Patents

Literature

134results about How to "Enhanced magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

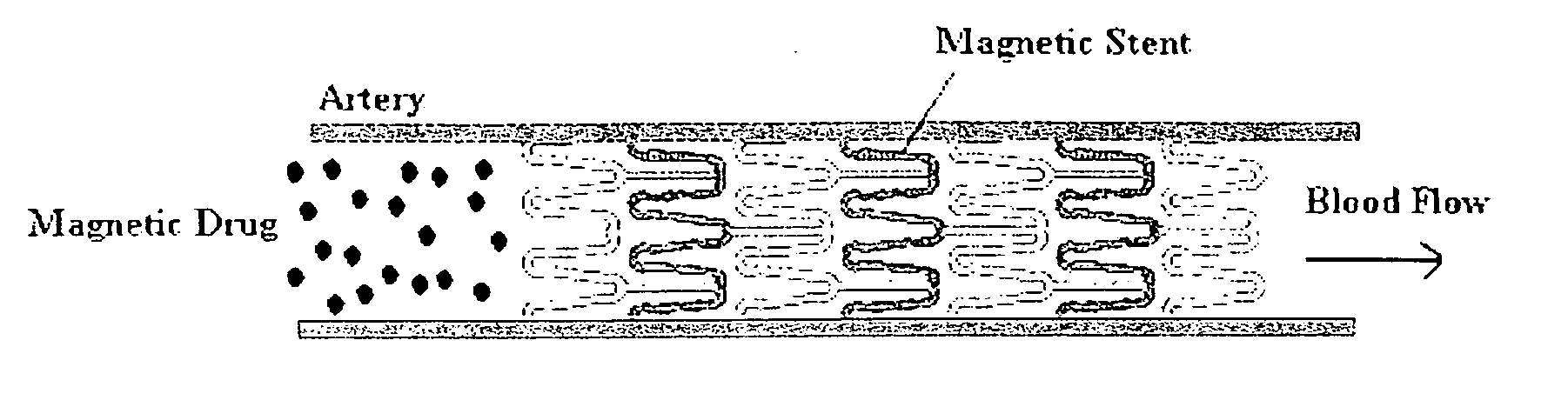

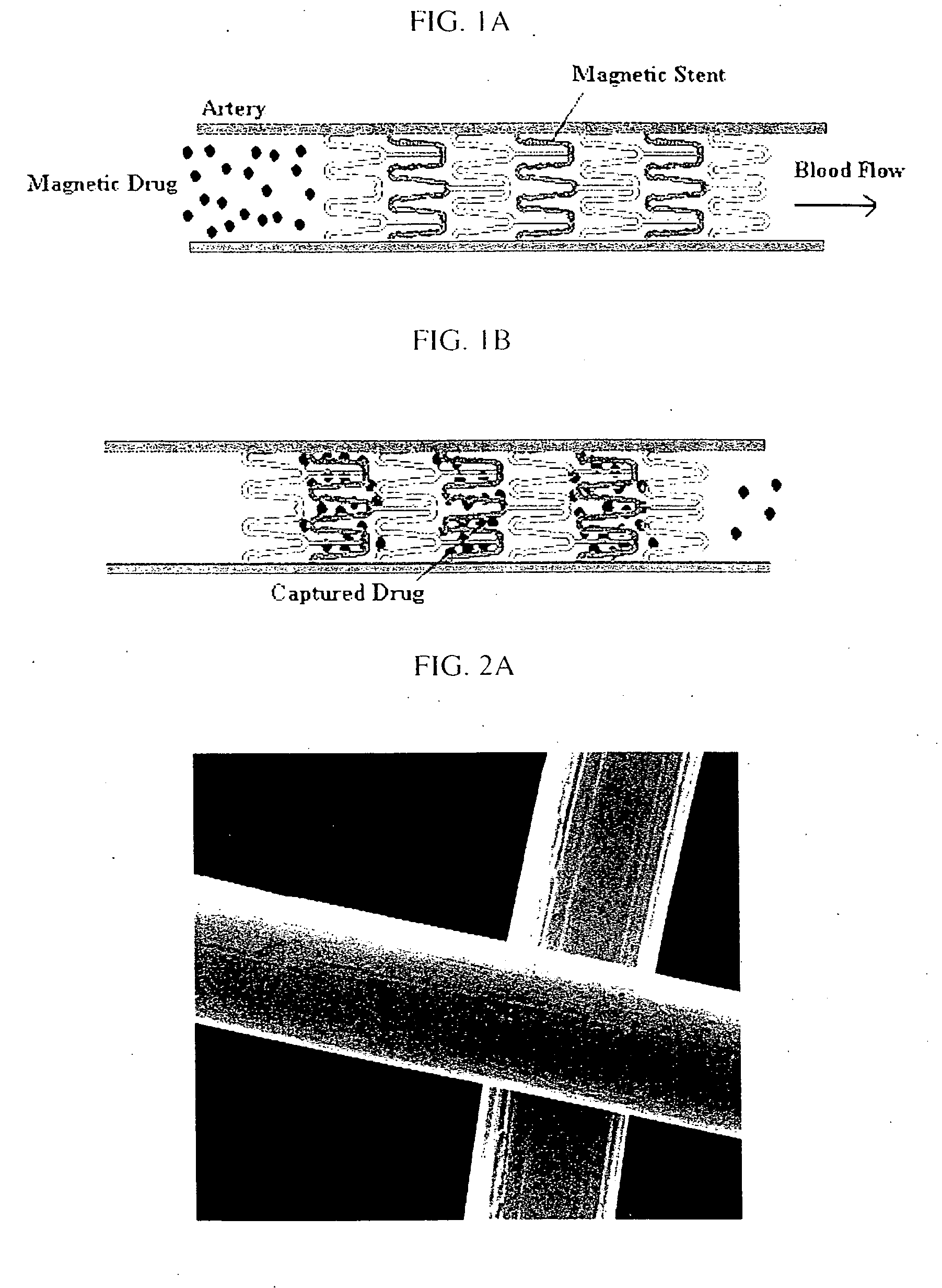

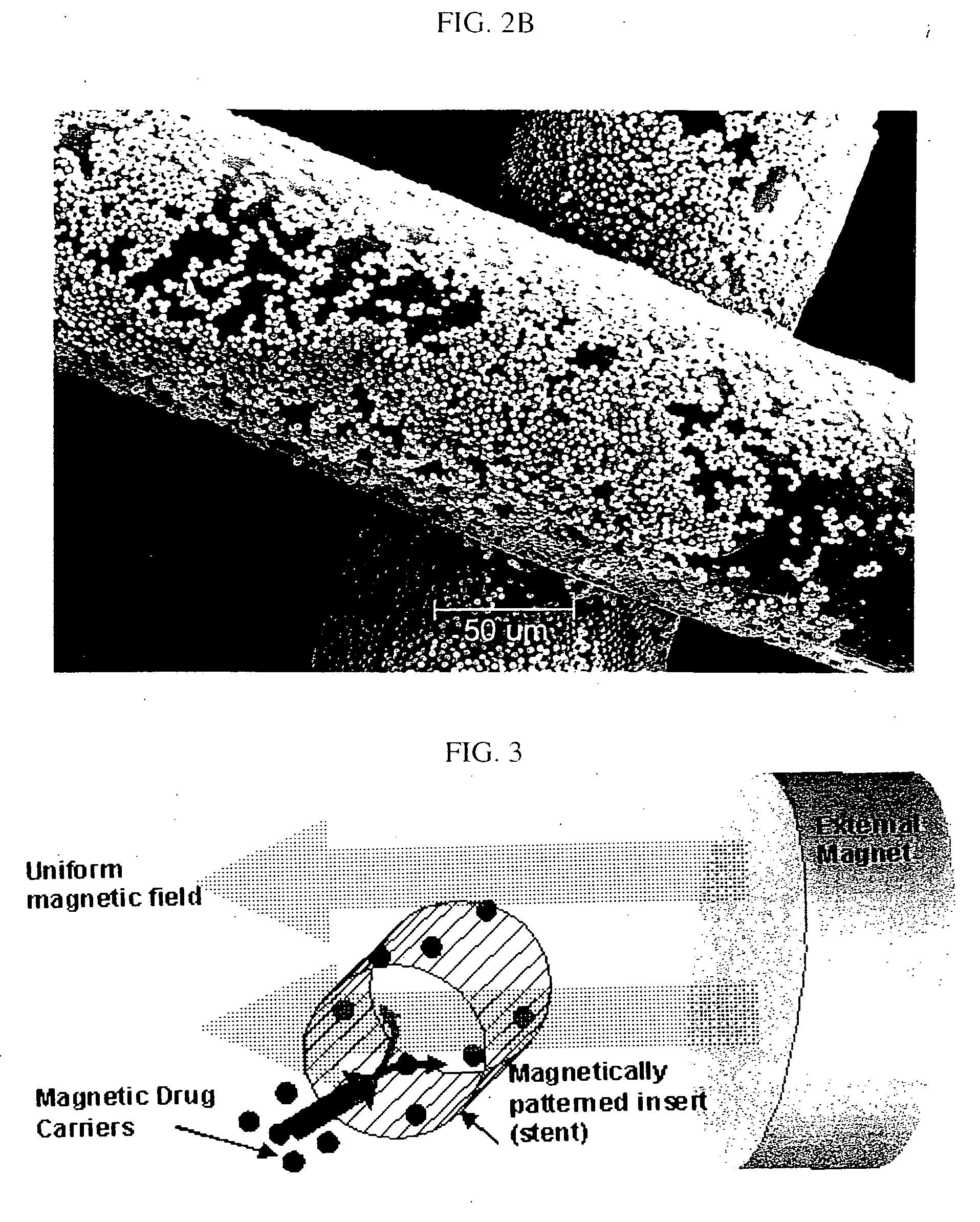

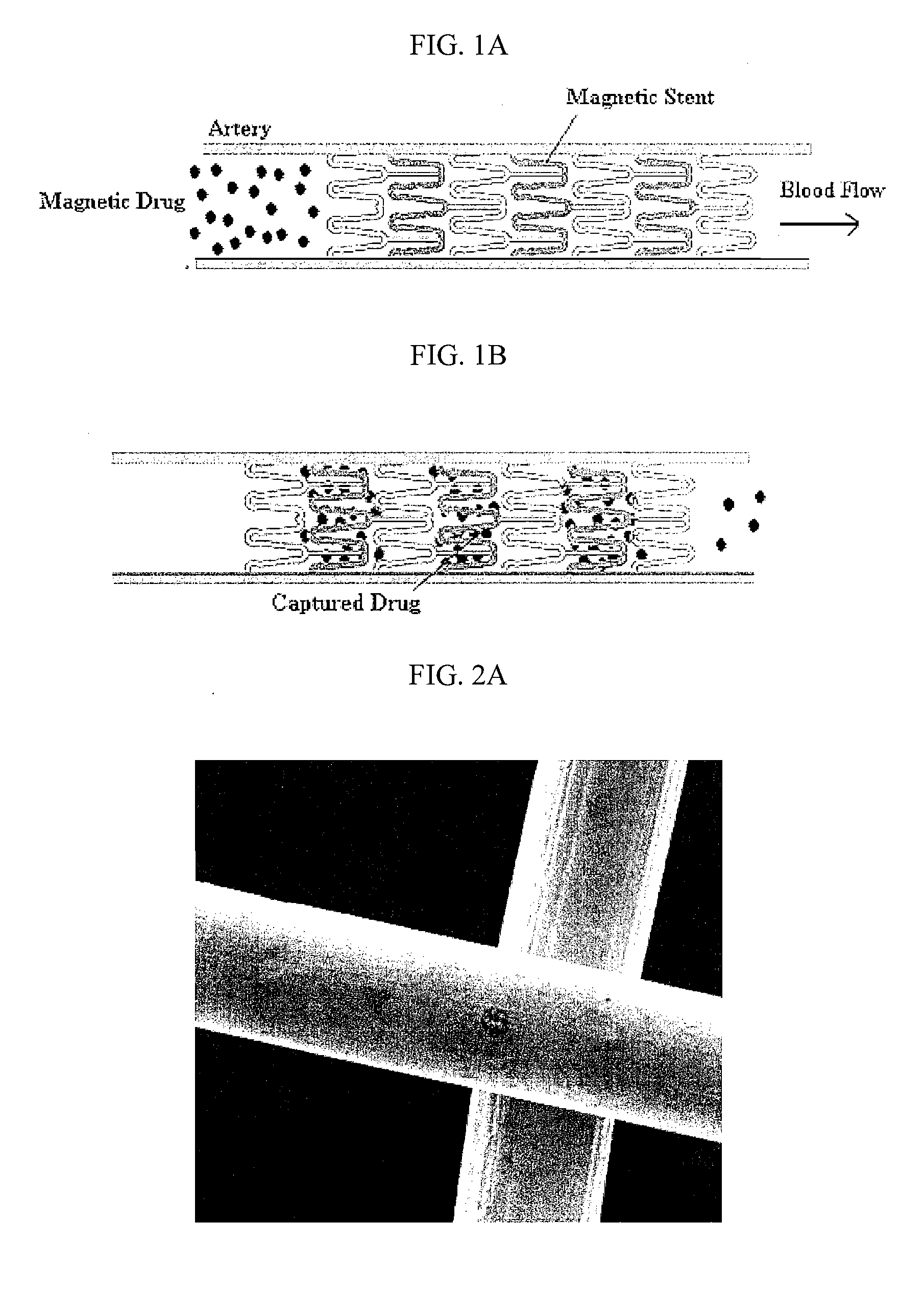

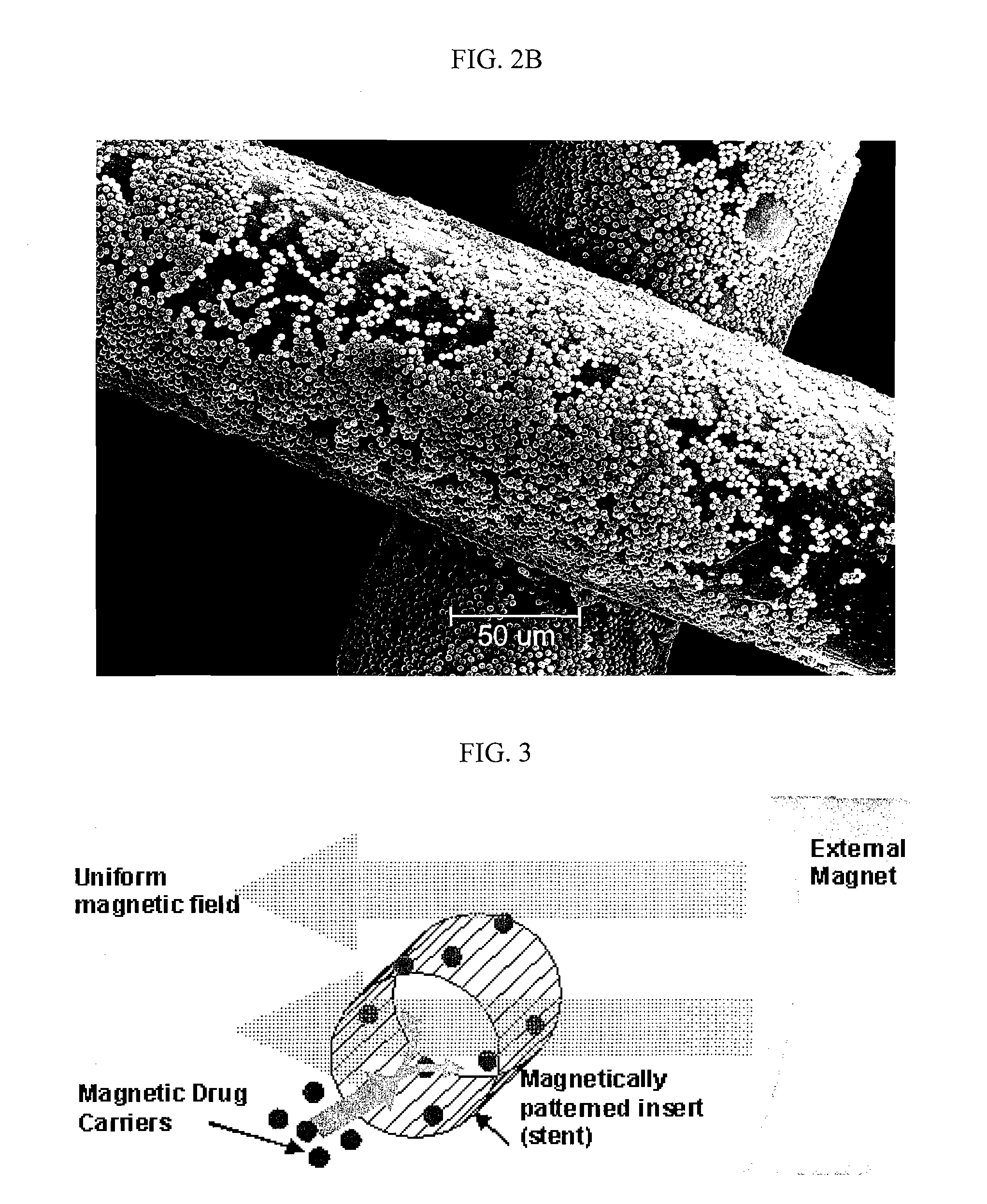

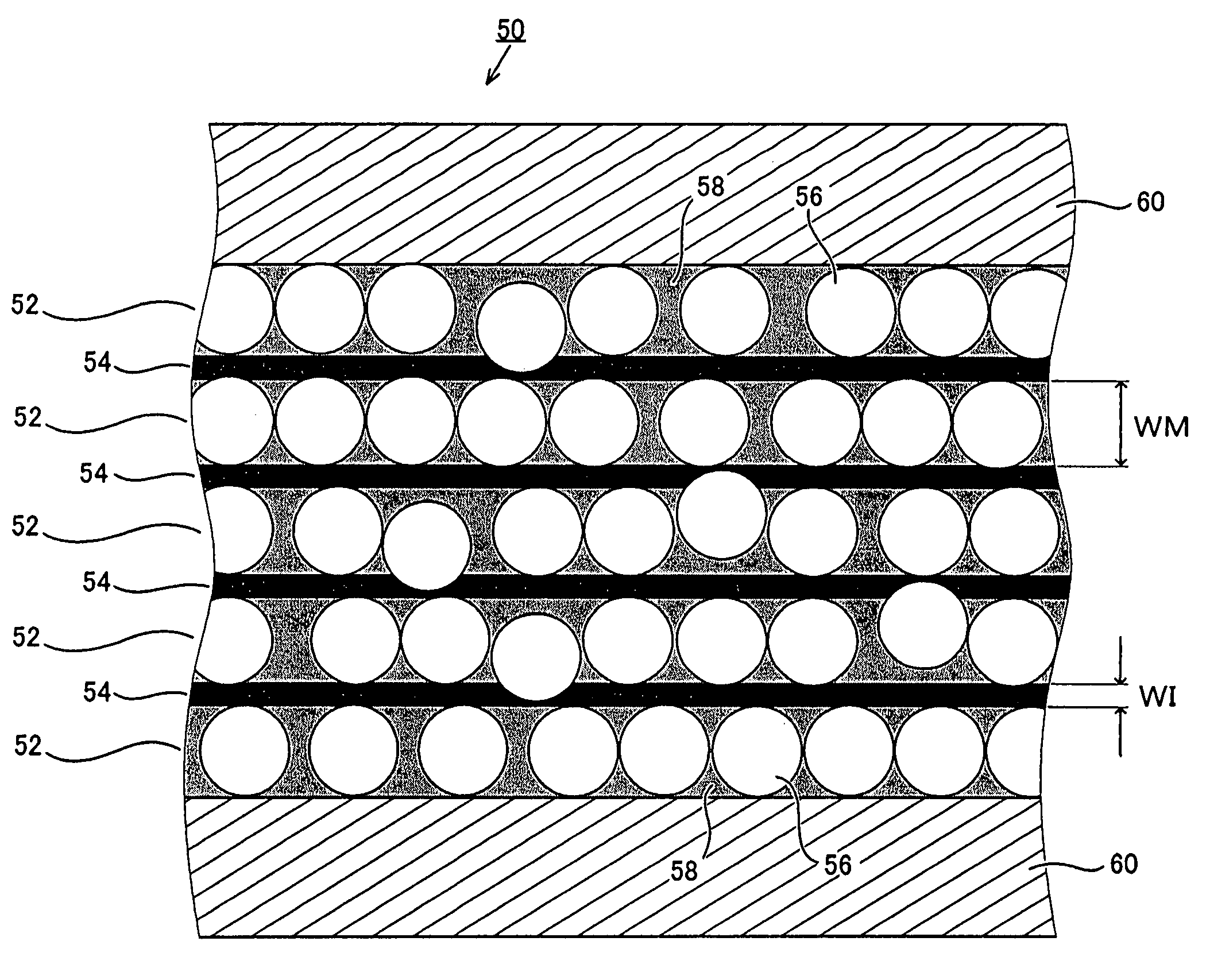

Magnetically-controllable delivery system for therapeutic agents

InactiveUS20060041182A1Enhanced magnetizationReduce penetrationStentsElectrotherapyMagnetic gradientMagnetization

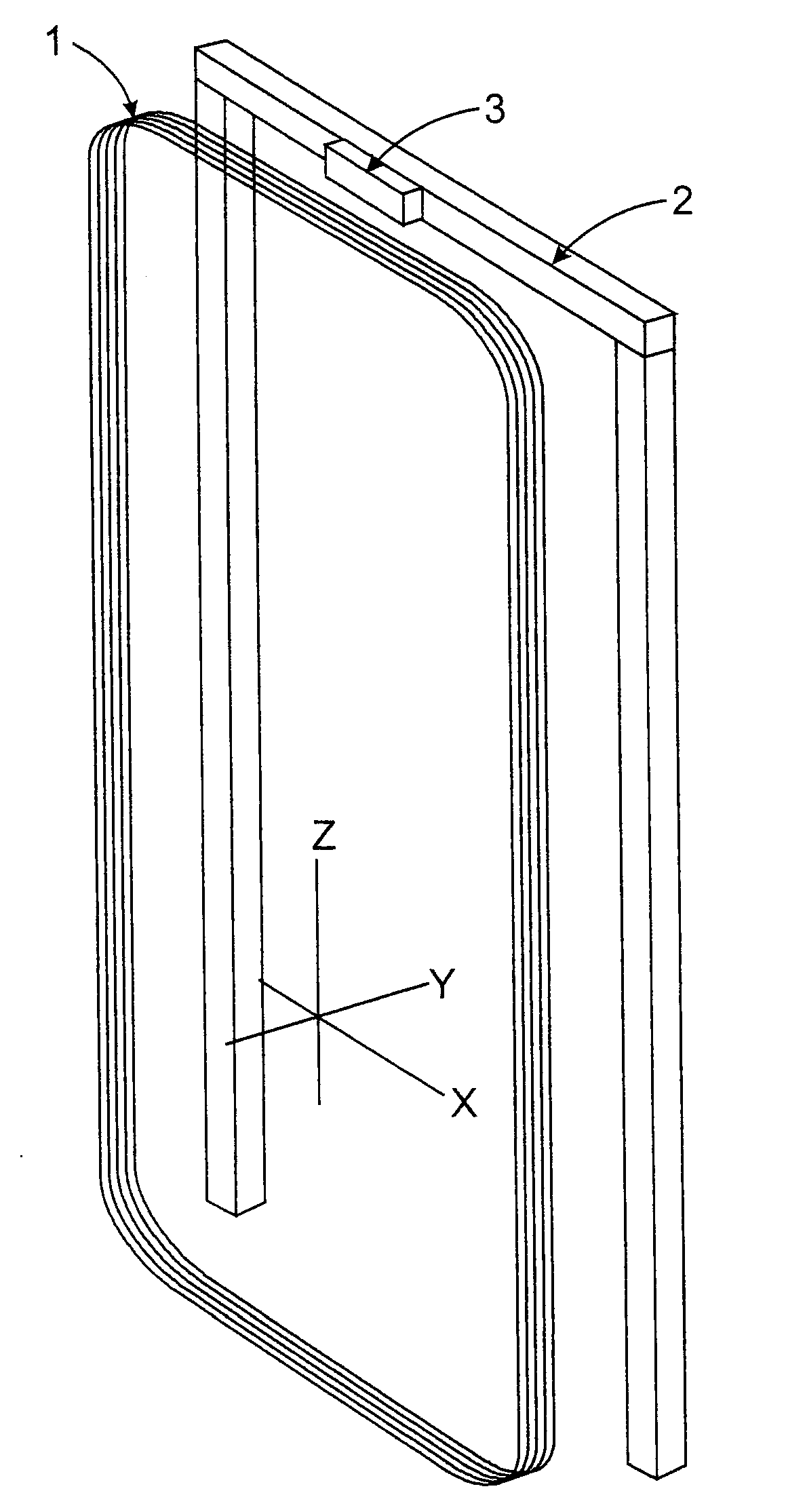

A magnetic delivery system for delivering a magnetizable particle to a location in a body, the device includes a magnetizable object implanted in the body, wherein the magnetizable object includes a plurality of segments distributed throughout the magnetizable object and wherein the segments are configured to provide a magnetic gradient for attracting the magnetizable particle and an external source of a magnetic field capable of (i) magnetizing the magnetizable particle and (ii) increasing a degree of magnetization of the magnetizable object and thereby creating the magnetic gradient. A drug delivery system including the magnetic delivery system and a magnetizable particle associated with a therapeutic agent and / or a cell. A cell delivery system based on the magnetic delivery system and a magnetizable particle associated with a cell. A method of using the magnetic delivery system for delivery of a therapeutic agent and / or a cell to a targeted location in a body.

Owner:DREXEL UNIV

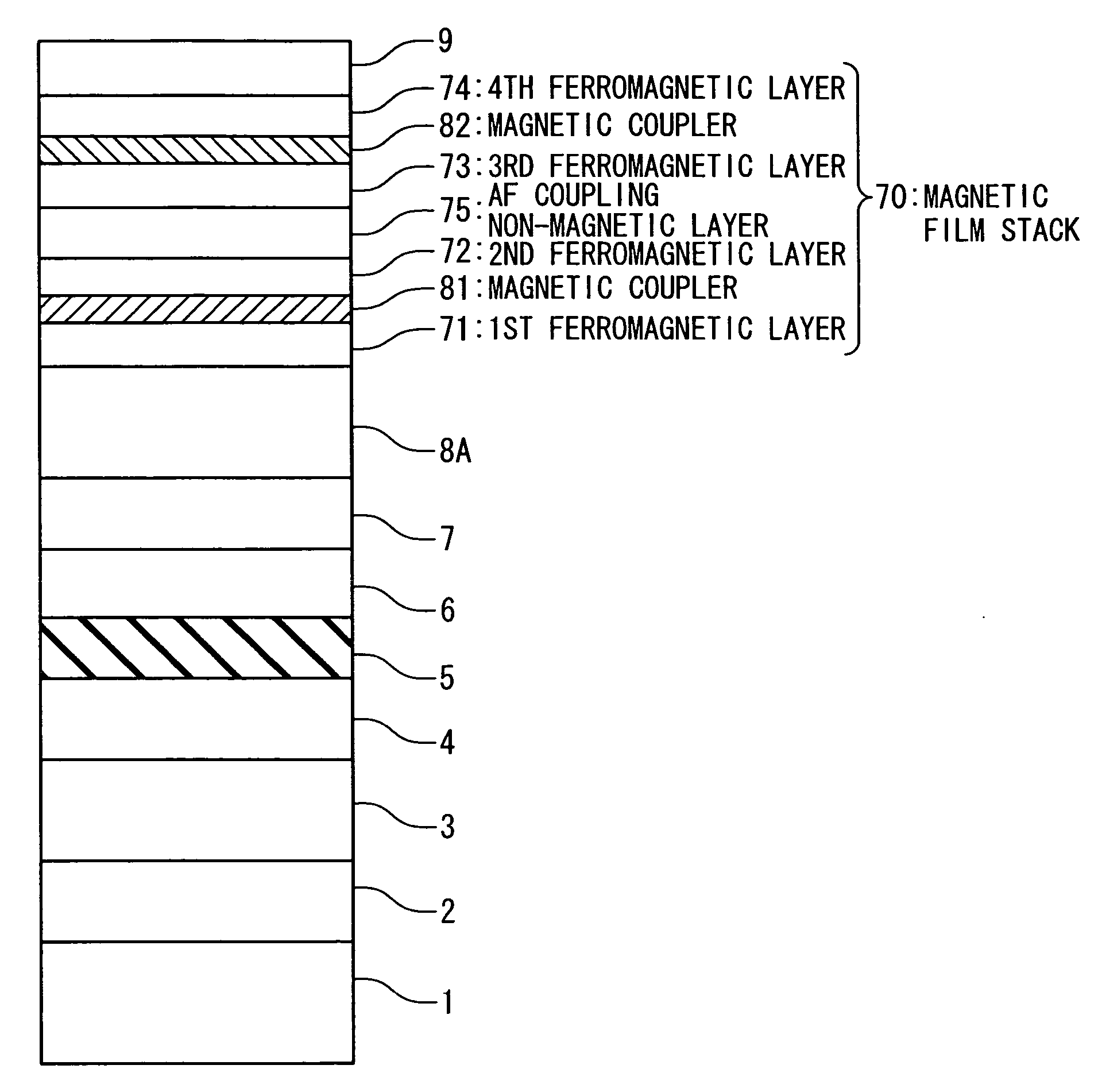

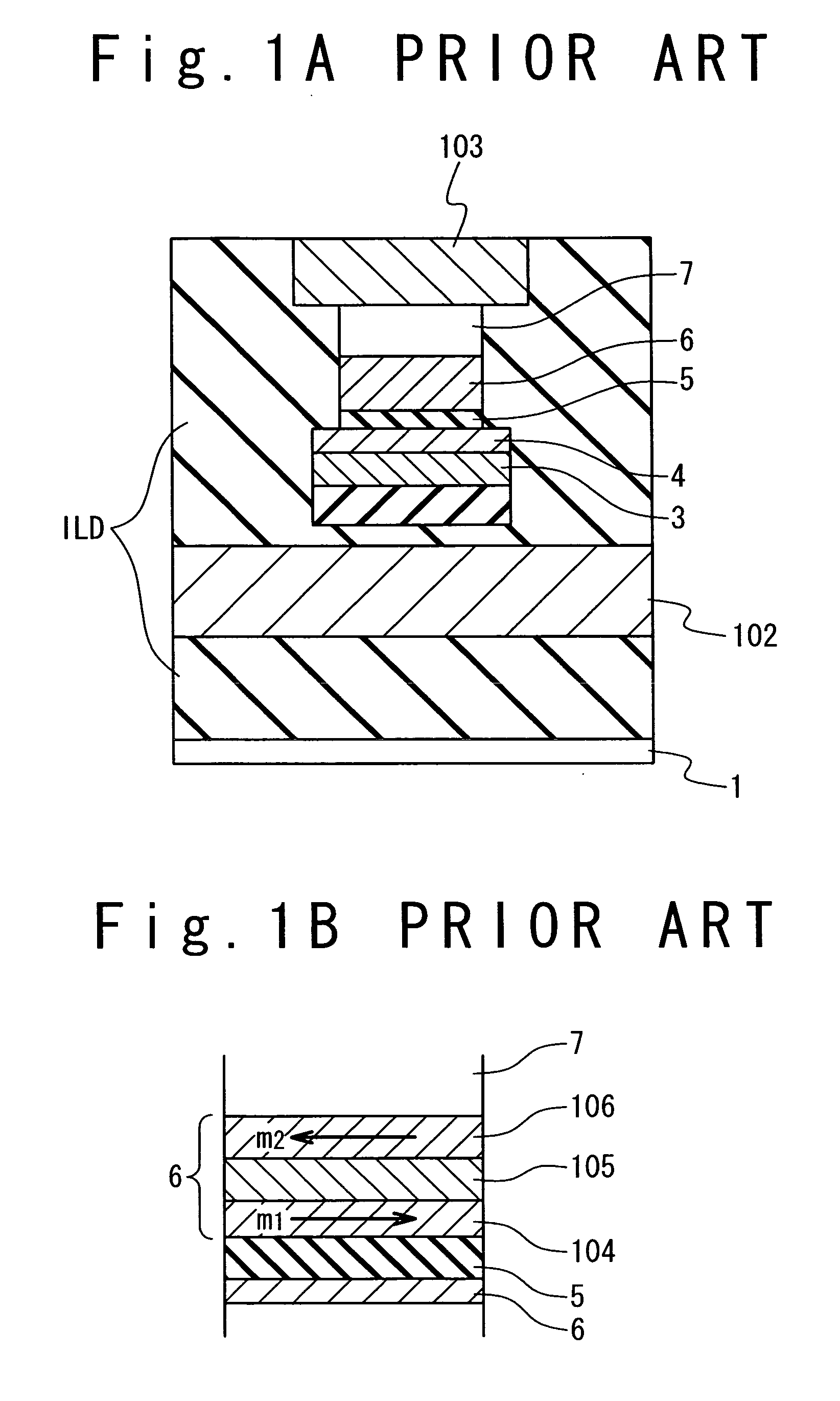

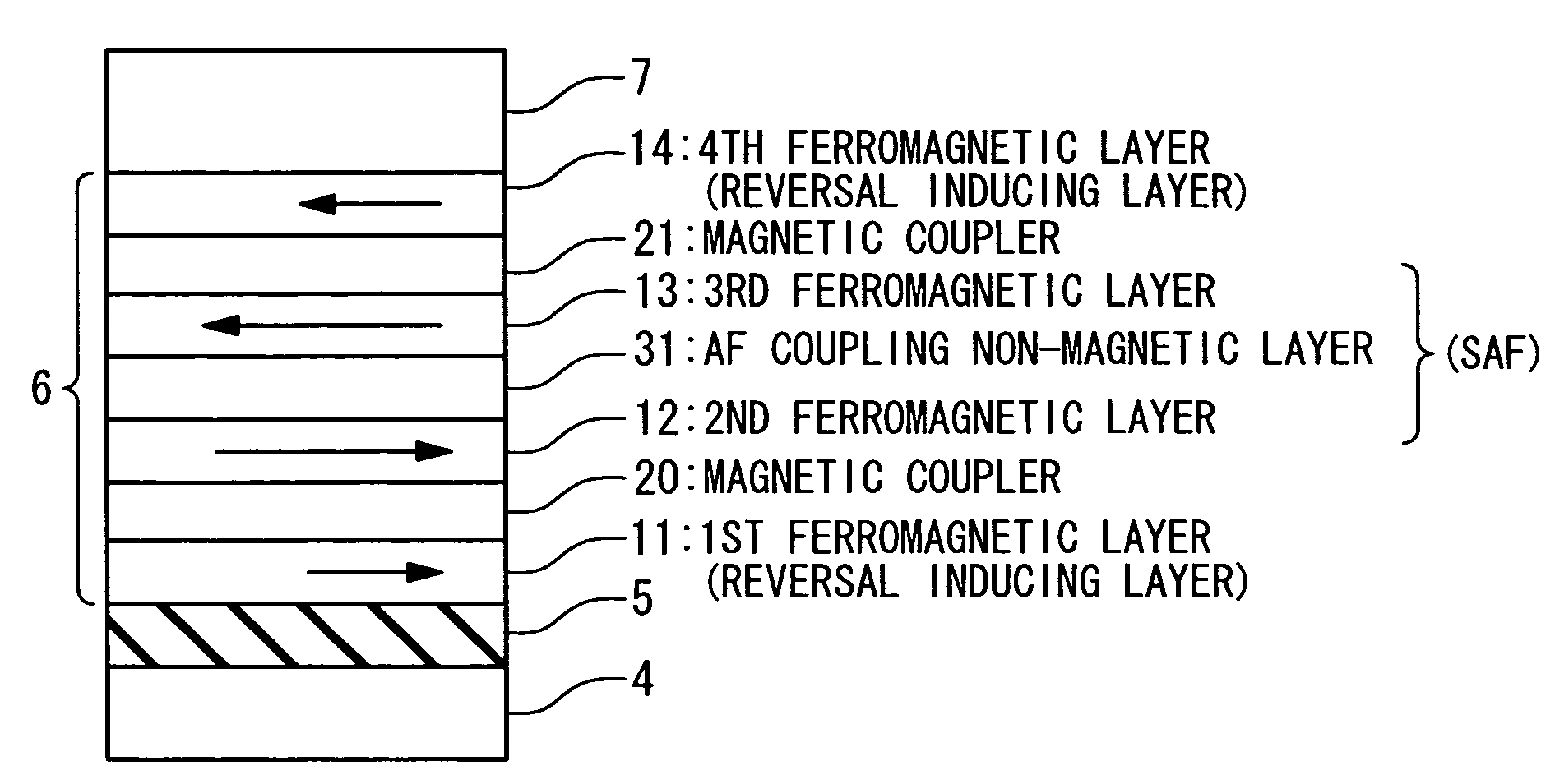

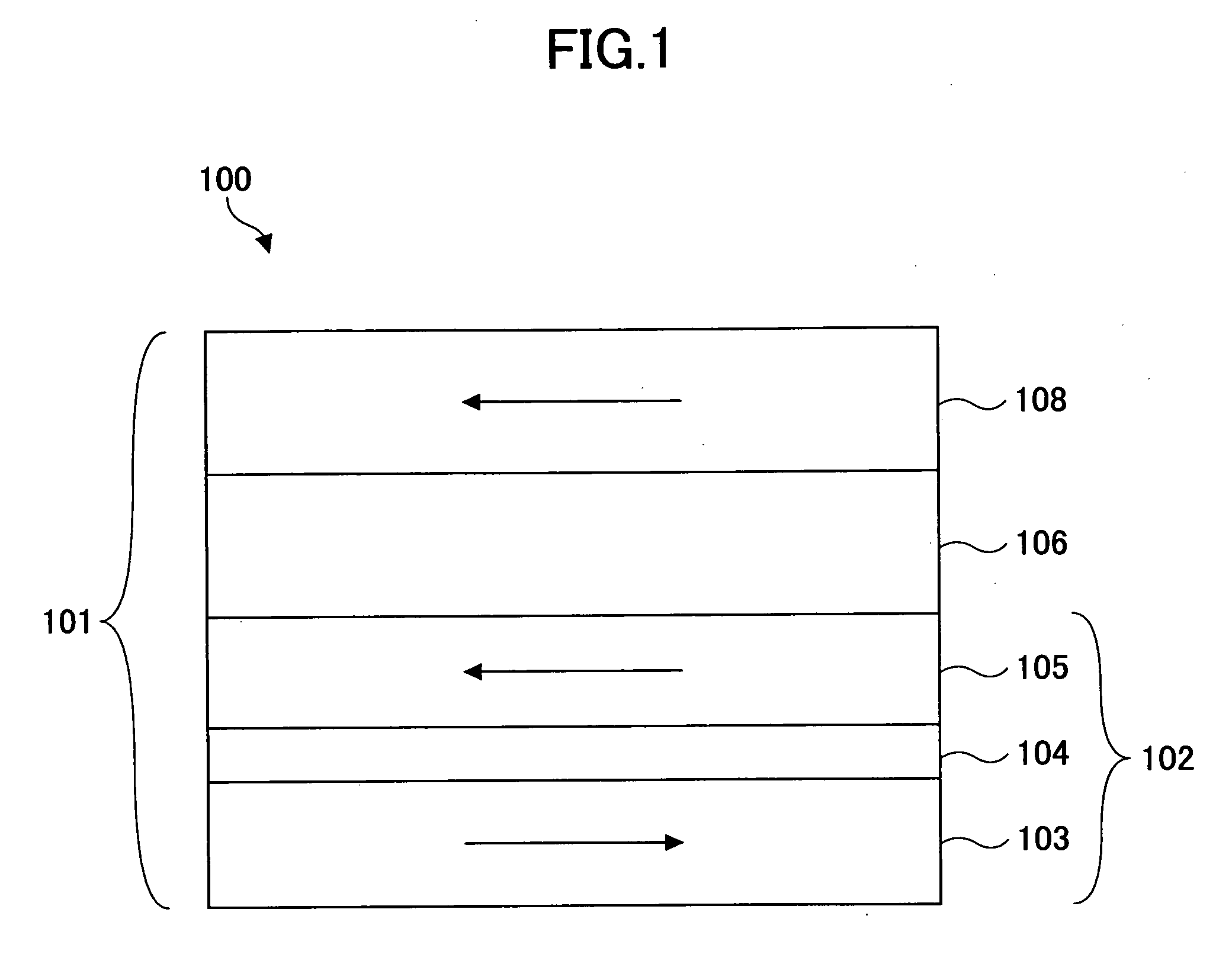

Magnetoresistive device and magnetic memory using the same

ActiveUS20060262594A1Reducing a magnetic field necessaryIncreased writing marginNanomagnetismDigital storageAntiferromagnetic couplingMagnetic memory

A magnetic film stack is composed of a synthetic antiferromagnet including a plurality of ferromagnetic layers, adjacent two of which are antiferromagnetically coupled through a non-magnetic layer; and a reversal inducing layer exhibiting ferromagnetism. The reversal inducing layer is ferromagnetically coupled to the synthetic antiferromagnet, and designed to have a coercive field smaller than a magnetic field at which antiferromagnetic coupling within the synthetic antiferromagnet starts to be decoupled.

