Patents

Literature

36 results about "Texture transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Texture transfer is a method that copies the texture of a reference image to a target image. This technique has an advantage in that various styles can be expressed according to the reference image, in a single framework.

Texture synthesis and transfer for pixel images

InactiveUS6919903B2Texturing/coloringCathode-ray tube indicatorsComputer graphics (images)Texture transfer

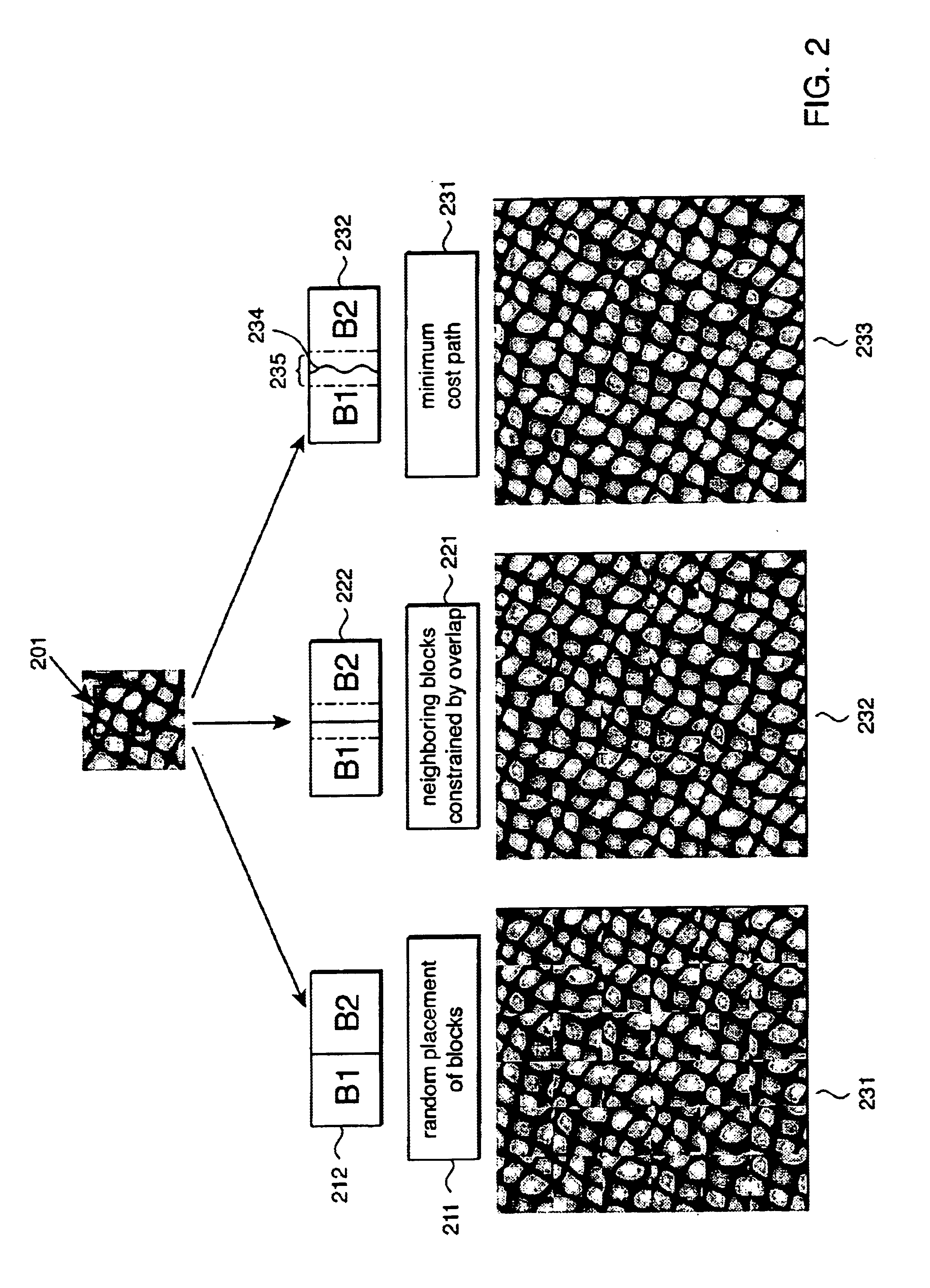

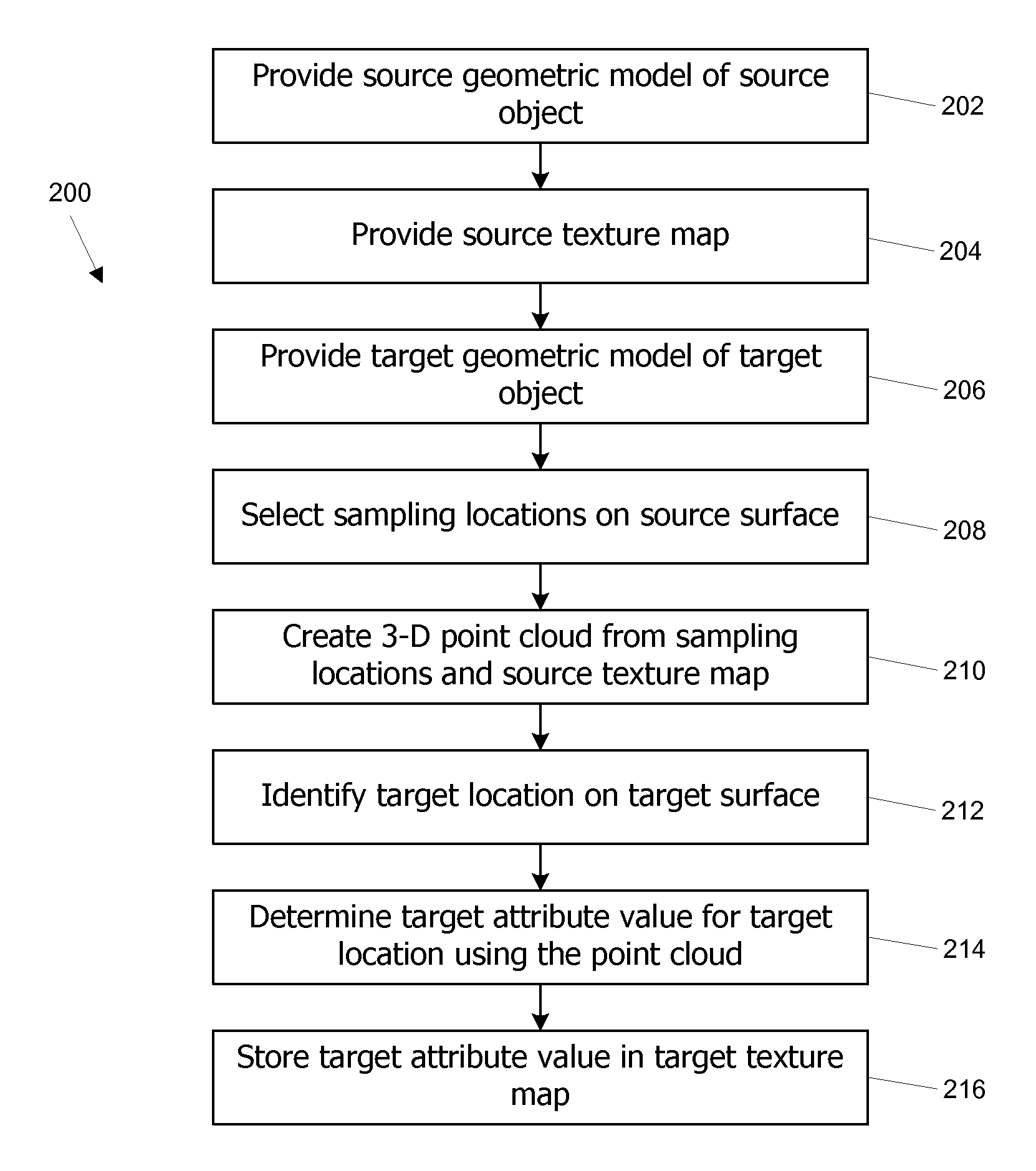

The invention provides an image-based method for generating novel visual appearance in a new image. Synthetic texture is stitching together from small patches in existing images. First, we use a least cost path determination to determine the local boundaries between the patches. Second, we perform texture transfer by rendering an arbitrary object with a synthetic texture taken from a different object. More generally, we provide methods for rendering entire images in styles of different images. The method works directly on pixel images, and does not require 3D information.

Owner:MITSUBISHI ELECTRIC INFORMATION TECH CENT AMERICA ITA +1

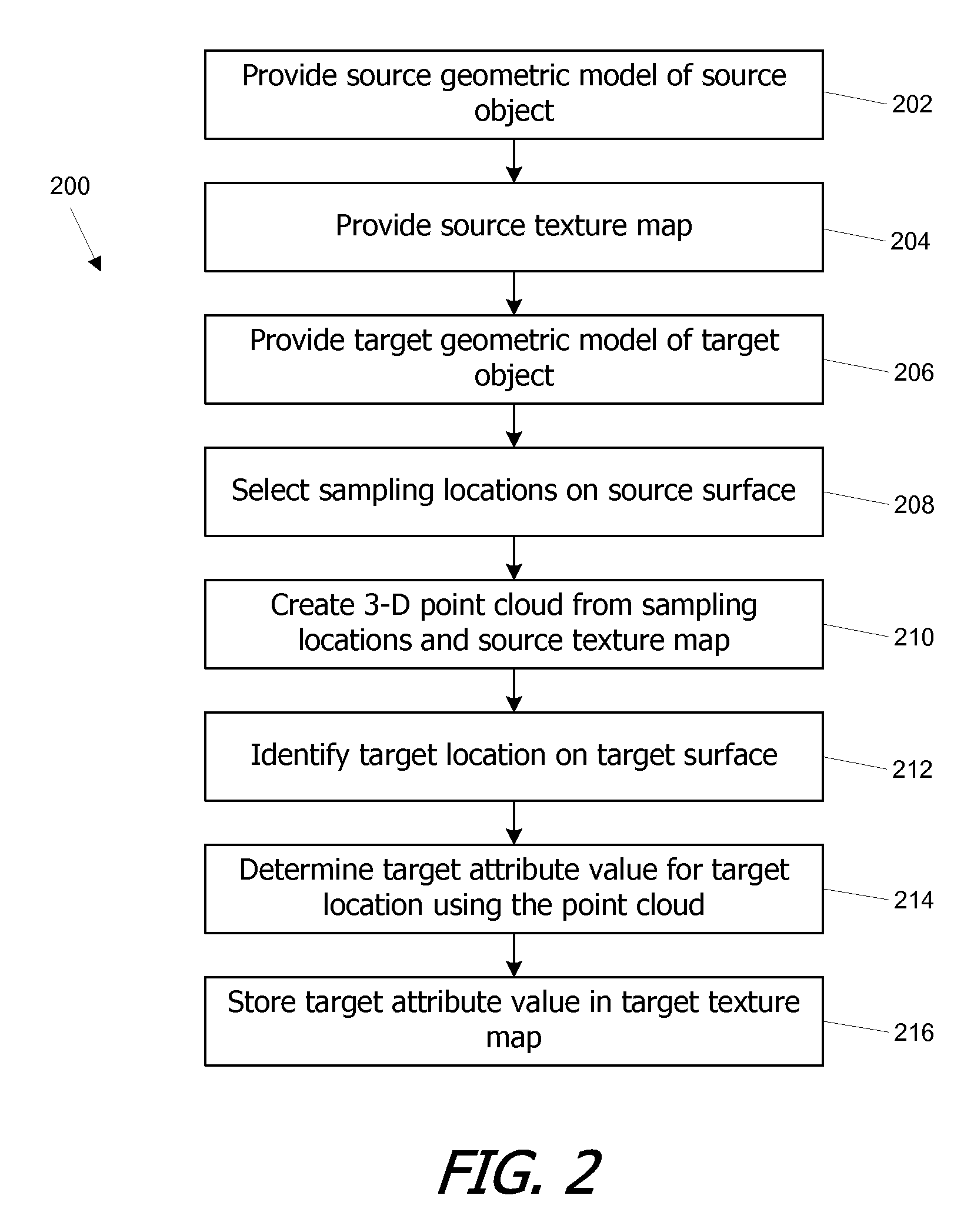

Three-dimensional location-based texture transfers

ActiveUS8040355B2Character and pattern recognitionCathode-ray tube indicatorsPoint cloudComputer graphics (images)

Owner:DISNEY ENTERPRISES INC

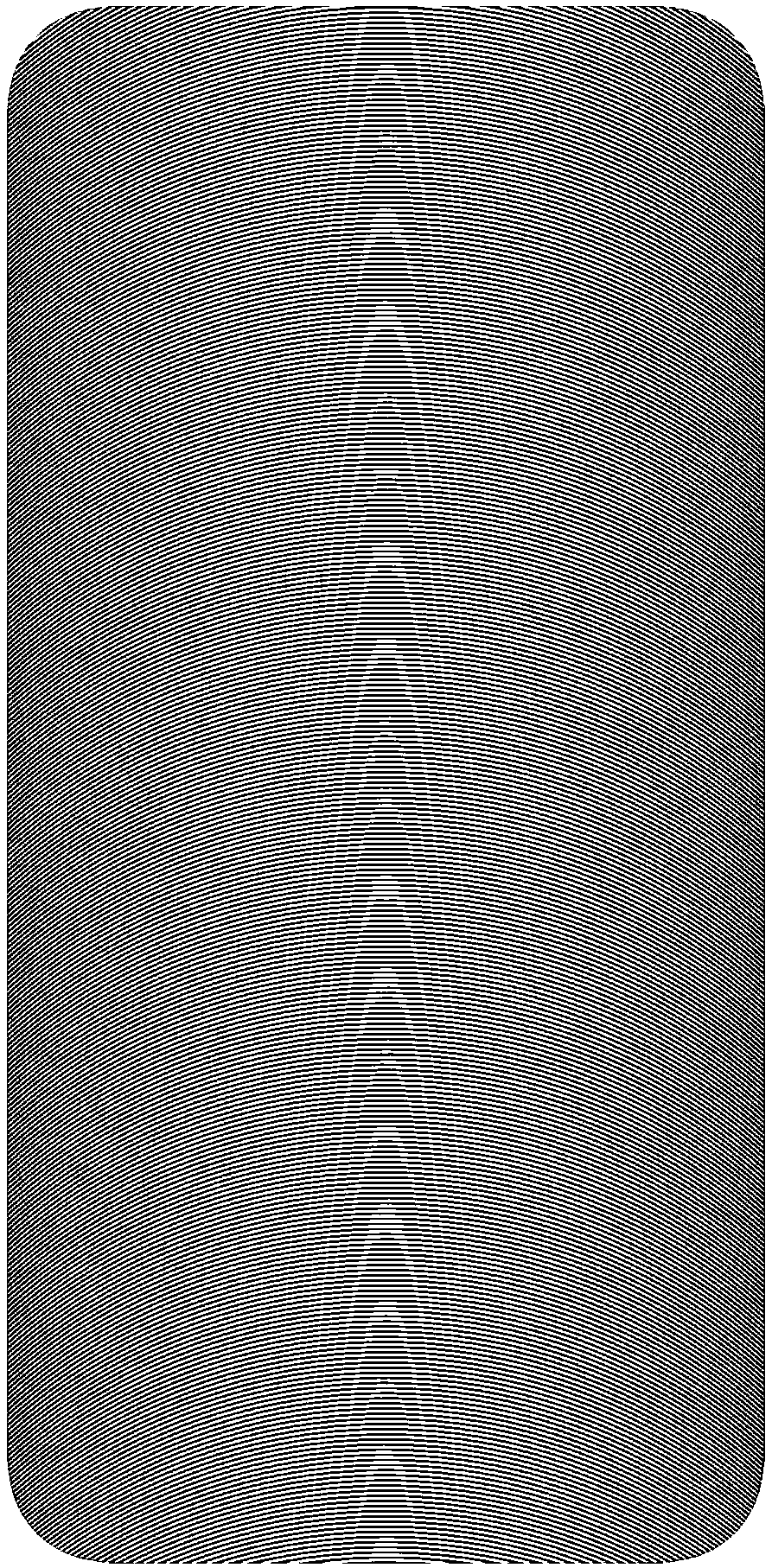

Mobile phone shell with 3D structure and processing technology thereof

The invention discloses a mobile phone shell with a 3D structure. The shell comprises a surface shell body and a bottom shell body. The surface shell body and the bottom shell body comprise sheet material layers which are made of a transparent material and possess outer transparent surfaces and inner transparent surfaces, hardening layers which form on the outer transparent surfaces and possess a predetermined thickness, local printing layers which form at any local positions of the inner transparent surfaces, texture transfer printing layers which form on the inner transparent surfaces and cover the local printing layers, vacuum electroplated layers and printing ink layers, wherein the vacuum electroplated layers and the printing ink layers are successively superimposed with the texture transfer printing layers. The invention also discloses a processing technology. By using the mobile phone shell with the 3D structure, on one hand, the shell possesses light transmittance performance which is similar to the light transmittance performance of glass, simultaneously can bear a large impact force and can not be fragmented so that a durability problem during a usage process is solved, and the shell accords with human engineering of a hand portion of a person and satisfies a customized demand of a consumer; on the other hand, through the above technology, mass production in industry is realized and production cost is reduced.

Owner:东莞市汇诚塑胶金属制品有限公司

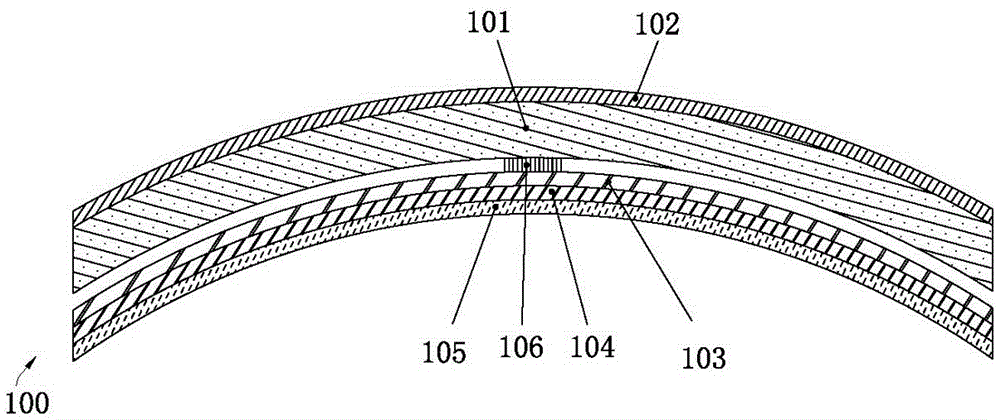

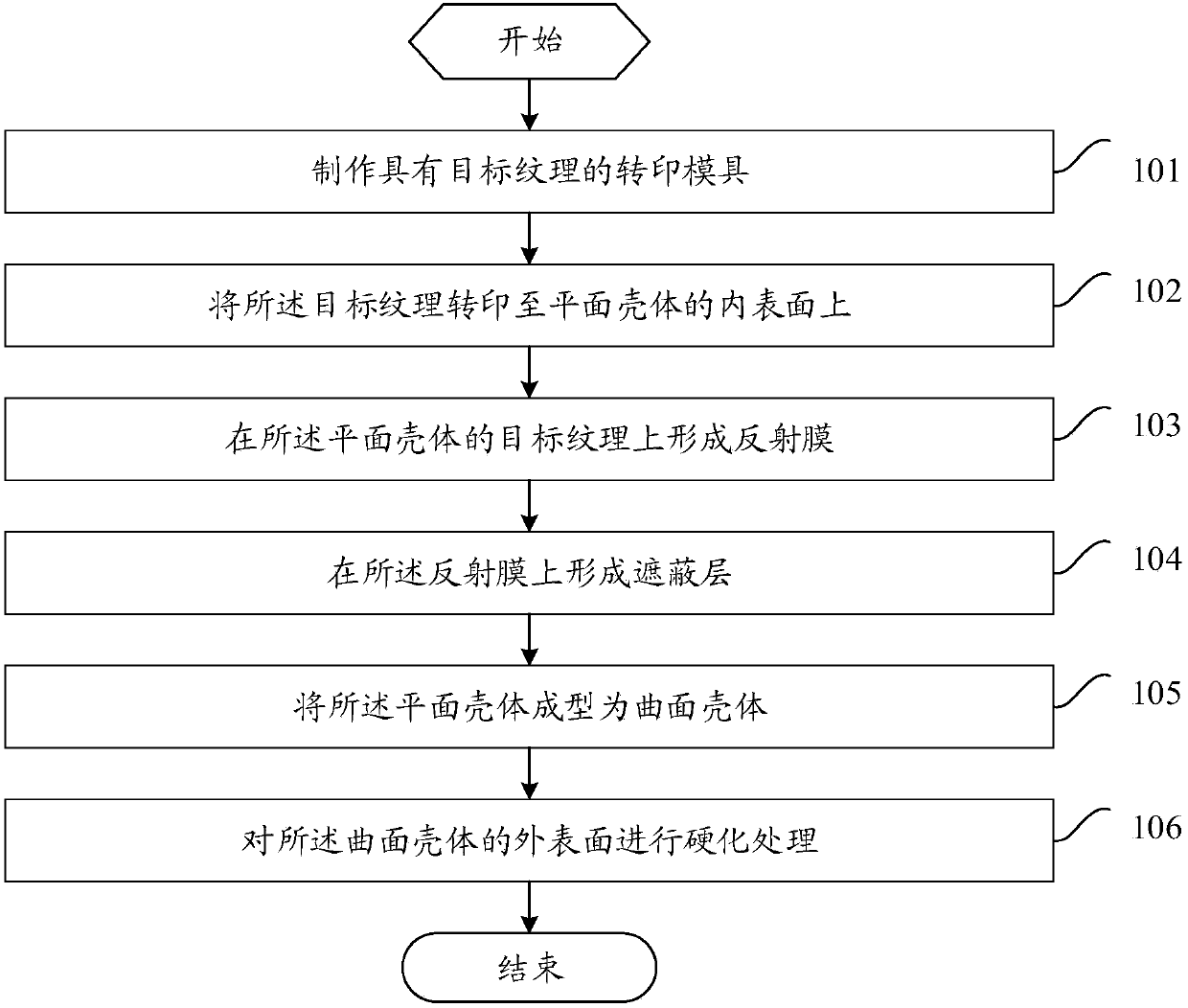

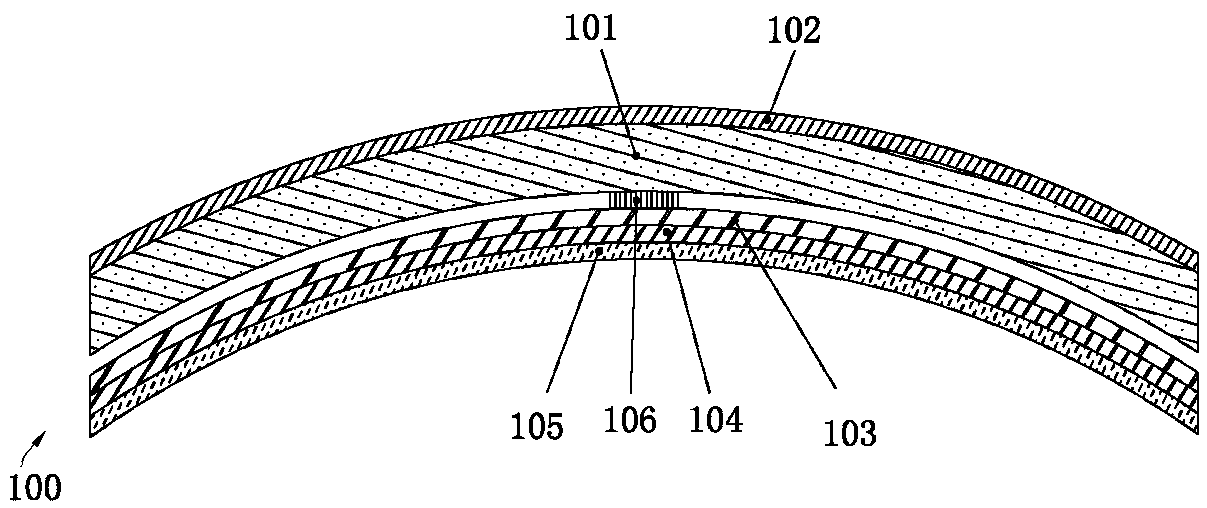

Surface machining method for shell, shell and mobile terminal

InactiveCN107672151ALow costUnbreakableDecorative surface effectsOrnamental structuresWear resistantEngineering

