Patents

Literature

61results about How to "Excellent scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing room-temperature self-crosslinking water-based polyurethane emulsion

ActiveCN101709108AImprove water resistanceImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsWater basedMechanical property

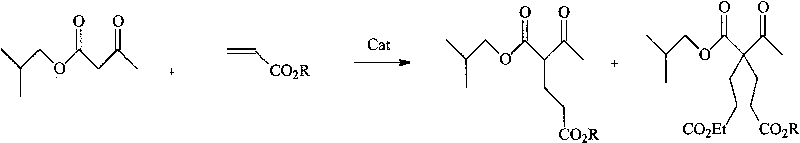

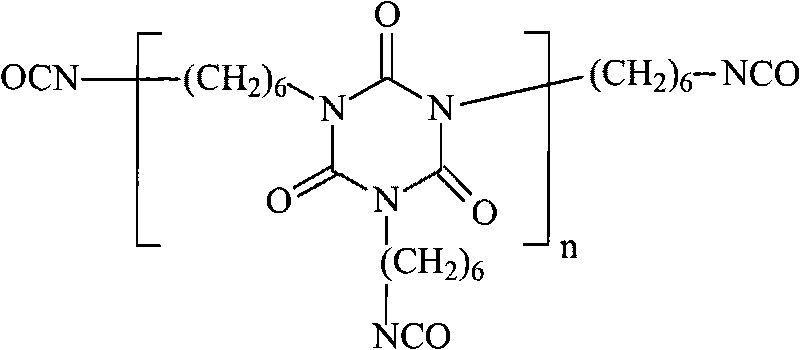

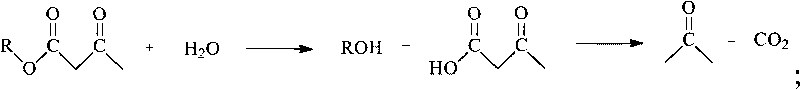

The invention discloses a method for preparing water-based polyurethane emulsion with a room-temperature self-crosslinking characteristic. The emulsion is prepared from the following raw materials in part by mass: 1) 100 parts of low-polymer diol, 2) 50 to 150 parts of polyisocyanate, 3) 8 to 28 parts of hydrophilic compound, 4) 5 to 50 parts of acetoacetyl compound, 5) 1 to 20 parts of micro-molecule dolichol compound, 6) 0.5 to 10 parts of polyamine compound, 7) 1 to 21 parts of ammonia or organic amine, selectively, 8) 0.01 to 0.1 parts of polyurethane reaction catalyst, and selectively, 9) 20 to 310 parts of organic solvent. After being formed into a film, the emulsion prepared by the method has excellent water resistance, acid and alkali resistance and chemical resistance, and also has the excellent physical and mechanical properties of high hardness, high elasticity, scratch resistance and the like.

Owner:WANHUA CHEM BEIJING +3

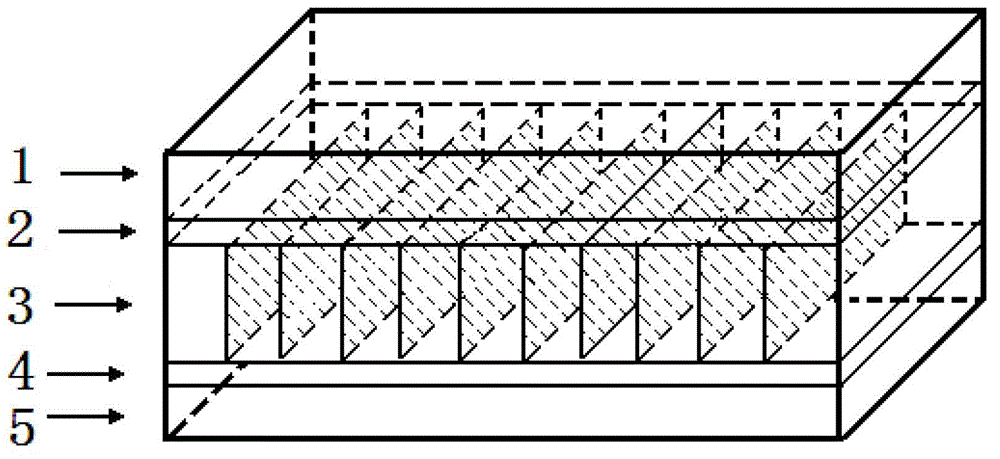

Nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film

ActiveCN102717549AExcellent scratch resistanceInnovative materials and treatmentsSynthetic resin layered productsFingerprintIn situ polymerization

The invention discloses a nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film, which comprises an organic silica gel layer, a peep-proof polarization film, a bonding agent layer, a PET (Polyester) film layer and an anti-glare fingerprint-resistant nano coating from inside to outside. The anti-glare fingerprint-resistant nano coating takes silicon-fluorine polymers as a substrate, and is prepared by forming a layer of silicon dioxide or calcium carbonate with nano microbumps on the surface of a PET film in a in-situ polymerization manner; the peep-proof polarization film comprises a plurality of strip-shaped photoresists that are arranged in parallel, the cross section of each strip-shaped photoresist is square, and a non-transparent interlayer is arranged on the strip-shaped photoresist; and the interval of the photoresist is half of the thickness of the photoresist. The surface hardness of the nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film is greater than 4H, and the fingerprint-resistant performance of the nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film obviously surpasses the commercial conventional merchandises; the peep-proof polarization film adopts photoresist solidification and non-transparent matter filling technologies, and has greater innovations in material and processing method; in addition, a PC (polycarbonate) film is replaced by the PET film with the effects of tough texture, good stiffness, high transparency and low price, so that the quality is ensured, and the cost is lowered at the same time.

Owner:SHANGHAI BENPU TECH DEV

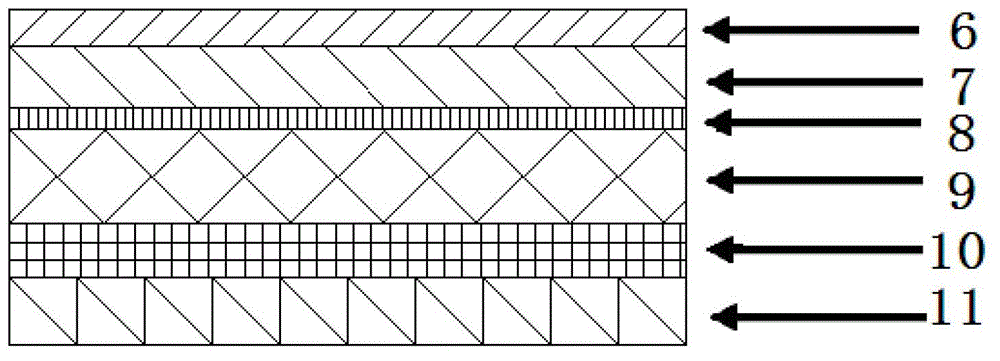

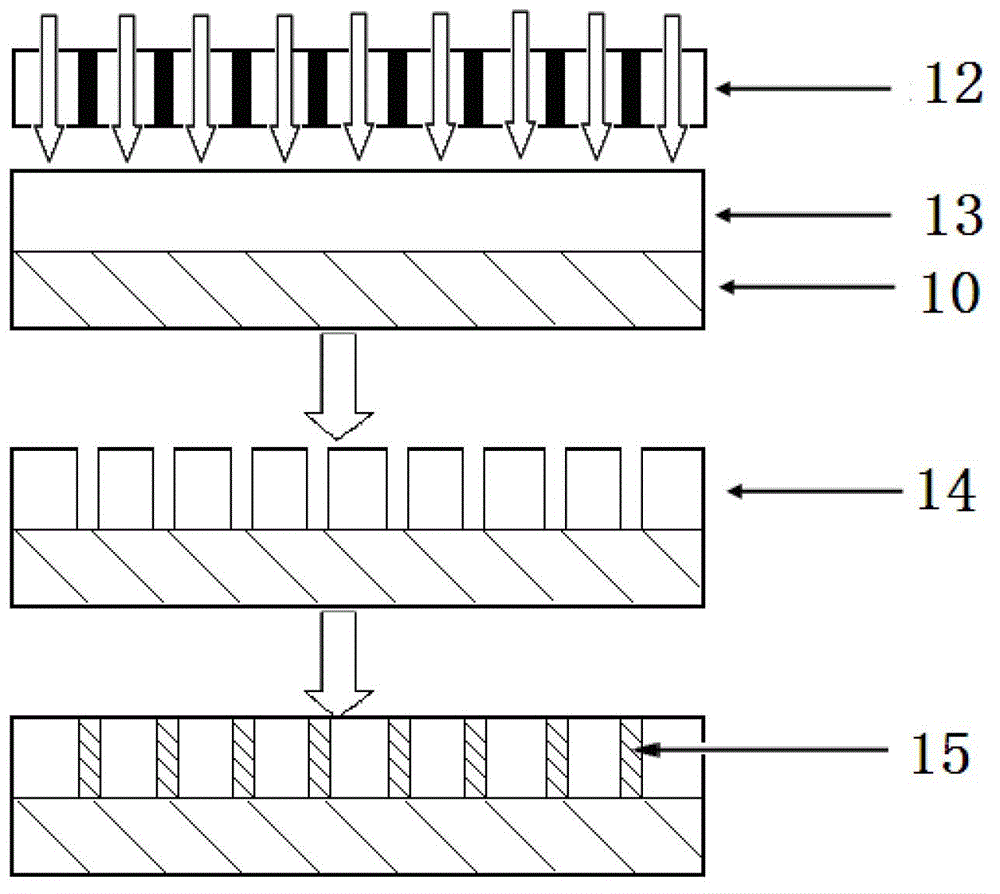

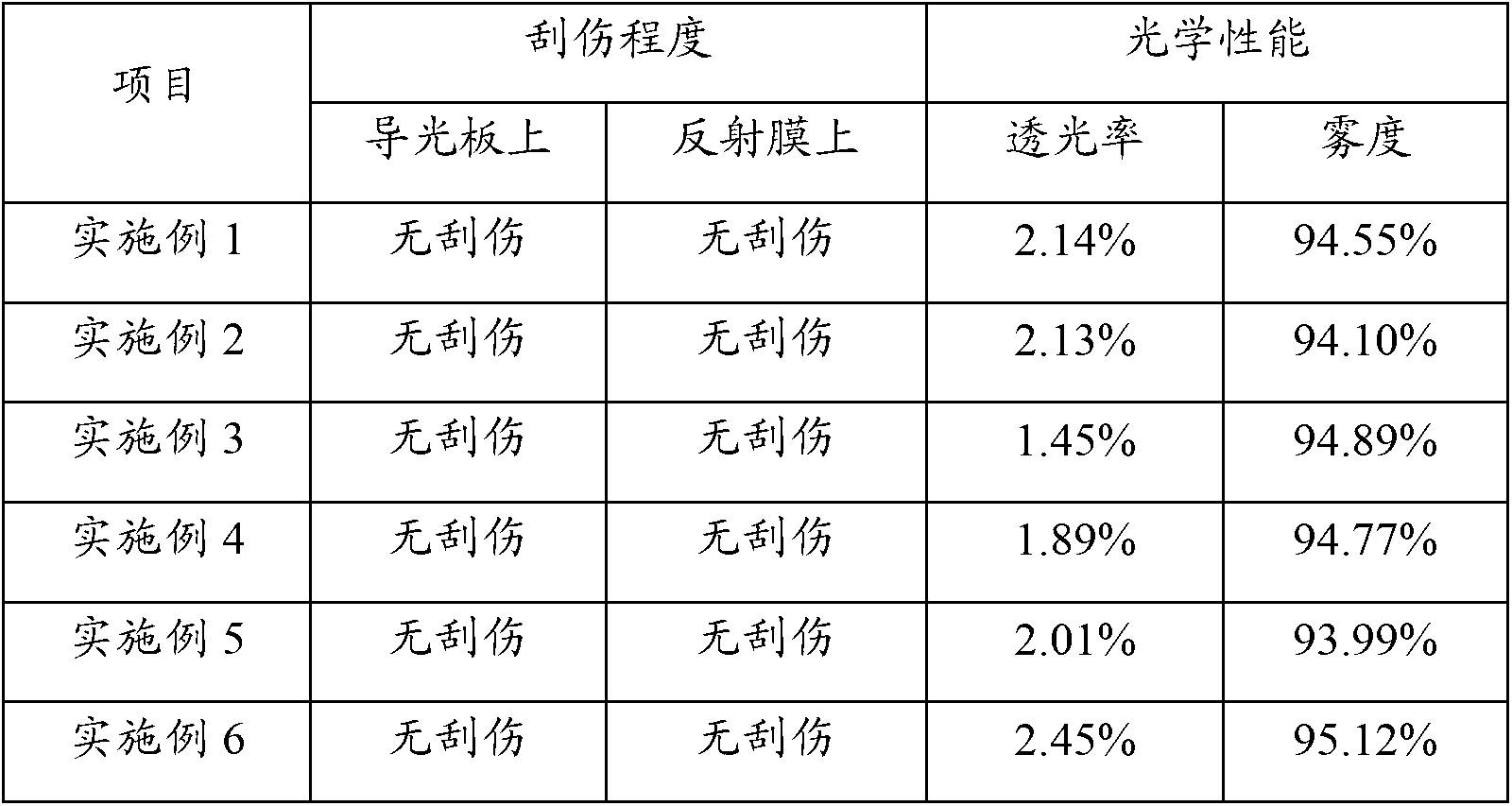

Anti-scratching optical reflecting film and manufacturing method of the same

ActiveCN103064139AReduce scratchesExcellent scratch resistanceMirrorsDiffusing elementsScratchingOptoelectronics

The invention relates to the technical field of optical thin films, in particular to an anti-scratching optical reflecting film and a manufacturing method of the same. The anti-scratching optical reflecting film and the manufacturing method of the same solve the problems that an existing reflecting film enables a light guide plate to be scratched easily or the reflecting film is creased or scratched easily. The reflecting film comprises a base material, wherein particles are arranged on the base material and are bonded on the base material through an adhesive layer, the particles comprise flexible particles and non-flexible particles, the flexible particles make up 40-100% of total weight of the particles, and the non-flexible particles make up 0-60% of the total weight of the particles. According to the anti-scratching optical reflecting film, scratching of the light guide plate is reduced obviously, and one side, in contact with the light guide plate, of the reflecting film is not creased or scratched easily. Furthermore, the anti-scratching optical reflecting film is simple in manufacturing method and technology, and easy to operate.