Owner:NEC CORP

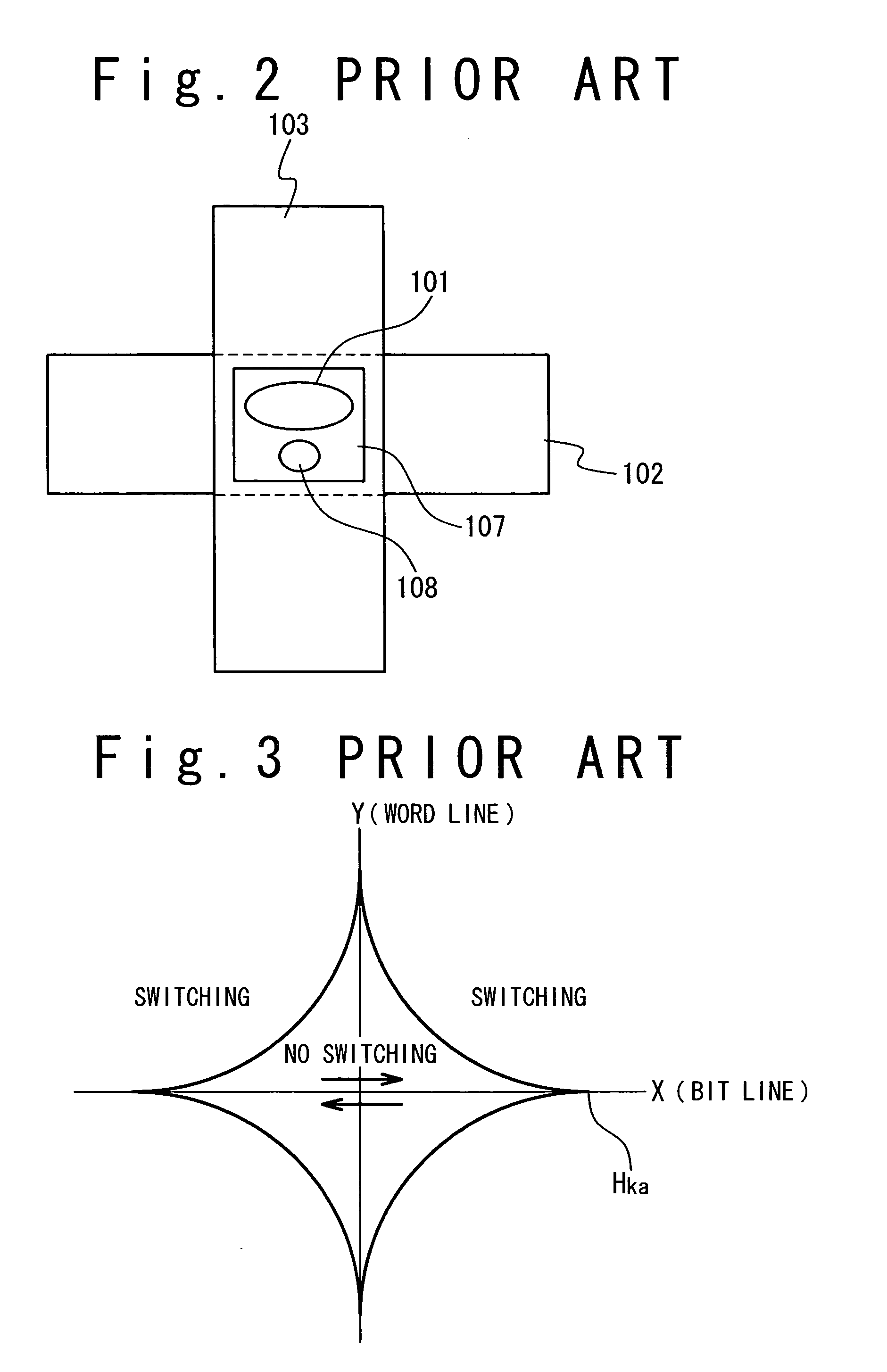

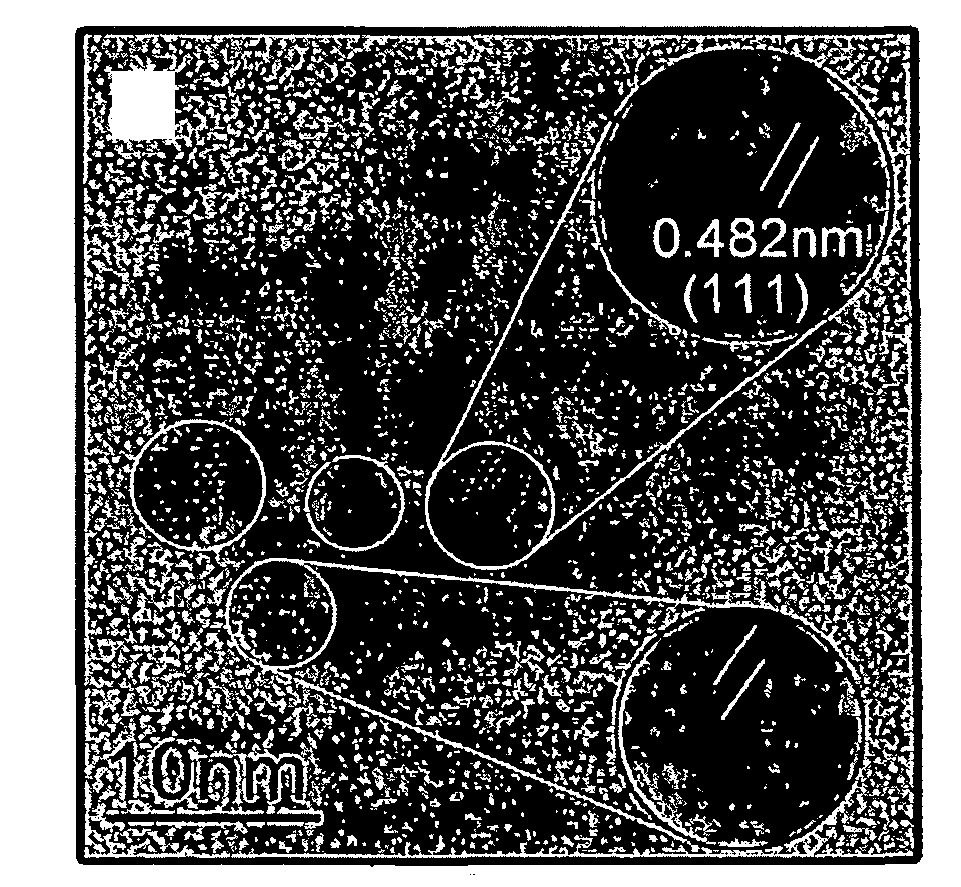

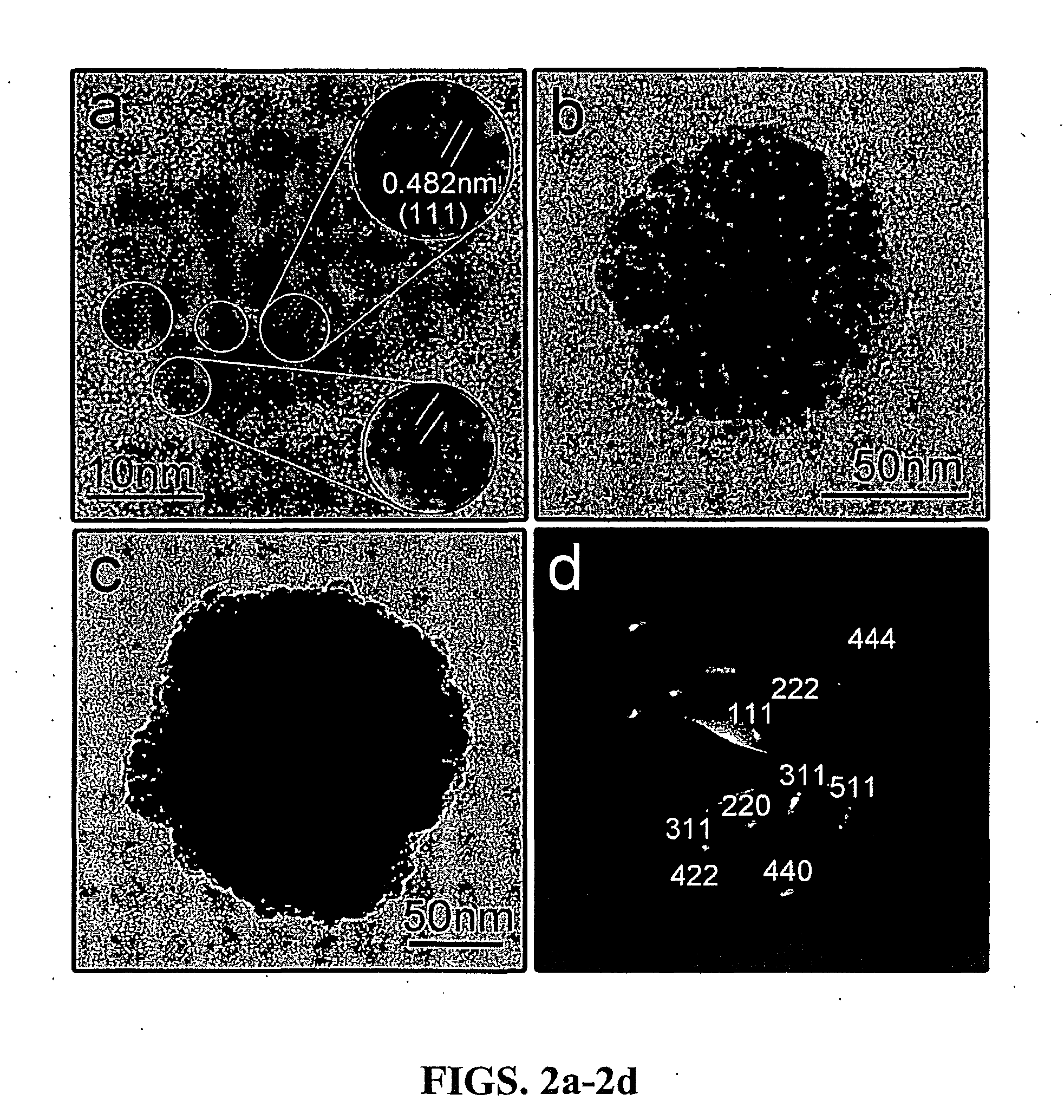

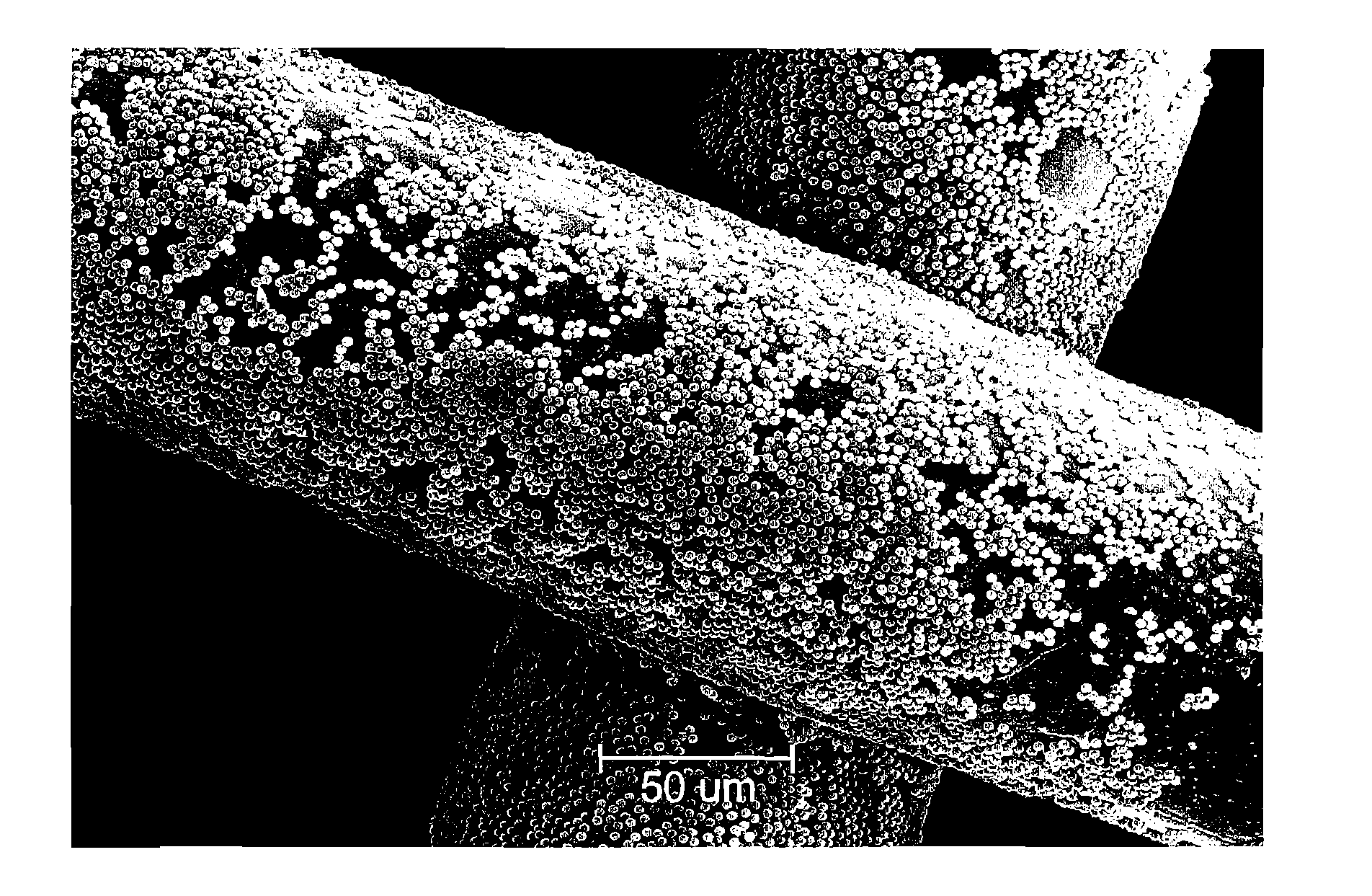

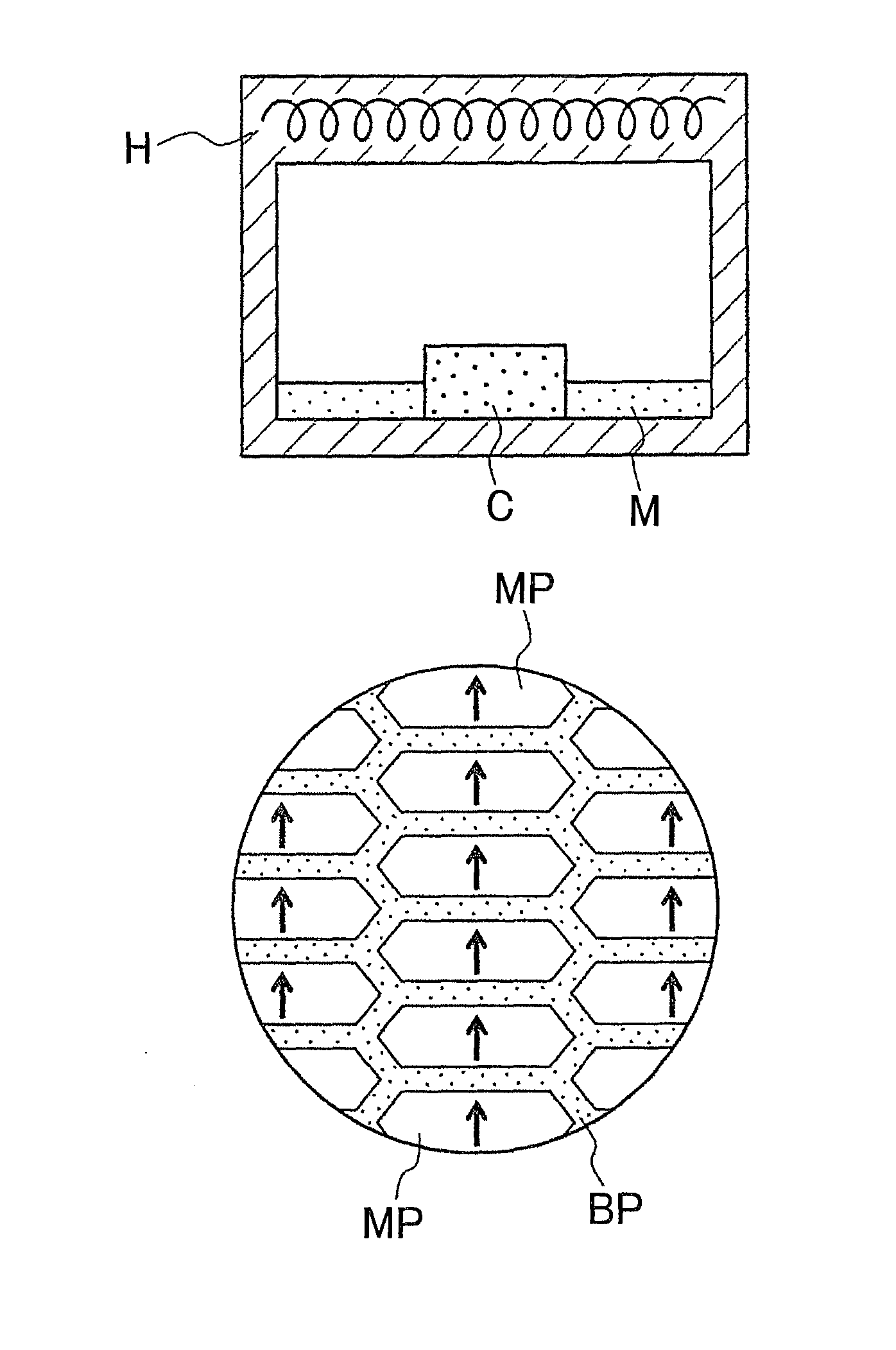

Superparamagnetic colloidal nanocrystal structures

ActiveUS20100224823A1High magnetizationGood water dispersibilityMaterial nanotechnologyPigmenting treatmentMagnetitePhotonics

Monodisperse colloidal nanocrystal clusters of magnetite (Fe3O4) with tunable sizes from about thirty to about three hundred nanometers have been synthesized using a high-temperature hydrolysis process. The colloidal nanocrystal clusters are capped with polyelectrolytes, and highly water soluble. Each cluster is composed of many single magnetite crystallites, thus retaining the superparamagnetic behavior at room temperature. The combination of superparamagnetic property, high magnetization, and high water dispersibility makes the colloidal nanocrystal clusters ideal candidates for various important biomedical applications such as drug delivery and bioseparation. The present invention is further directed to methods for forming colloidal photonic crystals from both aqueous and nonaqueous solutions of the superparamagnetic colloidal nanocrystal clusters with an external magnetic field applied thereto. The diffraction of the photonic crystals can be tuned from near infrared to visible and further ultraviolet spectral region by varying the external magnetic field.

Owner:RGT UNIV OF CALIFORNIA

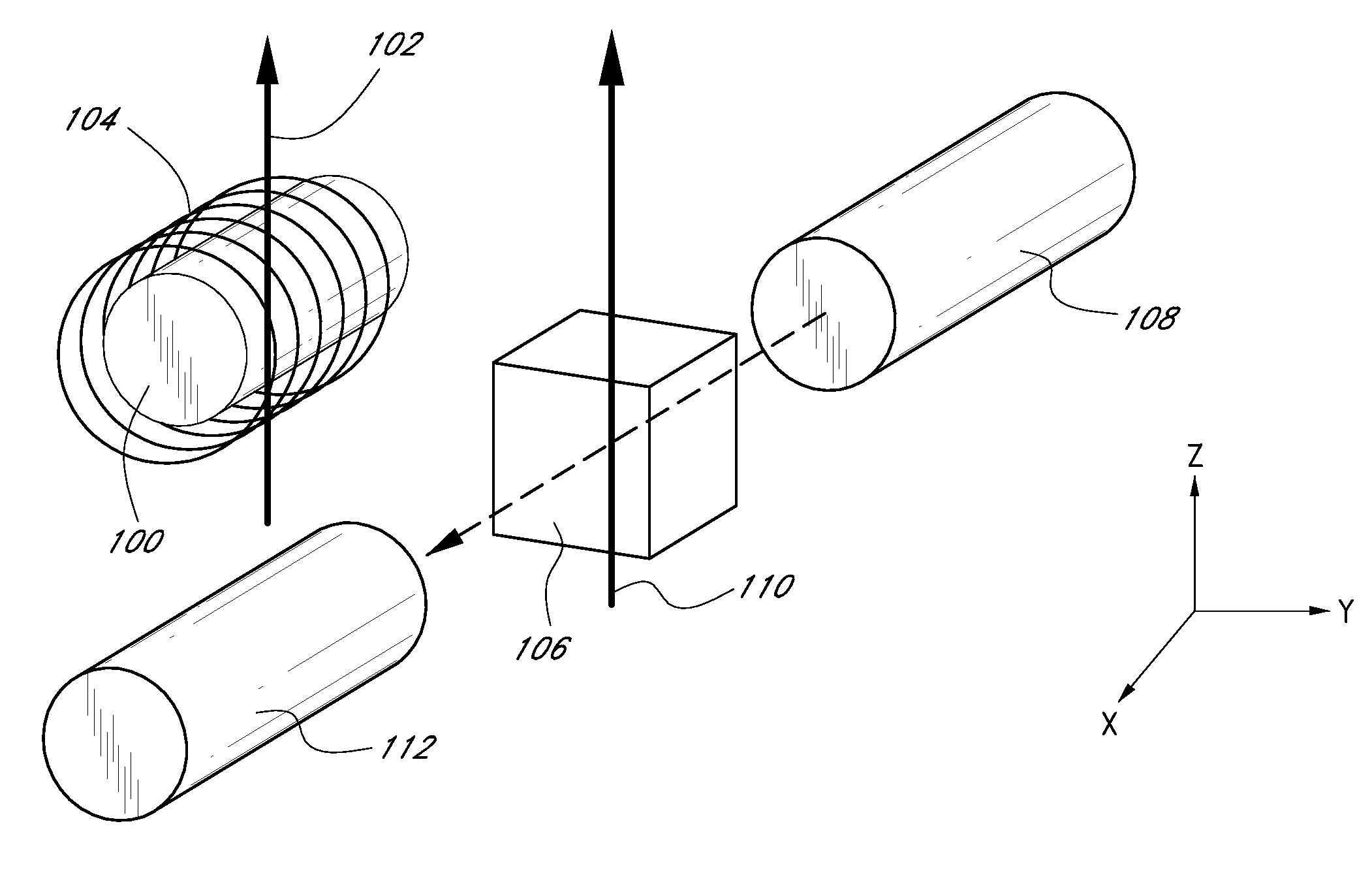

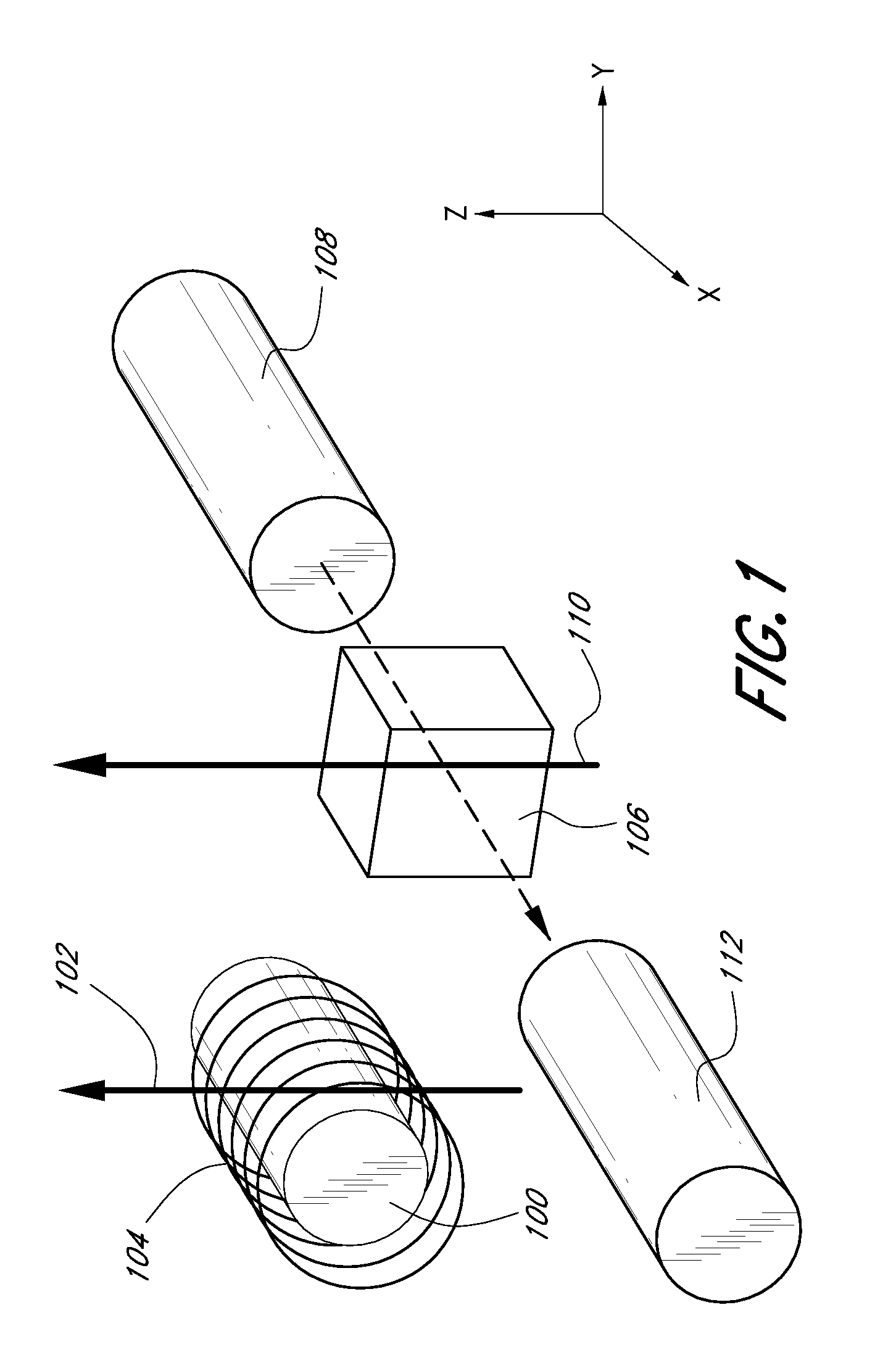

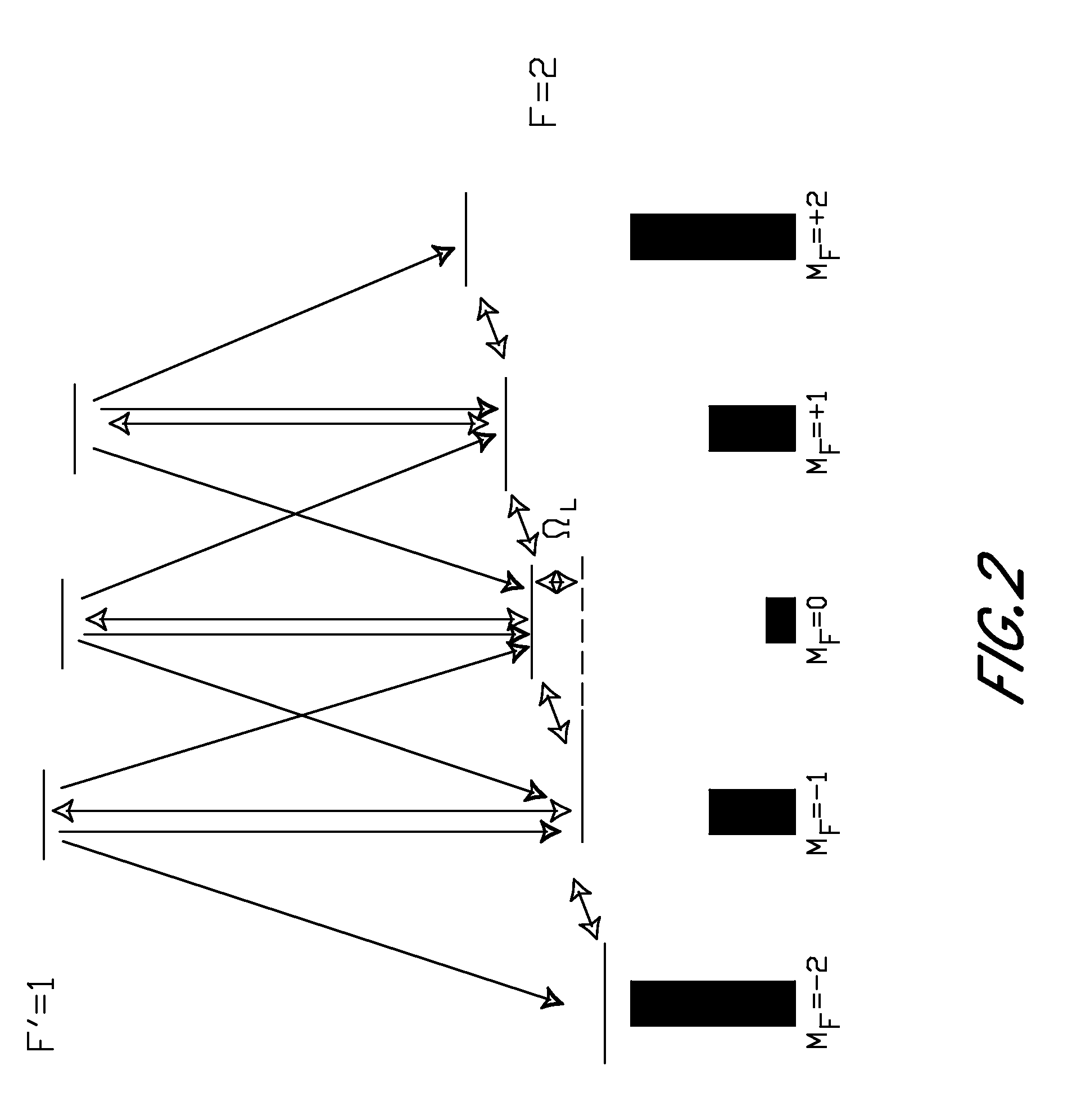

Radio frequency atomic magnetometer

InactiveUS20100289491A1Enhance nuclear magnetizationEnhanced magnetizationElectric/magnetic detectionMeasurements using NMRRadio frequency signalLight beam

An atomic magnetometer is used to detect radio frequency magnetic fields, such as those generated in nuclear resonance experiments. The magnetometer is based on nonlinear magneto-optical rotation and pumps an atomic vapor into a quadrupole aligned state. Detection of the modulation of the polarization of a linearly polarized beam provides the radio frequency signal, which can then be processed to extract the component frequencies.

Owner:BUDKER DIMITRY +2

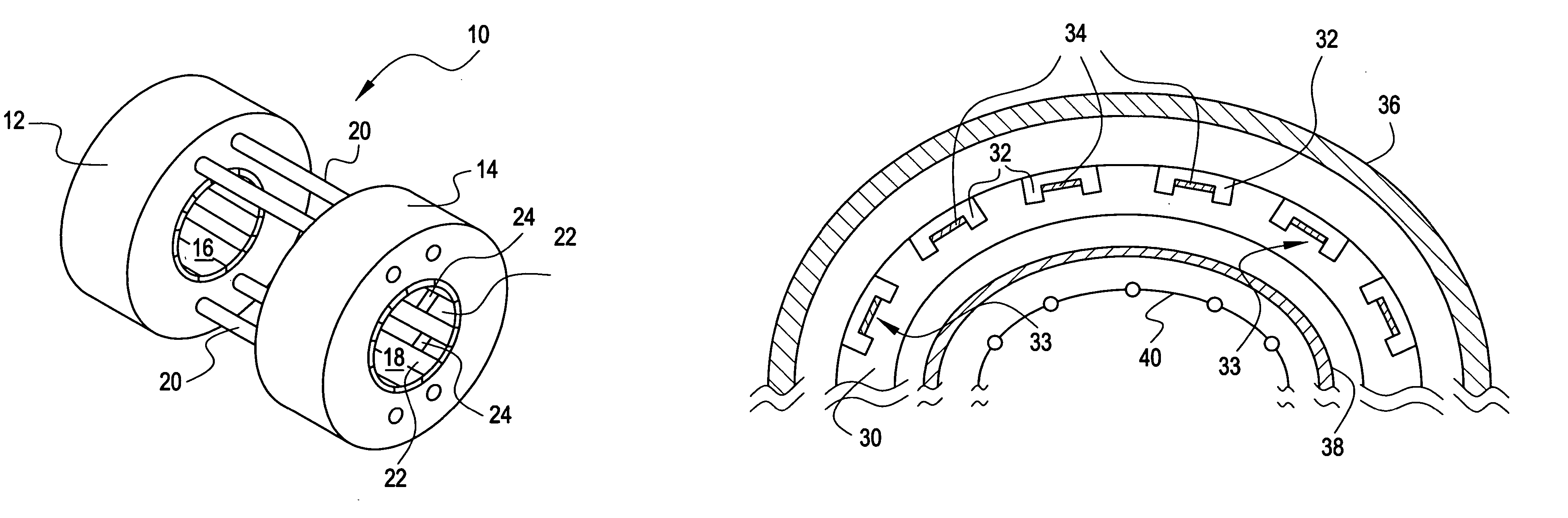

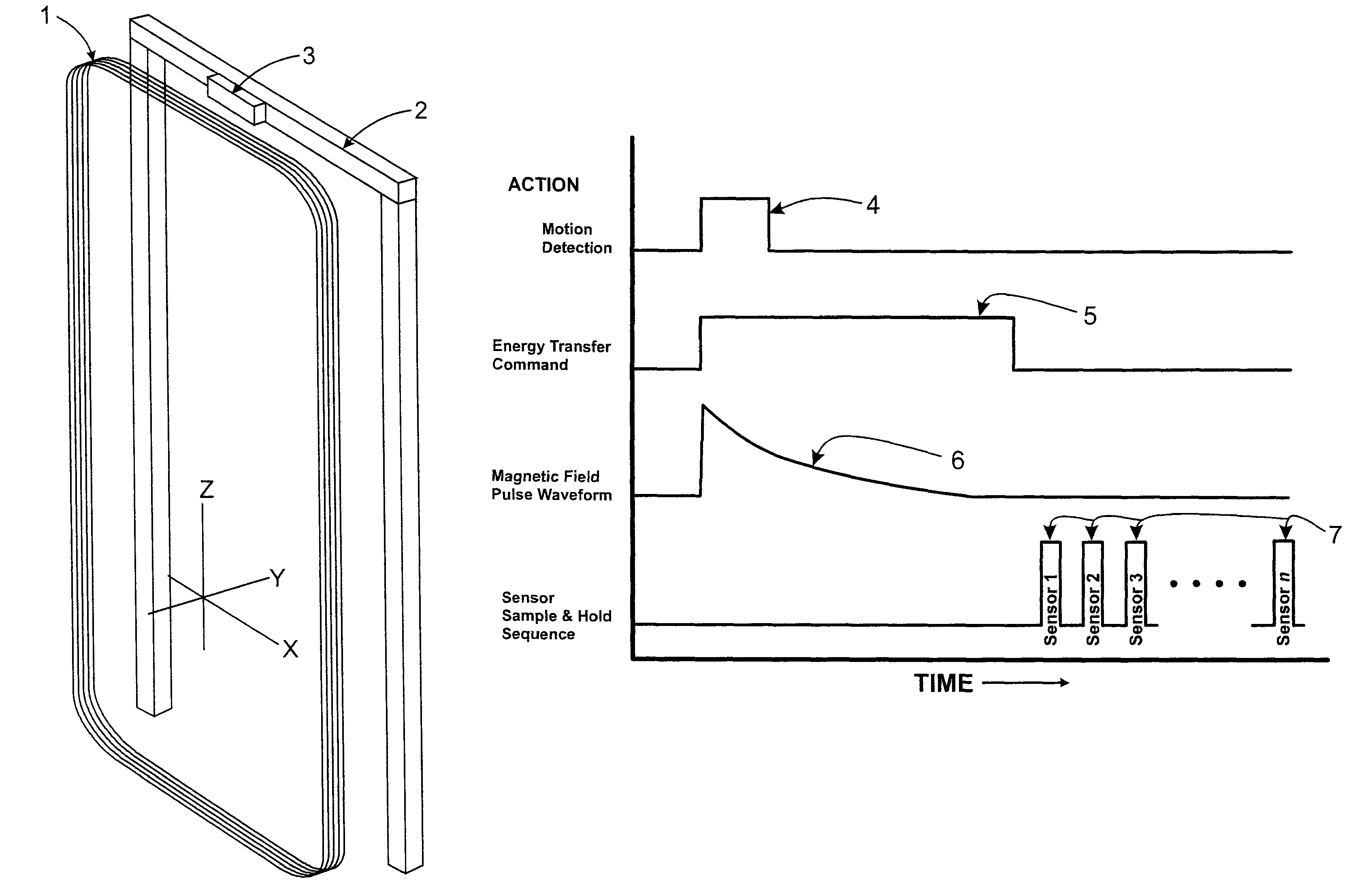

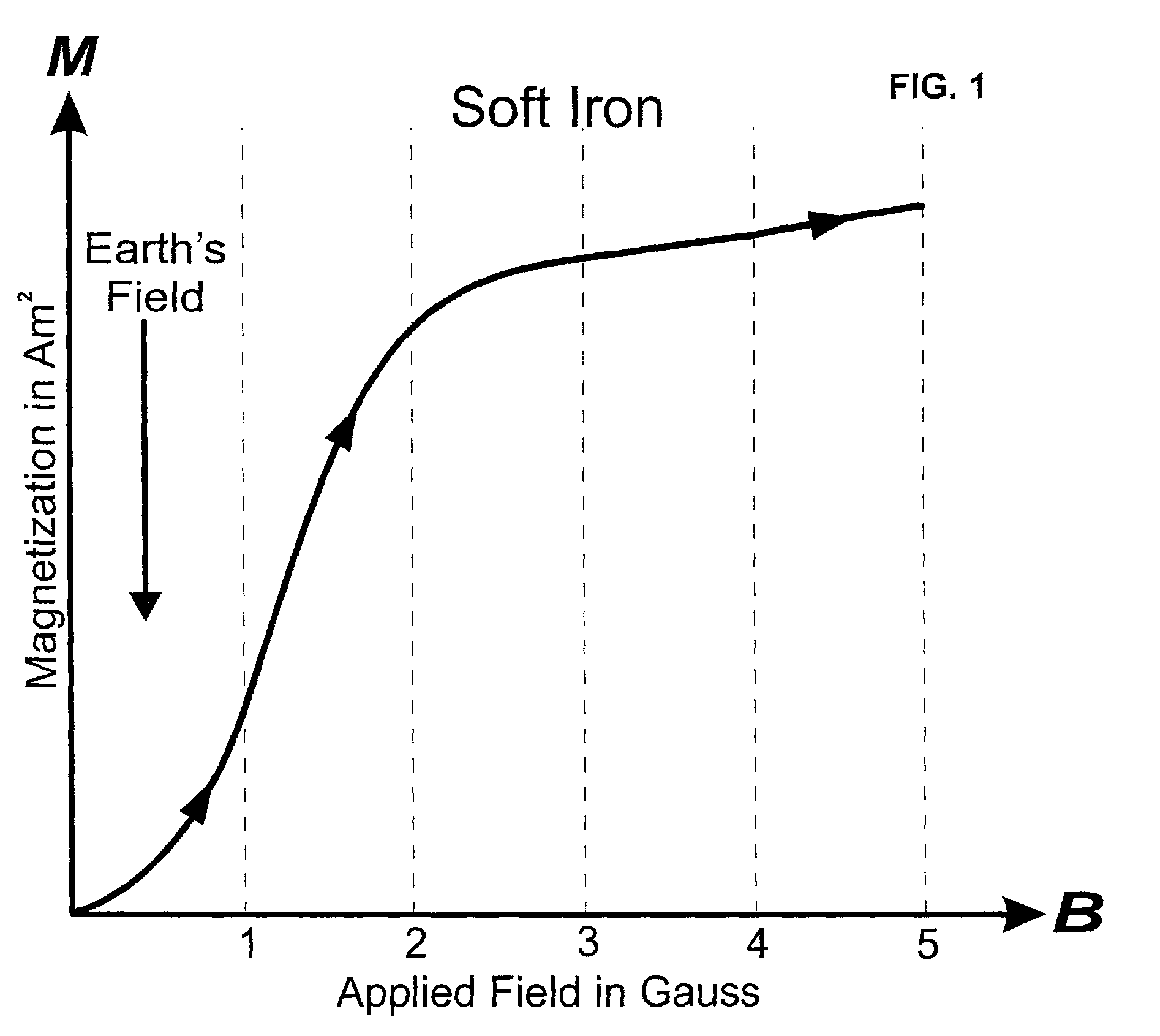

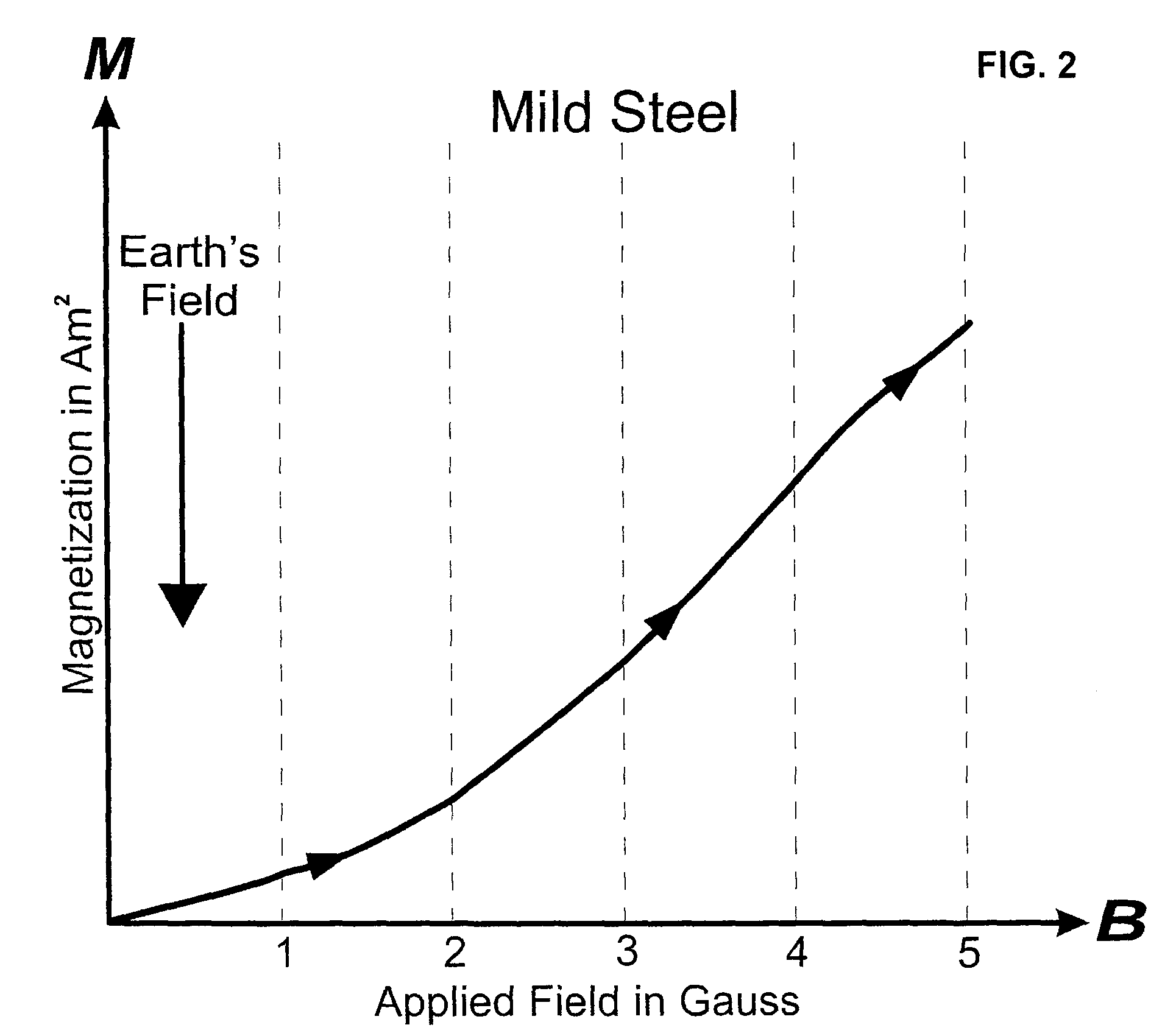

Ferromagnetic detection enhancer

ActiveUS20090167307A1Massive supply requirementAbility to detectElectric/magnetic detectionMeasurements using magnetic resonanceElectronic switchMagnetization

An apparatus for increasing the ability to detect ferromagnetic objects by increasing the magnetization of the objects. The apparatus includes at least one coil to generate a magnetic field positioned in the area of the object to be detected. The apparatus includes an electrical energy storage capacitor bank capable of quickly releasing stored energy. The apparatus includes a high speed, high current electronic switch capable of quickly transferring the stored energy from the capacitor bank to the coil thereby producing in the coil a short duration, single polarity magnetic field pulse. The apparatus includes a sample and hold circuit capable of acquiring magnetic field sensor data during periods when the pulsed magnetic field is not present. The apparatus includes a microprocessor controller to control timing and sequence of the magnetic pulse generation and the sensor data sample and hold process. The apparatus may be for portal handheld or head mounted applications.