The embodiment of the invention provides a surface machining method for a shell, the shell and a mobile terminal. The method comprises the steps that a transfer printing mold provided with a target texture is made, wherein the target texture comprises multiple arc-shaped grooves, and the cross section of each groove is in a V shape; the target texture is transfer-printed to the inner surface of aplanar shell; a reflective film is formed on the target texture of the planar shell; a shielding layer is formed in the reflective film; a curved surface shell is formed by the planar shell; and hardening treatment is conducted on the outer surface of the curved surface shell. A composite board can be used as the planar shell, the curved surface effect is achieved in target texture transfer printing, reflective film coating and forming manners, the forming radian is large, the size is stable and free of bounce, curved surface glass can be replaced in the appearance effect, and the composite board is low in cost, not prone to breakage and high in productivity, capable of achieving surface strengthening and good in wear-resistant and scratch-resistant performance.

Owner:VIVO MOBILE COMM CO LTD

System and method for feature-based light field morphing and texture transfer

InactiveUS7129943B2Simple working processShorten the timeGeometric image transformationCathode-ray tube indicatorsGraphicsMorphing

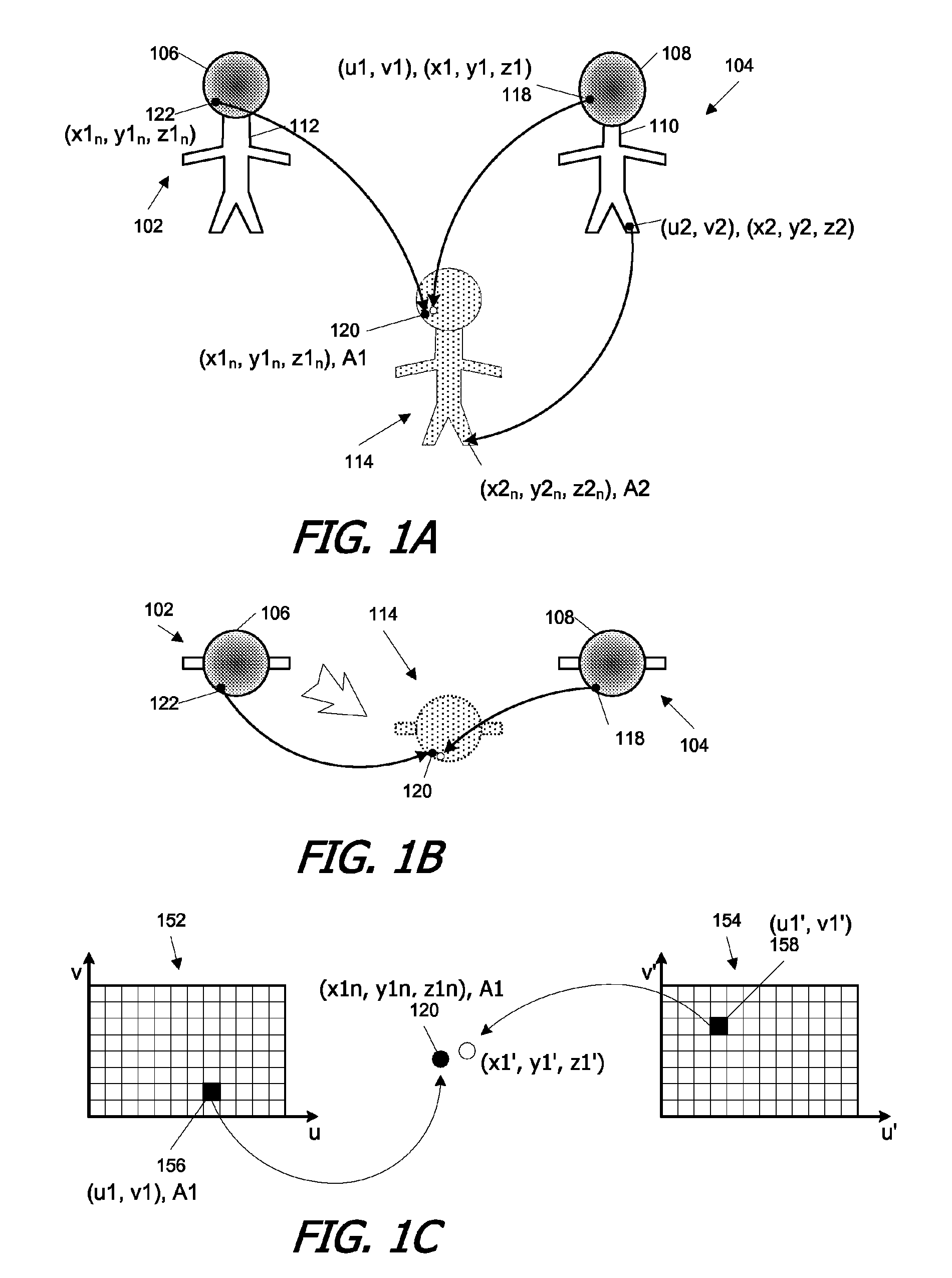

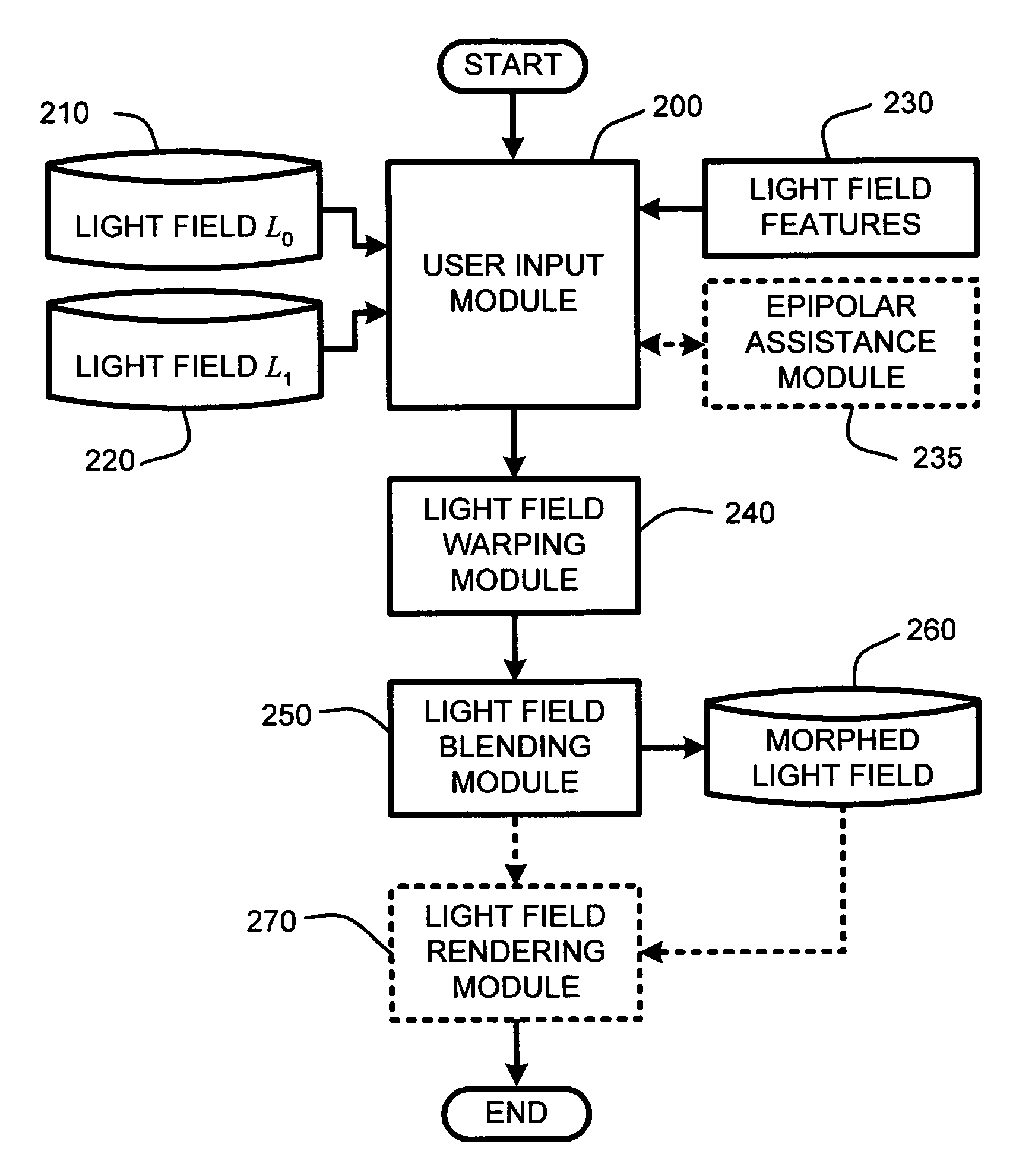

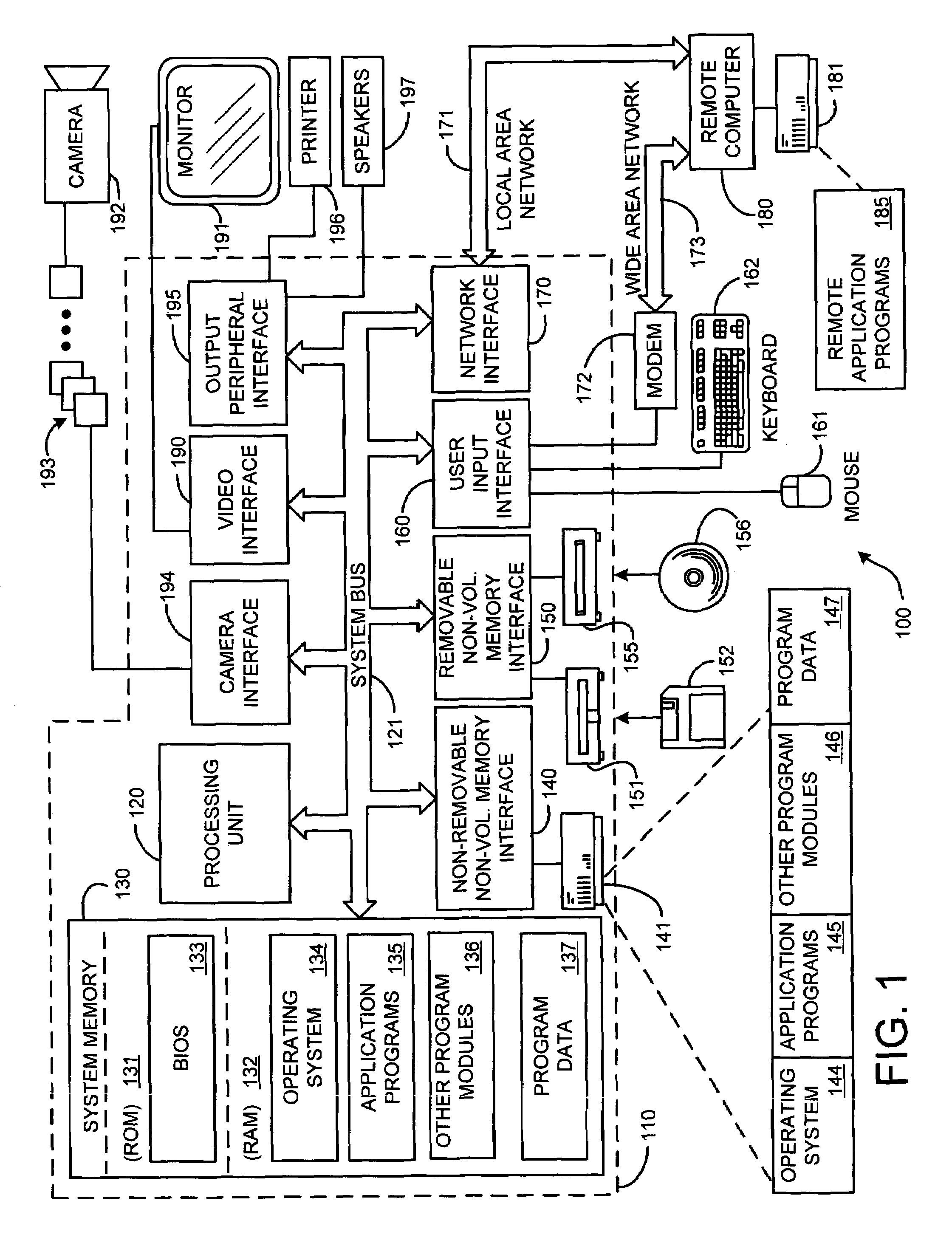

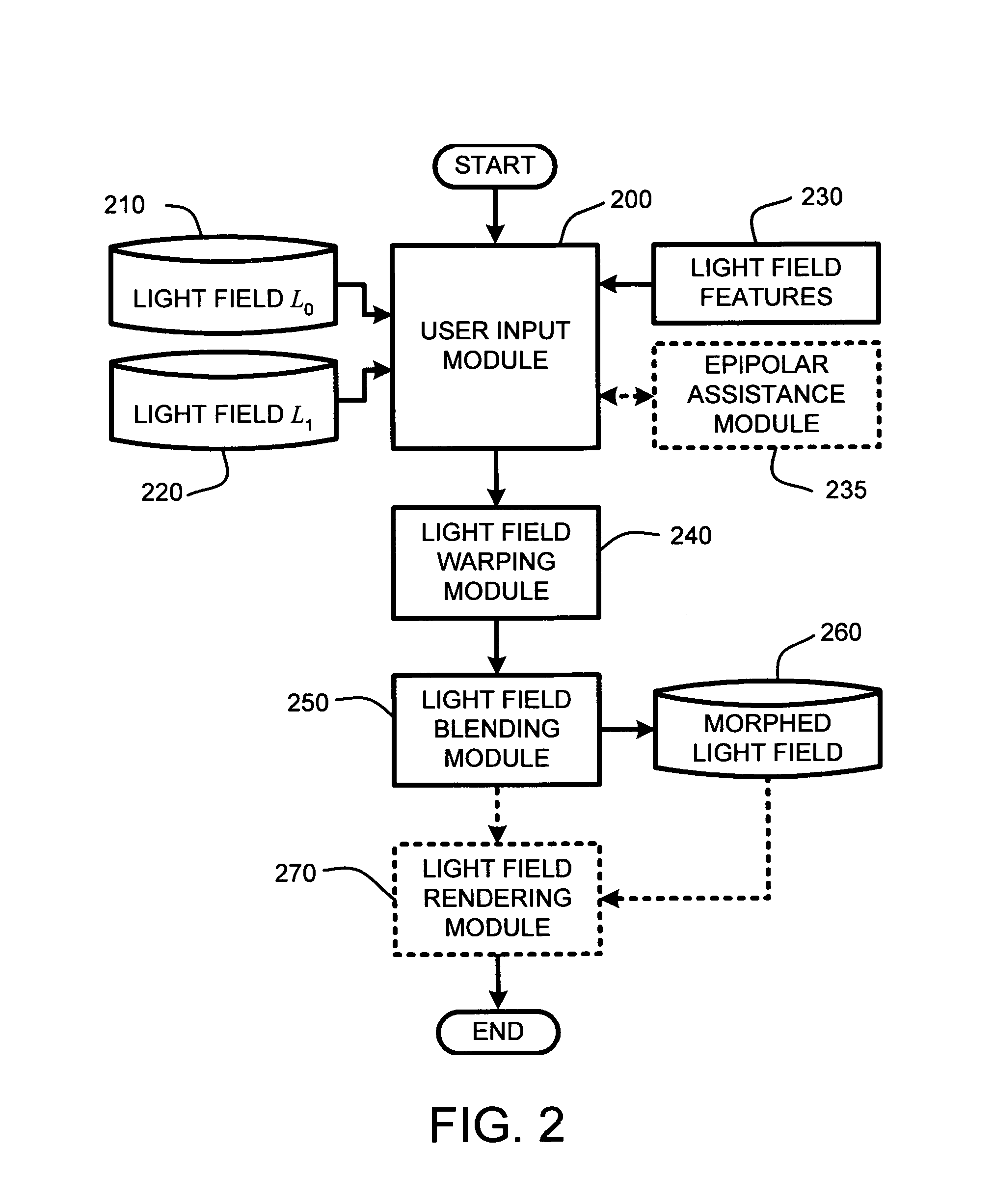

A “light field morpher,” as described herein, provides a computationally efficient system and method for image-based three-dimensional (3D) morphing and texture transfer of 3D objects by morphing “light fields” or “lumigraphs,” associated with source and target 3D objects. The light field morpher is applicable to morphing of objects having either or both Lambertian, or non-Lambertian surfaces, including surfaces having complex properties such as fur, subsurface scattering, and hypertextures, without the need for object modeling, or otherwise recovering detailed object geometry. Light field morphing begins by first specifying corresponding 2D and 3D feature elements, such as, “feature lines,”“feature polygons,” and “background edges,” in the input light fields representing the source and target light fields. Once the feature elements have been specified, “ray-space warping” of both light fields then warps those light fields to produce feature alignment. These warped light fields are then blended to produce a light field morph.

