Multi-set-rope sawing machine and control method thereof

A wire saw machine and frame technology, which is applied in the field of multiple sets of wire saw machines and their control, can solve the problems of increasing manufacturing and post-maintenance costs, high manufacturing and processing requirements, affecting the stability of the whole machine, etc., so as to facilitate rope changing operations. , Easy to manufacture, maintain and install, the effect of balanced force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

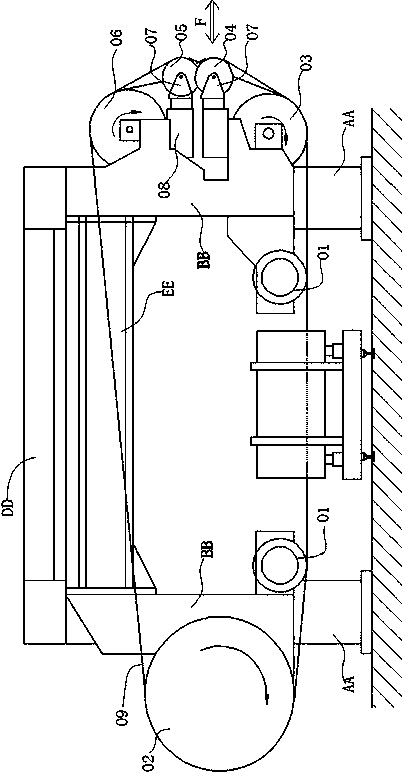

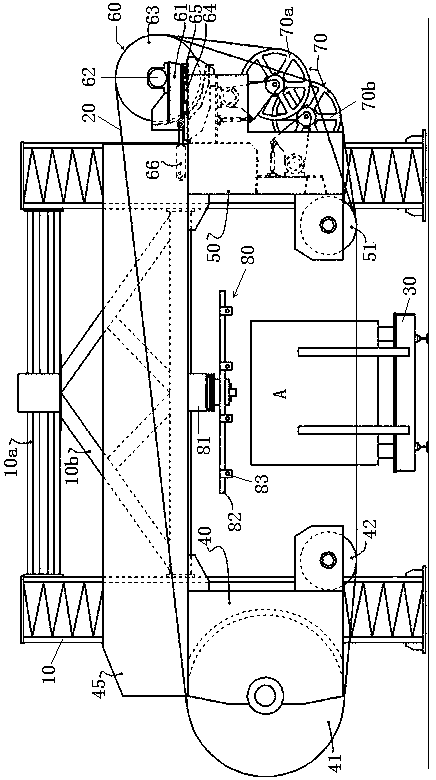

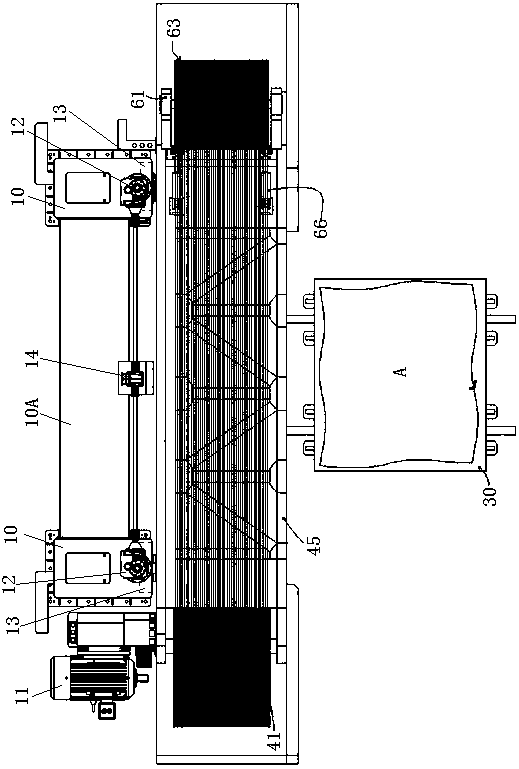

[0030] refer to Figure 2 to Figure 7

[0031]A multi-group wire saw machine, comprising a portal frame 10 and a plurality of diamond beaded ropes 20, the lower side of the beam 10a of the portal frame is provided with a tripod 10b for enhanced strength; the lower side of the portal frame is provided with a useful On the trolley 30 where the stone A is placed and can slide longitudinally, the front parts of both sides of the portal frame are correspondingly provided with a first rack box 40 and a second rack box 50 that are connected via trusses 45 and can be lifted. , the first frame box is provided with a main drive wheel 41 with a plurality of wheel grooves, the upper part of the second frame box is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com