Velvet anti-scratch waterborne polyurethane paint

A water-based polyurethane and polyurethane dispersion technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of weakened gloss, insufficient elastic touch, poor scratch resistance, weather resistance and chemical resistance, and achieve scratch resistance. Effects of sexual touch, good touch, excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

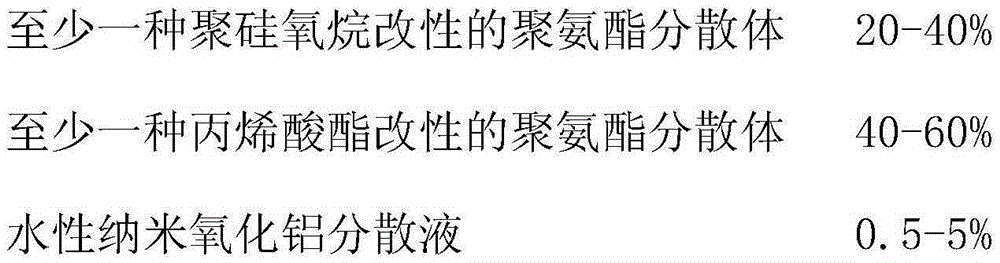

[0017] The invention provides a kind of water-based polyurethane coating with velvet feeling and anti-scratch. The water-based polyurethane coating is composed of the following components in terms of weight percentage: 20-40% of at least one polysiloxane-modified polyurethane dispersion , at least one acrylate-modified polyurethane dispersion 40-60%, aqueous nano-alumina dispersion 0.5-5%, polyurethane foaming elastic beads 1-8%, thickener 0.5-15%, defoamer 0.1 -1%, curing agent 1-5%. The preparation method of the water-based polyurethane coating comprises the following steps: weighing each component according to the above-mentioned percentage by weight, and mixing polysiloxane-modified polyurethane dispersion, acrylate-modified polyurethane dispersion, and water-based nano-alumina dispersion 1. Add polyurethane foam elastic beads and defoamer to the mixer and mix, then add thickener and curing agent, stir at 400-600 rpm for at least 30 minutes, and mix evenly to get a velvet-...

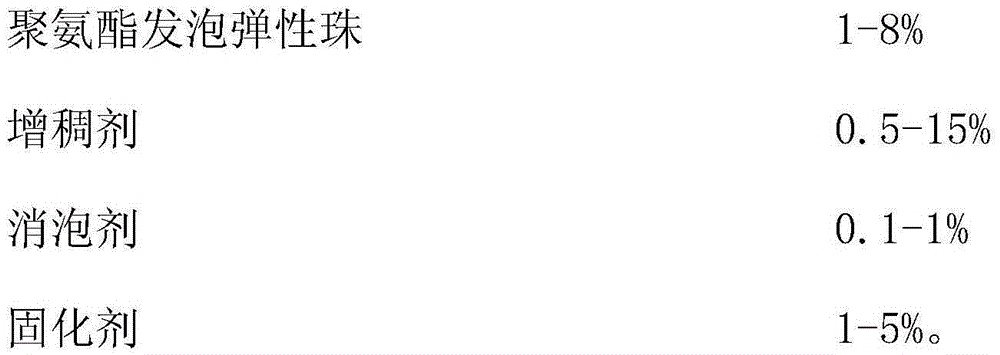

Embodiment 1

[0021] The velvety, scratch-resistant water-based polyurethane coating consists of the following components in percent by weight:

[0022]

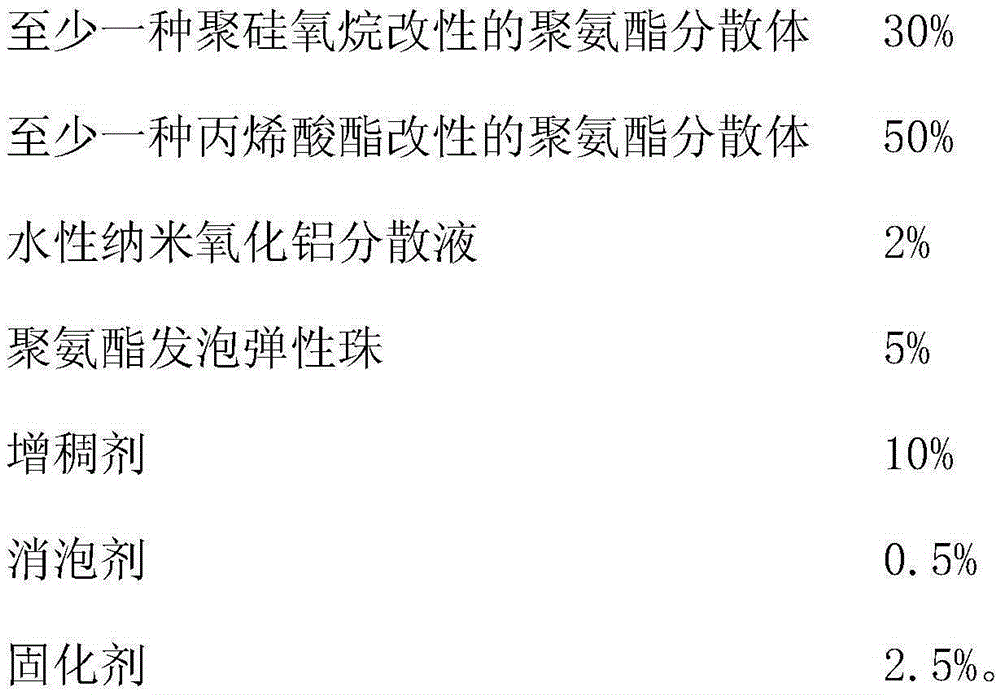

Embodiment 2

[0024] The velvety, scratch-resistant water-based polyurethane coating consists of the following components in percent by weight:

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com