Owner:MICROSOFT TECH LICENSING LLC

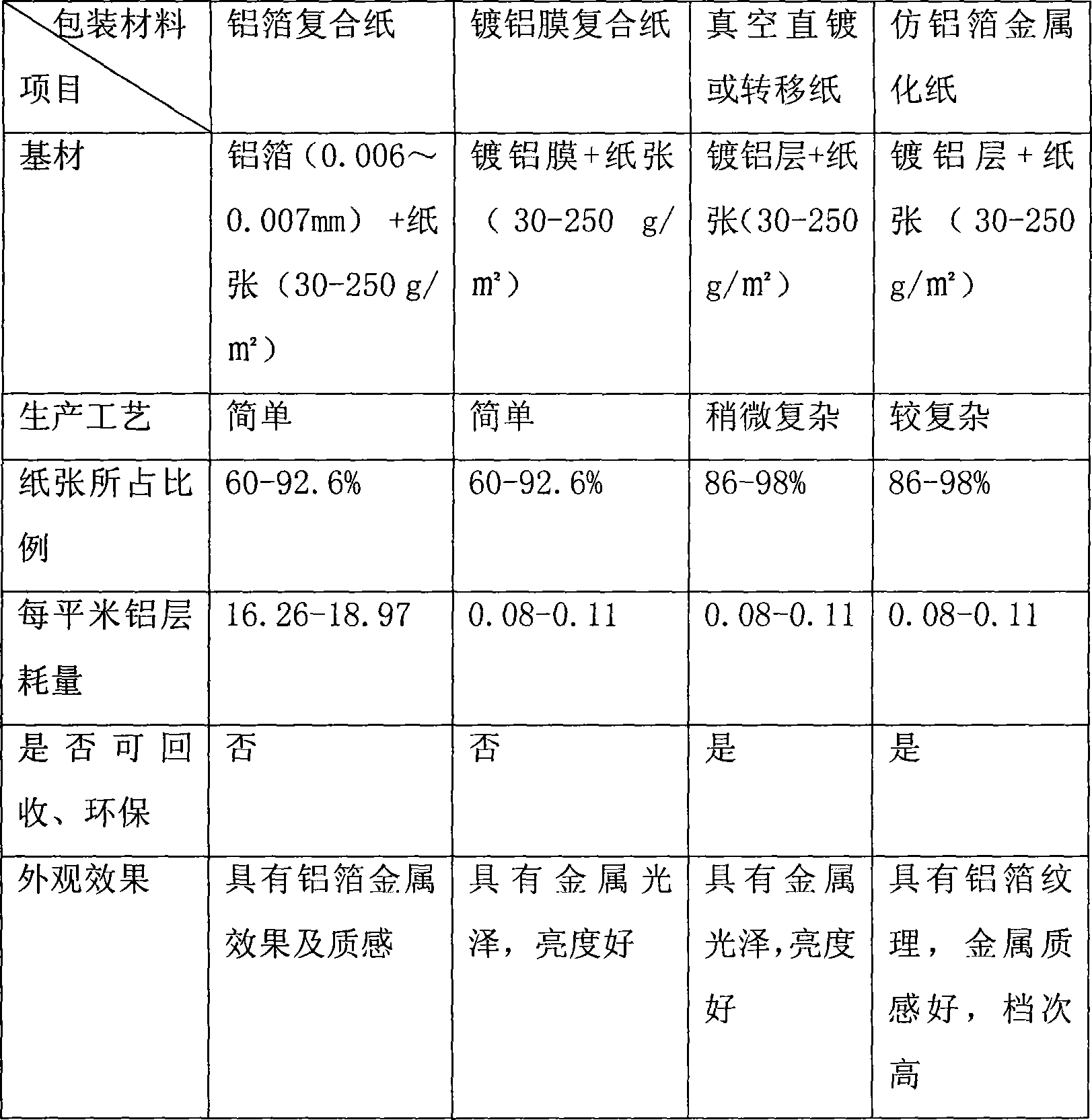

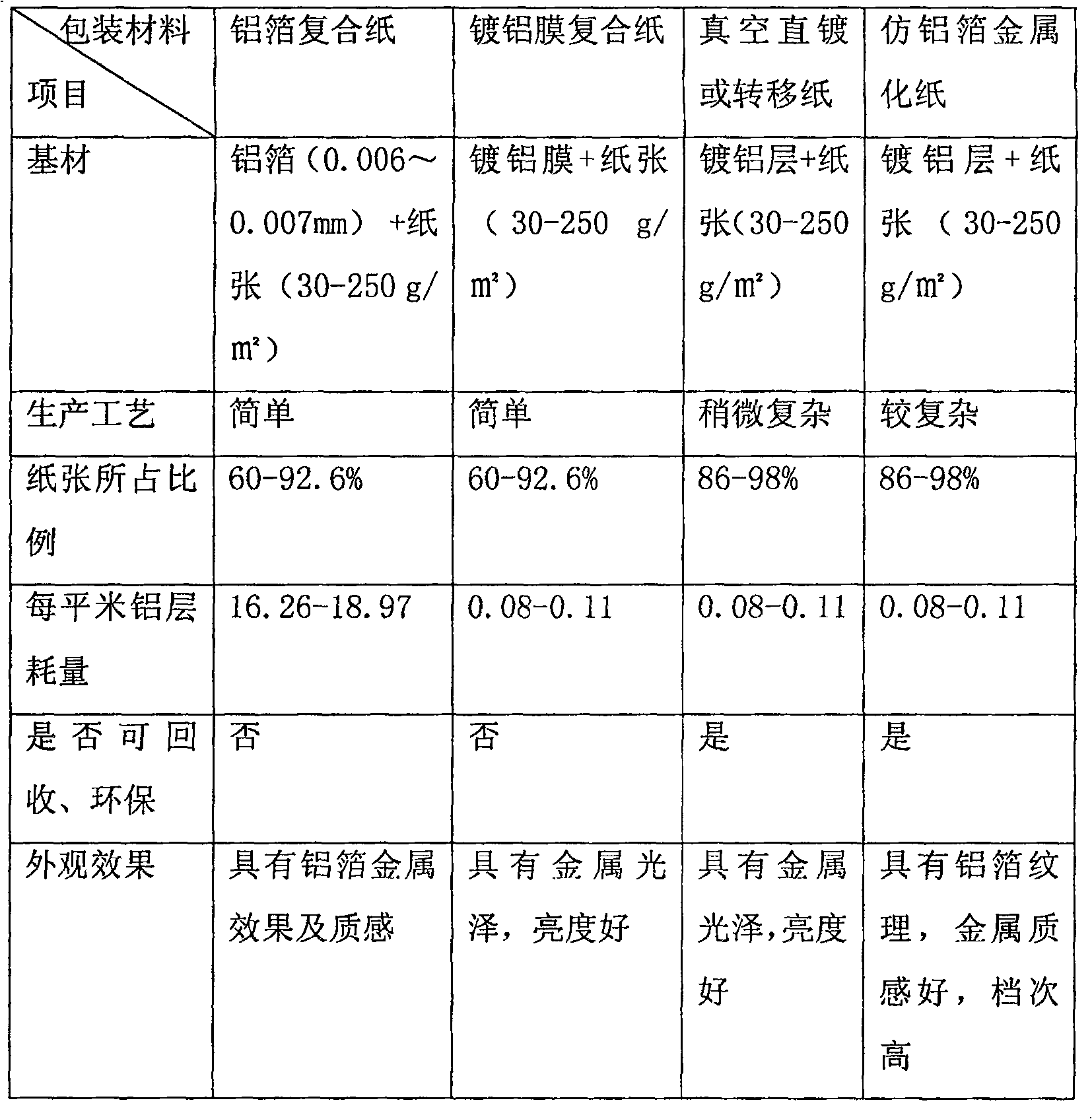

Process for manufacturing aluminum foil pseudo metal texture transition paper

InactiveCN101135128AStrong metal textureImprove visual effectsFlexible coversMechanical working/deformationPolyesterTexture transfer

The present invention relates to packing paper for cigarette and wine products, and is production process of aluminum foil-imitating metal texture transfer paper. The production process includes the following steps: spreading transfer paint to one or two sides of biaxially stretched polypropylene film, biaxially stretched polyester film or heat sealed biaxially stretched polypropylene film; pressing with molding roller; vacuum plating aluminum film on the film; wet compounding the film to paper with water thinned glue; slaking the film in the condition of 35-55 deg.c temperature and 30-60 % humidity for 24-48 hr; and stripping film. The aluminum foil-imitating transfer paper has strong metal texture, excellent visual effect, capacity of degrading naturally.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

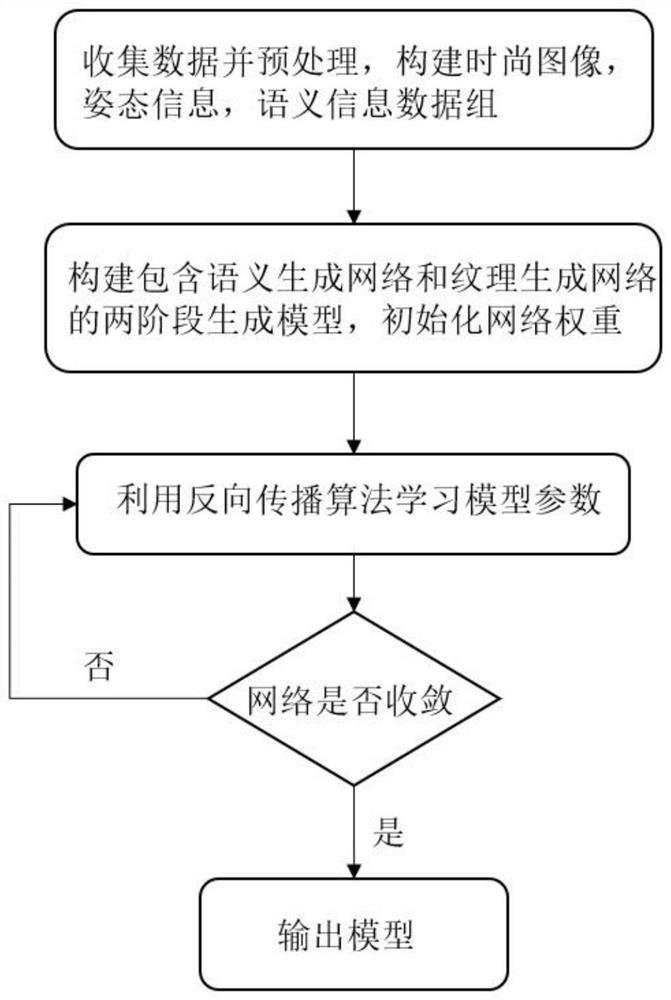

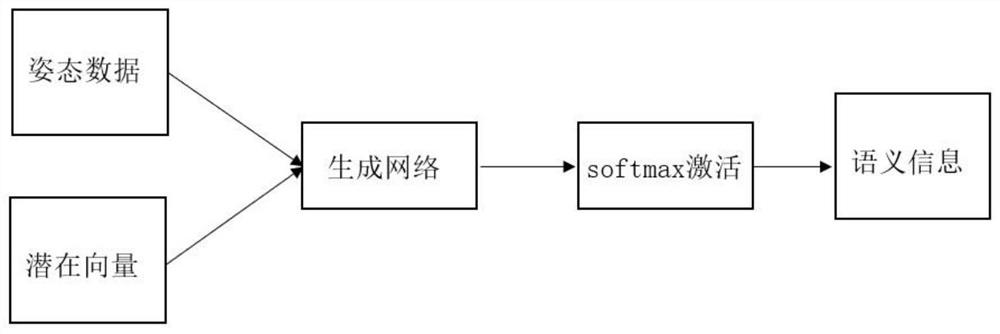

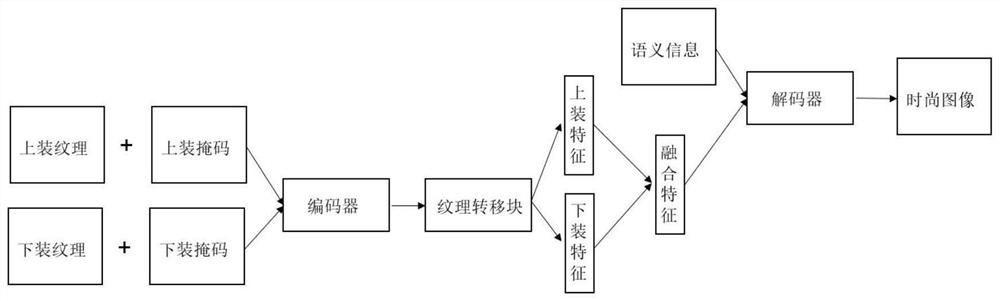

Posture and texture guided fashion costume design synthesis method

The invention discloses a posture and texture guided fashion costume design synthesis method. The method comprises the steps of 1, collecting task data by means of an existing fashion data set, preprocessing the data, and constructing a fashion image, posture information and semantic information data set; 2, by taking generation of a natural and accurate fashion image as a target, constructing a two-stage generation model; the generation model comprises a semantic layout generation network and a texture generation network, effective texture transfer is realized, and diversified fashion images are generated; 3, training a semantic layout generation network and a texture transfer network by using the collected data groups under the condition of minimizing adversarial loss, cross entropy loss, pixel-level loss, perception loss and style loss; and 4, training network parameters in the generated model through a back propagation algorithm until the whole model converges, and generating a corresponding fashion image. According to the method disclosed by the invention, an experiment is carried out on a Fast-Gen data set, and good results are obtained in both quantitative and qualitative aspects.

Owner:HANGZHOU DIANZI UNIV

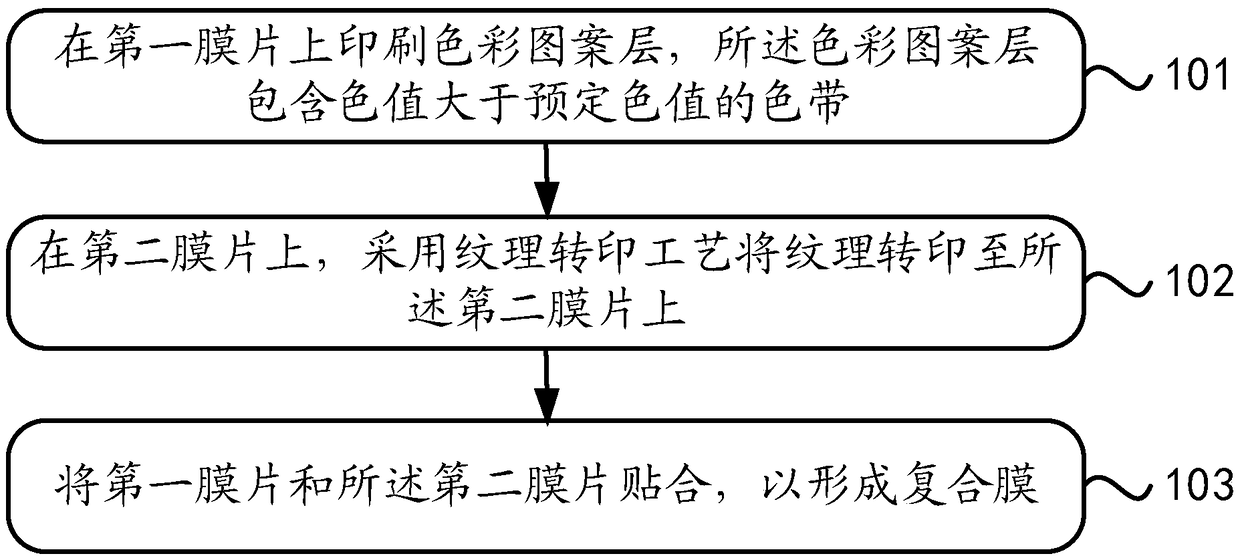

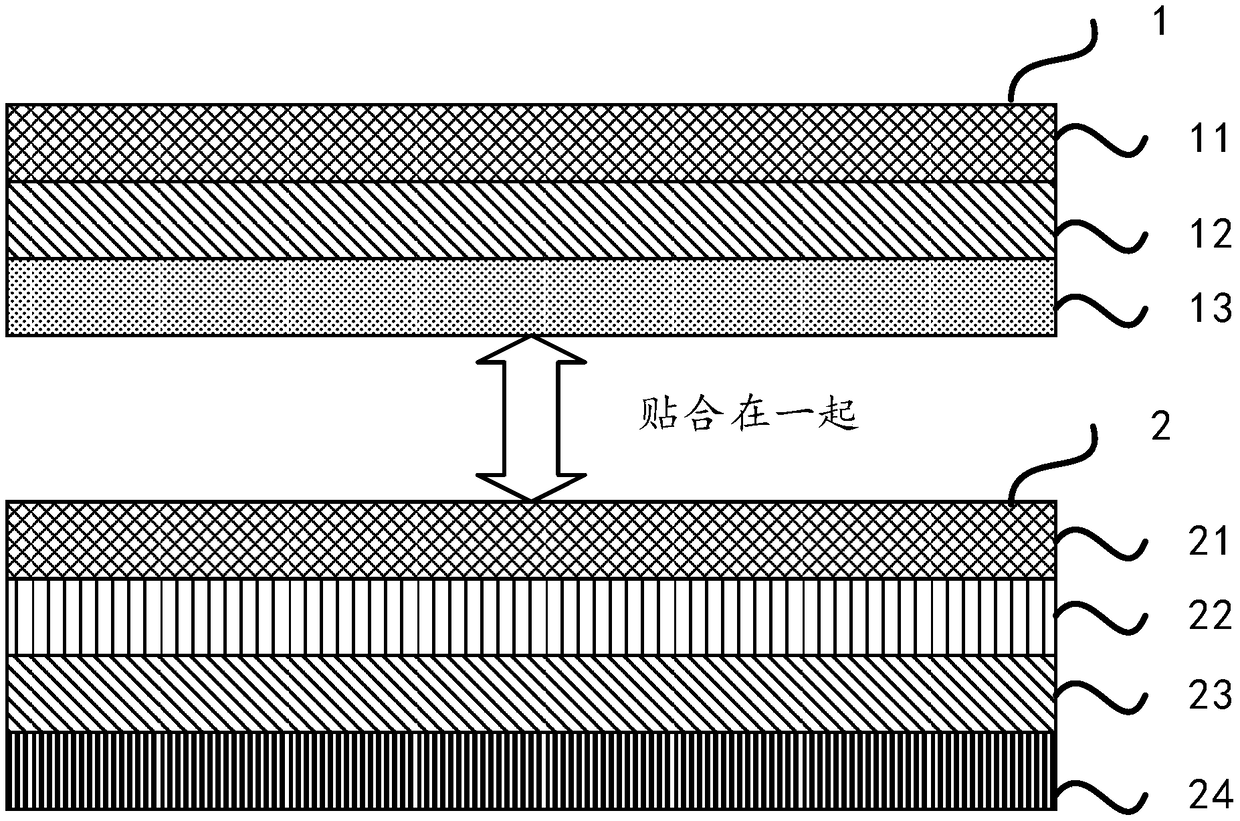

Preparation method of composite membrane, back cover and electronic equipment

InactiveCN108859565AEnsure qualityFormation does not existDecorative surface effectsSpecial ornamental structuresQuality performanceEngineering

The invention discloses a preparation method of a composite membrane, a back cover and electronic equipment. The method comprises the steps: printing a color pattern layer on a first diaphragm, wherein the color pattern layer contains a colored tape with the color value greater than a predetermined color value; transferring texture onto a second diaphragm by a texture transfer process; and gluingthe first diaphragm and the second diaphragm to form the composite membrane. According to the embodiment of the invention, a color pattern layer printing process and the texture transfer process are respectively completed on the two diaphragms, so that the colored tape with the color value greater than the predetermined color value in the color pattern layer on the first diaphragm does not affectthe formation of a texture surface on the second diaphragm, and the quality performance of the composite membrane is ensured.