Owner:NINGBO EXCITON TECH

Polypropylene resin composition with anti-scratch characteristics

ActiveUS7208536B2Excellent scratch resistanceOther chemical processesSpecial tyresMasterbatchPolyolefin

The present invention provides a propylene resin composition having excellent anti-scratch characteristic. Specifically, provided is a polyolefin resin composition comprising a high crystalline polypropylene resin, a rubber component, an inorganic filler and an aluminosiloxane masterbatch, with excellent damage resistance such as anti-scratch characteristic thereby giving very low surface damage, excellent heat resistance, good rigidity and impact properties and injection moldability, for car interior or exterior parts.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

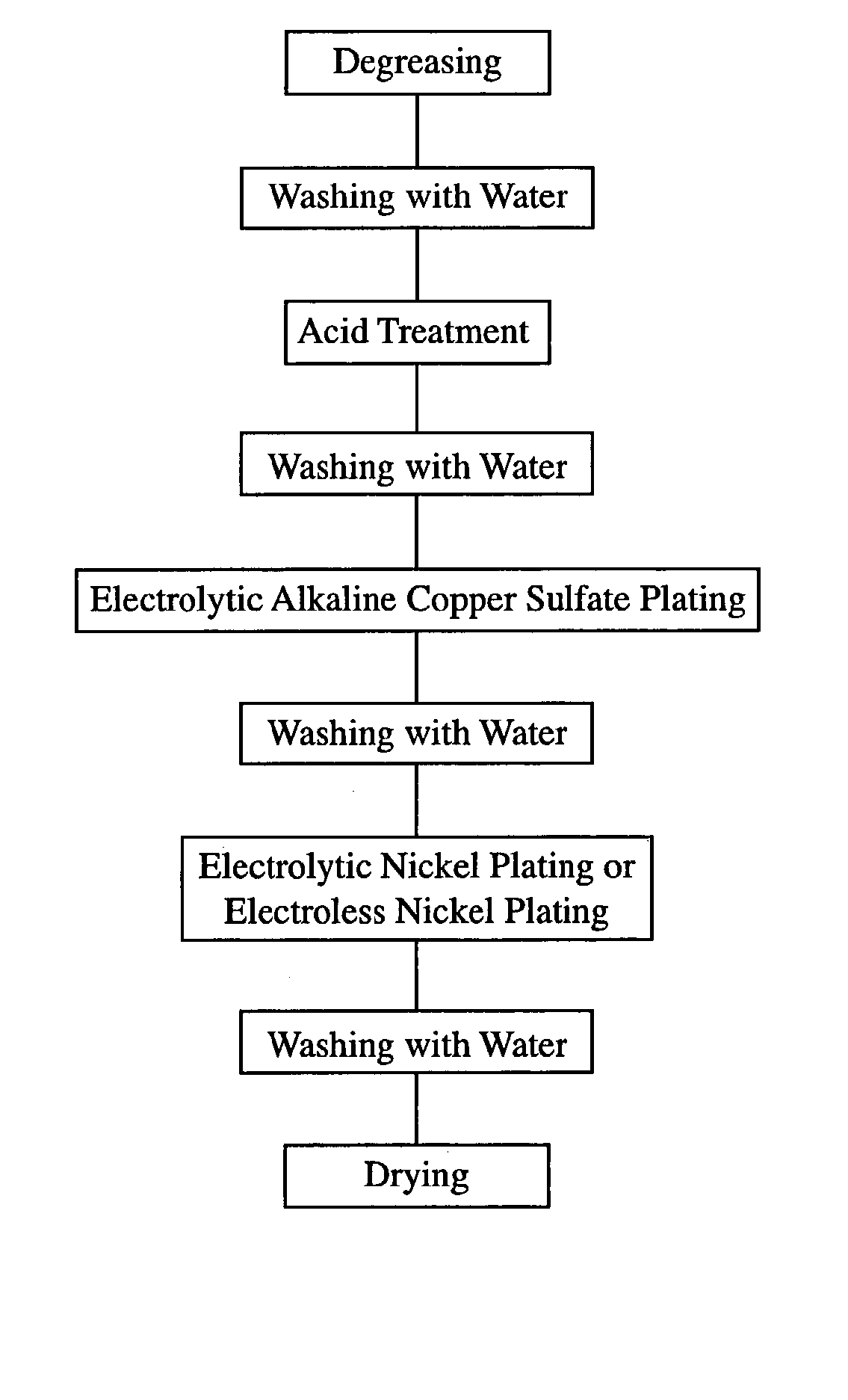

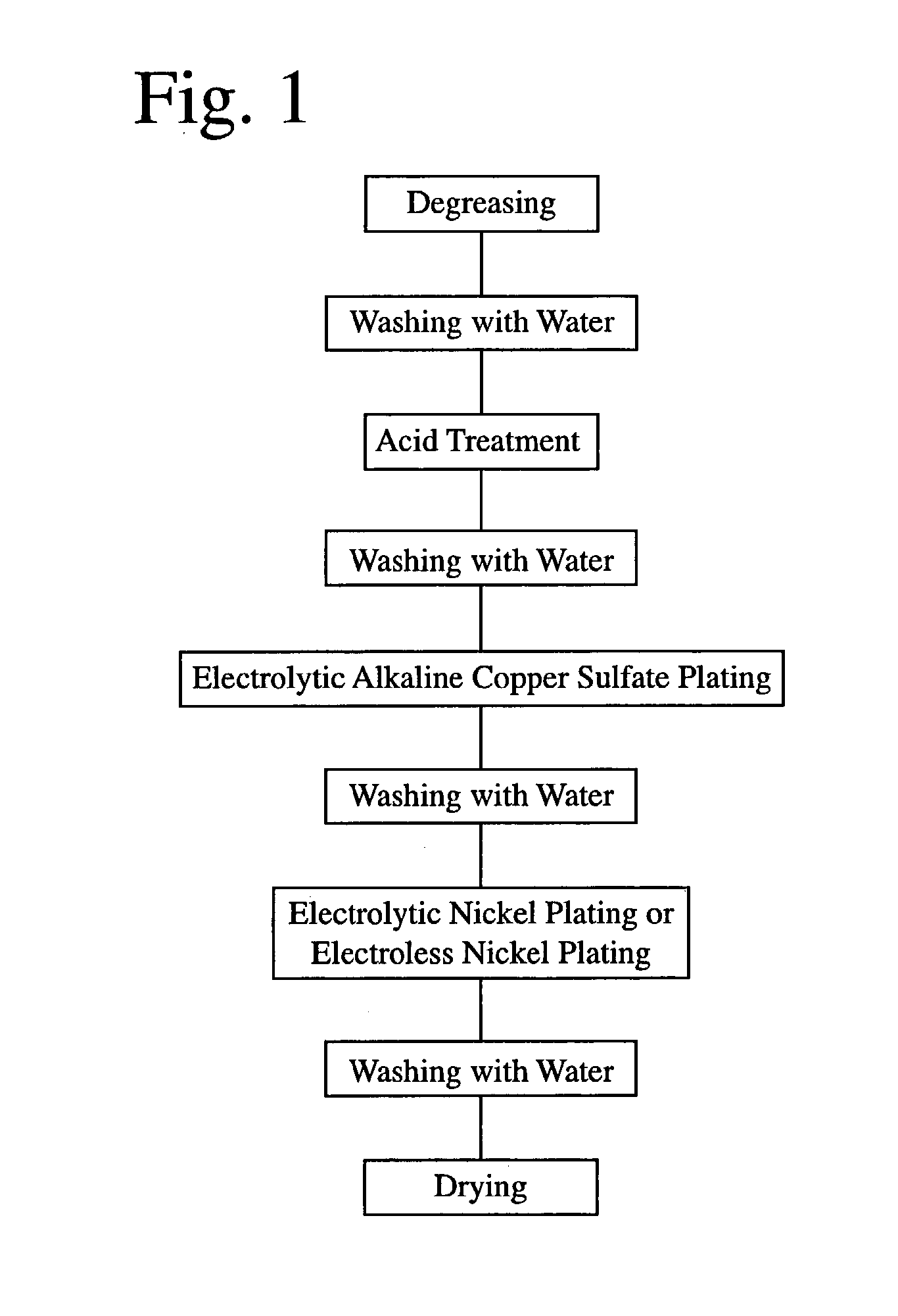

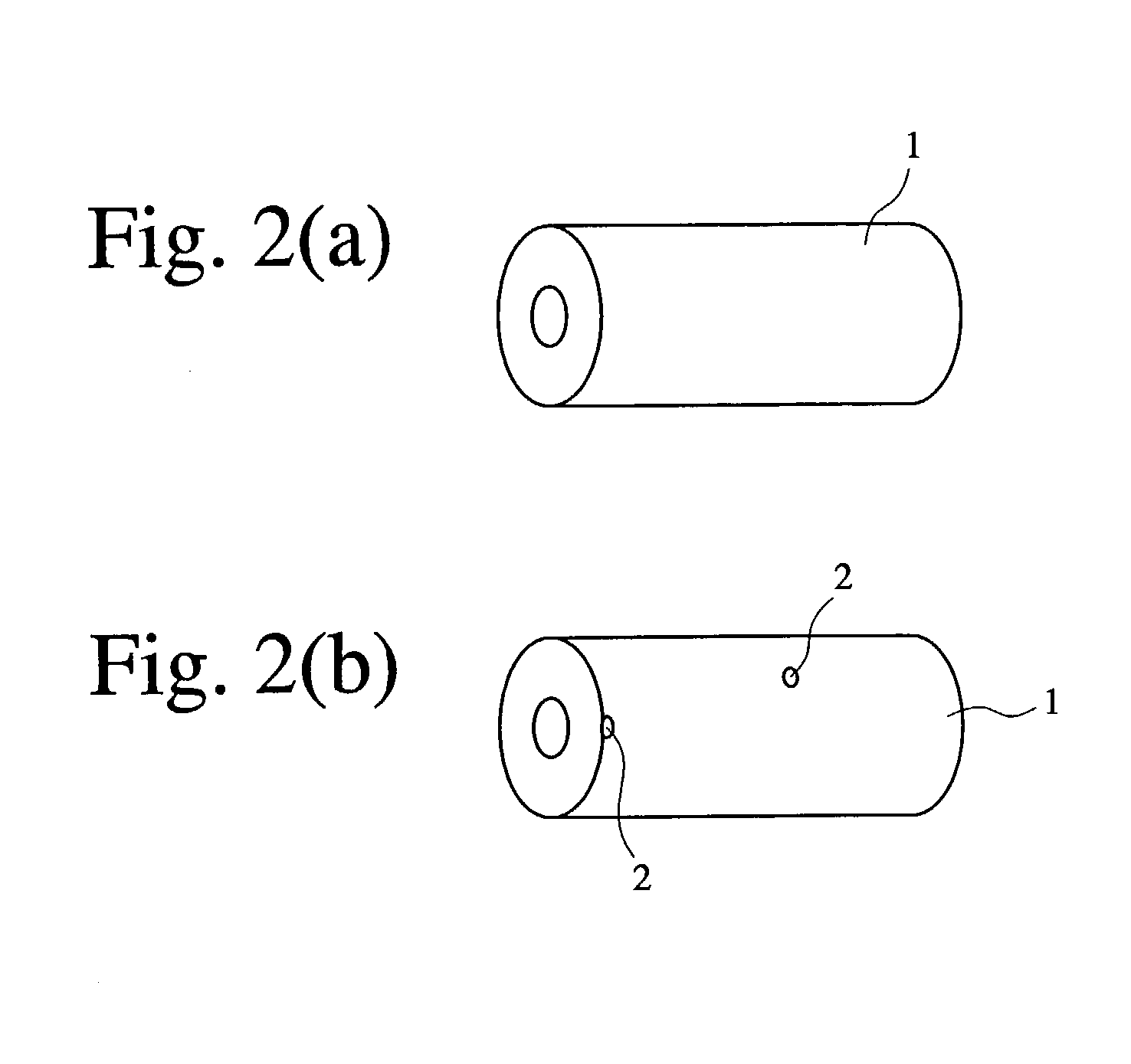

Electrolytic copper-plated r-t-b magnet and plating method thereof

InactiveUS20030052013A1Uniform thicknessExcellent scratch resistanceChromatisationBearing componentsRare-earth elementCopper plating

An R-T-B magnet (R is at least one kind of rare-earth elements including Y, and T is Fe or Fe and Co.) has an electrolytic copper-plating film where the ratio [I(200) / I(111)] of the X-ray diffraction peak intensity I(200) from the (200) plane to the X-ray diffraction peak intensity I(111) from the (111) plane is 0.1-0.45 in the X-ray diffraction by CuKal rays. This electrolytic copper-plating film is formed by an electrolytic copper-plating method using an electrolytic copper-plating solution which contains 20-150 g / L of copper sulphate and 30-250 g / L of chelating agent and contains no agent for reducing copper ions and has a pH adjusted to 10.5-13.5.

Owner:HITACHI METALS LTD

Liquid crystal polymer/cubic boron nitride master batch and preparation method for same

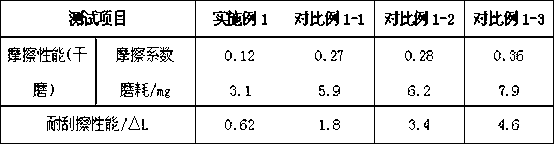

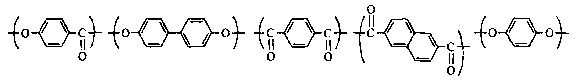

ActiveCN103013058AMake up for wear resistanceMake up for the defects of scratch-resistant masterbatchCrystallographyPhysical chemistry

The invention discloses a liquid crystal polymer / cubic boron nitride master batch prepared from a liquid crystal polymer, cubic boron nitride and dimethyl silicon oil, and a preparation method thereof. The liquid crystal polymer / cubic boron nitride master batch disclosed by the invention is mainly used as a wear-resistant and scratch-resistant master batch in a high-temperature-resistant polymer, and capable of obviously improving the wear resistance and scratch resistance of the high-temperature-resistant polymer. By using a cross scratch resistance instrument and a colorimeter for detecting the scratch resistance, the minimum Delta L value is 0.21, which fully shows that the liquid crystal polymer / cubic boron nitride master batch disclosed by the invention is greatly excellent in the wear resistance and the scratch resistance of the high-temperature-resistant polymer.

Owner:HEFEI GENIUS NEW MATERIALS

Hard coat film and curable resin composition for hard coat layer

ActiveCN101722691AExcellent scratch resistanceHigh hardnessLayered productsCoatingsInorganic ChemicalHardness

A curable resin composition for a hard coat layer capable of forming a hard coat layer having high hardness even with thin thickness and / or excellent in abrasion resistance and hardness, and a hard coat film using the curable resin composition are provided. A hard coat film in which a hard coat layer is provided on one side of a transparent substrate film, wherein the hard coat layer comprises a matrix in a crosslinked state and an aggregate in which 3 to 100 silica fine particles having an average primary particle diameter of 1 to 100 nm are aggregated, and wherein the aggregate is cross-linked to the matrix, and an irregularly shaped silica fine particle constituted with 3 to 20 silica fine particles having an average primary particle diameter of 1 to 100 nm connected to each other by inorganic chemical bonding is contained as a part of the aggregates. The hard coat layer further contains a silica fine particle preferably.

