Active Energy Ray-Curable Composition for Forming Cured Film on Cyclic Olefin-Based Resin Substrate and Hard Coat Film and Laminate

An active energy ray, olefin resin technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the properties of the laminate, such as friction resistance, insufficient transparency, and poor interlayer adhesion. sufficient and other problems to achieve the effects of excellent substrate adhesion, excellent curl resistance, and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

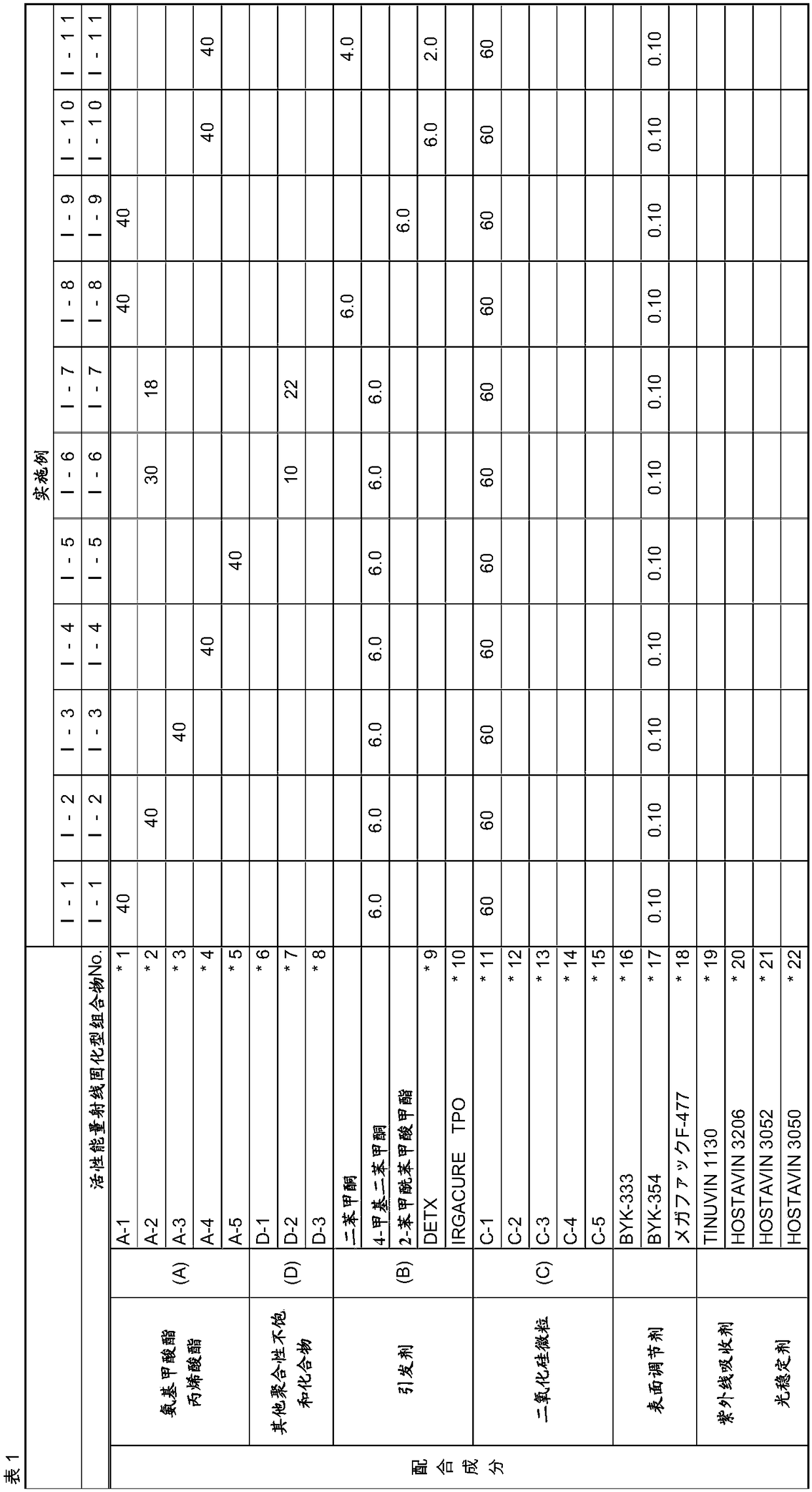

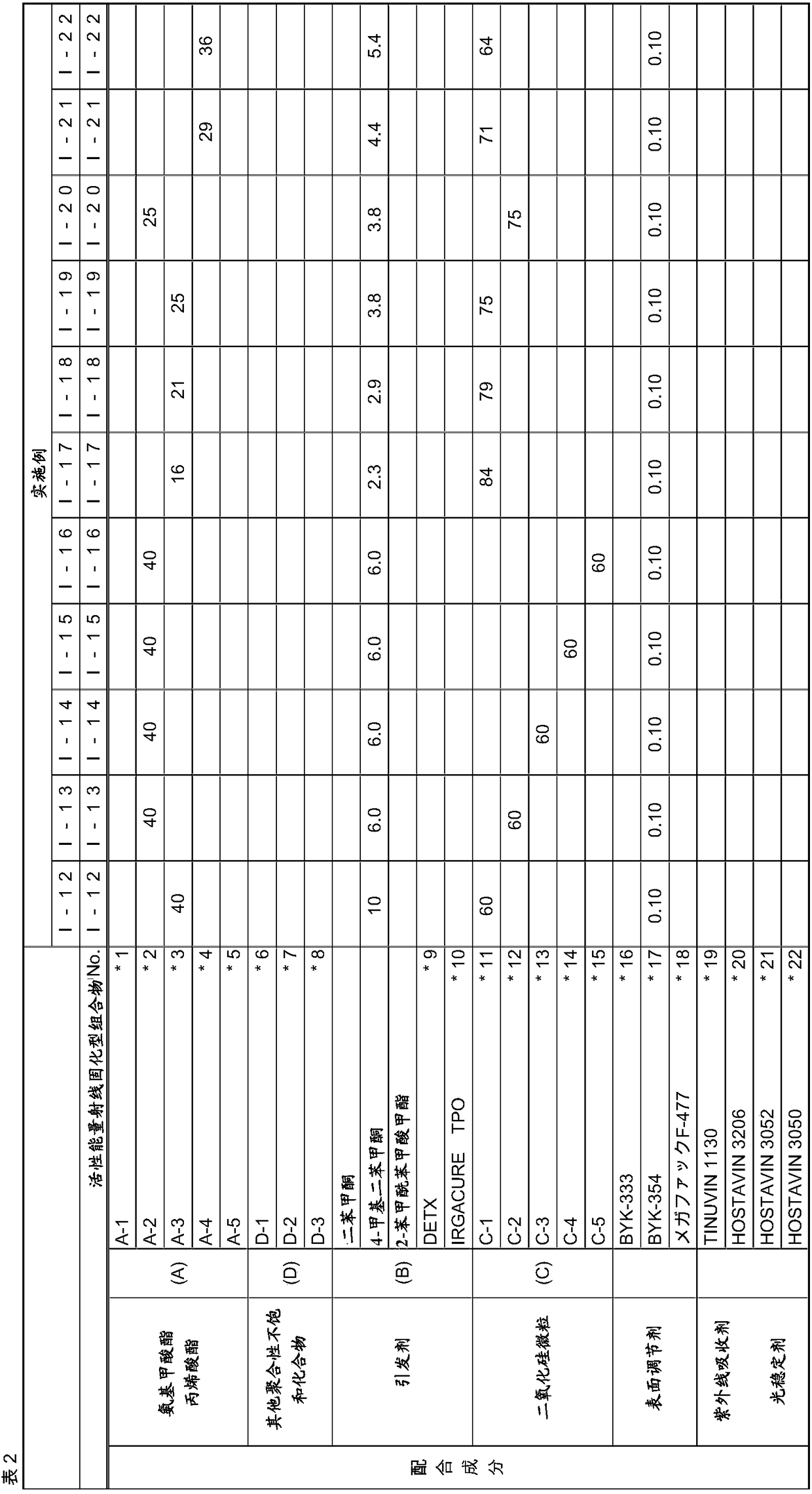

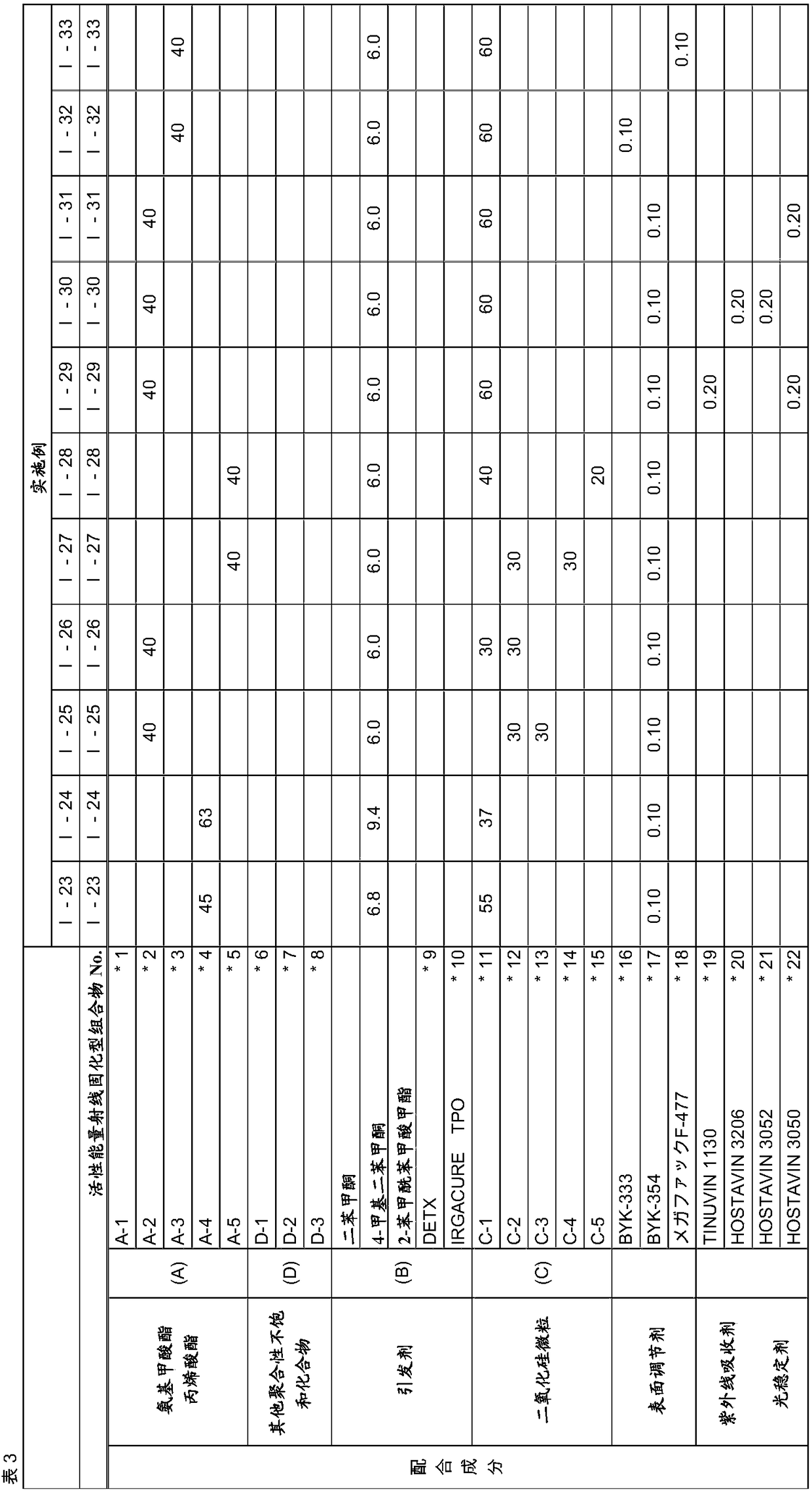

Examples

preparation example Construction

[0095]

[0096] The active energy ray-curable composition in the first aspect of the present invention contains the above-mentioned urethane (meth)acrylate (A), a benzophenone-based initiator and / or a thioxanthone-based initiator ( B) and silica fine particles (C) are essential main components, and additional components used as needed can be mixed, dissolved or dispersed in a solvent.