Owner:VIVO MOBILE COMM CO LTD

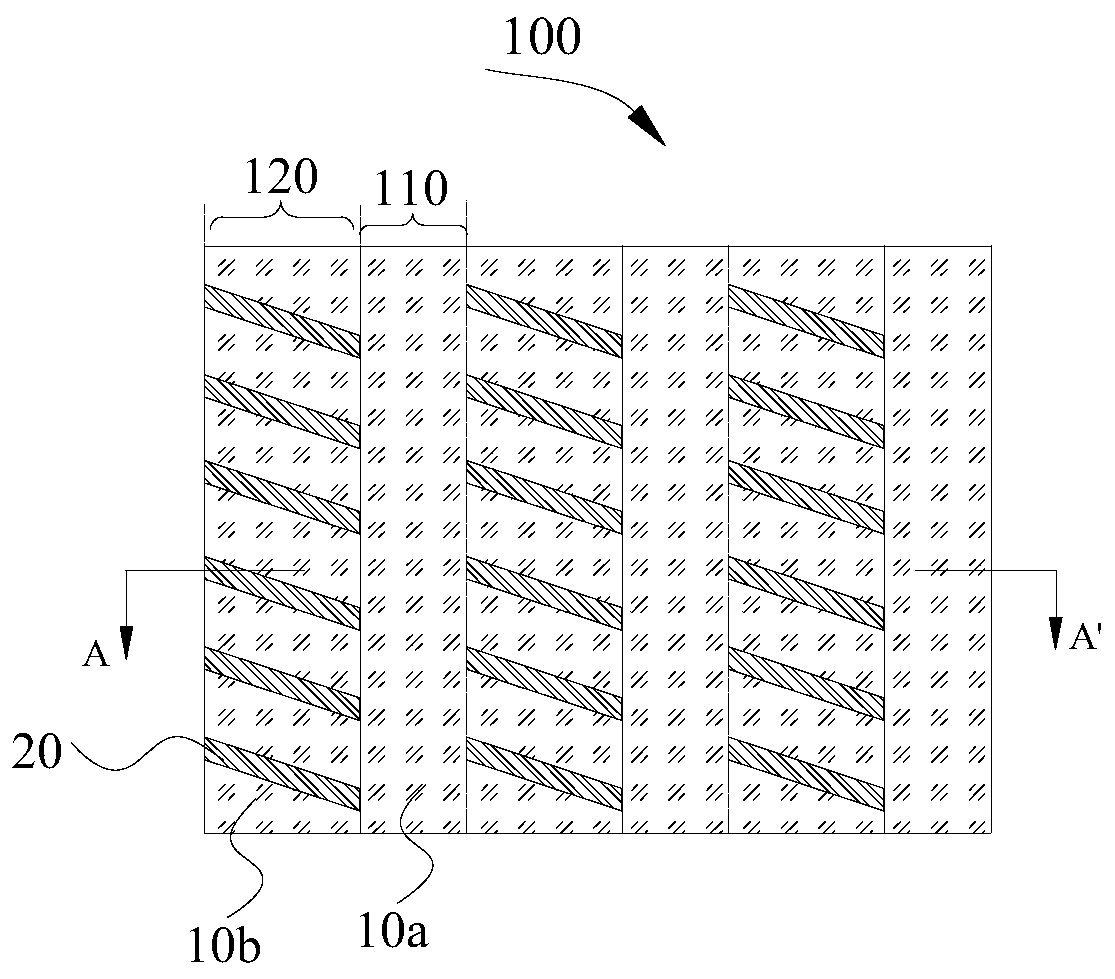

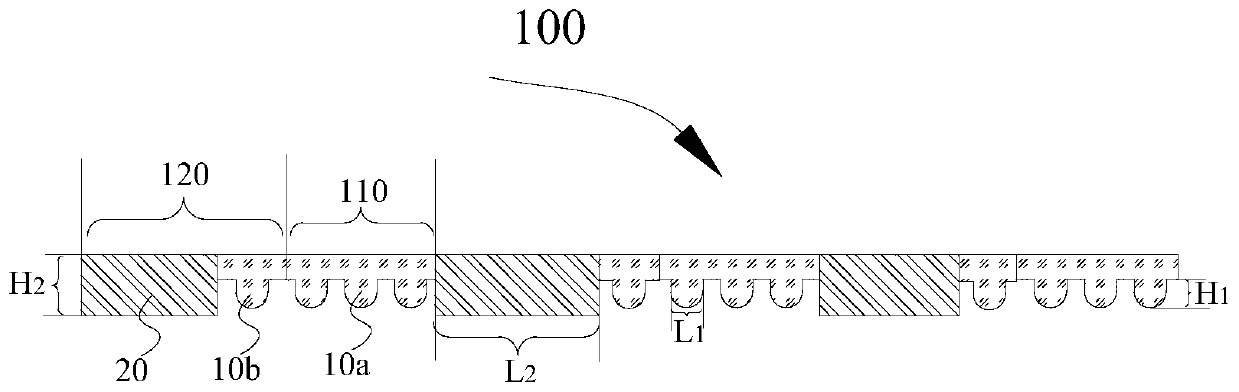

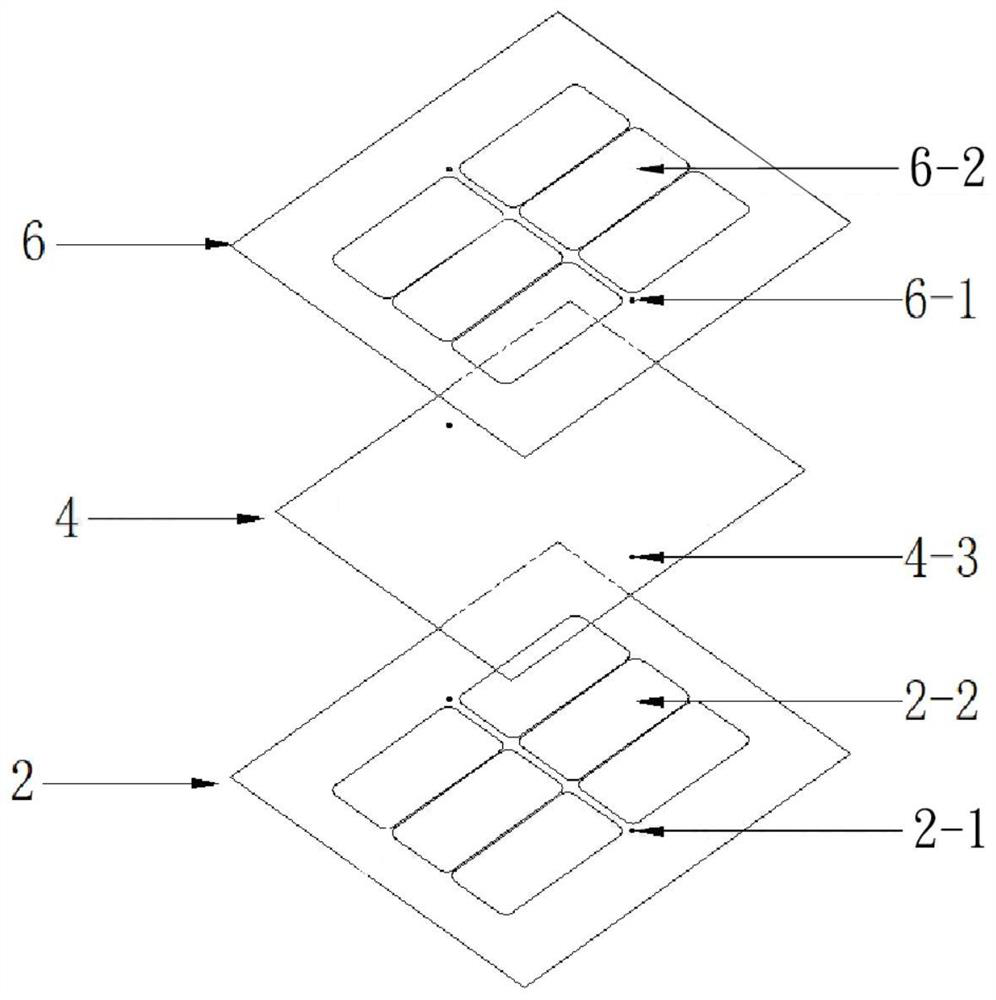

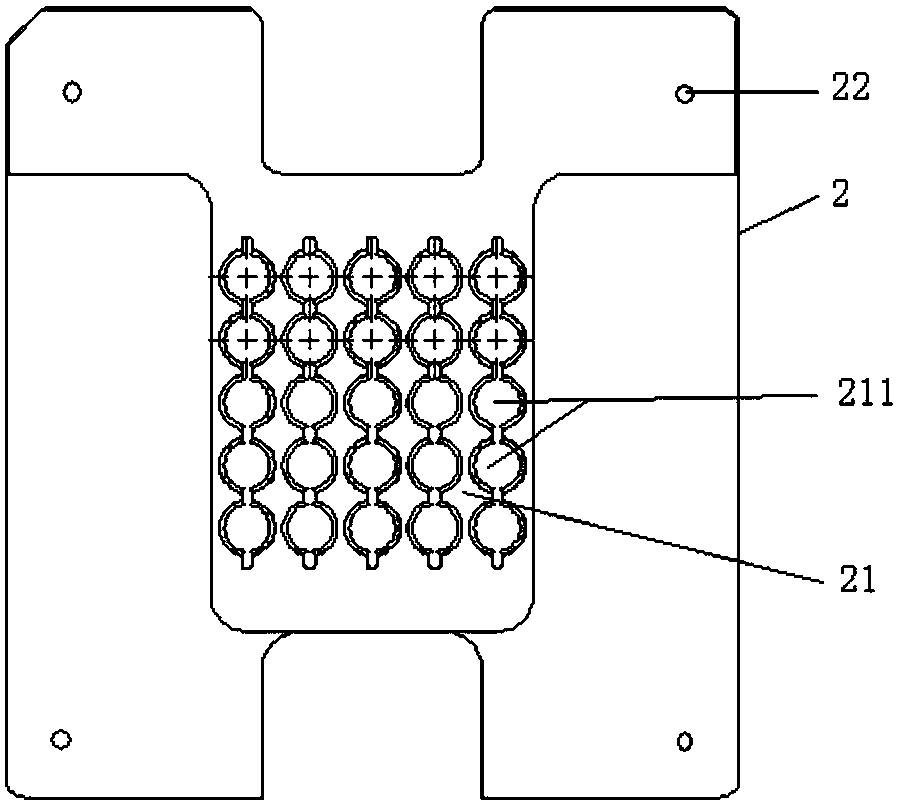

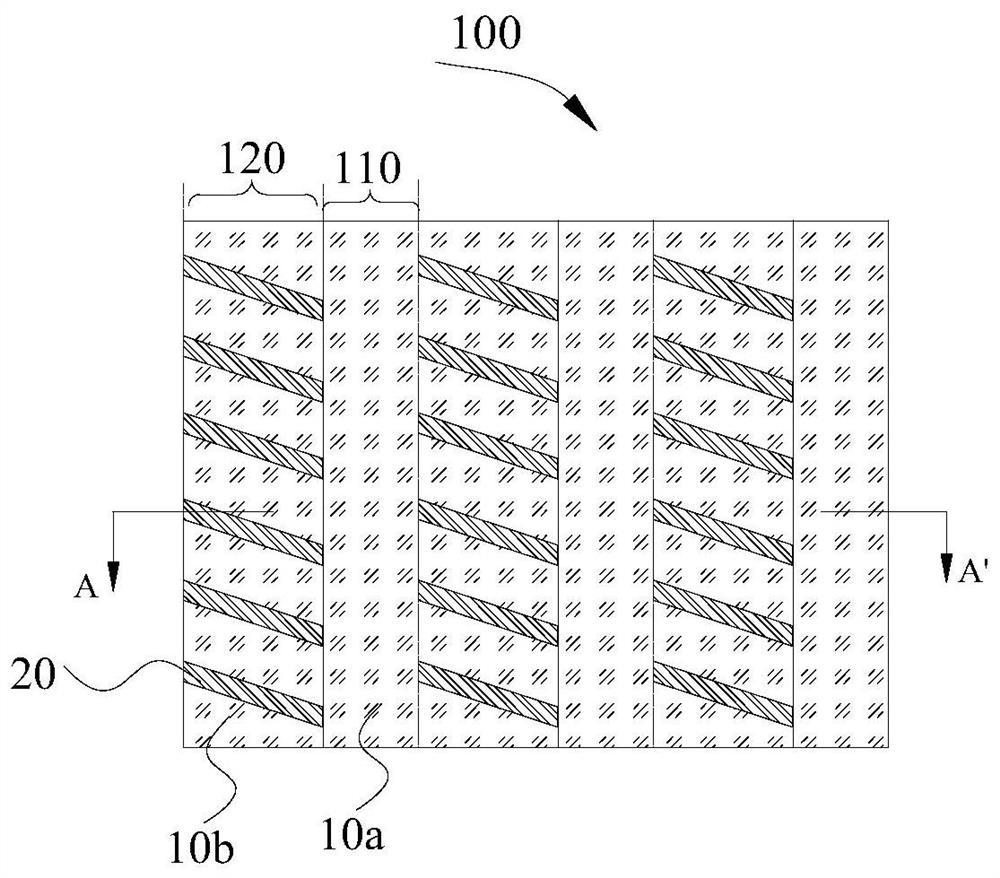

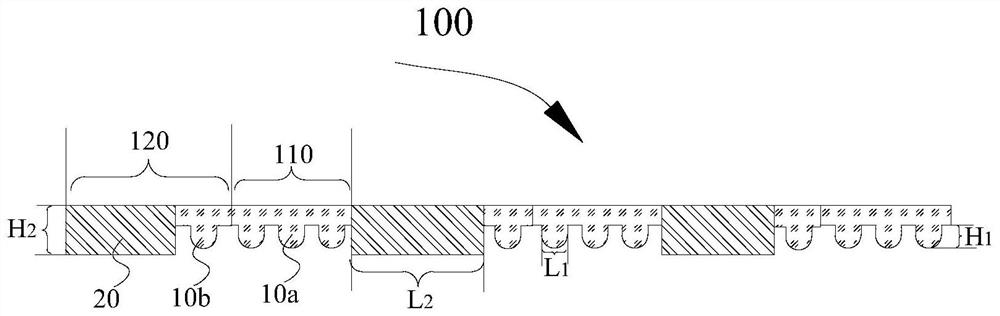

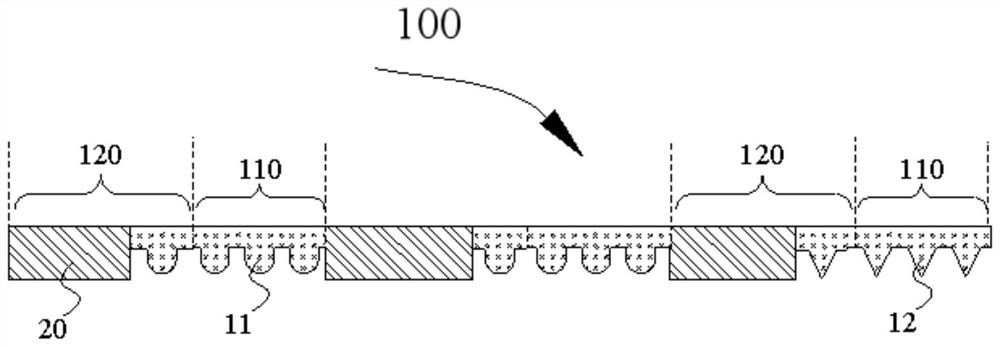

Texture transferring female die, plate and preparation method thereof, shell and electronic equipment

ActiveCN111016415ALower yieldIncrease production costTransfer printingOrnamental structuresEngineeringTexture transfer

The invention discloses a texture transferring female die, a plate and a preparation method thereof, a shell and electronic equipment, and particularly provides a texture transferring female die. A first texture area and a second texture area which are alternately arranged at an interval are arranged on the texture transferring female die. The texture transferring female die comprises a first texture and a second texture. The texture shapes of the first texture and the second texture are not completely identical, the first texture is located in the first texture area and part of the second texture area, and the second texture is located in the second texture area. The first texture and the second texture in the second texture area are arranged at an interval. Thus, a texture transferring sub-die formed by the texture transferring female die can form the effect that multiple kinds of textures are combined and overlaid through a one-time UV transferring process, a texture layer with a rich texture combined and overlaid effect can be easily and conveniently prepared through the texture transferring female die, the preparation process is simple, and the production cost can be reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

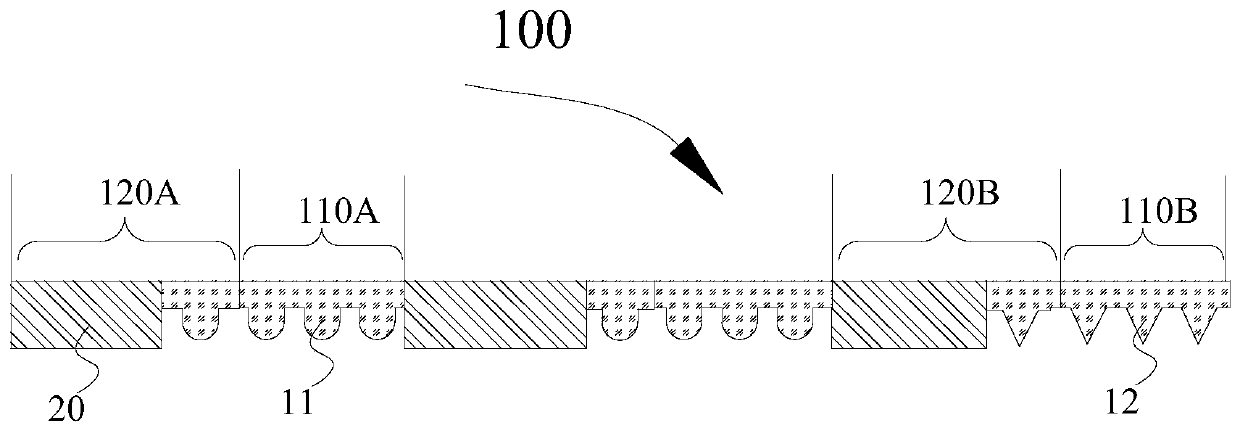

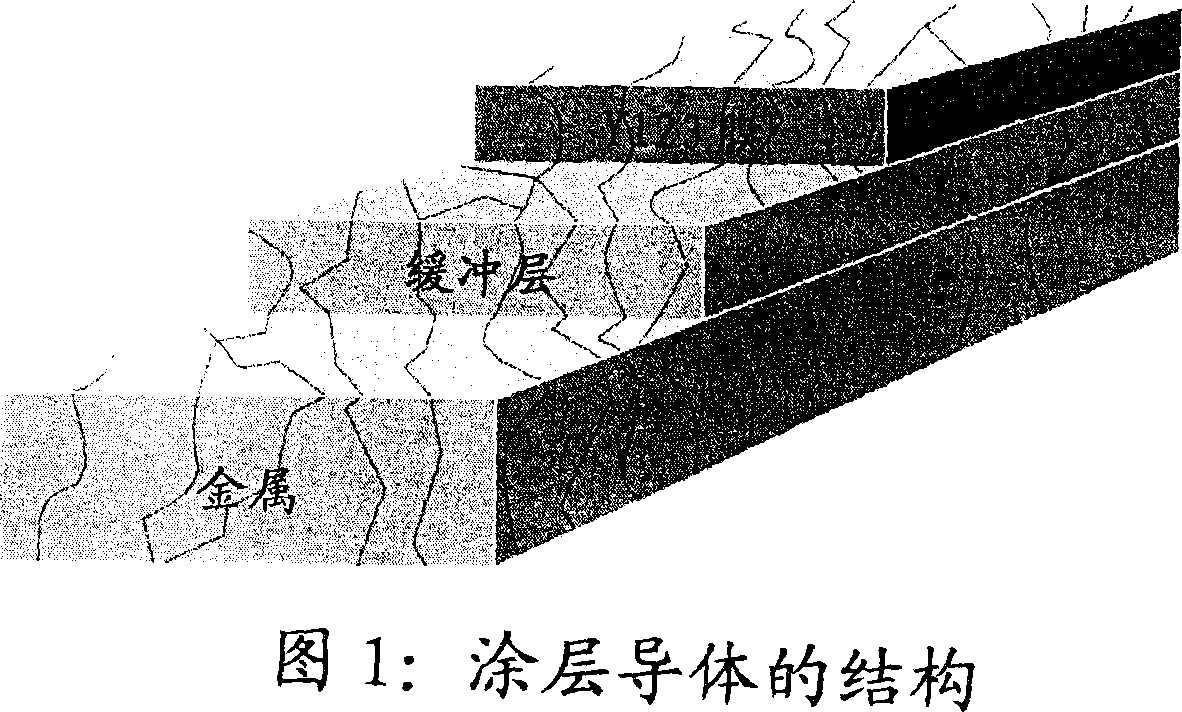

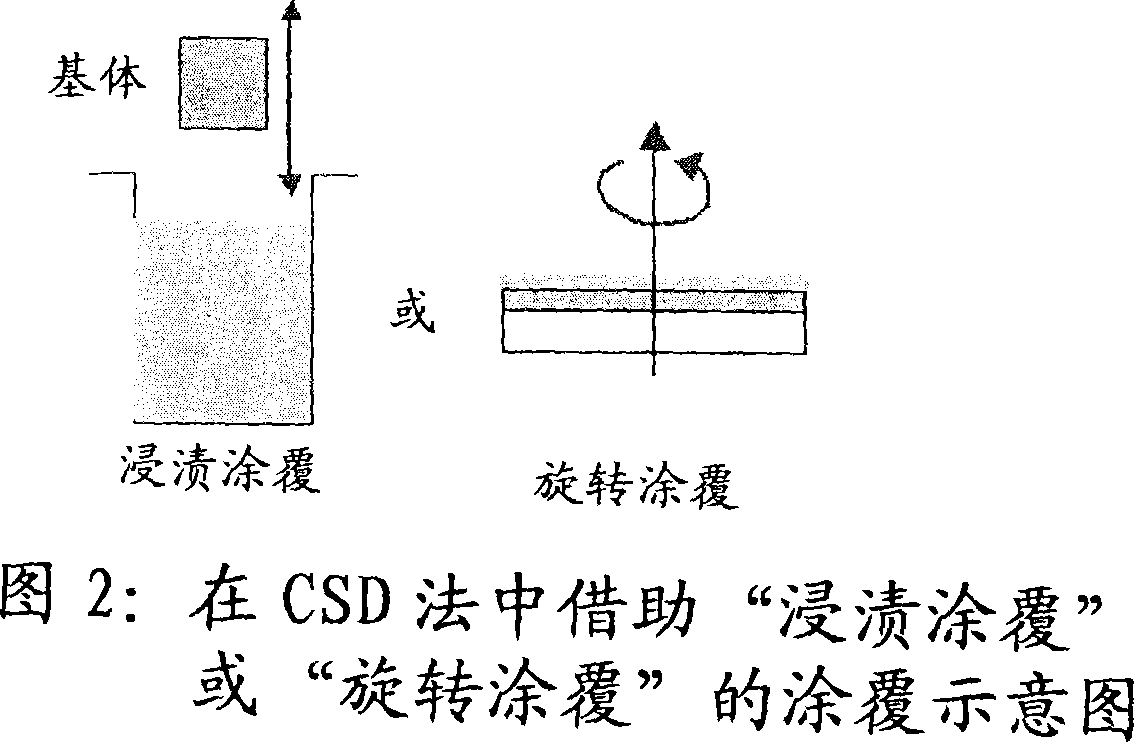

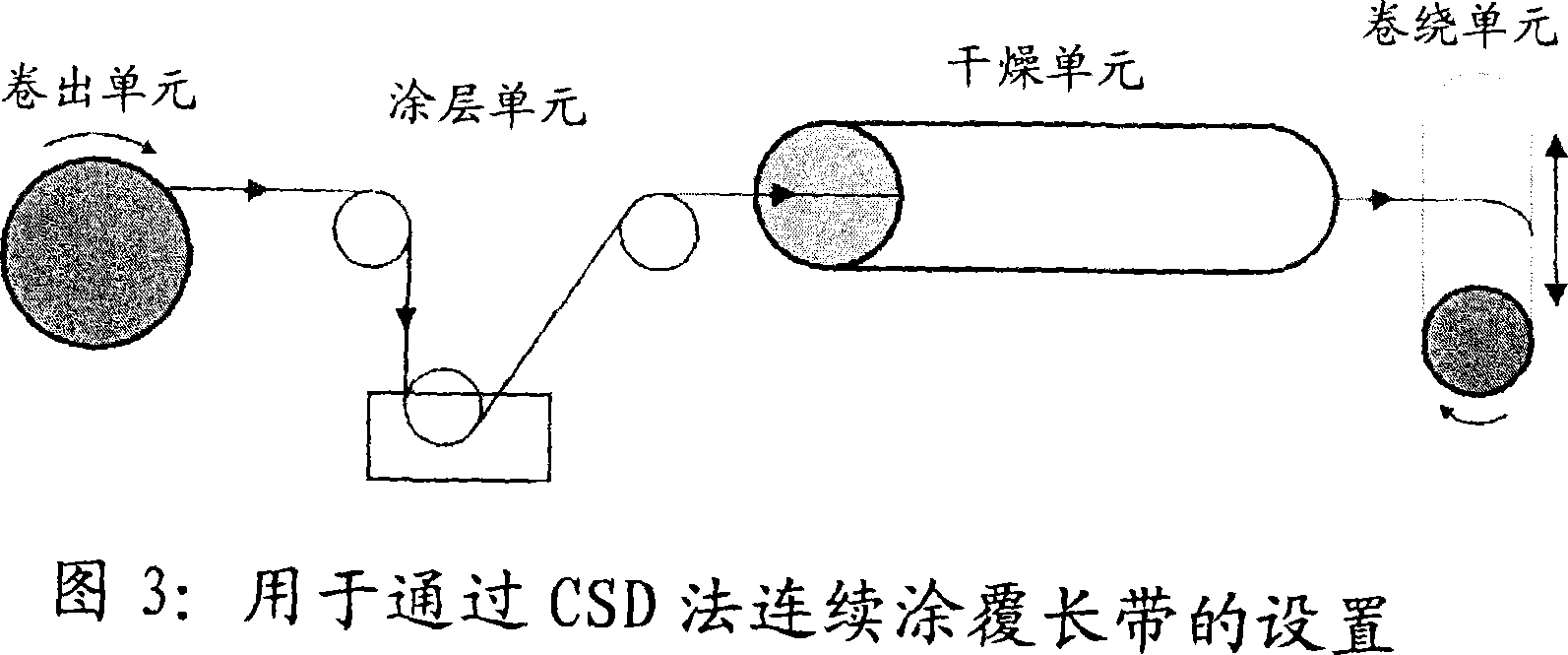

Method for producing highly-textured, strip-shaped, high-temperature superconductors

ActiveCN1993497ASuperconductors/hyperconductorsCeramicsElectrical conductorHigh temperature superconducting

The invention relates to a wet-chemical method for producing strip-shaped high-temperature superconductors comprising a metal substrate, at least one buffer layer and a high-temperature superconducting layer. The aim of the invention is to improve the texture transfer ability of the buffer layer. For this purpose, a polar solvent having at least one free hydroxyl group is used during production of a coating solution that is applied to the metal substrate and that forms the buffer layer after drying and annealing.

