Patents

Literature

69results about How to "Reduce free space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

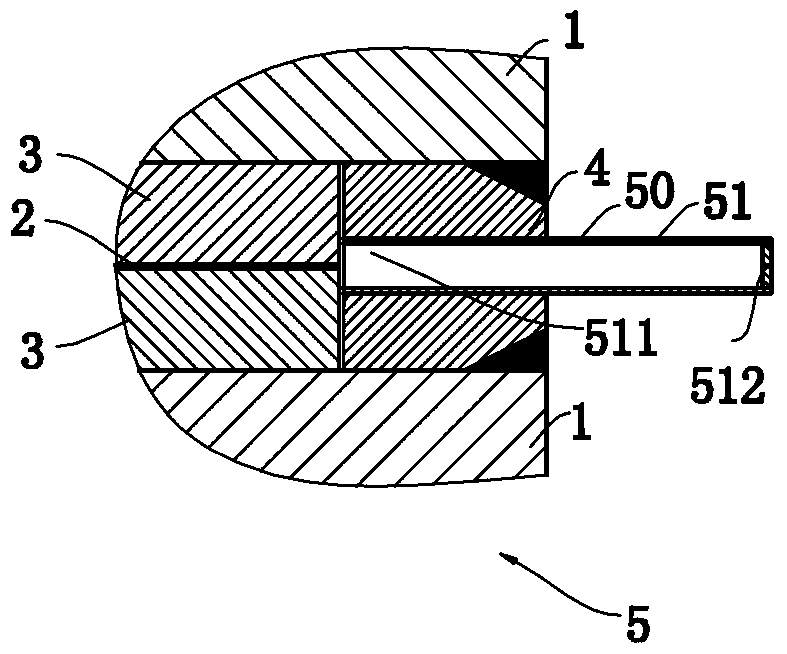

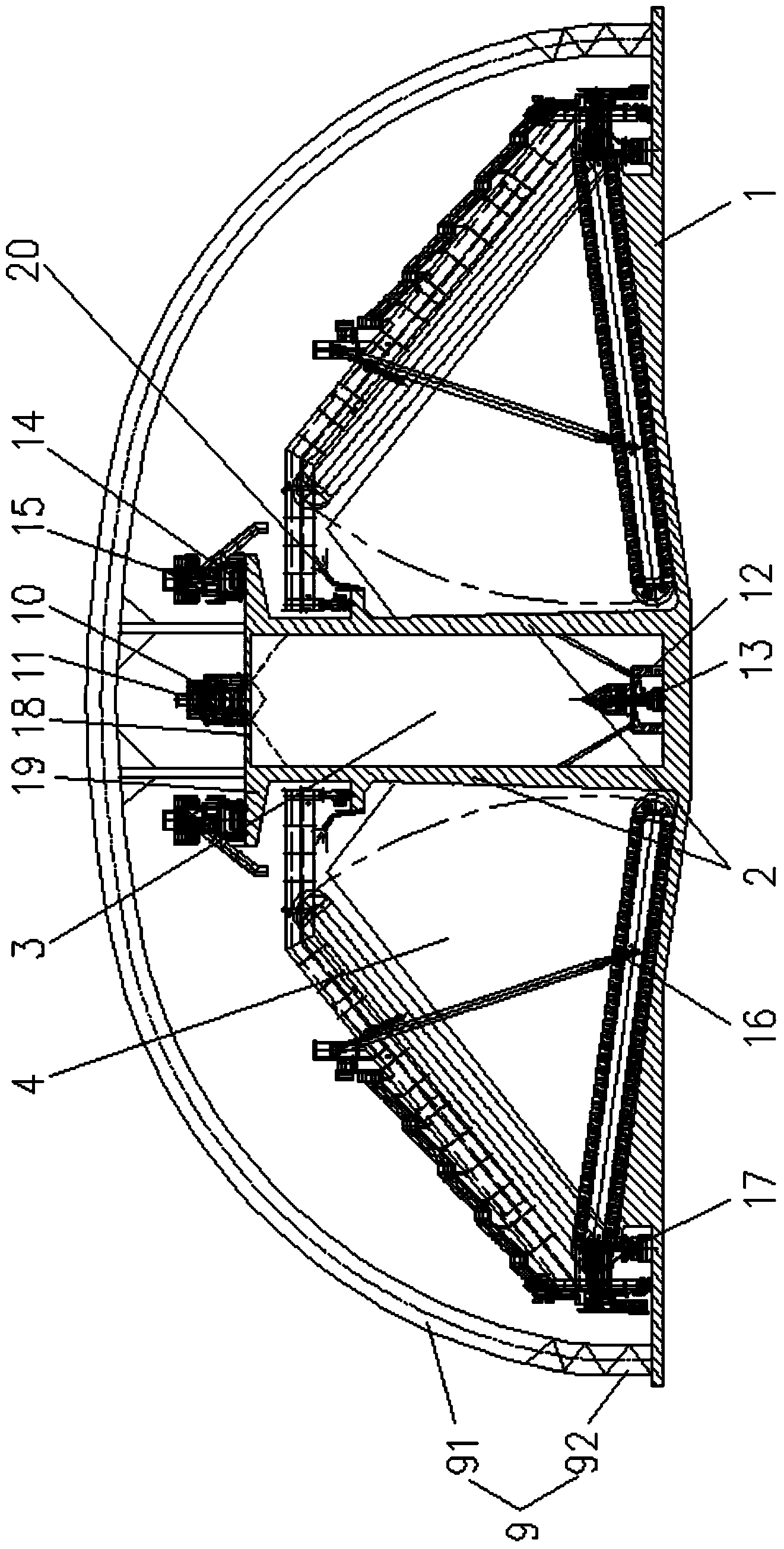

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

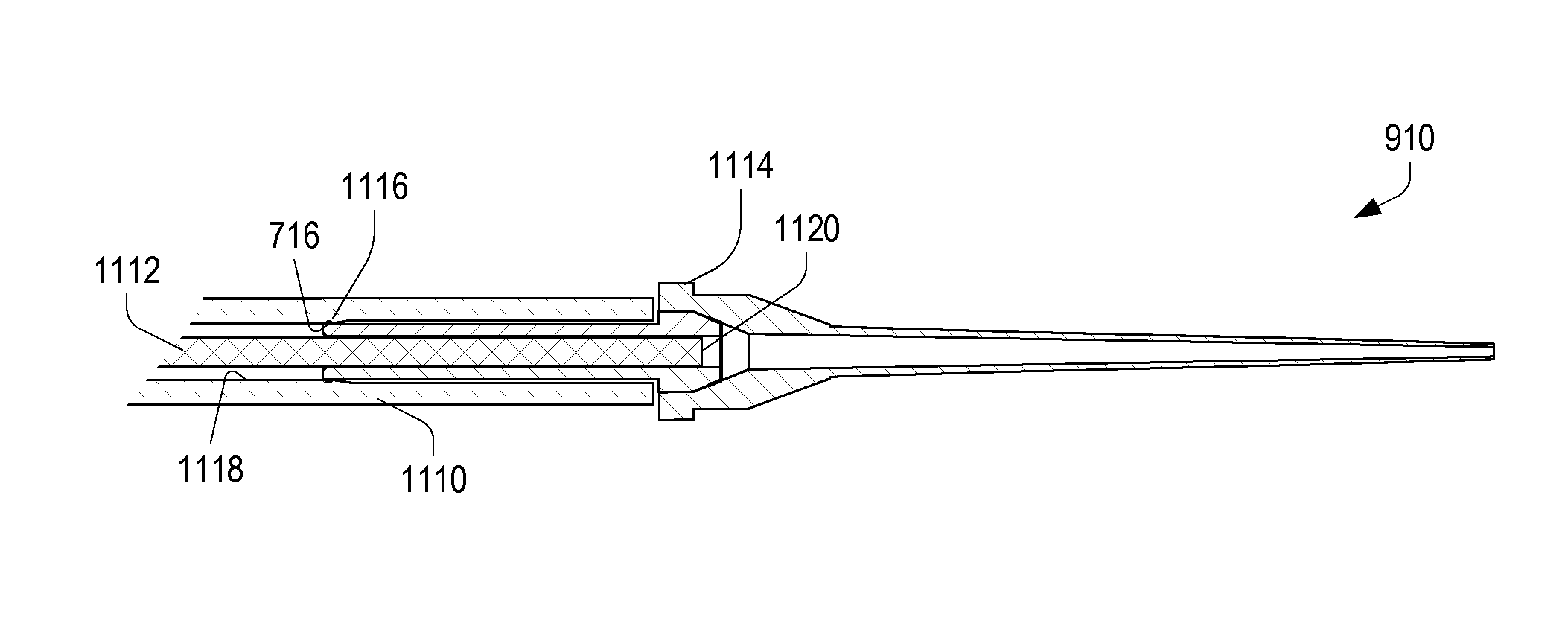

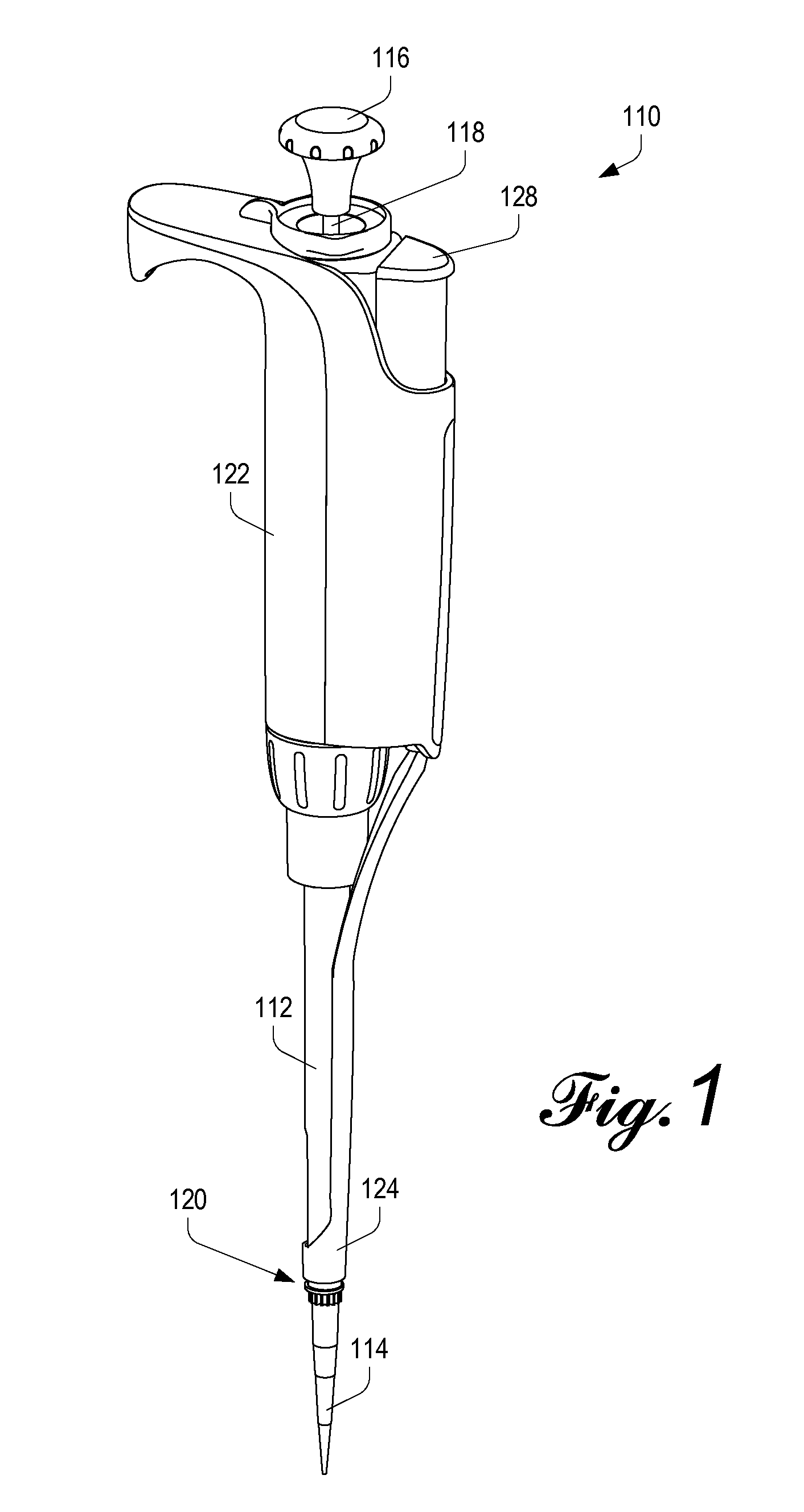

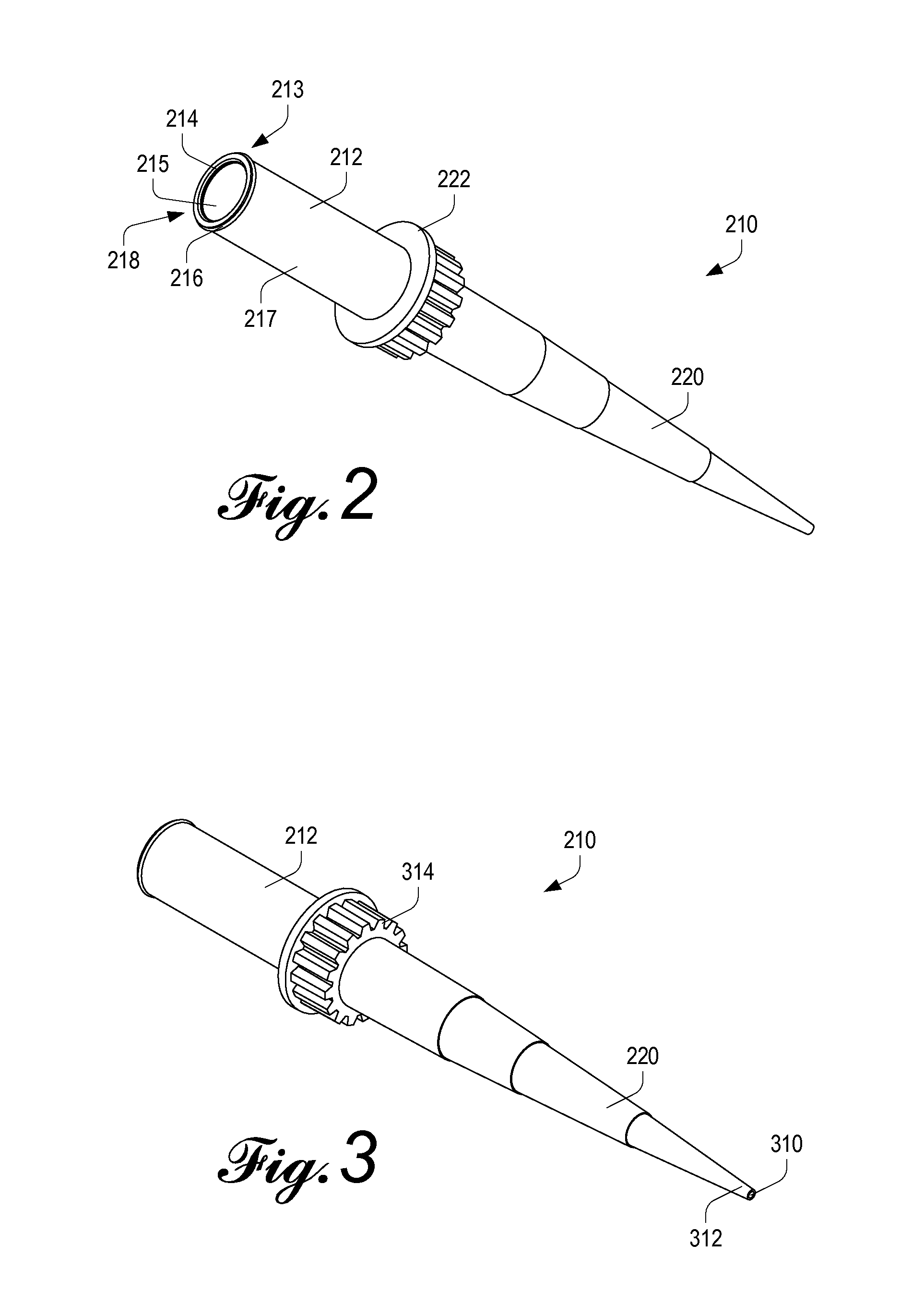

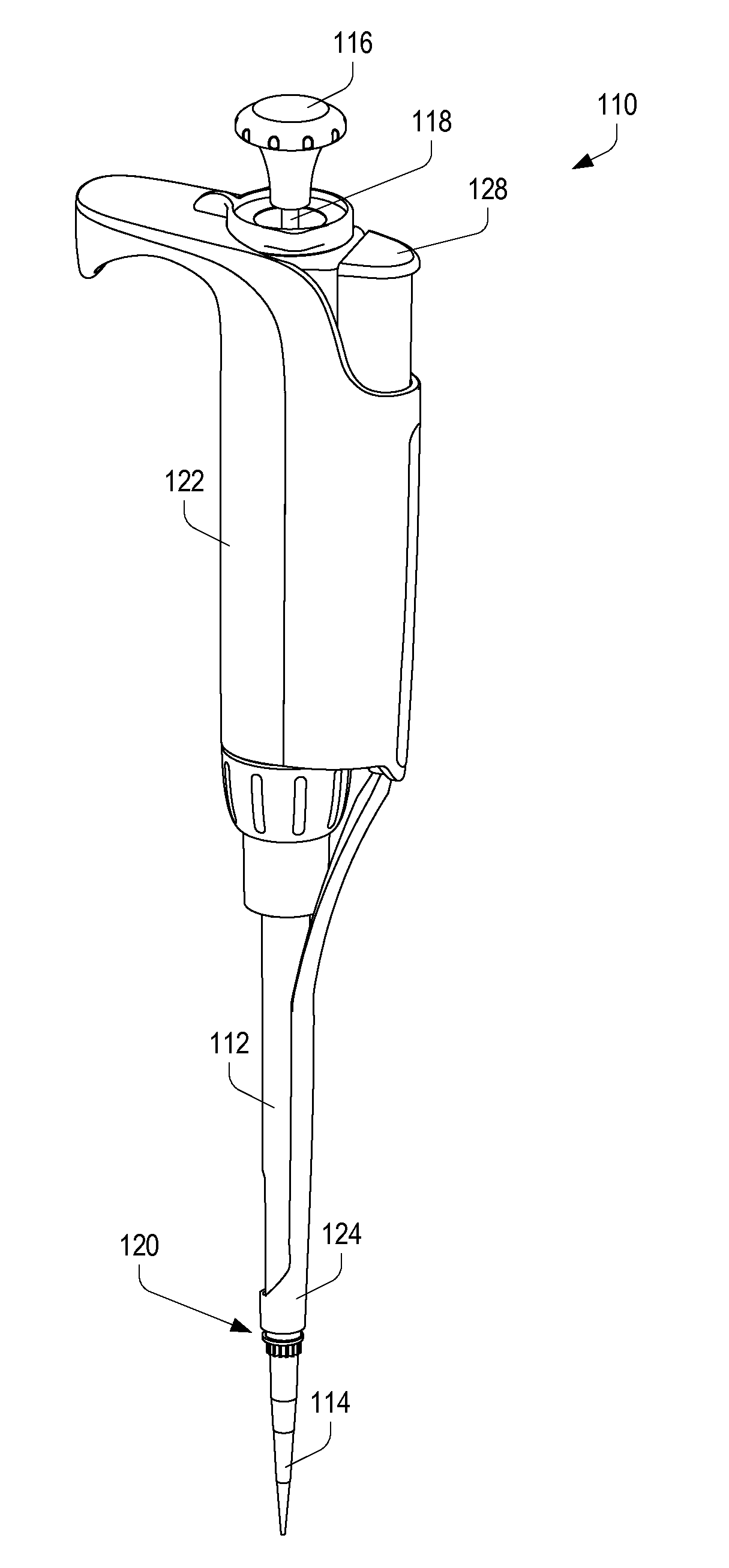

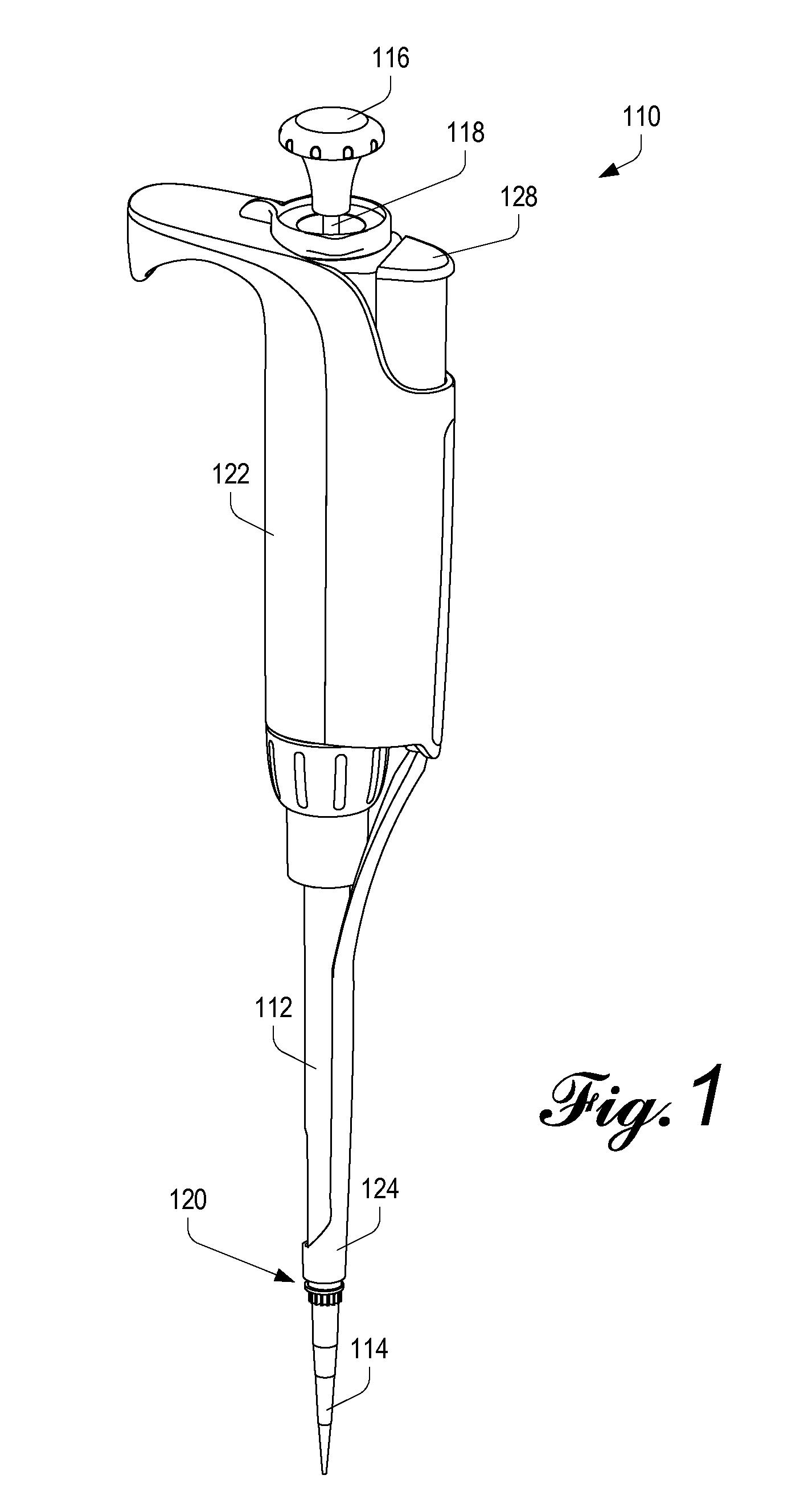

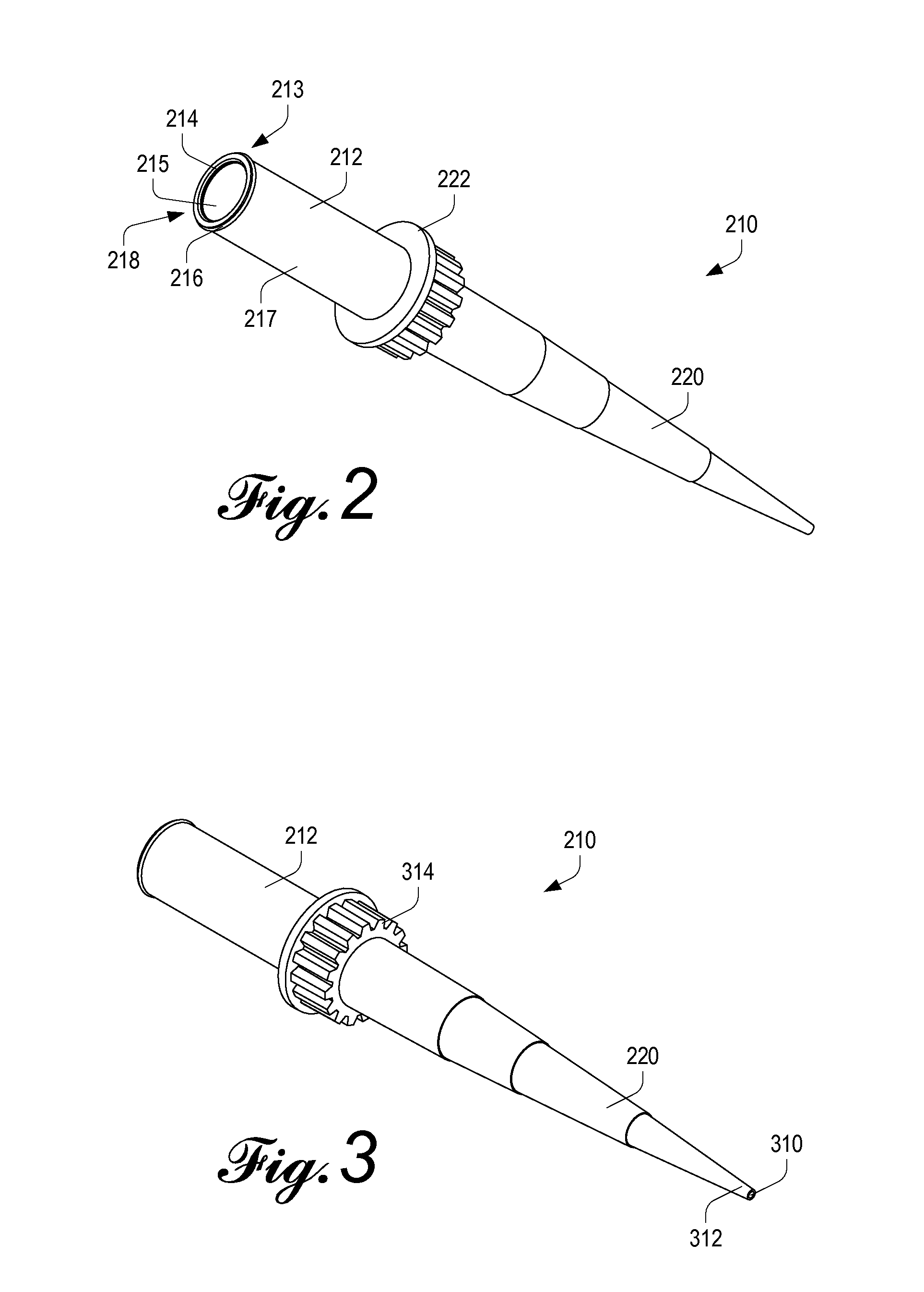

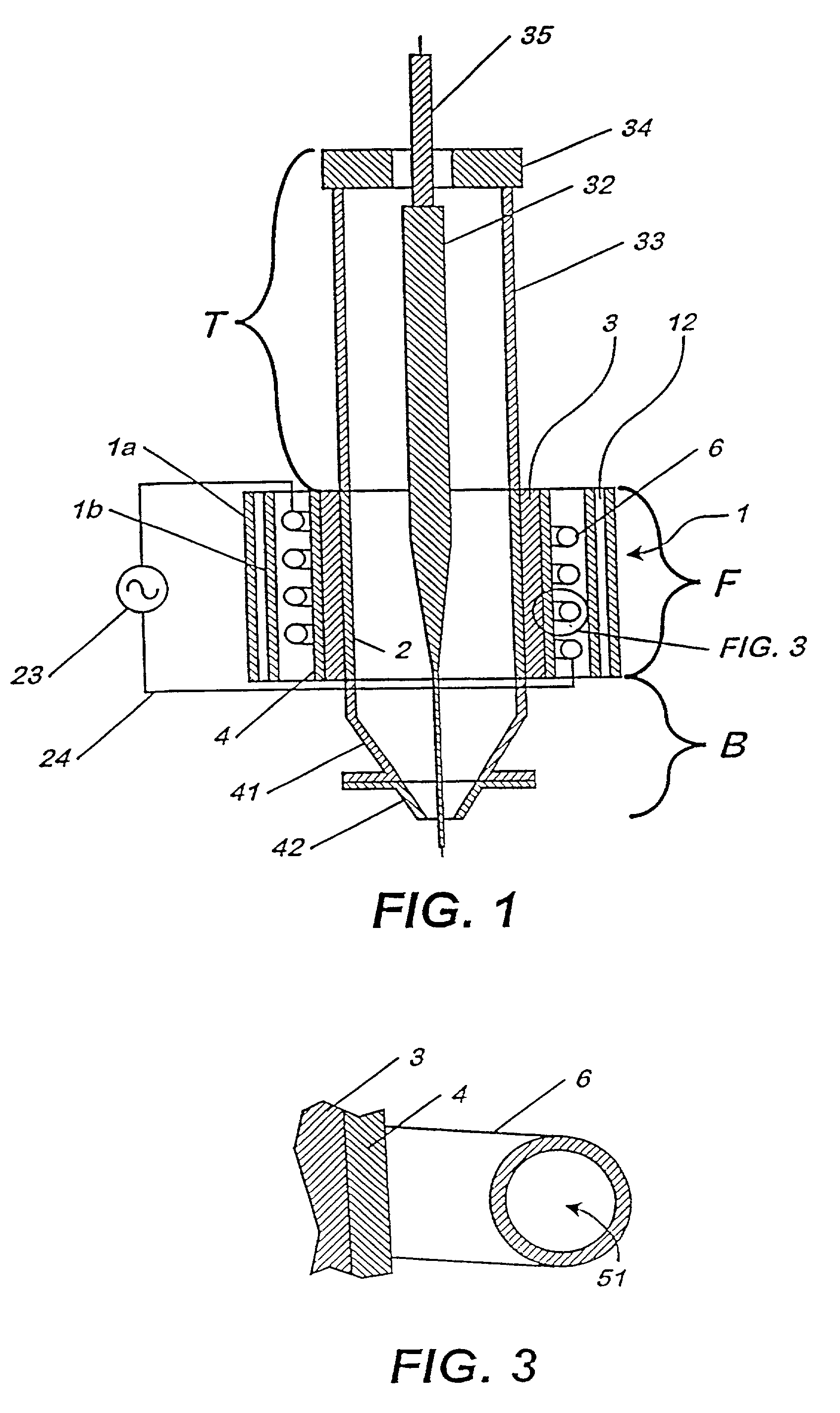

