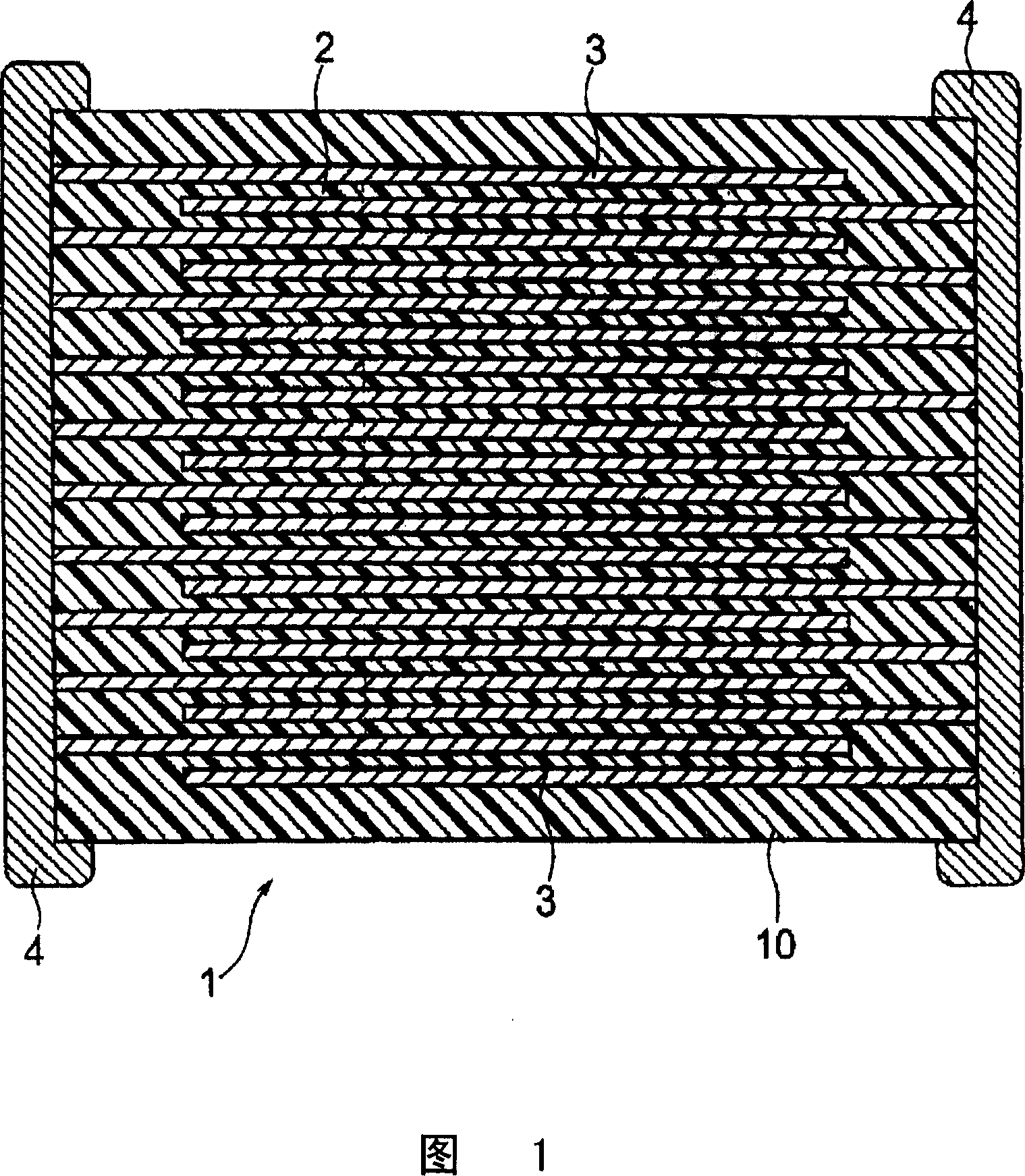

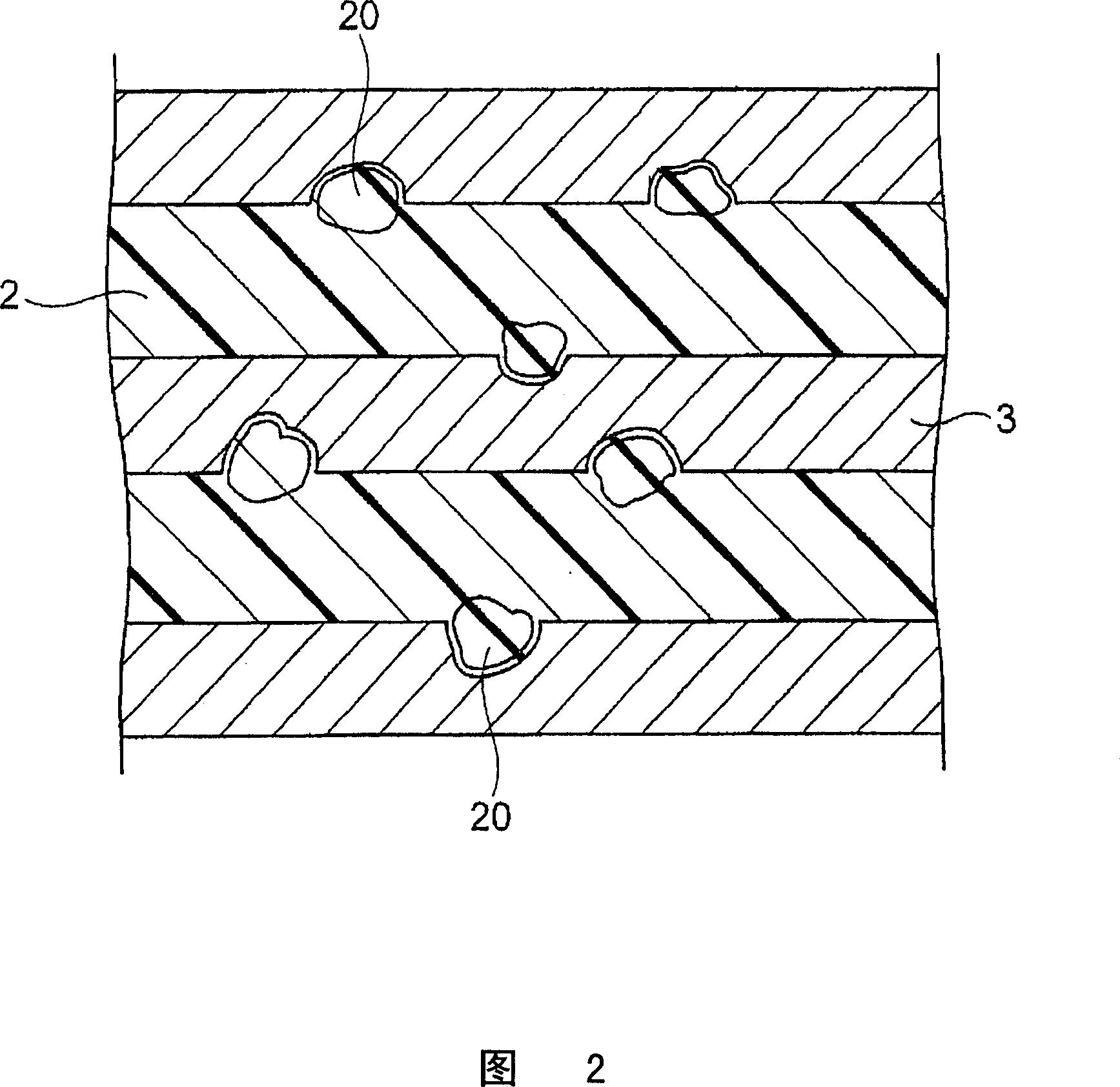

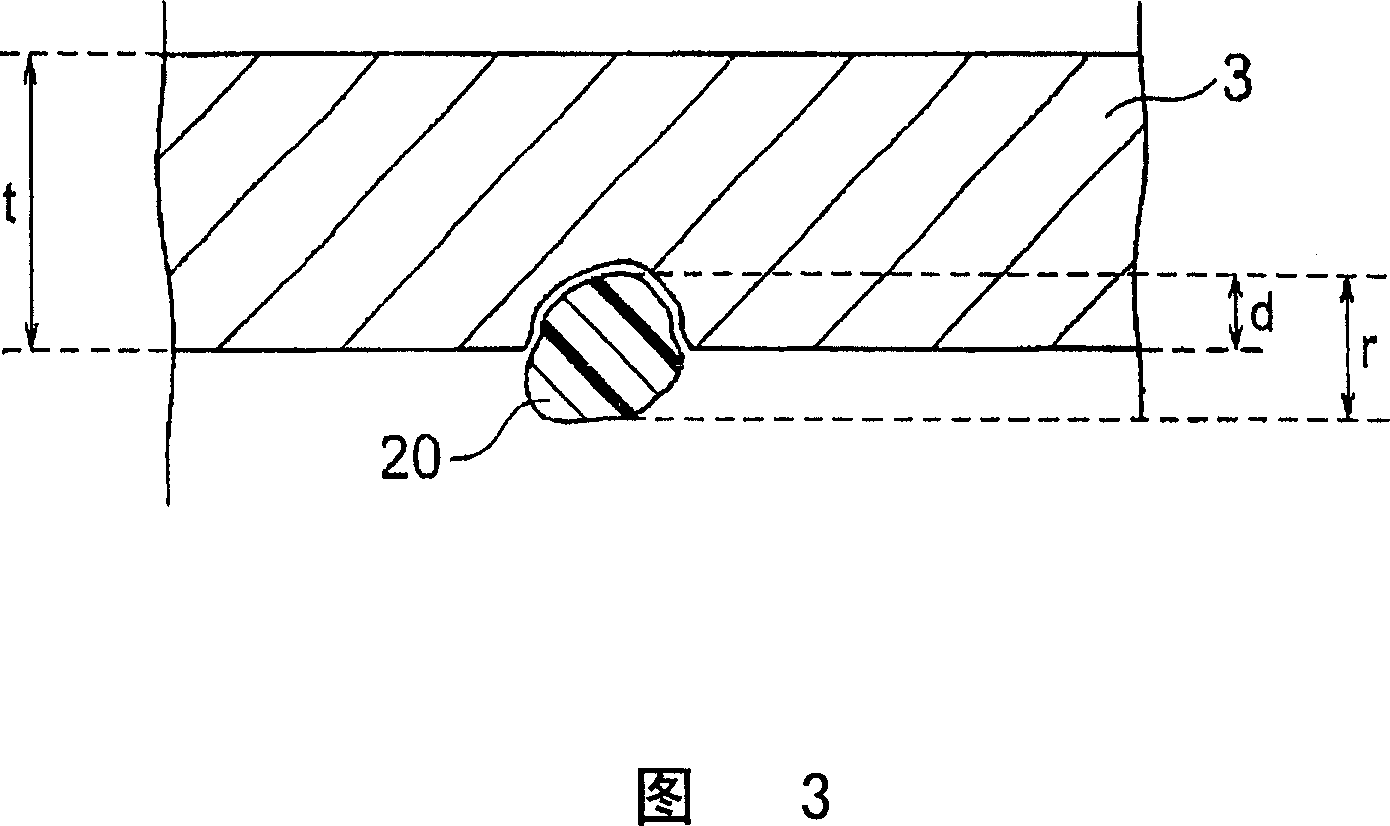

Production method of multilayer ceramic electronic device

A technology of electronic components and manufacturing methods, which is applied in the direction of capacitor manufacturing, laminated capacitors, fixed capacitor parts, etc., can solve the problems of deterioration of withstand voltage failure rate, thinning of dielectric layer, and short circuit failure rate, so as to prevent cracks, Improve the bonding strength and achieve the effect of electrostatic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] First, a main component material (BaTiO 3 ) and Y as a subcomponent raw material 2 o 3 , V 2 o 5 , CrO, MgO, SiO 2 and CaO. Next, the raw material prepared by wet mixing with a ball mill for 16 hours was prepared as a dielectric raw material.