Owner:DAI NIPPON PRINTING CO LTD

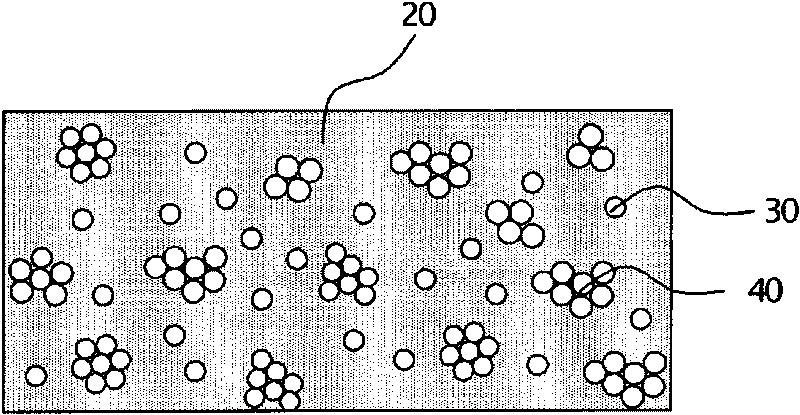

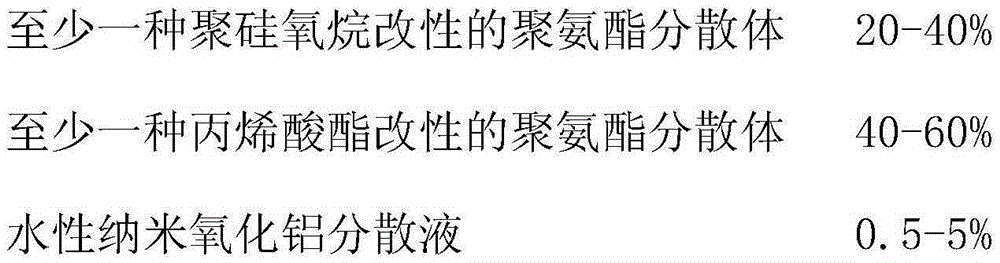

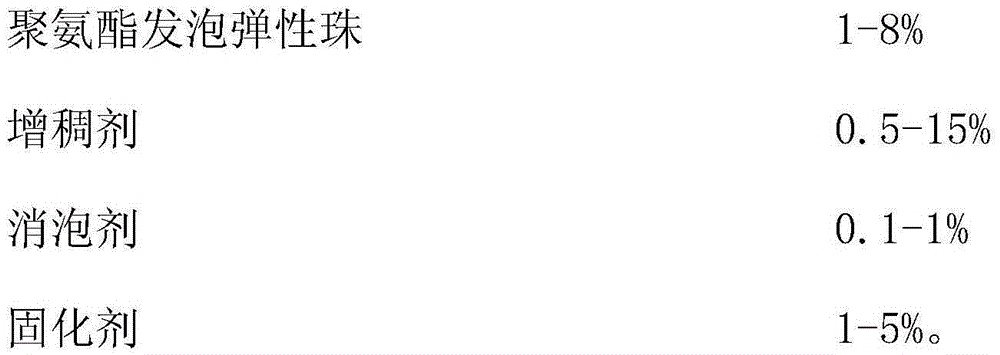

Velvet anti-scratch waterborne polyurethane paint

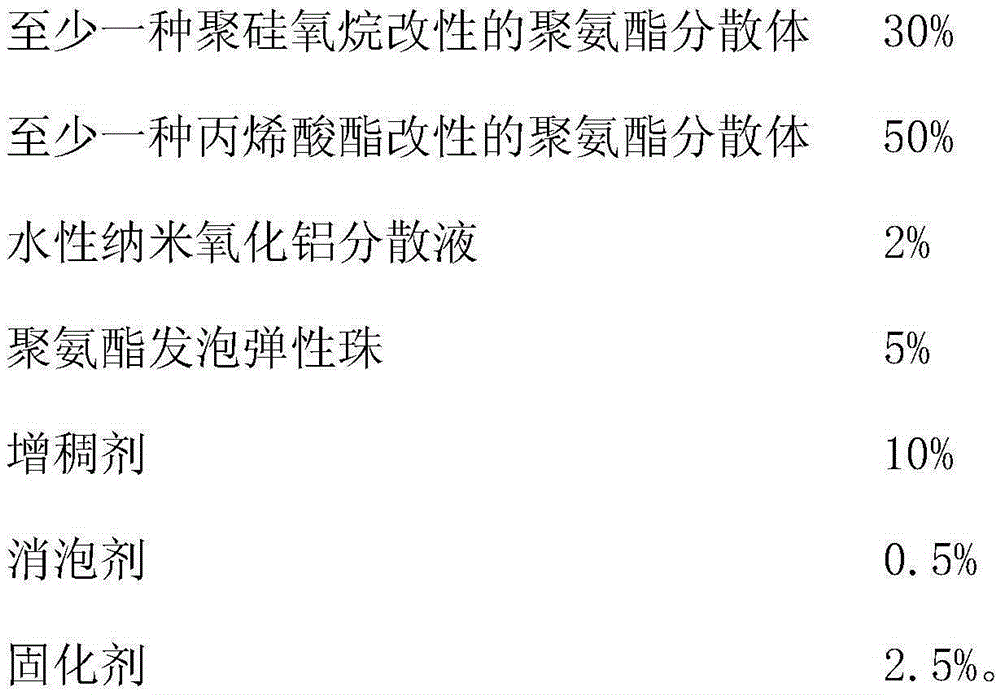

InactiveCN105385336AGood touchExcellent scratch resistancePolyurea/polyurethane coatingsChemistryDefoaming Agents

The invention relates to velvet anti-scratch waterborne polyurethane paint. The velvet anti-scratch waterborne polyurethane paint is prepared from, by weight, 20-40% of at least one type of polysiloxane-modified polyurethane dispersoid, 40-60% of at least one type of acrylate-modified polyurethane dispersoid, 0.5-5% of waterborne nanometer aluminium oxide dispersion liquid, 1-8% of polyurethane foaming elastic balls, 0.5-15% of thickening agent, 0.1-1% of defoaming agent and 1-5% of solidifying agent. A preparation method of the waterborne polyurethane paint includes the following steps of weighing the components according to the weight percents, adding polysiloxane-modified polyurethane dispersoid, acrylate-modified polyurethane dispersoid, waterborne nanometer aluminium oxide dispersion liquid, polyurethane foaming elastic balls and the defoaming agent in a stirring machine to be mixed, then adding the thickening agent and the solidifying agent, and conducting even mixing. Compared with the prior art, the waterborne polyurethane paint has excellent anti-scratch performance and a good touch sense and is mainly applied to thin film packaging materials.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Melamine dishware and production method thereof

The invention belongs to the field of melamine articles and particularly relates to melamine dishware and a production method thereof. The melamine dishware is made from the following materials according to percent by weight: 0.45-0.55% of zinc stearate, 0.02-0.2% of a food colorant, 0.04-0.1% of a curing agent, 70-80% of an amino molding material powder, and 20-30% of plant fiber, and the production method includes the following steps: (1), preparing materials: adding the amino molding material powder with the zinc stearate, food colorant, curing agent and plant fiber into a stock box accessory to a high-frequency machine; (2), curing: placing the stock box in the high-frequency machine so that the materials are cured and powered and clustered; (3), forming: pouring the cured materials into a mold on a hydraulic former for forming by pressing, the mold being provided with electric heating function; (4), grinding the edge. With the plant fiber, the melamine dishware has better strength, heat resistance and compactness and has higher quality.

Owner:襄汾县瑞德合成材料股份有限公司

Polypropylene resin composition with anti-scratch characteristics

The present invention provides a propylene resin composition having excellent anti-scratch characteristic. Specifically, provided is a polyolefin resin composition comprising a high crystalline polypropylene resin, a rubber component, an inorganic filler and an aluminosiloxane masterbatch, with excellent damage resistance such as anti-scratch characteristic thereby giving very low surface damage, excellent heat resistance, good rigidity and impact properties and injection moldability, for car interior or exterior parts.

Owner:SAMSUNG TOTAL PETROCHEMICALS CO LTD

UV matte top-coat paint for vacuum spraying

InactiveCN104530923ATo achieve the surface effectExcellent hardnessEpoxy resin coatingsGas phaseSilicon dioxide

The invention discloses a UV matte top-coat paint for vacuum spraying. The UV matte top-coat paint is prepared from the following components in parts by weight: 20-35 parts of epoxy acrylate, 35-60 parts of a monomer, 5-10 parts of a filler, 0.1-0.5 part of gas-phase silica, 3-6 parts of a photoinitiator, 0.4-0.6 part of a flow agent, 0.3-0.5 part of a defoamer and 0.2-0.5 part of a wetting dispersant, wherein the epoxy acrylate is modified epoxy acrylate with a Meiyatu code number of Changrunfa to be YTM2100. The UV matte top-coat paint is automatically sprayed on a substrate by using vacuum spraying equipment, so that the production efficiency can be greatly improved; by virtue or reasonable matching of the raw material, as very good levelling property can be obtained after the UV matte top-coat paint is cured, the surface effect of a PU paint can be achieved, and the rigidity and the scraping resistance are superior to those of the PU paint.

Owner:HUIZHOU CHANGRUNFA PAINT +1

High hardness multi-layer sheet

InactiveCN105705332AGood dimensional stabilityExcellent scratch resistanceSynthetic resin layered productsElectrical equipmentMeth-Hardness

The present invention provides a high hardness multi-layer sheet of polycarbonate multilayer structure comprising: a polymethyl methacrylate layer having an acrylic copolymer formed from 75 parts by weight to 88 parts by weight of (meth)acrylic acid ester monomer, 2 parts by weight to 5 parts by weight of styrene monomer, and 10 parts by weight to 20 parts by weight of N-substituted maleimide monomer; and a polycarbonate copolymer.

Owner:LG HAUSYS LTD

Composition of polypropylene having improved tactility and scratch resistance and methods of use thereof

ActiveUS20150094413A1Enhance tactilityExcellent scratch resistanceSpecial tyresPolypropylenePolymer chemistry

The present invention provides a polypropylene resin composition in a mixture of a pellet (A) and a pellet (B), which is characterized by mixing them with various inorganic fillers and additives, wherein the pellet (A) comprises a long fiber-reinforced composite resin (a) obtained via a pultrusion impregnation process, and the pellet (B) comprises a composite resin (b) that includes polypropylene and thermoplastic elastomer. The polypropylene resin composition of the present invention can directly replace thermoplastic elastomer overmolding or painting in automotive parts to which such processes are routinely applied (e.g., interior components of the vehicle), which makes it possible to simplify and reduce the cost of the production process for such parts.

Owner:HYUNDAI MOTOR CO LTD +2

Anticorrosive paint applied to surfaces of aluminum alloy materials

InactiveCN106833179AWide variety of sourcesReduce manufacturing costRubber derivative coatingsAnti-corrosive paintsEpoxyAcrylic resin

The invention discloses anticorrosive paint applied to surfaces of aluminum alloy materials. The anticorrosive paint comprises the following components in parts by weight: 30 to 50 parts of thermosetting acrylic resin, 20 to 40 parts of epoxy resin, 10 to 20 parts of amino resin, 10 to 20 parts of vinylidene chloride resin, 10 to 20 parts of chlorinated rubber, 5 to 10 parts of mica powder, 5 to 10 parts of sodium nitrite, 1 to 5 parts of tin dimethyl, 5 to 15 parts of kaolin, 1 to 5 parts of hydroxyethyl methyl cellulose, 1 to 5 parts of pigment, 1 to 5 parts of xylene, and 5 to 10 parts of silicon oil. The anticorrosive paint applied to the surfaces of the aluminum alloy materials, disclosed by the invention, is applied to the aluminum alloy materials, and can greatly improve performances of the aluminum alloy materials of corrosion resistance, oxidation resistance and the like to prolong the service life of the aluminum alloy materials.

Owner:黄波

Urethan coating composition, cured coating film and resin member

ActiveCN109306238AExcellent scratch resistanceExcellent anti-fog persistencePolyurea/polyurethane coatingsPolyolPolyurethane coating

The present invention provides a liquid polyurethane coating composition capable of forming a cured coating film having excellent scratch resistance and excellent antifogging durability, and a resin member having the cured coating film. The polyurethane coating composition contains a specific amount of a polyisocyanate (a), a polyether polyol (b), and a surfactant (c), and the polyether polyol (b)has a number average molecular weight of more than 300 and less than 600, a polyether polyol (b-2) having a number average molecular weight of more than 600 and less than 900, and a polyether polyol(b-3) having a number average molecular weight of more than 900 and less than 1800. The surfactant (c) is an ionic surfactant having a hydroxyl group in the molecule, and an anionic surfactant and / oran amphoteric surfactant having no group reactive with an isocyanate group.

Owner:NOF CORP

Resin particles, method for producing the resin particles, and use thereof

ActiveUS20140350171A1Excellent solvent resistanceExcellent scratch resistanceCoatingsMethyl groupMonomer

The present invention provides resin particles including polymer obtained of a monomer mixture containing a monofunctional (meth)acrylic ester monomer, a monomer represented by a general formula (I);CH2═C(R1)—COO—(CH2CH2O)n—CO—C(R1)═CH2 (I)where R1 is a hydrogen or a methyl group and n is an integer from 1 to 4, and a monomer represented by a general formula (II);CH2═C(R2)—COO—(CH2CH2O)m—CO—C(R2)═CH2 (II)where R2 is a hydrogen or a methyl group and m is an integer from 5 to 15. The resin particles have a volume average particle diameter of 5 to 50 μm, a recovery rate of 15% or more to less than 30%, and a compression strength (MPa) that provides a multiplication product in the range of 24.5 to 60.0 obtained by multiplying the compression strength and the volume average particle diameter (μm).

