Method for producing highly-textured, strip-shaped, high-temperature superconductors

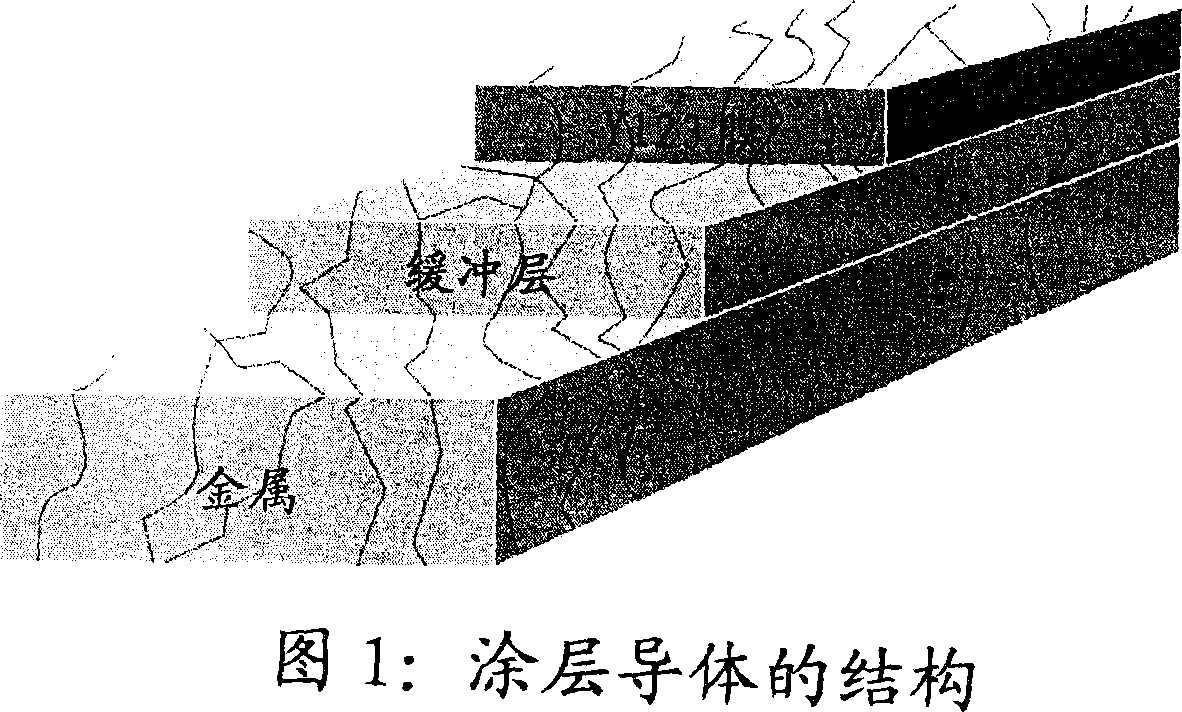

A strip-shaped, metal-based technology, applied in the field of manufacturing high-textured strip-shaped high-temperature superconductors, can solve problems such as limiting the choice of metal substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] On a textured metal tape, La was applied in a reproducible experiment 2 Z r2 o 7 (LZO) as a buffer layer. The metal strip is a pure nickel strip. By adding a proportion of tungsten alloy components up to 8%, the tensile strength of the strip can be increased without affecting the coating results in this example. Other alloys such as Ni-0.1%Mn may also be used without affecting the results of this example. In comparative experiments, different coating solvents were used, the first solution corresponding to the prior art and the second solution according to the invention.

[0044] Both coating solutions are based on (2,4) lanthanum(III) glutarate and (2,4) zirconium(IV) glutarate (acetylacetonate) ((2,4) lanthanum(III) glutarate , La[CH 3 COCHCOCH 3 ] 3 · x H 2 O: Alfa Aesar, 99.9% (REO), powder, melting point: 14.3°C; (2,4) zirconium glutarate, Zr[CH 3 COCHCOCH 3 ] 4 ; Strem Chemical, > 98%, crystalline). According to buffer stoichiometry (Pufferstchiometri...

example 2

[0050] On textured metal tapes (Ni-5%W) the same reproducible application of Y by the CSD method 2 o 3 . In the comparative tests, different coating solutions were used as in Example 1. Solution 1 corresponds to the prior art, while the second solution is according to the invention.

[0051] In all experiments, 2,4-glutaric acid Y(III) (yttrium(III) acetylacetonate, Y(CH 3 COCHCOCH 3 ) 3 · x H 2 O; Alfa Aesar, 99.9%, powder) as raw material. Previous precursor solutions were prepared according to the prior art by using 2-methoxyethanol (CH 3 OCH 2 CH 2 OH): Merck, for analysis, ACS, 99.3%, melting point: -85°C, boiling point: 124-125°C, flash point: 46°C) or acetylacetone (2, 4-pentanedione, CH 3 COCH 2 COCH 3 : Merck, ≥99.5%, melting point: -23°C, boiling point: 140°C, flash point: 34°C), methanol (CH 3 OH: Merck, for analysis, ACS, ISO, ≥99.8%, melting point: -98°C, boiling point: 64.5°C, flash point: 11°C) and isobutylamine (1-amino-2-methylpropane, (CH 3 ) 2...

example 3

[0058] On textured metal strips (Ni-5%W), La 2 Zr 2 o 7 (LZO) as a buffer layer.