Owner:KOPP KEITH

Magnetically-Controllable Delivery System for Therapeutic Agents

InactiveUS20100204674A1Enhanced magnetizationSaturation magnetizationStentsElectrotherapyMagnetic gradientMagnetization

A magnetic delivery system for delivering a magnetizable particle to a location in a body, the device includes a magnetizable object implanted in the body, wherein the magnetizable object includes a plurality of segments distributed throughout the magnetizable object and wherein the segments are configured to provide a magnetic gradient for attracting the magnetizable particle and an external source of a magnetic field capable of (i) magnetizing the magnetizable particle and (ii) increasing a degree of magnetization of the magnetizable object and thereby creating the magnetic gradient. A drug delivery system including the magnetic delivery system and a magnetizable particle associated with a therapeutic agent and / or a cell. A cell delivery system based on the magnetic delivery system and a magnetizable particle associated with a cell. A method of using the magnetic delivery system for delivery of a therapeutic agent and / or a cell to a targeted location in a body.

Owner:DREXEL UNIV

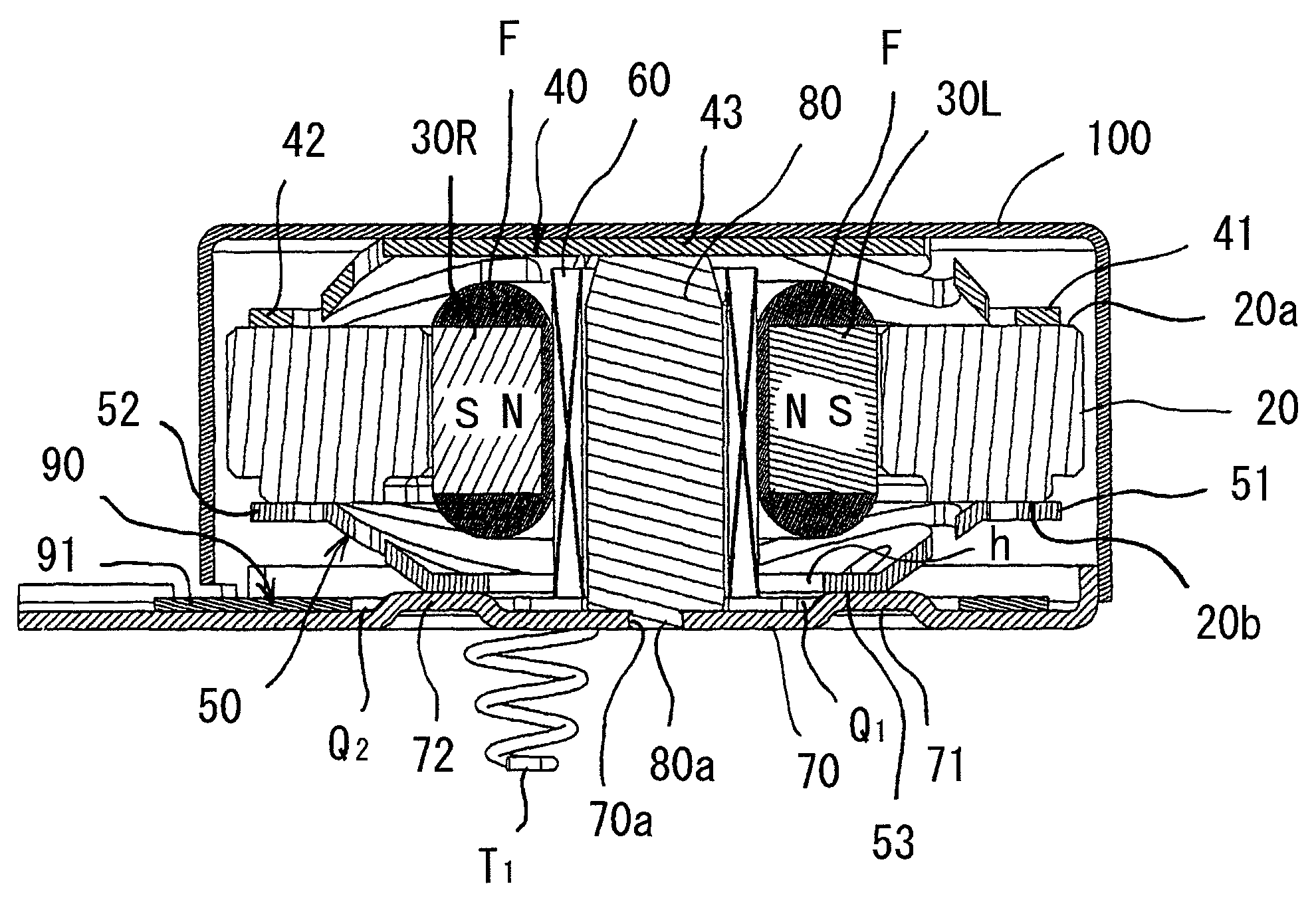

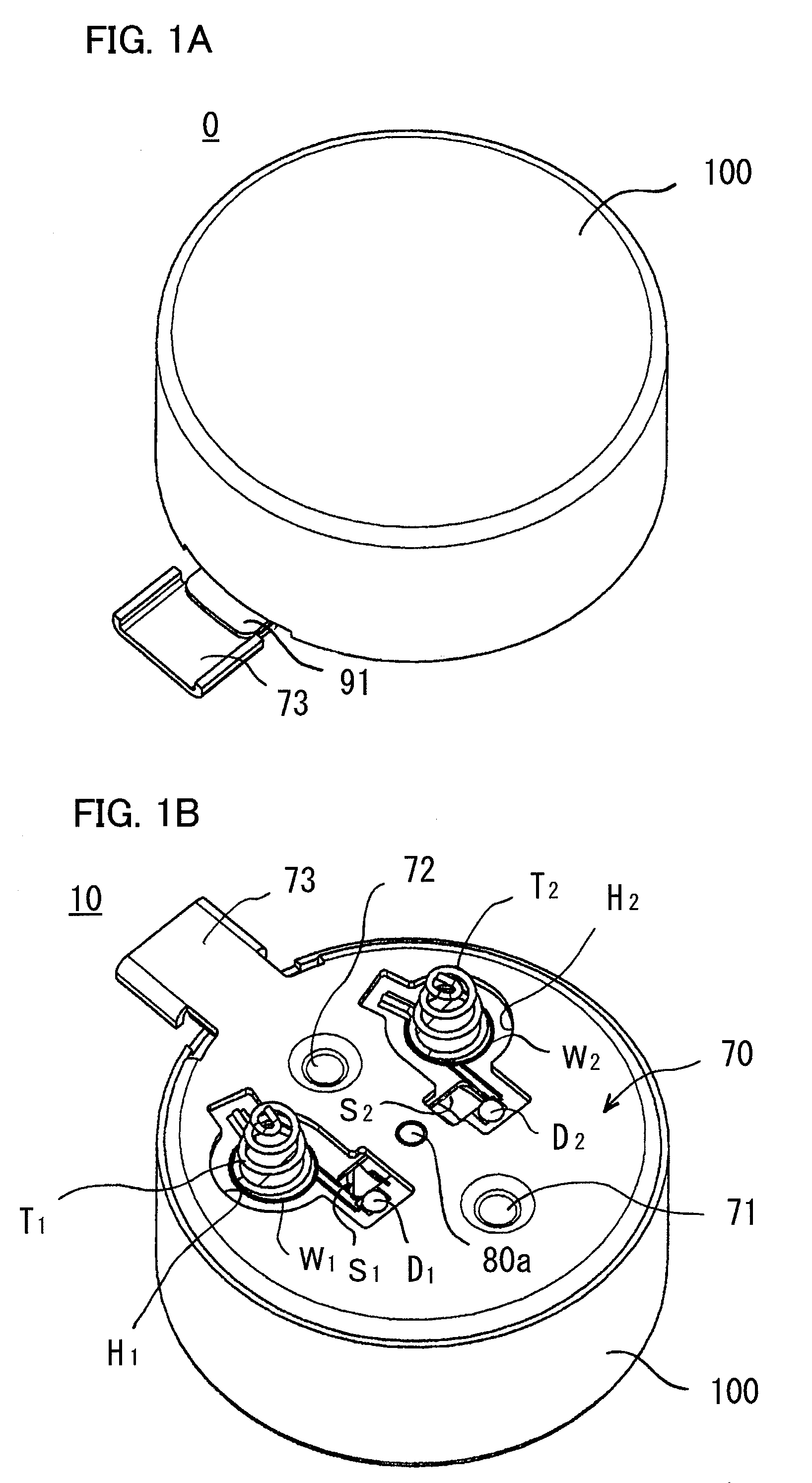

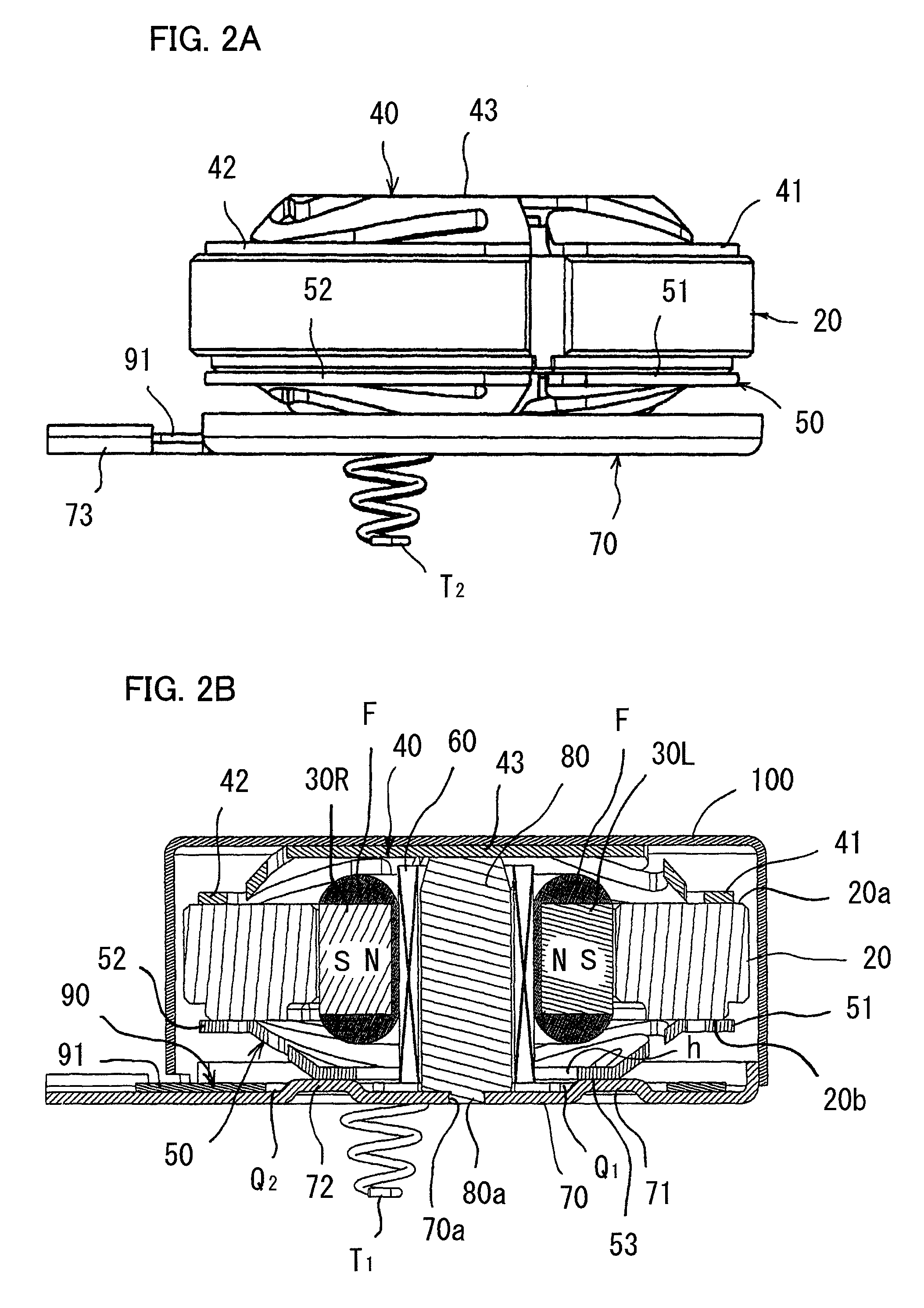

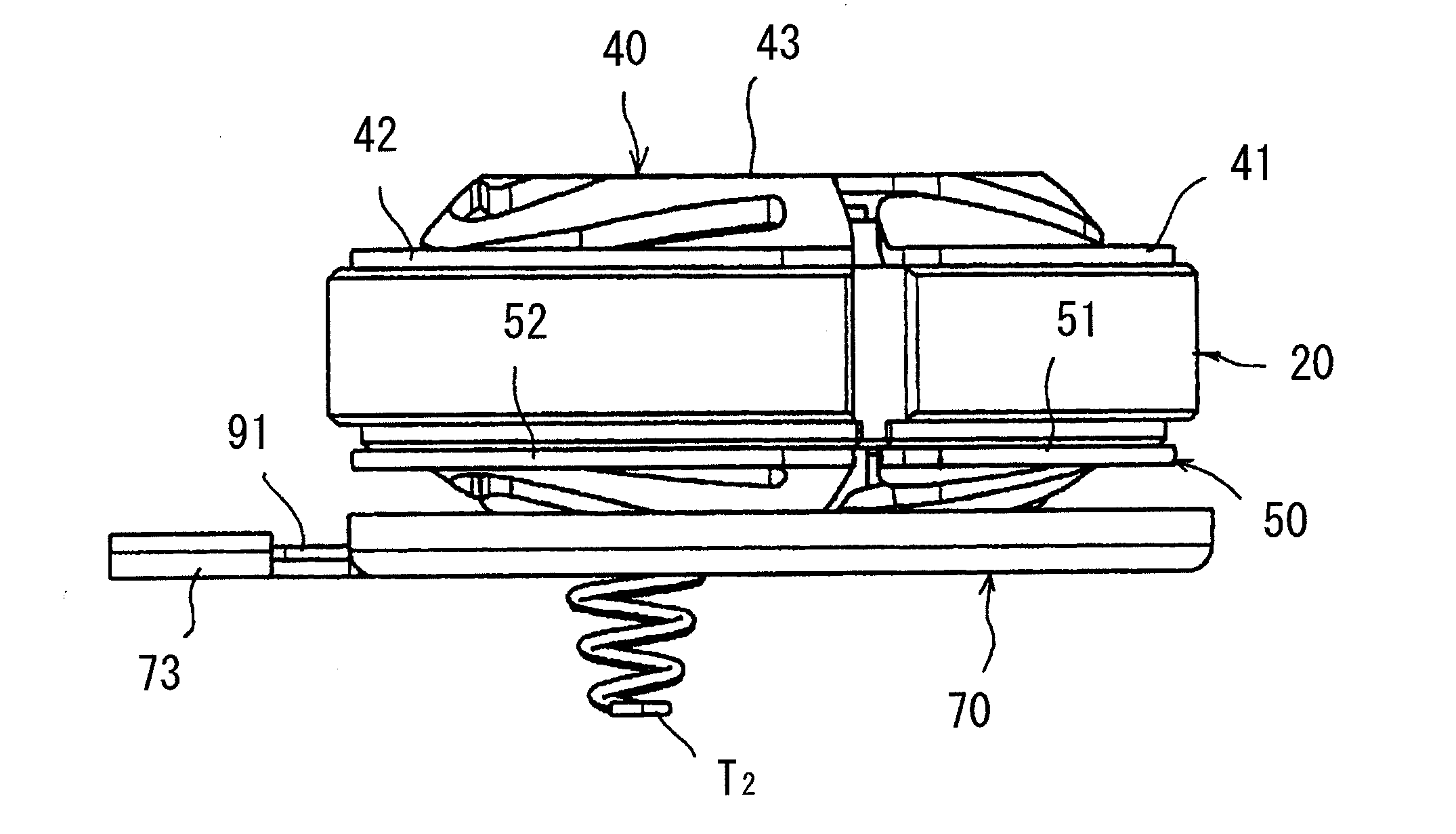

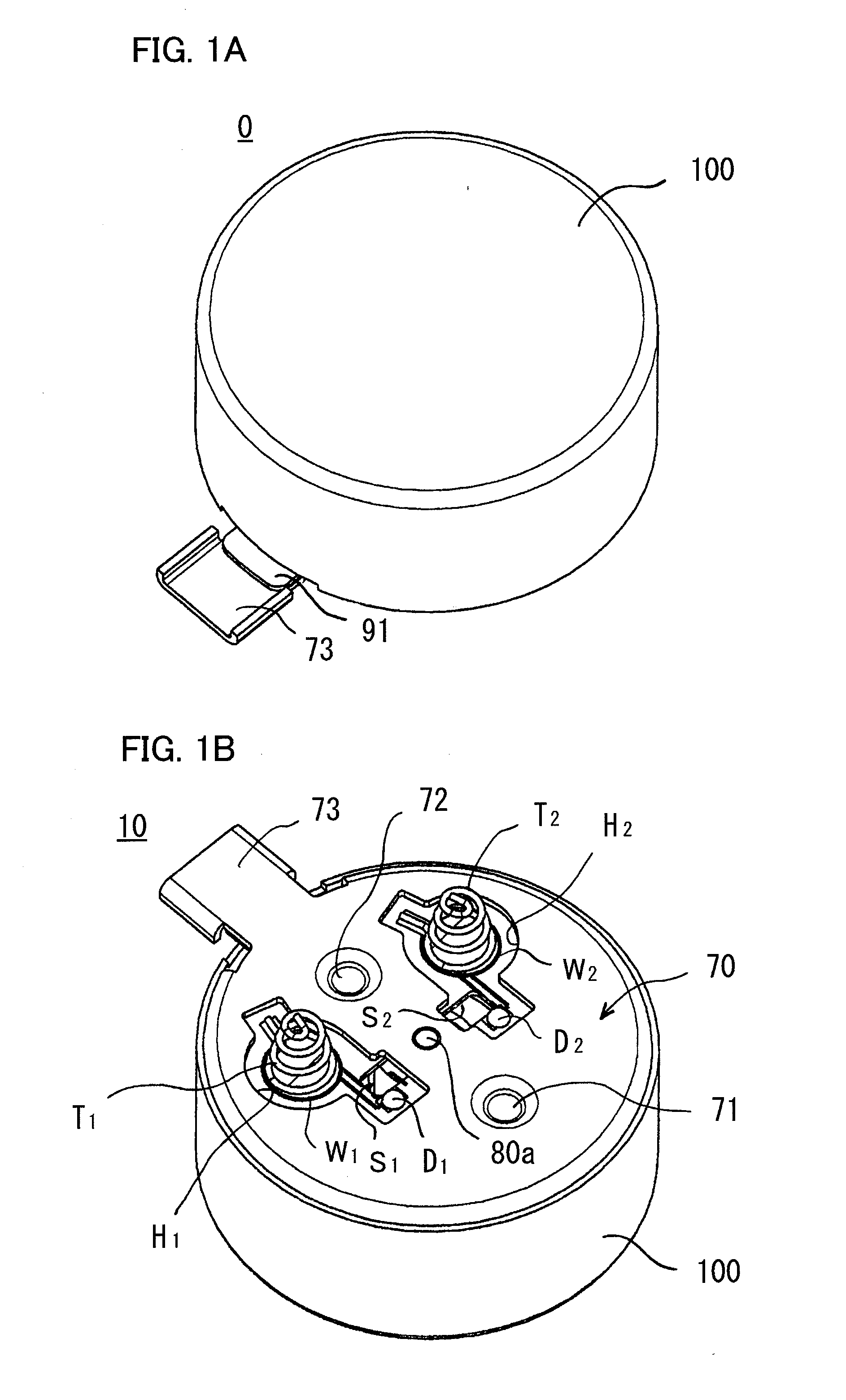

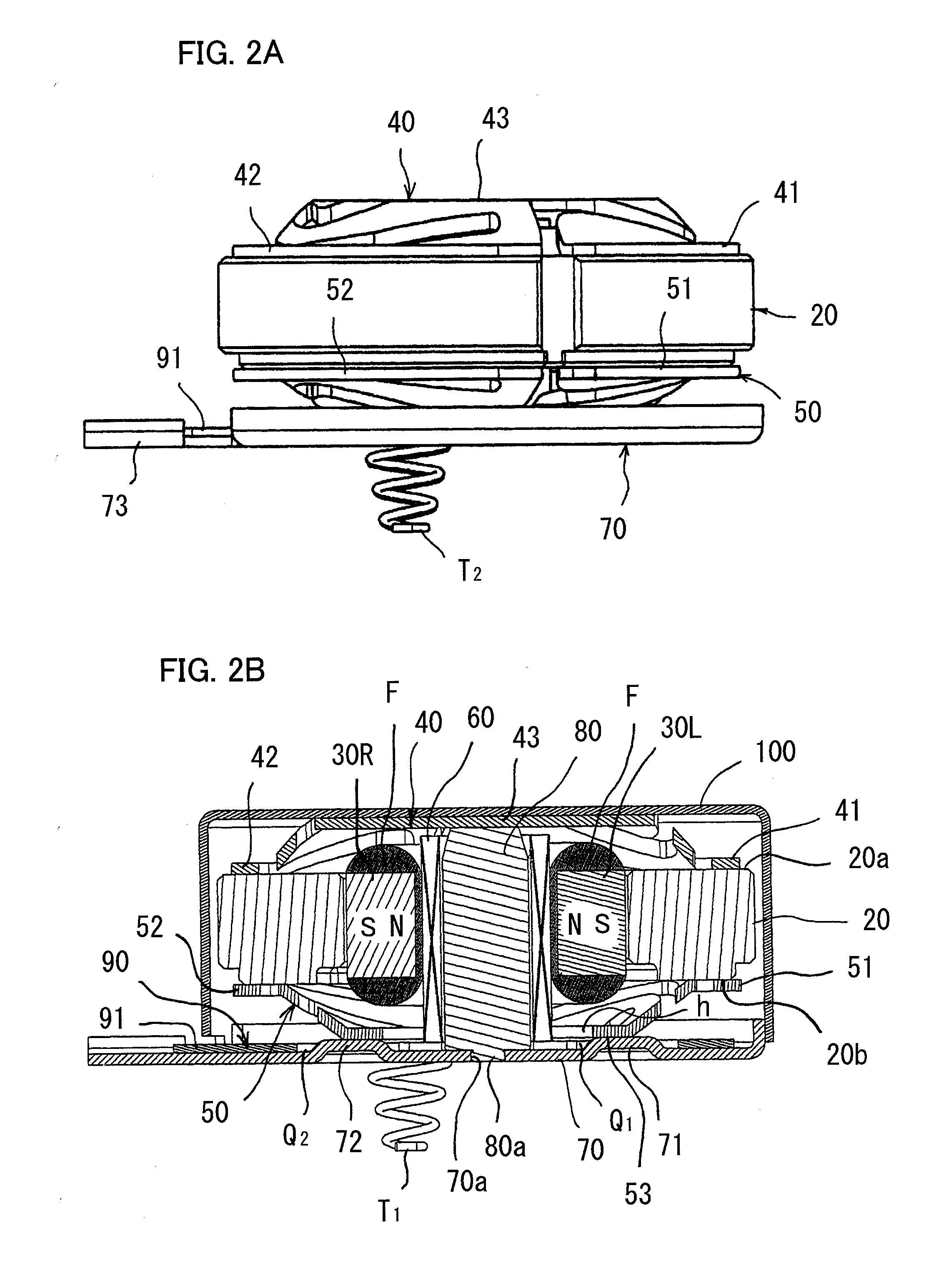

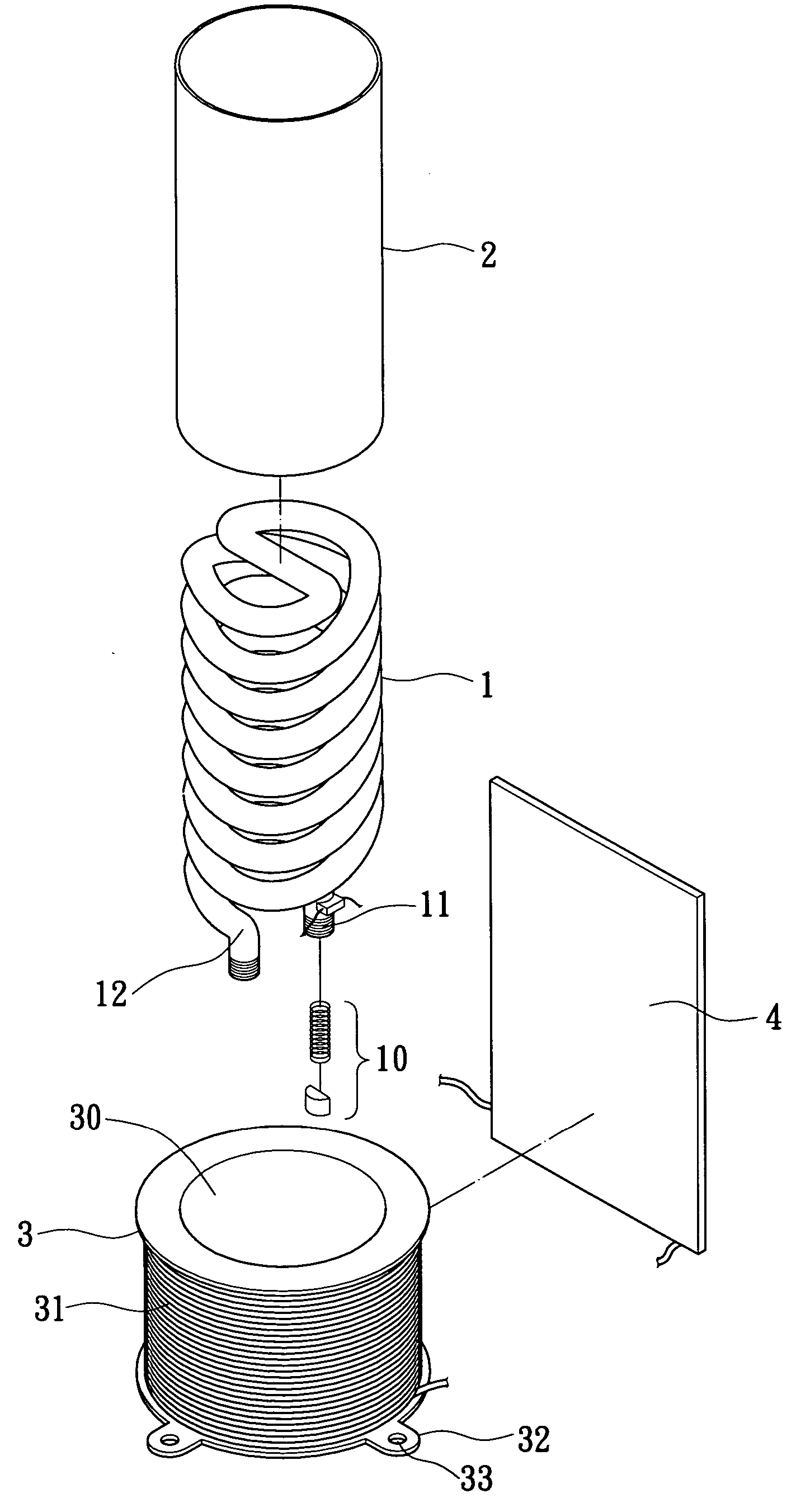

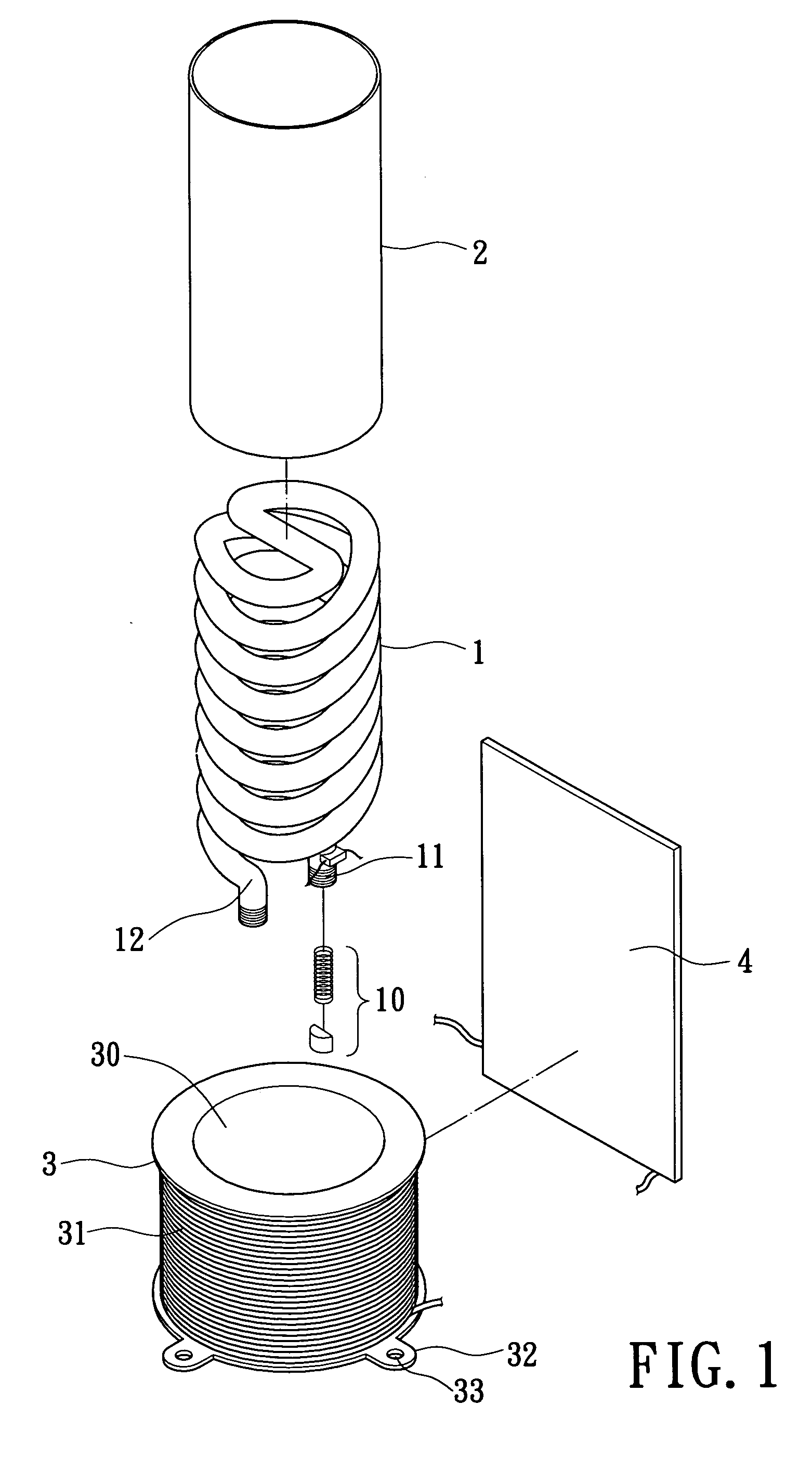

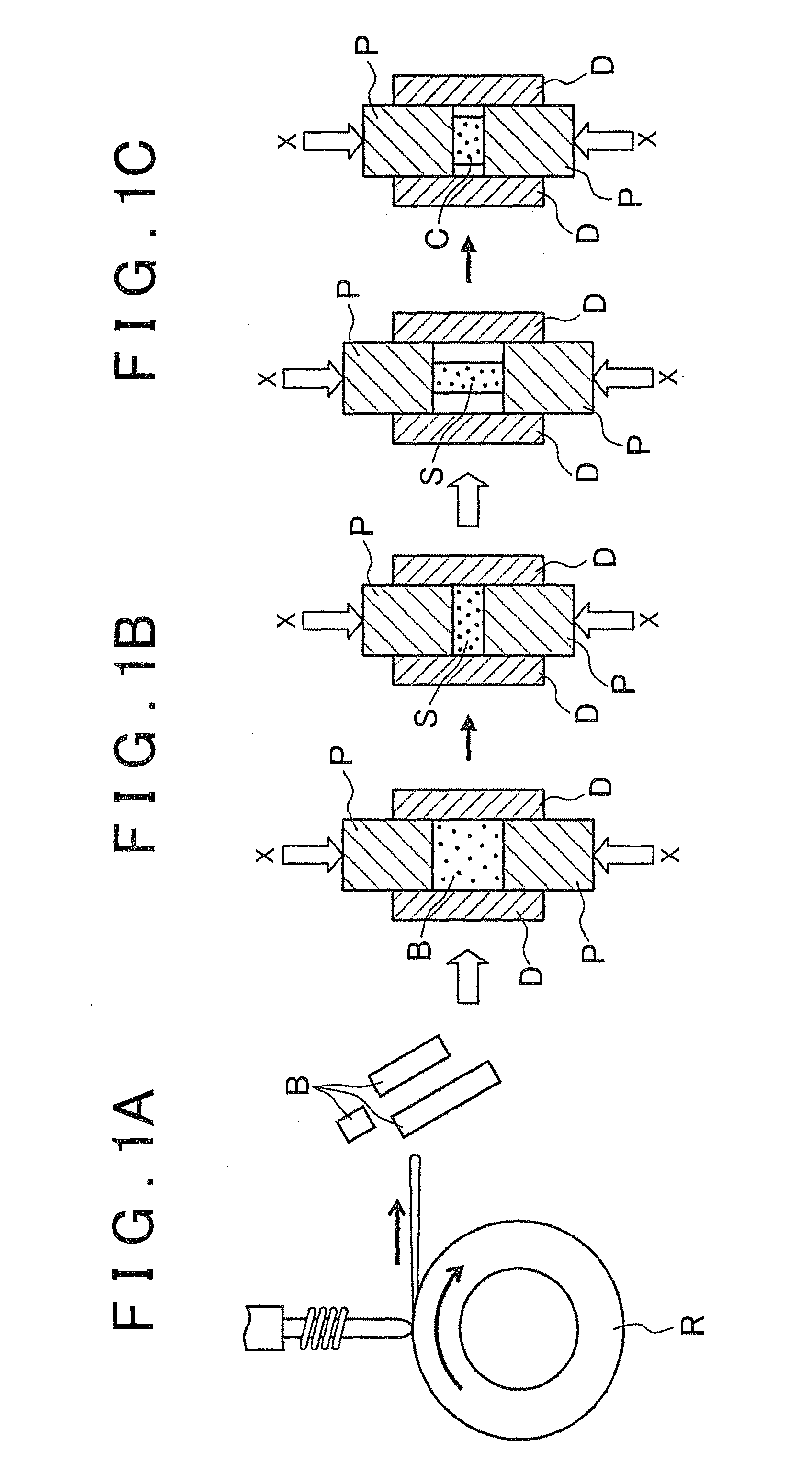

Reciprocating vibration generator

A reciprocating vibration generator of a structure enabling force of a reciprocating vibrating body striking a coil to be absorbed by magnetic fluid even if an external impact force is applied, that is, a reciprocating vibration generator provided in a case body 100 with an upper plate spring 40 and a lower plate spring 50 for supporting a ring-shaped weight 20 having a ring-shaped permanent magnet 30 comprised of a combination of semi-ring-shaped permanent magnets 30R, 30L at its inner circumference side so as to be able to reciprocally vibrate in a vertical direction and a cylindrical excitation coil 60 passing through the inside of the ring-shaped permanent magnet 30 in the vertical direction and generating a reciprocating vibrating magnetic field, wherein the semi-ring-shaped permanent magnets 30R, 30L are magnetized in a direction spanning the inner circumferential surface and outer circumferential surface, the inner circumferential surface and top and bottom end faces of the semi-ring-shaped permanent magnet 30R, 30L are covered by magnetic fluid F, and a gap between the inner circumferential surface and the outer circumferential surface of the excitation coil 60 is filled with magnetic fluid F.

