Three-dimensional (3D) texture transfer printing film and method for preparing same

A texture transfer, 3D technology, applied in the direction of copying/marking methods, chemical instruments and methods, printing, etc., can solve the problem that the industry cannot be reached, the second texture 130 has shallow texture, and the first texture 110 cannot effectively transfer the second texture. Colloid and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

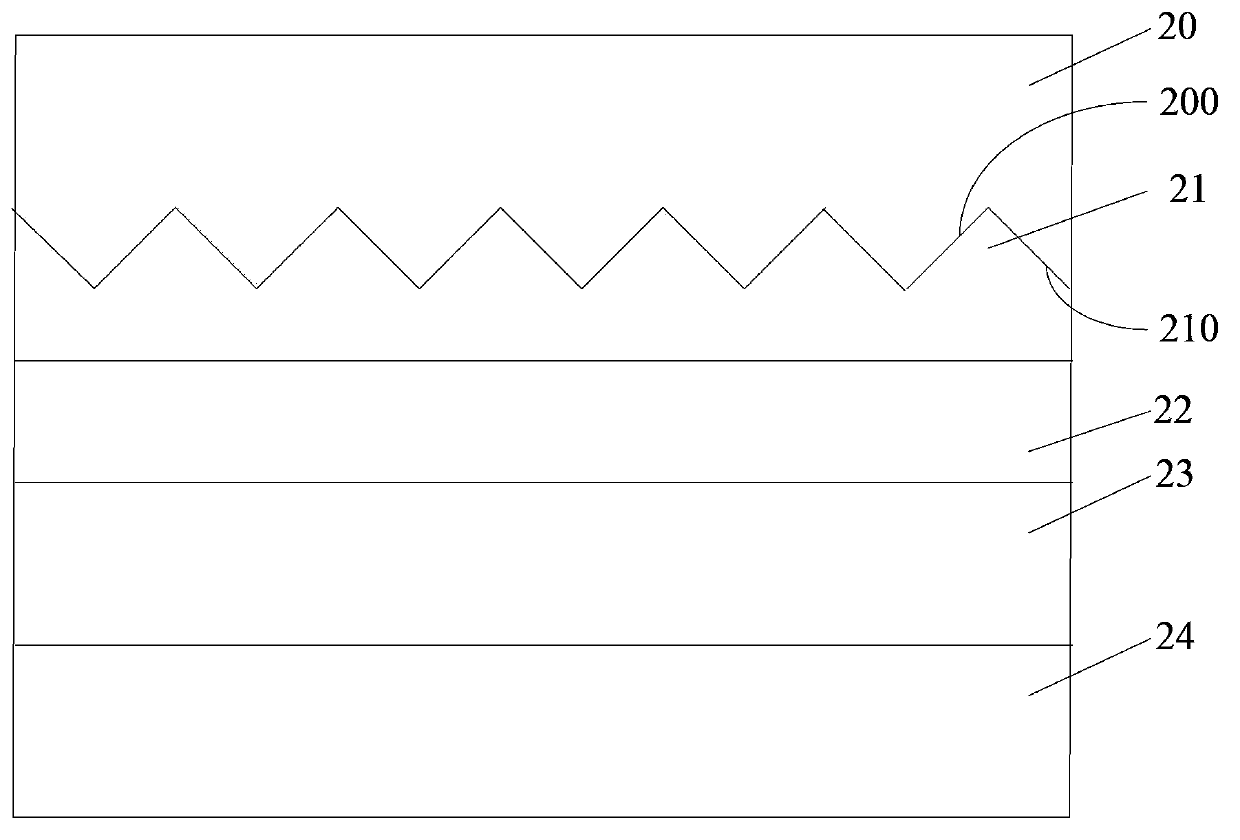

[0028] Such as figure 2 As shown, the first embodiment of a 3D texture transfer film of the present invention has a carrier layer 20 , an adhesive layer 21 , a printing layer 22 , a metal layer 23 and an adhesive layer 24 .

[0029] The carrier layer 20 is a material with release force, for example, such as polypropylene (Polypropylene, PP), o-phenylphenol (O-phenylphenol, OPP), polyolefin (Polyolefine, PO), polyvinyl alcohol (Polyvinyl Alcohol, P.V.A) or cast polypropylene (Cast Polypropylene, CPP), one side of the carrier layer 20 has a first texture 200, and the first texture 200 is to press the carrier layer 20 with a textured roller or mold pair, so that the carrier layer One side of 20 has a first texture 200 .

[0030] An adhesive layer 21 is disposed on the side of the carrier layer 20 having the first texture 200, so that the first texture 200 is transferred to the adhesive layer 21, so that a second texture 210 is formed on the adhesive layer 21, for example, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com