Owner:SEKISUI KASEIHIN KOGYO KK

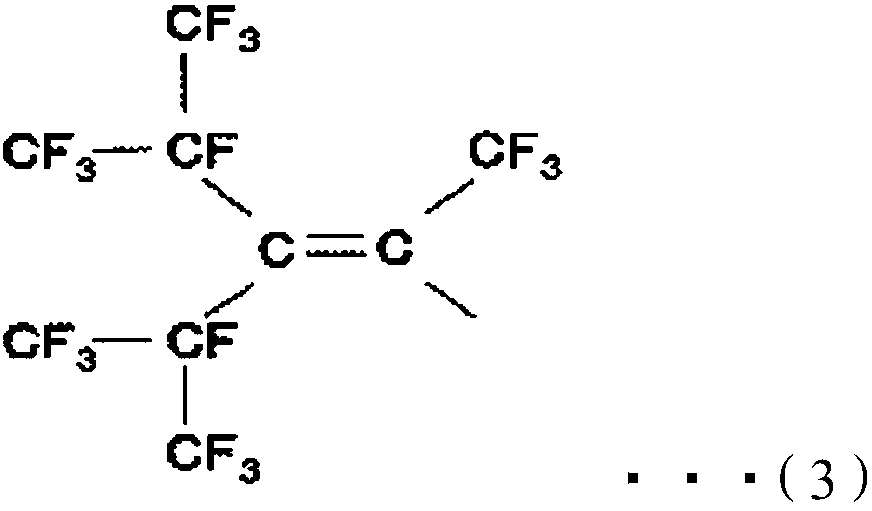

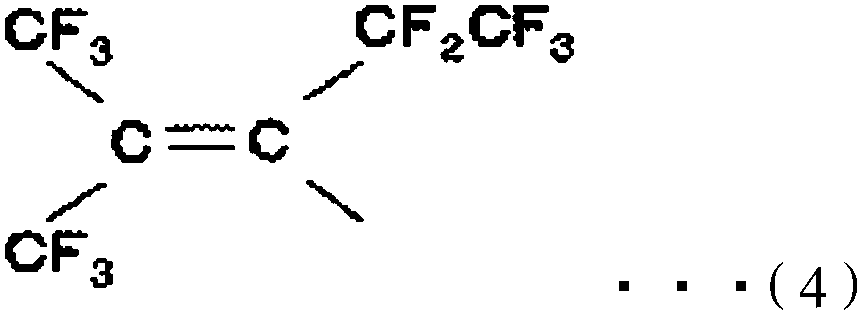

PC/AS/ acrylic resin alloy material and preparation method thereof

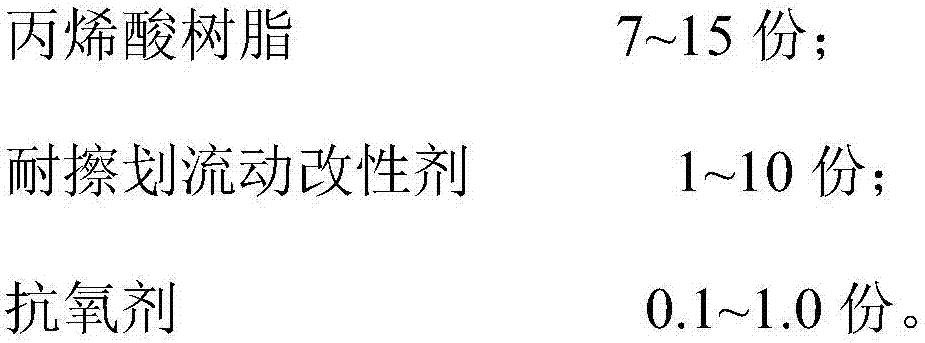

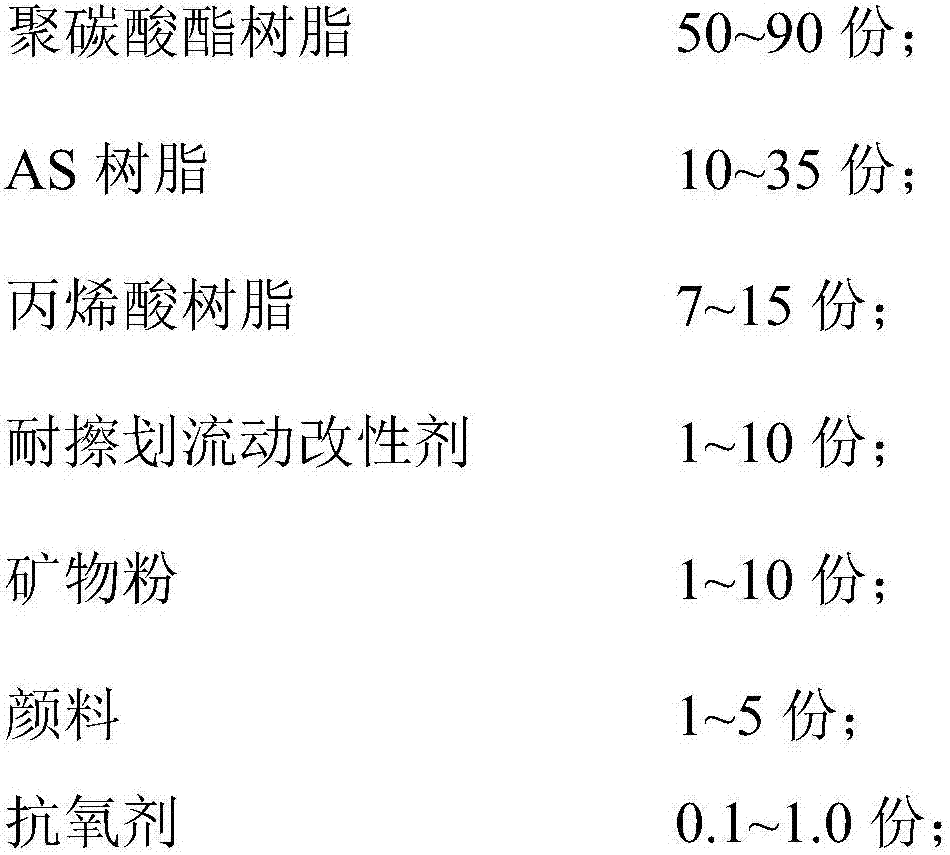

The invention relates to a PC / AS / acrylic resin alloy material, and belongs to the technical field of a high molecular material. The PC / AS / acrylic resin alloy material is prepared from, by weight, 50-90 parts of polycarbonate resin, 10-35 parts of AS resin, 7-15 parts of acrylic resin, 1-10 parts of anti-scraping flowing modifier, and 0.1-1.0 part of antioxidant. The PC / AS / acrylic resin alloy material has excellent scraping resistance weather resistance, workability, and coloring easiness.

Owner:四川长虹智能制造技术有限公司

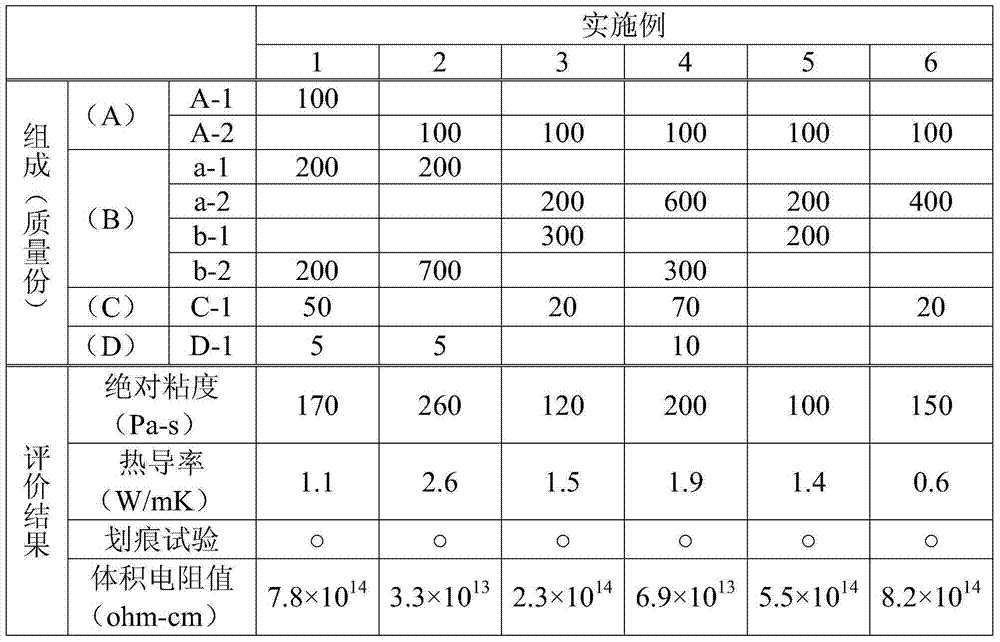

Silicone composition and lubricating grease

ActiveCN103772991AImprove cooling effectExcellent scratch resistanceHeat-exchange elementsLubricant compositionFilling materialsAluminium hydroxide

The invention aims to provide a silicone composition and lubricating grease and provide heat-radiating lubricating grease excellent in insulation property and anti-scratch property. The invention provides a silicone composition and lubricating grease containing the silicon composition. The silicon composition comprises (A) 100 parts by mass of organic polysiloxane with a dynamic viscosity of from 10mm<2> / s to 500,000mm<2> / s below 25 DEG C, and (B) from 100 parts to 1300 parts by mass of thermal conductive filler. The silicon composition is characterized in that the thermal conductive filler comprises (a) from 100 parts to 1000 parts by mass of calcium carbonate powder with an average particle size of from 0.1[mu]m to 100[mu]m, and (b) from 0 part to 1000 parts by mass of aluminium hydroxide powder with an average particle size of from 0.1[mu]m to 100[mu]m.

Owner:SHIN ETSU CHEM IND CO LTD

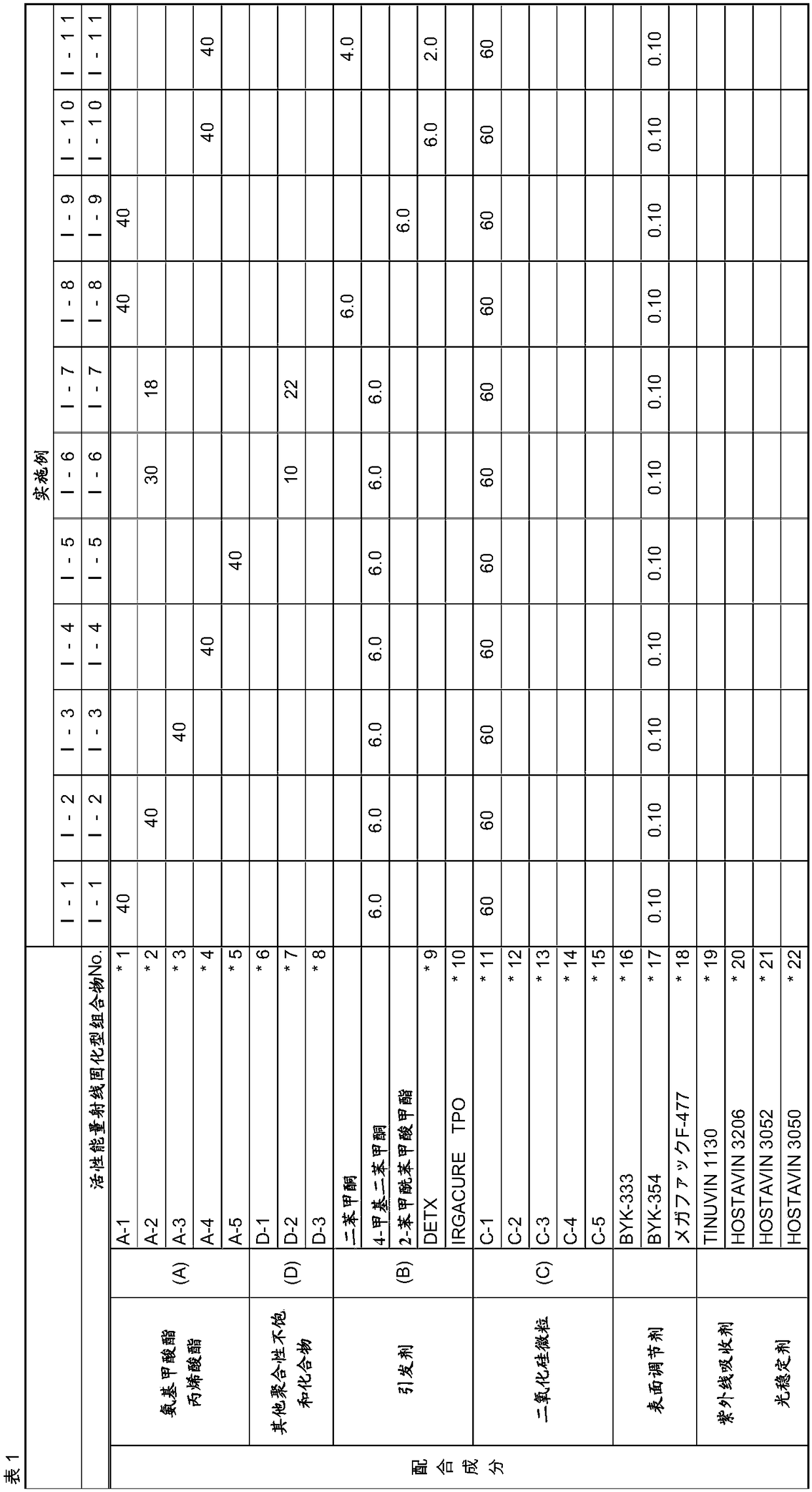

Active Energy Ray-Curable Composition for Forming Cured Film on Cyclic Olefin-Based Resin Substrate and Hard Coat Film and Laminate

ActiveCN108976452AImplementation processExcellent scratch resistancePolyurea/polyurethane coatingsChemistryCyclic Olefins

The present invention provides an active energy ray-curable composition for forming a cured film on a cyclic olefin-based resin substrate, a hard coat film using cyclic olefin-based resin as a substrate and a laminate. The composition has excellent adhesion to a cyclic olefin-based resin substrate and can provide scratch resistance. As the active energy ray-curable composition for forming a curedfilm on a cyclic olefin-based resin substrate, the active energy ray curable composition having a specific composition including silica fine particles, a polymerizable unsaturated compound, and a photopolymerization initiator is employed. As a result, a film excellent in scratch resistance and substrate adhesion can be obtained. In addition, the laminate formed by laminating a cured film layer ofthe active energy ray-curable composition and an inorganic substance layer in sequence on the cyclic olefin-based resin substrate has sufficient interlayer adhesion and further shows excellent characteristics in transparency, scratch resistance, hardness and crimpiness resistance.