[0059] The coating solution is based on (2,4) lanthanum(III) glutarate and (2,4) zirconium(IV) glutarate (acetylacetonate) ((2,4) lanthanum(III) glutarate, La[ CH 3 COCHCOCH 3 ] 3 · x H 2 O: Alfa Aesar, 99.9% (REO), powder, melting point: 14.3°C; (2,4) zirconium (IV) glutarate, Zr[CH 3 COCHCOCH 3 ] 4 ; Strem Chemical, > 98%, crystalline). According to buffer stoichiometry, for La 2 Zr 2 o 7 Both solutions were adjusted to a concentration of 0.1M. In order to precisely adjust the metal content, the raw material is characterized by means of ICP-OES (Inductively Coupled Plasma-Atomic Emission Spectroscopy). As a solvent for the solution, propionic acid (propionic acid, CH 3 CH 2 COOH: Merck, ≥99%, melting point: -21°C, boiling point: 141°C, flash point: 50°C).

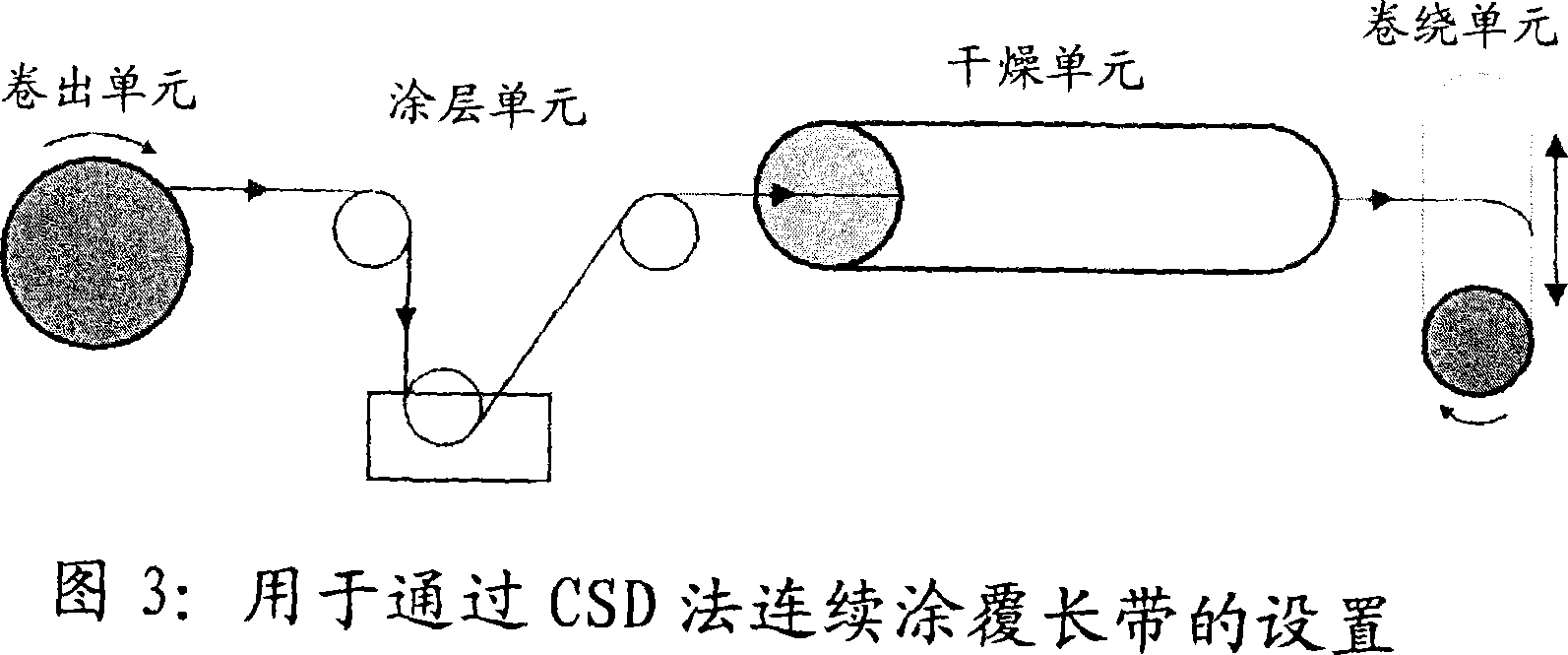

[0060] coated on a 5 x 0.1mm 2 The cross-section and the length of 50m are carried out in a continuous coating device. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com