Owner:AMERICAN SUPERCONDUCTOR

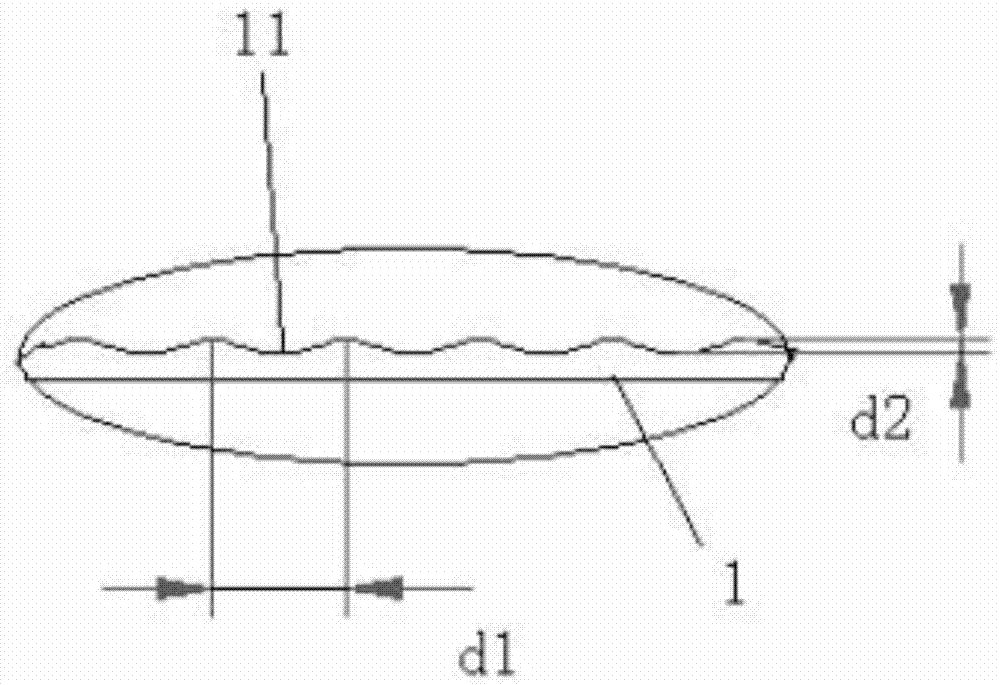

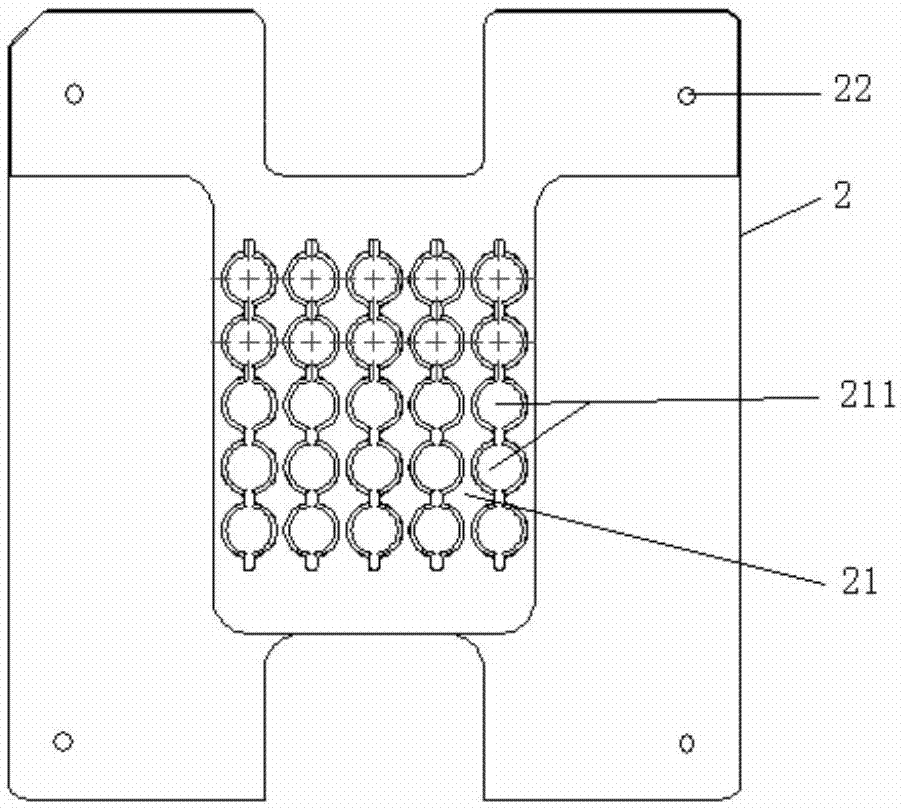

Apparatus for performing texture transfer printing on camera protection glass, and texture transfer printing method

ActiveCN107097504AEasy to getLow costLamination ancillary operationsLaminationEngineeringTexture transfer

A first purpose of the present invention is to provide an apparatus for performing texture transfer printing on a camera protection glass, wherein the whole apparatus has advantages of simple structure and easy part obtaining. A second purpose of the present invention is to provide a texture transfer printing method using the apparatus. The texture transfer printing method comprises: A, placing a camera protection glass to be subjected to texture transfer printing into the positioning concave groove of a drawing film adhesion base; B, positioning a drawing positioning film onto the drawing film adhesion base; C, rolling the back surface of the drawing positioning film by using a roller; D, positioning the drawing positioning film adhered with the camera protection glass to be subjected to texture transfer printing onto the base of a drawing mold; E, placing a supporting film; F, covering the mold, and rolling the back surface of the mold through a roller; and G, irradiating with UV light to make the UV glue in a non-occlusion be subjected to exposure, and carrying out washing and other steps to obtain the camera protection glass with the transferred texture. According to the present invention, the texture transfer printing method is suitable for the camera protection glass, the operation is convenient, and the three-dimensional effect of the texture is strong.

Owner:WINTEK CHINA TECH LTD

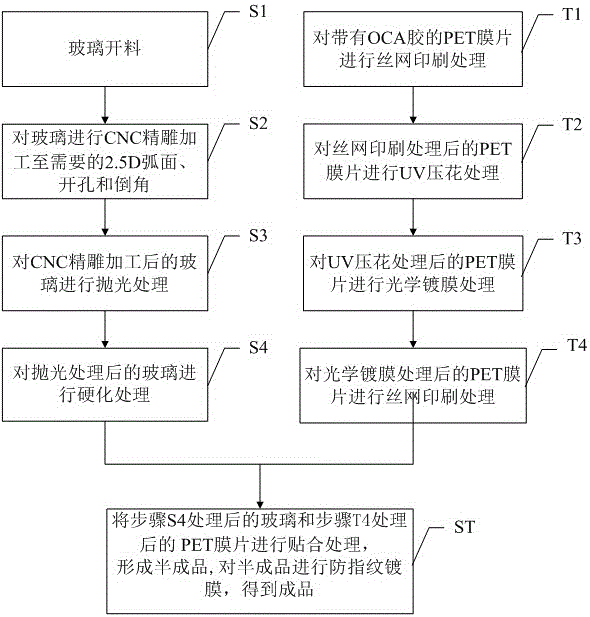

Optical coating and transfer printing combined surface treatment method

InactiveCN106218187AReduce presenceRich and varied visual effectsLamination ancillary operationsLaminationScreen printingAdhesive

The invention discloses an optical coating and transfer printing combined surface treatment method. The method comprises the steps that glass is subjected to rough shape cutting; the glass is subjected to CNC carving machining to obtain the needed 2.5 D cambered surface, tapped holes and chamfers; the glass is subjected to polishing treatment; the glass is subjected to hardening treatment; a PET membrane with an OCA adhesive is subjected to silk-screen printing treatment; the PET membrane is subjected to UV embossing treatment; the PET membrane is subjected to optical coating treatment; the PET membrane is subjected to silk-screen printing treatment; the treated glass and the treated PET membrane are subjected to laminating treatment, a semi-finished product is formed, the semi-finished product is subjected to anti-fingerprint coating, and the finished product is obtained. According to the optical coating and transfer printing combined surface treatment method, secondary machining is conducted on the periphery of the glass, certain radian is formed, ergonomics is better met, and a more comfortable touch feeling is achieved; by conducting surface treatments such as optical coating and texture transfer printing on the 2.5 D glass, the 2.5 D glass has a richer and more changeable visual effect, and the appearance competitiveness of the product is greatly promoted.

Owner:TCL COMM TECH NINGBO CO LTD

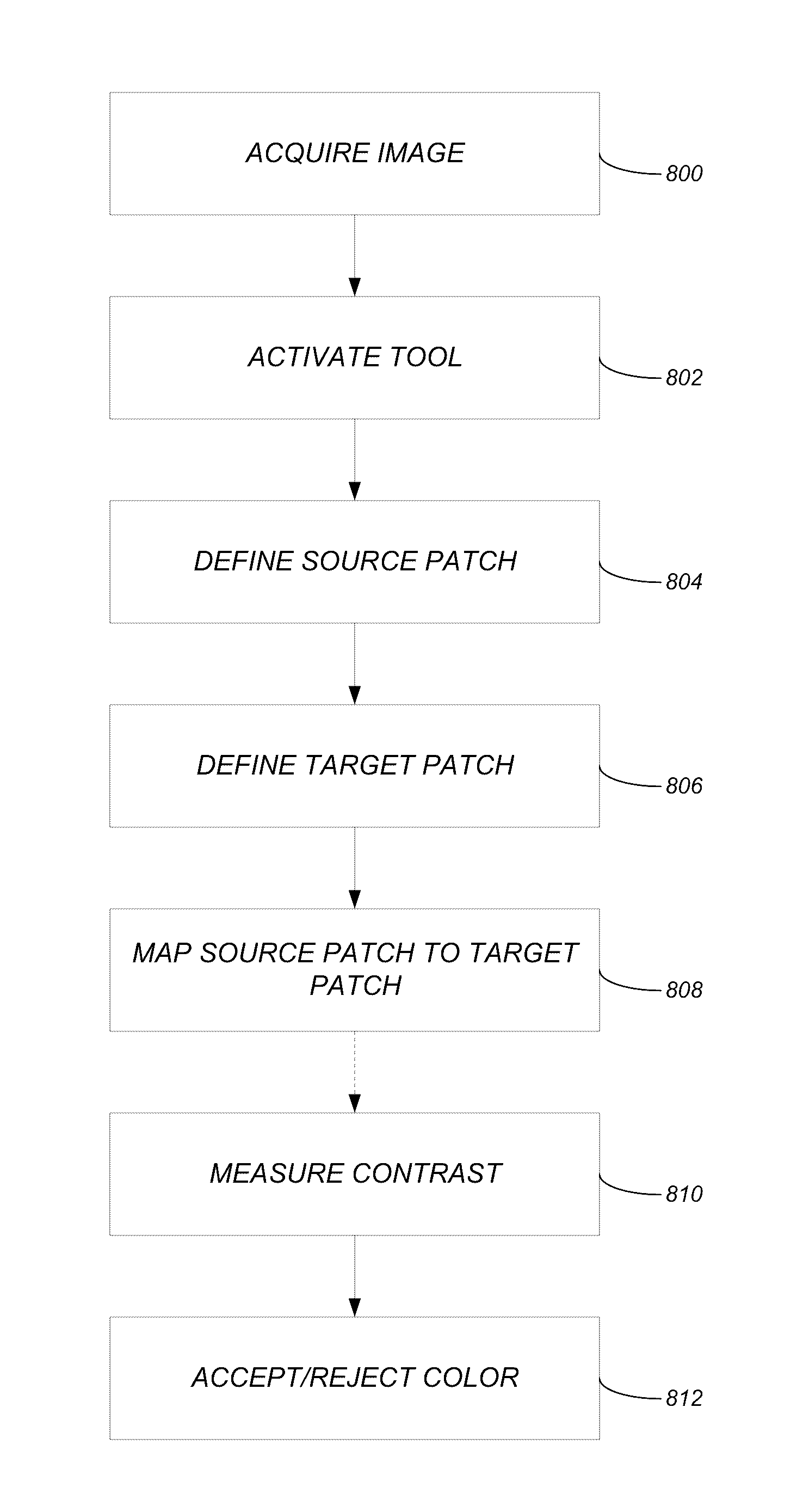

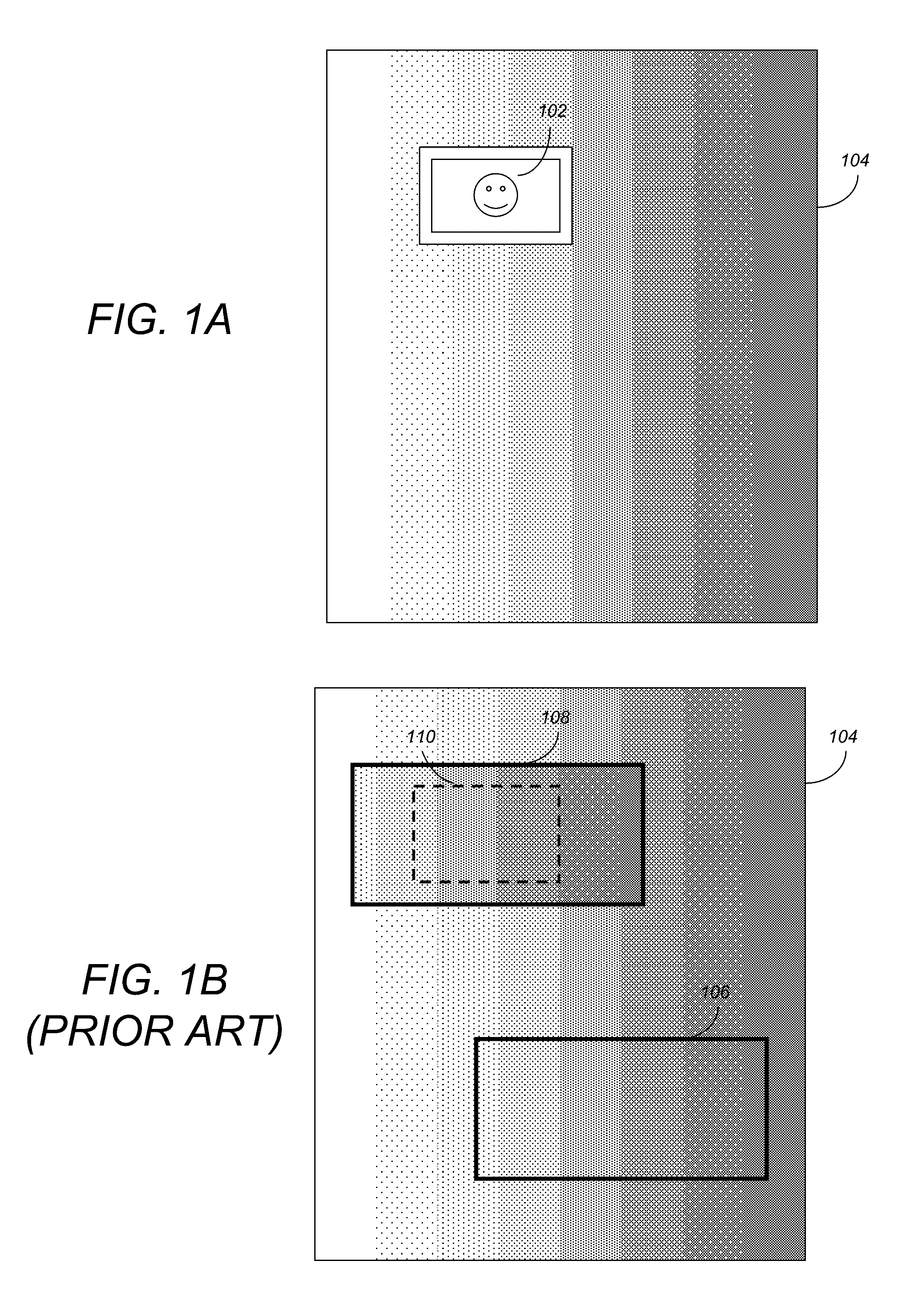

Seamless texture transfer

A method, apparatus, system, and article of manufacture provide the ability to seamlessly transfer a texture. An image that has an object to be concealed is acquired. A conceal tool is activated. A source patch of a first collection of pixels within the image is defined. A target patch of a second collection of pixels within the image is defined and located over the object to be concealed. The source patch is mapped onto the target patch using a transformation (T). A contrast between the source patch and the target patch along a boundary of the source patch and the target patch is measured. A color one of the one or more pixels in the second collection is accepted / rejected based on the contrast.