Owner:SANYO SEIMITSU

Magnetoresistive device and magnetic memory using the same

ActiveUS7538402B2Reducing a magnetic field necessaryIncreased writing marginNanomagnetismDigital storageAntiferromagnetic couplingMagnetic memory

Owner:NEC CORP

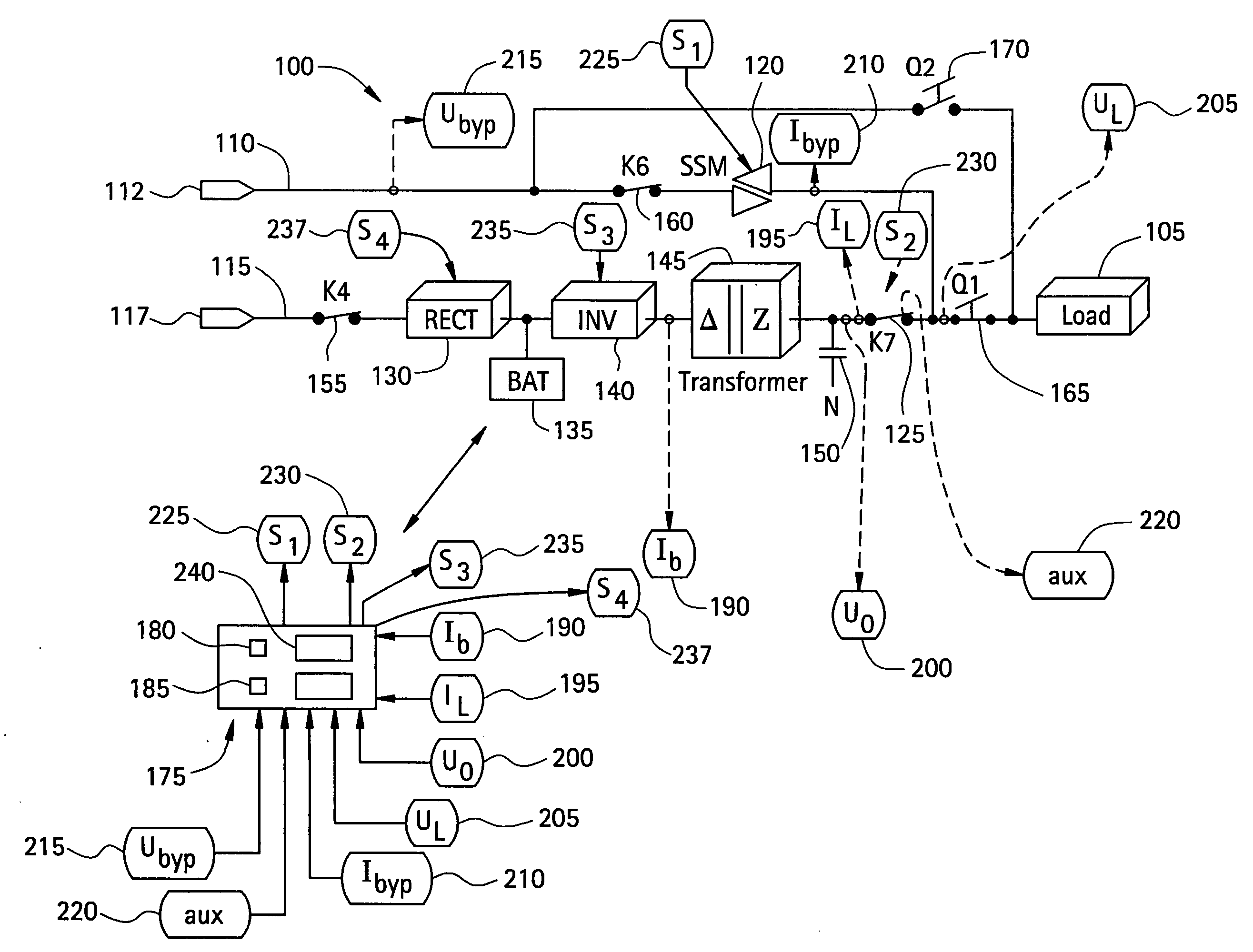

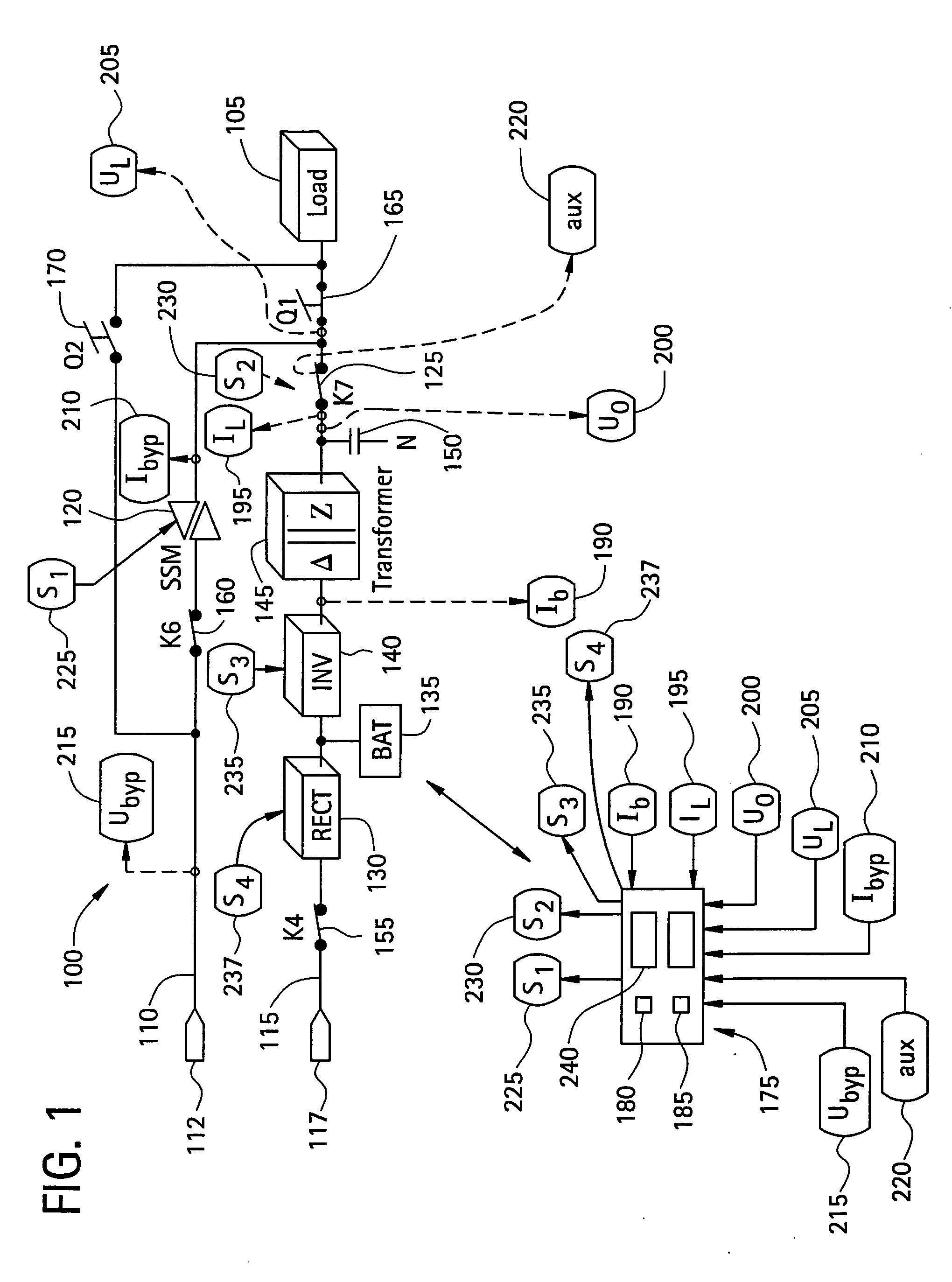

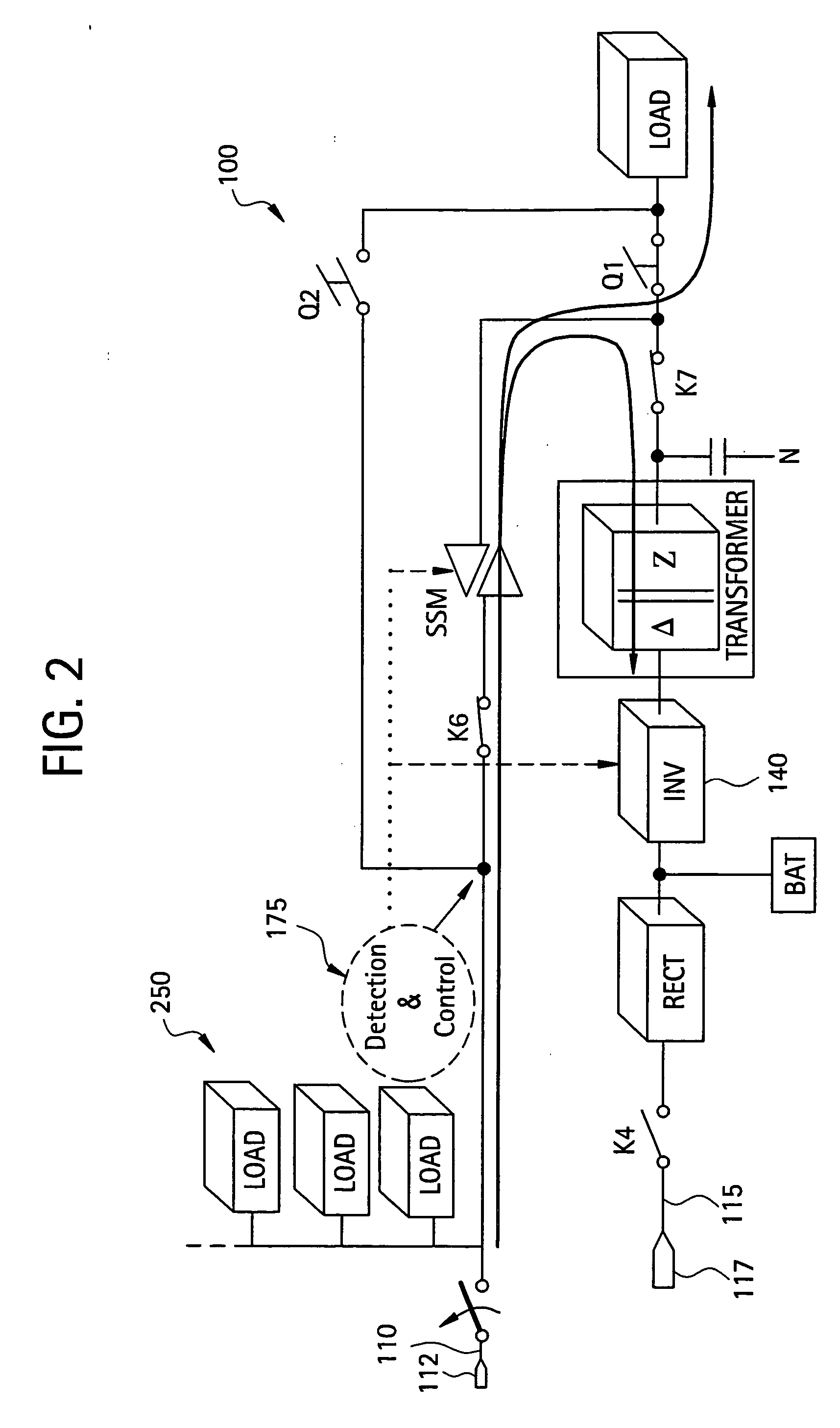

Control system, method and product for uninterruptible power supply

ActiveUS20060164782A1Overcomes drawbackEnhanced magnetizationBatteries circuit arrangementsElectric powerOutput transformerElectricity

A control system for an uninterruptible power supply (UPS) for servicing a load is disclosed. The UPS includes a first feed path and a second feed path, where the first feed path is operable in parallel with the second feed path. The first feed path is engagable via a first switch to deliver a bypass current to the load. The second feed path includes a rectifier, an inverter responsive to a control signal and in electrical communication with the rectifier, and an output transformer in electrical communication with the inverter. The second feed path is engagable via a second switch to deliver an inverter current to the load. The control system is configured for facilitating magnetization of the transformer via a back-feed from the first feed path in response to the load being fed by the first feed path, the rectifier being off, and the inverter being off.

Owner:ABB (SCHWEIZ) AG

Reciprocating vibration generator

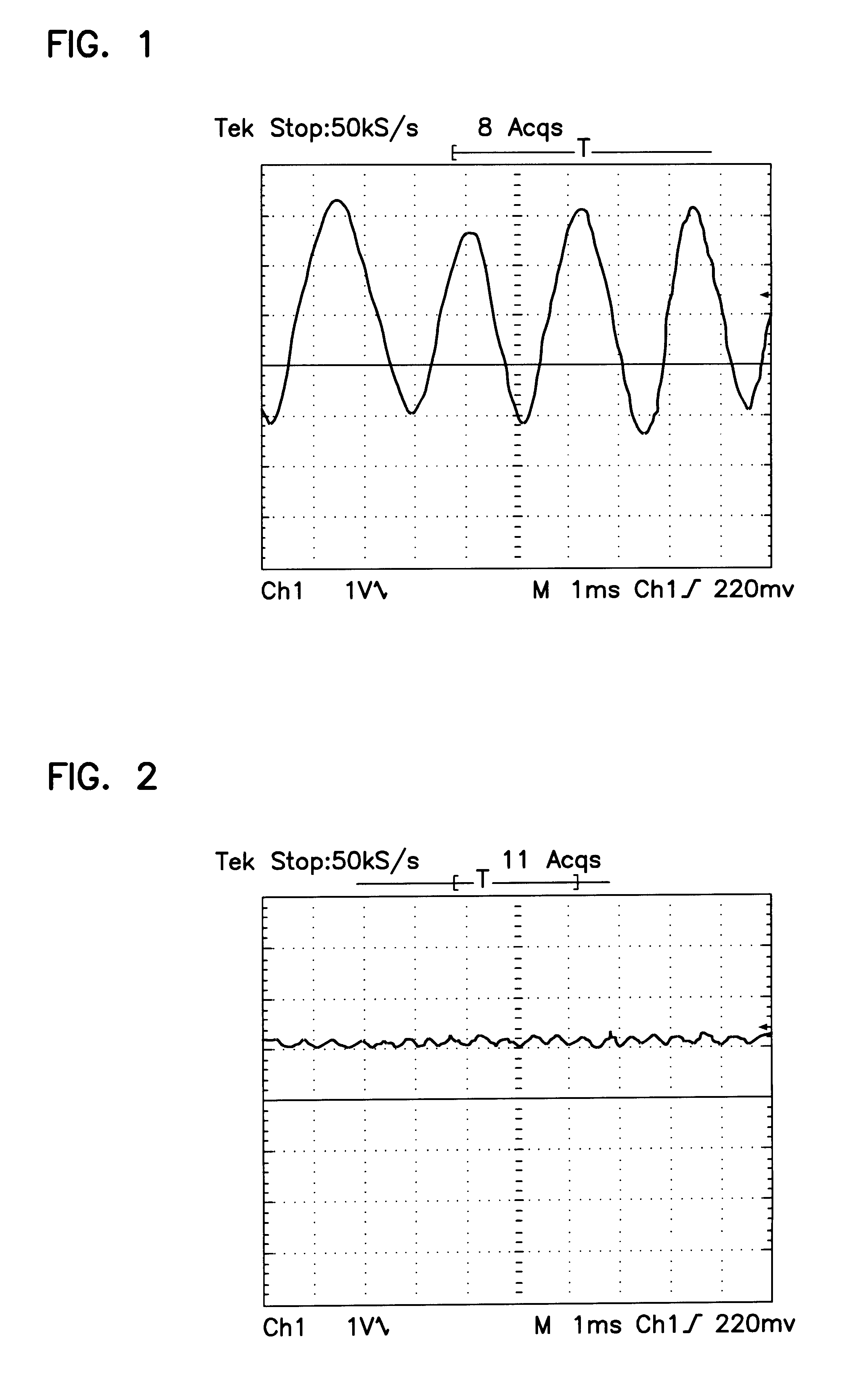

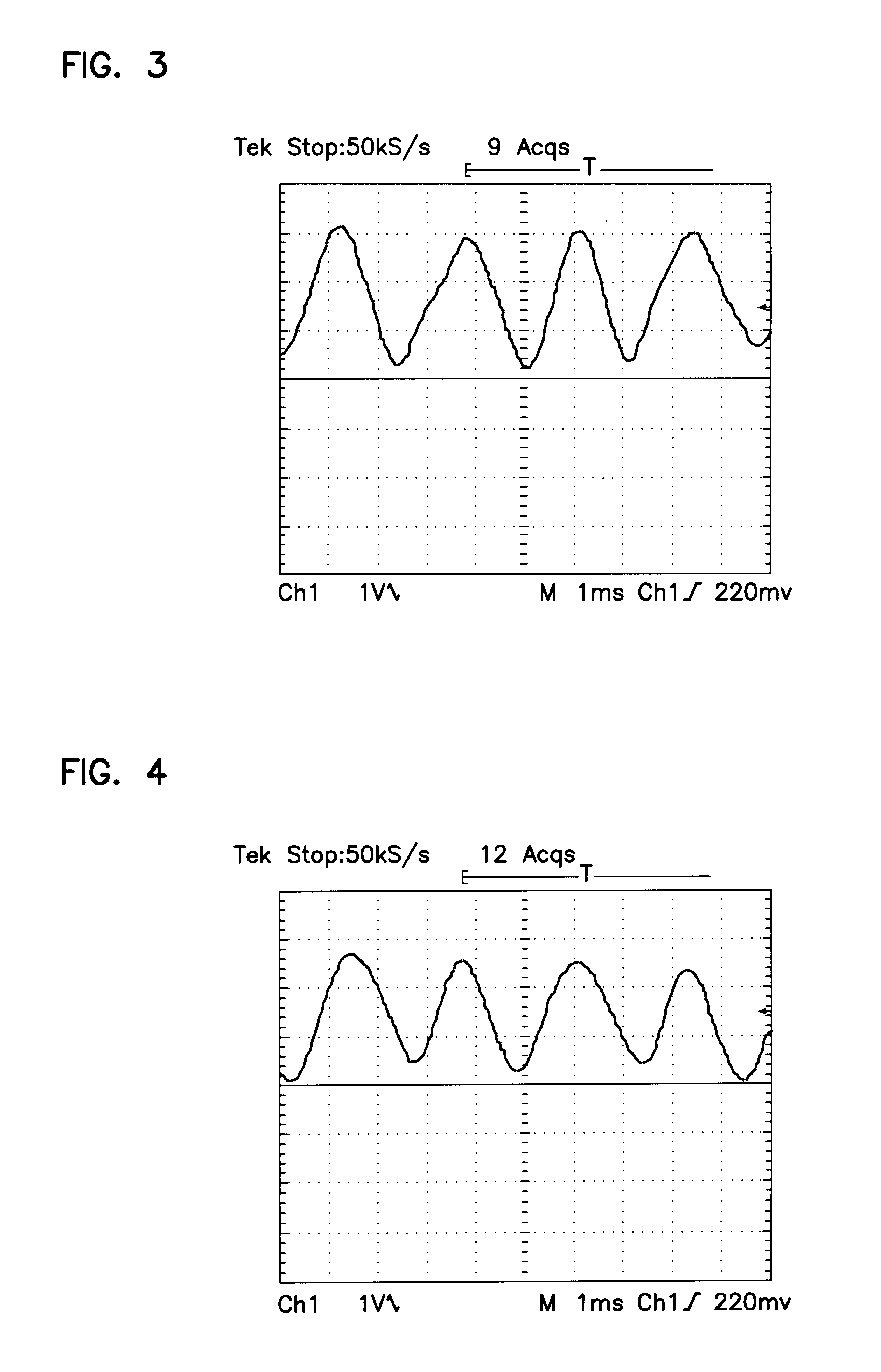

ActiveUS20100102646A1Enhanced magnetizationAvoid damageSupports/enclosures/casingsDynamo-electric machinesMagnetExcitation coil

A reciprocating vibration generator of a structure enabling force of a reciprocating vibrating body striking a coil to be absorbed by magnetic fluid even if an external impact force is applied, that is, a reciprocating vibration generator provided in a case body 100 with an upper plate spring 40 and a lower plate spring 50 for supporting a ring-shaped weight 20 having a ring-shaped permanent magnet 30 comprised of a combination of semi-ring-shaped permanent magnets 30R, 30L at its inner circumference side so as to be able to reciprocally vibrate in a vertical direction and a cylindrical excitation coil 60 passing through the inside of the ring-shaped permanent magnet 30 in the vertical direction and generating a reciprocating vibrating magnetic field, wherein the semi-ring-shaped permanent magnets 30R, 30L are magnetized in a direction spanning the inner circumferential surface and outer circumferential surface, the inner circumferential surface and top and bottom end faces of the semi-ring-shaped permanent magnet 30R, 30L are covered by magnetic fluid F, and a gap between the inner circumferential surface and the outer circumferential surface of the excitation coil 60 is filled with magnetic fluid F.

Owner:SANYO SEIMITSU

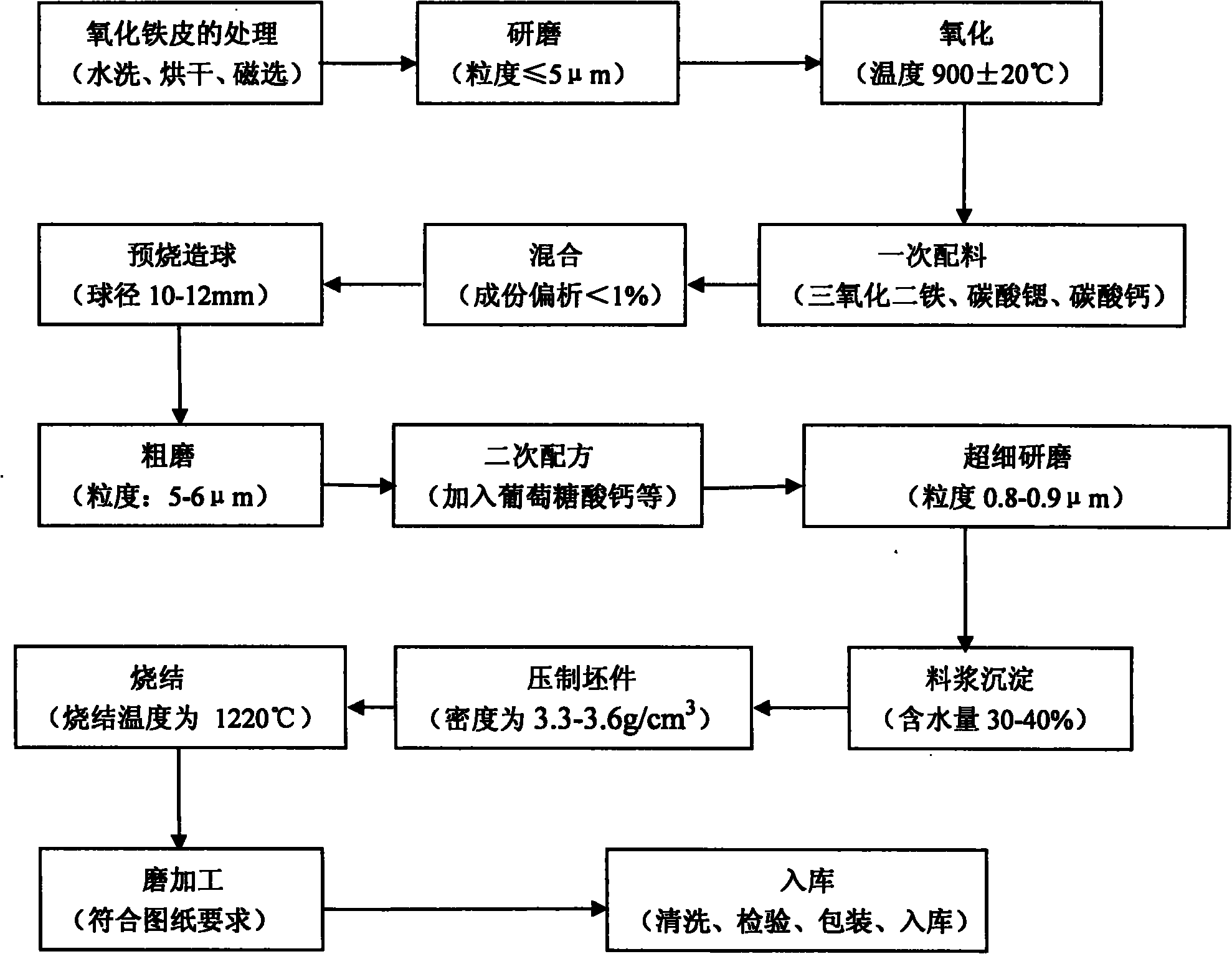

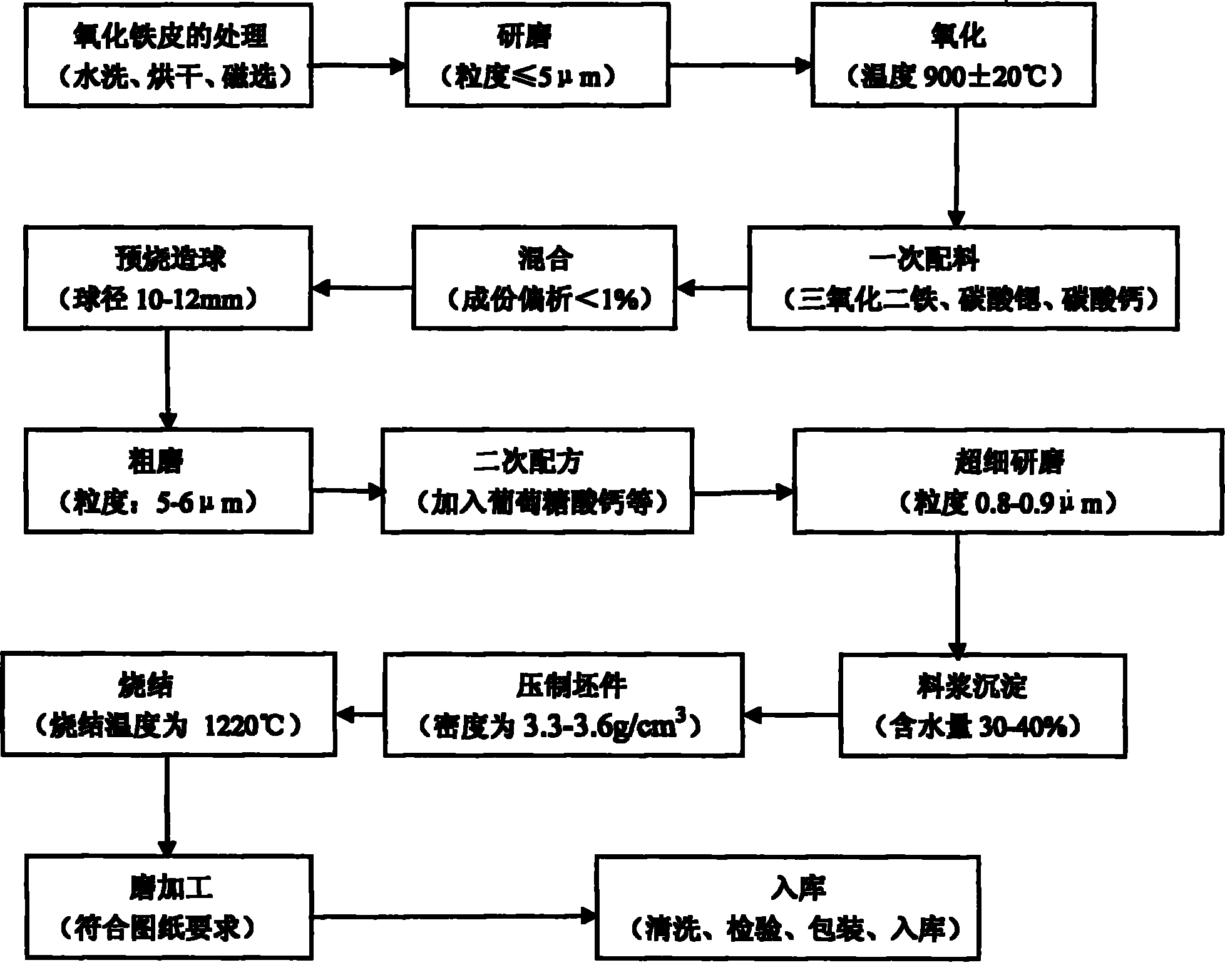

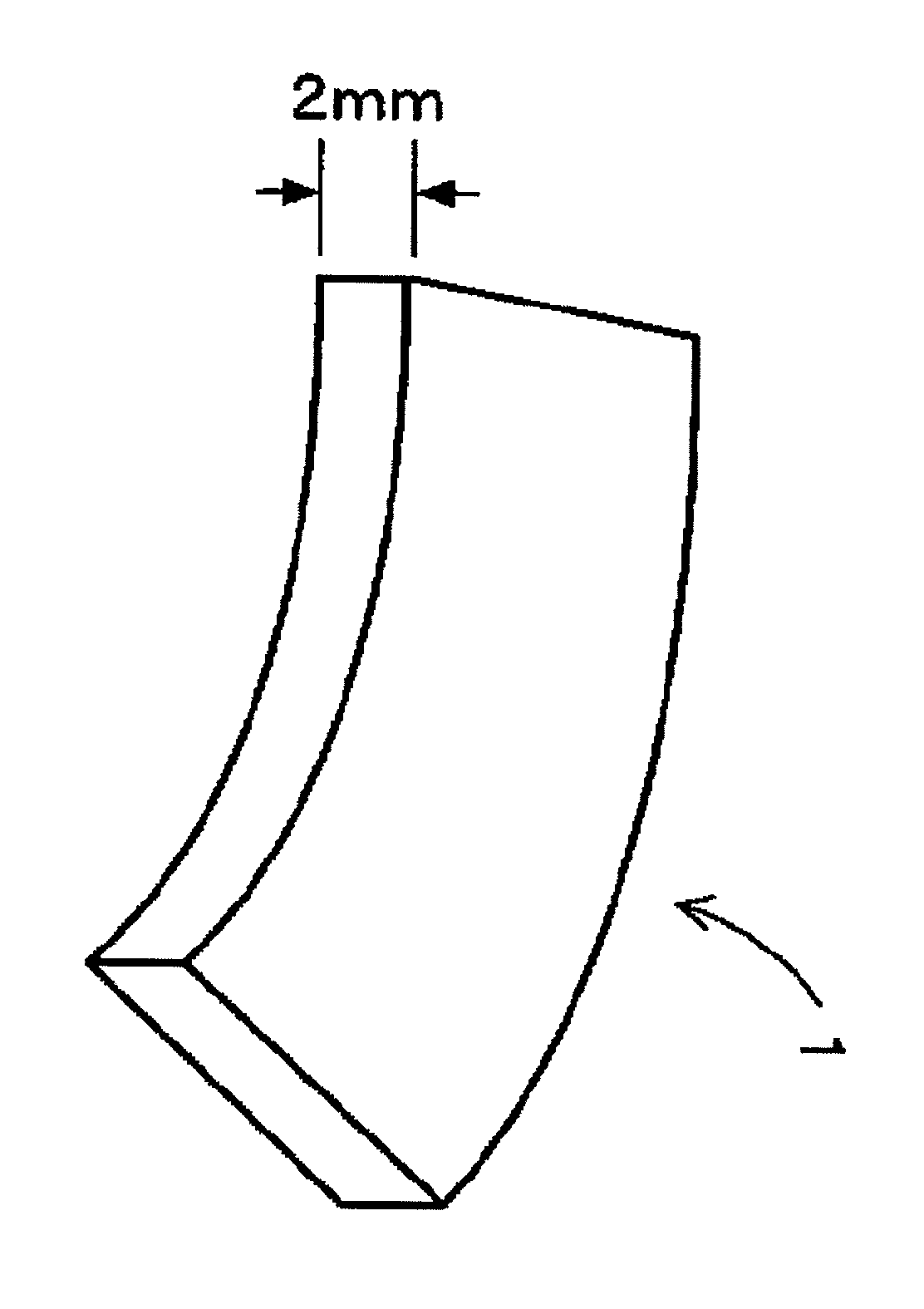

Preparation method for rare earth permanent ferrite magnetic shoe and product

ActiveCN101860091AIncrease the degree of magnetic orientationImproved Grinding MethodMagnetic circuitManufacturing dynamo-electric machinesRare earthUltra fine

The invention discloses a preparation method for a permanent ferrite magnetic shoe containing a rare earth material and an organic material, and a product. The preparation method comprises the following steps of: treating an iron scale; grinding; oxidizing; primary dosing; mixing; preburning and palletizing; rough grinding; secondary dosing; ultra-fine grinding; slurry precipitation; pressing blanks; sintering; grinding; and warehousing. The preparation method of the invention has the characteristics that: the magnetic orientation degree of crystal grains is improved by adding calcium gluconate and improving a grinding method; and magnetic performance and magnetic characteristics thereof are improved by displacing the components of a conventional strontium ferrite permanent magnet material by adopting an additive mode of secondary dosing. The rare earth permanent ferrite magnetic shoe obtained by the preparation method has the characteristics of high residual magnetic flux density, high intrinsic coercive force and low intrinsic coercive force temperature coefficient.

