Improved sticking touch control panel body and manufacture method thereof

A touch panel and face-to-face technology, which is applied to instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of increased defect rate, unstable quality, and high labor costs, so as to reduce defect rate and save money. The effect of removing the man-hours for film setting and improving the quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

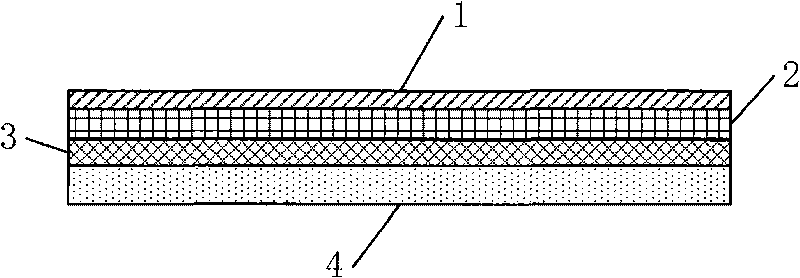

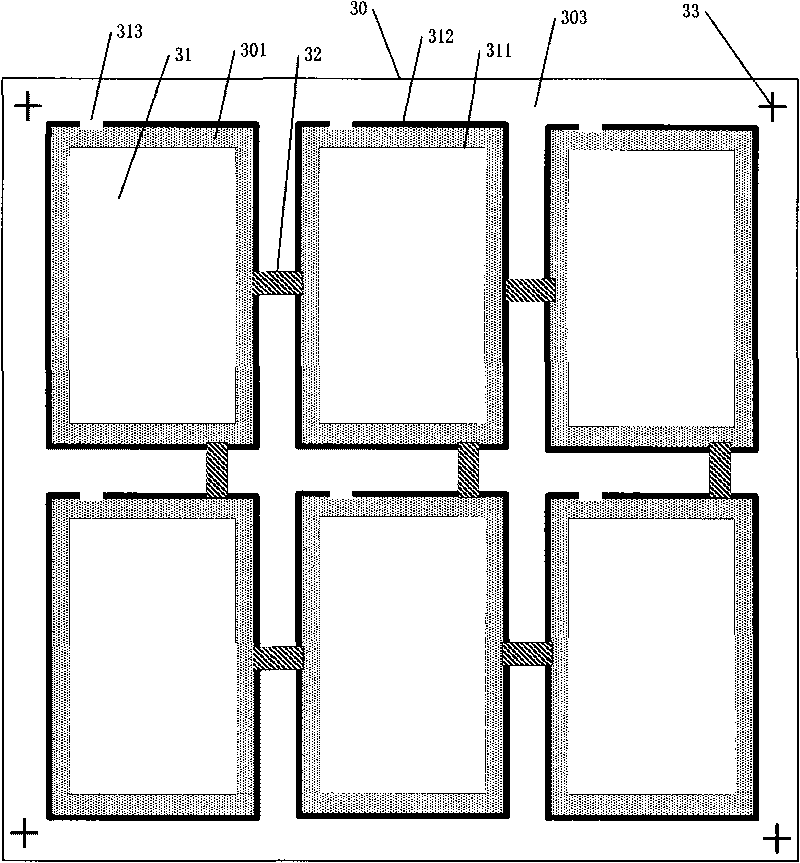

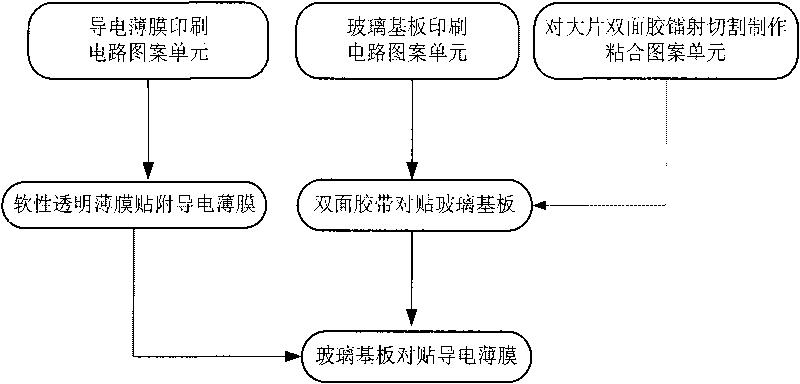

[0040] The improved laminated touch panel body consists of a soft transparent film layer 1, a conductive film layer 2, a double-sided adhesive layer 3, and a conductive glass substrate layer 4. Wherein, the double-sided adhesive layer 3 is formed by connecting the bonding pattern units 31 arranged at intervals through the connecting section 32; the circuit pattern unit is arranged on the conductive surface of the conductive film layer 2 and the conductive glass substrate layer 4 respectively and is connected with the bonding pattern unit 31. The pattern unit 31 coincides; the non-conductive surface of the conductive film layer 2 is pressed against one side of the soft transparent film layer 1, and the circuit pattern unit of the conductive glass substrate layer 4 is correspondingly pasted with the glue surface of the adhesive pattern unit 31, The other adhesive surface of the adhesive pattern unit 31 corresponds to the circuit pattern unit pasted with the conductive film layer ...

Embodiment 2

[0042] The improved laminated touch panel body consists of a soft transparent film layer 1, a conductive film layer 2, a double-sided adhesive layer 3, and a conductive glass substrate layer 4. Wherein, the double-sided adhesive layer 3 is formed by connecting the bonding pattern units 31 arranged at intervals through the connecting section 32; the circuit pattern unit is arranged on the conductive surface of the conductive film layer 2 and the conductive glass substrate layer 4 respectively and is connected with the bonding pattern unit 31. The pattern unit 31 coincides; the non-conductive surface of the conductive film layer 2 is pressed against one side of the soft transparent film layer 1, and the circuit pattern unit of the conductive glass substrate layer 4 is correspondingly pasted with the glue surface of the adhesive pattern unit 31, The other adhesive surface of the adhesive pattern unit 31 corresponds to the circuit pattern unit pasted with the conductive film layer ...

Embodiment 3

[0044] The improved laminated touch panel body consists of a soft transparent film layer 1, a conductive film layer 2, a double-sided adhesive layer 3, and a conductive glass substrate layer 4. Wherein, the double-sided adhesive layer 3 is formed by connecting the bonding pattern units 31 arranged at intervals through the connecting section 32; the circuit pattern unit is arranged on the conductive surface of the conductive film layer 2 and the conductive glass substrate layer 4 respectively and is connected with the bonding pattern unit 31. The pattern unit 31 coincides; the non-conductive surface of the conductive film layer 2 is pressed against one side of the soft transparent film layer 1, and the circuit pattern unit of the conductive glass substrate layer 4 is correspondingly pasted with the glue surface of the adhesive pattern unit 31, The other adhesive surface of the adhesive pattern unit 31 corresponds to the circuit pattern unit pasted with the conductive film layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com