Owner:AUTODESK INC

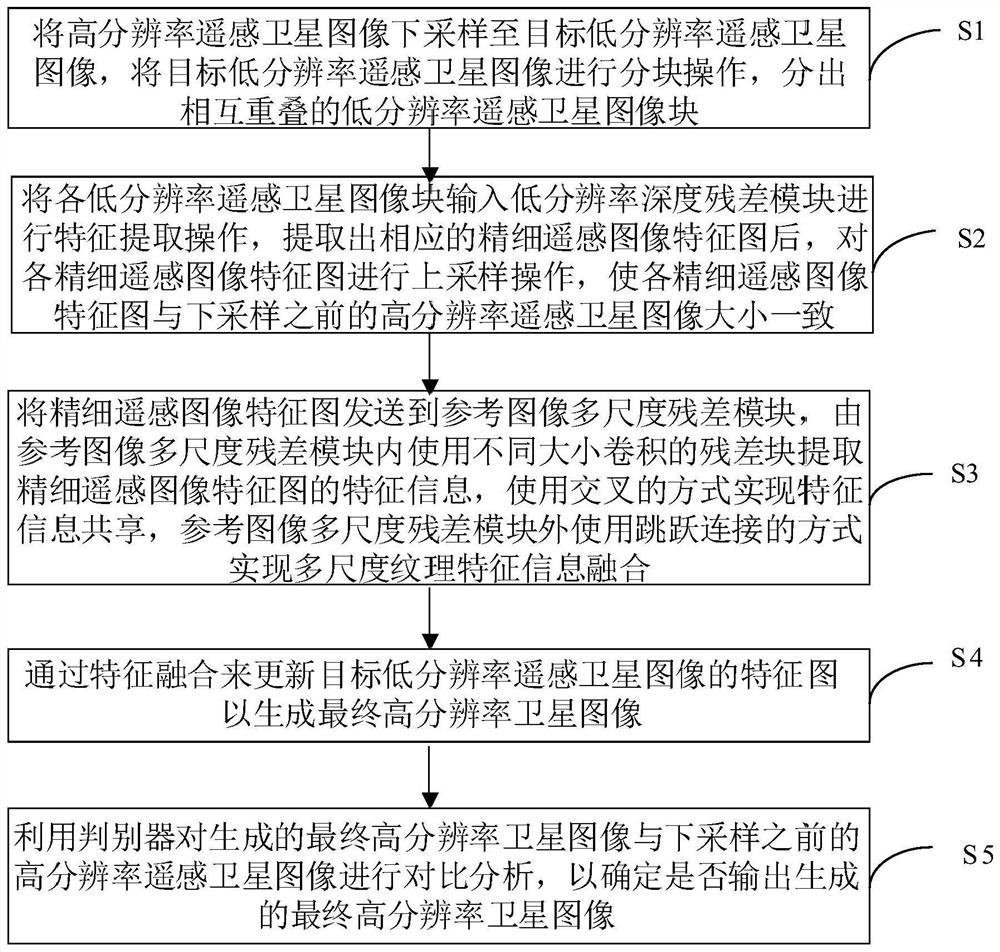

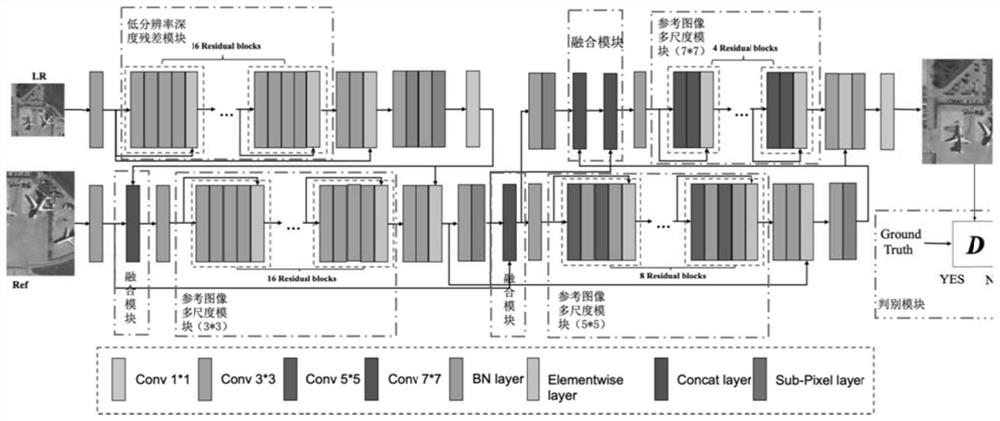

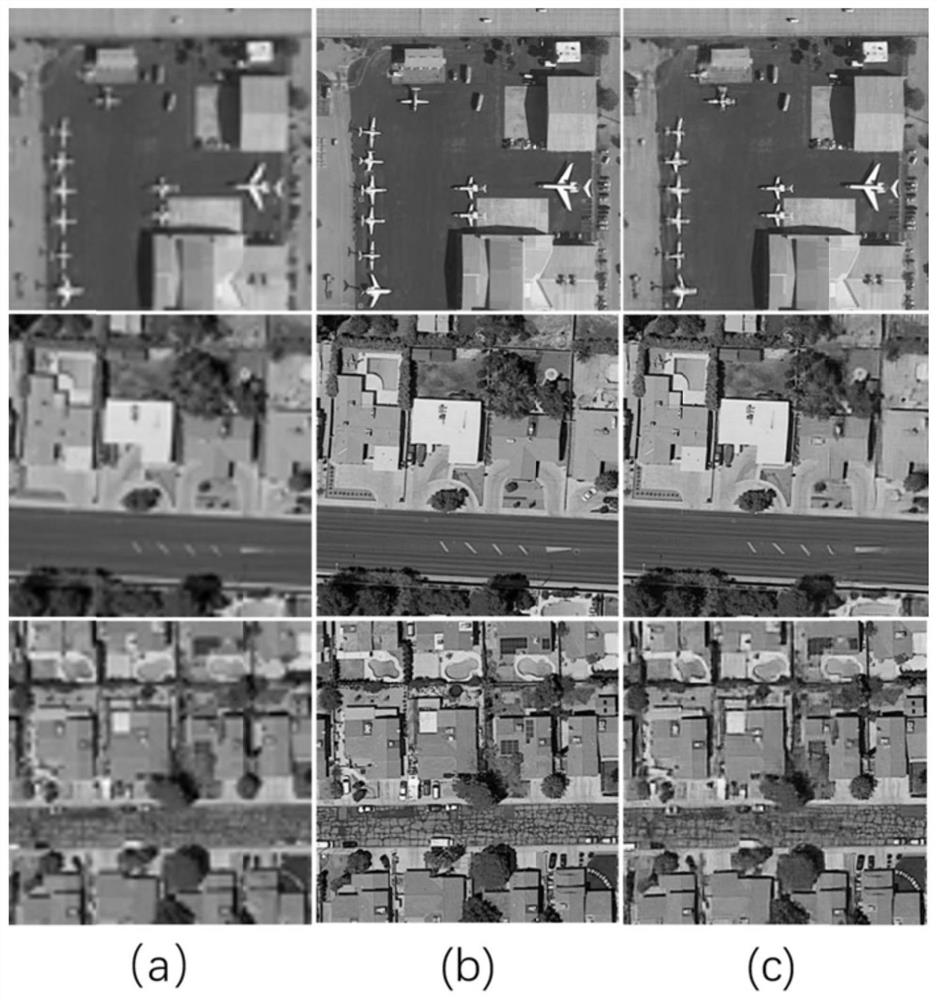

Remote sensing satellite super-resolution method and device of multi-scale texture transfer residual network

ActiveCN112734642ASolve the problem of insufficient texture detailProof of validityGeometric image transformationScene recognitionInformation sharingSatellite image

The invention discloses a remote sensing satellite super-resolution method and device of a multi-scale texture transfer residual error network, and belongs to the field of remote sensing satellite image super-resolution. The method comprises the steps: carrying out the feature extraction of a target low-resolution image after down-sampling through a depth residual error network, carrying out the two times of up-sampling operation of an extracted feature map, and obtaining a target low-resolution image; wherein the size of the image is consistent with that of an original high-resolution satellite image; feature information of the feature map is extracted by using different convolution residual blocks in the multi-scale residual module, feature information sharing is realized by using a cross mode, and multi-scale feature information fusion is realized by using a jump connection mode outside the residual module; updating the feature map of the target low-resolution satellite image through feature fusion to generate a final high-resolution satellite image; and comparing the generated high-resolution image with the original high-resolution image by using a discriminator. The network provided by the invention is superior to other latest remote sensing satellite image super-resolution algorithms, and satellite images with higher quality can be generated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

UV texture transfer print preparing technology for 3D glass window protection screen

InactiveCN106564313AReduce manufacturing costLower requirementDuplicating/marking methodsOther printing apparatusEngineeringTexture transfer

A UV texture transfer print preparing technology for a 3D glass window protection screen is disclosed. The invention relates to a UV texture transfer print preparing technology for a 3D glass window protection screen and aims at solving the problems that in the prior art, most of products are rough and uneven in vein, and fine veins cannot be made. The method comprises the steps that 3D tempered glass is prepared; a protection layer is designed and arranged; a UV transfer print film is prepared; and ultraviolet curing demolding is conducted. The UV texture transfer print preparing technology is used for decoration of the surface of the 3D glass window protection screen.

Owner:广东星弛光电科技有限公司

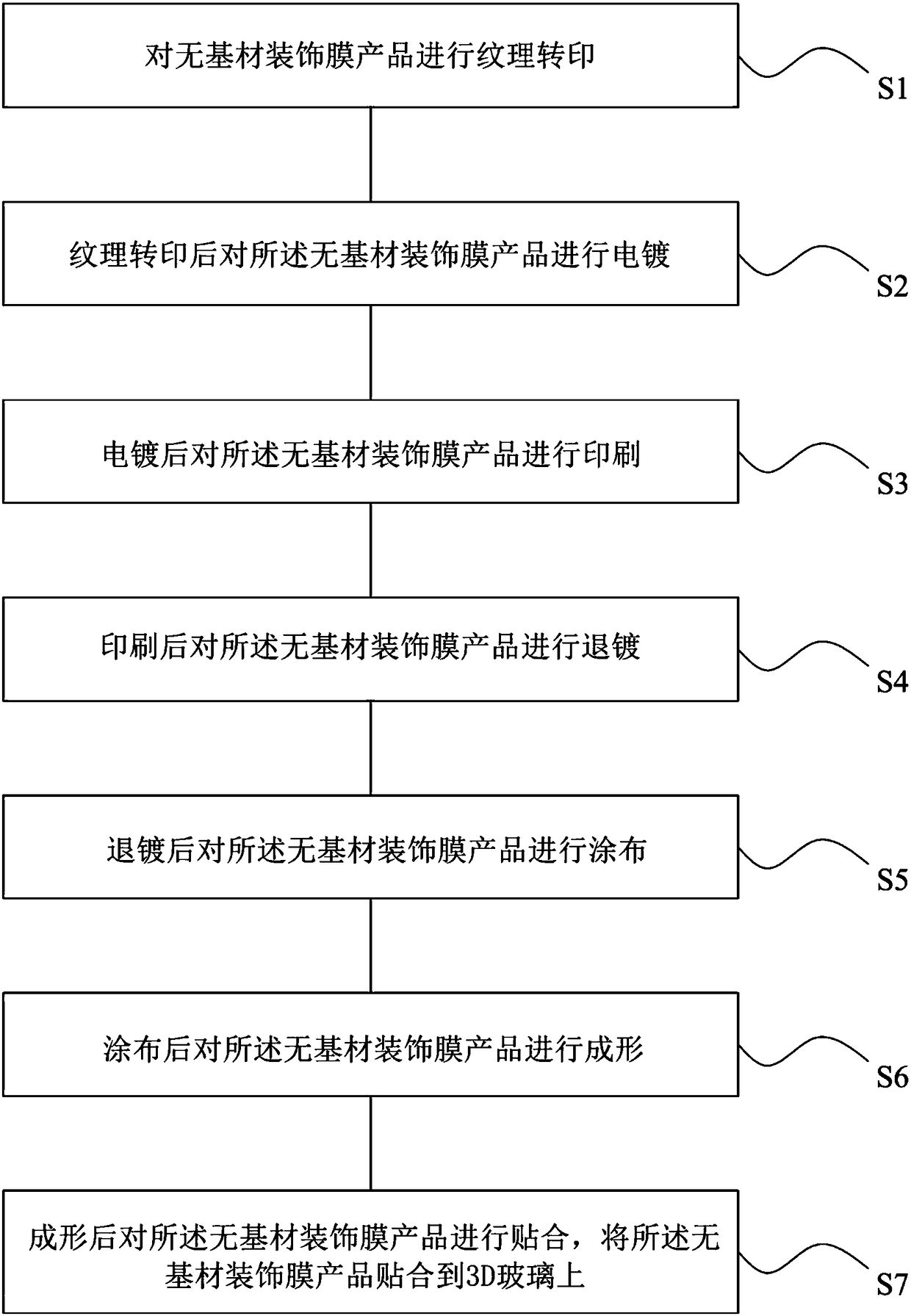

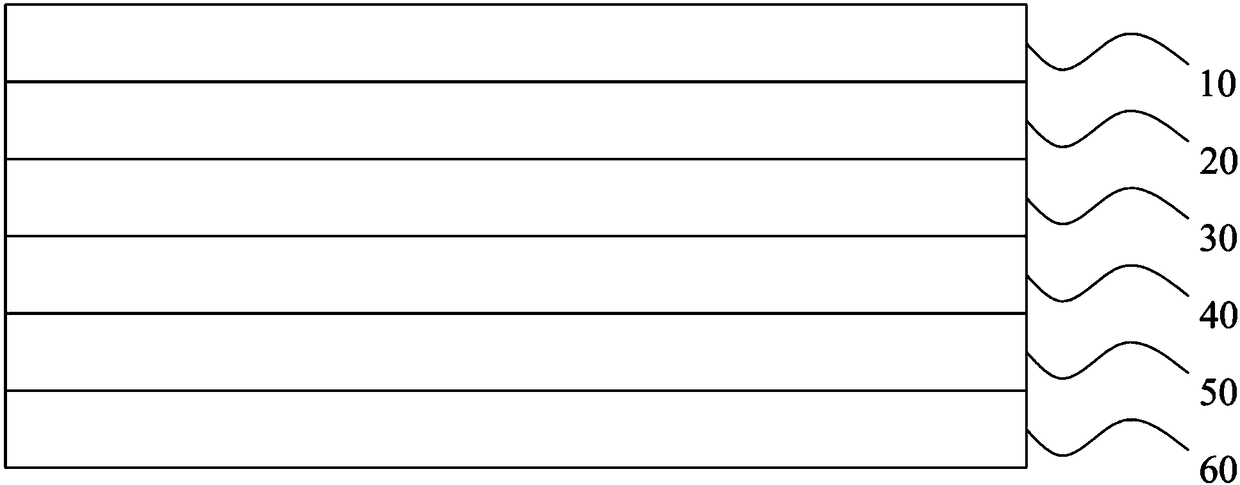

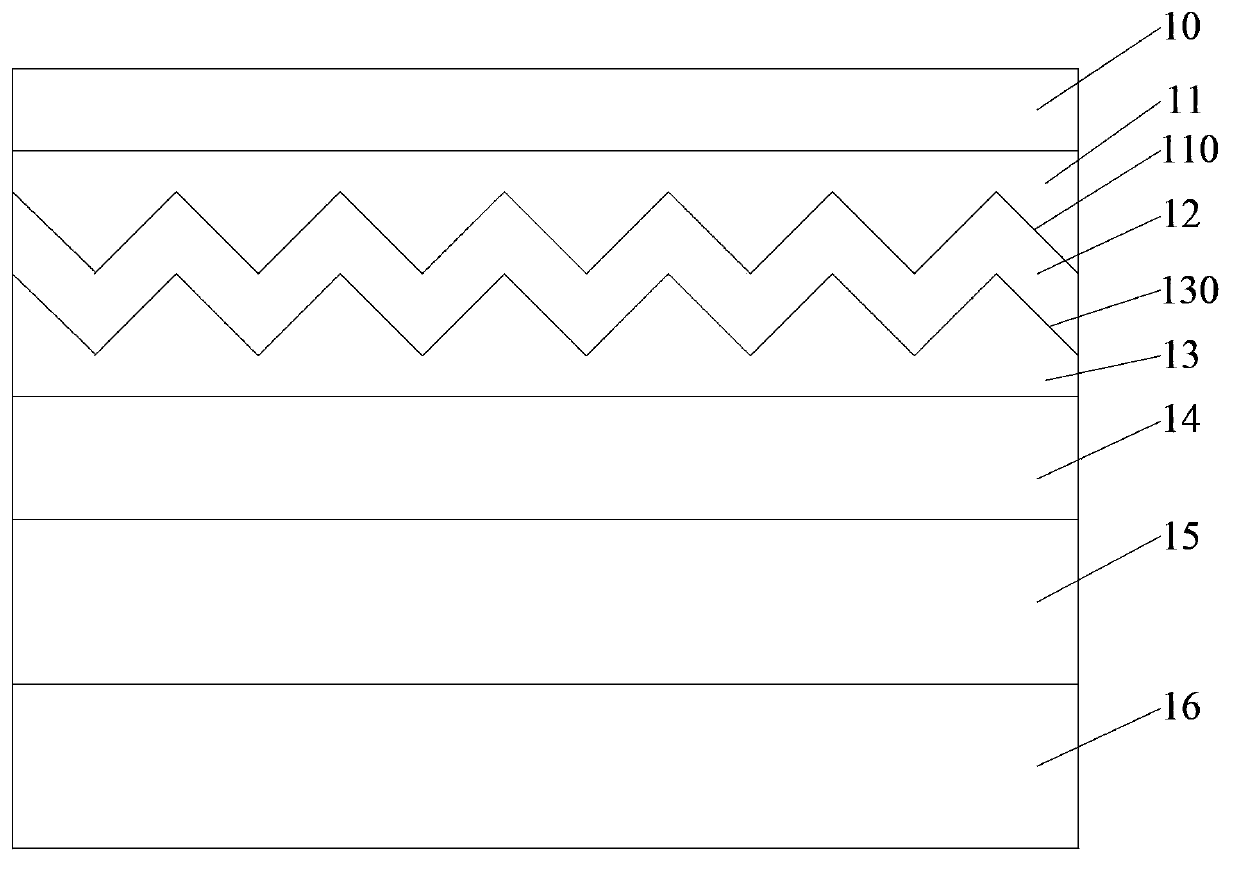

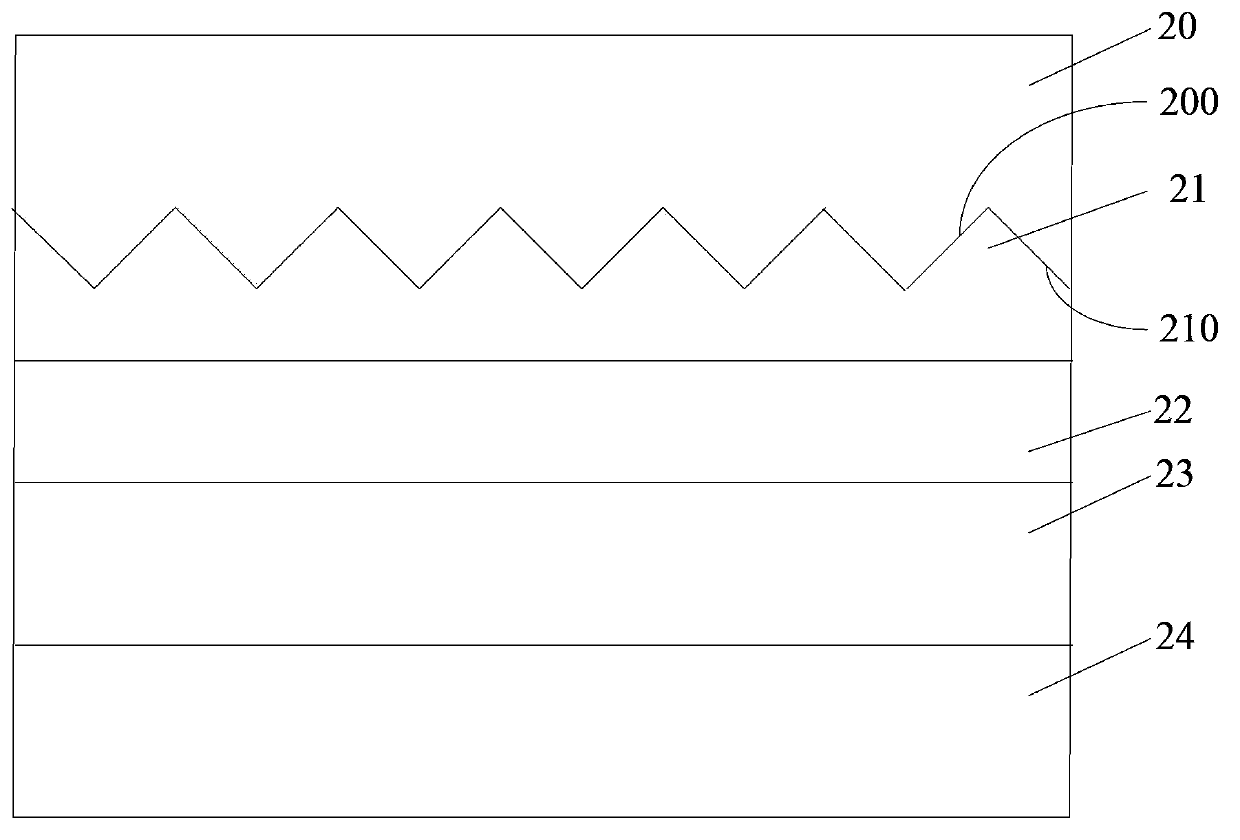

Manufacturing method of 3D glass substrate-less decorative film product

InactiveCN108297393AReduce material costsReduce the ratioDuplicating/marking methodsOther printing apparatusEngineeringTexture transfer

The invention provides a manufacturing method of a 3D glass substrate-less decorative film product. The manufacturing method comprises the following steps of step S1, performing texture transfer printing on a substrate-less decorative film product; step S2, after texture transfer printing, performing electroplating on the substrate-less decorative film product; step S3, after electroplating, performing printing on the substrate-less decorative film product; step S4, after printing, performing stripping on the substrate-less decorative film product; step S5, after stripping, performing coatingon the substrate-less decorative film product; step S6, after coating, performing formation on the substrate-less decorative film product; and step S7, after formation, performing adhesion on the substrate-less decorative film product, and adhering the substrate-less decorative film product to 3D glasses. The manufacturing method provided by the invention is lower in material cost, lighter and thinner in structure of a product and higher in optical transmission, is less in adhesion bubble ratio during adhesion, can effectively increase the yield rate and improve the efficiency and particularlyhas greater advantage on improvement of adhesion bubbles at four-curved or irregular curved surface R angle positions of the 3D glasses.

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

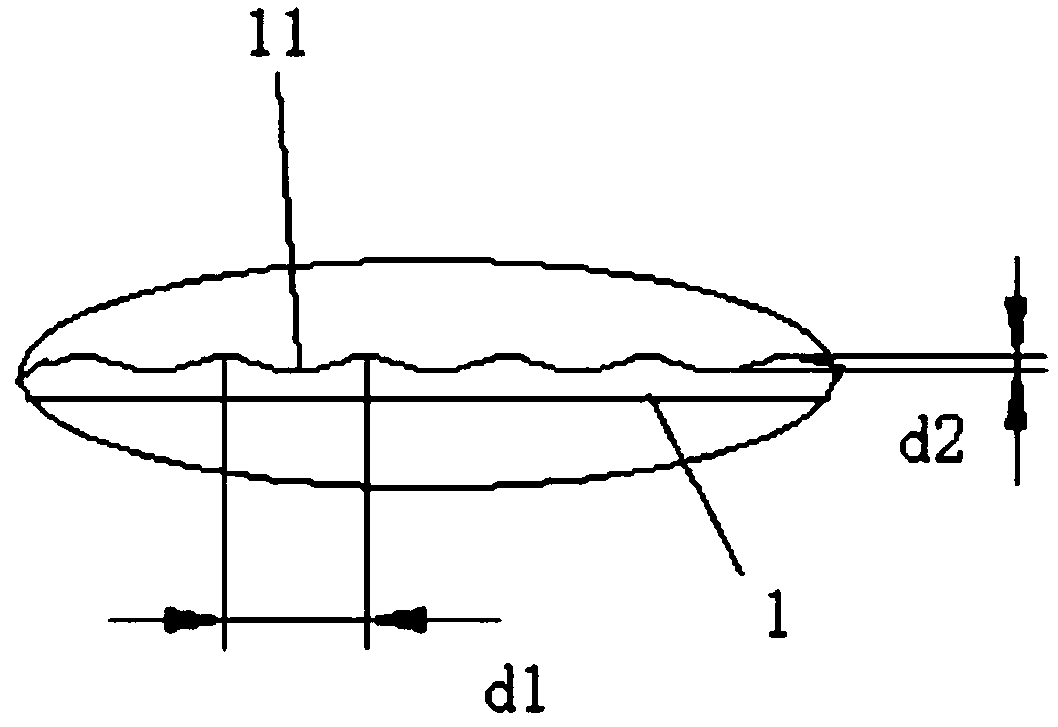

Three-dimensional (3D) texture transfer printing film and method for preparing same

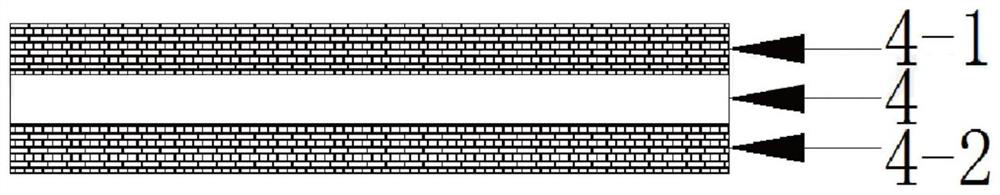

ActiveCN103963506AMeet demandReduce demandLamination ancillary operationsDuplicating/marking methodsRapid processingEngineering

The invention relates to a three-dimensional (3D) texture transfer printing film and a method for preparing the same. The three-dimensional (3D) texture transfer printing film includes a carrier layer having a first texture on one face, a glue layer which is disposed on the face where the carrier layer having the first texture and has a second texture in a position corresponding to the position of the first texture, and a bonding layer which is disposed on one face of the glue layer. The first texture is directly forme don the carrier layer rather than another hardened layer. No release layer is arranged between the first texture and the second texture. Lines of the second texture are obvious and deep. Therefore, user demands of rapid processing, low cost, etc. are met.

