Liquid crystal display panel

A technology for liquid crystal display panels and display areas, which is applied in nonlinear optics, instruments, optics, etc., and can solve the problems that liquid crystal molecules cannot be fully filled, the yield and quality of the display panel 10 decrease, and the diffusion of liquid crystal molecules slows down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Relevant technical content and detailed description of the present invention, now cooperate accompanying drawing to explain as follows:

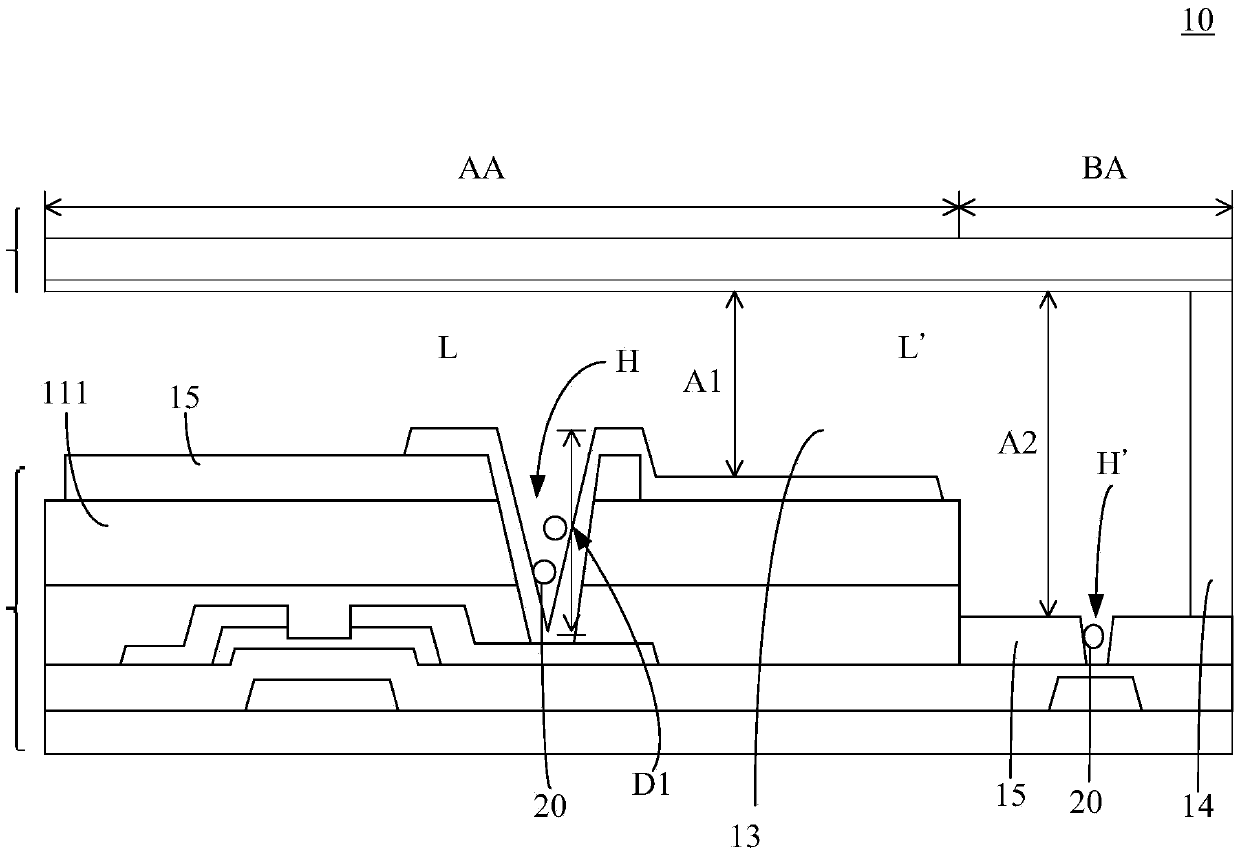

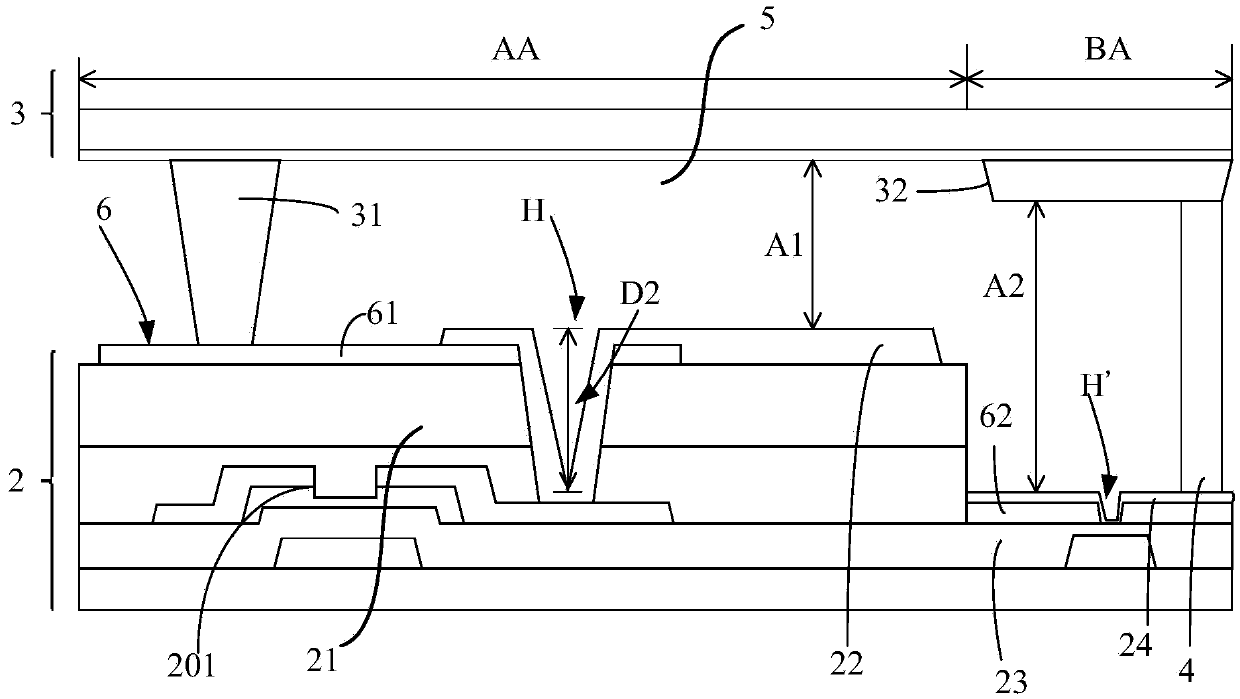

[0020] see figure 2 , which is a schematic structural diagram of a liquid crystal display panel in a preferred embodiment. The present invention provides a liquid crystal display panel 1, which belongs to a BOA (Blackmatrix on Array, BOA) type liquid crystal display panel, that is, the color photoresist layer and the black matrix are both Technology fabricated on thin film transistor array substrates. The liquid crystal display panel 1 includes: an array substrate 2 configured with a display area AA and a non-display area BA surrounding the display area AA; an opposing substrate 3 disposed above the array substrate 2; a sealant 4 disposed on the Between the array substrate 2 and the opposite substrate 3, the sealant ring 4 is wound around the non-display area BA; the liquid crystal layer 5 is arranged between the array substrate 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com