[0086] Using a ball mill, mix the dielectric material prepared according to the above: 100 parts by weight, acrylic resin: 4.8 parts by weight, ethyl acetate: 100 parts by weight, mineral spirits: 6 parts by weight, toluene: 4 parts by weight, and make a paste to obtain Paste for dielectric layer.

[0087] Next, Ni particles with an average particle diameter of 0.2 μm: 100 parts by weight were kneaded by a 3-roll machine, and BaTiO as the first co-material 3 (average particle size: 0.05μm): 20 parts by weight, BaTiO as the second co-material 3 (average particle diameter: 0.5 μm): the amount shown in Table 1, organic vehicle (8 parts by weight of ethyl cellulose dissolved in 92 parts by weight of terpineol): 40 parts by we...

Embodiment 2

[0114] As the Ni powder contained in the conductor paste, while using Ni powder with an average particle diameter of 0.1 μm, and changing the content of the second co-material as shown in Table 2, a laminate was produced in the same manner as in Example 1. The ceramic capacitor samples were evaluated in the same manner as in Example 1. The results are shown in Table 2.

[0115] sample

[0116] From Table 2, when using Ni powder with an average particle diameter of 0.1 μm as the Ni powder, the same tendency as in Example 1 was confirmed.

Embodiment 3

[0118] Except changing the ratio of the first co-material contained in the conductive paste as shown in Table 3, a multilayer ceramic capacitor sample was produced in the same manner as in the sample No. 6 of Example 1, and evaluated in the same manner as in Example 1. The results are shown in Table 3.

[0119] sample

conductor paste

Multilayer ceramic capacitor samples

Ni powder

(μm)

1st co-material

2nd common material

internal electrode

(μm)

2nd common material

particle size / internal

Crack incidence

(ppm)

(%)

defective rate

(%)

withstand voltage

defective rate

(%)

(μm)

(parts by weight)

(μm)

(parts by weight)

Below 1000ppm

-10% or less

50% or less

50% or less

18

0.2

-

0

0.5

5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com