Owner:马鞍山市鑫洋永磁有限责任公司

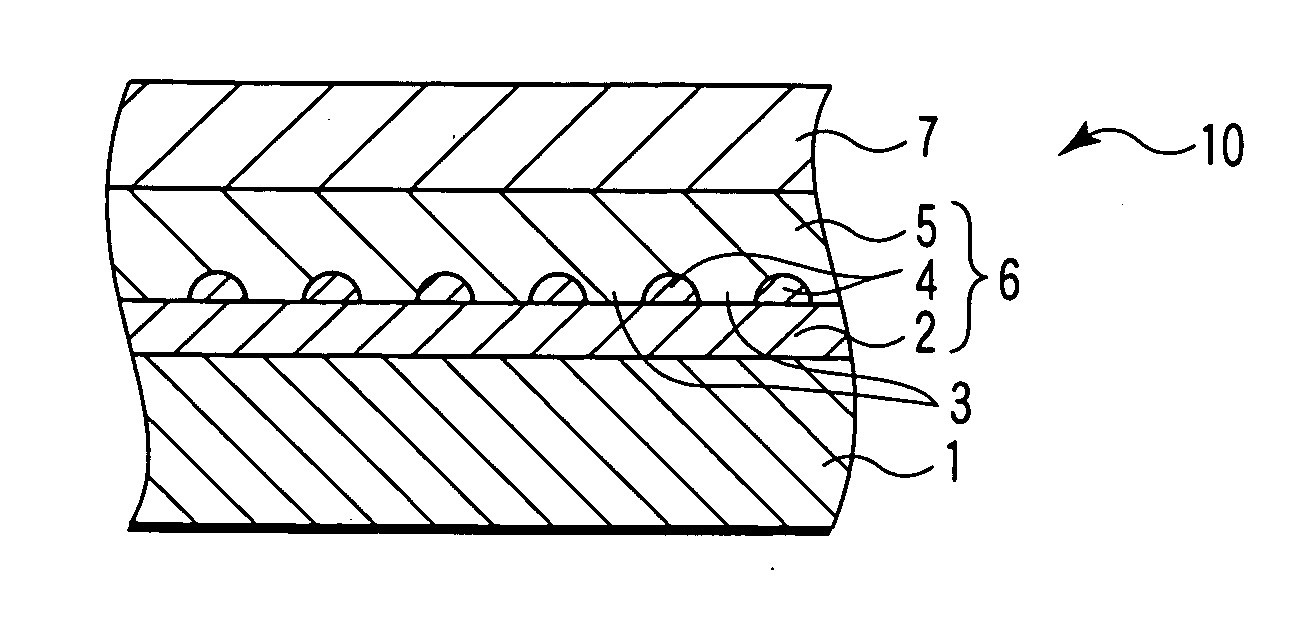

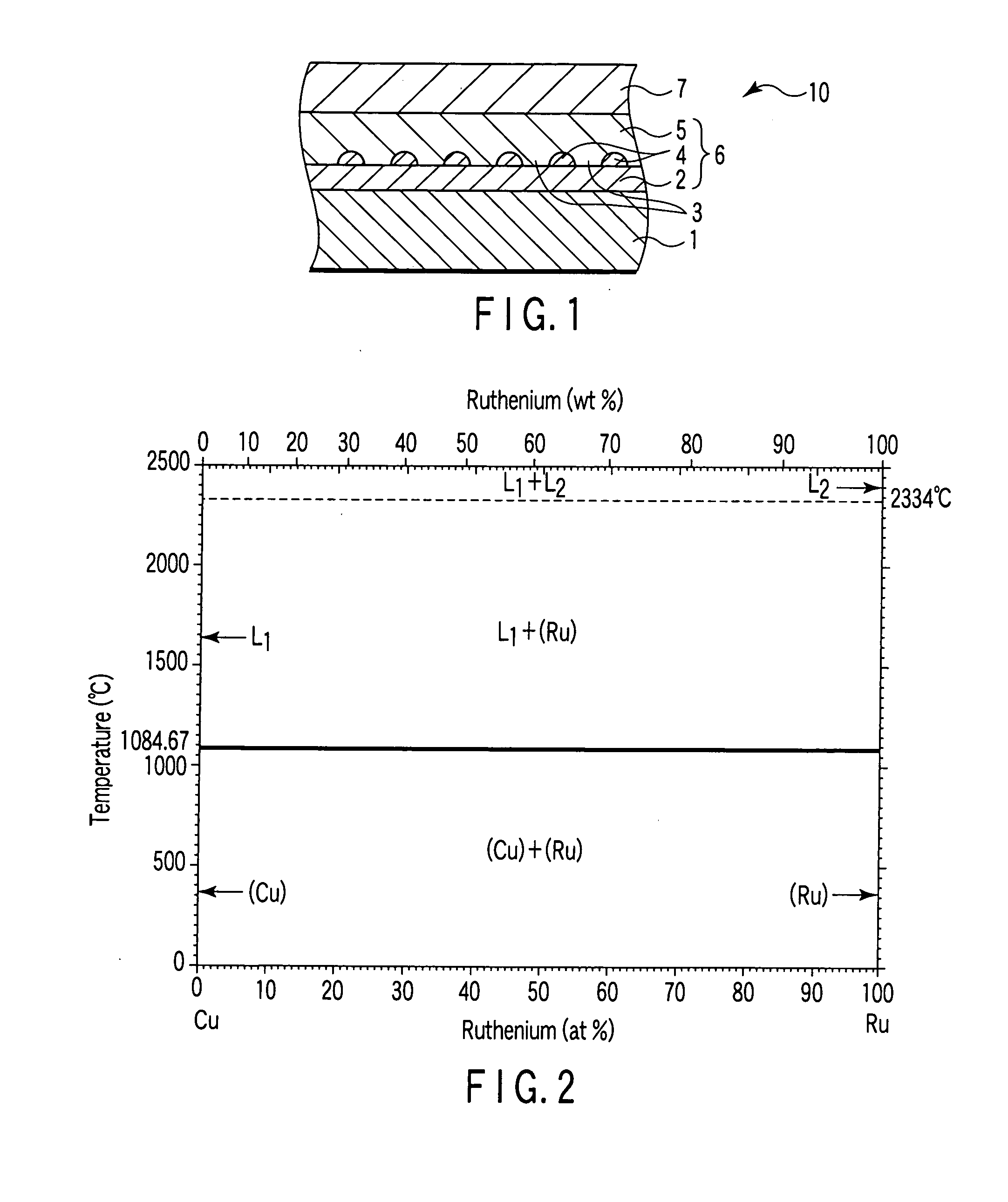

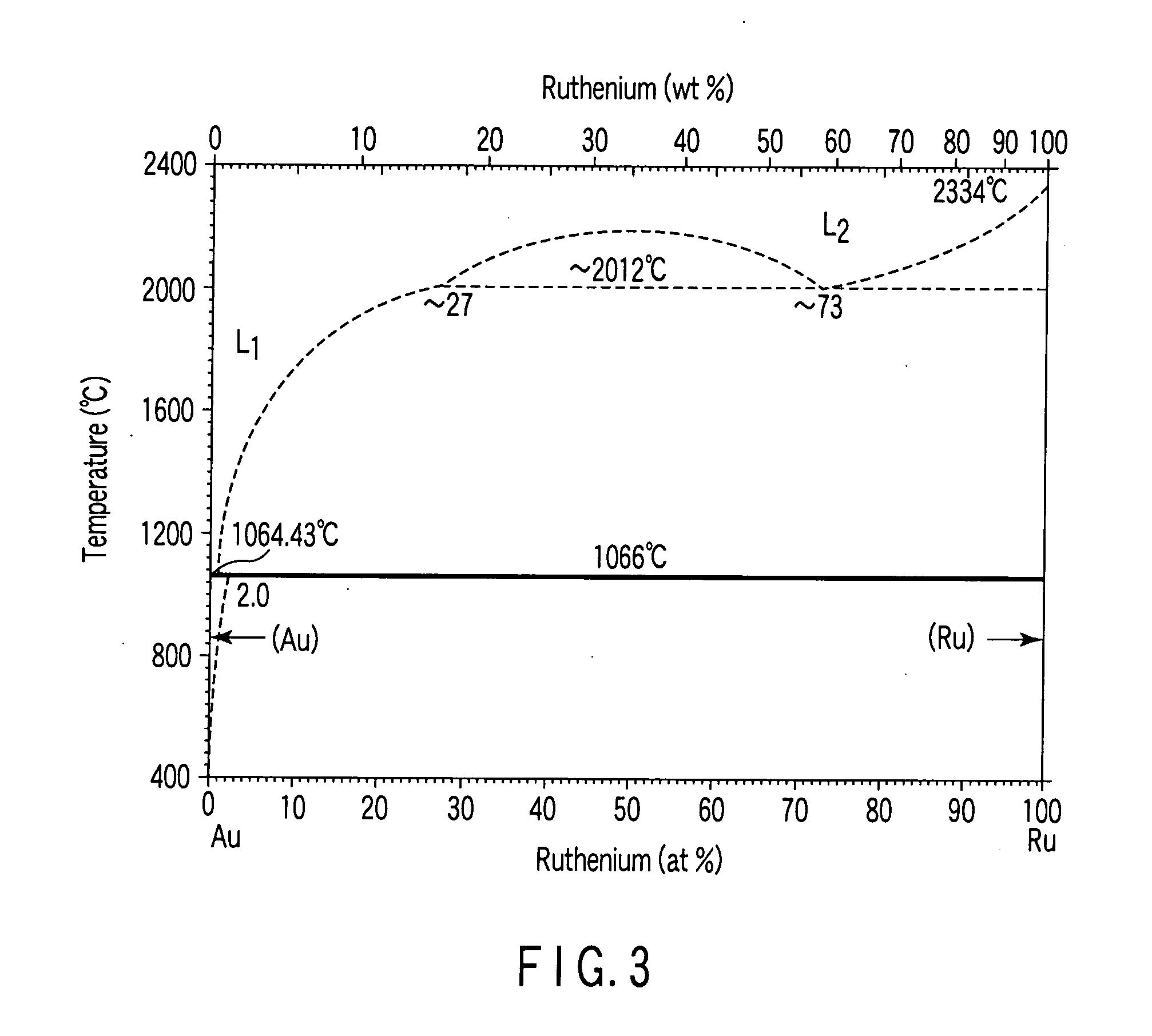

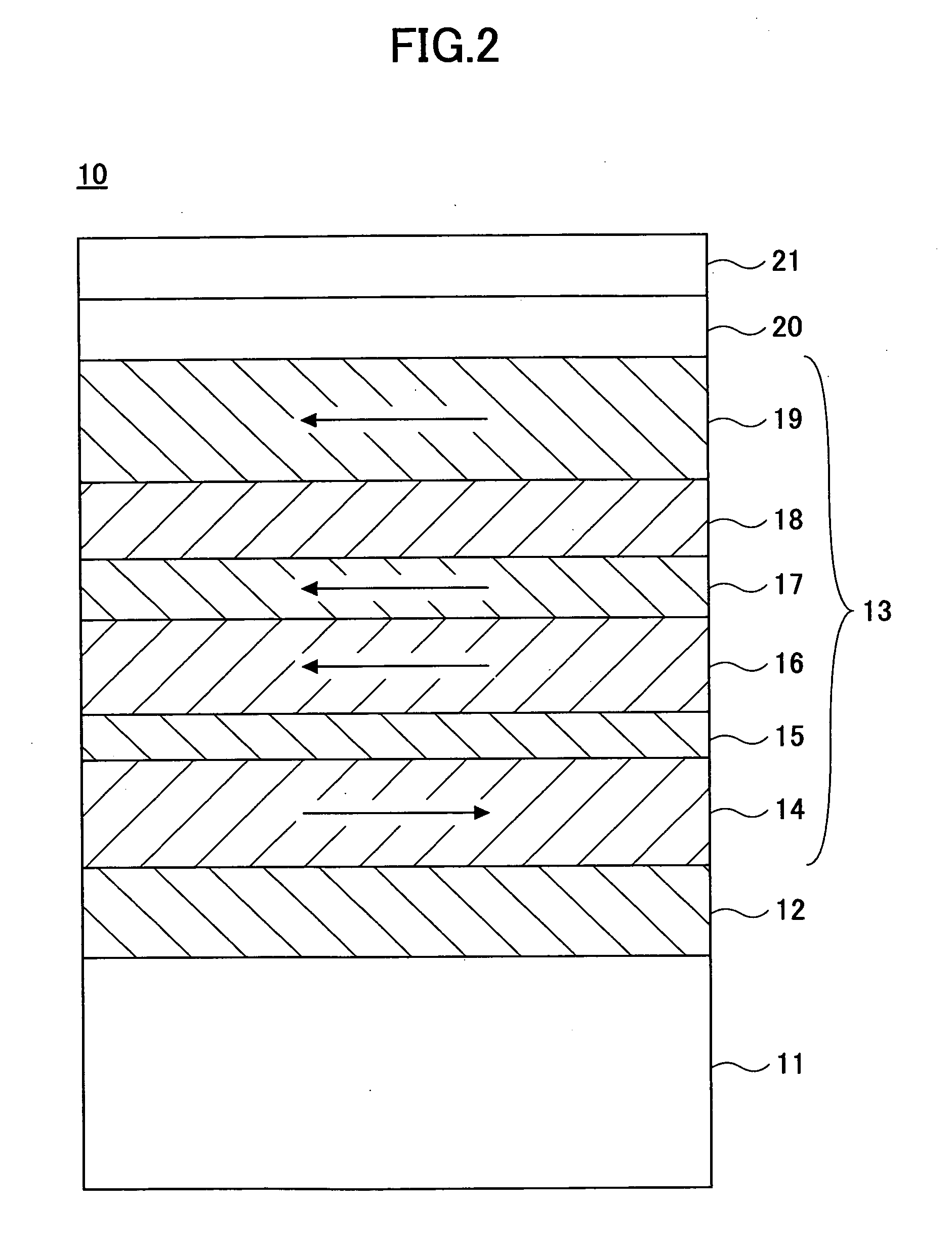

Perpendicular magnetic recording medium and perpendicular magnetic recording/reproducing apparatus

ActiveUS20060269794A1Saturation magnetization can be enhancedSignal output lower and lowRecord information storageBase layer manufactureSolid solutionRecording layer

In a perpendicular magnetic recording medium, a multilayered underlayer including a first metal underlayer, a second metal underlayer having no solid solution properties with respect to the first metal underlayer and having a hole, and a third metal underlayer having solid solution properties with respect to the first metal underlayer and having no solid solution properties with respect to the second metal underlayer is formed on a substrate, and a magnetic recording layer is formed on the multilayered underlayer.

Owner:KK TOSHIBA

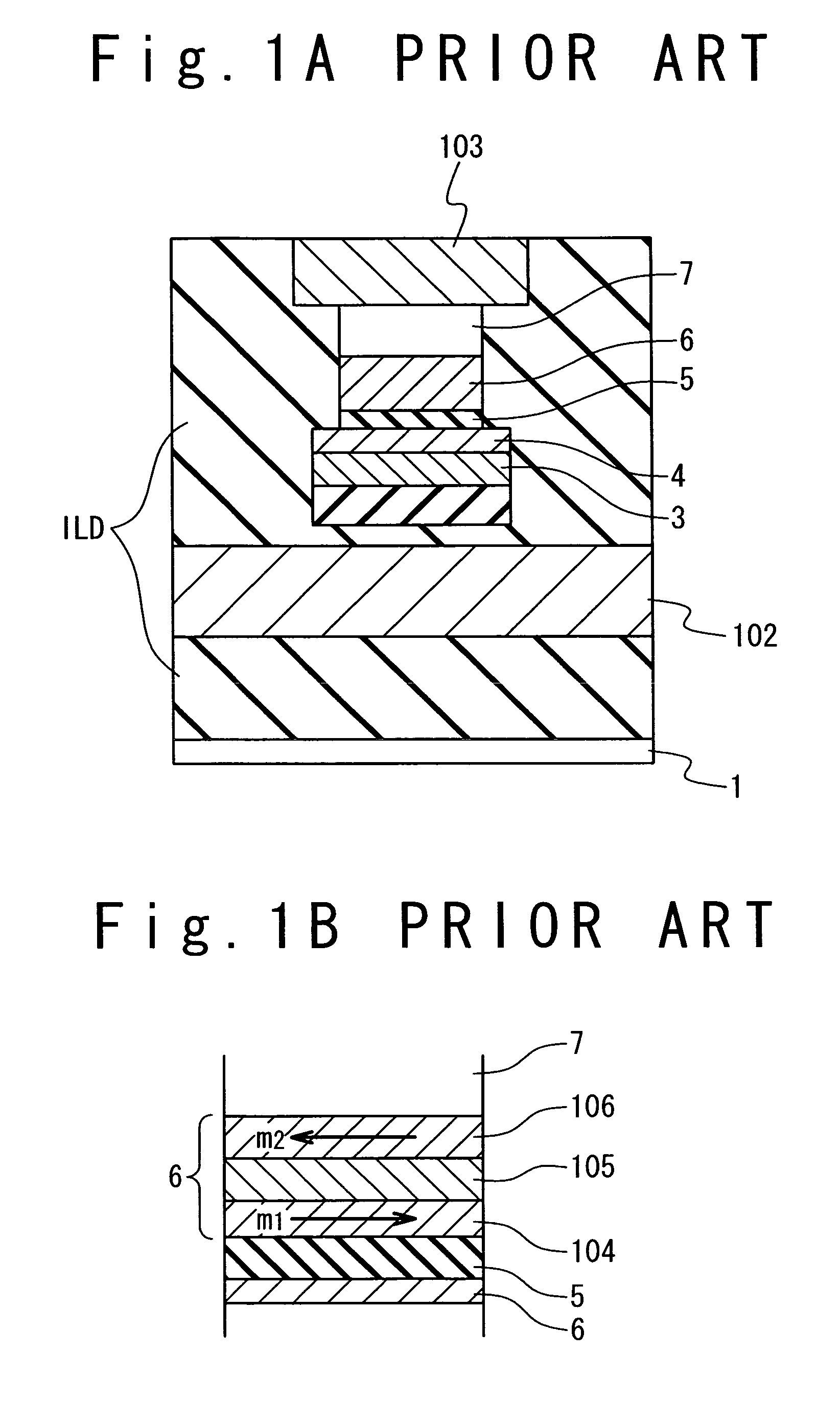

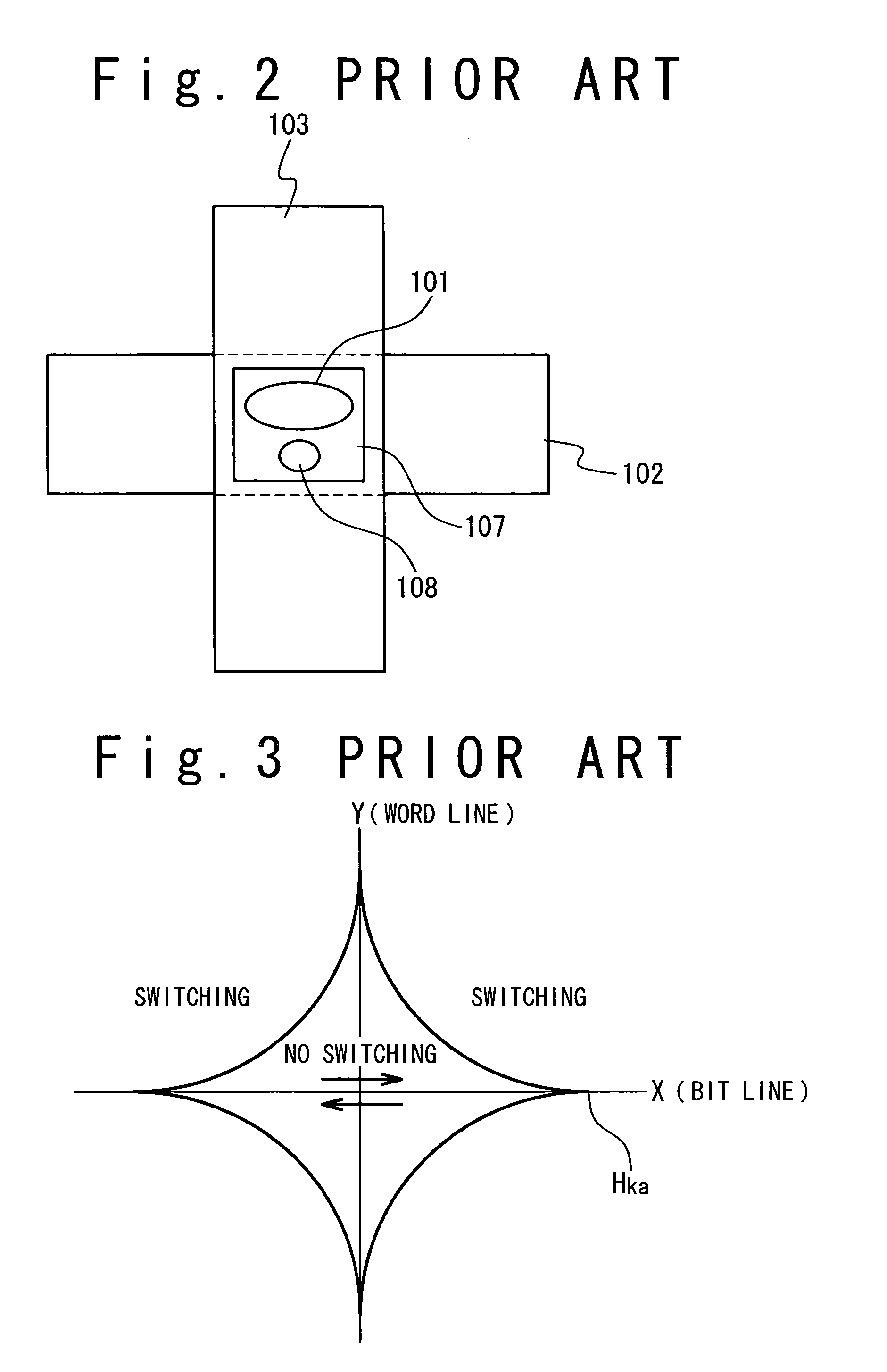

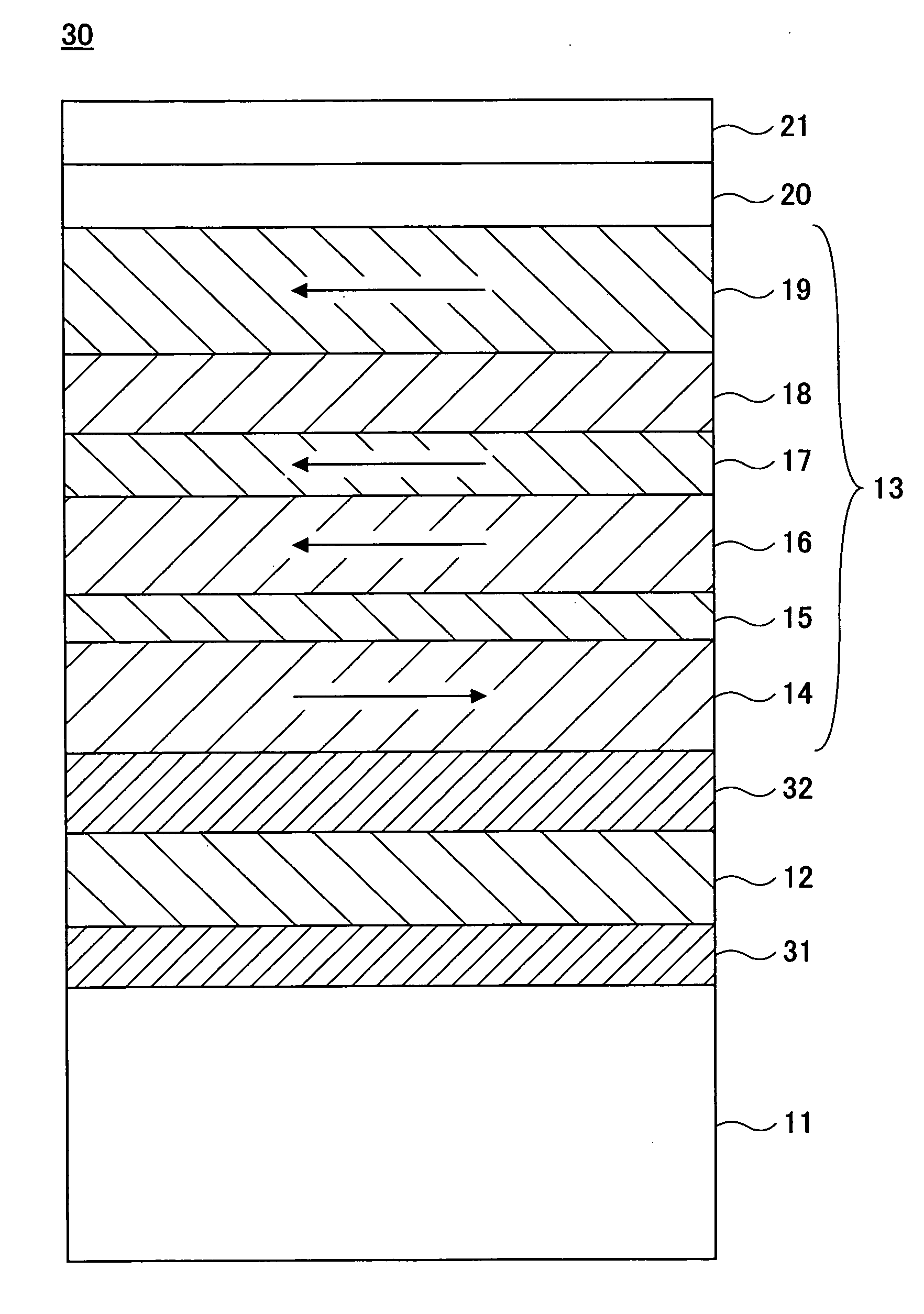

Magnetic recording medium and magnetic storage unit

InactiveUS20070275269A1Eliminate the problemGood coverageRecord information storageMagnetic recordingMagnetic storageCoupling

A magnetic recording medium is disclosed that includes a substrate; and an underlayer, a first magnetic layer, a non-magnetic coupling layer, a second magnetic layer, a third magnetic layer, a non-magnetic separation layer, and a fourth magnetic layer stacked in this order on the substrate. The first magnetic layer and the second magnetic layer are antiferromagnetically exchange-coupled, and the second magnetic layer and the third magnetic layer are ferromagnetically exchange-coupled. The third magnetic layer has an anisotropic magnetic field smaller than the anisotropic magnetic field of the second magnetic layer, and has a saturation magnetization greater than the saturation magnetization of the second magnetic layer.

Owner:SHOWA DENKO KK

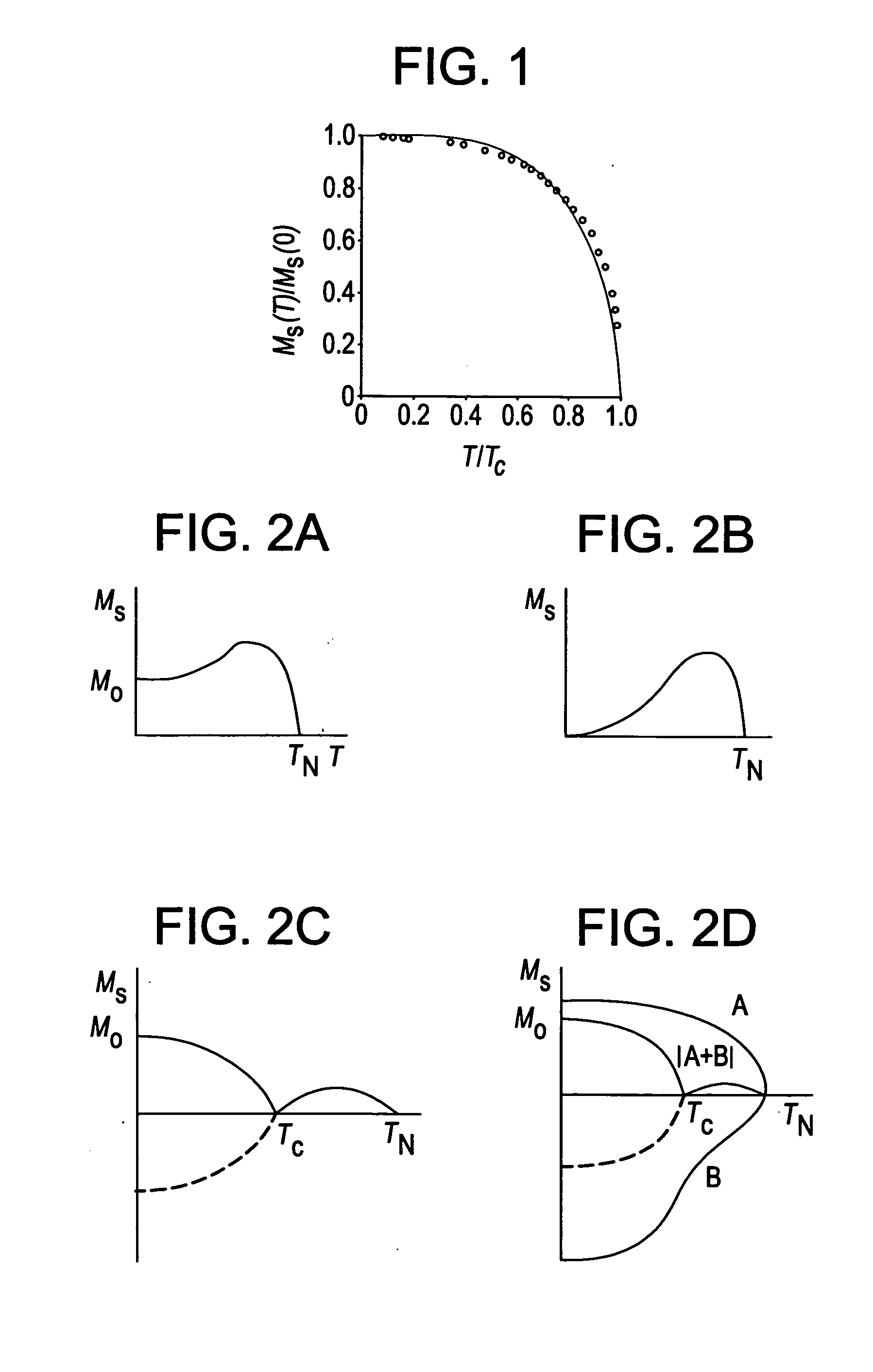

Magnetic materials, passive shims and magnetic resonance imaging systems

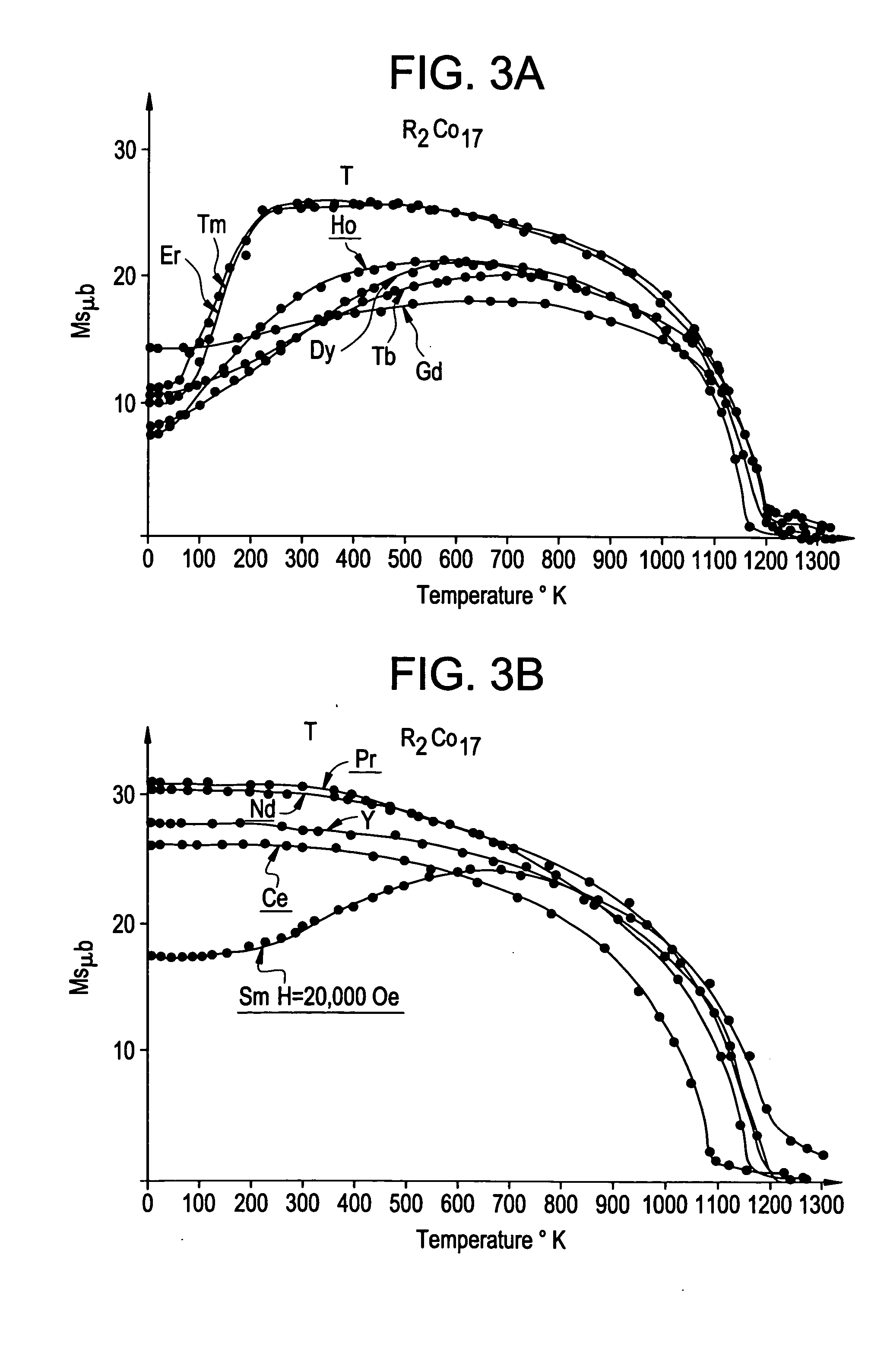

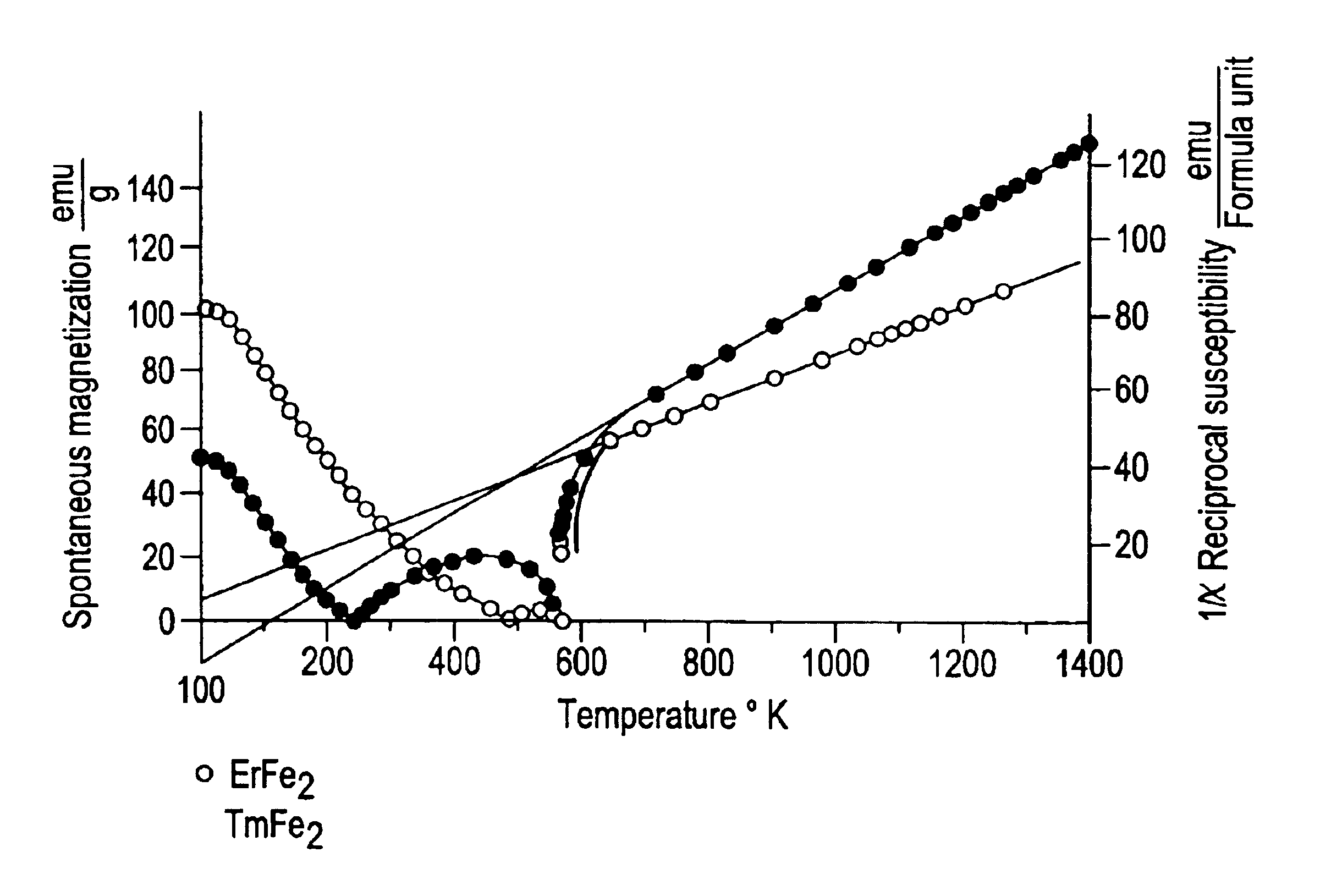

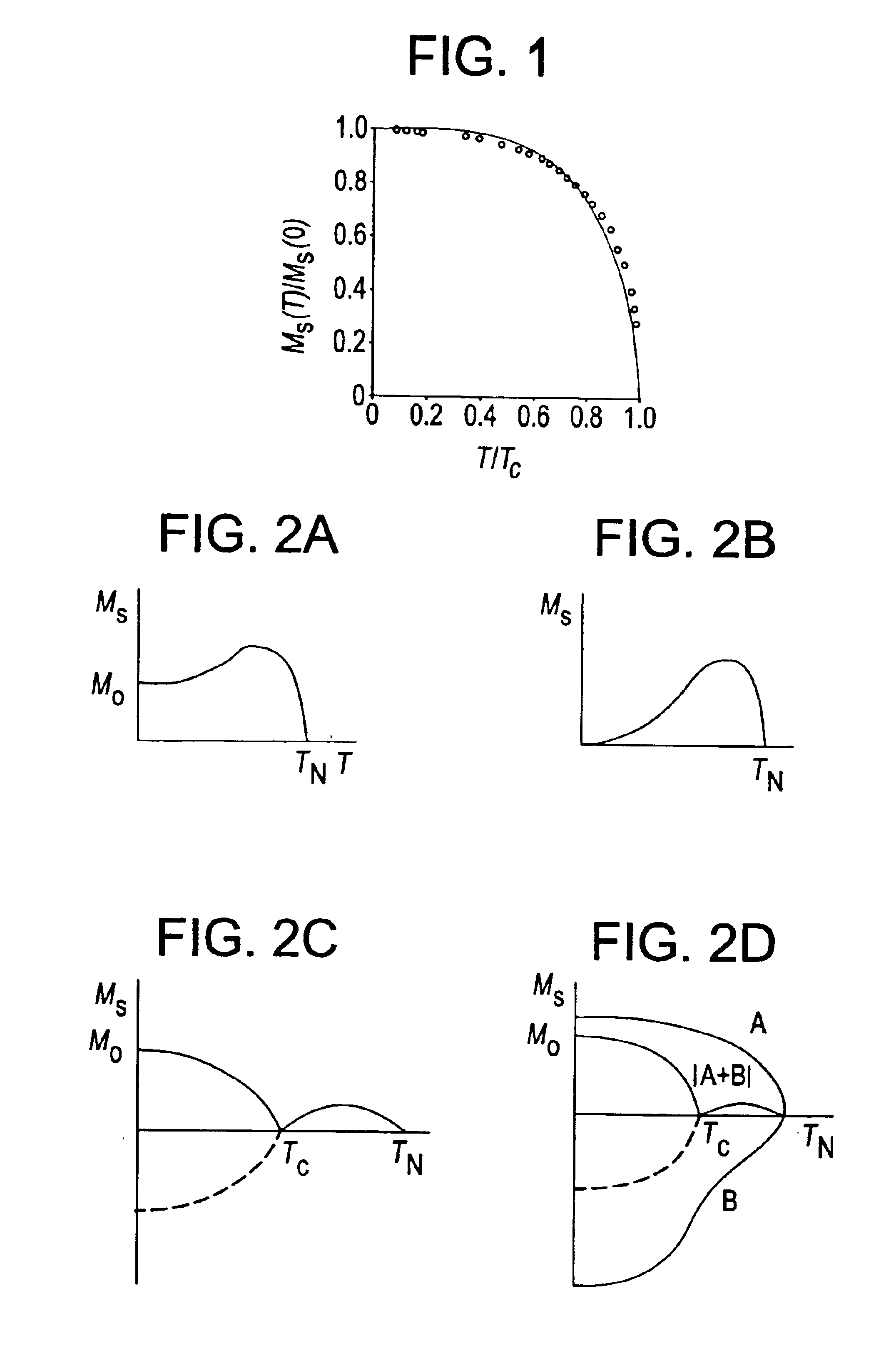

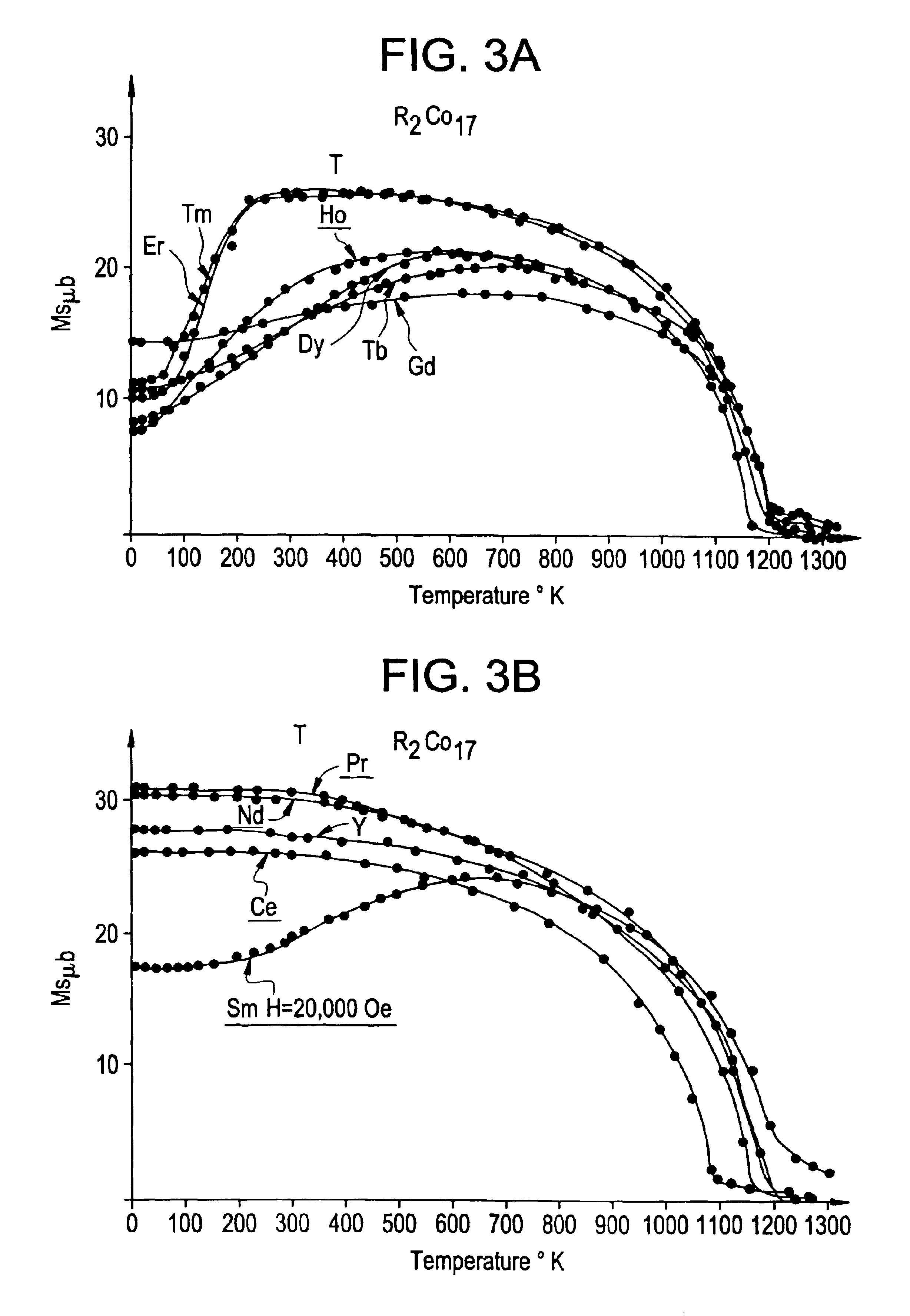

ActiveUS20050077899A1Increase in spontaneous magnetizationIncrease temperatureMagnetic measurementsMagnetsSpontaneous magnetizationUltimate tensile strength

A shim adapted for altering a magnetic field of a magnet includes a first material which exhibits an increase in spontaneous magnetization with an increase in temperature for a predetermined temperature range.

Owner:GENERAL ELECTRIC CO

Magnetic materials, passive shims and magnetic resonance imaging systems

InactiveUS6906606B2Enhanced magnetizationIncrease temperatureMagnetsInorganic material magnetismSpontaneous magnetizationUltimate tensile strength

Owner:GENERAL ELECTRIC CO

Magnetic energy wave device

ActiveUS20050098486A1Enhanced magnetizationEfficient arrangementLiquid separation auxillary apparatusElectrostatic separatorsElectricityMagnetic energy

A magnetic energy wave device has a winding spiral pipe, a magnetic conductive metal layer, a hollow coil holder, and a circuit board. A magnetic switch is assembled at a water inlet of the winding spiral pipe. The magnetic conductive metal layer is sleeved outside the winding spiral pipe. The winding spiral pipe and the magnetic conductive metal layer are assembled in the hollow coil holder. A coil is wound around the hollow coil holder. The circuit board is connected to an external power source, and is electrically connected to the magnetic switch and the coil. When water passes through the water inlet, the magnetic switch connects the power source and the coil. The coil and the magnetic conductive metal layer therefore produce dynamic magnetic fields to magnetize fully water in the pipe.