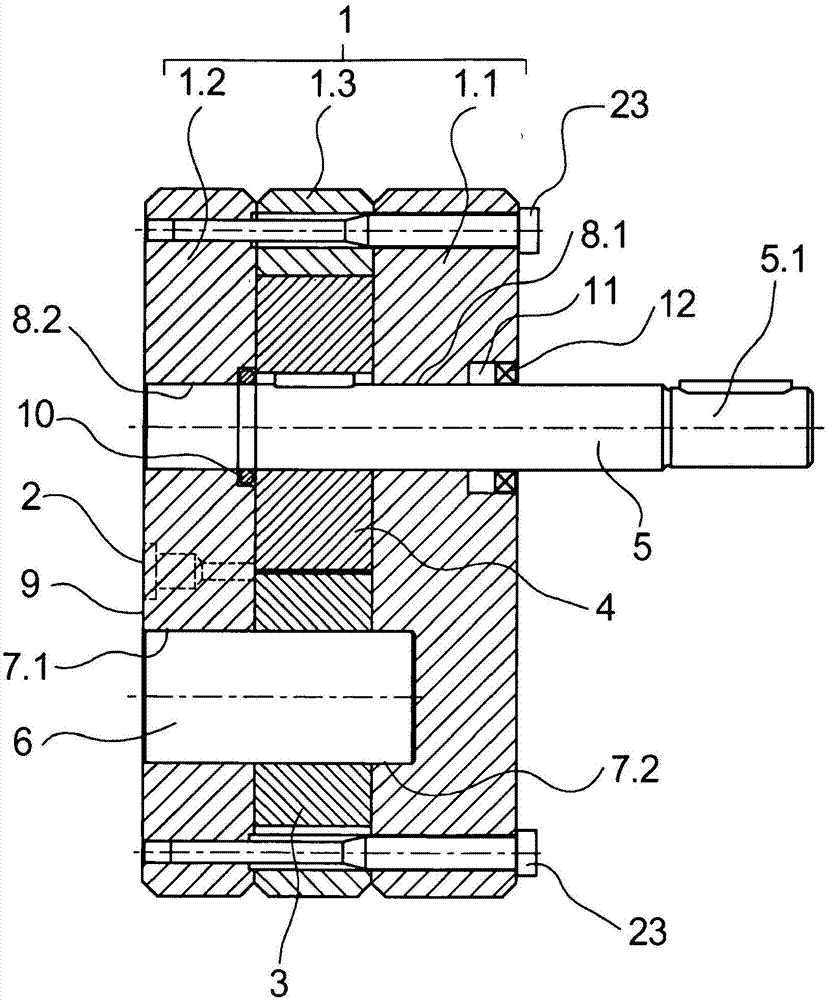

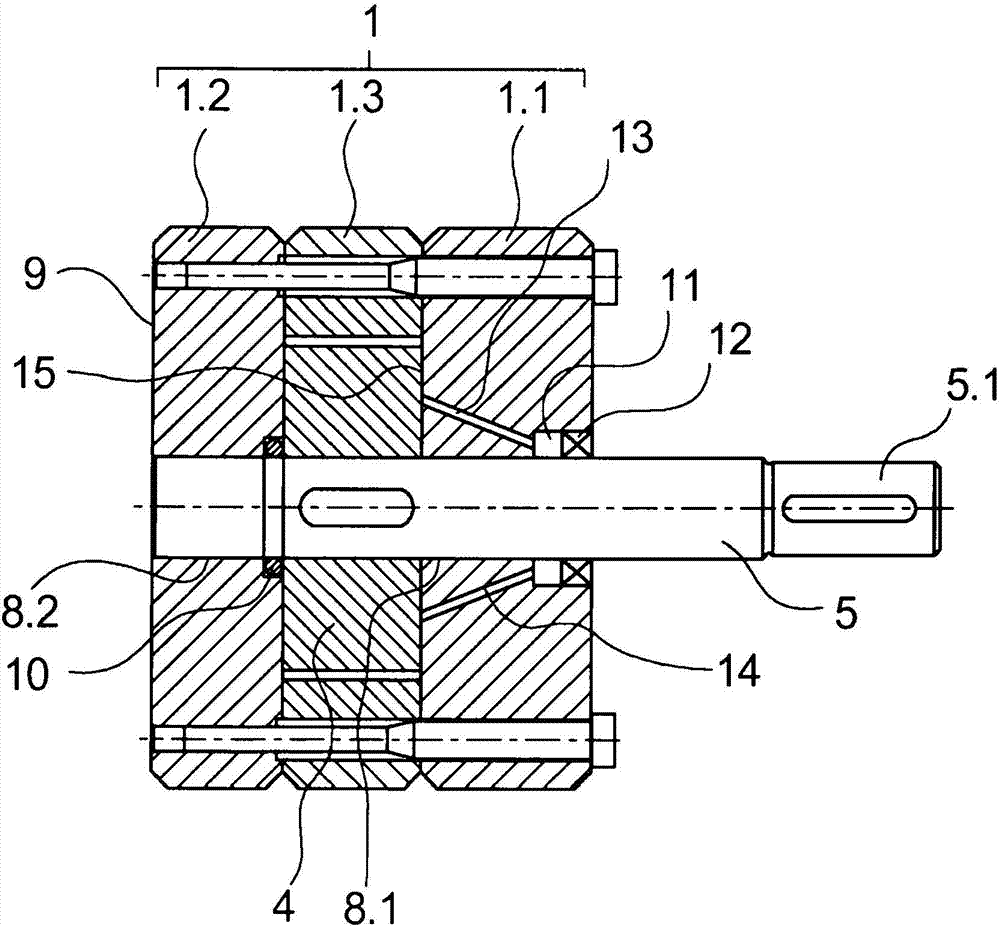

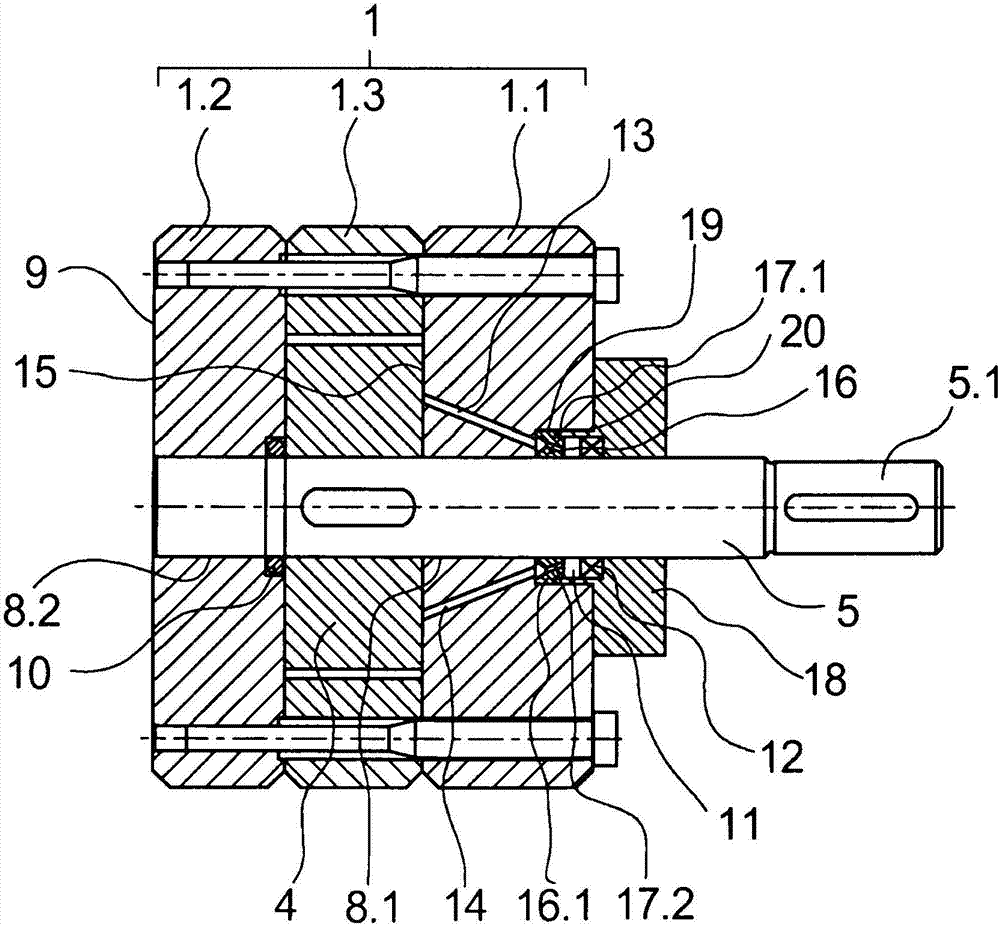

Pipette and sealing tip

ActiveUS8524170B2Reduce needLow ejectionWithdrawing sample devicesBurettes/pipettesPipetteEngineering

A sealing pipette tip includes features to seal the tip directly against the piston in an air displacement pipette, avoiding the need for a piston seal within the pipette. This configuration reduces potential points of failure, allows the pipette-tip interface to be optimized, and improves liquid handling characteristics of the pipette.

