Texture transferring female die, plate and preparation method thereof, shell and electronic equipment

A texture transfer, texture technology, applied in electrical equipment shell/cabinet/drawer, transfer printing, rotary printing machine and other directions, can solve problems to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the application are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary, and are intended to explain the present application, and should not be construed as limiting the present application.

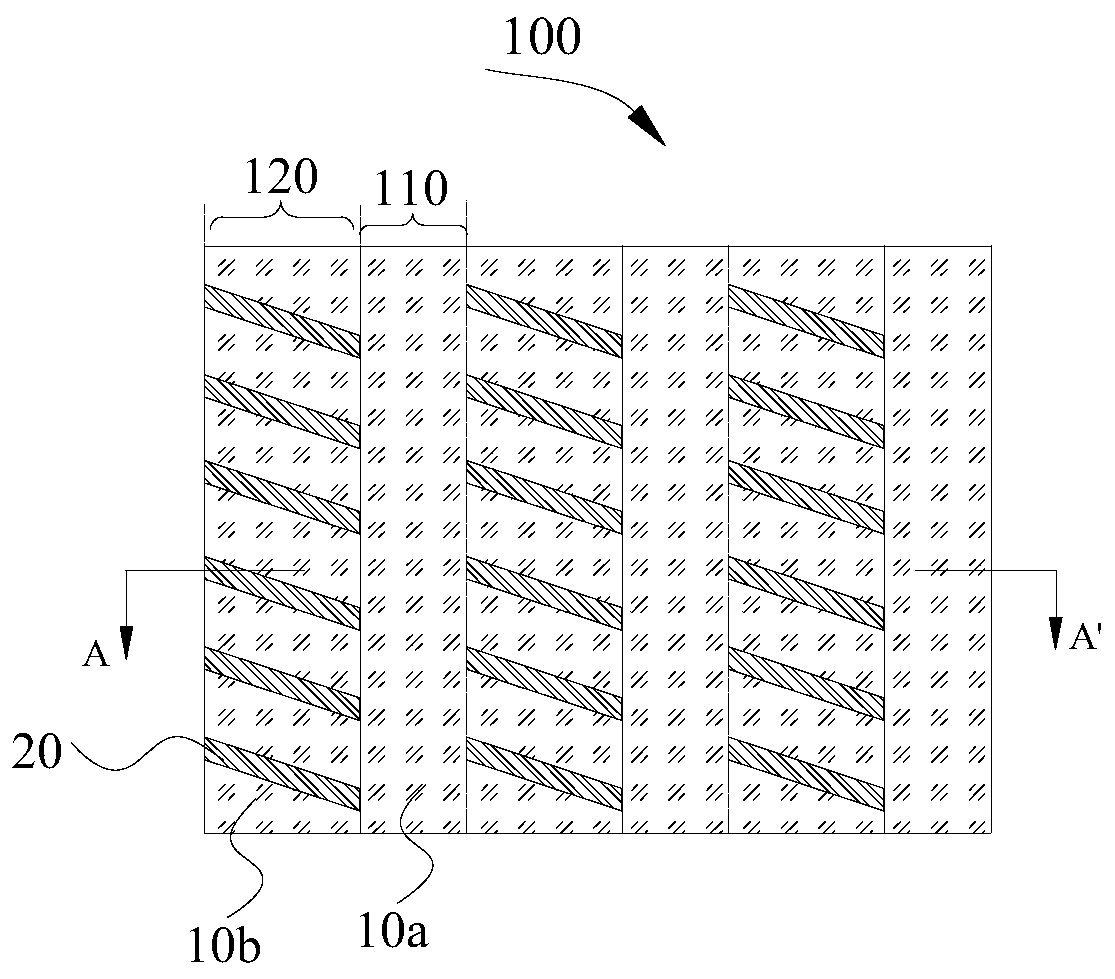

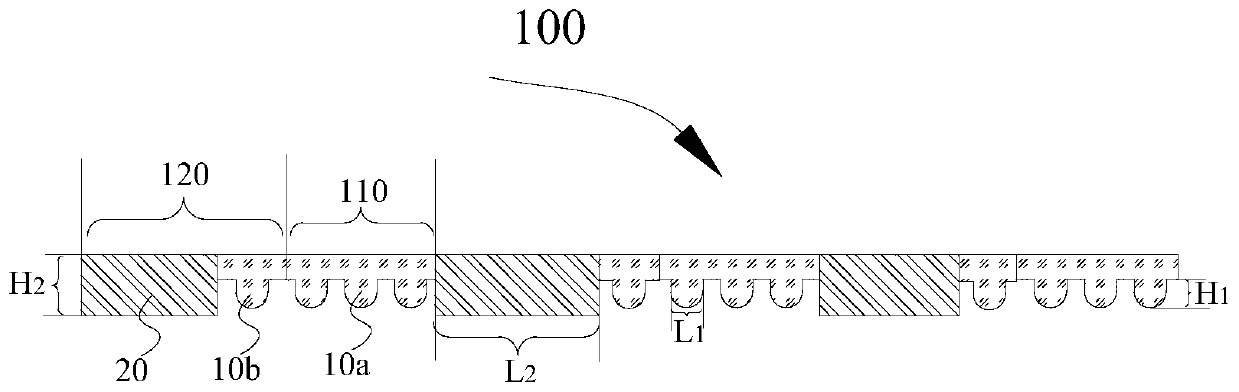

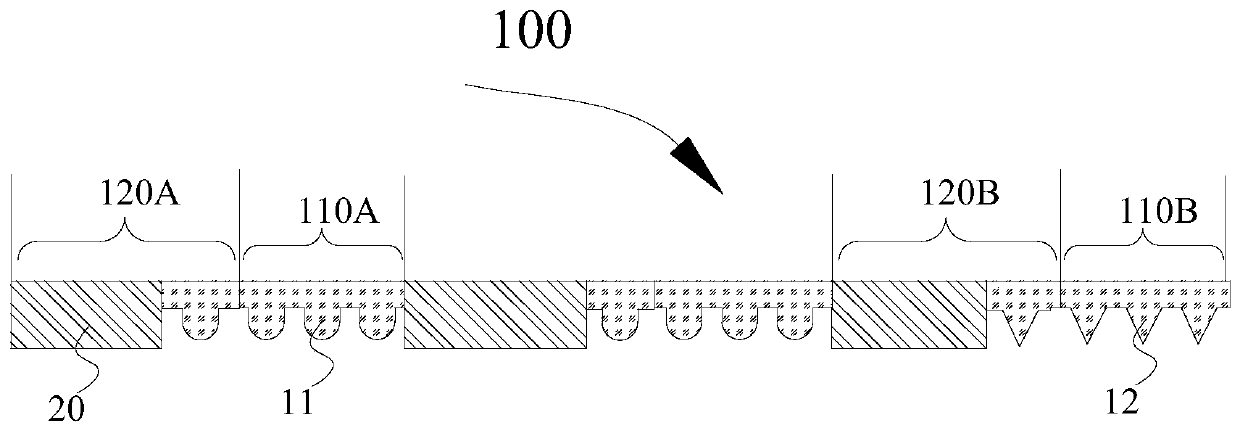

[0027] In one aspect of the present application, the present application provides a texture transfer master. According to some examples of this application, refer to figure 1 and figure 2 ( figure 2 for along figure 1 Schematic diagram of the cross-sectional structure in the AA' direction in the center), the texture transfer master mold 100 has alternately spaced first texture regions 110 and second texture regions 120, and the texture transfer master mold 100 includes the first texture 10 and the second texture 20 , wherein the texture shapes of the first texture 10 and the second texture 20 are not completely the same, and the first texture 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com