Gas phase rustproof protecting bush of cold-rolled sheet coil

A gas-phase anti-rust, cold-rolled thin plate technology, applied in the direction of closing, packaging, transportation and packaging, etc., can solve the problems of high cost, poor anti-rust effect, inconvenient operation, etc., and achieve low cost of anti-rust, convenient turnover, anti-rust high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The invention discloses a gas-phase antirust sheath for cold-rolled thin plate coils, which includes a gas-phase antirust sheet 1, a fixing belt 2, and a fixing buckle 3. The structure and connection relationship of the above-mentioned components will be described in detail below.

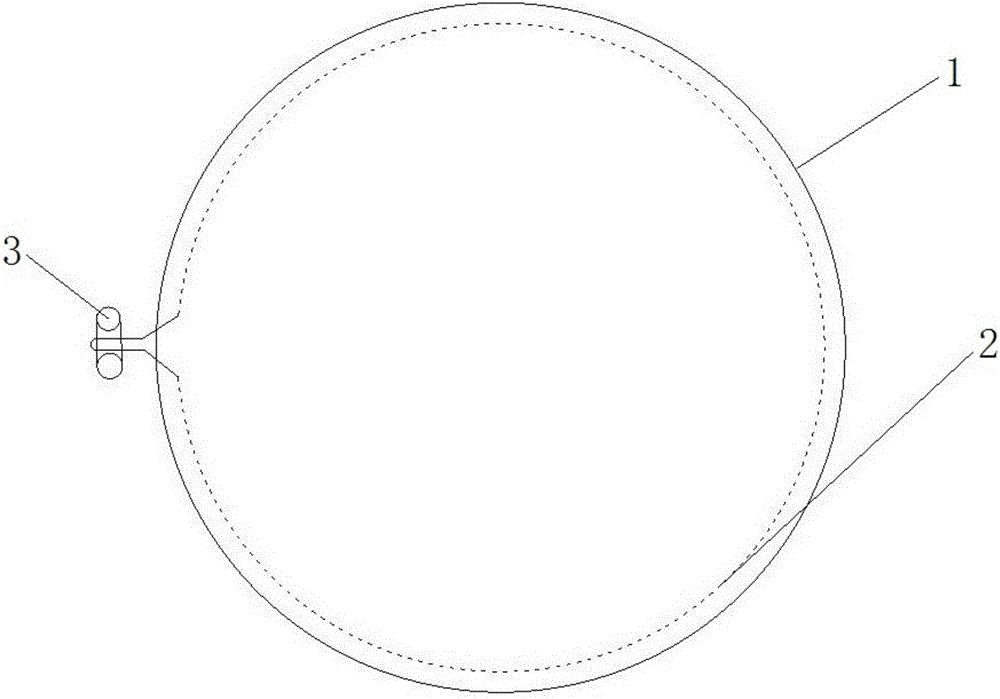

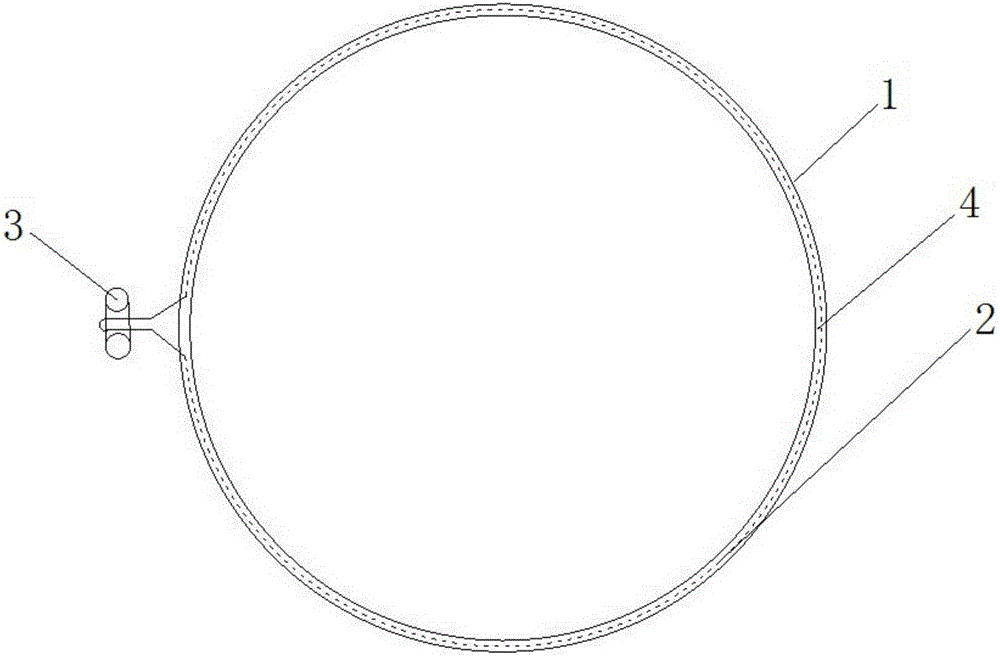

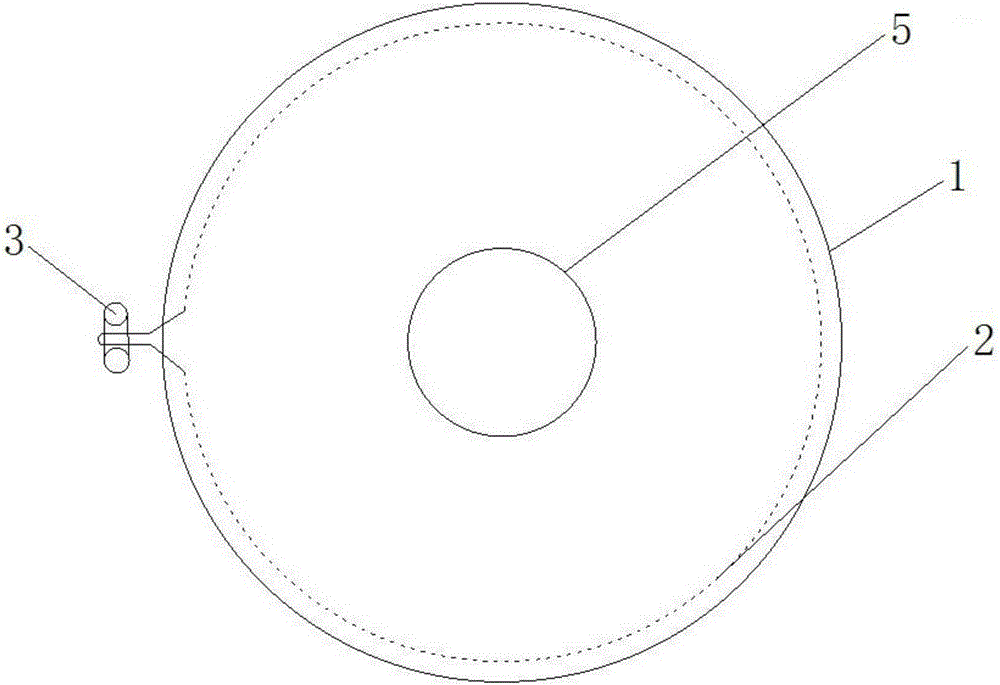

[0022] Such as figure 1 The weather antirust sheet 1 is a disc-shaped part, and a fixing belt 2 is provided near the edge of its circumference. The fixing belt 2 surrounds the circumference of the weather antirust sheet and is connected end to end by a fixing buckle. The fixing belt 2 intermittently passes through the edge of the gas phase antirust sheet 1, and the fixing belt is 10-25mm away from the outer peripheral edge of the gas phase antirust sheet. Fixing belt 2 comprises elastic band, plastic rope, cotton rope. Be provided with fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com