Gas-phase corrosion inhibitor used for carbon steel, and preparation method, application method, and purpose thereof

A gas-phase corrosion inhibitor and carbon steel technology, which is applied in the field of metal vapor-phase rust prevention, can solve the problems of low corrosion inhibition performance and toxicity of corrosion inhibitors, and achieve the effects of excellent corrosion inhibition performance, simple steps, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

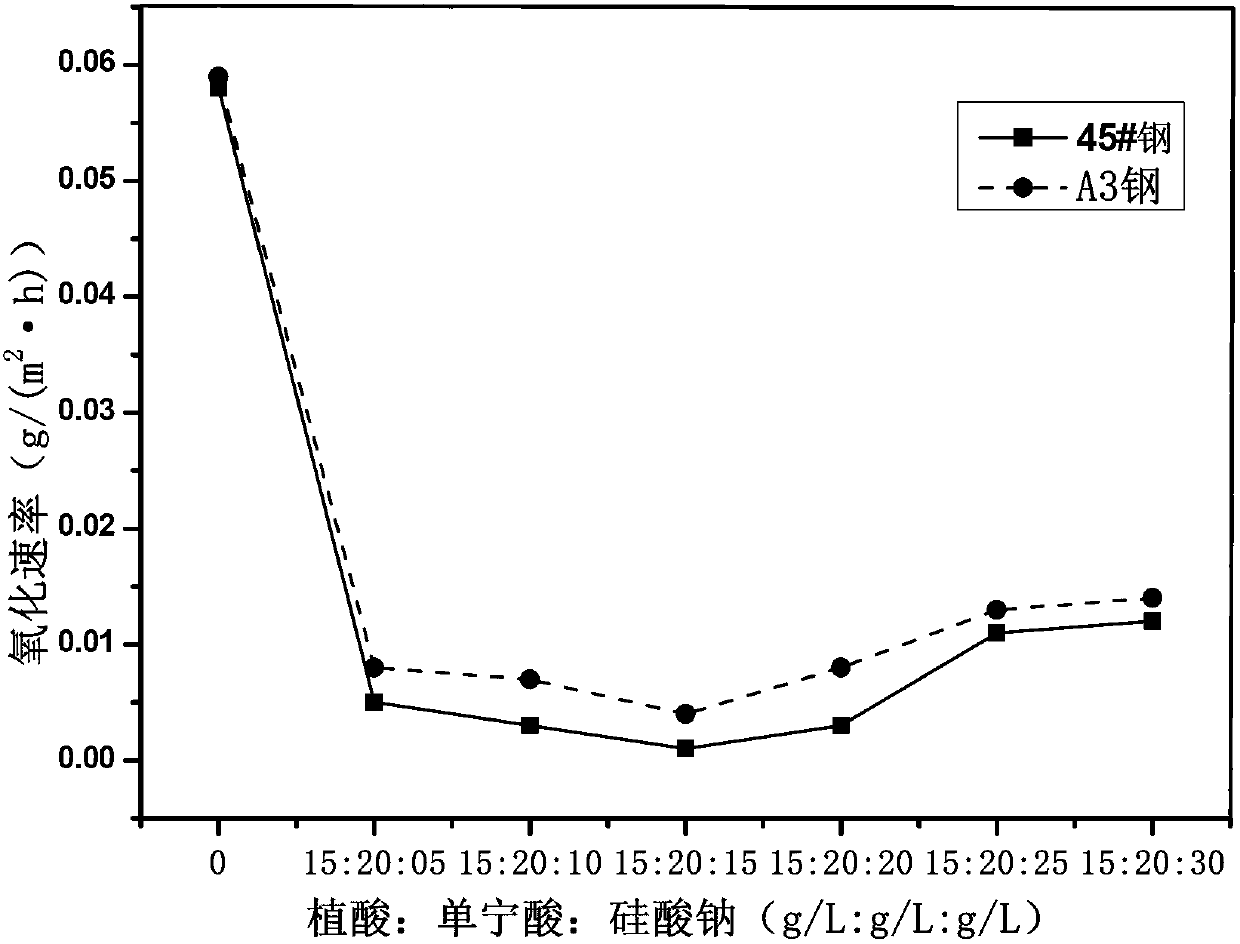

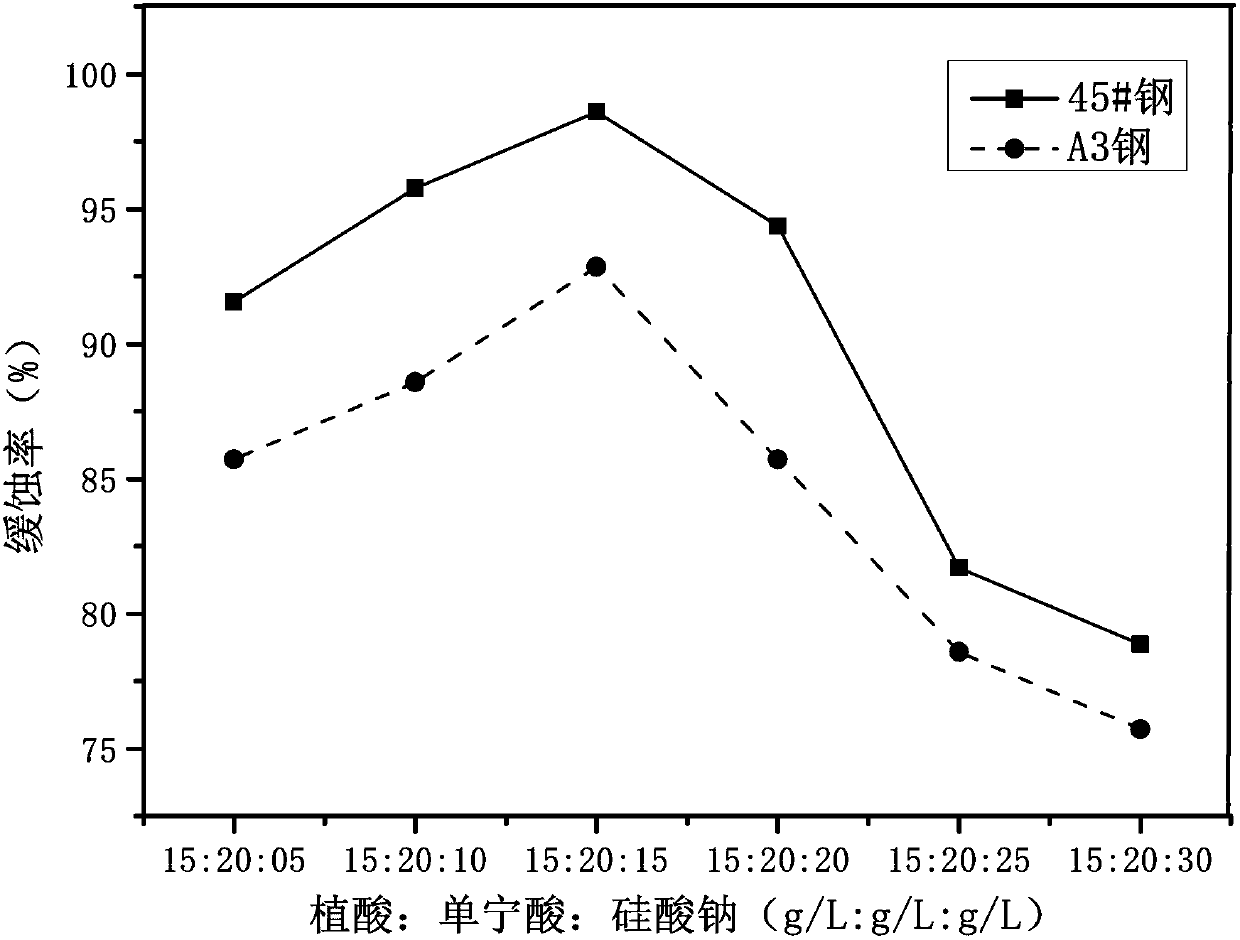

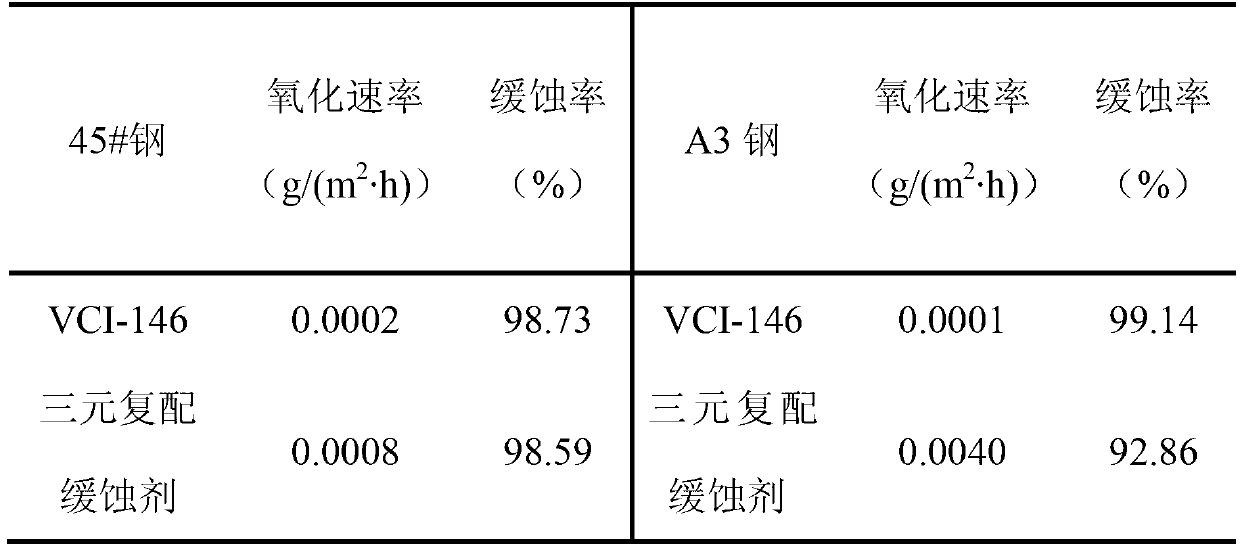

[0031] Weigh 30% of phytic acid, 40% of tannic acid and 30% of sodium silicate according to the mass percentage, put the weighed phytic acid, tannic acid and sodium silicate into distilled water respectively to prepare phytic acid solution , tannic acid solution and sodium silicate solution, its mass-volume concentration is 27g / L, 40.5g / L and 37g / L respectively, then these three kinds of solutions are all left to stand for 3 minutes and then mixed, stirred for 10 minutes to make it Fully mixed, a gas phase corrosion inhibitor for carbon steel of the present invention is obtained.

