Preparation method for rare earth permanent ferrite magnetic shoe and product

A permanent magnet ferrite, magnetic tile technology, applied in the direction of magnetic circuit, manufacture of motor generators, electrical components, etc., can solve the problems of uneven particle size, poor magnetic performance, affecting the quality of magnetic tiles, etc., to improve the degree of magnetic orientation, The effect of improving the magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

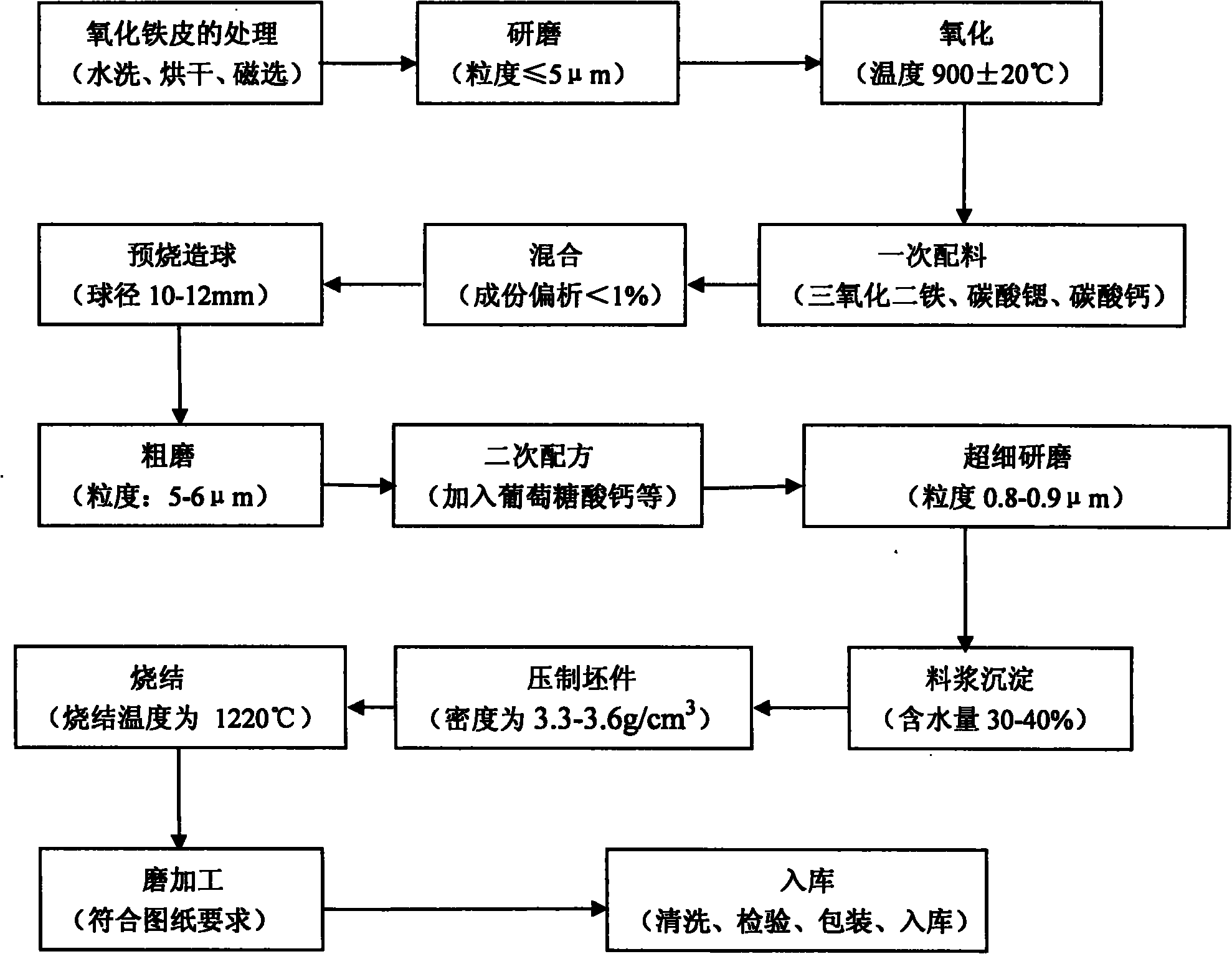

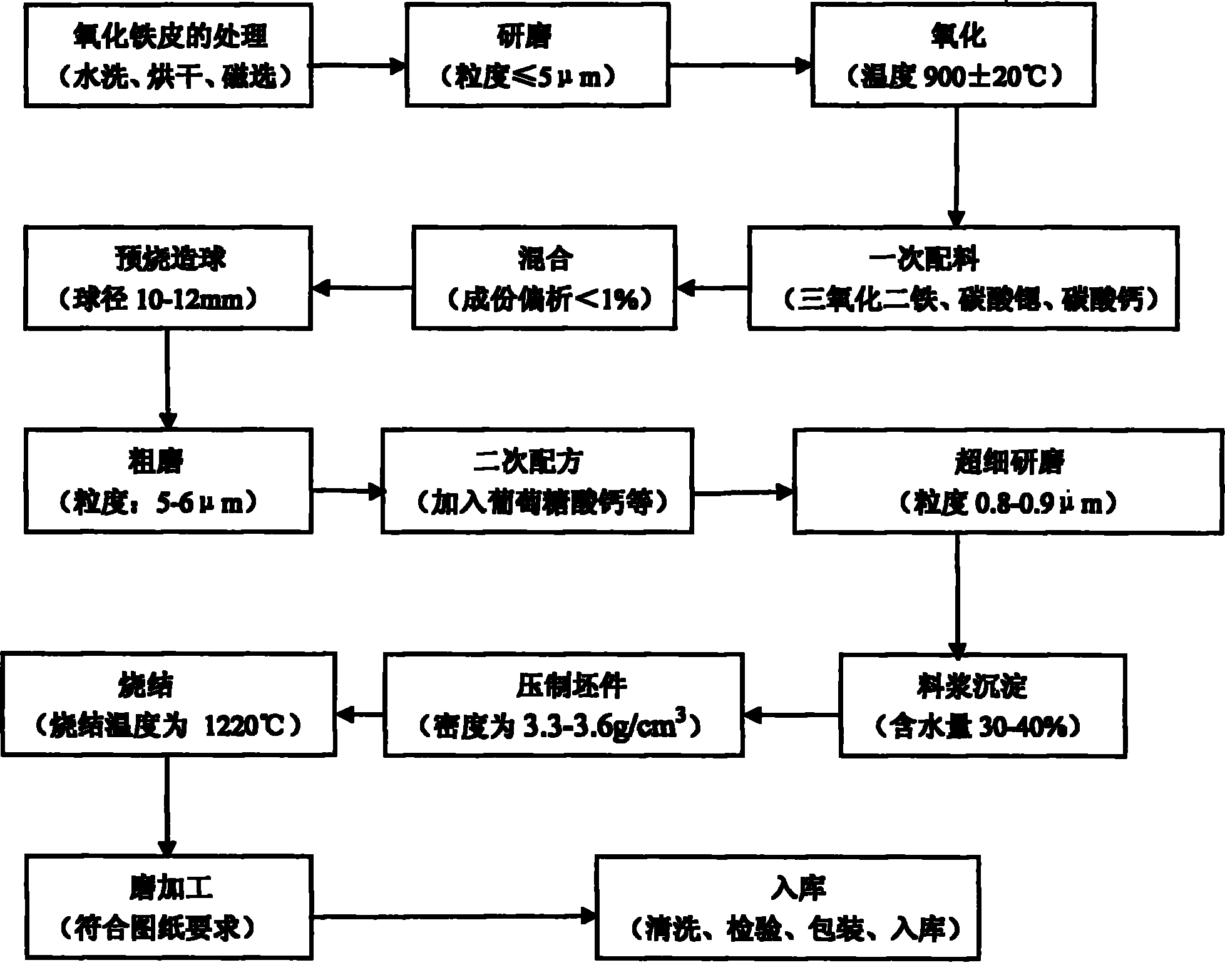

[0023] The preparation method of the present invention is specifically described below:

[0024] (1) Treatment of iron oxide scale: After the iron oxide scale is washed with water, it is dried in a rotary drying furnace, and the sundries are removed by magnetic separation:

[0025] (2) Grinding: Grind the treated iron oxide scale into iron oxide powder in a ball mill, the particle size of which is ≤5 μm; the ball mill is equipped with φ50mm, φ40mm, φ30mm steel balls, and the weight percentage is 3:5:3.

[0026] (3) Oxidation: Put the iron oxide powder into the externally heated rotary kiln for heating and oxidation. The content of iron is less than 0.2%;

[0027] (4) Primary ingredients: mix and stir ferric oxide, strontium carbonate and calcium carbonate, the mass percentages of which are 84.96-85.56%, 14.2-14.8%, 0.22-0.26%;

[0028] (5) Mixing: Put the mixed material into a ball mill for ball milling, so that it is evenly mixed, and the component segregation is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com