[0097]

[0098] From the viewpoint that the active energy ray-curable composition in the first aspect of the present invention can obtain a cured film having excellent adhesion especially to a cyclic olefin-based resin, the base material is preferably a cyclic olefin-based resin molded article, Especially preferably, it is a cyclic olefin resin film.

[0099] According to the first aspect of the present invention, there is provided a method for producing a hard coat film, which includes the step of: coating the active energy ray-cured coating according to the first aspect of the present inv...

Embodiment

[0204] Hereinafter, the present invention will be described more specifically with reference to production examples, examples, and comparative examples. However, the present invention is not limited thereto. In each example, unless otherwise specified, "part" and "%" are based on mass. In addition, the film thickness of the coating is based on the cured coating.

[0205] (first method)

manufacture example I-1

[0206] (Manufacture example I-1) Manufacture of silica microparticles No.C-1

[0207] Colloidal silica (dispersion medium: water, silica concentration: 40% by mass, average primary particle diameter: 23nm, trade name: スノーテックス ST -O-40, manufactured by Nissan Chemical Industry Co., Ltd.) 250 parts (the amount of silica fine particles is 100 parts), 3-methacryloxypropyltrimethoxysilane 10 parts, p-methoxyphenol 0.2 part and iso 143 parts of propanol, and then heated up while stirring. When the volatile components began to reflux, propylene glycol monomethyl ether was added to make them azeotropically distilled to replace the solvent in the reaction system.

[0208] Next, it reacted stirring at 95 degreeC for 2 hours, then lowered temperature to 60 degreeC, added 0.03 part of quaternary ammonium salts, and reacted stirring for 1 hour more. After the reaction was completed, the volatile components were distilled off under reduced pressure, and then propylene glycol monomethyl et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com