Process for manufacturing aluminum foil pseudo metal texture transition paper

A metal texture and production process technology, applied in paper/cardboard layered products, paper, papermaking, etc., can solve problems such as losses in the cigarette industry, and achieve the effect of good visual effect and strong metal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

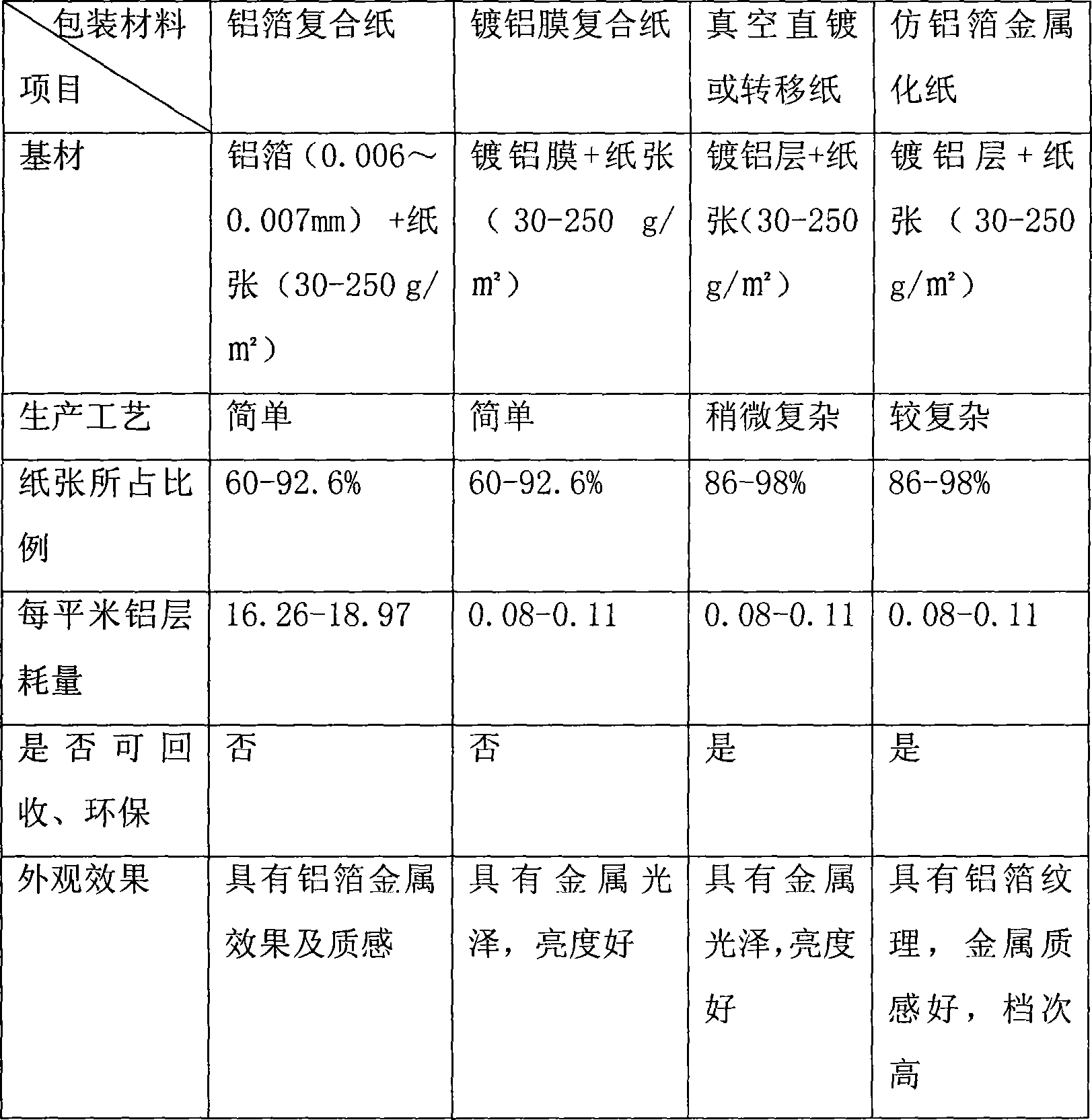

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A production process for imitating aluminum foil metallic texture transfer paper, which is carried out in the following steps in sequence:

[0048] ① Apply oil-based transfer coating on either side of the non-corona 22μm BOPP film, and the dry weight of the coating is 1g / m 2

[0049] ②Make steel rolls on the molding machine according to the roll diameter size required by the equipment, polish the roll blank, copper-plated and chrome-plated, and then polish it into a metal effect on the aluminum foil surface, with a surface brightness of 20. Use a roll on the molding machine to coat the transfer paint BOPP film for molding;

[0050] ③The molded BOPP film is vacuum-coated in a winding-type vacuum aluminum coating machine, and the thickness of the coating is 300 angstroms.

[0051] ④ Combine the coated, molded and aluminized BOPP film with 30g / m 2 The paper is wet compounded with water-based glue;

[0052] ⑤ Place the compounded film in an environment with a temperatur...

Embodiment 2

[0055] A production process for imitating aluminum foil metallic texture transfer paper, which is carried out in the following steps in sequence:

[0056] ①Double-coat water-based transfer coating on either side of the non-corona 25μm BOPP film, and the dry weight of coating is 1.5g / m 2

[0057] ②Make steel rolls on the molding machine according to the roll diameter size required by the equipment, polish the roll blank, copper-plated and chrome-plated, and then polish it into an aluminum foil surface effect with a surface brightness of 35. BOPP film for molding;

[0058] ③The molded BOPP film is vacuum-coated in a winding-type vacuum aluminum coating machine, and the thickness of the coating is 350 angstroms.

[0059] ④ Combine the BOPP film after coating, molding and aluminizing with 100g / m 2 The paper is wet compounded with water-based glue;

[0060] ⑤ Place the compounded film in an environment with a temperature of 40°C and a humidity of 45% for 35 hours for curing;

...

Embodiment 3

[0063] A production process for imitating aluminum foil metallic texture transfer paper, which is carried out in the following steps in sequence:

[0064] ①Single-coat water-based transfer coating on either side of the 15μm non-corona BOPET film, and the dry weight of the coating is 2g / m 2

[0065] ②Make steel rolls on the molding machine according to the roll diameter size required by the equipment, polish the roll blank, copper-plate and chrome-plate it, and then polish it into an aluminum foil surface effect with a surface brightness of 45. BOPET film for molding;

[0066] ③ After molding, the BOPET film is vacuum-coated in a winding-type vacuum aluminum coating machine, and the thickness of the coating is 400 angstroms.

[0067] ④ Combine the coated, molded and aluminum-plated BOPET film with 250g / m 2 The paper is wet compounded with water-based glue;

[0068] ⑤ Place the compounded film in an environment with a temperature of 55°C and a humidity of 60% for 48 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com