Preparation method of composite membrane, back cover and electronic equipment

A composite membrane and membrane technology, applied in the field of production and manufacturing, can solve the problems of poor quality and performance of membranes, and achieve the effect of ensuring quality performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

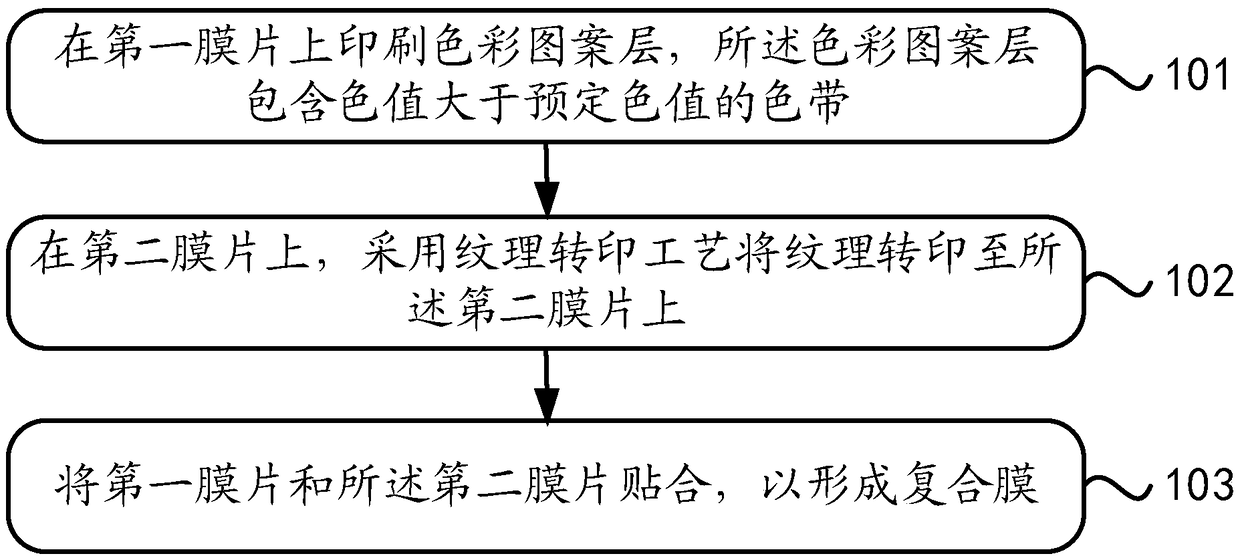

[0019] figure 1 The flow chart of the preparation method of the composite membrane provided for the embodiment of the present invention, as figure 1 As shown, the method may include:

[0020] Step 101 , printing a color pattern layer on the first film, the color pattern layer including a color band with a color value greater than a predetermined color value.

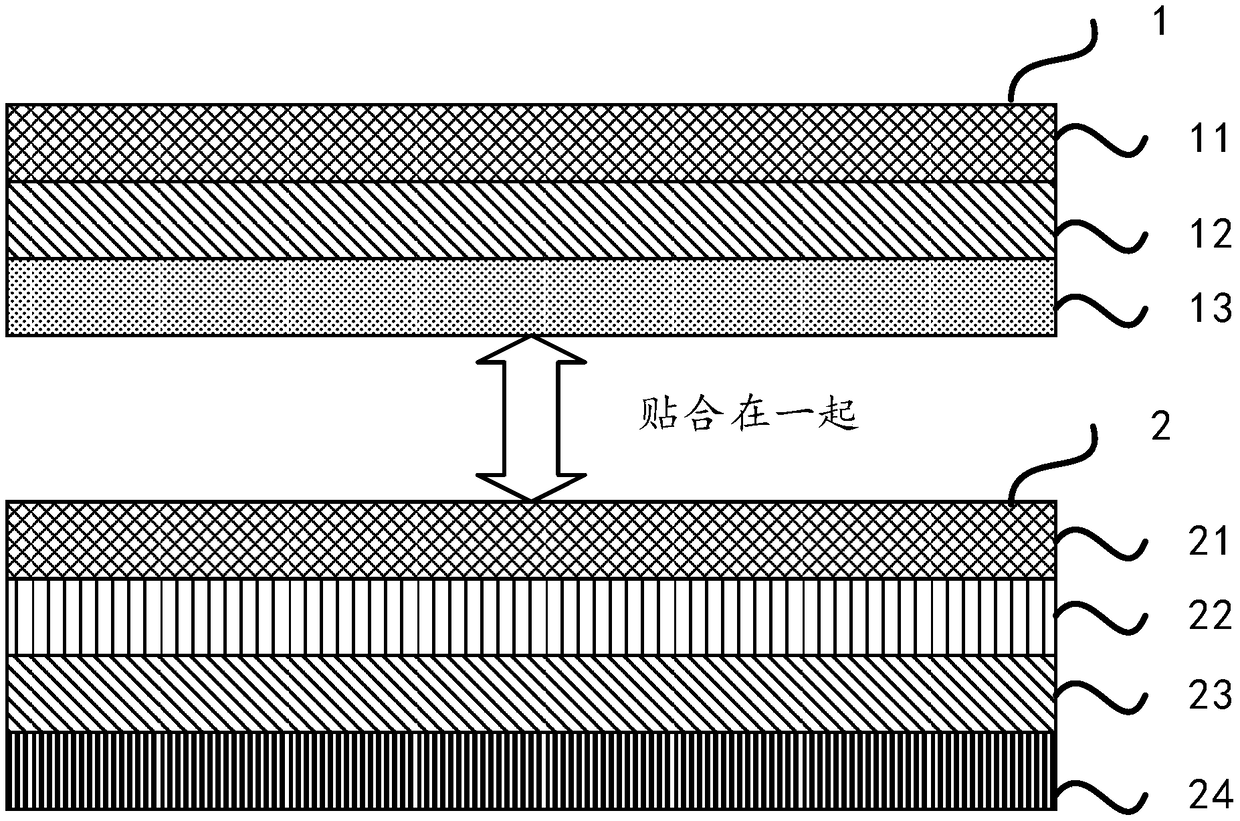

[0021] combine figure 2 As shown, the base film 11 of the first die sheet can be polyethylene terephthalate (Polyethyleneterephthalate, PET), and its chemical formula is COC 6 h 4 COOCH 2 CH 2 O.

[0022] The color pattern layer 12 can be a solid color pattern or a colored pattern.

[0023] The predetermined color value may refer to a color value capable of forming a critically dark color. Correspondingly, the color band whose color value is greater than the predetermined color value may refer to a darker color band.

[0024] The color pattern layer contains a color band with a color value greater than a predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com