Owner:FONG SHIN TECH +1

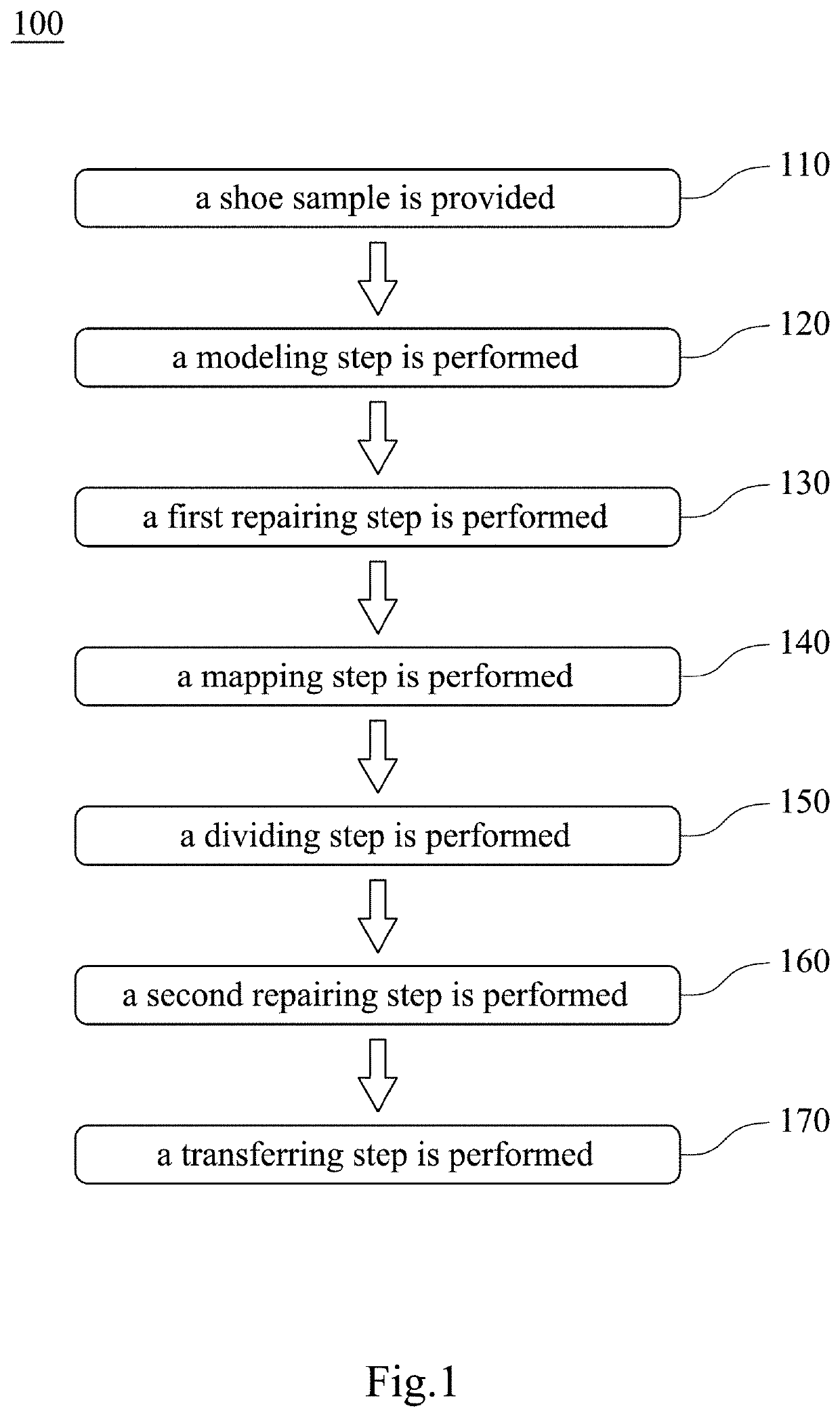

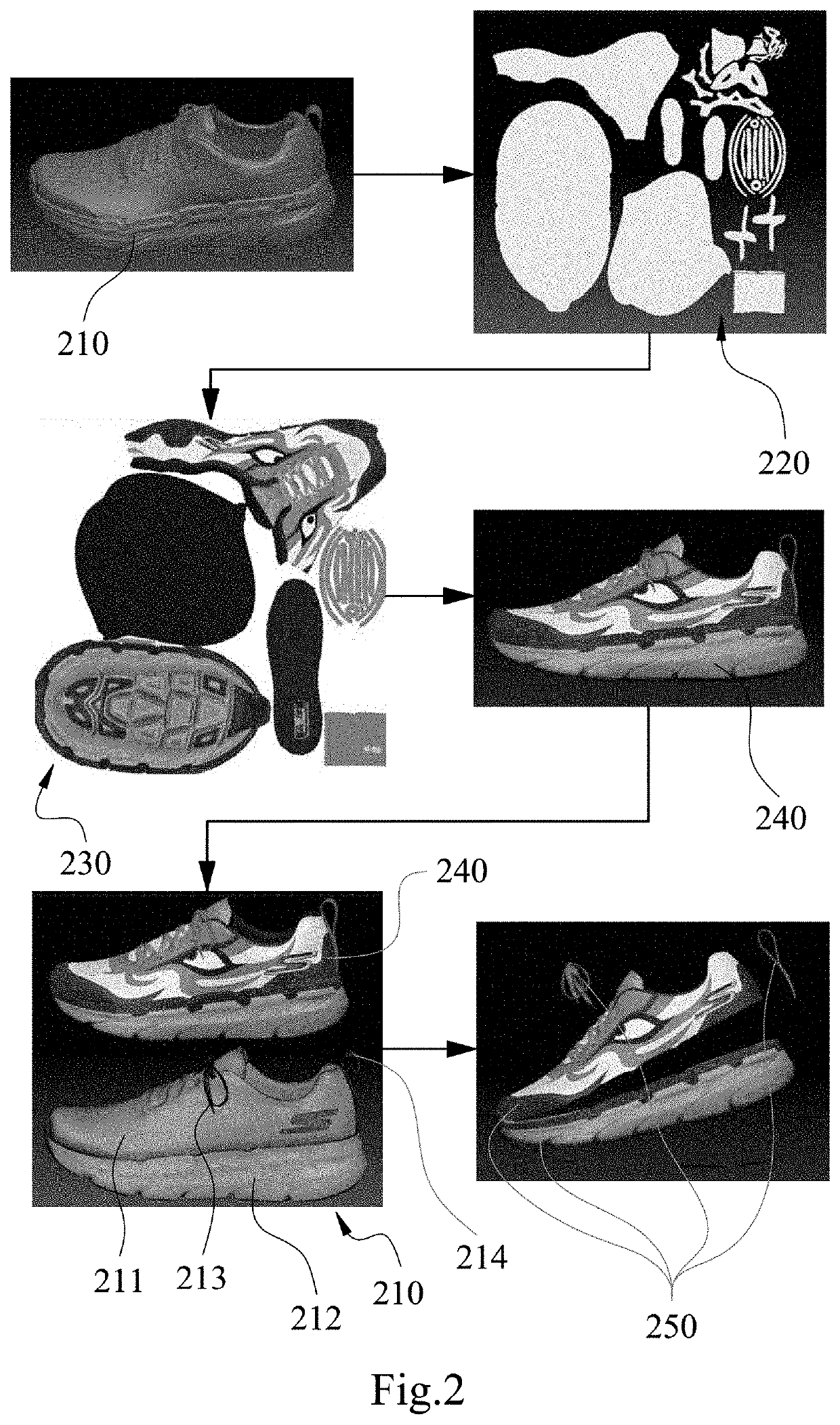

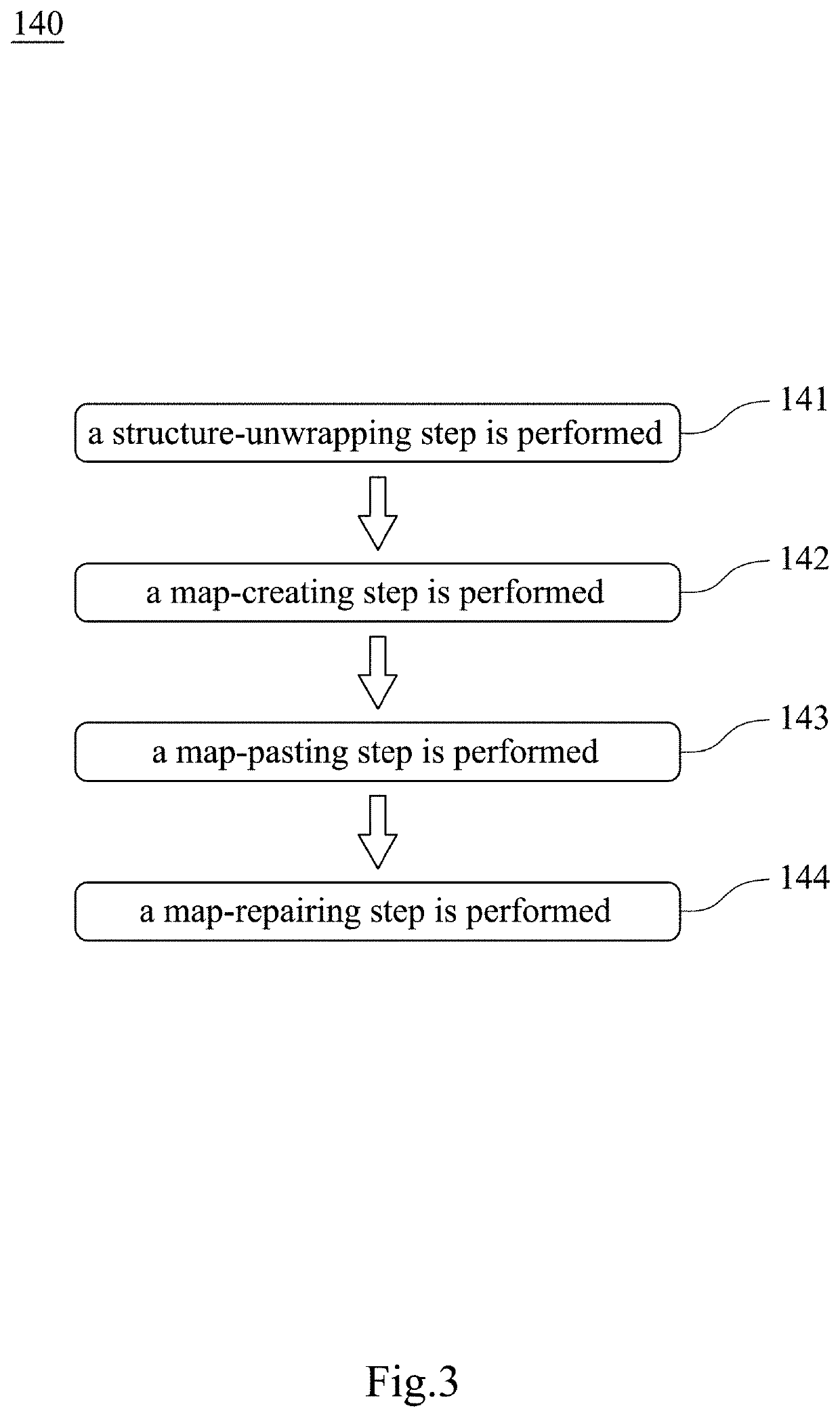

Method of modeling part of shoe and method of shoe designing

Owner:DAH LIH PUH

Wood grain printing method of wooden floor groove chamfer angle

InactiveCN101362354AClear linesDelicate linesWood working apparatusAgricultural engineeringTongue and groove

The invention discloses a wood grain printing method for a tongue-and-groove chamfer of a wood floor, which comprises: paint is coated on the tongue-and-groove chamfer of the floor firstly, and after the paint is dried, wood texture transfer printing is applied to the tongue-and-groove chamfer. The method overcomes the defects that the visual effect of the wood grain is poor, the equipment investment is high and the process is complex since the one-time mould pressing method is adopted in the prior art to perform wood grain printing to the tongue-and-groove chamfer of the floor, the wood grain of the tongue-and-groove chamfer of the wood floor printed by adopting the method has the characteristics that the grain is clear, fine and smooth, the line is mellow and soft, visual effect is good, the process is simple, the printed grain is coordinated and consistent with the grain at the other parts of the floor, the adhesive force of the wood grain is stronger, and the phenomenon that the grain falls off does not occur.

Owner:ZHEJIANG SHIYOU TIMBER

UV texture transfer-printing preparation process for plain glass window protective screen

InactiveCN107672331AModerate thicknessEvenly distributedPattern printingOther printing apparatusUV curingTexture transfer

The invention relates to the technical field of printing of plain glass window protective screens, in particular to a UV texture transfer-printing preparation process for a plain glass window protective screen. The UV texture transfer-printing preparation process comprises the steps that a UV transfer-printing mould with the texture effect is manufactured; tempered glass is adhered to a fixing piece; the fixing piece is placed in the specific position of an operation platform; UV glue drips onto the fixing piece; the UV transfer-printing mould covers the fixing piece; the height of a rubber roller is adjusted, and laminating is conducted; UV curing is conducted; redundant UV glue is cleared away; and coloring is conducted. Thus, the surface of the plain glass window protective screen can be decorated with the effects of a wire drawing texture, a CD texture, a natural texture, a linear texture and the like, accordingly the diversity of surface decoration of the plain glass window protective screen is improved, and the UV texture transfer-printing preparation process is simple and easy to operate.

Owner:广东星弛光电科技有限公司

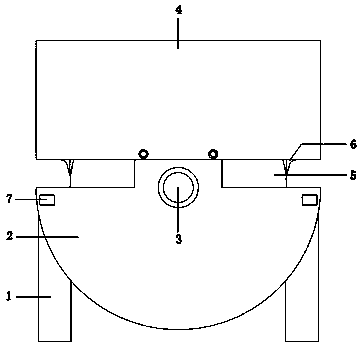

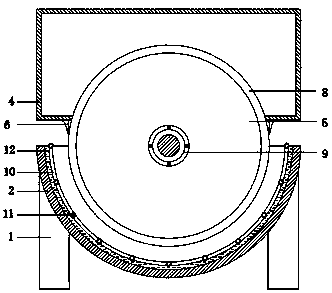

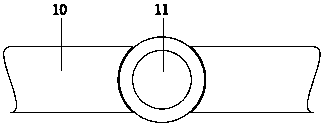

An anti-cracking pet tennis ball texture transfer equipment

The invention discloses an anti-cracking pet tennis texture transfer printing device in the technical field of rubber ball skin texture transfer devices. The anti-cracking pet tennis texture transferprinting device comprises supporting legs, wherein a base is welded to the tops of the supporting legs, a driving device is installed on the front surface of the base, the driving device penetrates through the outer wall of the base, the rear side of the driving device is connected with a heating printing device, and guide blocks are connected to the left side and the right side of the bottom of aprotective top cover through bolts separately. According to the anti-cracking pet tennis texture transfer printing device, the arc-shaped heat transfer printing device is arranged, the space occupation ratio is decreased, and the most important hot printing roller is reserved, so that the volume optimization is achieved; and the functions of hot printing and rubber transmission driving are simultaneously achieved through the hot printing roller, and the requirement of the driving device is saved. A humidifying layer and a sealing shaft are arranged, so that in the rubber transmission process,the sealing shaft is driven to carry out a small amount of water transfer, heating and heat preservation are carried out on the bottom (non-hot printing surface) of the rubber, and the anti-crackingeffect is achieved.

Owner:天长市富宝橡塑制品有限公司

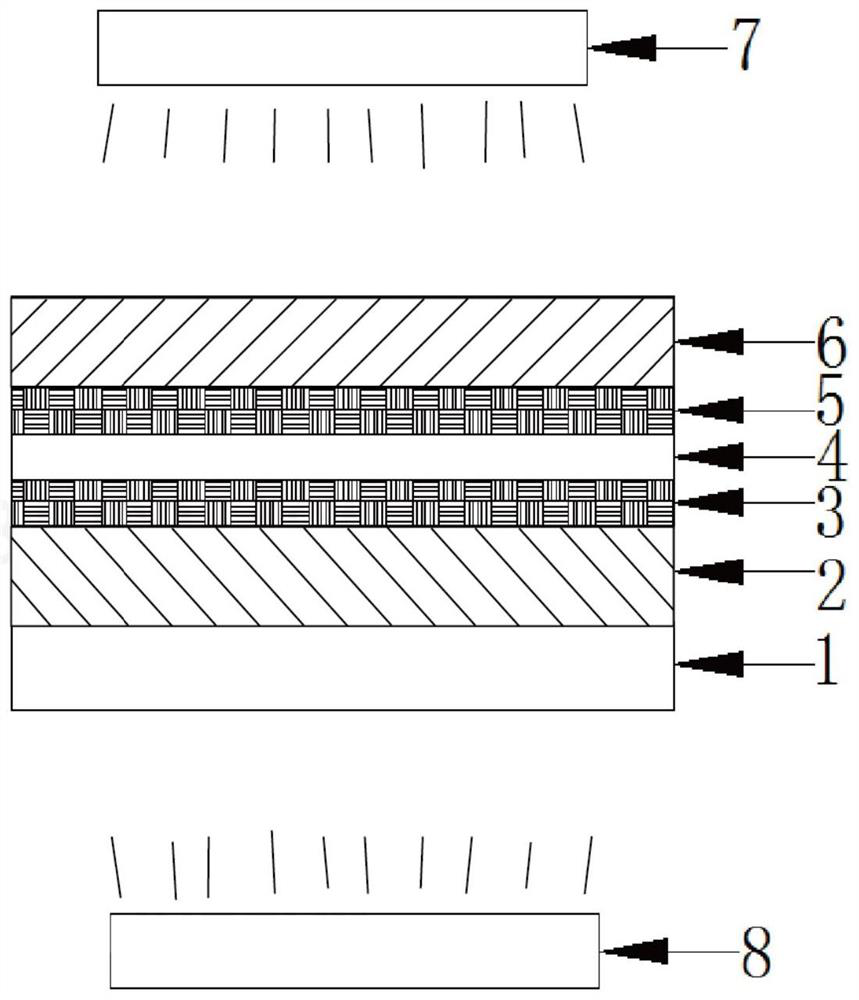

Double-sided texture transfer printing method and base material with double-sided texture layers

PendingCN113682065AIncrease diversityGuaranteed appearanceInk transfer from master sheetTexture designTexture transfer

The invention provides a double-sided texture transfer printing method and a base material with double-sided texture layers, and relates to the technical field of texture transfer printing. According to the double-sided texture transfer printing method, a transparent base, a first mold, a base material and a second mold are utilized to form a stacked structure, and first UV glue between the base material and the first mold and second UV glue between the base material and the second mold are fully cured and transferred to the front surface and the back surface of the base material through double-sided UV light irradiation, so that the purpose of processing double-layer textures at one time is achieved, the diversity of texture design is achieved, the attaching procedure in the prior art is reduced, the production cost is saved, and meanwhile, it can be guaranteed that the appearance and reliability of a product with the double-sided texture layers meet the requirements of customers; and the double-sided texture transfer printing method is convenient to operate and high in reliability, the production capacity is improved, base materials are saved, the process is simplified, large-batch delivery can be met, and the method has high practical value. The invention also provides the base material with the double-sided texture layers.

