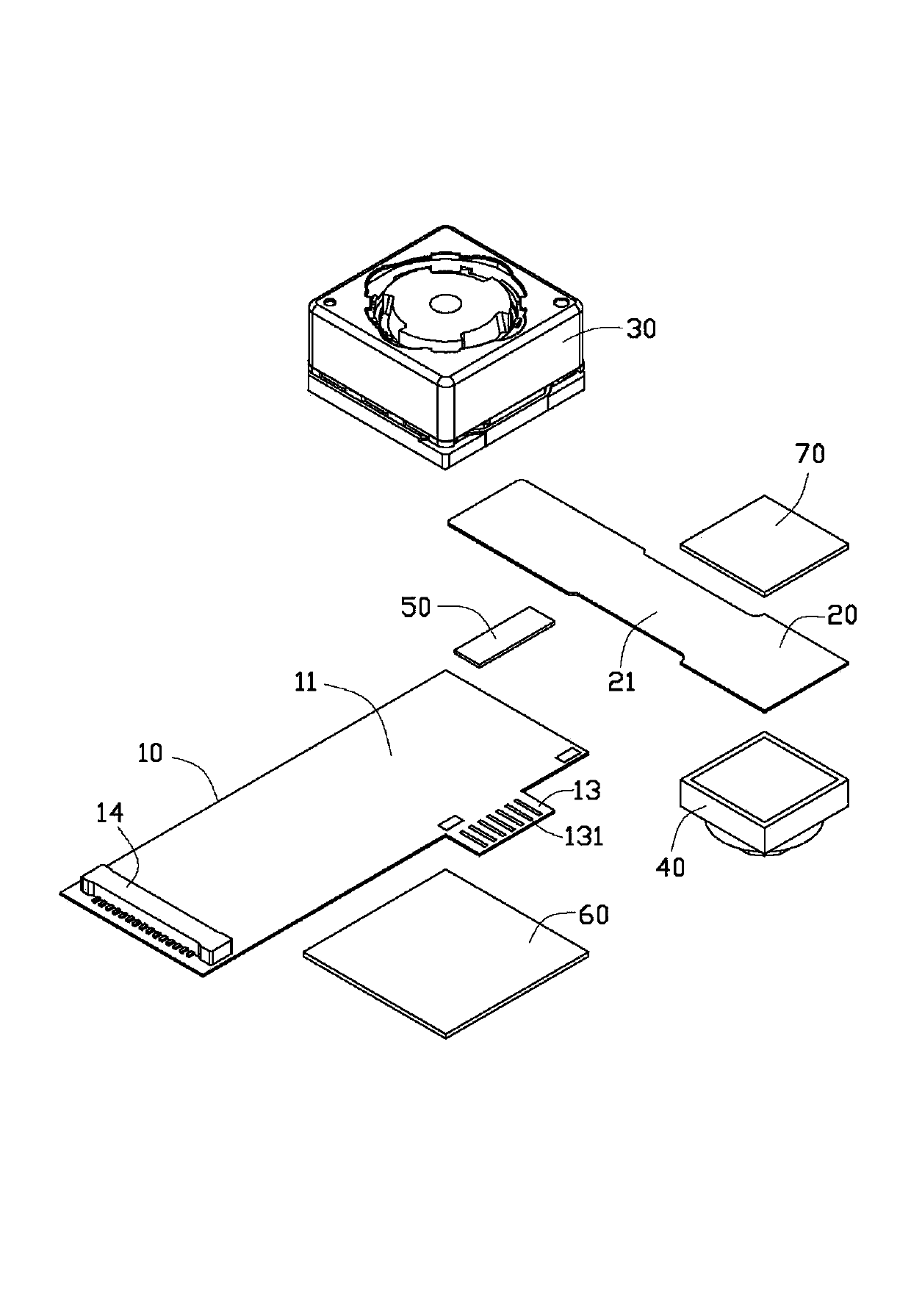

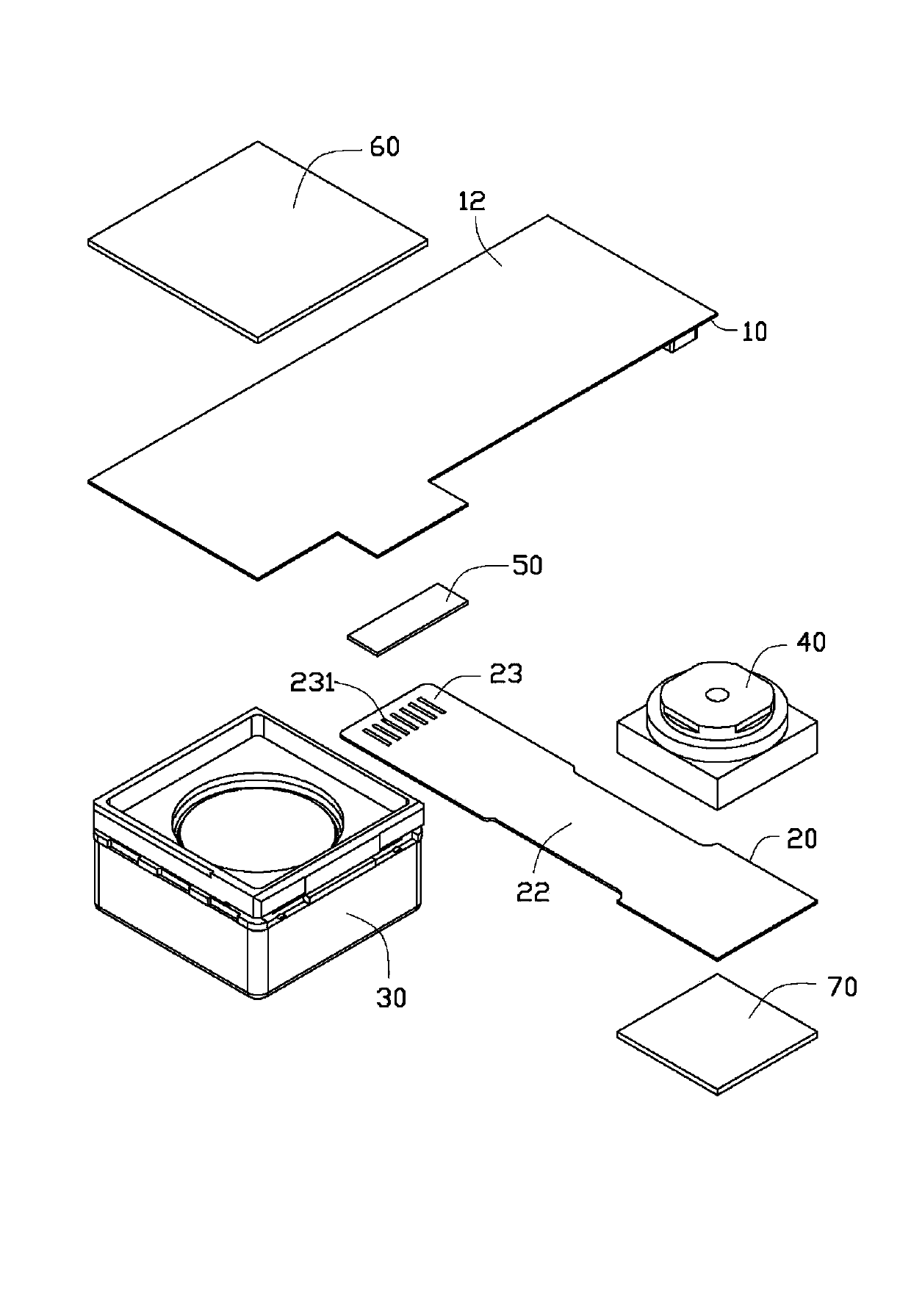

Double-camera module

InactiveCN103973943ALower yieldImprove yieldTelevision system detailsColor television detailsCamera modulePrinted circuit board

The invention provides a double-camera module which comprises a first flexible printed circuit board, a second flexible printed circuit board, a first camera and a second camera. The first flexible printed circuit board comprises a first electric connector and an external electric connector, the external electric connector is electrically connected with the first electric connector, and the first camera is fixed onto the first flexible printed circuit board. The second flexible printed circuit board comprises a second electric connector, and the second camera is fixed onto the second flexible printed circuit board. The first electric connector is detachably connected with the second electric connector, and the second electric connector is connected with the external electric connector by the first electric connector. The double-camera module has the advantages that the two cameras are respectively fixed onto the two flexible printed circuit boards, accordingly, yield factors of the two cameras can be respectively tested, and a yield factor of the double-camera module can be effectively improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