Owner:METTLER TOLEDO RAININ LLC

Pipette and sealing tip

ActiveUS20120213677A1Reduce needIncrease resistanceWithdrawing sample devicesBurettes/pipettesPipetteEngineering

A sealing pipette tip includes features to seal the tip directly against the piston in an air displacement pipette, avoiding the need for a piston seal within the pipette. This configuration reduces potential points of failure, allows the pipette-tip interface to be optimized, and improves liquid handling characteristics of the pipette.

Owner:METTLER TOLEDO RAININ LLC

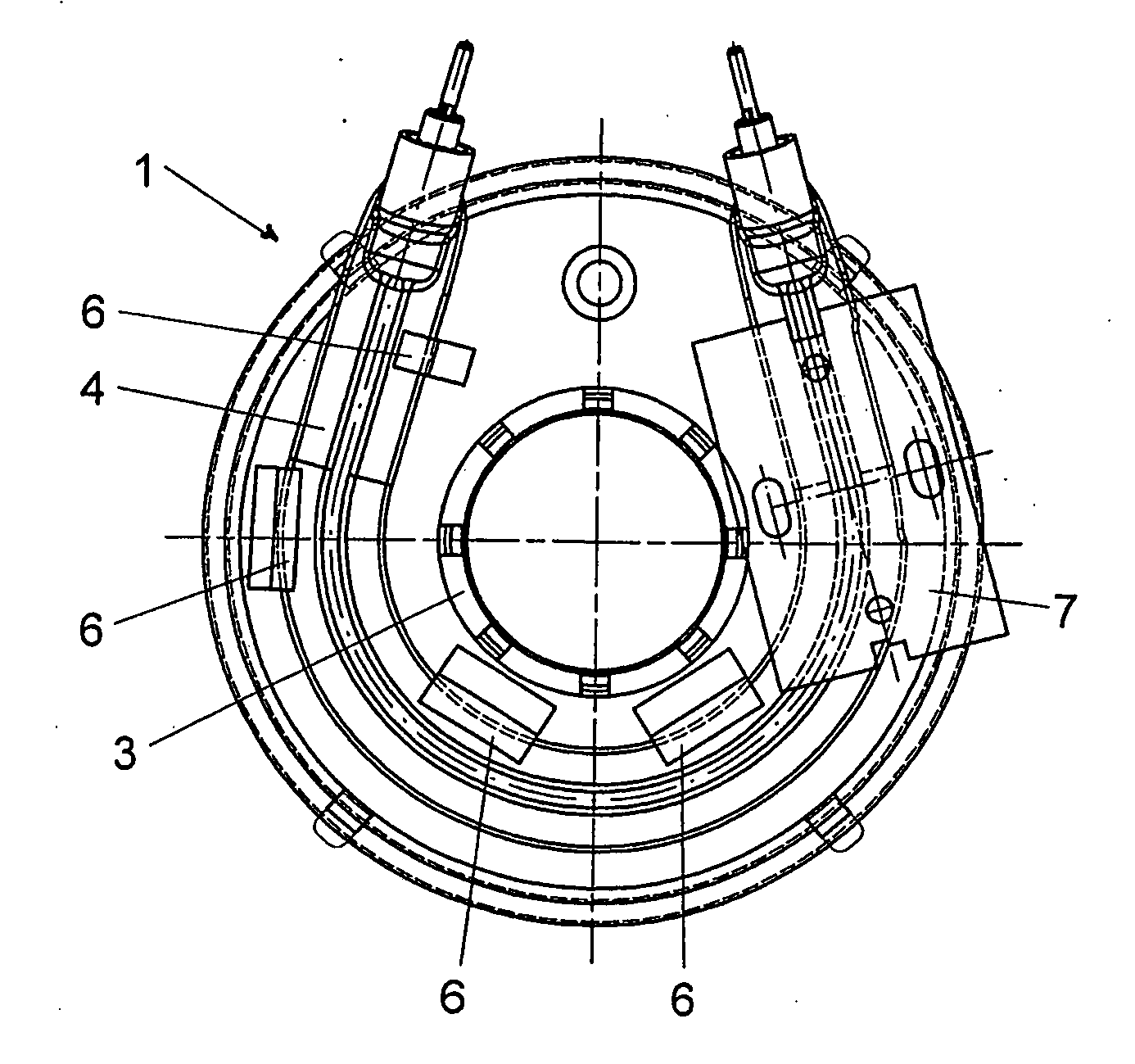

Heatable part of a pump housing

InactiveUS20100119360A1Increase contact areaSpread heatTableware washing/rinsing machine detailsBlade accessoriesEngineeringHeat distribution

The description relates to a heatable pump housing part comprising a heat distribution sheet fixed on the housing part and a tubular heating element fixed on the heat distribution sheet. According to the invention the tubular heating element is positioned in a groove or a step on the housing part that is covered by the heat distribution sheet.

