PC/AS/ acrylic resin alloy material and preparation method thereof

A technology of acrylic resin and alloy materials, which is applied in the field of polymer materials, can solve the problems of difficult coloring of ASA materials, limited use of PC-ASA alloys, and difficulty in coloring, etc., and achieves the effects of easy processing, low cost, and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

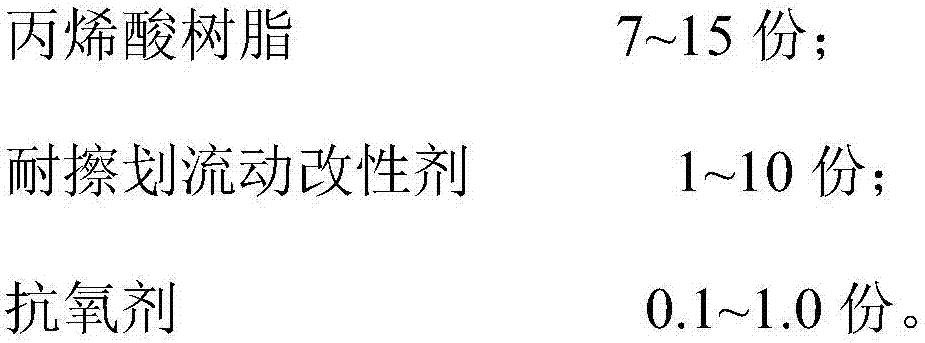

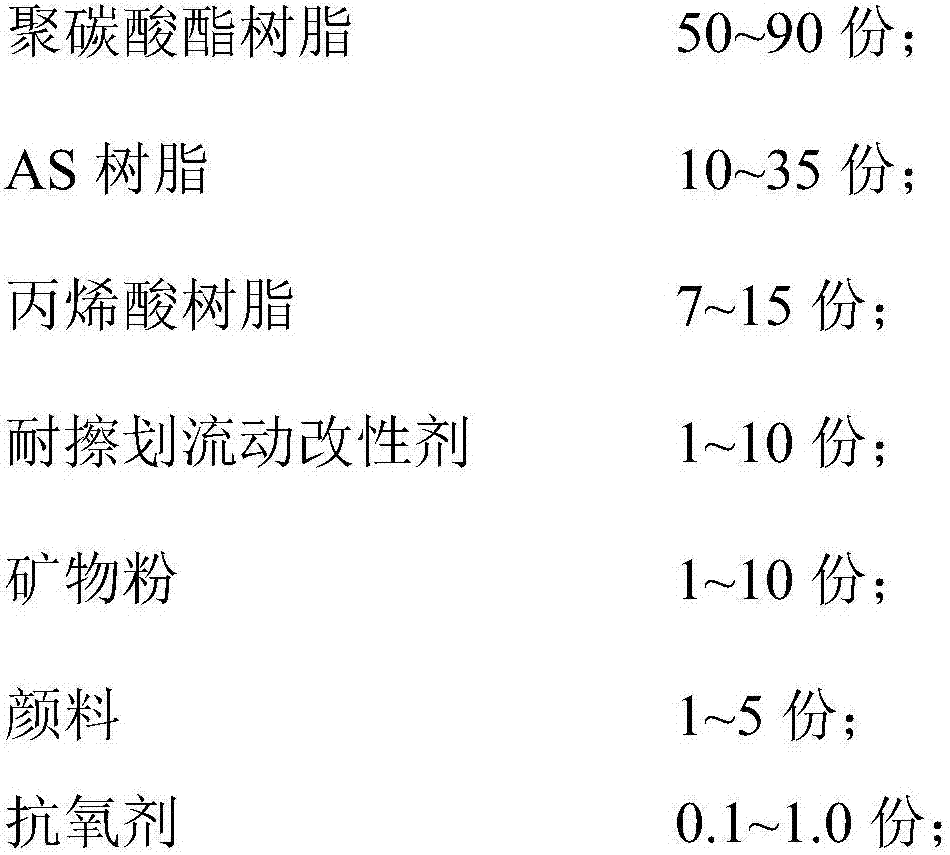

[0043] The PC / AS / acrylic resin alloy material described in this embodiment is composed of the following raw materials in weight fractions: 50 parts of polycarbonate resin; 35 parts of AS resin; 15 parts of acrylic resin; scratch-resistant flow modifier is 4 parts; the antioxidant is 0.1 part, wherein in this embodiment, the heat distortion temperature of the polycarbonate resin is 105°C, and the heat distortion temperature of the AS resin is 110°C; the heat distortion temperature of the acrylic resin is 115°C, and the processing temperature is 210°C; the scratch-resistant flow modifier is methyl methacrylate; the antioxidant can be selected from conventional antioxidants in the prior art. The oxygen agent is preferably 1010.

[0044] The preparation method of PC / AS / acrylic resin alloy material described in this embodiment comprises the following steps:

[0045] (1) First, dry the polycarbonate and AS resin with the above-mentioned specific physical properties at 80°C for 6 ho...

Embodiment 2

[0049] The PC / AS / acrylic resin alloy material described in this embodiment is composed of the following raw materials in weight fractions: 60 parts of polycarbonate resin; 30 parts of AS resin; 10 parts of acrylic resin; scratch-resistant flow modifier is 1 part; the antioxidant is 0.2 parts; wherein in this embodiment, the heat distortion temperature of the polycarbonate resin is 110°C, and the heat distortion temperature of the AS resin is 80°C; the heat distortion temperature of the acrylic resin is 90°C, and the processing temperature is 230°C; the scratch-resistant flow modifier is silicone; the antioxidant can be a conventional antioxidant in the prior art, and the antioxidant in this embodiment is preferably It is antioxidant 168.

[0050] The preparation method of PC / AS / acrylic resin alloy material described in this embodiment comprises the following steps:

[0051] (1) First, dry the polycarbonate and AS resin with the above-mentioned specific physical properties at ...

Embodiment 3

[0055] The PC / AS / acrylic resin alloy material described in this embodiment is composed of the following raw materials in weight fractions: 70 parts of polycarbonate resin; 22 parts of AS resin; 8 parts of acrylic resin; scratch-resistant flow modifier 8 parts; 0.5 parts of antioxidant; 3 parts of pigment; wherein in this embodiment, the heat distortion temperature of the polycarbonate resin is 140°C, and the heat distortion temperature of the AS resin is 100°C; the acrylic resin The heat distortion temperature is 105°C, and the processing temperature is 240°C; the scratch-resistant flow modifier is a thermoplastic acrylonitrile-styrene polymer, and AS accounts for the polymer in the thermoplastic acrylonitrile-styrene polymer The mass percentage is 50wt%; The antioxidant can be selected from conventional antioxidants in the prior art, and the antioxidant in the present embodiment is preferably antioxidant 1024; the pigment can be selected from conventional antioxidants in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com