Owner:NIPPON KAKO TORYO CO LTD +1

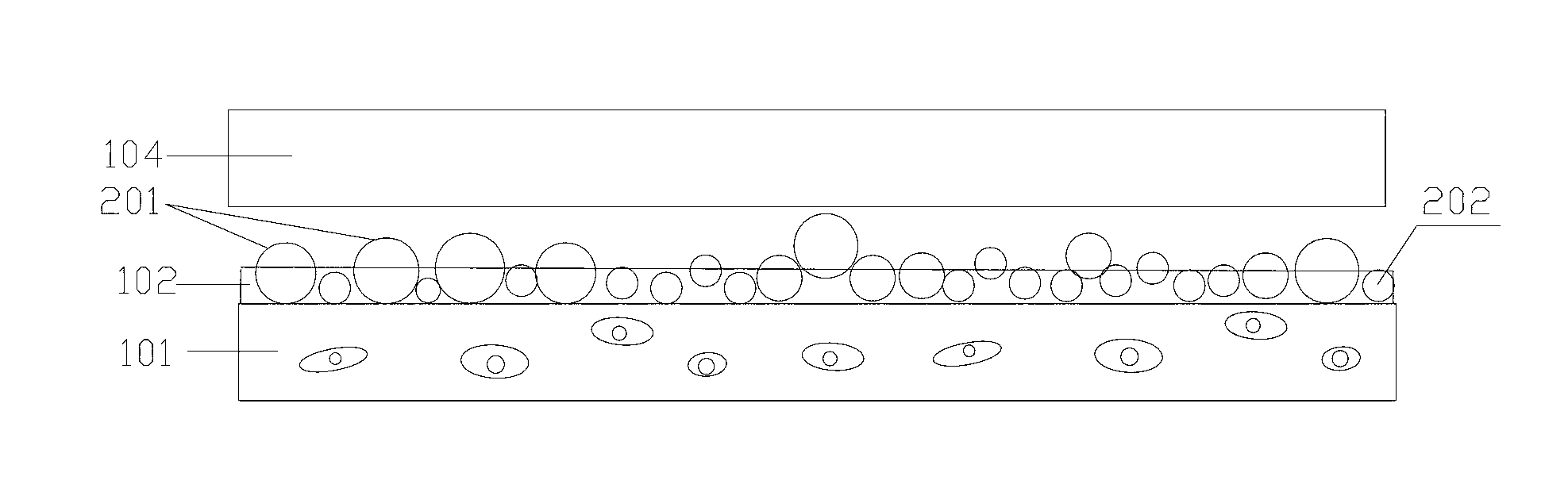

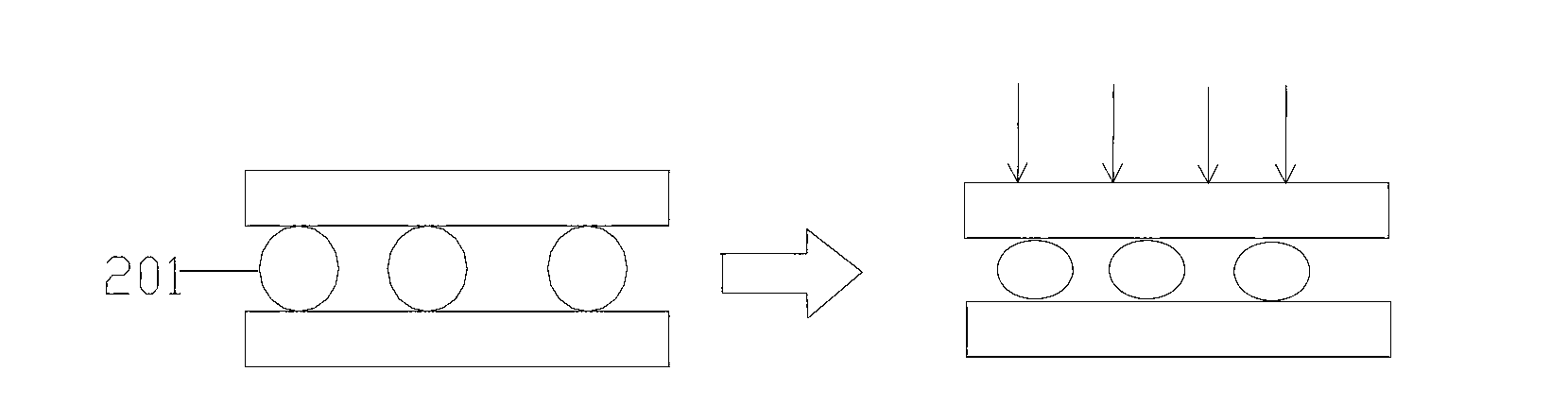

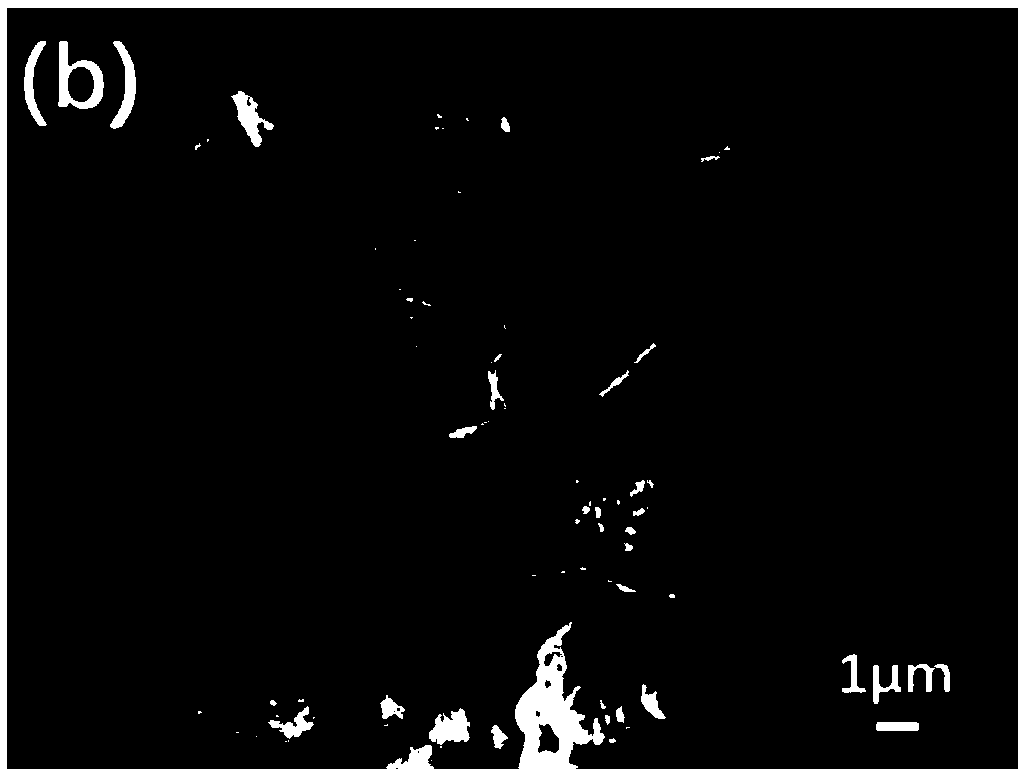

Scratch-resistant super-hydrophobic material based on fiber array and preparation method thereof

InactiveCN110947602AExcellent superhydrophobic propertiesExcellent scratch resistancePretreated surfacesCoatingsFiber arrayPolymer chemistry

The invention provides a scratch-resistant super-hydrophobic material based on a fiber array and a preparation method thereof. The scratch-resistant super-hydrophobic material is composed of a substrate, an adhesive, chopped fibers and nanoparticles, wherein the surface of the substrate is coated with the adhesive; one ends of the chopped fibers are arranged on the surface, coated with the adhesive, of the substrate; and the surfaces of the chopped fibers are coated with the nanoparticles. The scratch-resistant super-hydrophobic material based on the fiber array has an excellent super-hydrophobic characteristic, meanwhile, the surface of the material has an excellent scratch-resistant characteristic, and the material has a wide application prospect in the fields of civil products, aerospace and precise instruments.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

