Apparatus for performing texture transfer printing on camera protection glass, and texture transfer printing method

A technology for protecting glass and texture transfer, which is applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc. It can solve problems such as unclear textures, inability to meet customer personalization, and weak three-dimensional textures. The process parameters are easy to control, convenient for large-scale production, and the effect of low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A device for texture transfer printing of camera protection glass, which processes camera protection glass with a thickness of 0.27mm, specifically includes the following components:

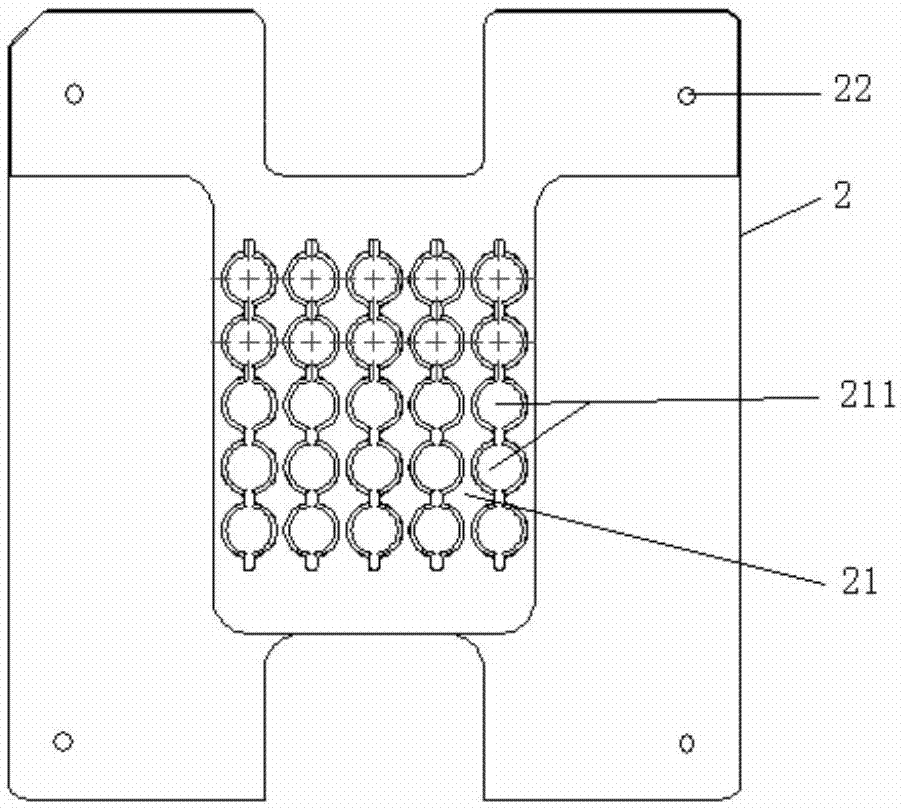

[0064] A brushed film base 2 (see image 3 ), the upper surface of the brushed film base 2 is provided with a positioning area 21 and 4 positioning pins 22, and 25 positioning grooves 211 are evenly distributed in the positioning area 21.

[0065] A drawing positioning film, the drawing positioning film includes a body and positioning through holes arranged on the body and matched with the 4 positioning pins on the drawing film base, the body includes a front side and a back side provided with a release film.

[0066] A set of drawing dies, including the base and die 3 (see Figure 4 ), the base is provided with 4 positioning columns and a working area arranged on its upper surface, the mold includes a back surface, a bonding surface that is provided with 25 transfer areas 31 and matches...

Embodiment 2- Embodiment 5

[0089] Embodiment 2-embodiment 5 differs from embodiment 1 only in Table 1, and others are the same as embodiment 1.

[0090] Table 1 The parameter comparison table of embodiment 1 and embodiment 2-5

[0091]

[0092] See Table 2 for the performance parameters of the textured camera cover glass obtained in Example 1-Example 5 and Comparative Example.

[0093] Table 2 Comparison table of the performance of the camera cover glass with texture obtained in the comparative example and the present example 1-embodiment 5

[0094] case\parameter

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com