Owner:QUALITY PURE CO LTD

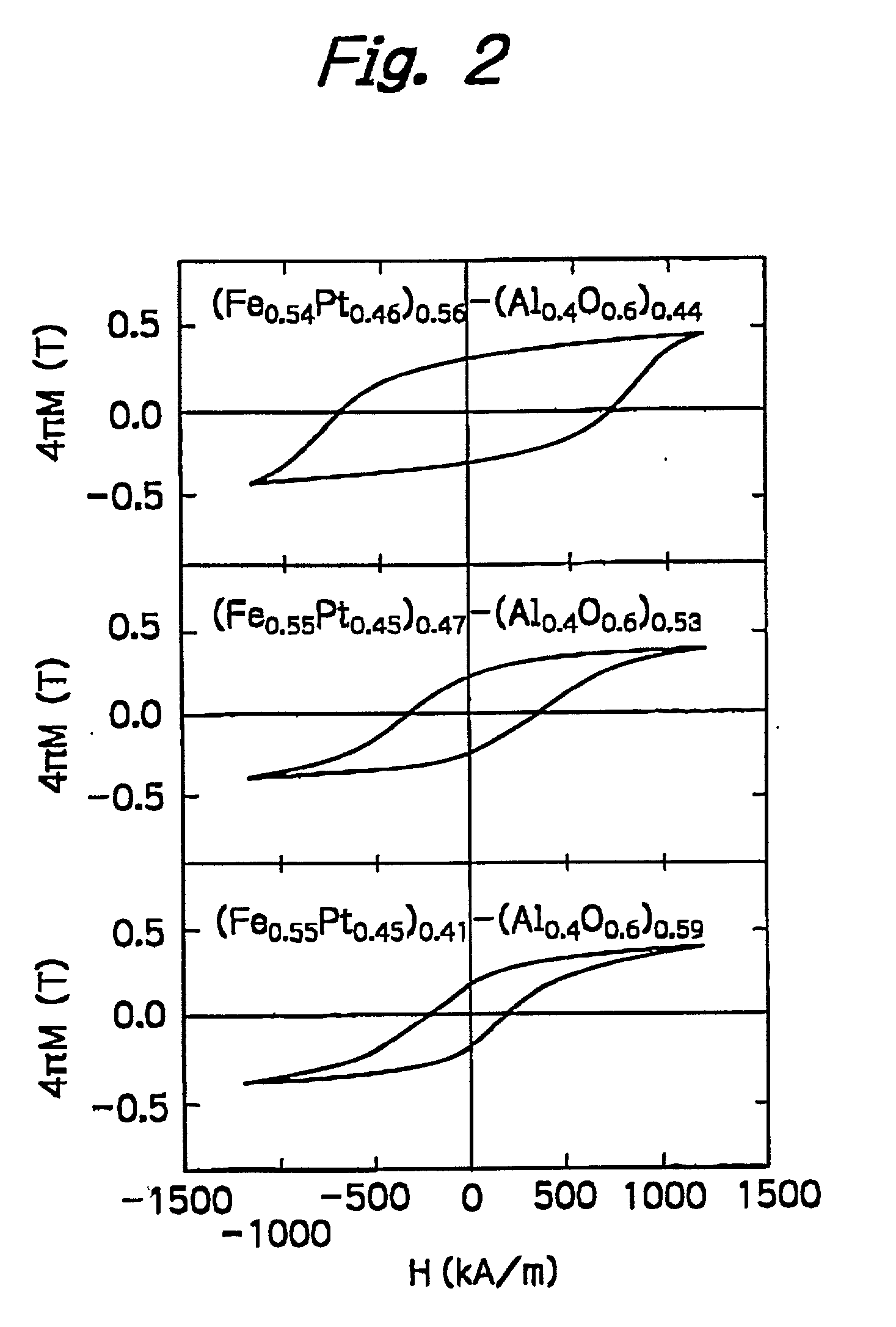

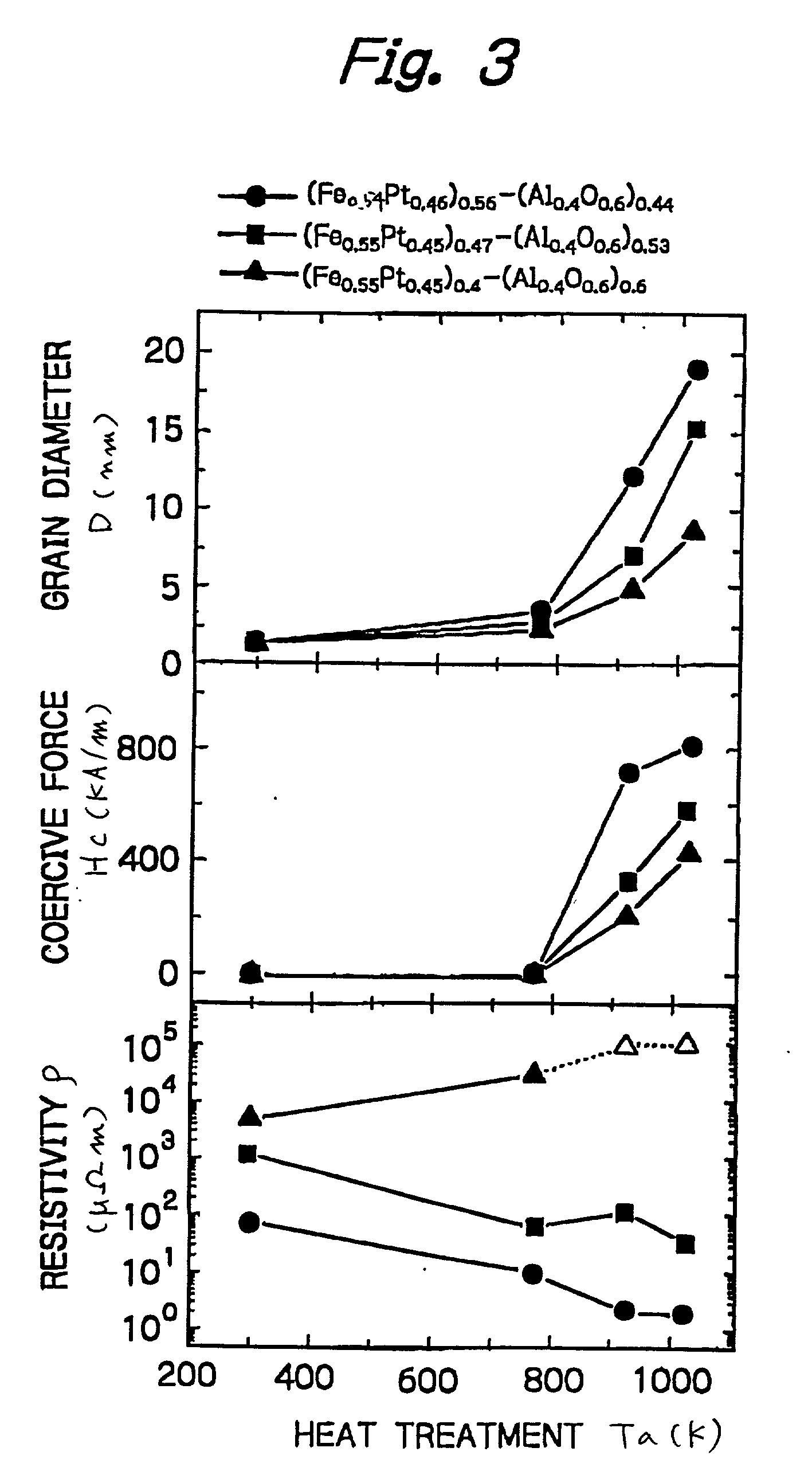

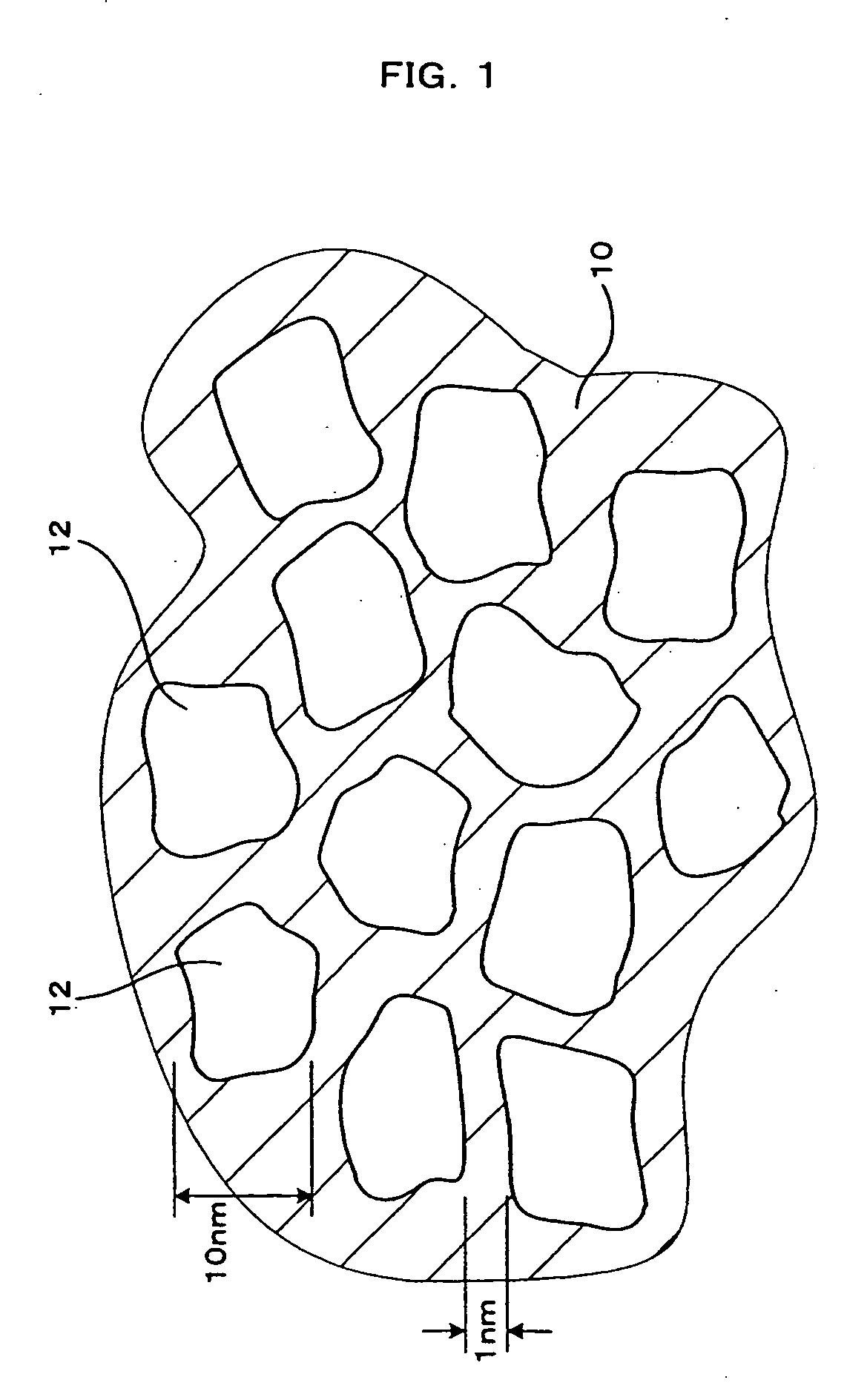

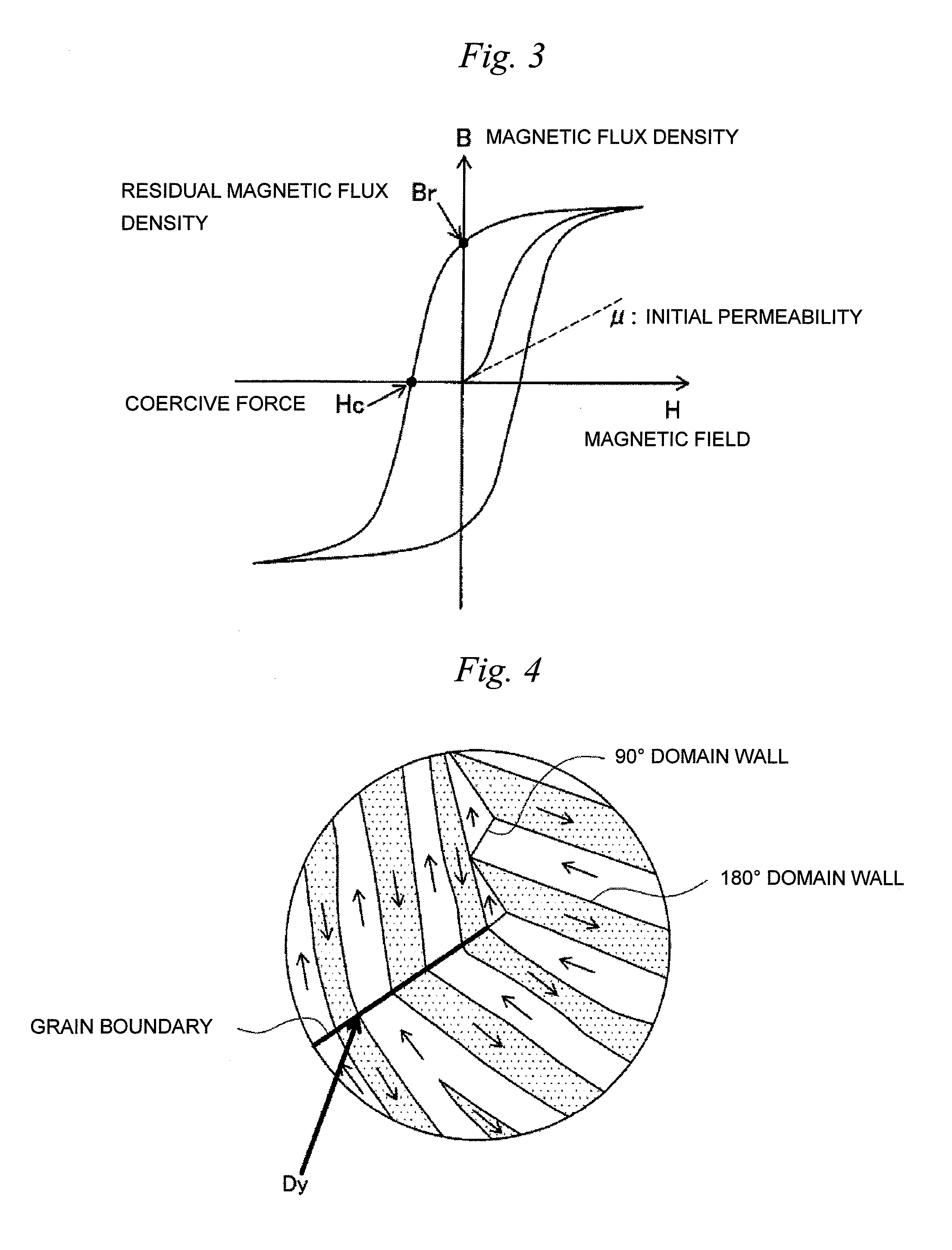

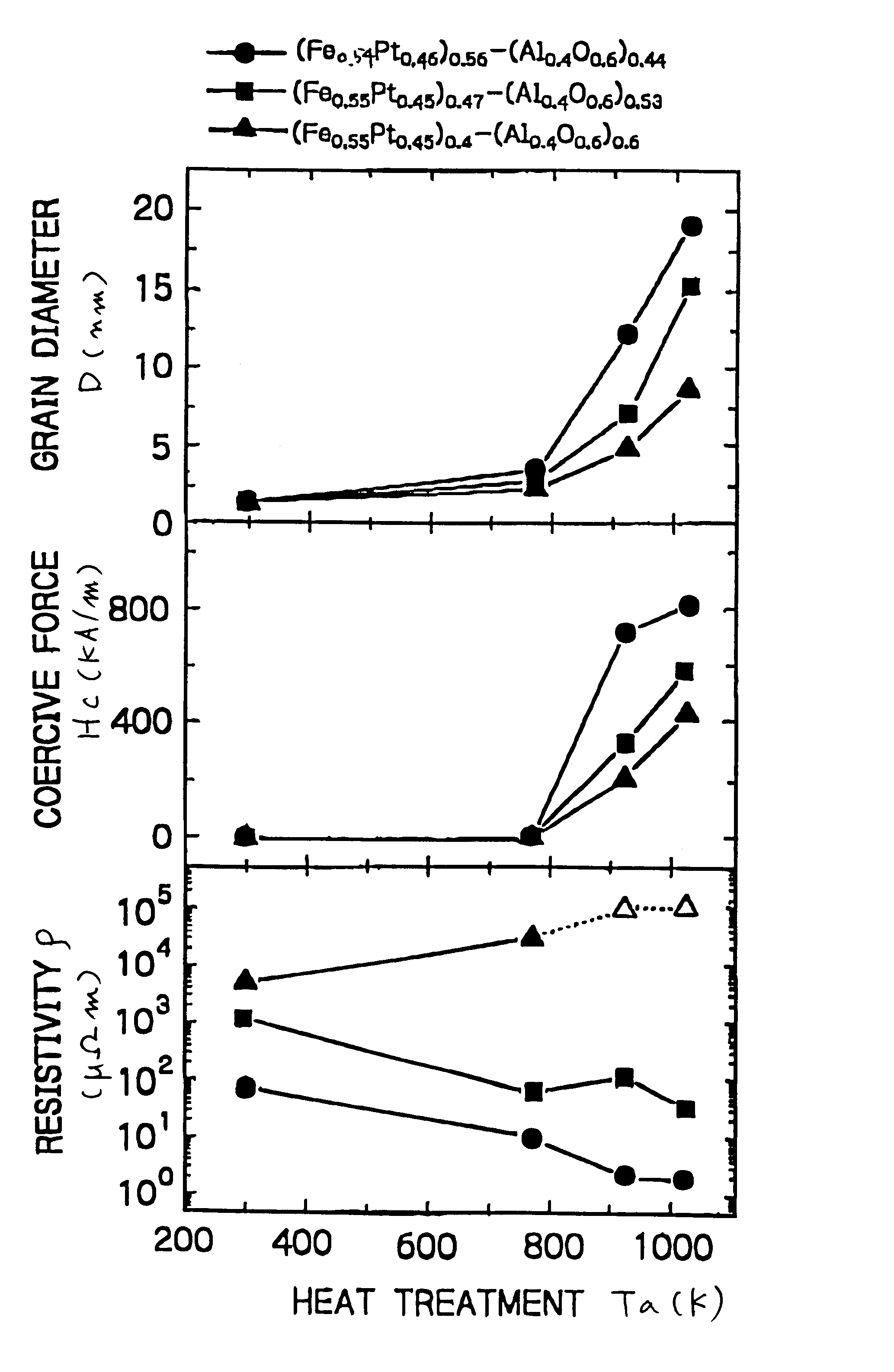

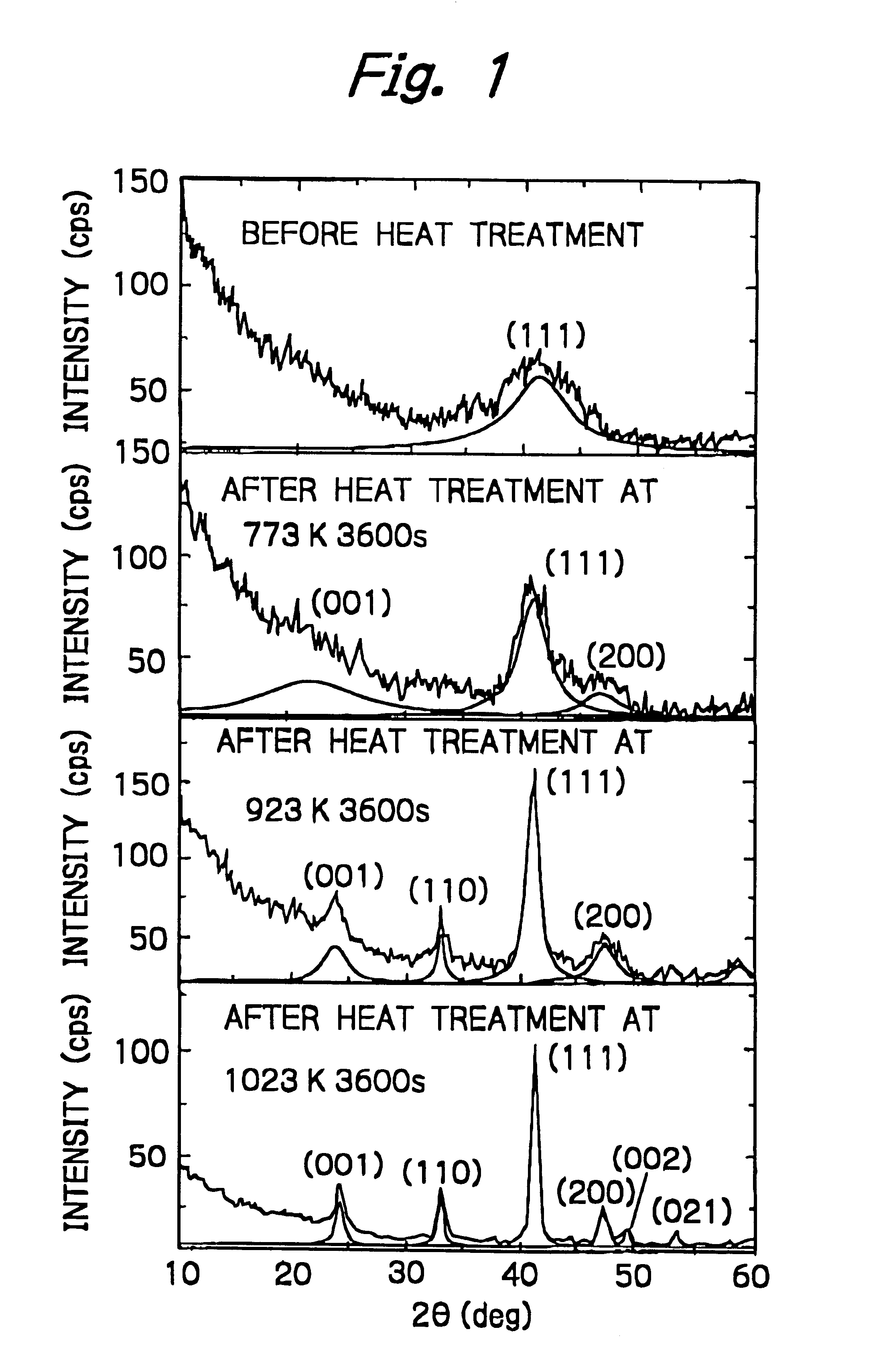

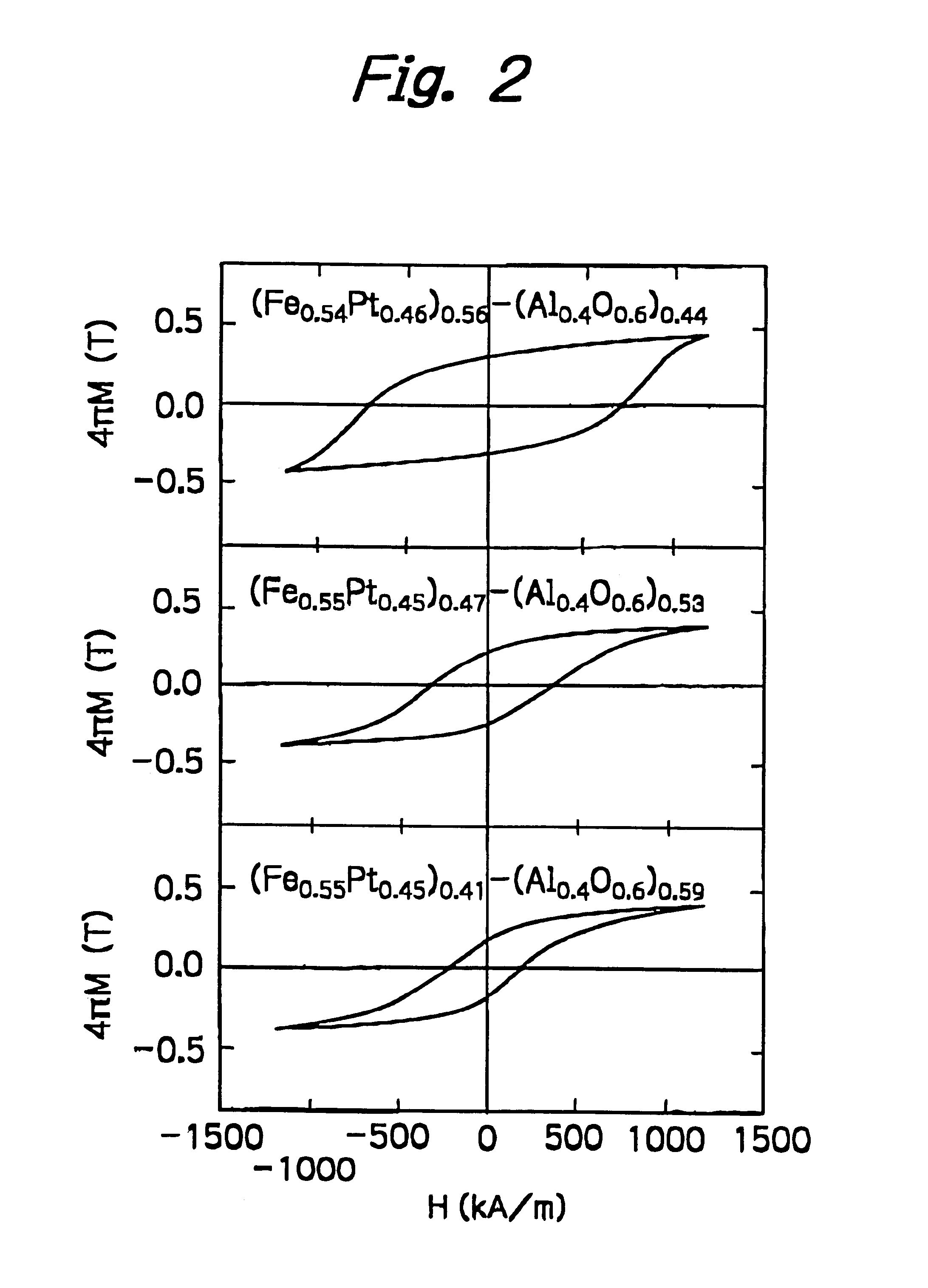

Nanogranular thin film and magnetic recording media

InactiveUS20010036563A1Improve thermal stabilityReduce noiseNanomagnetismMaterials with cobaltNanometreOptoelectronics

A nanogranular thin film consisting of nonmagnetic matrix and ferromagnetic fine particles in nano scale is improved to enhance the thermal stability and the S / N ratio. The ferromagnetic fine particles consist of (FeaCo1-a)1-xPtx, (0.3<=x<=0.7, 0.1<=x<=1), (FeaCo1-a)1-xPdx, (0.3<=x<=0.7, 0.1<=x<=1) or (FeaCo1-a)1-x(PtbPd1-b)x, (0.3<=x<=0.7, 0.1<=x<=1, and 0<b<1).

Owner:FOUND THE RES INST FOR ELECRTRIC & MAGNETIC MATERIALS THE

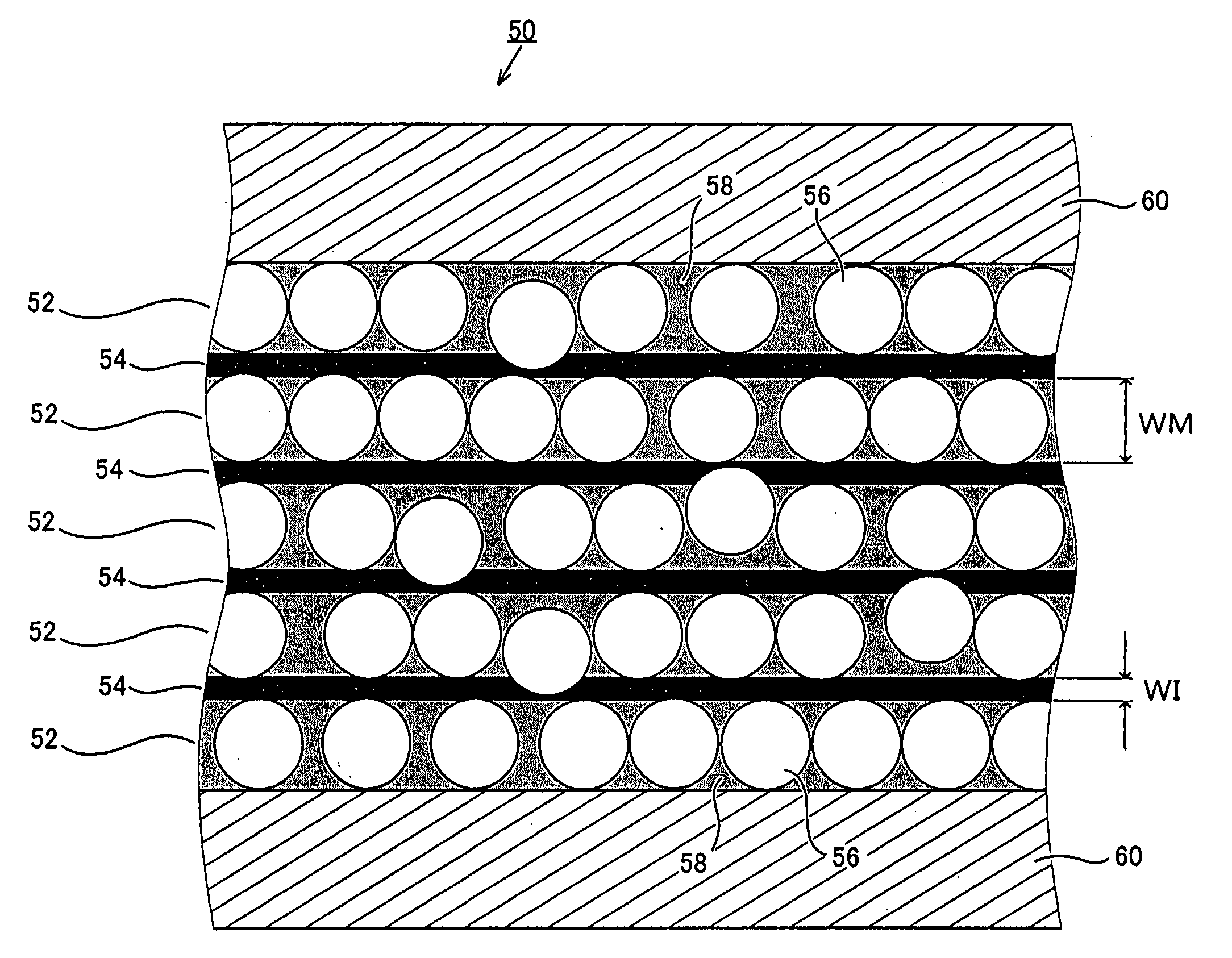

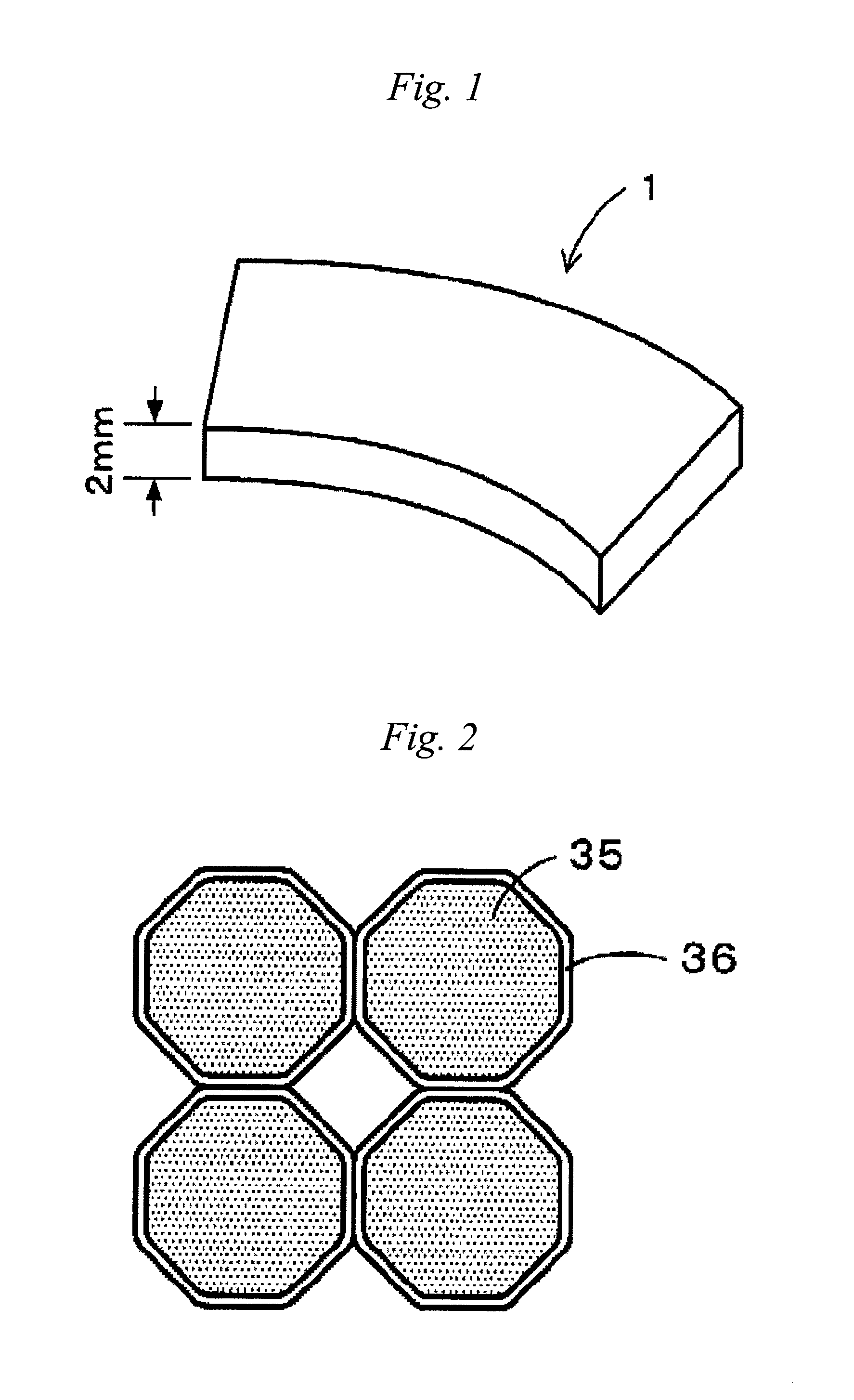

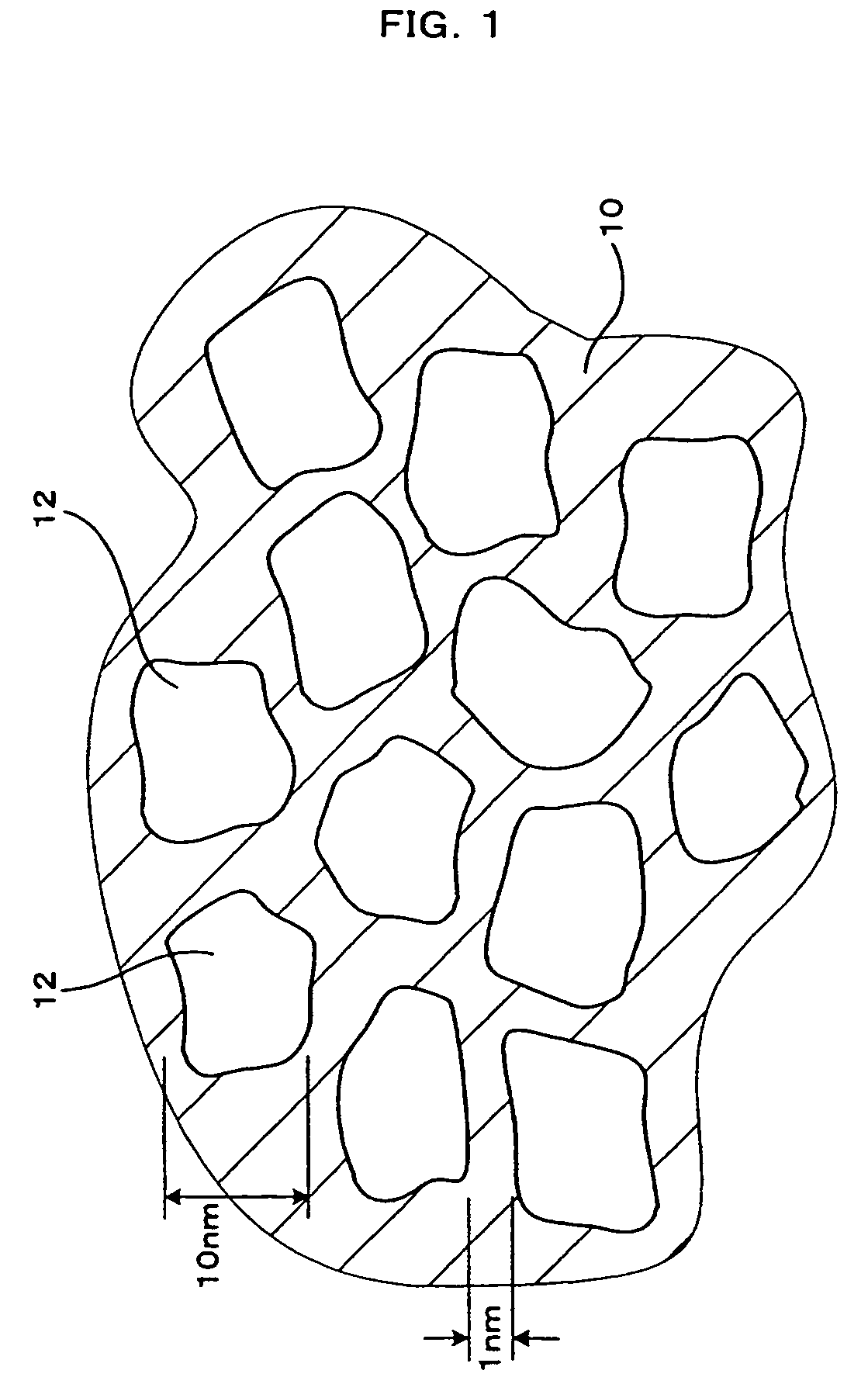

Granular magnetic thin film and method for making the same, multilayered magnetic film, magnetic components and electronic equipment

InactiveUS20040209098A1Improved high-frequency characteristicExcellent soft magnetic propertiesNanostructure applicationNanomagnetismHigh resistivityMaterials science

There are provided a magnetic thin film utilizing a granular film and having excellent high frequency characteristics and a method of manufacturing the same, and a multilayered magnetic film and magnetic components and electronic equipment utilizing the same. A nonreactive sputtering is performed so that there is no oxidation of a magnetic metal, and a saturation magnetization is increased to increase a resonant frequency of permeability. Also, a multi-target simultaneous sputtering is combined with the nonreactive sputtering so that in a granular structure including magnetic grains and an insulating layer a size of the magnetic grains and a thickness of the insulating layer are optimized thereby ensuring a proper magnitude for a crystalline magnetic anisotropy within the grains and excellent soft magnetic properties. Further, the optimization of the thickness of the insulating layer has the effect of improving a resistivity, decreasing an eddy current and improving an exchange interaction between the magnetic grains.