Owner:EICHENAUER HEIZELEMENTE

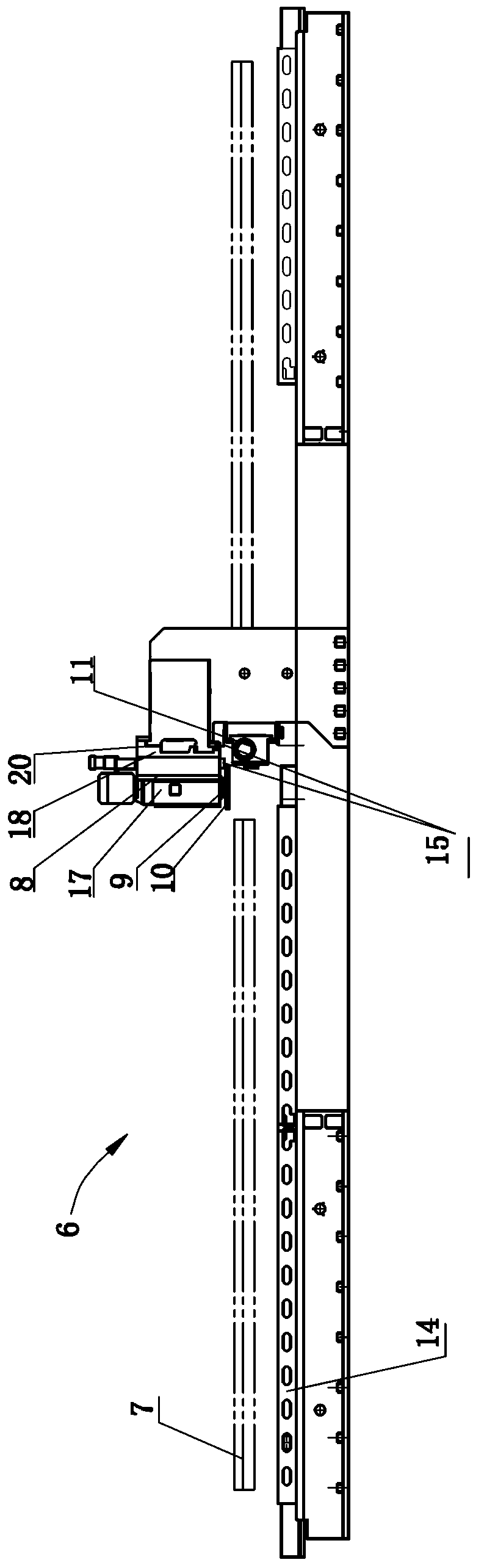

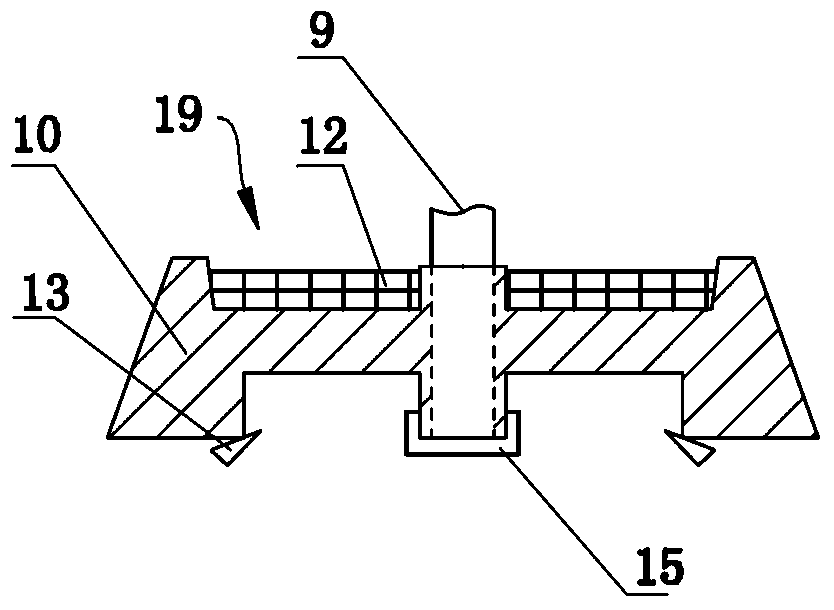

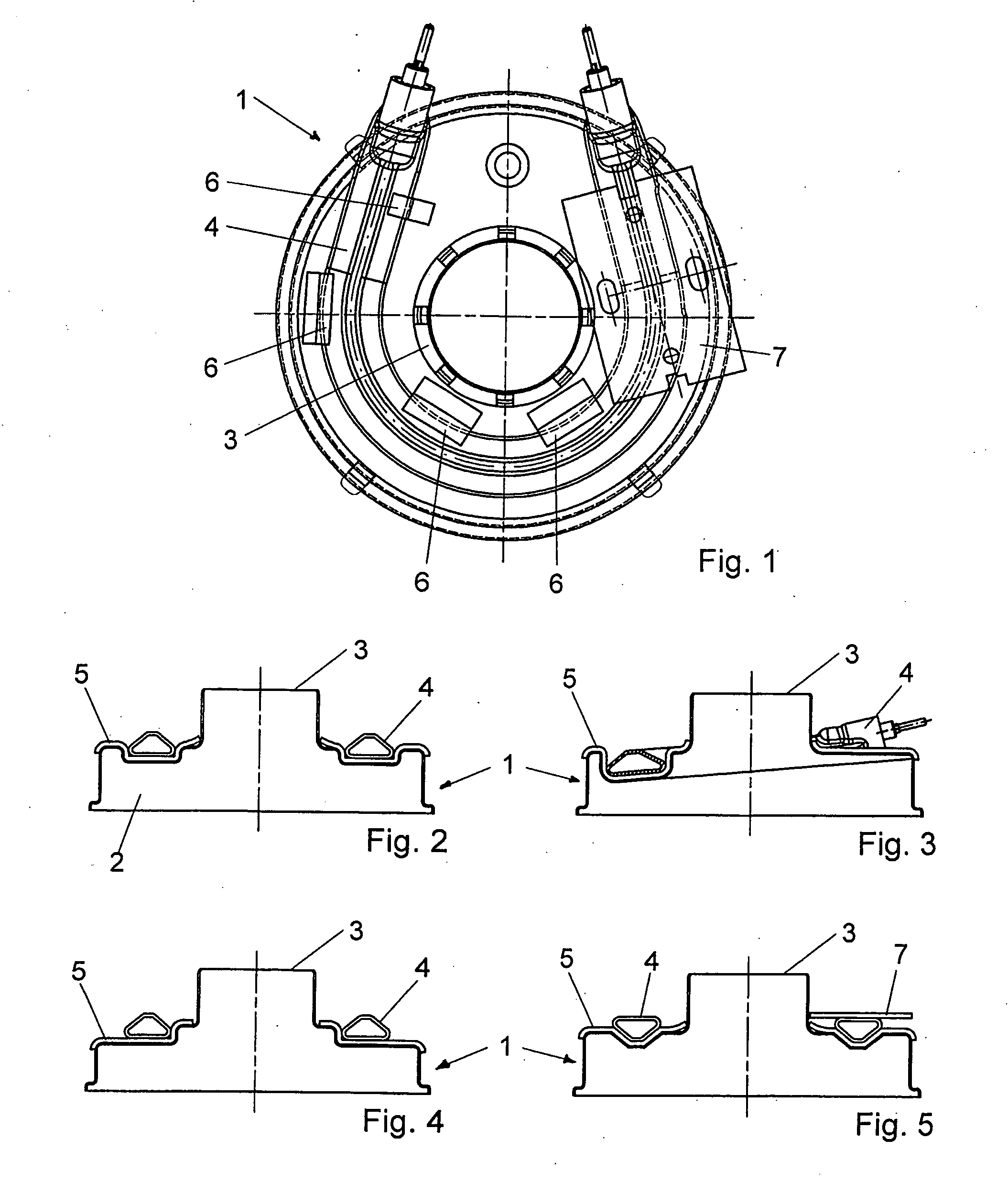

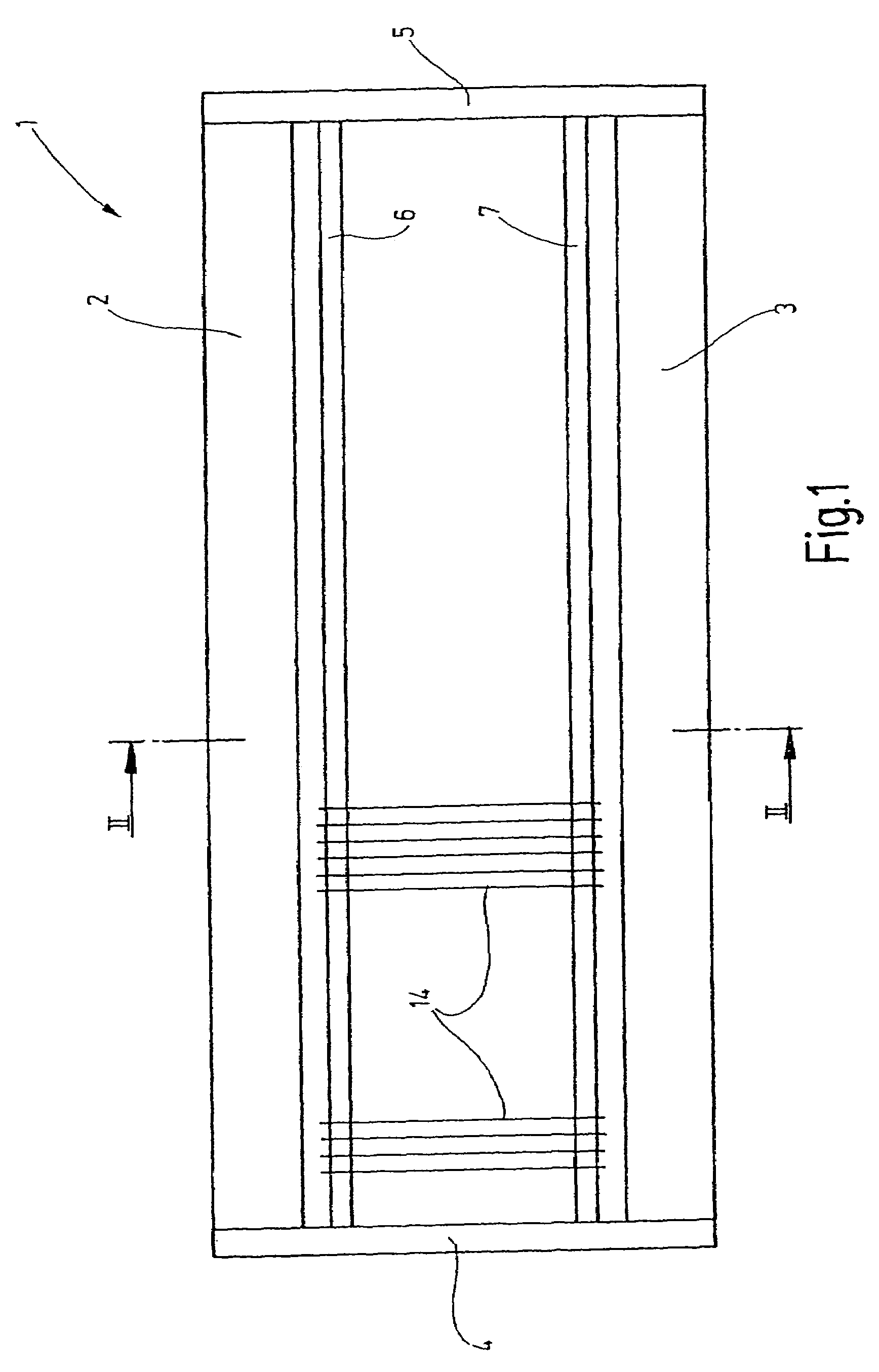

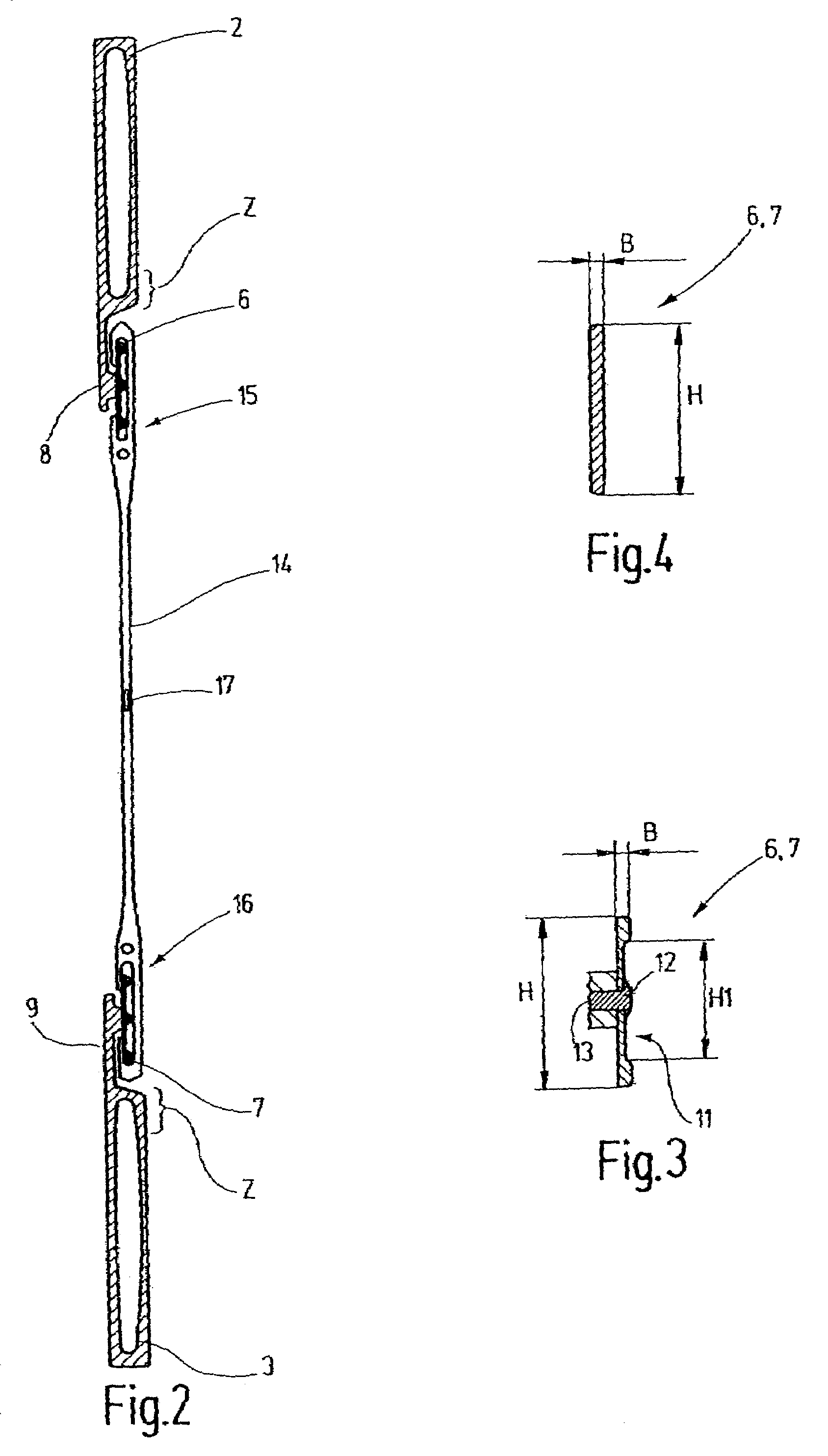

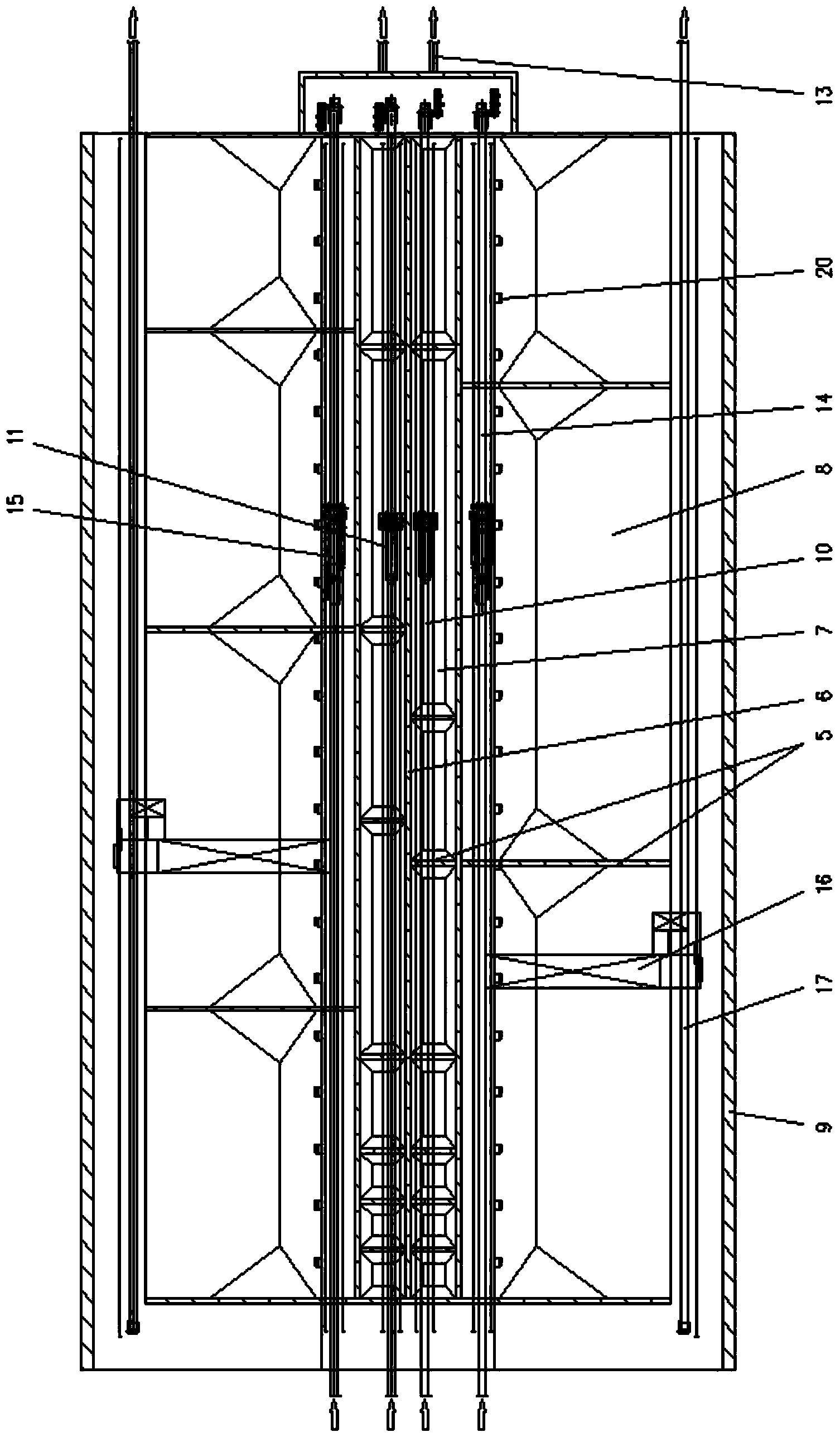

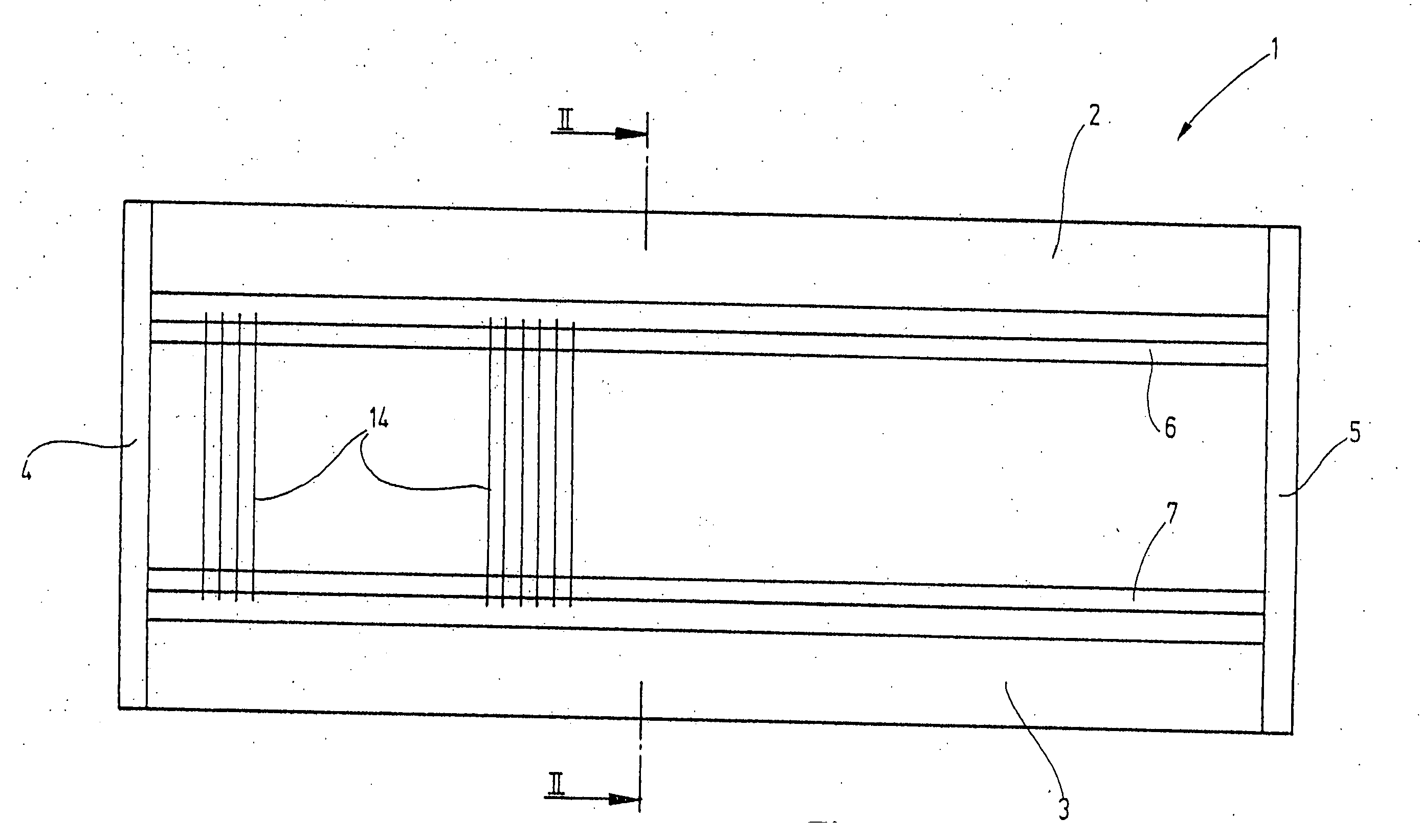