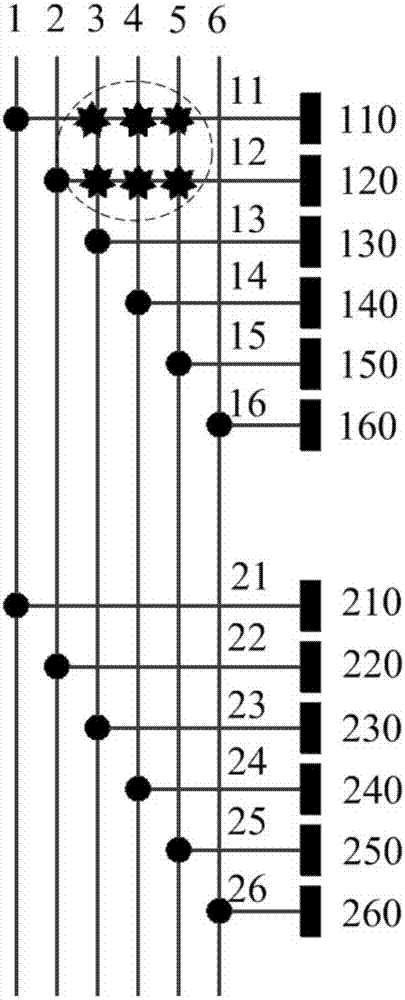

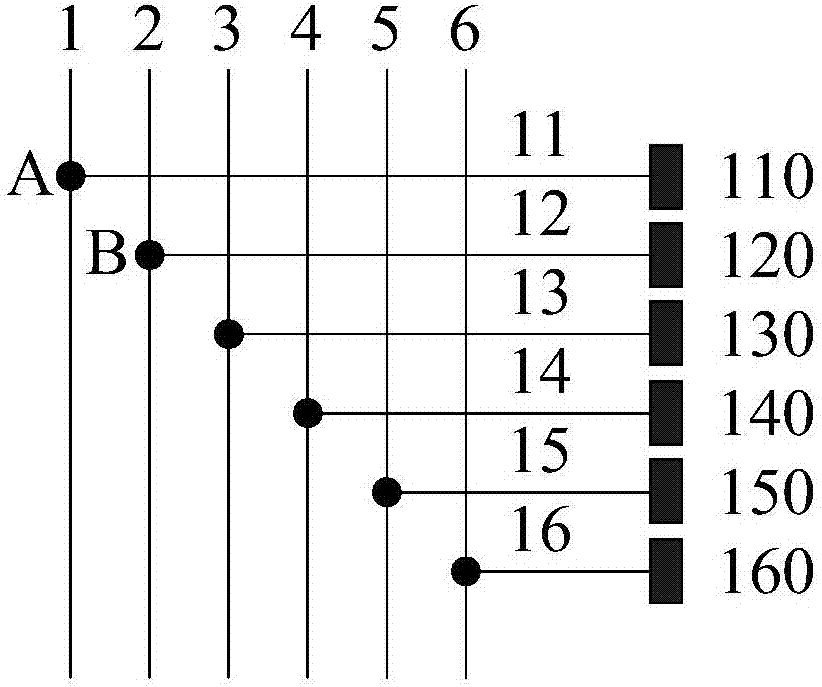

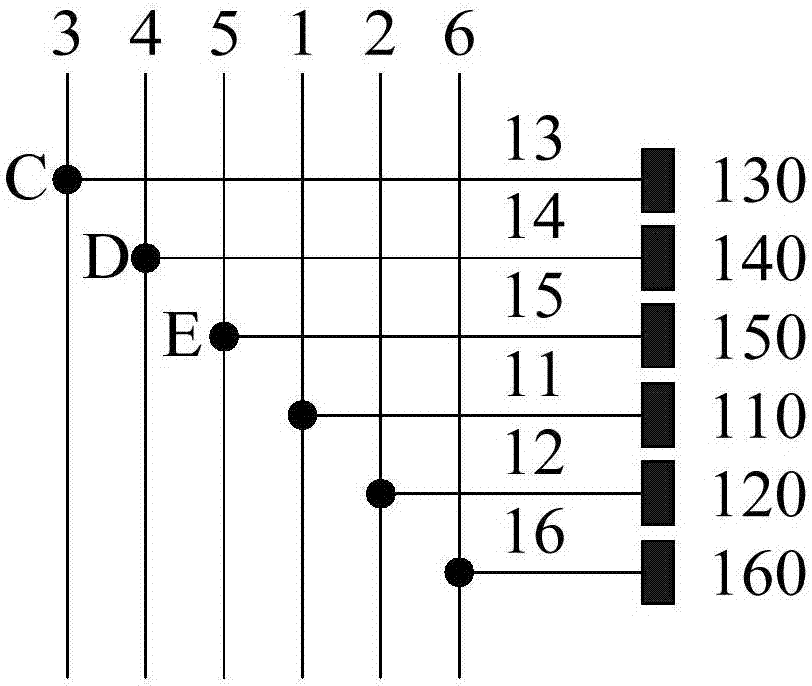

Detection circuit structure of liquid crystal display panel and the liquid crystal display panel