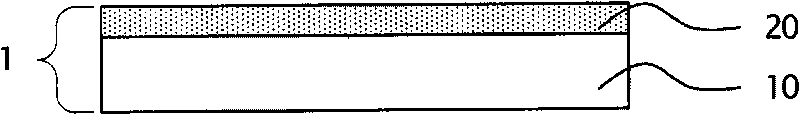

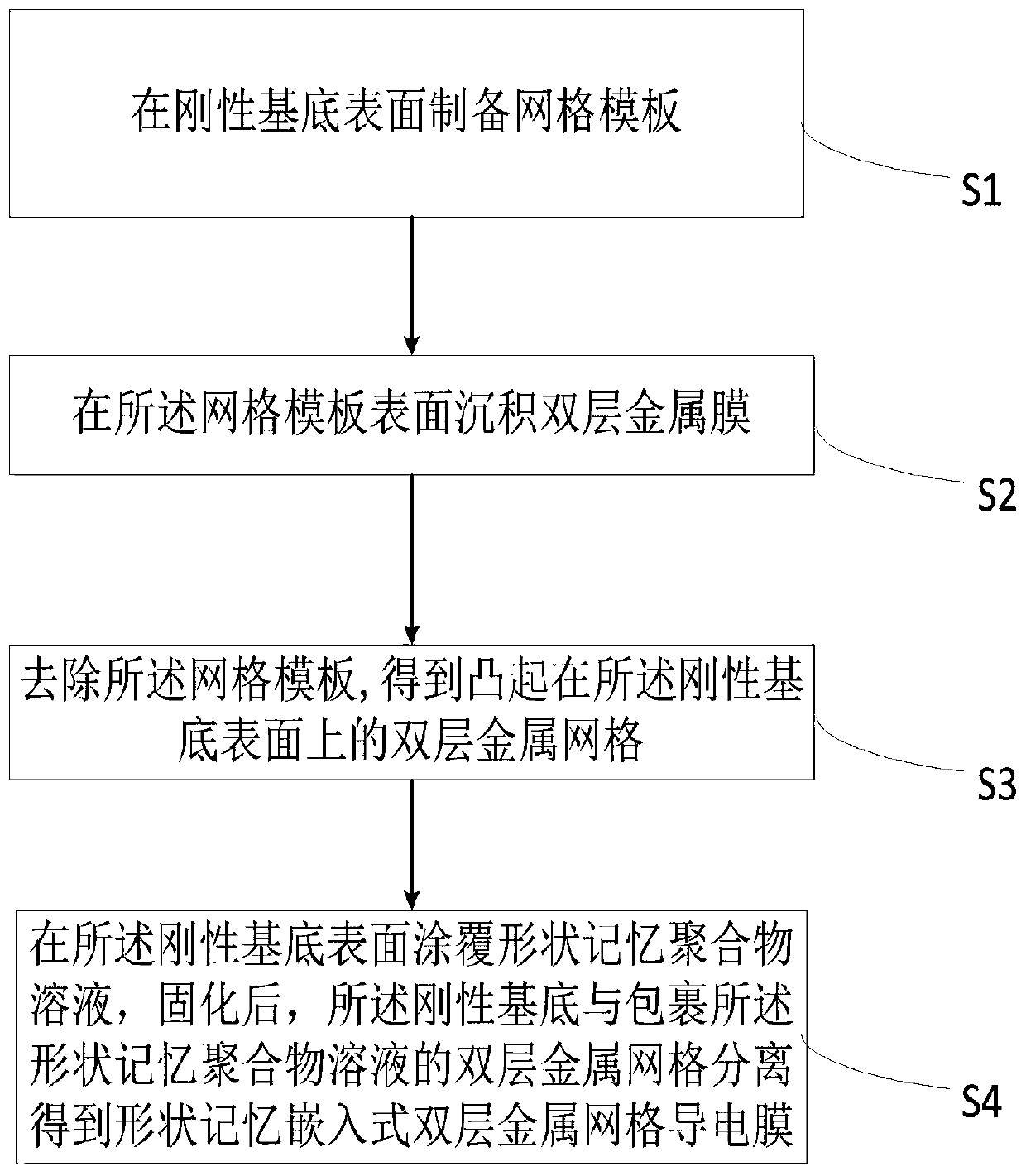

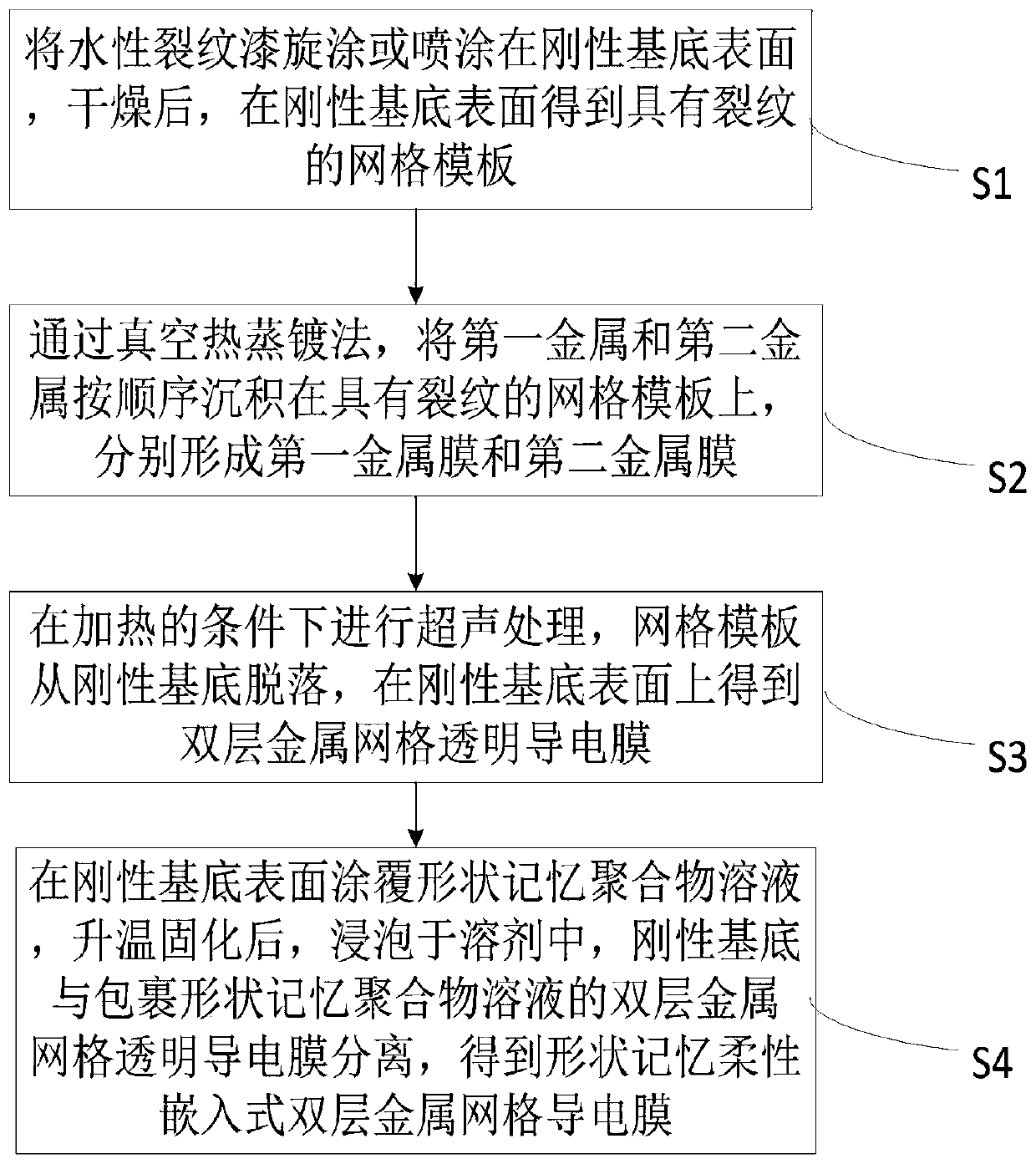

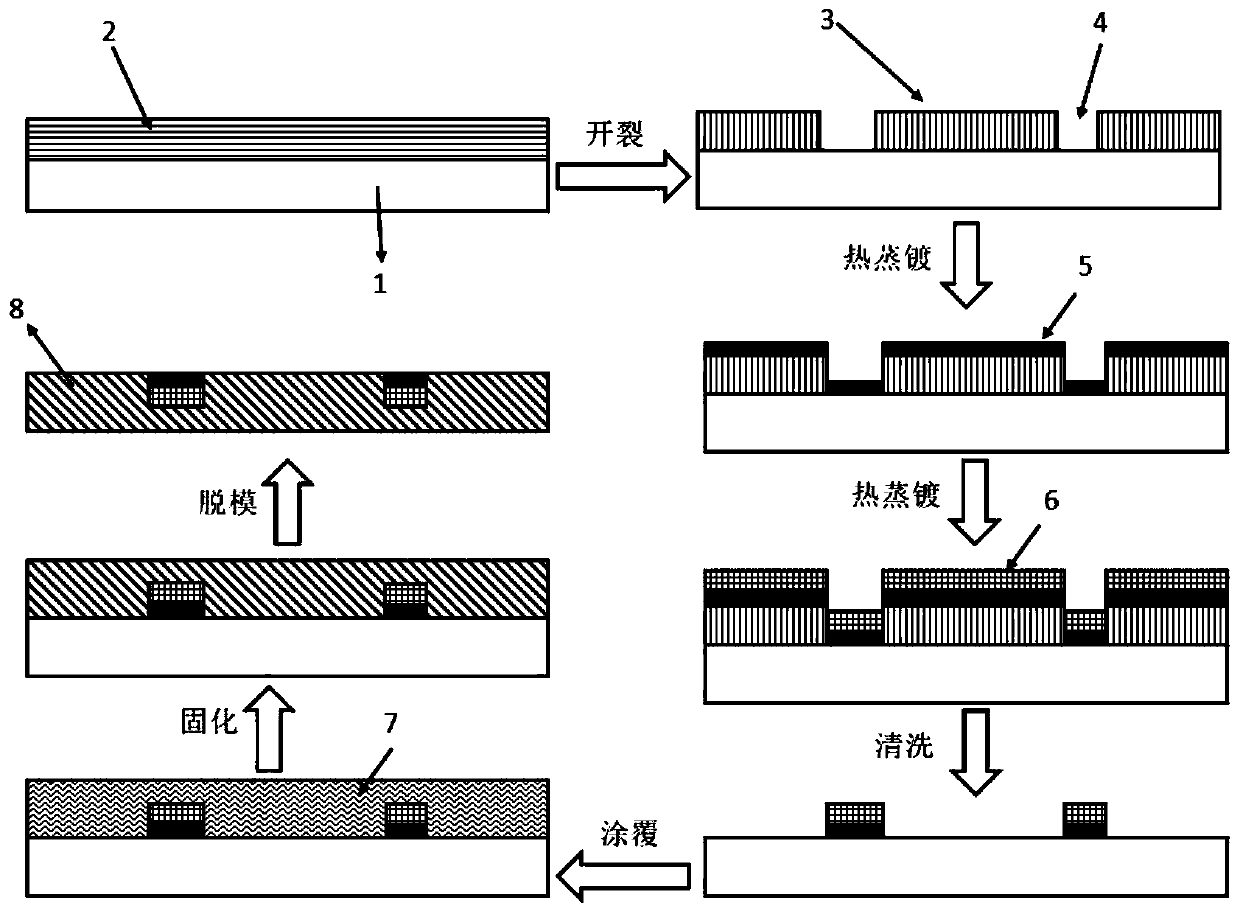

Shape memory embedded double-layer metal grid conducting film and preparation method thereof

InactiveCN110838386AGood scratch resistanceReduce surface roughnessConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersMetal gridElectrically conductive

The invention provides a shape memory embedded double-layer metal grid conducting film and a preparation method thereof, which belong to the technical field of flexible photoelectrons. The preparationmethod for the shape memory embedded double-layer metal grid conducting film comprises the following steps of: preparing a grid template on the surface of a rigid substrate, depositing a double-layermetal film on the surface of the grid template, removing the grid template to obtain a double-layer metal grid protruding on the surface of the rigid substrate, and coating the surface of the rigid substrate with a shape memory polymer, and after curing, separating the rigid substrate from the double-layer metal grid wrapping the shape memory polymer to obtain the shape memory embedded double-layer metal grid conducting film. Compared with the prior art, the shape memory embedded double-layer metal grid conducting film prepared by the invention has good scratch resistance, bending stability,corrosion resistance, oxidation resistance and shape memory performance.

Owner:HARBIN INST OF TECH

Anticorrosive paint for metal pipes

InactiveCN106833180AWide variety of sourcesReduce manufacturing costAnti-corrosive paintsEpoxy resin coatingsEpoxyLacquer

The invention discloses an anticorrosive paint for metal pipes, which comprises the following components in parts by weight: 30-50 parts of thermosetting acrylic resin, 20-40 parts of epoxy resin, 10-20 parts of perchlorethylene resin, and 10 parts of chlorinated rubber ~20 parts, 5~10 parts of mica powder, 5~10 parts of sodium nitrite, 1~5 parts of dimethyl tin, 5~15 parts of kaolin, 1~5 parts of hydroxyethyl methylcellulose, 1~5 parts of pigment 1-5 parts of xylene, 5-10 parts of silicone oil. The invention is applied to the metal pipeline and can greatly improve the performances of the metal pipeline such as corrosion resistance and oxidation resistance, and prolong the service life of the metal pipeline.

Owner:黄波

X-luminoscope fusion sample preparation method

InactiveCN103808559AChemically stableNot easy to absorb moistureMaterial analysis using wave/particle radiationPreparing sample for investigationCrucibleFree cooling

The invention discloses an X-luminoscope fusion sample preparation method, comprising the following steps: grinding a solid sample into powder of not less than 200 meshes for later use, wiping a crucible, a stirrer and a medicine spoon to be clean by using alcohol, placing in an oven for drying for 30min and more, taking out and placing on a tray, wiping the inner wall of a die to be clean by using alcohol, naturally withering for later use; weighing a certain mass of PE material to be put into a crucible, heating until the solvent is completely fused; weighing a certain mass of sample powder in S1 to place in a crucible in the S4, turning on the stirrer, stirring while heating, stopping stirring and heating after 30min; fetching melt at the upper layer in the crucible in S5 with a medicine spoon in a die in the S3, wherein the melt is about 2 / 3 of the height of the die, naturally cooling to completely solidify to obtain the sample sheet. The borate flux is replaced by the PE material, the manufactured sample sheet is hard to break, crack and pollute, easy to de-mold and store, the sample preparation time is effectively shortened, and the sample preparation cost is greatly reduced.

Owner:南京大展机电技术研究所

Wear and corrosion resistant oil paint

InactiveCN106833182AWide variety of sourcesReduce manufacturing costRubber derivative coatingsAnti-corrosive paintsEpoxyAcrylic resin

The invention discloses wear and corrosion resistant oil paint. The wear and corrosion resistant oil paint comprises the following components in parts by weight: 30-50 parts of thermosetting acrylic resin, 20-40 parts of epoxy resin, 10-20 parts of polyurethane, 10-20 parts of chlorinated polyvinyl chloride resin, 10-20 parts of chlorinated rubber, 5-10 parts of mica powder, 5-10 parts of sodium nitrite, 1-5 parts of tin dimethyl, 1-5 parts of graphite powder, 5-15 parts of kaolin, 1-5 parts of hydroxyethyl methyl cellulose, 1-5 parts of a pigment, 1-5 parts of xylene and 5-10 parts of silicone oil. The wear and corrosion resistant oil paint is applied to aluminium profiles, the wear and scratch resistance, the corrosion resistance, the oxidation resistance and the like of the aluminium profiles are greatly improved, and the service lives of the aluminium profiles are prolonged.

