Formation method of lithium ion battery

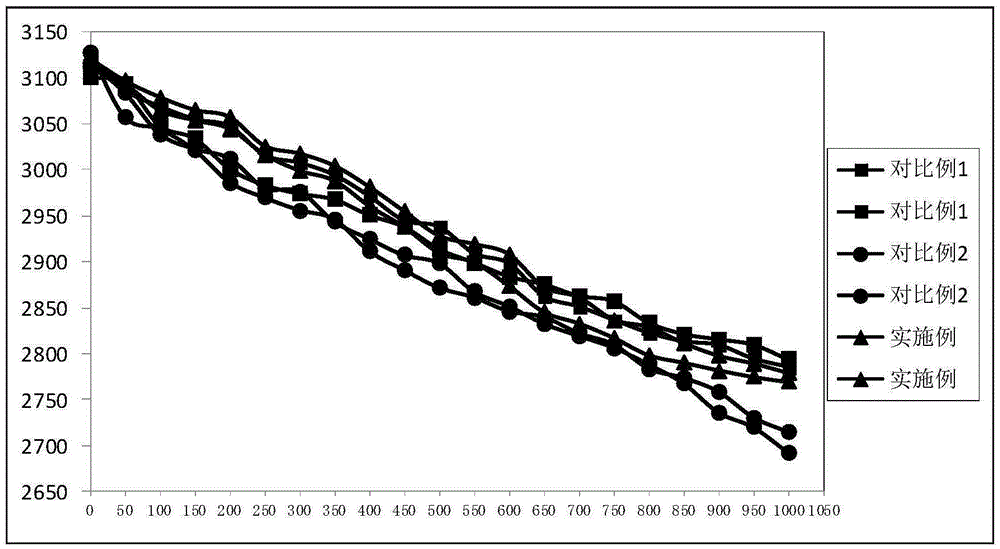

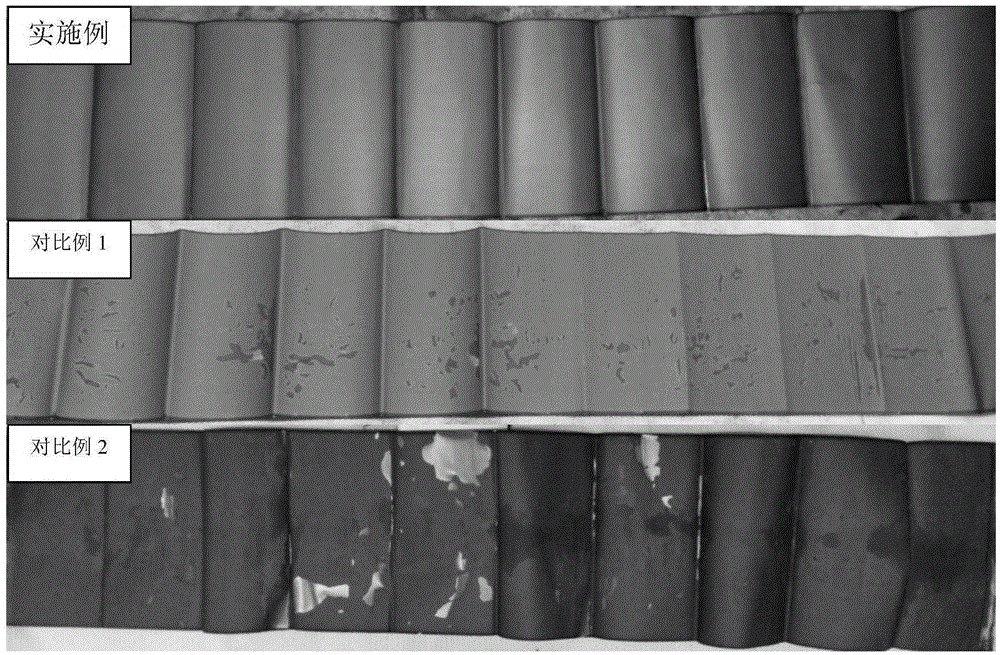

A lithium ion battery and a technology of a chemical formation method, which are applied in the field of polymer lithium ion battery manufacturing, can solve the problems of poor consistency of the interface state of the positive and negative electrode sheets of the battery, insufficient battery hardness, and uneven appearance of the battery, and reduce the Appearance defect rate and scrap rate, long-term cycle capacity improvement, and the effect of solving the long-term formation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation process of the positive electrode of the lithium battery in this example is as follows: according to the conventional manufacturing process of the polymer lithium ion battery, lithium cobaltate is used as the positive electrode material, and a conductive agent and an adhesive are added to form a slurry, and the prepared slurry is continuously , Evenly coated on the surface of the base material with aluminum foil as the current collector, and dried, the coated and baked pole piece was rolled and cut into strips and welded with tabs to make a positive pole piece;

[0033] The preparation process of the negative electrode of the lithium battery in this example is as follows: according to the conventional manufacturing process of the polymer lithium ion battery, graphite is used as the negative electrode material, a conductive agent, an adhesive and other auxiliary materials are added to form a slurry, and the prepared slurry Continuously and evenly coated on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com