ActiveCN107093391AAvoid influenceLower yieldStatic indicating devicesElectrostatic dischargeLiquid-crystal display

The invention discloses a detection circuit structure of a liquid crystal display panel and the liquid crystal display panel. The detection circuit structure comprises a first lead wire layer and a second lead wire layer, wherein the first lead wire layer possesses a plurality of signal lead wires; and the second lead wire layer possesses a plurality of test lead wires corresponding to the plurality of signal lead wires. In the plurality of test lead wires, first ends of the at least two test lead wires are connected to the corresponding signal lead wires through a gating unit respectively, and the first ends of the rest test lead wires are connected to the corresponding signal lead wires respectively. Second ends of the test lead wires are connected to a detection terminal used for inputting a test signal. The test lead wire connected to the gating unit transmits the test signal and is started so that the test lead wire and the corresponding signal lead wire are electrically connected. By using a detection circuit structure, a problem that HVA orientation generates an abnormity because of ESD electrostatic discharge is solved, an influence of an array test process on an HVA orientation process is avoided and manufacturing cost is saved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

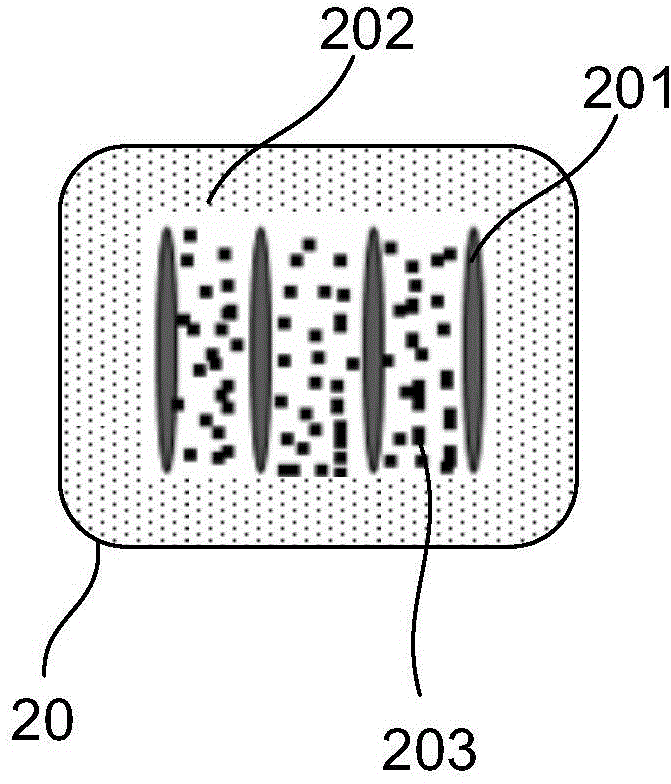

Decorative thin film and glass

PendingCN107433816ADoes not change hueChange color single effectOrnamental structuresSynthetic resin layered productsDiffraction effectEngineering

The invention discloses a decorative thin film. The decorative thin film comprises a base material layer, a pattern layer and an adhesive layer, wherein the pattern layer is arranged on one side of the base material layer and provided with evenly arranged microstructure units, and the microstructure units are provided with a plurality of parallelly arranged periodic cylindrical surface structures; and the adhesive layer is arranged on the other side of the base material layer relative to the pattern layer. At the same time, the invention further discloses decorative glass. According to the decorative thin film and glass, compared with the prior art, the decorative thin film can obtain a special dynamic light discoloration effect; by forming a microstructure on the thin film, the decorative thin film has the special visual effect on the macroscopic effect, the more shiny effect on the visual effect, and the higher diffraction effect; and the decorative thin film and the decorative glass are applied to the surface of a product and play roles on all aspects of decorative, brand protecting, cost controlling and environmental protecting.

Owner:苏州迈塔光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com