Owner:LENS TECH CHANGSHA

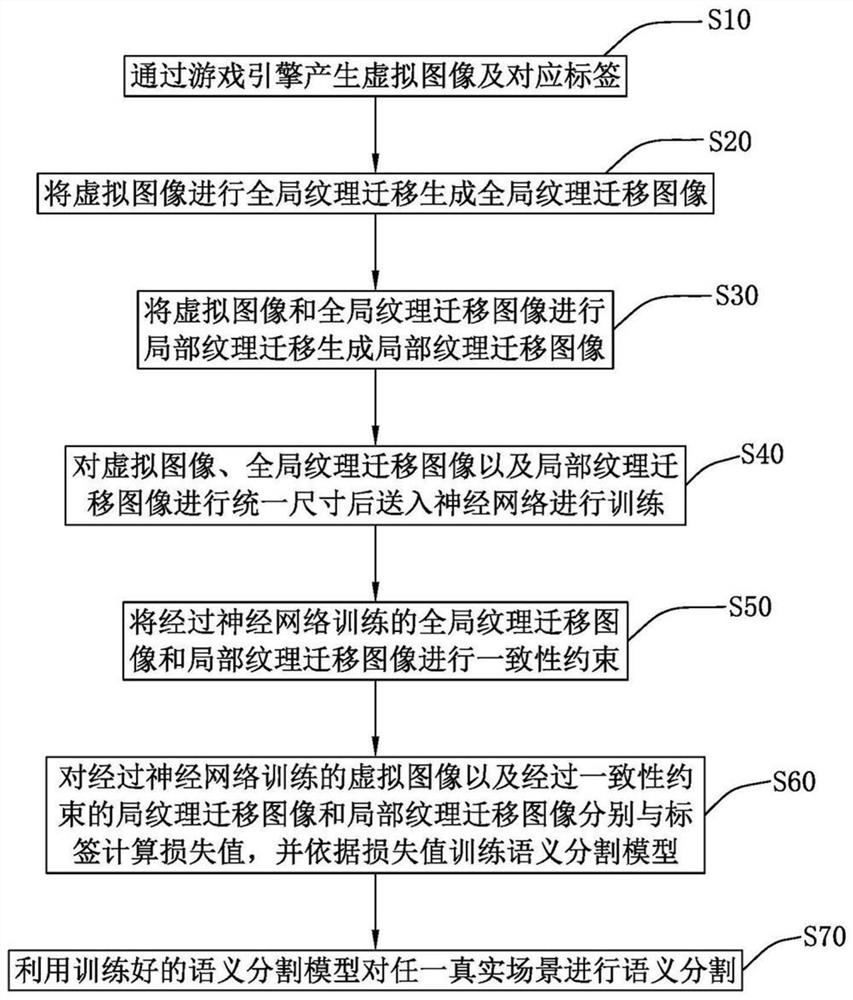

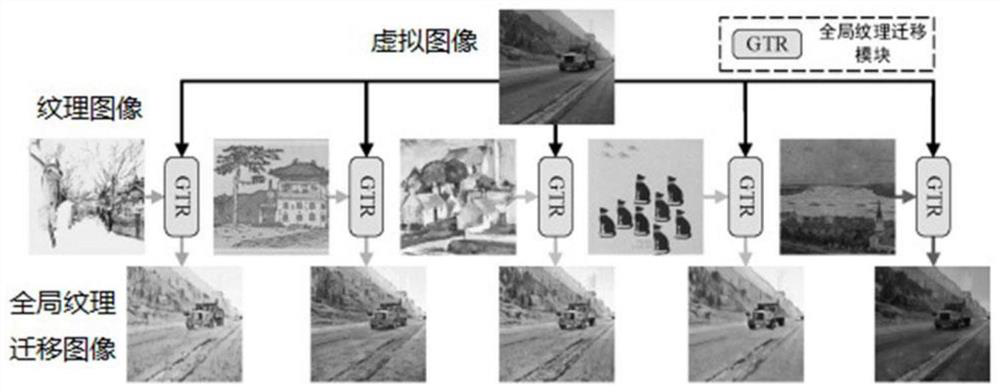

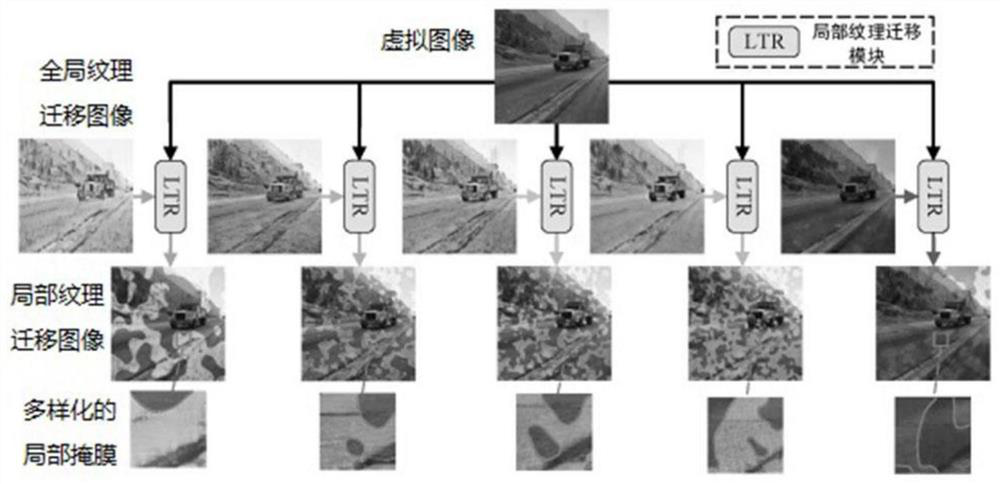

High generalization method and system for semantic segmentation of cross-domain road scenes

ActiveCN112819873BEasy access to dataLabor savingImage enhancementImage analysisPattern recognitionTexture transfer

The invention discloses a highly generalizable cross-domain road scene semantic segmentation method, which includes: generating virtual images and corresponding labels through a game engine; using virtual images to generate global / local texture migration images; and performing virtual image and global / local texture migration. The image is sent to the neural network for training; the global / local texture transfer image trained by the neural network is subject to consistency constraints; the virtual image trained by the neural network and the local texture transfer image and local texture transfer image that have been constrained by the consistency are respectively associated with the label Calculate the loss value and train the semantic segmentation model based on the loss value; use the trained semantic segmentation model to perform semantic segmentation. This invention realizes data enhancement through global texture migration and local texture migration of virtual images, attacks the neural network, and forces the model to learn cross-domain invariant shape information; and this method only performs network training in the source domain, achieving reliable cross-domain Segmentation effect and strong generalization performance.

Owner:SICHUAN UNIV

Device and method for texture transfer for camera protection glass

ActiveCN107097504BEasy to getLow costLamination ancillary operationsLaminationEngineeringTexture transfer

A first purpose of the present invention is to provide an apparatus for performing texture transfer printing on a camera protection glass, wherein the whole apparatus has advantages of simple structure and easy part obtaining. A second purpose of the present invention is to provide a texture transfer printing method using the apparatus. The texture transfer printing method comprises: A, placing a camera protection glass to be subjected to texture transfer printing into the positioning concave groove of a drawing film adhesion base; B, positioning a drawing positioning film onto the drawing film adhesion base; C, rolling the back surface of the drawing positioning film by using a roller; D, positioning the drawing positioning film adhered with the camera protection glass to be subjected to texture transfer printing onto the base of a drawing mold; E, placing a supporting film; F, covering the mold, and rolling the back surface of the mold through a roller; and G, irradiating with UV light to make the UV glue in a non-occlusion be subjected to exposure, and carrying out washing and other steps to obtain the camera protection glass with the transferred texture. According to the present invention, the texture transfer printing method is suitable for the camera protection glass, the operation is convenient, and the three-dimensional effect of the texture is strong.

Owner:WINTEK CHINA TECH LTD

Texture transfer master mold, plate and preparation method, texture transfer sub-mold, housing, electronic equipment

ActiveCN111016415BLower yieldIncrease production costTransfer printingOrnamental structuresEngineeringTexture transfer

The application discloses a texture transfer printing master mold, a board and a preparation method, a texture transfer printing sub-mold, a shell, and electronic equipment. Specifically, the present application proposes a texture transfer master, which has first texture regions and second texture regions alternately arranged at intervals on the texture transfer master, and the texture transfer master includes the first texture and the second texture. The second texture, wherein the texture shapes of the first texture and the second texture are not completely the same, the first texture is located in the first texture region and part of the second texture region, and the second texture The texture is located in the second texture area, and the first texture and the second texture in the second texture area are arranged at intervals. The texture transfer sub-mold formed by using the texture transfer master mold can form a variety of texture combination and superimposition effects through a UV transfer process, and the texture transfer master mold can be used to easily prepare textures with rich texture combination and superposition effects layer, and the preparation process is simple, which can save production cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A mobile phone case with 3D structure and its processing technology

ActiveCN106603768BBeautiful appearanceErgonomicTelephone set constructionsPersonalizationTransmittance

Owner:东莞市汇诚塑胶金属制品有限公司

Process for manufacturing aluminum foil pseudo metal texture transition paper

InactiveCN100575605CStrong metal textureImprove visual effectsFlexible coversWrappersPolyesterTexture transfer

The present invention relates to packing paper for cigarette and wine products, and is production process of aluminum foil-imitating metal texture transfer paper. The production process includes the following steps: spreading transfer paint to one or two sides of biaxially stretched polypropylene film, biaxially stretched polyester film or heat sealed biaxially stretched polypropylene film; pressing with molding roller; vacuum plating aluminum film on the film; wet compounding the film to paper with water thinned glue; slaking the film in the condition of 35-55 deg.c temperature and 30-60 % humidity for 24-48 hr; and stripping film. The aluminum foil-imitating transfer paper has strong metal texture, excellent visual effect, capacity of degrading naturally.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

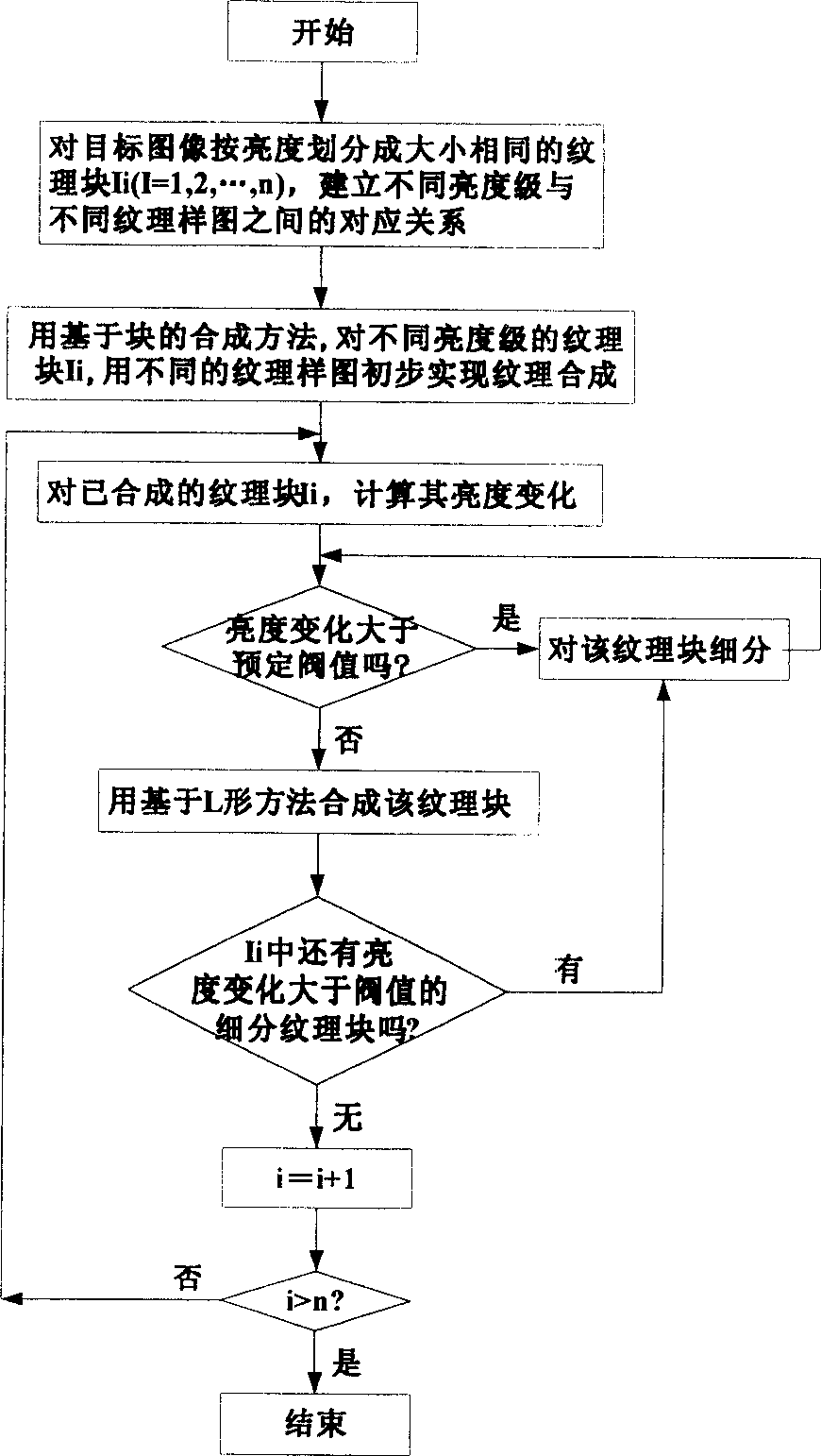

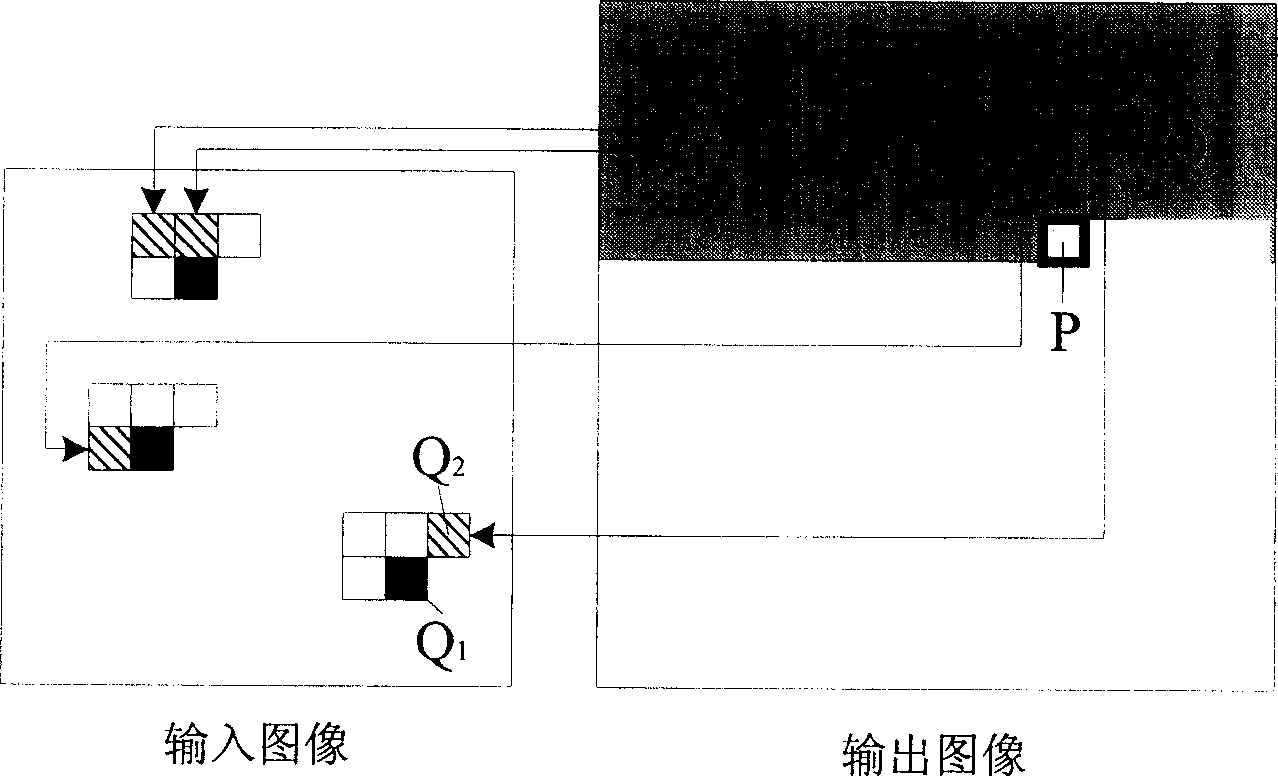

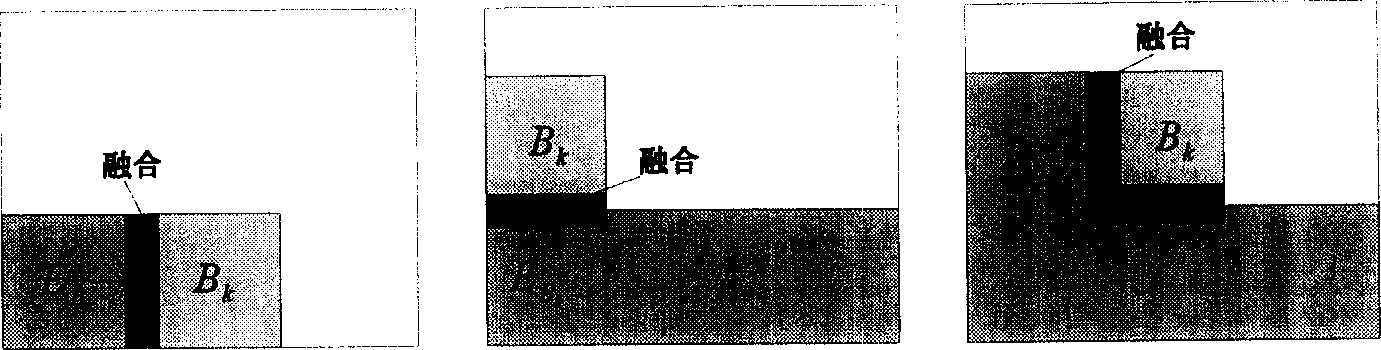

Grain transferring method based on multiple drawings

InactiveCN1256706CHigh speedTexture transfer implementation3D-image renderingPattern recognitionNeighborhood search

The present invention is a texture transfer method based on diverse graphs. This method first divides the brightness value given by the target image into several levels with the participation of the user; then, uses a block-based method to synthesize textures using different texture samples for different brightness levels; finally, for the synthesized block, calculate the brightness difference of each texture block, if it is greater than the threshold value input by the user, subdivide the block into small blocks until the brightness difference in the subdivided blocks is smaller than the threshold value input by the user. For these subdivided blocks, an L-shaped neighborhood search method is used for texture synthesis. The invention is characterized in that the texture is synthesized from coarse to fine, the texture transfer speed is fast, the user can control the whole process, and the purpose of generating a new texture image according to the known texture image is realized.

Owner:BEIHANG UNIV

Shell assembly, preparation method thereof and electronic equipment

PendingCN114683506AQuality improvementImprove wear resistanceDomestic articlesAdhesive glueTexture transfer

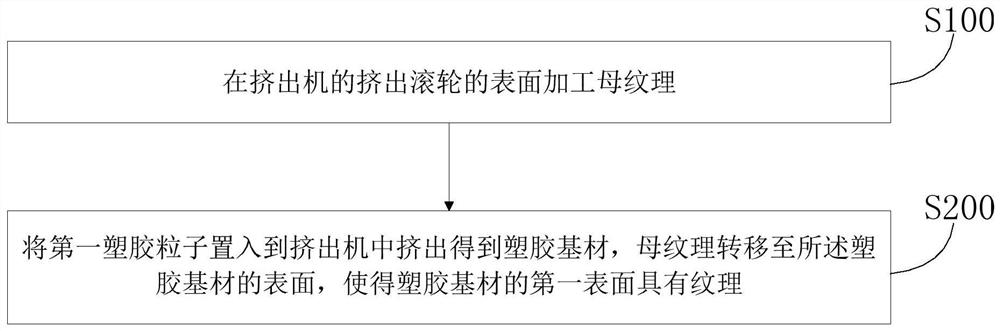

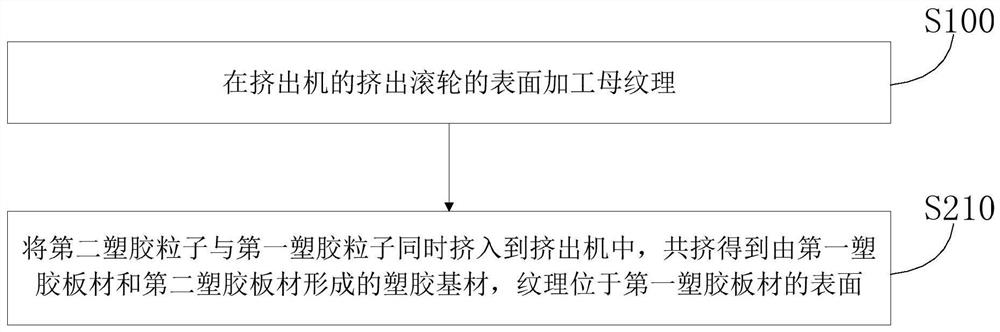

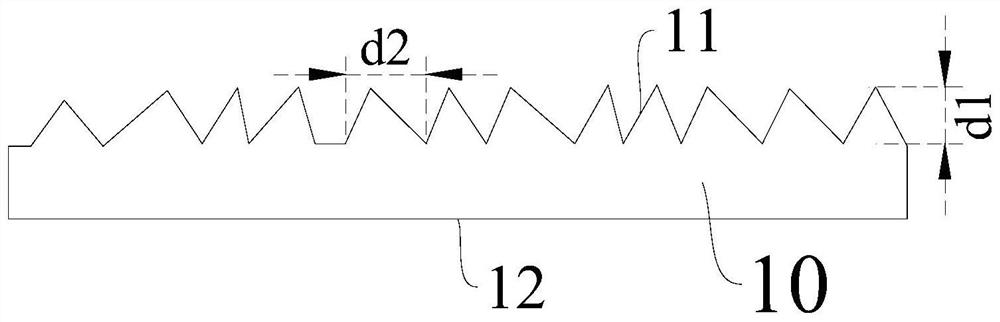

The invention provides a shell assembly, a preparation method thereof and electronic equipment. The method for preparing the shell assembly comprises a method for preparing a plastic base material, and the method for preparing the plastic base material comprises the following steps: processing mother textures on the surface of an extrusion roller of an extruder; the first plastic particles are placed into an extruder to be extruded to obtain the plastic base material, and the mother texture is transferred to the surface of the plastic base material, so that the first surface of the plastic base material has the texture. Therefore, the texture is directly manufactured on the first surface of the plastic base material, that is, the plastic base material has the texture, and compared with a texture layer formed on the first surface (for example, the texture layer is formed on the first surface through UV glue), the technical scheme of the application can greatly improve the wear resistance of the texture, the hand feeling is better, smooth and fine, and the flash visual effect is better.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A kind of manufacturing method of recombined decorative material

The invention discloses a method for manufacturing a recombined decorative material, which comprises the steps of making veneers from logs, folding, bending and dyeing the veneers, drying the veneers after dyeing, repairing the veneers, forming blanks of the veneers, gluing them, and pressing them into wooden squares. , wood maintenance, lumber, and then sliced into recombined decorative veneers. The present invention solves the problem of single color, unnatural transition, dark and light texture of technical wood by changing the structure of the dyeing vat and veneer dyeing cage, and adjusting the veneer cage method, the height of the dye solution level and the billet assembly method. Problems such as transfer may occur, and the recombined decorative material product produced by the method of the invention is very realistic.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com