Owner:TAIYO YUDEN KK

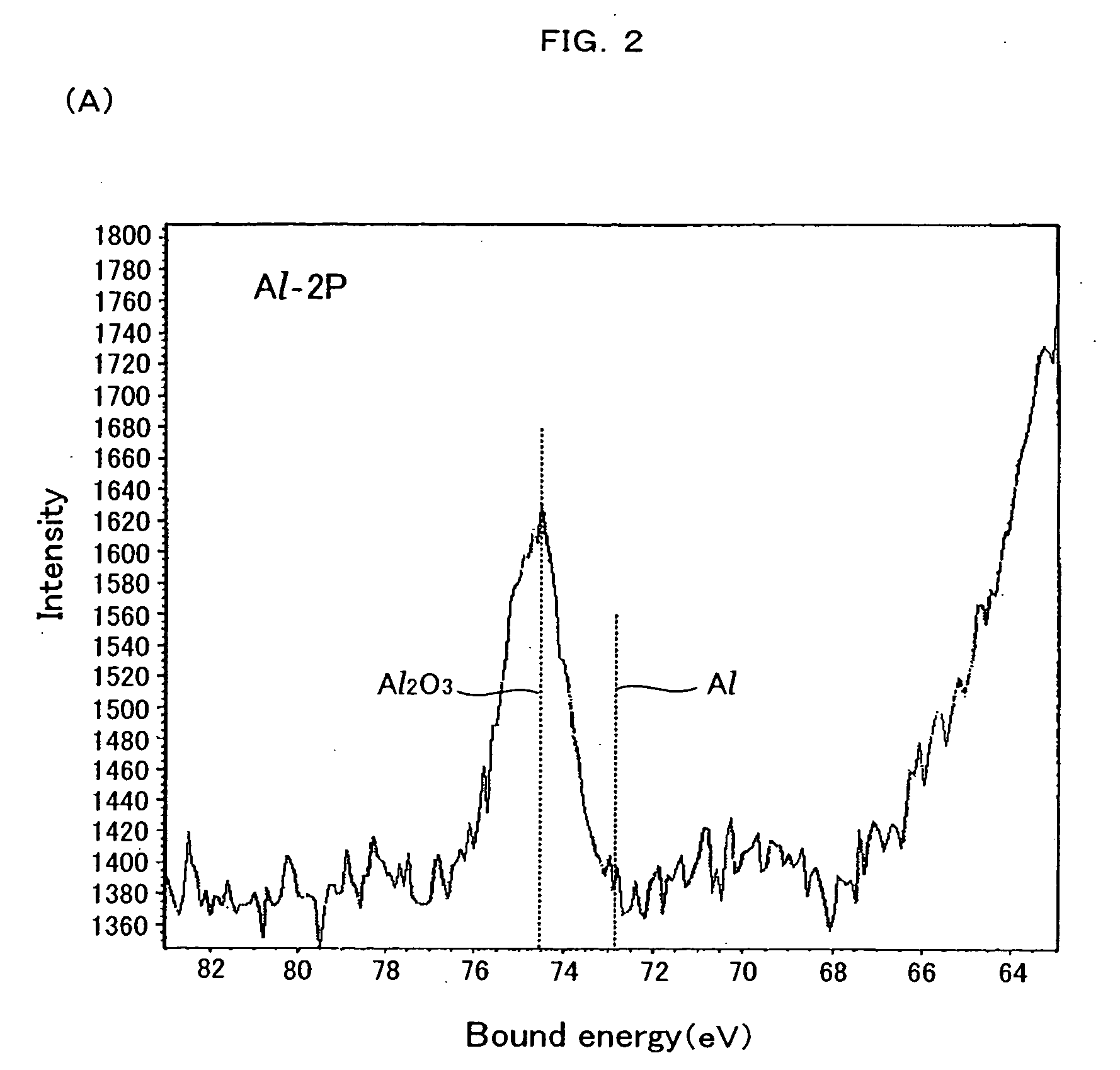

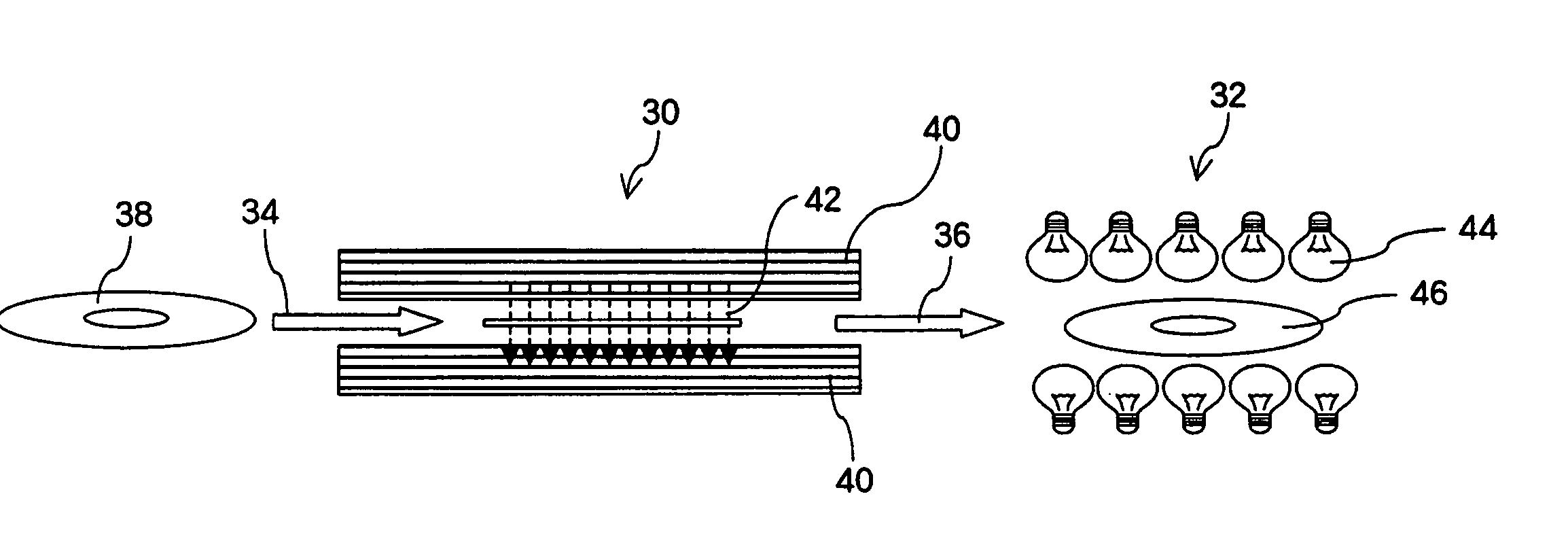

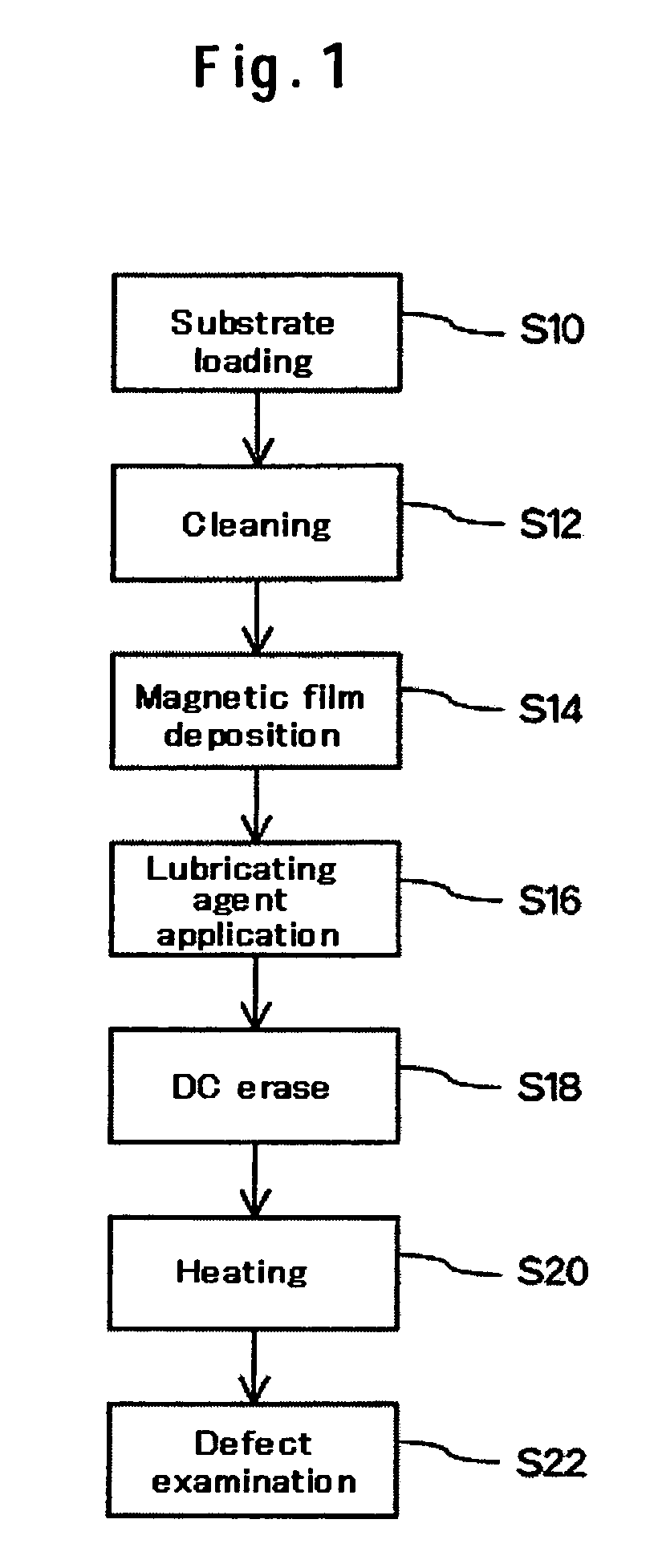

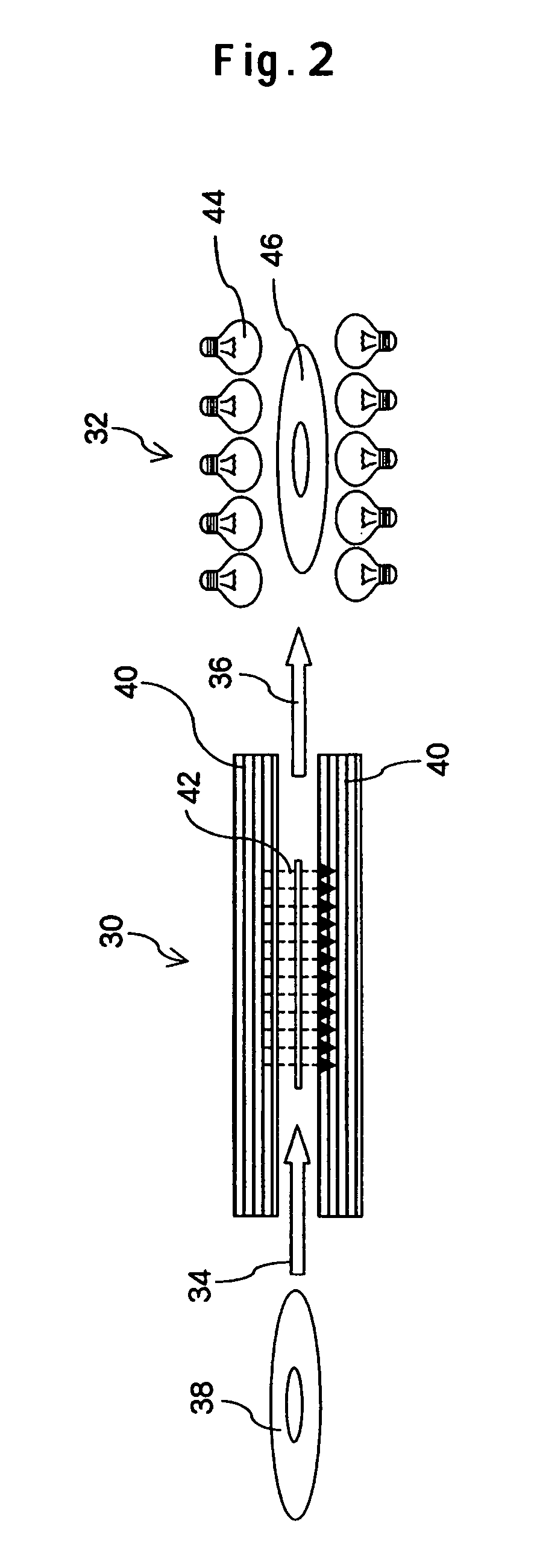

Defect inspection method for perpendicular magnetic recording medium, magnetic disk device, and method of registering defects in magnetic disk device having a perpendicular magnetic recording medium therein

InactiveUS20060109000A1Efficient detectionLower performance requirementsMagnetic property measurementsRecord information storageDemagnetizing fieldManufacturing technology

Because of its characteristics, a perpendicular magnetic recording medium has the inconvenience that since sections with low signal stability due to magnetic defects are not easily detectible in advance, these sections are detected after mounting of the medium in a magnetic disk device or after product shipping. According to one embodiment, in the manufacturing processes for the perpendicular magnetic recording medium, a DC-erase process step for direct-current demagnetizing the medium is performed after a magnetic film deposition process step and a lubricating-agent application process step. This maximizes the effects of a demagnetizing field and intentionally increases directional instability of magnetization. After the above processes, the medium is further provided with a heating process to accelerate the reversal of magnetization in latent defective sections. A defect examination step for detecting the magnetization reversal sections on the basis of changes in the baseline of the signal read out from the medium under the above state is performed, whereby defects can be detected efficiently.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Permanent magnet and method for manufacturing the same

InactiveUS20110018664A1Improve coercive forceDecrease residual magnetizationPermanent magnetsCeramic shaping apparatusMagnetMetallurgy

The present invention relates to a permanent magnet obtained by wet-mixing a Dy compound or a Tb compound with a magnet raw material to coat a surface of the magnet raw material with the Dy compound or the Tb compound, and sintering a green sheet obtained by mixing the resulting magnet raw material with a resin binder and molding the resulting mixture. Since the present invention has the above-mentioned constitution, it becomes possible to sufficiently improve coercive force by Dy or Tb while decreasing the amount of Dy or Tb used. Further, it can be prevented that Dy or Tb is solid-solutionized in magnet particles to decrease residual magnetization.

Owner:NITTO DENKO CORP

Nanogranular thin film and magnetic recording media

InactiveUS6623857B2Improve thermal stabilityReduce noiseNanomagnetismMaterials with cobaltNanoparticleOptoelectronics

A nanogranular thin film consisting of nonmagnetic matrix and ferromagnetic fine particles in nano scale is improved to enhance the thermal stability and the S / N ratio. The ferromagnetic fine particles consist of (FeaCo1-a)1-xPtx, (0.3<=x<=0.7, 0.1<=a<=1), (FeaCo1-a)1-xPdx, (0.3<=x<=0.7, 0.1<=a<=1) or (FeaCo1-a) 1-x(PtbPd1-b)x, (0.3<=x<=0.7, 0.1<=a<=1, and 0<b<1).

Owner:FOUND THE RES INST FOR ELECRTRIC & MAGNETIC MATERIALS THE

Granular magnetic thin film and method for making the same, multilayered magnetic film, magnetic components and electronic equipment

InactiveUS7060374B2Enhanced magnetizationReduce in quantityNanostructure applicationNanomagnetismHigh resistivityElectron

Owner:TAIYO YUDEN KK

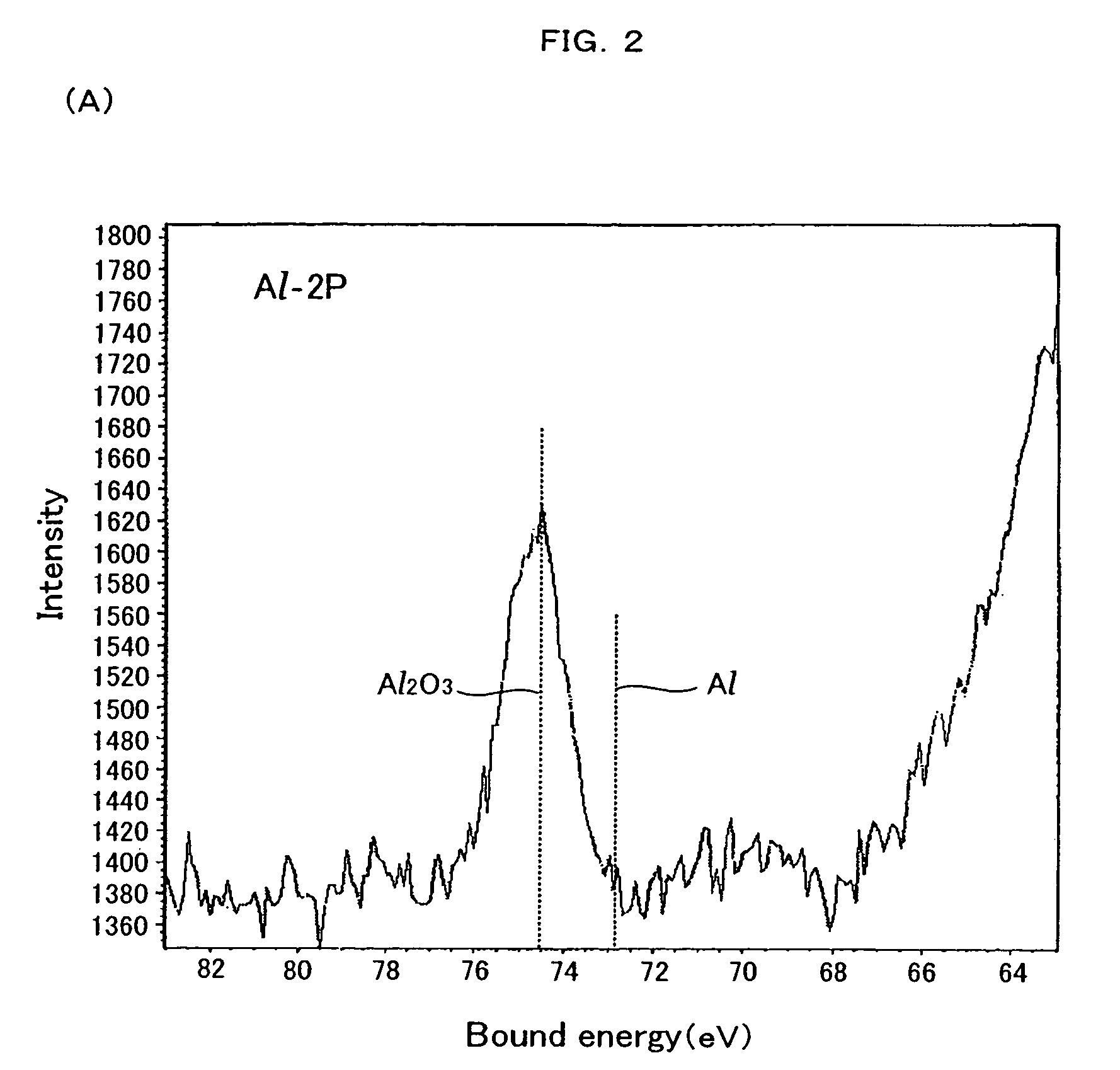

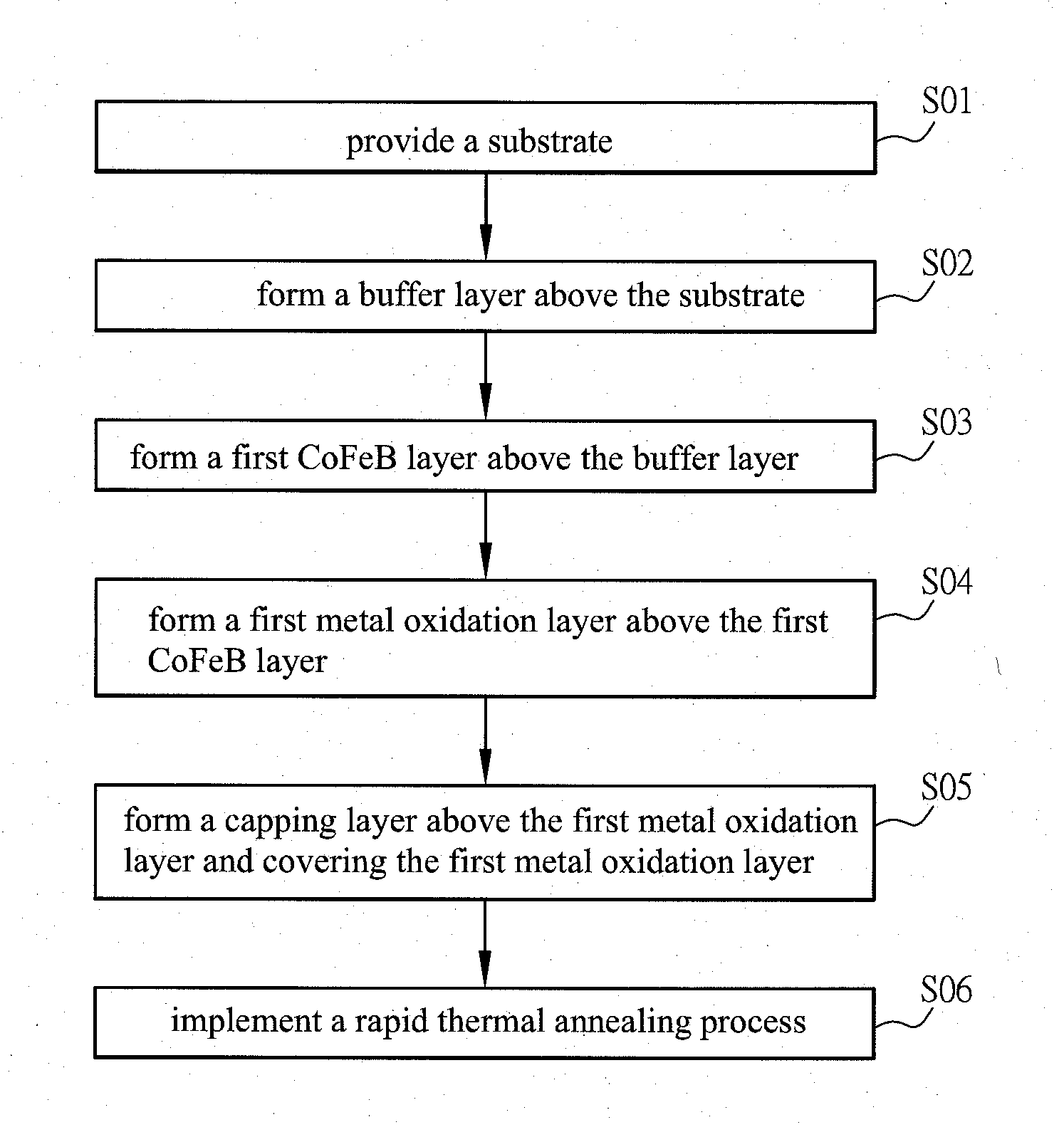

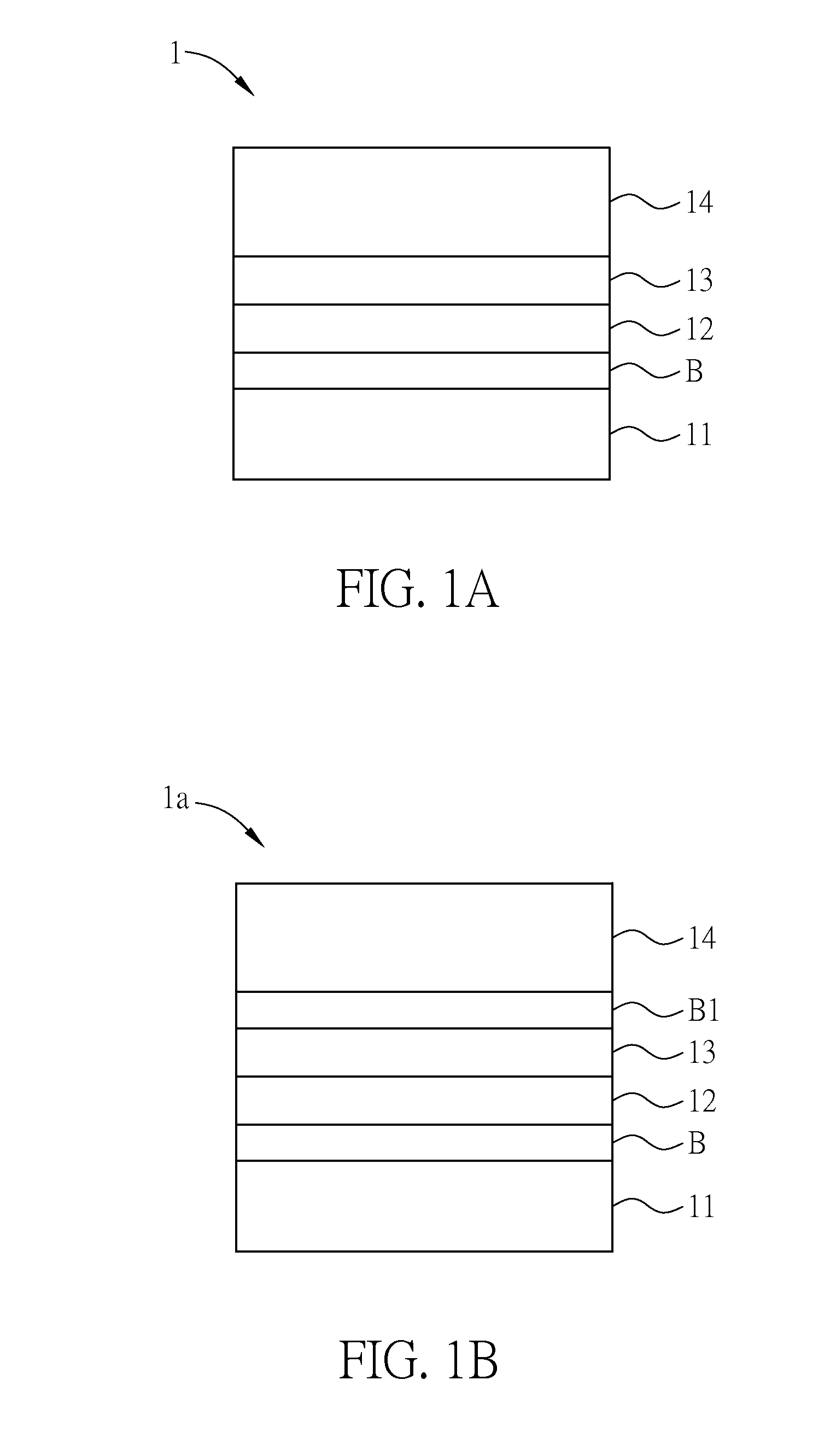

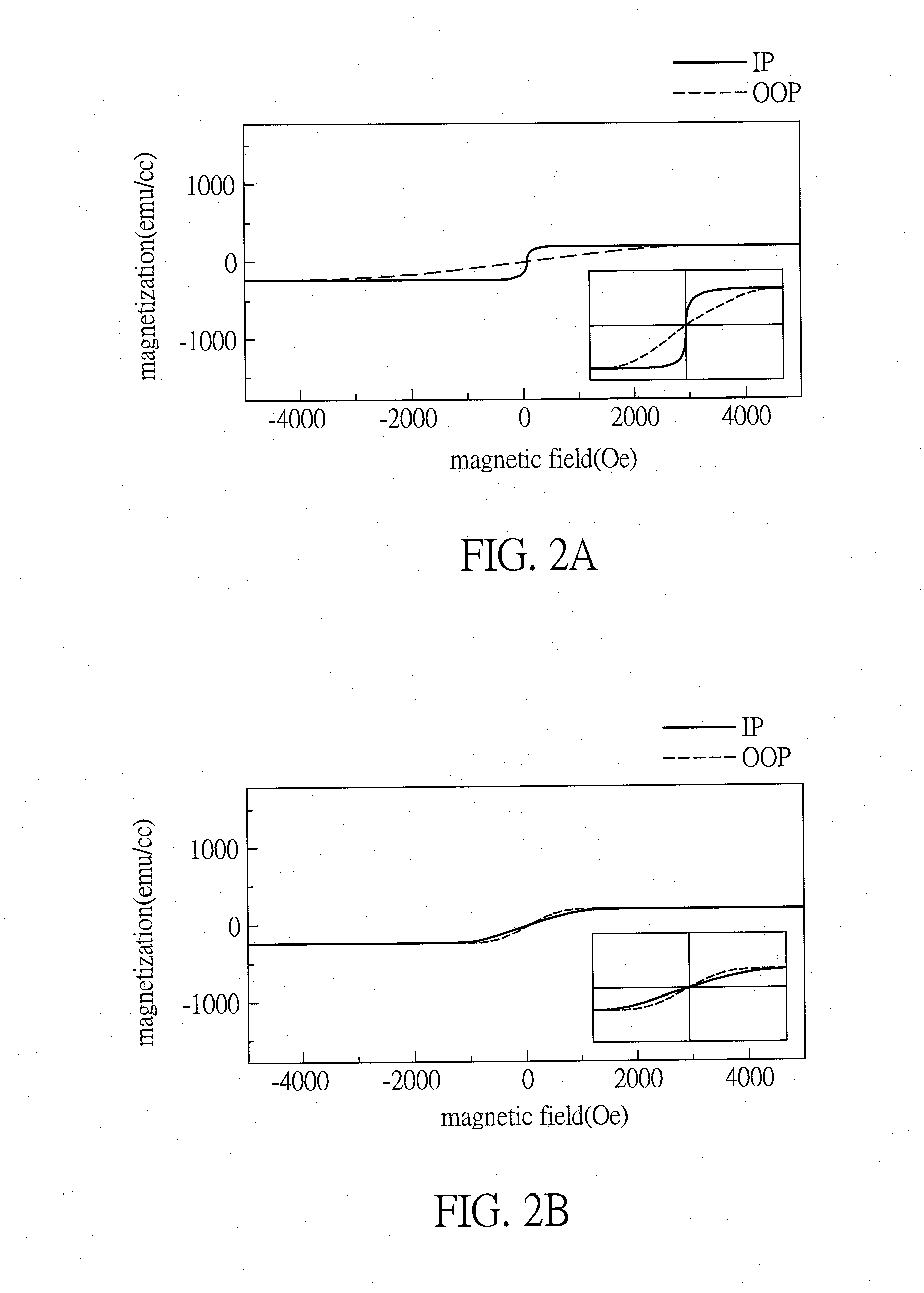

Magnetic electronic device and manufacturing method thereof

ActiveUS20140252515A1Improve responseImprove thermal stabilitySemiconductor/solid-state device manufacturingGalvano-magnetic device detailsElectric devicesCondensed matter physics

A magnetic electronic device comprises a substrate, a buffer layer, a first CoFeB layer, a first metal oxidation layer and a capping layer. The buffer layer is disposed above the substrate. The first CoFeB layer is disposed above the buffer layer. The first metal oxidation layer is disposed above the first CoFeB layer. The capping layer is disposed above the first metal oxidation layer and covers the first metal oxidation layer. A manufacturing method of the magnetic electronic device is also disclosed.

Owner:NATIONAL TSING HUA UNIVERSITY

Ferromagnetic detection enhancer compatible with magnetic resonance

InactiveUS8148989B2Ability to detectQuick releaseElectric/magnetic detectionAcoustic wave reradiationElectronic switchMagnetization

An apparatus for increasing the ability to detect ferromagnetic objects by increasing the magnetization of the objects. The apparatus includes at least one coil to generate a magnetic field positioned in the area of the object to be detected. The apparatus includes an electrical energy storage capacitor bank capable of quickly releasing stored energy. The apparatus includes a high speed, high current electronic switch capable of quickly transferring the stored energy from the capacitor bank to the coil thereby producing in the coil a short duration, single polarity magnetic field pulse. The apparatus includes a sample and hold circuit capable of acquiring magnetic field sensor data during periods when the pulsed magnetic field is not present. The apparatus includes a microprocessor controller to control timing and sequence of the magnetic pulse generation and the sensor data sample and hold process. The apparatus may be for portal handheld or head mounted applications.

Owner:KOPP KEITH

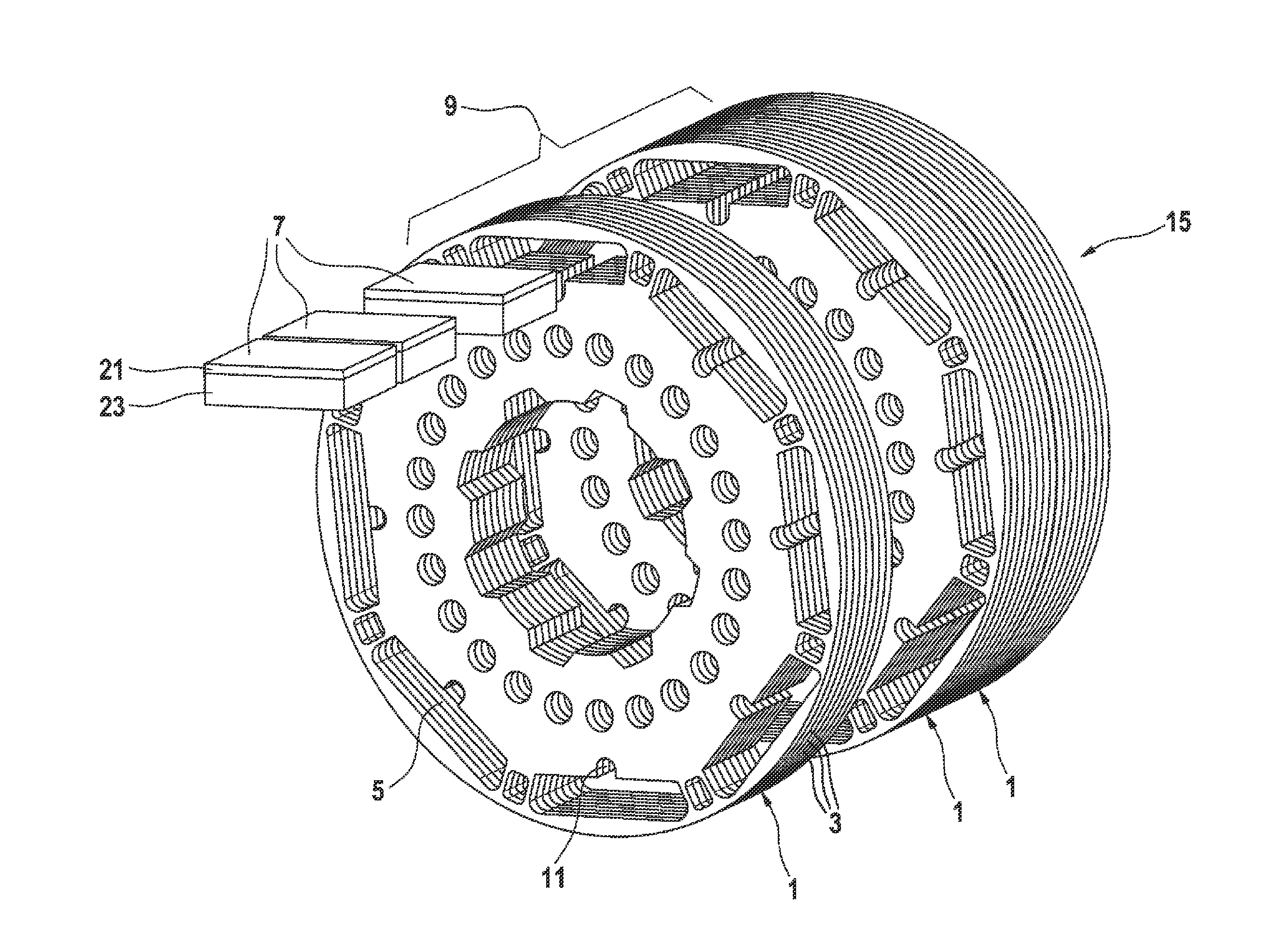

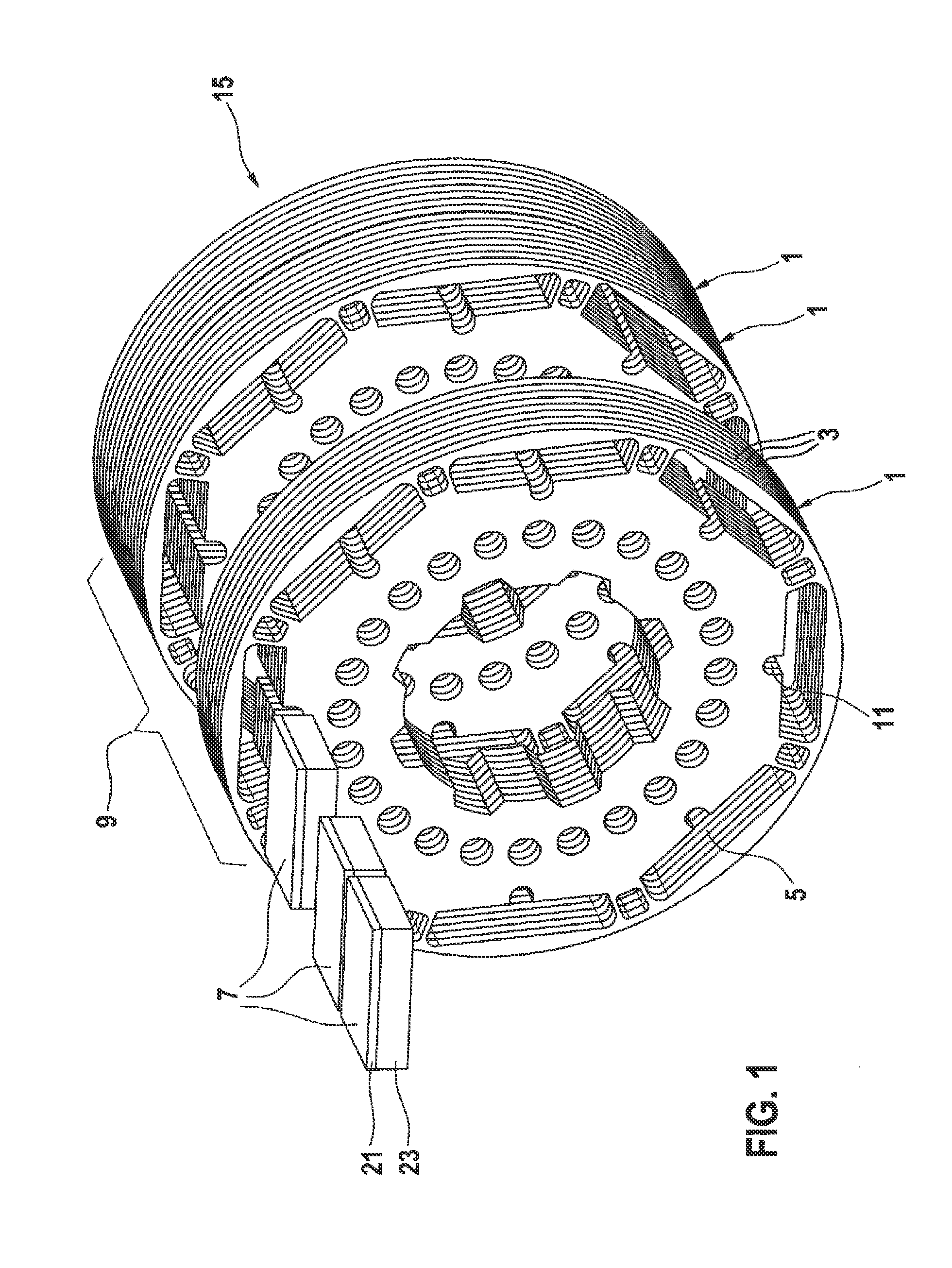

Permanent magnet electric machine with two part or multi part permanent magnets

InactiveUS20130270949A1Improve coercive forceEnhanced magnetizationSynchronous machinesMagnetic circuit characterised by magnetic materialsElectric machineMagnet

A permanent magnet electric machine (2), in which permanent magnets (7) are arranged on a stator (13) and / or a rotor (15). In this case, a permanent magnet (7) has at least one first macroscopic permanent magnet element and one second macroscopic permanent magnet element (21, 23), wherein the permanent magnet elements (21, 23) are formed from different materials, which have different magnetic coercitivities.