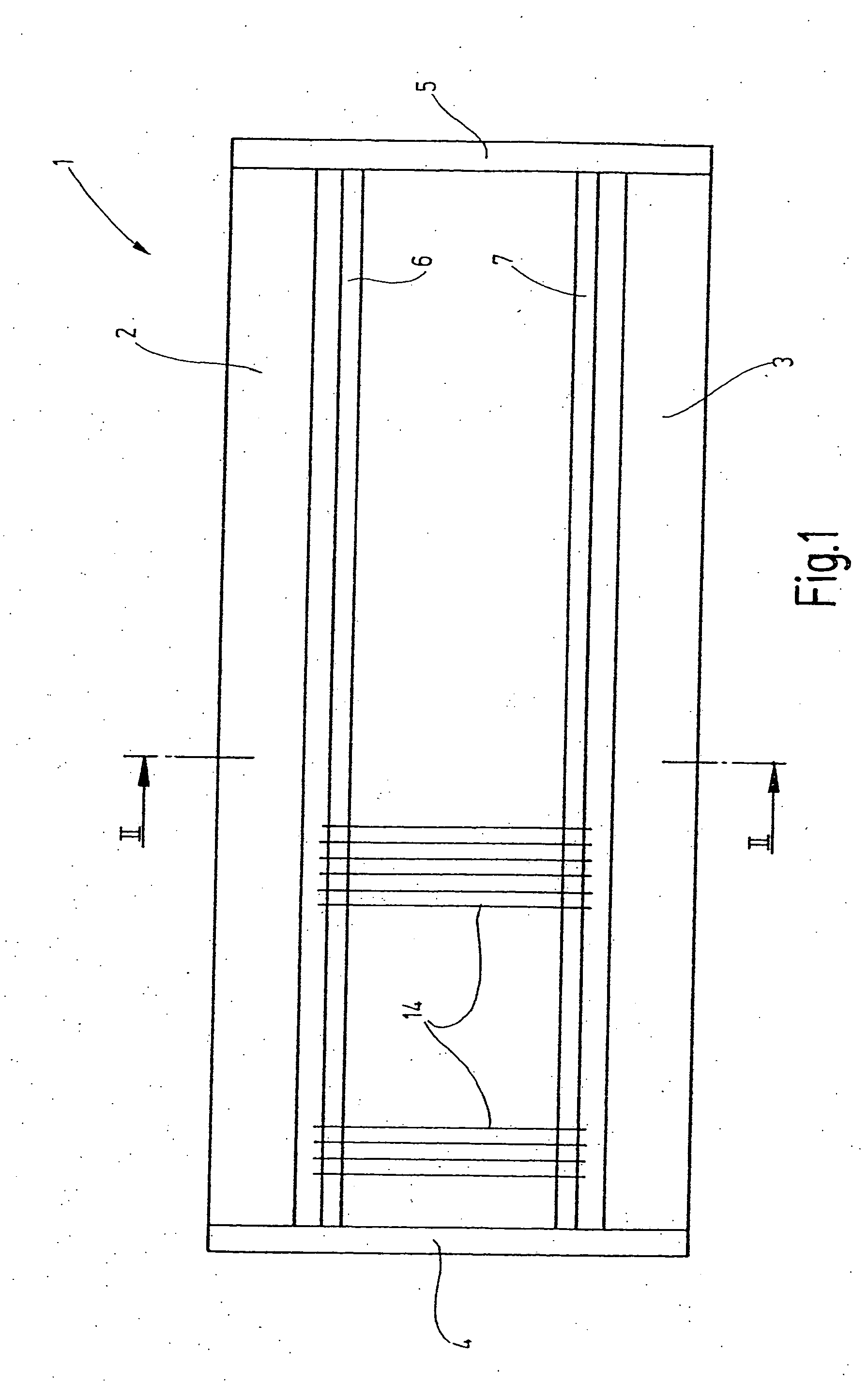

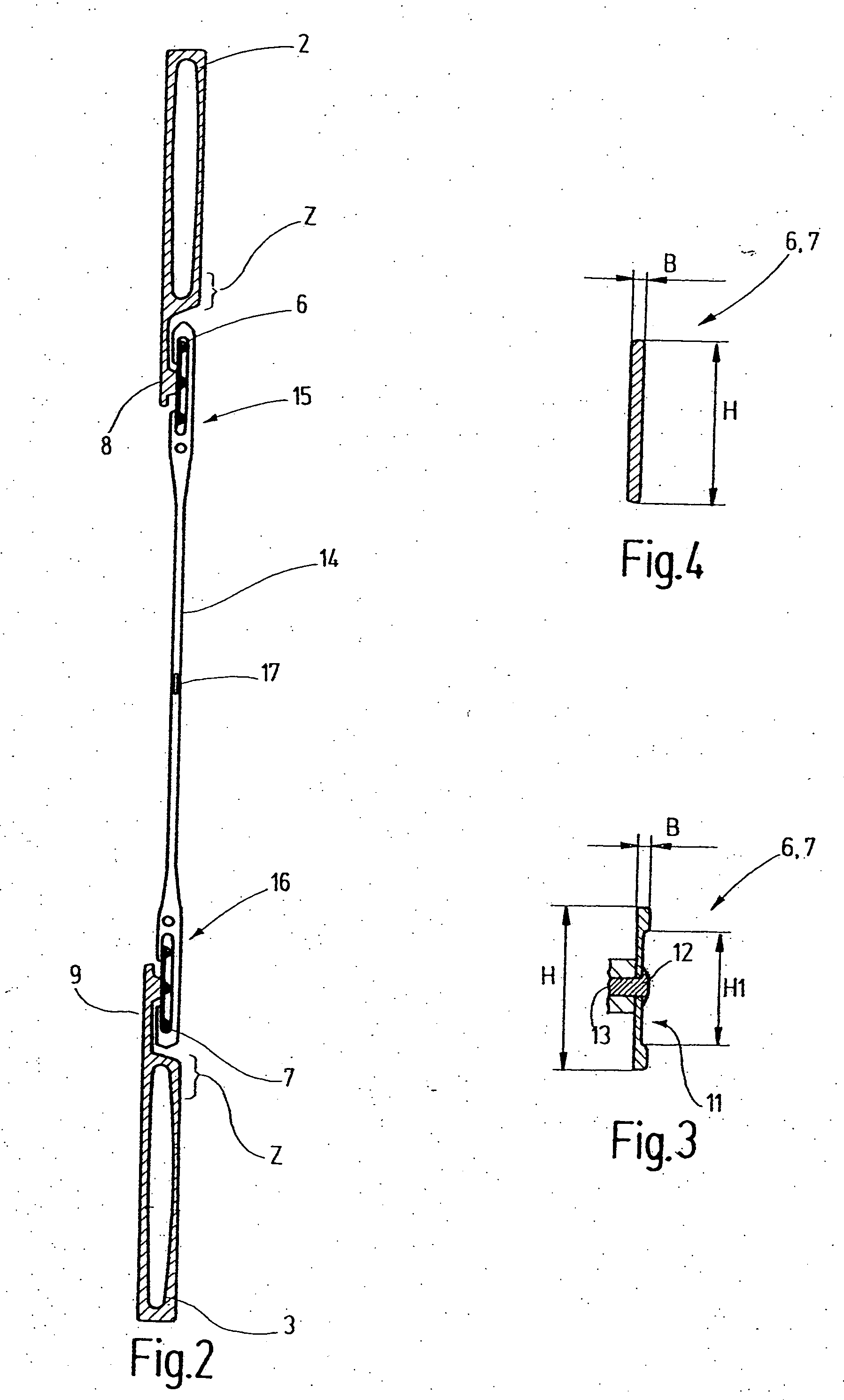

Heddle with reduced play

A heddle (14) of the invention is distinguished by end eyelets (15, 16) of reduced size, with which heddle support rails (6, 7) of reduced cross section are associated. The axial play of the heddles on the heddle support rails (6, 7) is limited to from 0.5 mm to 1.5 mm. The lateral play is in the range of 0.2 mm to 0.5 mm. This system formed of heddle support rails and heddles is especially suitable for particularly rigid heddle shafts for power looms with an extremely high operating speed.

