Intelligent multi-work-section hook face polishing machine

A polishing machine and work section technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of reducing processing efficiency, affecting production efficiency, increasing workbench, etc., to improve work efficiency, improve Workpiece processing efficiency, the effect of increasing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

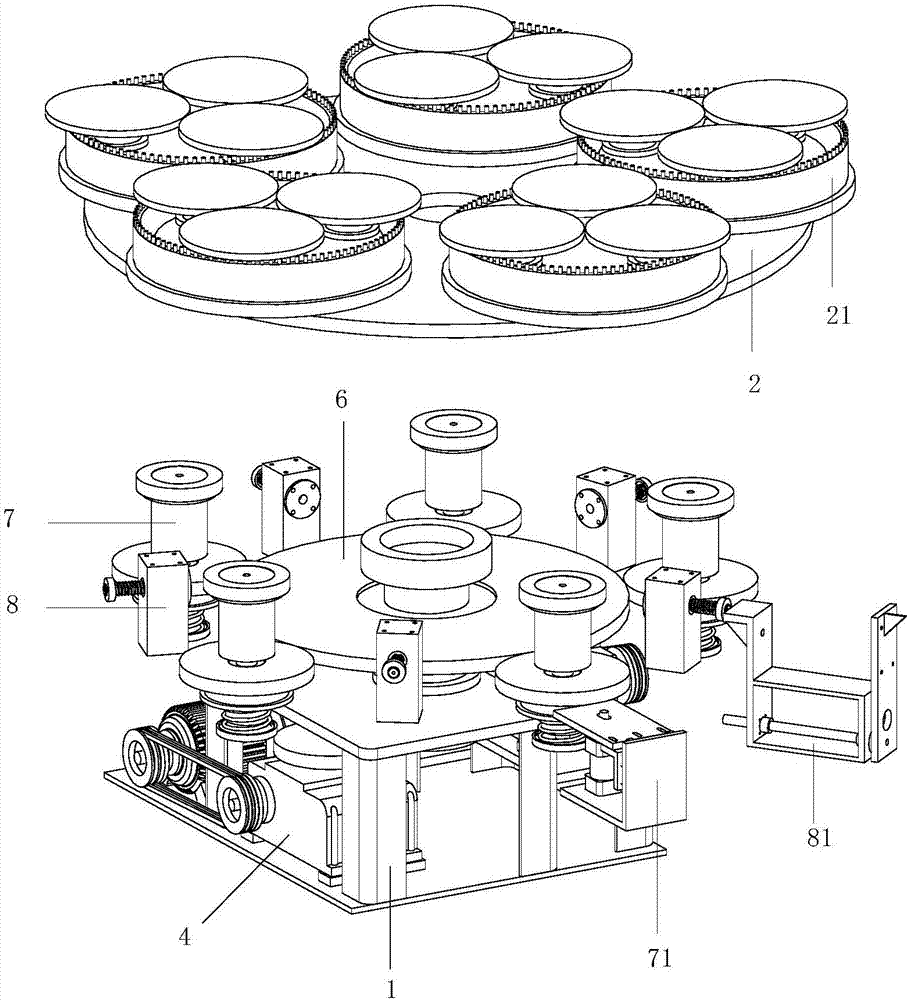

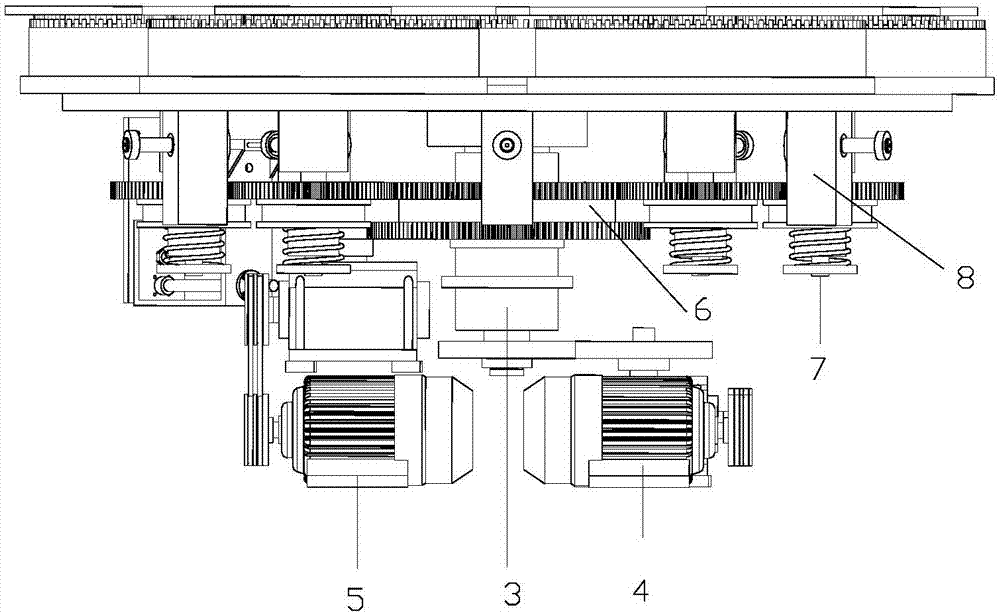

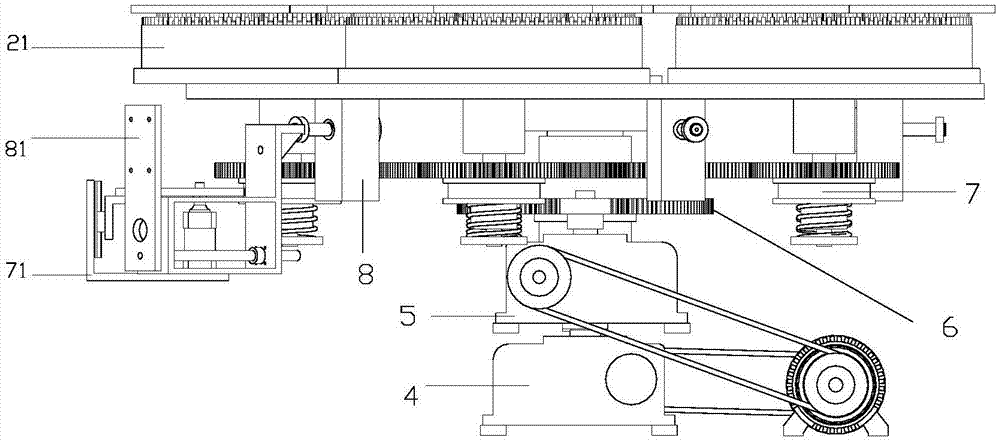

[0043] refer to Figure 1 to Figure 3 As shown, the present invention provides an intelligent multi-segment curved surface polishing machine, including: a support 1 and a working disc 2 arranged on the support 1, a first transmission assembly, a second transmission assembly and several rotation control stop devices 71; A transmission assembly is arranged at the bottom of the work disk 2 , and after the first transmission assembly is activated, the first transmission assembly drives the work disk 2 to rotate around the axis of the work disk 2 . The upper surface of the working disk 2 is provided with several rotation assemblies 21 around, and the second transmission assembly passes through the second transmission assembly connected between the work disk 2 and the rotation assembly 21. After starting the second transmission assembly, the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com