Owner:黄波

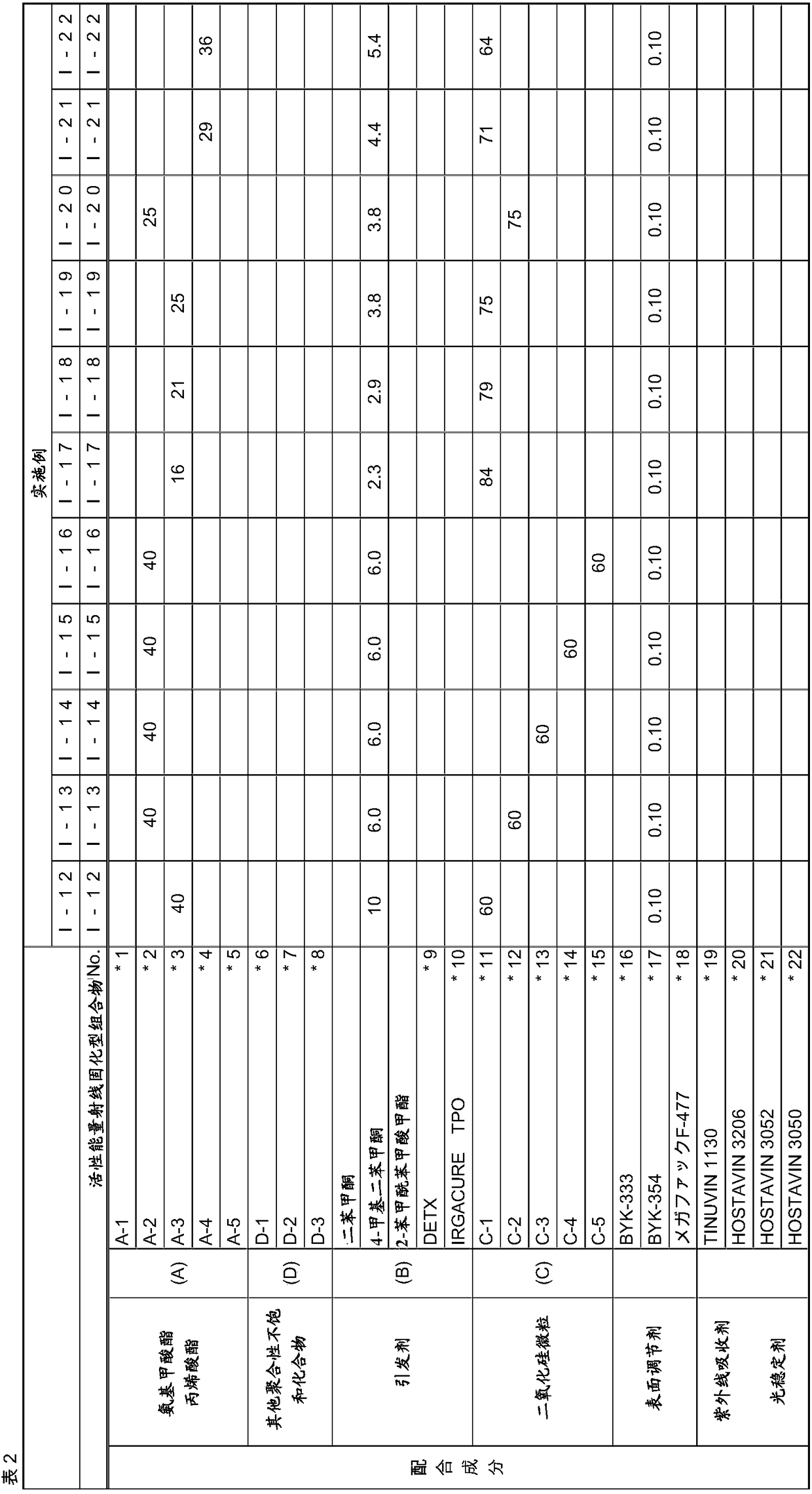

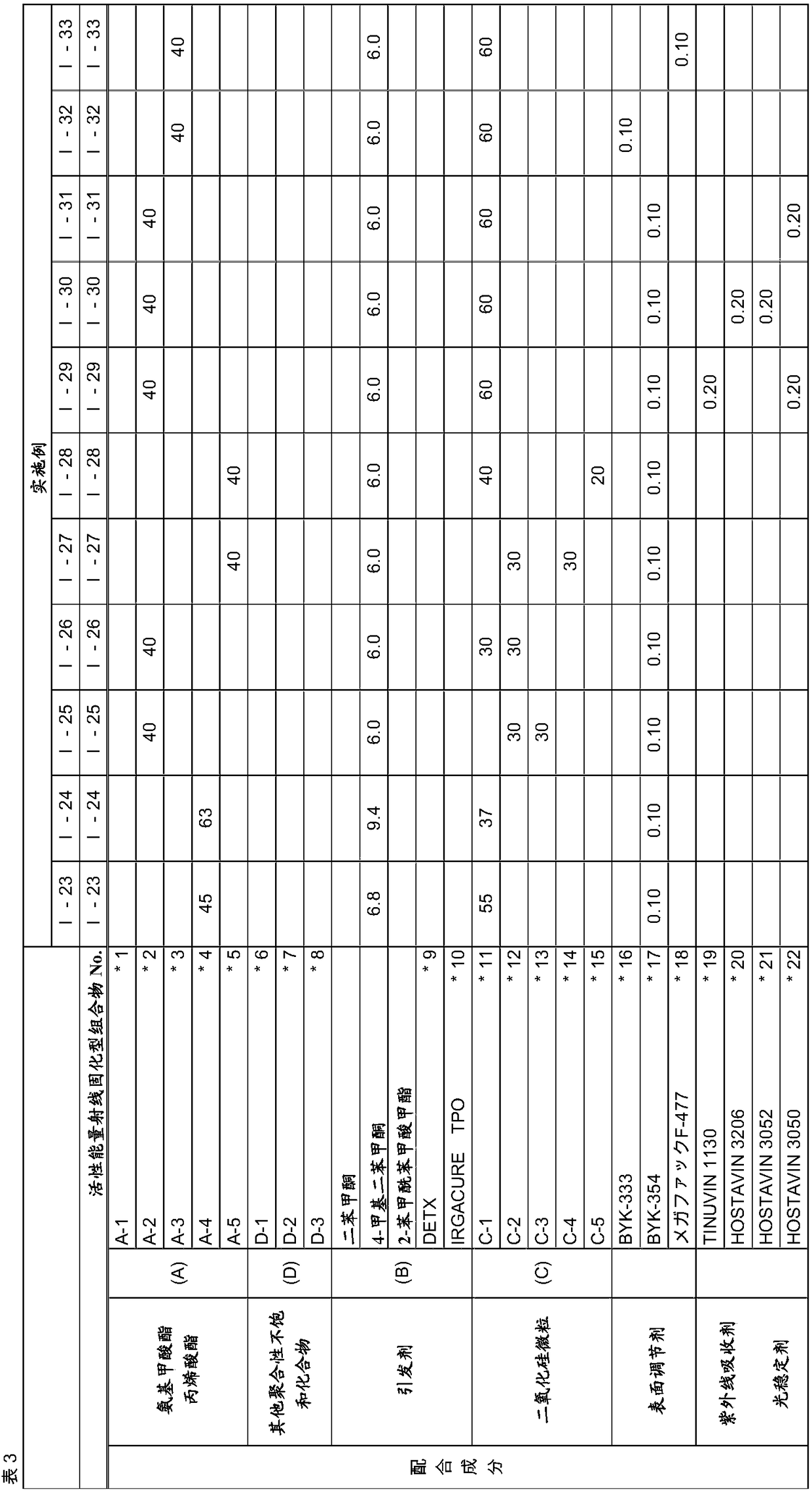

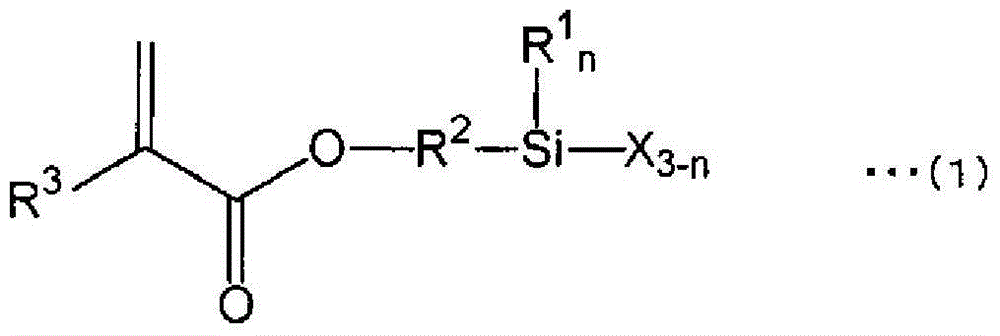

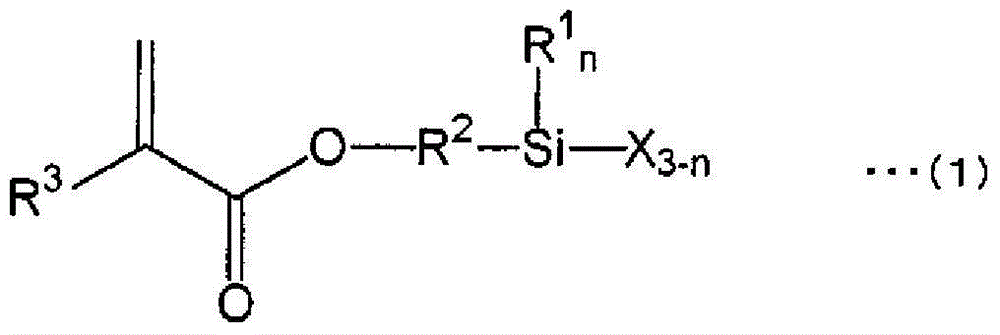

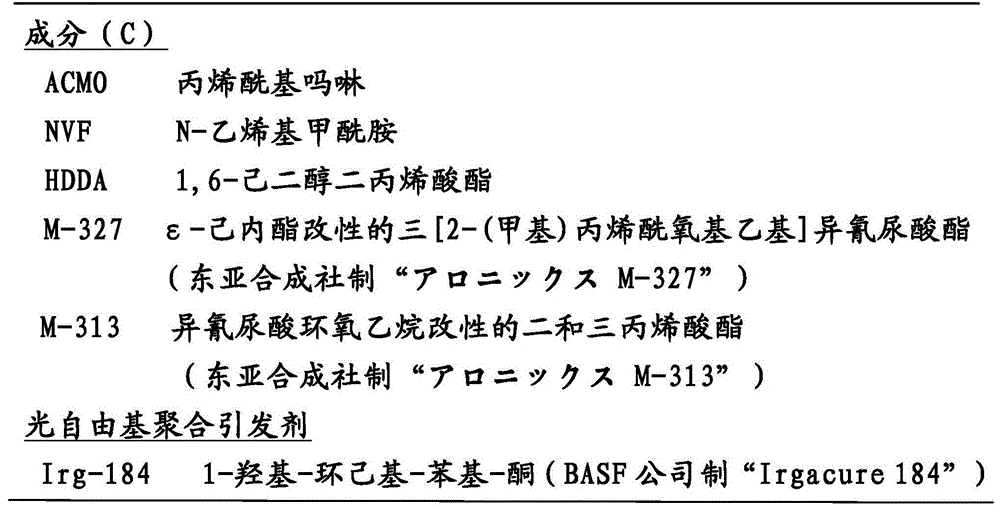

Active-energy-ray-curable coating composition

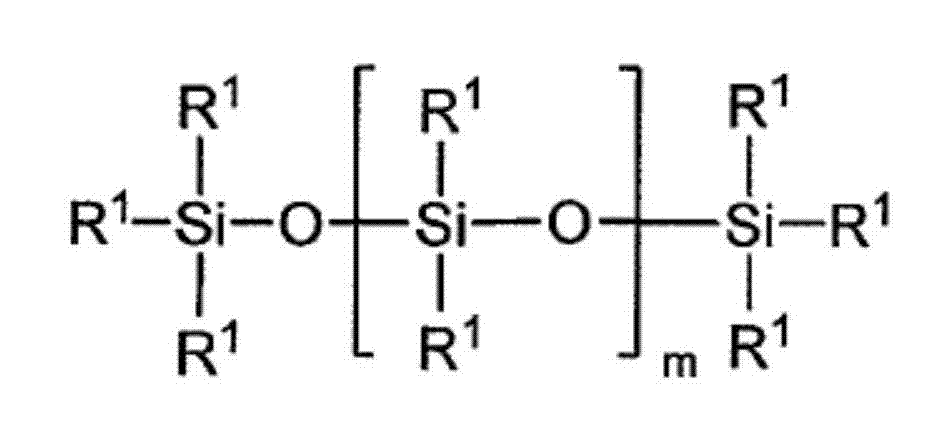

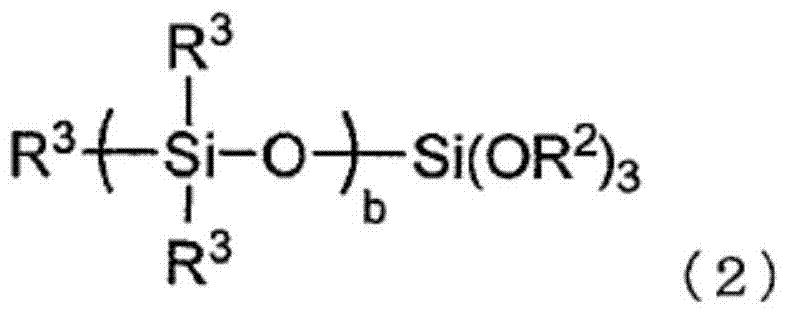

ActiveCN104981525AExcellent scratch resistanceHigh hardnessPolyurea/polyurethane coatingsIsocyanateOrganosilicon

An active-energy-ray-curable coating composition according to the invention of the present application comprises the following components (A) to (C) at a specified content ratio: (A) an organosilicon compound produced by the hydrolysis and copolycondensation of a (meth)acryloyl-group-containing silicon compound (a1) represented by general formula (1) and a silicon compound (a2) represented by the formula SiY4 (wherein Y represents a group capable of generating a siloxane bond) at the ratio of 0.3 to 1.8 moles of the component (a2) per 1 mole of the component (a1); (B) a (meth)acrylate mixture composed of a urethane adduct compound (b1) and a (meth)acrylate (b2), wherein the component (b1) is produced by the addition reaction of a (meth)acrylate that is derived from an aliphatic polyhydric alcohol having a valency of 3 or more and has at least two (meth)acryloyl groups and at least one hydroxy group with a polyisocyanate and the component (b2) has at least three (meth)acryloyl groups and has no hydroxy group; and (C) a radically polymerizable unsaturated compound having a nitrogen atom in the molecule.

Owner:TOAGOSEI CO LTD

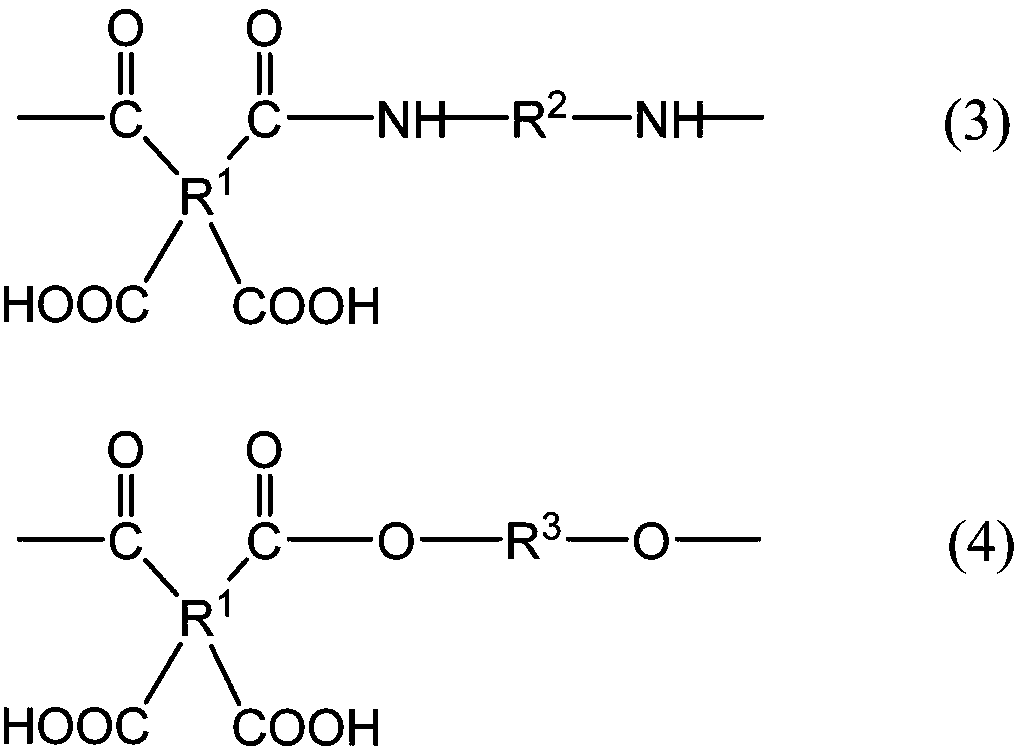

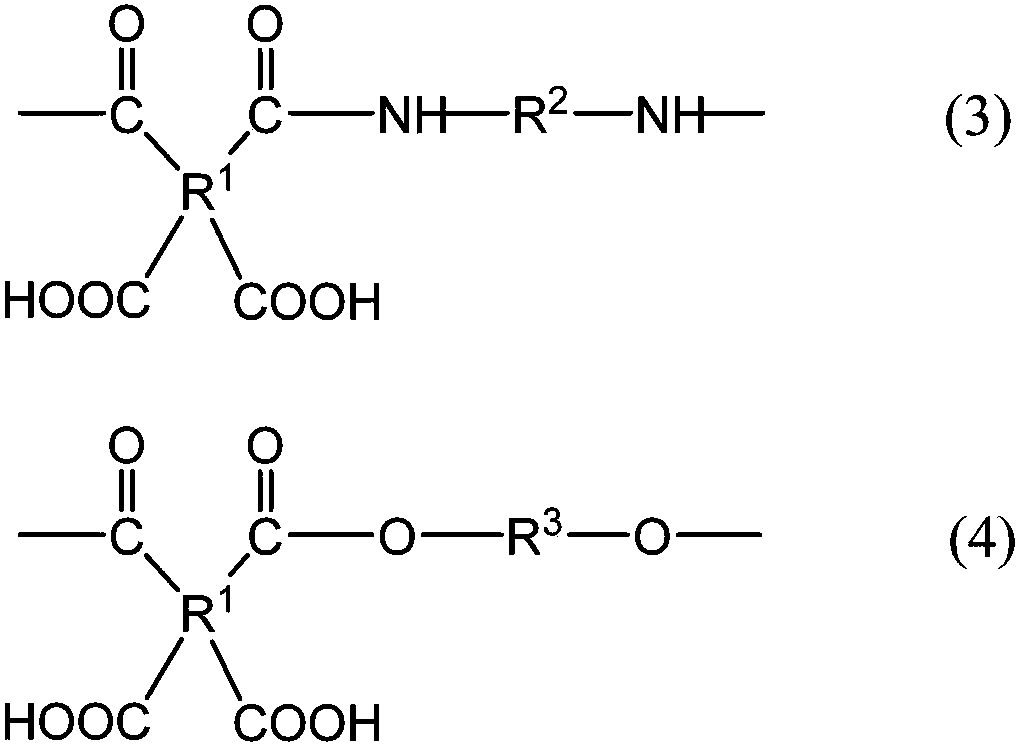

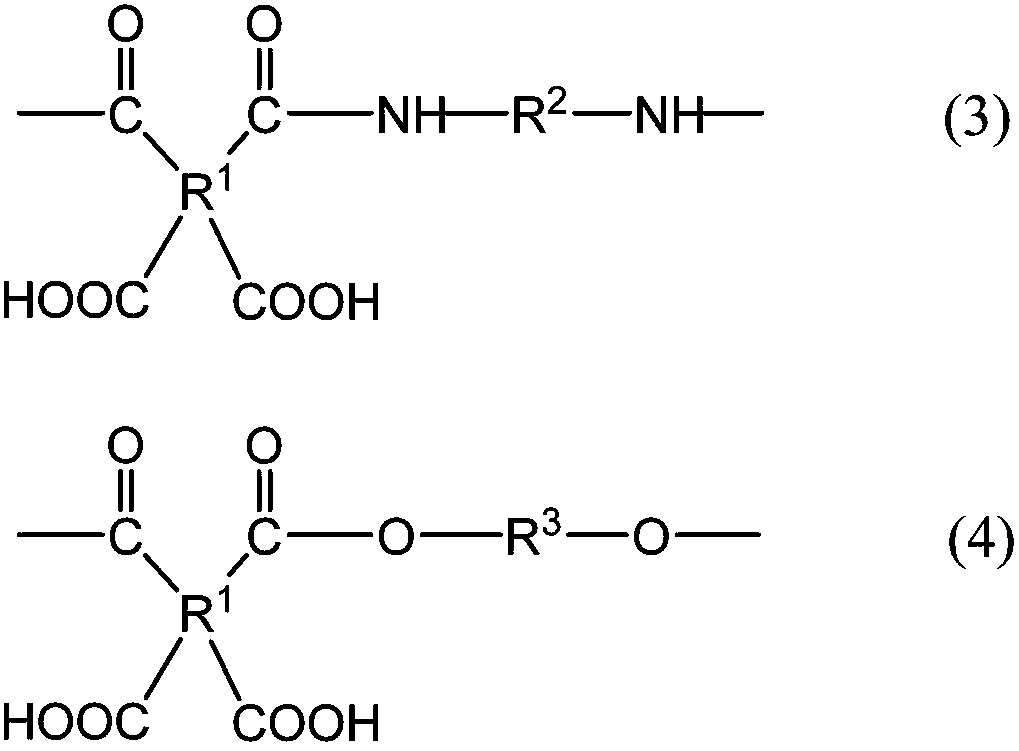

Thermosetting composition, hard coating film and color filter

PendingCN107722685AExcellent flatnessExcellent scratch resistanceOptical filtersCoatingsDiamineDouble bond

The present invention relates to a thermosetting composition, a hard coating film and a color filter. The thermosetting composition comprises polyesteramide acid (A), an epoxy compound (B) and a compound (c) having polymerization double bonds, and is characterized in that the polyesteramide acid (A) is a reaction product of a raw material containing X mol of tetracarboxylic acid dianhydride, Y molof diamine and Z mol of polyhydroxy compound with a ratio enabling a formula (1) 0.2<=Z / Y<=8.0, and a formula (2) 0.2<=(Y+Z) / X<=5.0, and the compound (c) having the polymerization double bonds is a compound of which each molecule has more than two polymerization double bonds. According to the thermosetting composition of the present invention, the hard coating film preferably used for the electronic part and having excellent flatness and scratch resistance can be formed.

