Vertically structured LED chip preparation method

A LED chip and vertical structure technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex vertical chip process, chip appearance deformation, gallium nitride material corrosion and other problems, so as to reduce the risk of unintentional conduction Possibility, improvement of product comprehensive yield, and effect of shortening etching process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

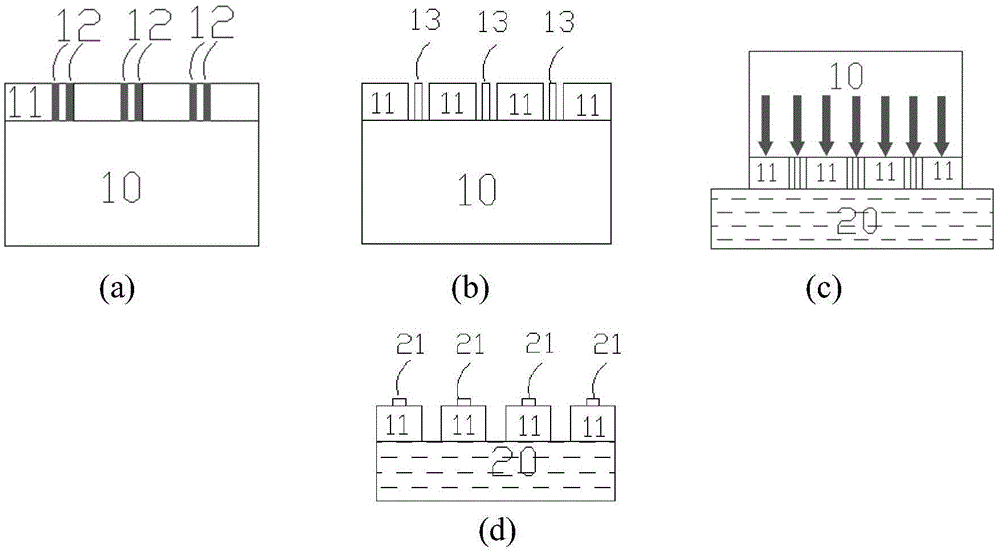

[0023] A kind of vertical structure LED chip preparation method of the present invention, comprises the following steps:

[0024] 1) Obtain an LED epitaxial layer 11 with an LED structure by using an epitaxial growth method on the heterogeneous substrate 10; wherein, the heterogeneous substrate 10 is made of sapphire, silicon or silicon carbide; the LED epitaxial layer 11 is made of GaN, AlN, Made of InGaN, AlGaN or AlInGaN materials.

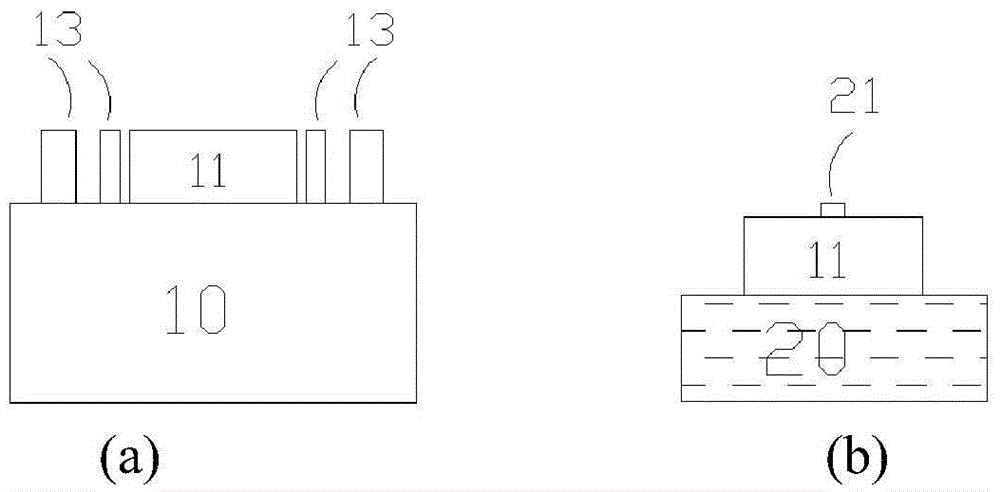

[0025] 2) On the upper surface of the LED epitaxial layer 11, a plurality of staggered grooves 12 are processed by laser to form a columnar surrounding gallium nitride high-pressure gas release sacrificial region 13; wherein, the number of the multi-channel staggered grooves is greater than or equal to 2, using Non-positioning blind scribing or positioning scribing based on the flat edge of the wafer, its surrounding shape is a regular or irregular vertical chip graphic outline according to the design requirements, the multiple staggered groove...

Embodiment 1

[0031](1) Firstly, the epitaxial material layer 11 of the gallium nitride system LED is prepared on the heterogeneous substrate 11 by epitaxial method. , multiple quantum well MQW, electron blocking layer EBL, heavily doped P-GaN, its thickness is controlled at 5-6 microns, the heterogeneous substrate includes but not limited to sapphire, silicon, silicon carbide, or various types of high temperature resistant and A support substrate with a transition layer that matches the lattice of the III-N material, the preferred solution is a sapphire substrate, and the epitaxial layer includes the LED epitaxial structure composed of GaN / AlN / InGaN / AlGaN / AlInGaN and other material systems One or more, the preferred solution is GaN / InGaN;

[0032] (2) On the epitaxial layer 11 of the LED wafer, a layer of silicon oxide or silicon nitride material protective layer is prepared by PECVD, and grooves are processed on the gallium nitride surface by using an equal-spaced laser scribing method, a...

Embodiment 2

[0037] The general process is the same as in Example 1, the difference is that when laser scribing is performed to prepare the columnar high-pressure gas surrounding GaN to release the sacrificial region, multiple channels of laser processing with unequal spacing are used to form multi-layer high-pressure gas surrounding GaN columnarly with unequal spacing. Release the sacrificial area, the number of layers is greater than or equal to 2, using the unequal spacing area, effectively relieve the high-pressure gas impact at the moment of stripping, and provide more contact interfaces for high-temperature wet etching, and at the same time, the edge of the outermost scribe line in the columnar area The distance from the edge of the effective area of the adjacent vertical chip is not less than ten microns, and then the chip manufacturing process is the same as that of Embodiment 1, and finally the vertical structure LED chip preparation is completed.

[0038] The invention adopts hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com