UV crosslinking and curing acrylic ester-modified EVA optical adhesive film and preparation method thereof

An acrylate, cross-linking and curing technology, applied in adhesives, film/sheet adhesives, non-polymer organic compound adhesives, etc., can solve the problem of no obvious improvement in water vapor barrier properties, thermal stability and weather resistance Insufficient thermal stability, easy thermal expansion and contraction, etc., to achieve excellent light transmission, reduce lamination failure rate and production cost, and strong shock and explosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

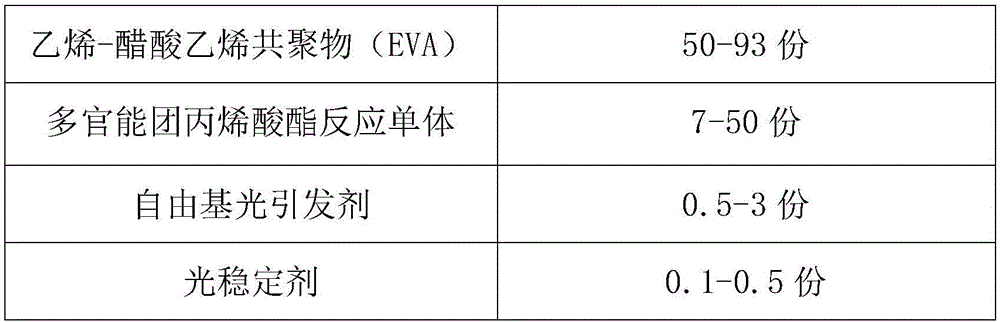

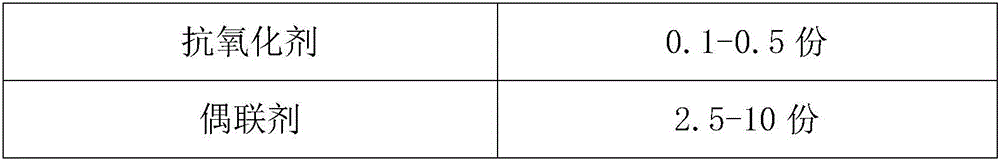

Method used

Image

Examples

Embodiment 1

[0029] According to the proportion of parts by weight, 93 parts of EVA with 28% VA content and MI of 5 and 7 parts of trimethylolpropane trimethacrylate, a multifunctional acrylate reactive monomer, are immersed in a heatable sealed mixing device until complete Absorb and dry and mix uniformly to obtain a mixture; add 0.5 parts of free radical photoinitiator 1-hydroxycyclohexyl phenyl ketone, light stabilizer succinic acid and 4-hydroxy-2,2,6,6-tetramethyl 0.2 part of polymer of 1-piperidinol, 0.1 part of antioxidant diphenylisodecyl phosphite, β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid n-octadecyl 0.1 part of carbon alcohol ester, 2.5 parts of coupling agent 3-methacryloxypropyltrimethoxysilane, and mix them uniformly to obtain a mixture. Put the mixture into the casting machine at an extrusion temperature of 100°C. After casting, cooling, pulling, and winding, at the same time, a layer of PE and PET protective film is attached to the front and back of the extrudate i...

Embodiment 2

[0031] Place 86 parts of EVA with 33% VA content and MI of 1 and 14 parts of trimethylolpropane trimethacrylate, a multifunctional acrylate reactive monomer, in a heatable sealed mixing device according to parts by weight. Absorb dry and mix uniformly to obtain a mixture; add 1 part of free radical photoinitiator 1-hydroxycyclohexyl phenyl ketone, light stabilizer succinic acid and 4-hydroxy-2,2,6,6-tetramethyl 0.3 parts of polymer of 1-piperidinol, 0.15 parts of antioxidant diphenylisodecyl phosphite, β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid n-octadecyl Carbon alcohol ester 0.15 parts, coupling agent 3-methacryloxypropyl trimethoxysilane 3 parts, and mixed uniformly to obtain a mixture, put the mixture into the casting machine, the extrusion temperature is 100 ℃, the extrudate After casting, cooling, pulling, and winding, at the same time, a layer of PE and PET protective film is attached to the front and back of the extrudate in the casting section. After casting, ...

Embodiment 3

[0033] According to the proportion of parts by weight, 72 parts of EVA with 41% VA content and MI of 2 and 28 parts of trimethylolpropane trimethacrylate, a multifunctional acrylate reactive monomer, are immersed in a heatable sealed mixing device until complete Absorb and dry and mix uniformly to obtain a mixture; add 2 parts of free radical photoinitiator 1-hydroxycyclohexyl phenyl ketone, light stabilizer succinic acid and 4-hydroxy-2,2,6,6-tetramethyl 0.4 parts of polymer of 1-piperidinol, 0.2 parts of antioxidant diphenyl isodecyl phosphite, β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid n-octadecyl Carbon alcohol ester 0.2 parts, coupling agent 3-methacryloxypropyl trimethoxysilane 6 parts, and mixed uniformly to obtain the mixture, put the mixture into the casting machine, the extrusion temperature is 100 ℃, the extrudate After casting, cooling, pulling, and winding, at the same time, a layer of PE and PET protective film is attached to the front and back of the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com