Owner:JNC CORP

Novel environment-friendly all natural traditional Chinese medicine plant color wax oil paint for furniture

InactiveCN109337579AHarmless to healthInhale fresh and healthyShellac coatingsWax coatingsMyrrhLacquer

The invention discloses novel environment-friendly all natural traditional Chinese medicine plant color wax oil paint for furniture, which comprises the following raw materials: all natural ambergris,all natural catechu, all natural benzoin, all natural aloe, all natural tabasheer, all natural camphor, all natural stir-fried dried lacquer, all natural myrrh, all natural gamboge, all natural pistacia lentiscus, all natural turpentine, all natural resina liquidamberis, transparent glass powder, all natural sea wax, all natural honey wax, all natural amber beeswax, all natural lacca oil, all natural storax oil, all natural arabia gum oil, all natural rosinol, all natural cordaites resin oil, all natural dammar resin oil, protogenic lac resin oil, all natural sandarac oil and edible high-degree white spirit. The paint is simple in construction method, few in application technical process, low in waste, high in drying rate, short in construction cycle, good in transparence and layered sense, strong in stereoscopic effect and more environmentally friendly, is all natural traditional Chinese medicine plant color wax oil and causes no harm or pollution to a human body and an aerosphere.

Owner:成都丽涂水性环保漆科技有限公司

Scratch-resistant epoxy resin paint

InactiveCN105062324AExcellent scratch resistanceGood solvent resistancePolyurea/polyurethane coatingsEpoxy resin coatingsSolventChemistry

The invention discloses a scratch-resistant epoxy resin paint, which is prepared from 550-650 parts of polycarbodiimide resin, 2-6 parts of zinc bromide, 650-690 parts of bisphenol A diglycidyl ether resin, 2-8 parts of tetrabutylammonium iodide, and 300-500 parts of acetone. Therefore, the scratch-resistant epoxy resin paint is good in scratch resistance and solvent resistance, large in hardness and bright and transparent.

Owner:QIDONG CHUNJIANG POLYURETHANE

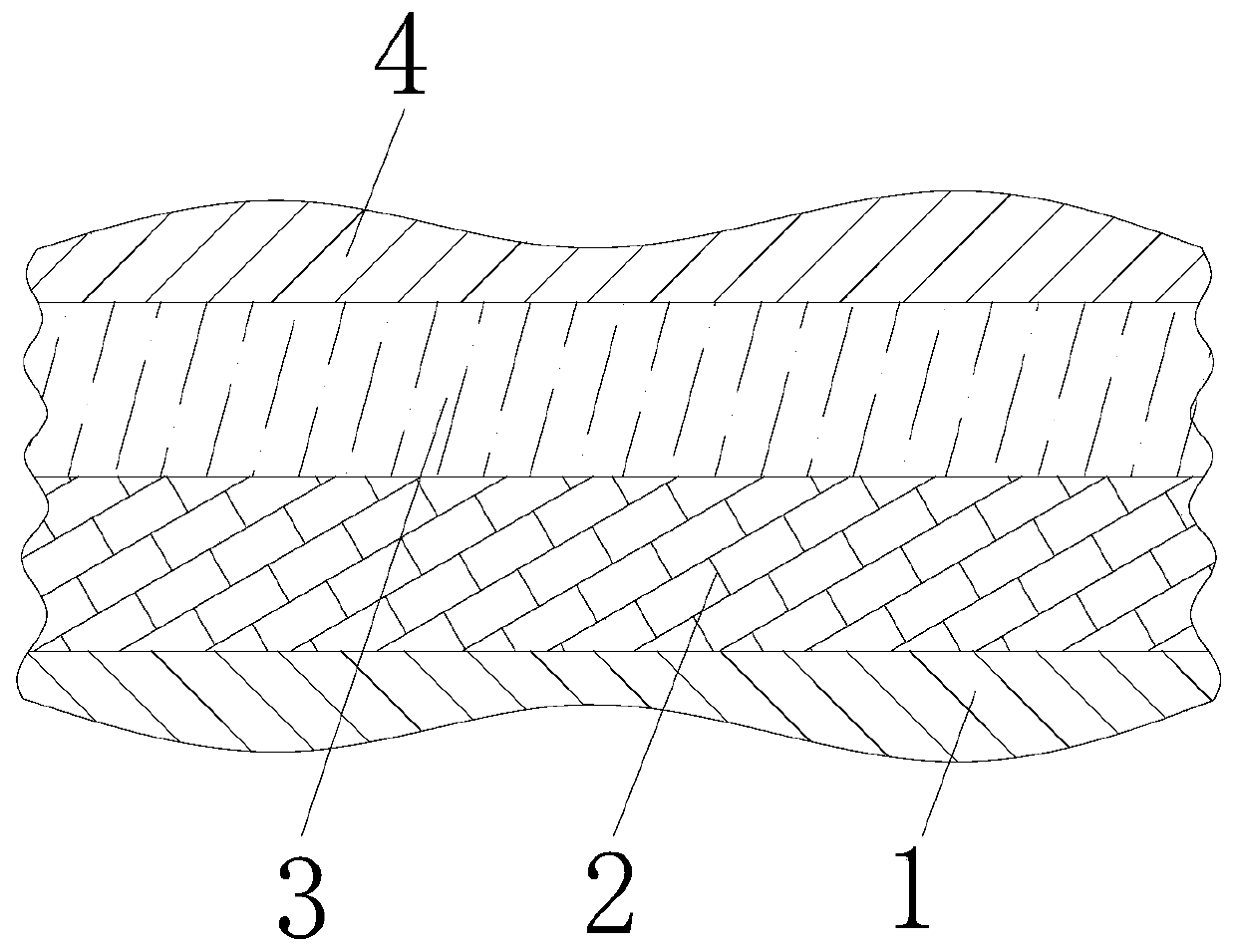

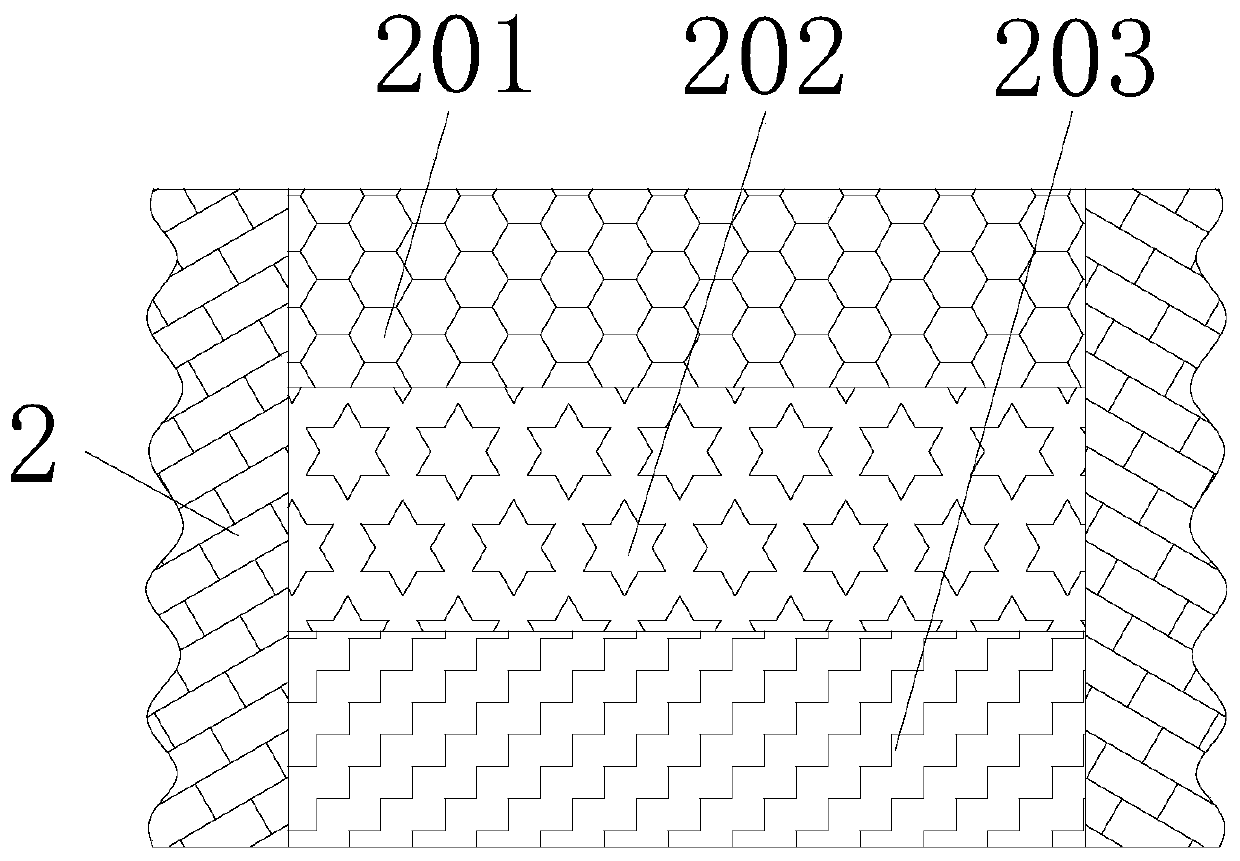

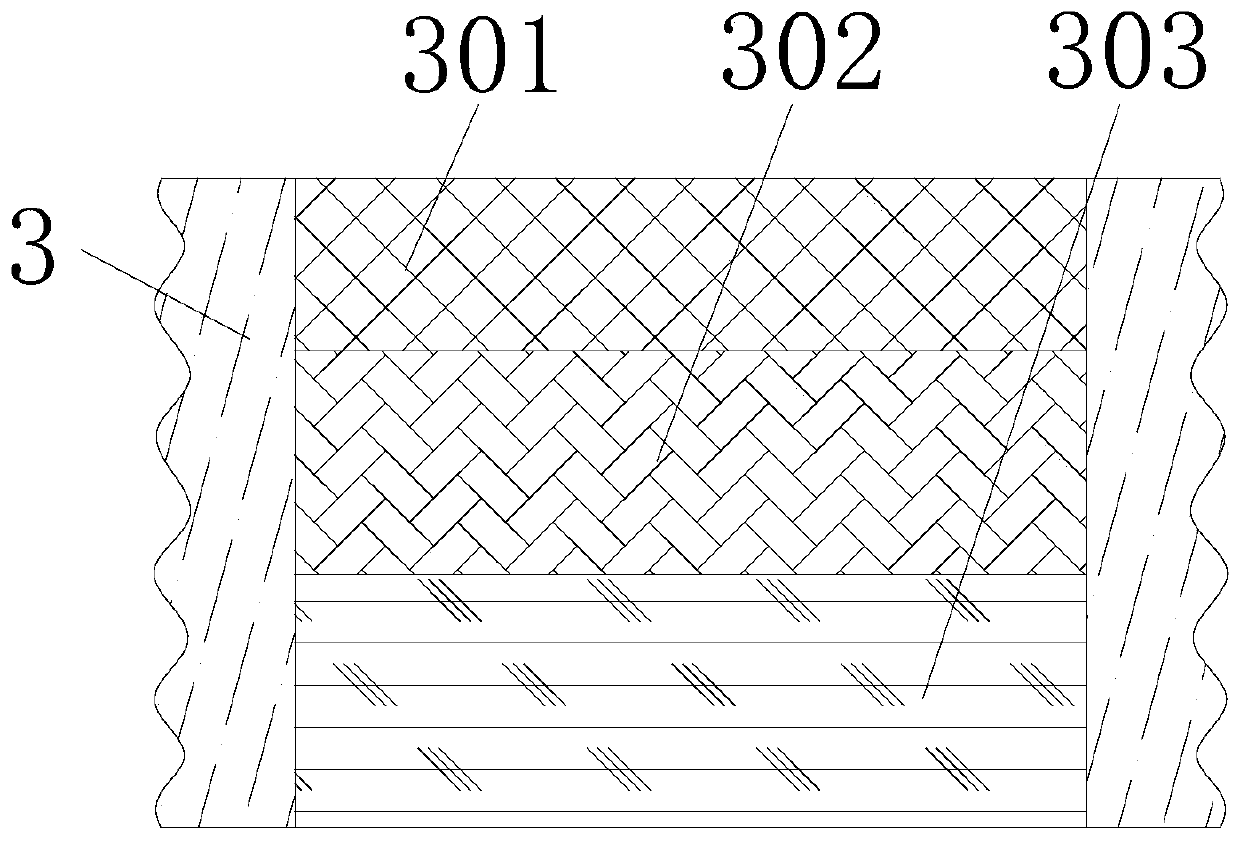

Chemical fabric with good wear resistance

PendingCN110303749AImprove wear resistanceHeat resistantSynthetic resin layered productsPolyesterChemical fiber cloth

The invention discloses a chemical fabric with good wear resistance. The chemical fabric comprises a lower chemical fabric, the top of the lower chemical fabric is fixedly connected with a wear-resistant layer which comprises an acrylic acid fiber layer, a melamine fiber layer and a polyphenylene sulfide fiber layer, the top of the wear-resistant layer is fixedly connected with a flame-retardant layer, the flame-retardant layer comprises a polyester tire fiber layer, a polyimide fiber layer and a polyphenyl dimethyl phenone diamine fiber layer, and the top of the flame-retardant layer is fixedly connected with an upper chemical fabric. By cooperation of the lower chemical fabric, the wear-resistant layer, the acrylic acid fiber layer, the melamine fiber layer and the polyphenylene sulfidefiber layer, the chemical fabric has the advantage of good wear resistance and solves the problems that an existing chemical fabric without the function of good wear resistance frequently rubs with anobject when in use, and the service life of the existing chemical fabric is reduced in long-time use.

Owner:吴江市盛泽蓝翔纺织有限公司

Two-component middle coating primer

The invention provides a two-component middle coating primer. The two-component middle coating primer is prepared from, by mass, 44%-66.25% of saturated polyester resin, 15%-25% of synthetic fatty acid resin, 4%-6% of bentonite slurry of 10%, 0.5%-2% of a dispersing agent, 0.15%-0.5% of a flatting agent, 0.1%-0.3% of an antifoaming agent, 1%-3% of xylene, 2%-3.5% of zinc stearate, 0.5% of n-butyl acetate, 8%-12% of cellulose acetate of 20%, 1%-2% of a light stabilizer and 1.5%-3% of n-butyl acetate; all the ingredients are mixed and dispersed to be even till the fineness is smaller than or equal to 35 microns, and the viscosity is 2,500 mpa.s / 25 DEG C to 3,500 mpa.s / 25 DEG C. The two-component middle coating primer has the advantages of being high in hardness, good in wear resistance and scratching resistance and capable of well meeting outdoor woodware.

Owner:广东花王涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com