[0032] The method of using the vapor phase corrosion inhibitor for carbon steel is as follows: when the vapor phase corrosion inhibitor is prepared for 12 hours, the vapor phase corrosion inhibitor is coated on the antirust base paper to make it into vapor phase antirust paper; Then treat the antirust 45# steel surface to be clean, dry and free of foreign matter; finally, wrap the 45# surface tightl...

Embodiment 2

[0034] Weigh 27% of phytic acid, 45% of tannic acid, and 28% of sodium silicate according to mass percentage, respectively put the weighed phytic acid, tannic acid and sodium silicate into distilled water to prepare phytic acid solution , tannic acid solution and sodium silicate solution, its mass-volume concentration is 30g / L, 45g / L and 22g / L respectively, and then these three kinds of solutions are mixed after standing for 4 minutes, and stirred for 7.5 minutes to make it Fully mixed, a gas phase corrosion inhibitor for carbon steel of the present invention is obtained.

[0035] The above method of using the gas phase corrosion inhibitor for carbon steel is: when the gas phase corrosion inhibitor is prepared for 24 hours, the gas phase corrosion inhibitor is coated on the antirust base paper, and it is made into a gas phase antirust film; Then the surface of the antirust A3 steel is treated to be clean, dry and free of foreign matter; finally, the surface of the A3 steel is ...

Embodiment 3

[0037] Weigh respectively 22.5% of phytic acid, 40.5% of tannic acid, and 37% of sodium silicate according to mass percentage, and put the weighed phytic acid, tannic acid, and sodium silicate into distilled water to prepare phytic acid solution, monosodium silicate, respectively. Nitric acid solution and sodium silicate solution, its mass-volume concentration is 33g / L, 36g / L and 29.5g / L respectively, and then these three kinds of solutions are mixed after standing for 5 minutes, and stirred for 5 minutes to make it fully Mixing, a kind of vapor phase corrosion inhibitor for carbon steel of the present invention is obtained.

[0038] The method of using the above gas phase corrosion inhibitor for carbon steel is as follows: after the gas phase corrosion inhibitor is prepared, the gas phase corrosion inhibitor is immediately coated on the plastic film to make it into gas phase antirust paper; The rust-proof 45# steel surface is treated to be clean, dry and free of foreign matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com