Superelastic decorative cable and its manufacturing and installation method

A production method and super-elastic technology, which is applied in the field of decorative cables, can solve the problems of affecting aesthetic requirements, uneven cables, and influence of tower beams, etc., and achieve the effect of convenient cable replacement, straight cables, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A superelastic decorative cable with fork lug structure at both ends:

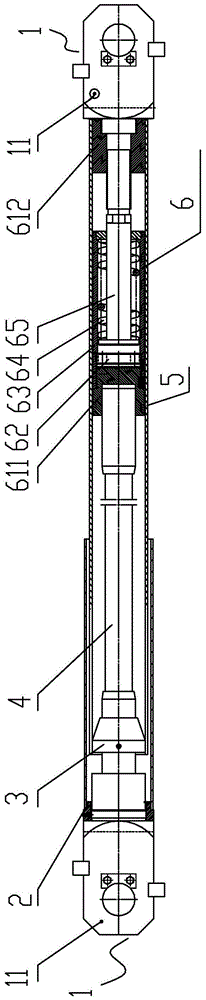

[0089] Such as figure 1 As shown, the basic structure of the superelastic decorative cable with the lug structure at both ends includes an anchor cable body 4, two anchor assemblies positioned at both ends of the anchor cable body 4 and a sleeve outside the anchor cable body 4, Support ring 3 and a superelastic adjustment device 6 in the casing;

[0090] The two anchor assemblies 1 positioned at the two ends of the anchor cable body 4 are fork ear assemblies 11, and the superelastic adjustment device 6 is located in the lower casing, and one end of the lower casing 5 extends into the upper casing 2, and the superelastic adjustment device 6 One end is connected to the lower sleeve through the connector 611, and the other end is connected to the fork assembly 11 at the other end of the anchor cable body 4 through the connector 612 of the superelastic adjustment device 6. For the structure of the conn...

Embodiment 2

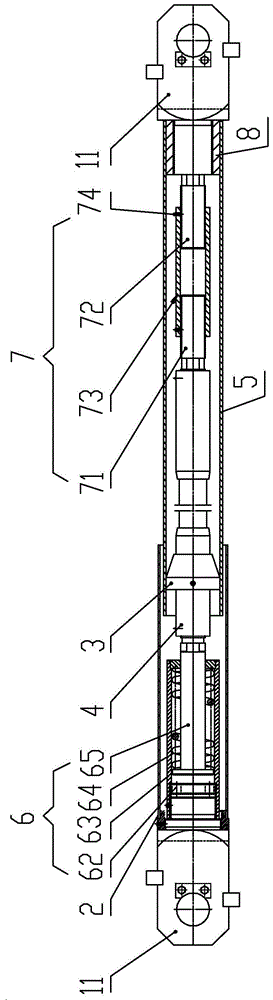

[0092] A superelastic decorative cable with lug structure at both ends of the cable length adjustment device:

[0093] Such as figure 2 As shown, the two anchor assemblies 1 located at the two ends of the anchor cable body 4 of the superelastic decorative cable with the fork lug structure at both ends are the fork lug assemblies 11. The difference from Embodiment 1 is that the superelastic adjustment device 6 is located in the upper casing 2, and there is a cable length adjusting device 7 in the lower casing 5. The cable length adjusting device 7 includes an adjusting sleeve 73, an adjusting rod I71 and an adjusting rod II72 respectively located at both ends of the adjusting sleeve 73. The adjusting rod I 71 is connected to the anchor cable body 4 , and one end of the adjusting rod II 72 is connected to the other end of the anchor cable body 4 through the positioning column 8 .

[0094] In the superelastic decorative cable described in Embodiment 1 or Embodiment 2, the ancho...

Embodiment 3

[0098] A method for making a superelastic decorative cable, which is a method for making a superelastic decorative cable with two ends fork lug structure described in Embodiment 1, it comprises the following steps:

[0099] Step 1: Lay the anchor cable body 4 flat on the bridge deck, install the support ring 3 on the flat anchor cable body 4 (see Figure 6 );

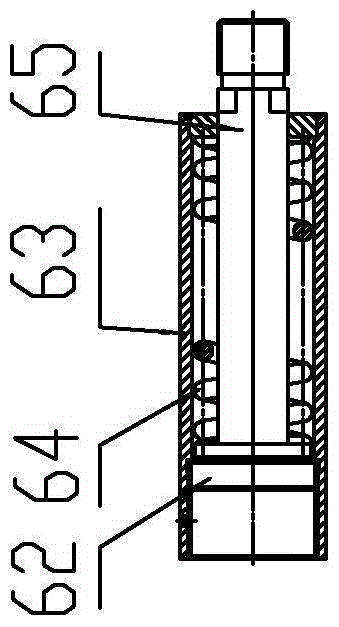

[0100] Step 2: Assemble the superelastic adjustment device 6; the superelastic adjustment device 6 is composed of a connector 61, a stopper 62, a casing 63, a superelastic body 64 and a pressing rod 65; place the stopper 62 and the pressing rod 65 in sequence into the casing 63, the superelastic body 64 is sleeved on the pressure rod 65 (see image 3 );

[0101] Step 3: Assemble the anchor cable body 4 and the super-elastic adjusting device 6; one end of the super-elastic adjusting device 6 is connected to one end of the anchor cable body 4 through the connector 611, and the anchor cable body 4 is connected to the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com