Owner:ROBERT BOSCH GMBH

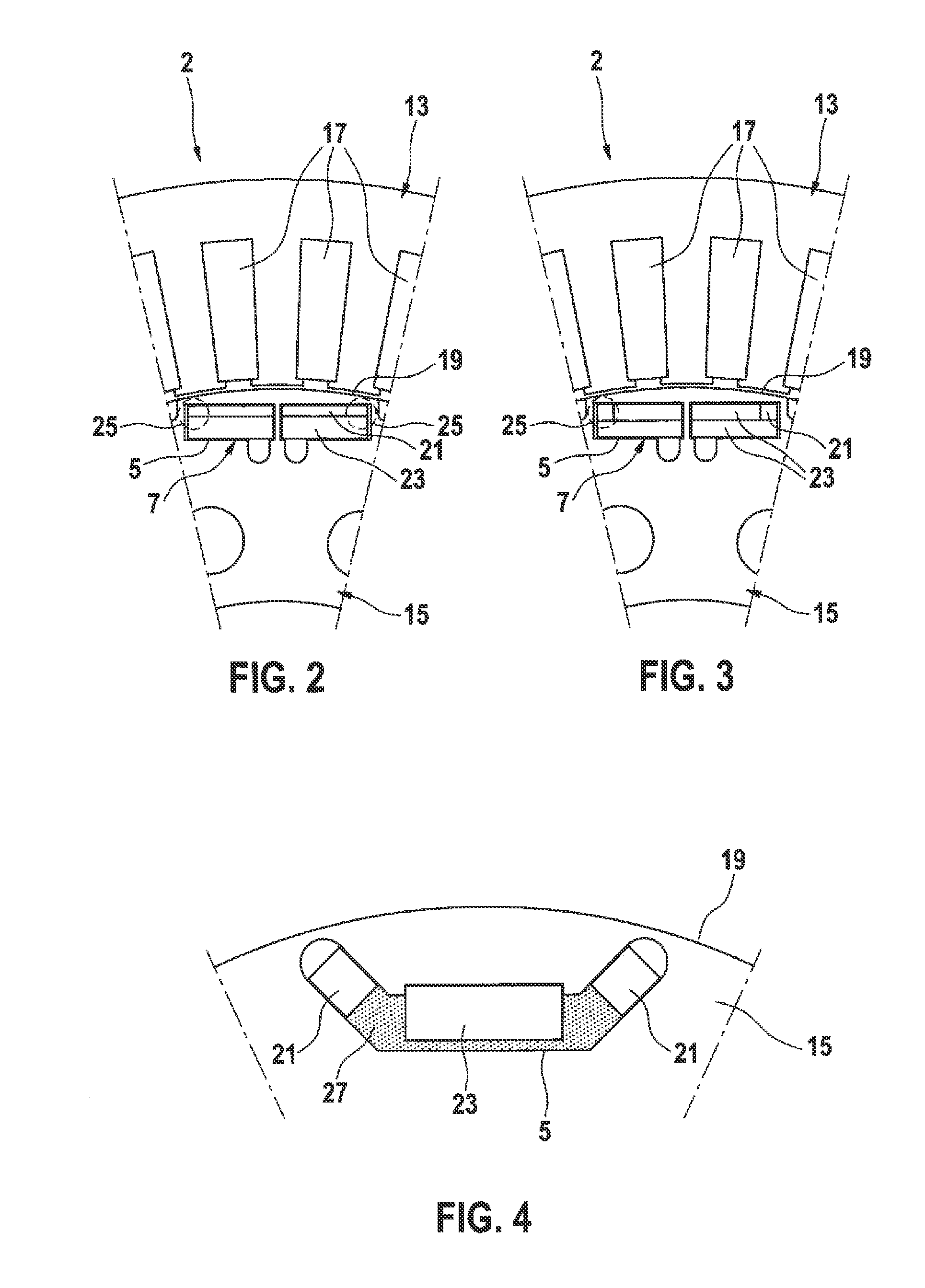

Method of manufacturing rare-earth magnets

InactiveUS20140308441A1Improve coercive forceSuppress coarseningTransportation and packagingMetal-working apparatusRare-earth elementRare-earth magnet

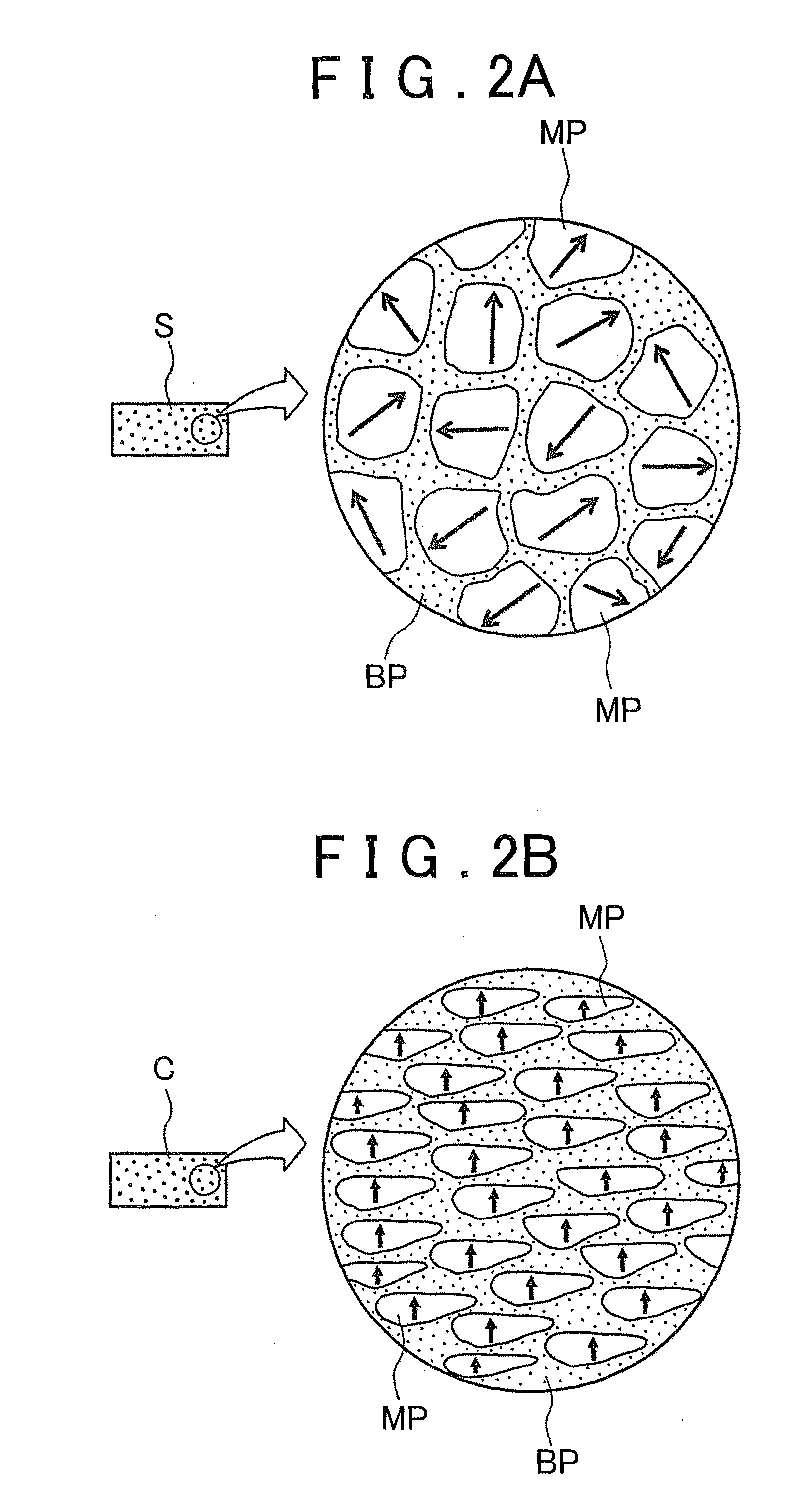

A method of manufacturing rare-earth magnets includes, a first step of producing a compact C by subjecting a sintered body S, which is formed of a RE—Fe—B main phase MP having a nanocrystalline structure (where RE is at least one of neodymium and praseodymium) and a grain boundary phase BP of an RE—X alloy (where X is a metal element) located around the main phase, to hot plastic processing that imparts anisotropy; and a second step of producing a rare-earth magnet RM by melting a RE—Y—Z alloy which increases the coercive force of the compact C (where Y is a transition metal element, and Z is a heavy rare-earth element), together with the grain boundary phase BP, and liquid-phase infiltrating the RE—Y—Z alloy melt from a surface of the compact C.

Owner:TOYOTA JIDOSHA KK

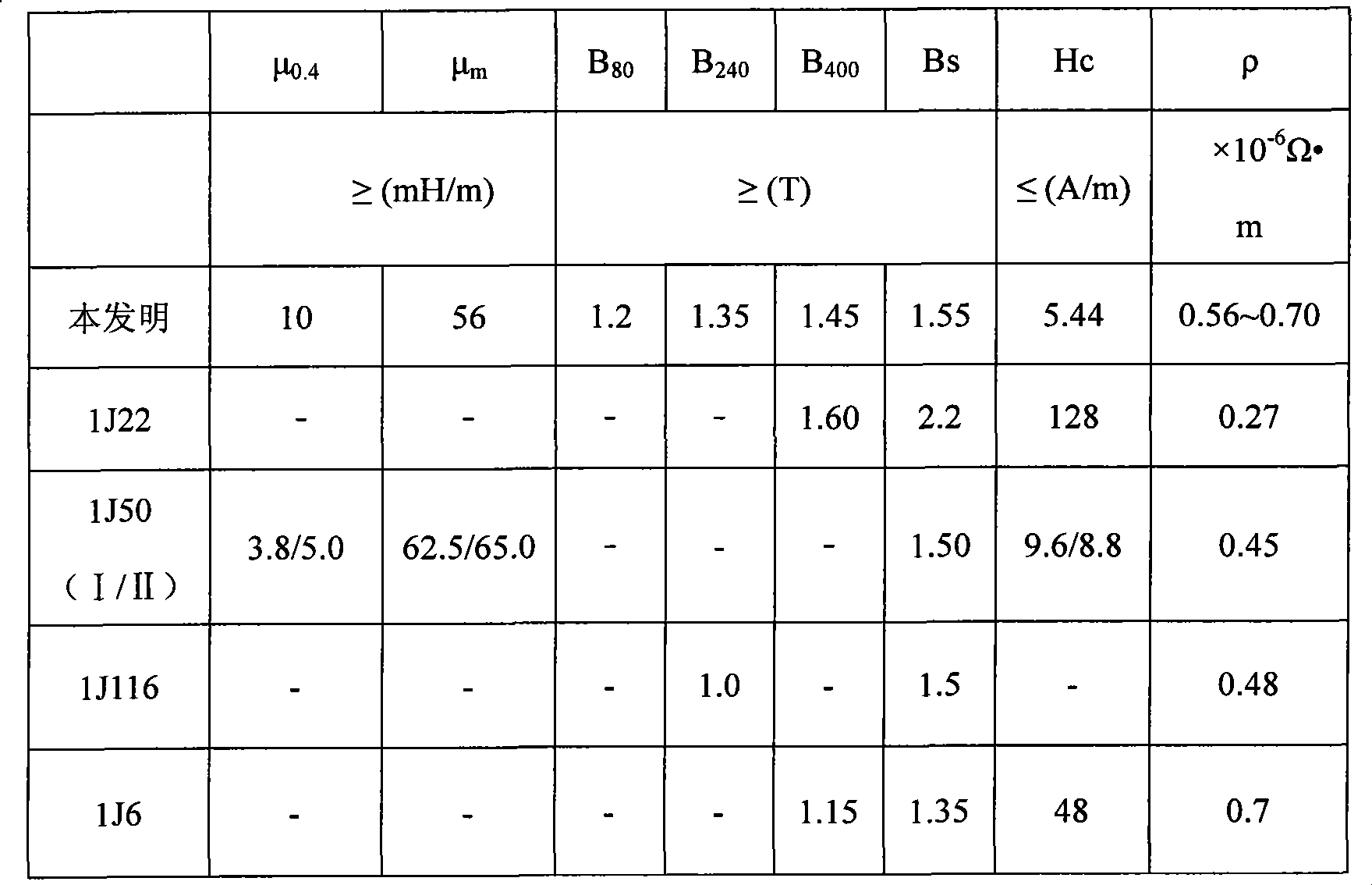

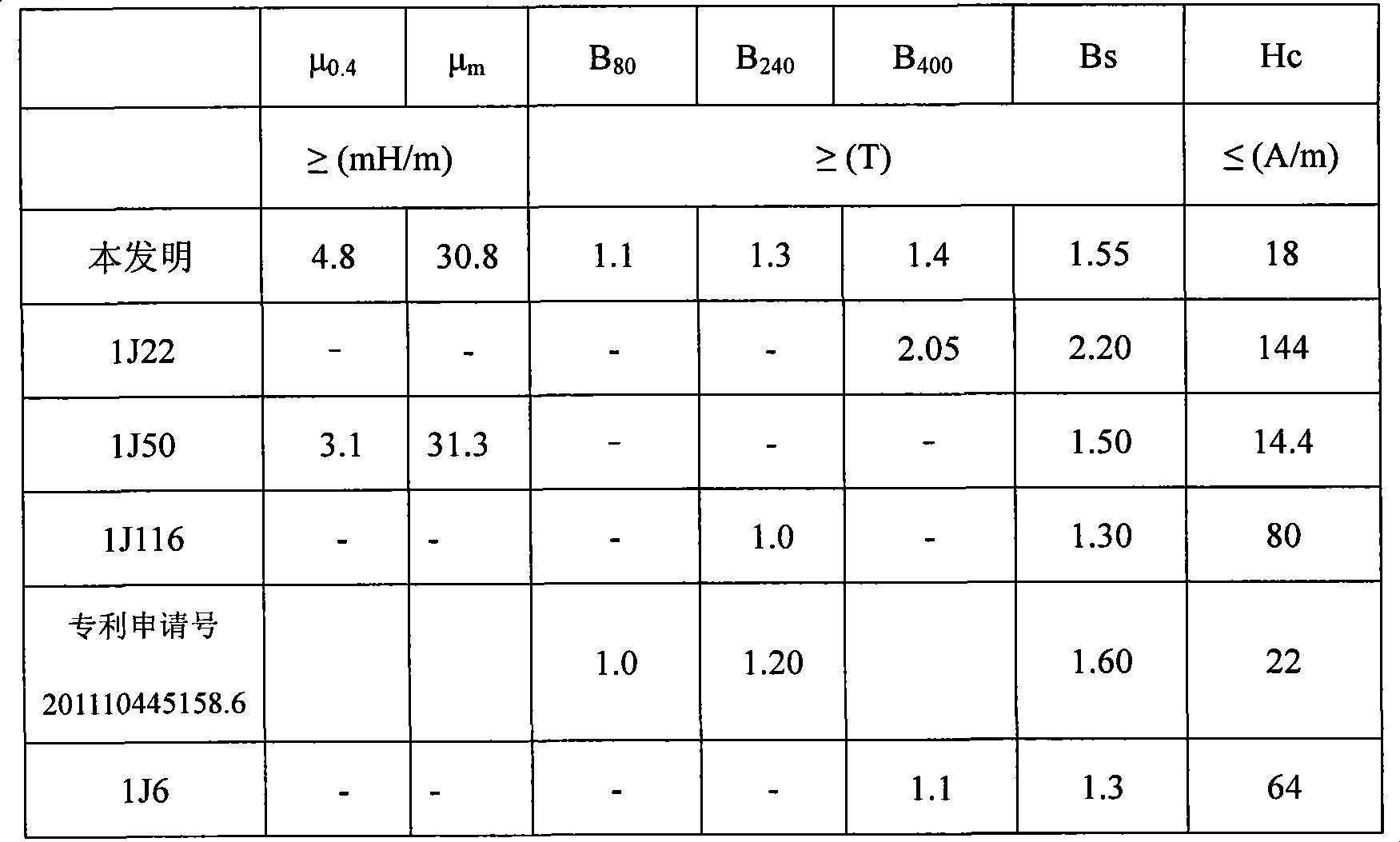

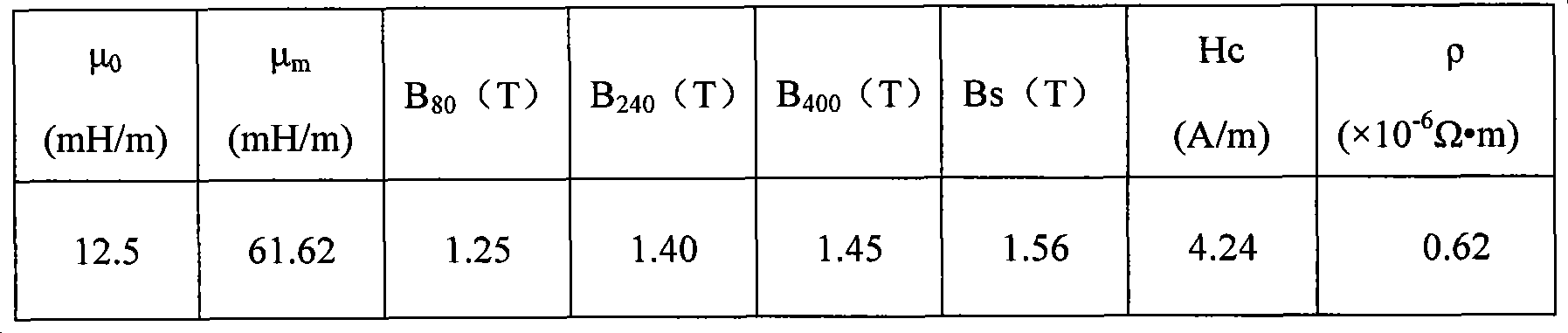

Anti-corrosion FeNiCo magnetically soft alloy with high magnetic induction intensity

The invention includes a FeNiCo magnetically soft alloy and a production method thereof, wherein the FeNiCo magnetically soft alloy has high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field. The FeNiCo magnetically soft alloy comprises the following components by mass percent: not more than 0.02 percent of C, 0.2-0.80 percent of Si, not more than 0.50 percent of Mn, 29.00-35.00 percent of Ni, 25.00-32.00 percent of Co, not more than 5.00 percent of Mo, not more than 0.50 percent of Cu, 0.01-0.55 percent of microelements including 0.001-0.05 percent of rare earth elements, and the balance of Fe and inevitable impurities. The FeNiCo magnetically soft alloy is processed and manufactured by adopting the methods of vacuum melting, forging, hot rolling and cold rolling, and after heat treatment, the FeNiCo magnetically soft alloy has the characteristics of high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field, and can be manufactured into the transducer, the filter, the electromagnetic valve, the transformer and the like in the field of aviation, aerospace, navigation, electron, electric power and the like.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

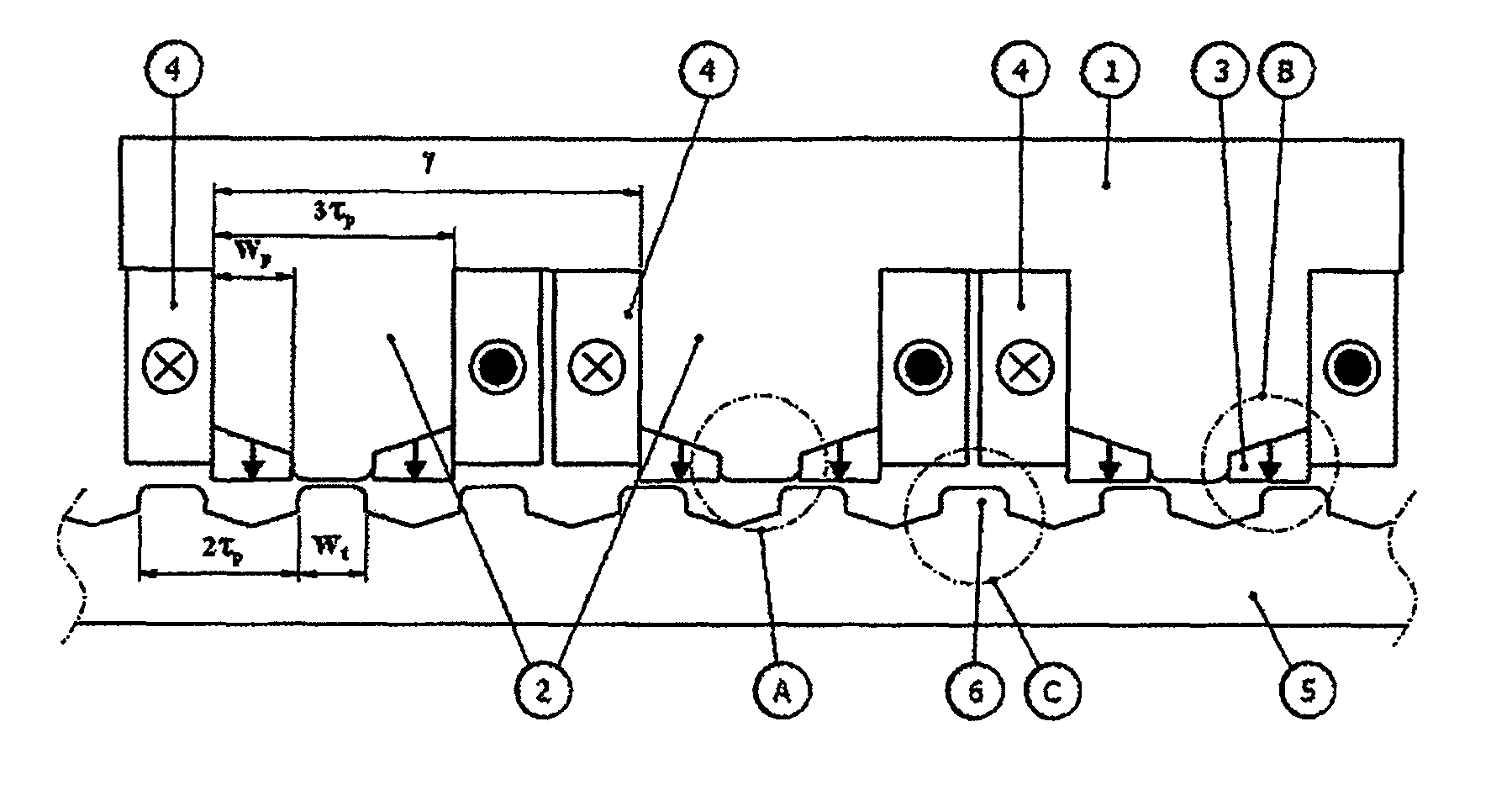

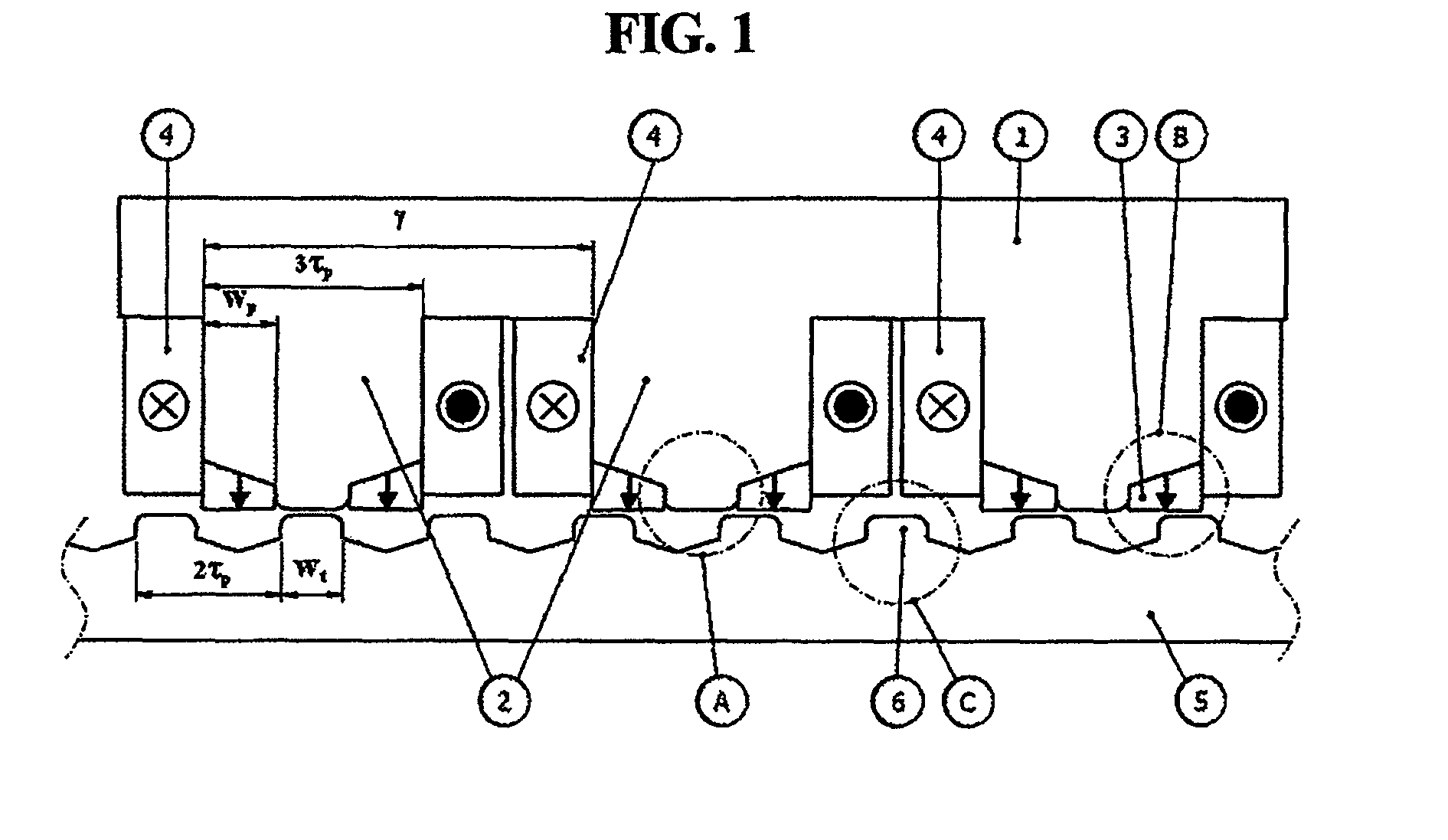

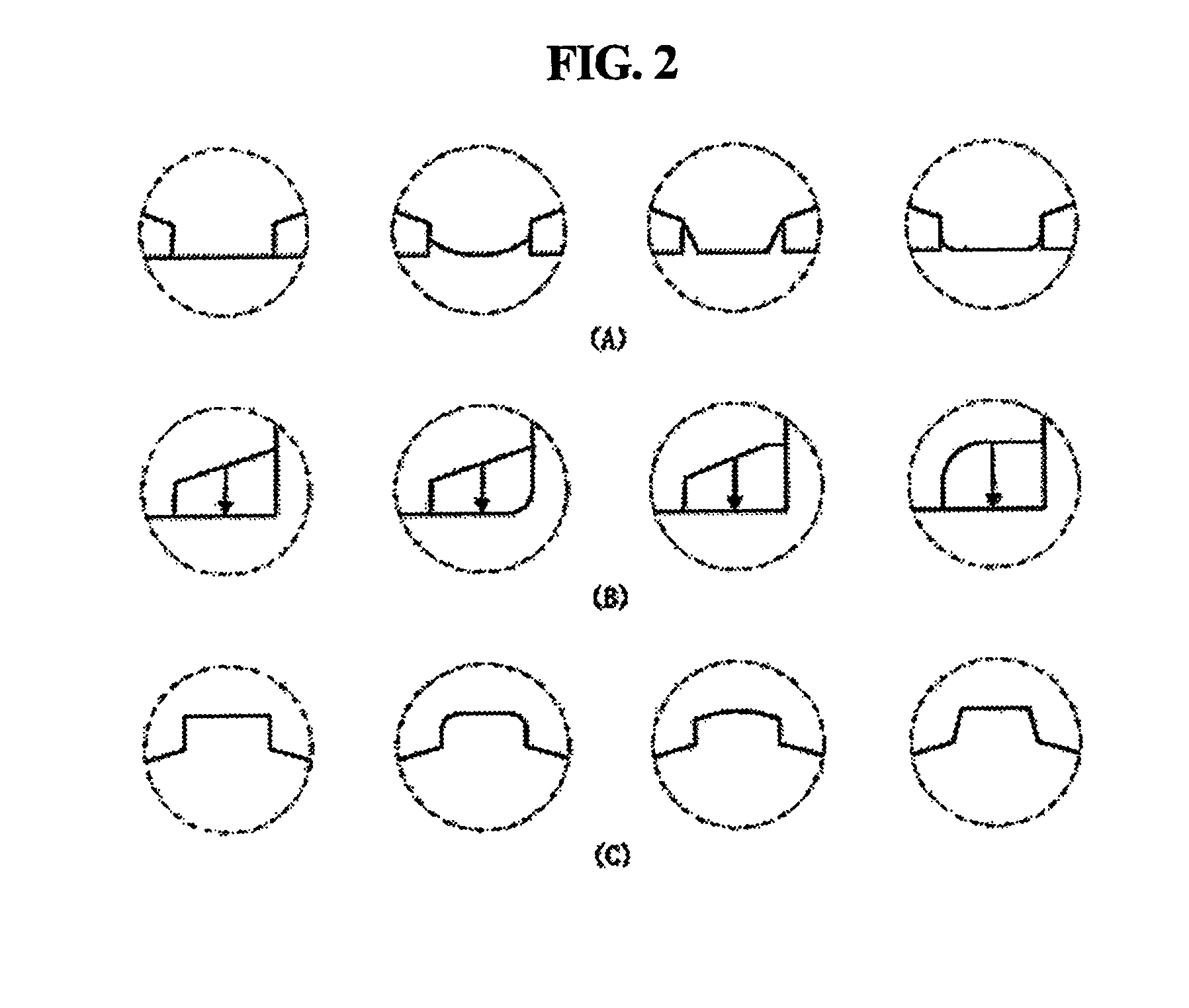

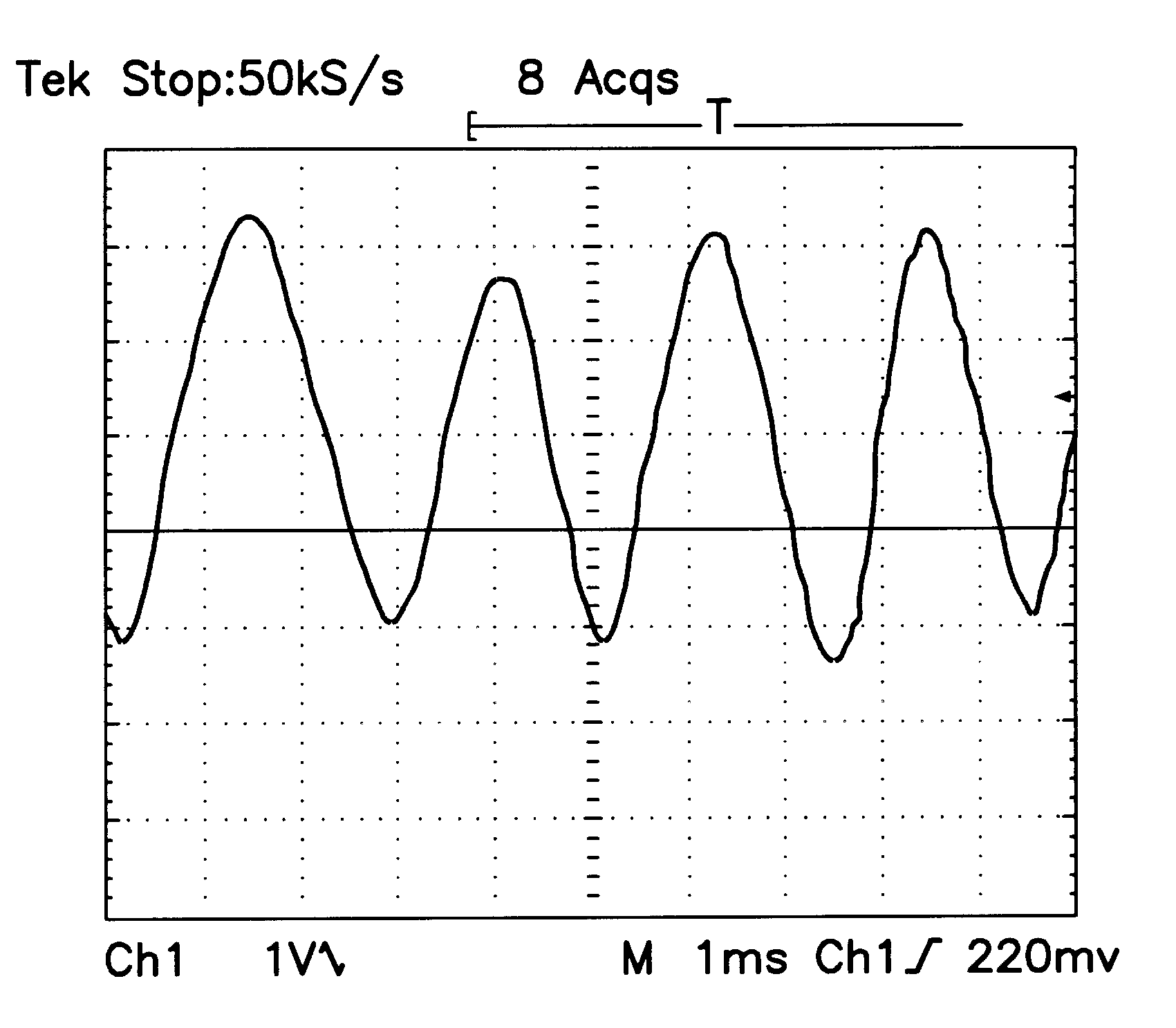

Low-noise, high-speed, high precision and high-thrust flux reversal motor for linear or rotary motion system

ActiveUS7928612B2Reduce manufacturing costEnhanced magnetizationMagnetic circuitMaster clocksLow noiseElectric machine

Owner:KOREA ELECTROTECH RES INST

Electrodeposition process of a cobalt-chromium film on aluminum alloys for magnetic recording

InactiveUS6187461B1Enhanced magnetizationClear signalBase layers for recording layersMagnetic layer production by platingPhosphateMagnetization

A cobalt-chromium (Co-Cr) magnetic film electrodeposited on the surface of an aluminum alloy. A process for making an aluminum alloy electrodeposited a cobalt-chromium (Co-Cr) magnetic film comprises the steps of chemically polishing an aluminum alloy substrate, pretreating either with phosphate or with zincate and electrodepositing in a plating bath containing cobalt and chromium ions to prepare the cobalt-chromium thin film on the aluminum alloy. Chromium content in the film can be designed by adjusting the parameters of pretreatment and electroplating. The produced cobalt-chromium film can flexibly adjust the magnetic characteristics (e.g. coercive force (Hc) and ramanence magnetization (Mr)) and is suitable for use in a magnetic recorder. The chemical composition, adhesion, microhardness, magnetic properties of the deposits indicate that the Co-Cr films produced are satisfactory for magnetic recording service.

Owner:NAT SCI COUNCIL

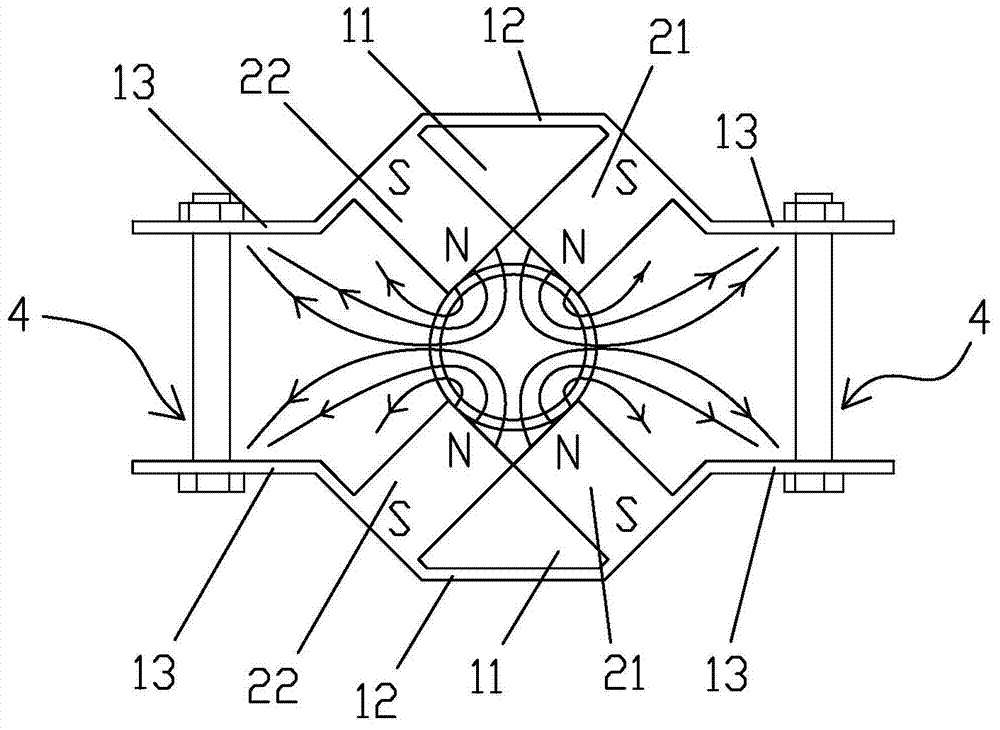

Fluid magnetizer

InactiveCN104752017AImprove the magnetization effectReduce magnetic energy lossMagnetic bodiesWater/sewage treatment by magnetic/electric fieldsMagnetPhysics

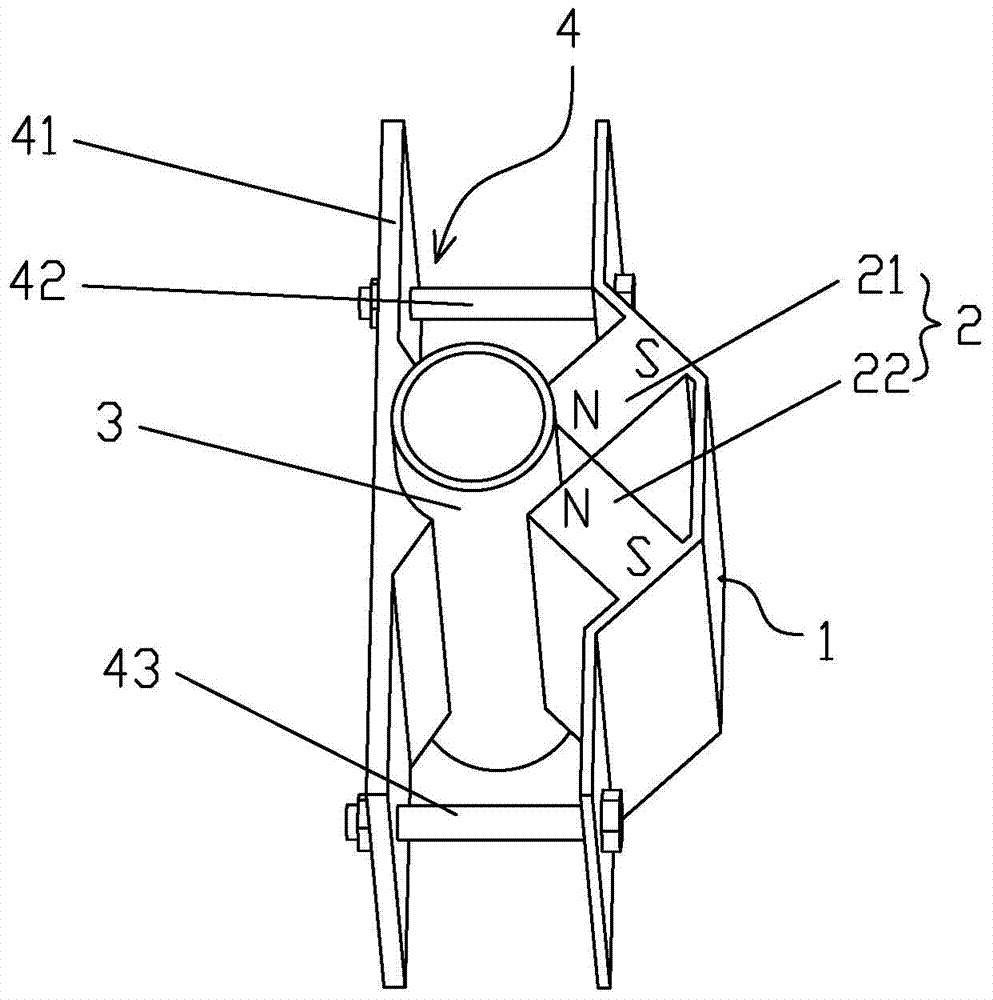

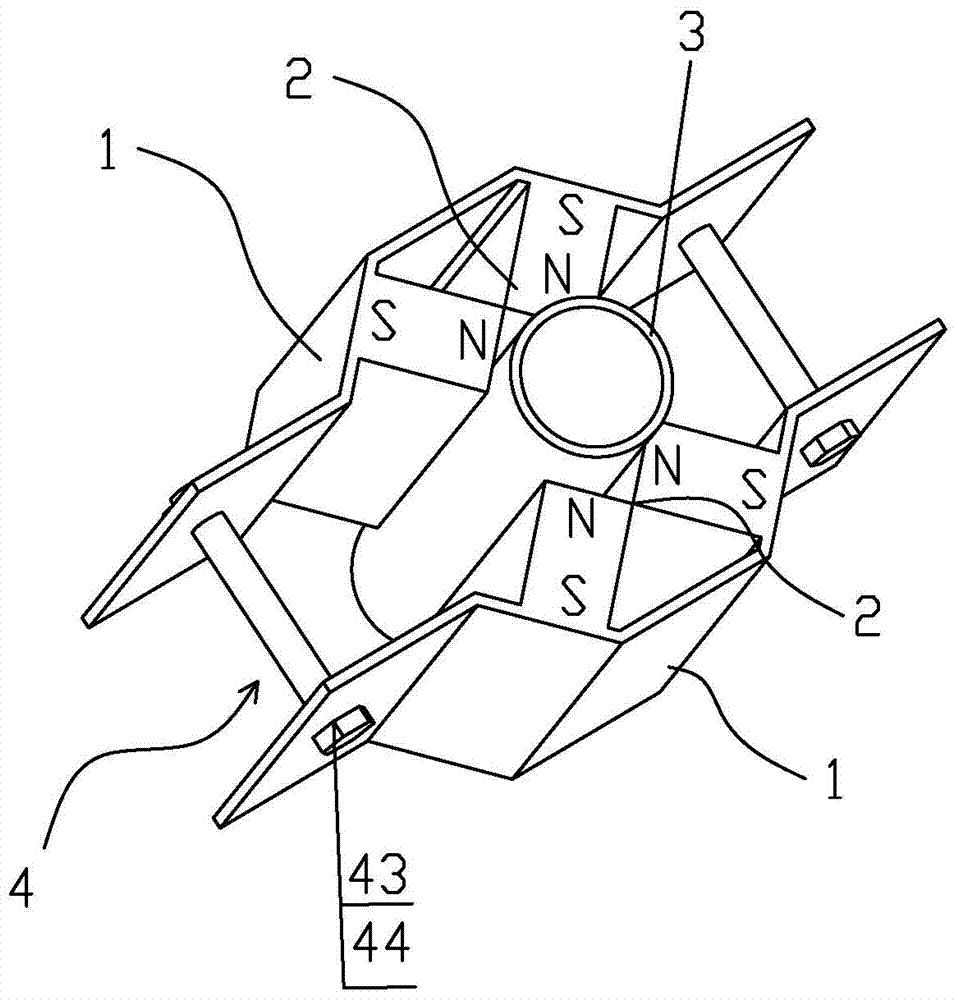

The invention discloses a fluid magnetizer which comprises a supporting frame and a mounting device. At least one permanent magnet group is arranged on the supporting frame and comprises a first permanent magnet and a second permanent magnet which are mutually inclined, one end of each first permanent magnet and one end of each second permanent magnet are respectively connected with the supporting frame, the other end of the first permanent magnet and the other end of the second permanent magnet are abutted to a fluid pipeline, the polarity of one connecting end of each first permanent magnet and the supporting frame is as same as that of each second permanent magnet and the supporting frame, the distances of the first permanent magnets and the second permanent magnets close to the supporting frame are larger than those of the first permanent magnets and the second permanent magnets far away from the supporting frame, and the fluid magnetizer is mounted on the fluid pipeline through the mounting device. The fluid magnetizer is simple in structure, low in cost and fine in fluid magnetizing effect.

Owner:余任文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com