Owner:GROZ BECKERT KG

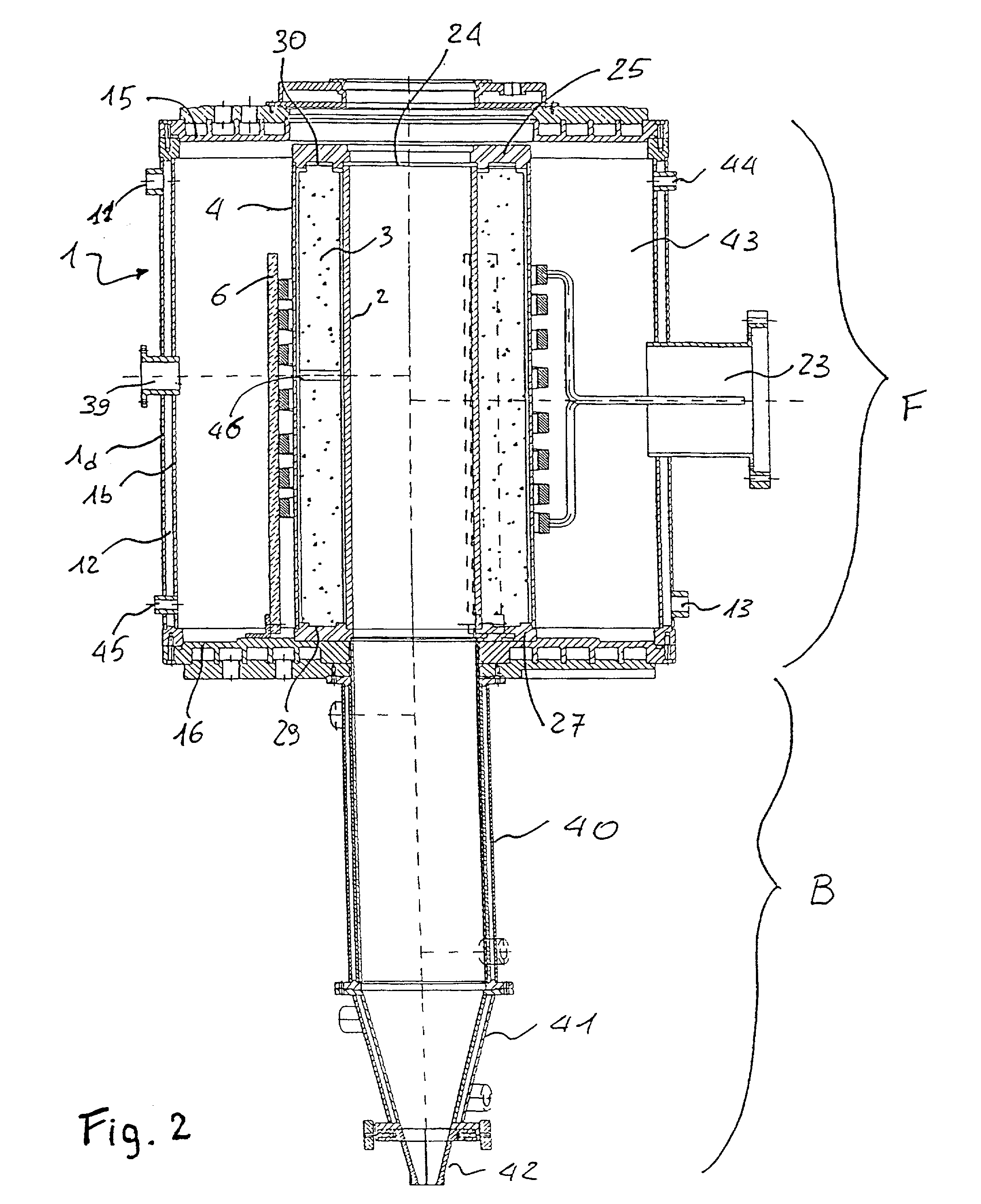

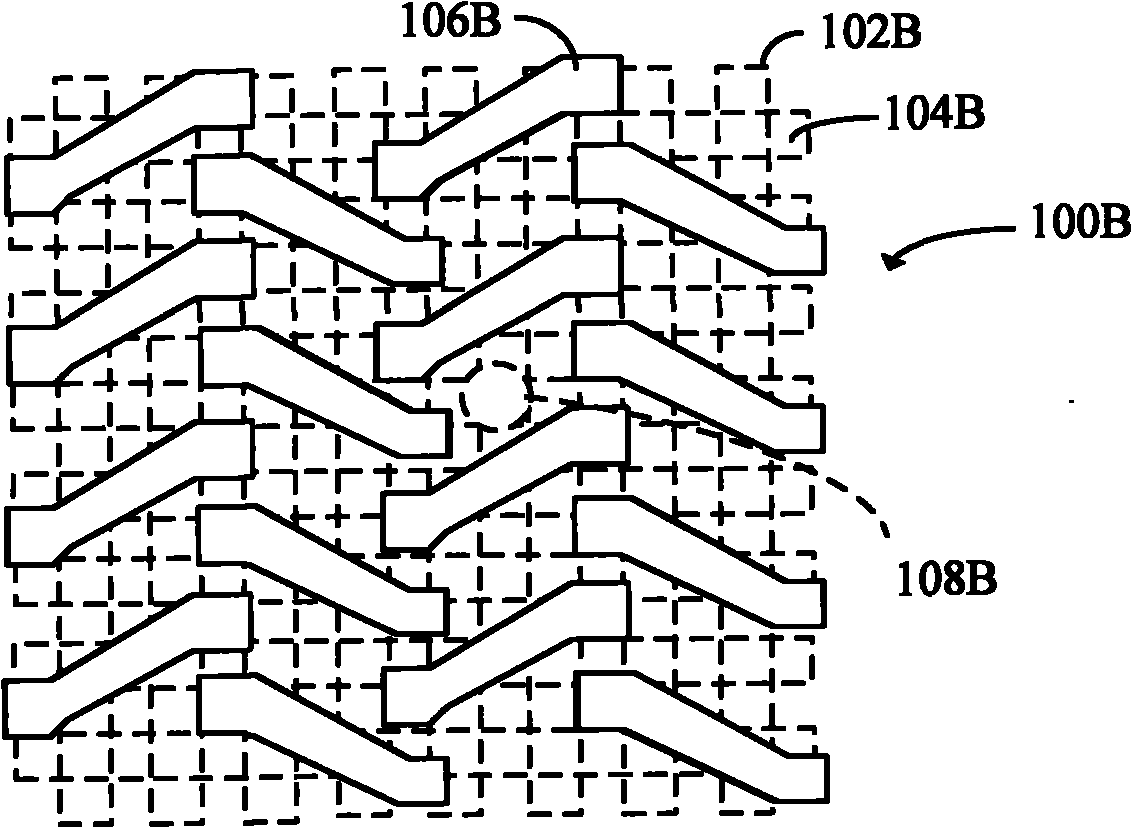

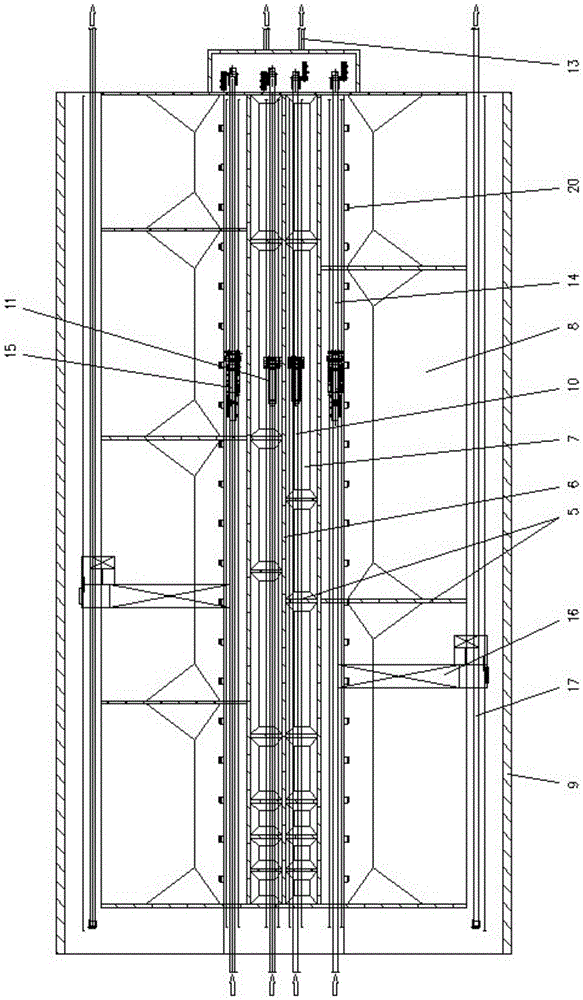

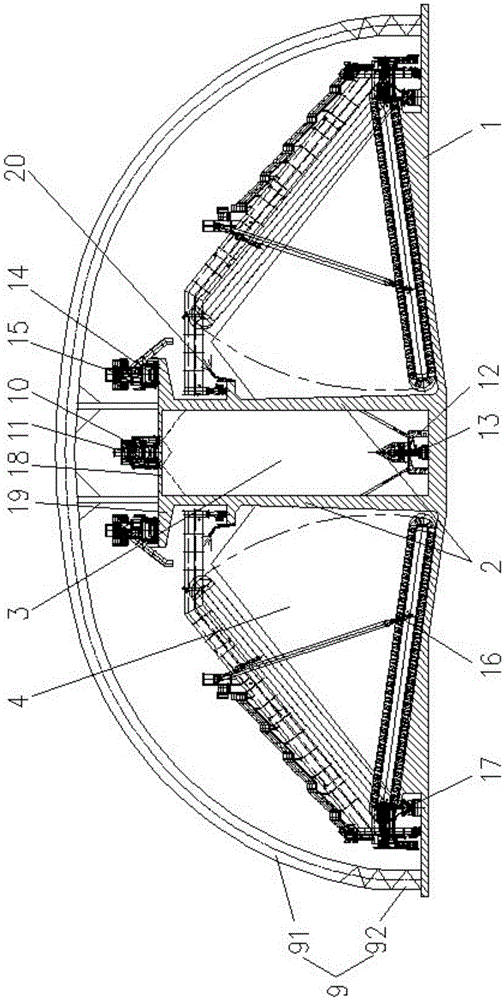

Material storage device of storage yard and closed storage yard

ActiveCN103640832AIncrease storage capacityImprove space utilizationLoading/unloadingStorage devicesEngineeringYard

The invention discloses a material storage device of a storage yard. The material storage device comprises a material storage bearing bottom plate and two retaining walls, wherein a material storage bin is formed between the two retaining walls, and material storage lattices are arranged on two longitudinal sides or one side of the material storage bin. The invention further discloses a closed storage yard which comprises a material storage shed and the material storage device arranged in the material storage shed. According to the invention, the material storage bin can eliminate V-shaped space at the top of the material, then the space utilization rate is increased, and the occupied area as well as energy consumption for ventilation, heating, lighting and the like of the storage yard are reduced; more independent unit storage bins and unit material lattices are provided, and the variety adaptability of the storage yard is higher; an across bulkhead can support the retaining walls, the rigidity and pressure bearing performance of the retaining walls can be improved greatly, the thickness of each retaining wall is smaller, and the construction investment cost is lower; size of the material exposed in the air in the material storage bin is smaller, raising amount of dust in feeding and discharging processes is smaller, so that the material with high environmental protection requirement can be stored in the material storage bin, and the environmental protection performance is better.

Owner:CISDI ENG CO LTD

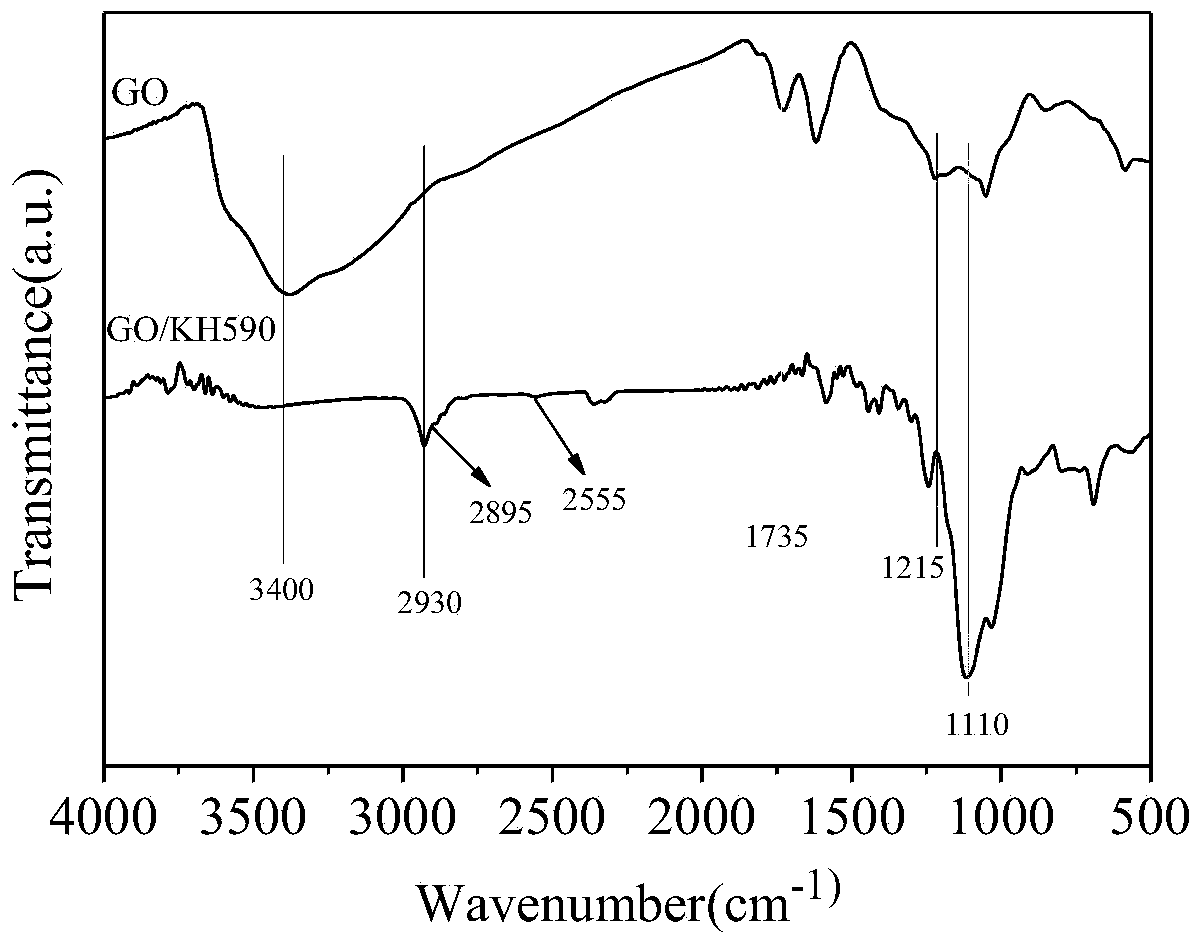

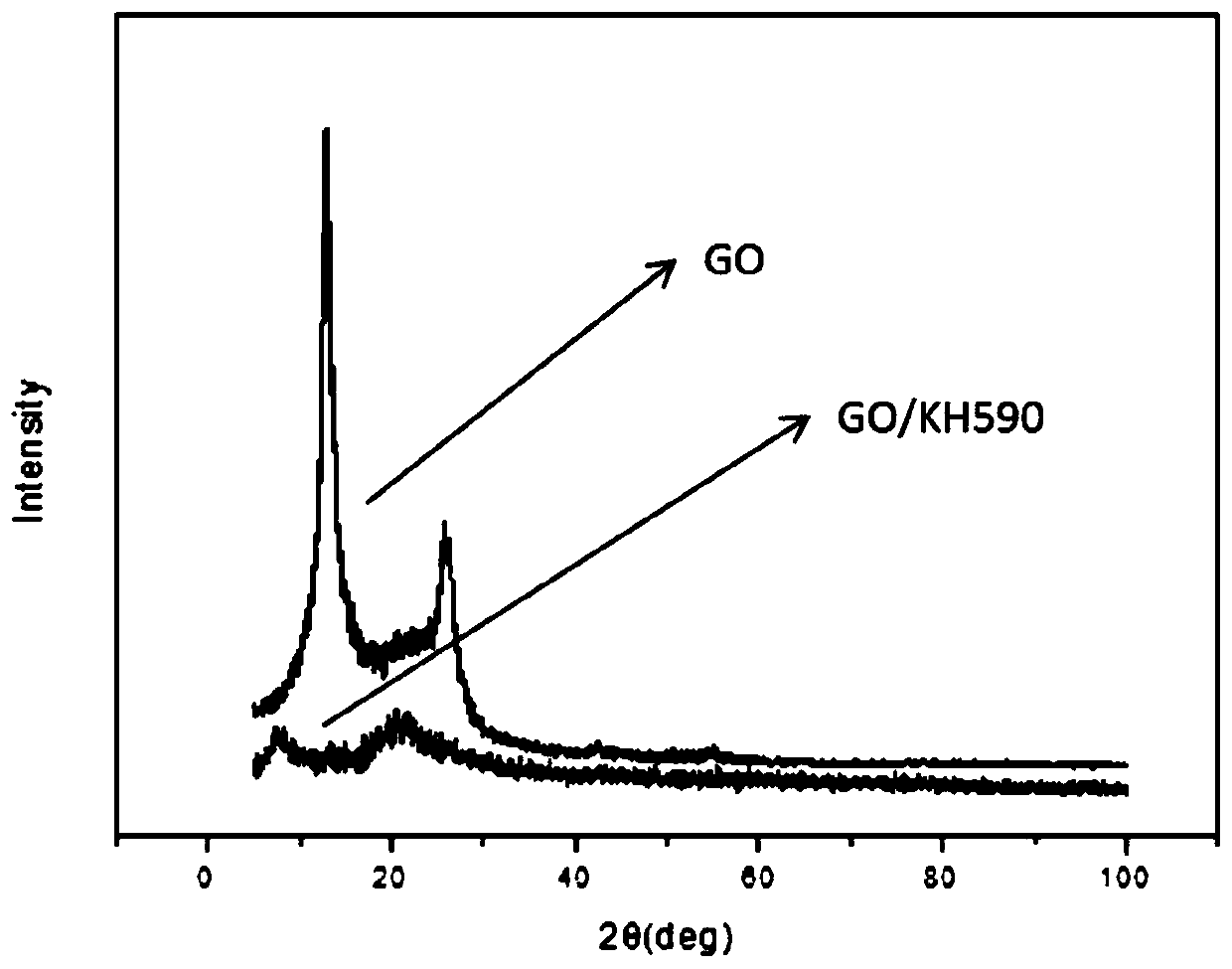

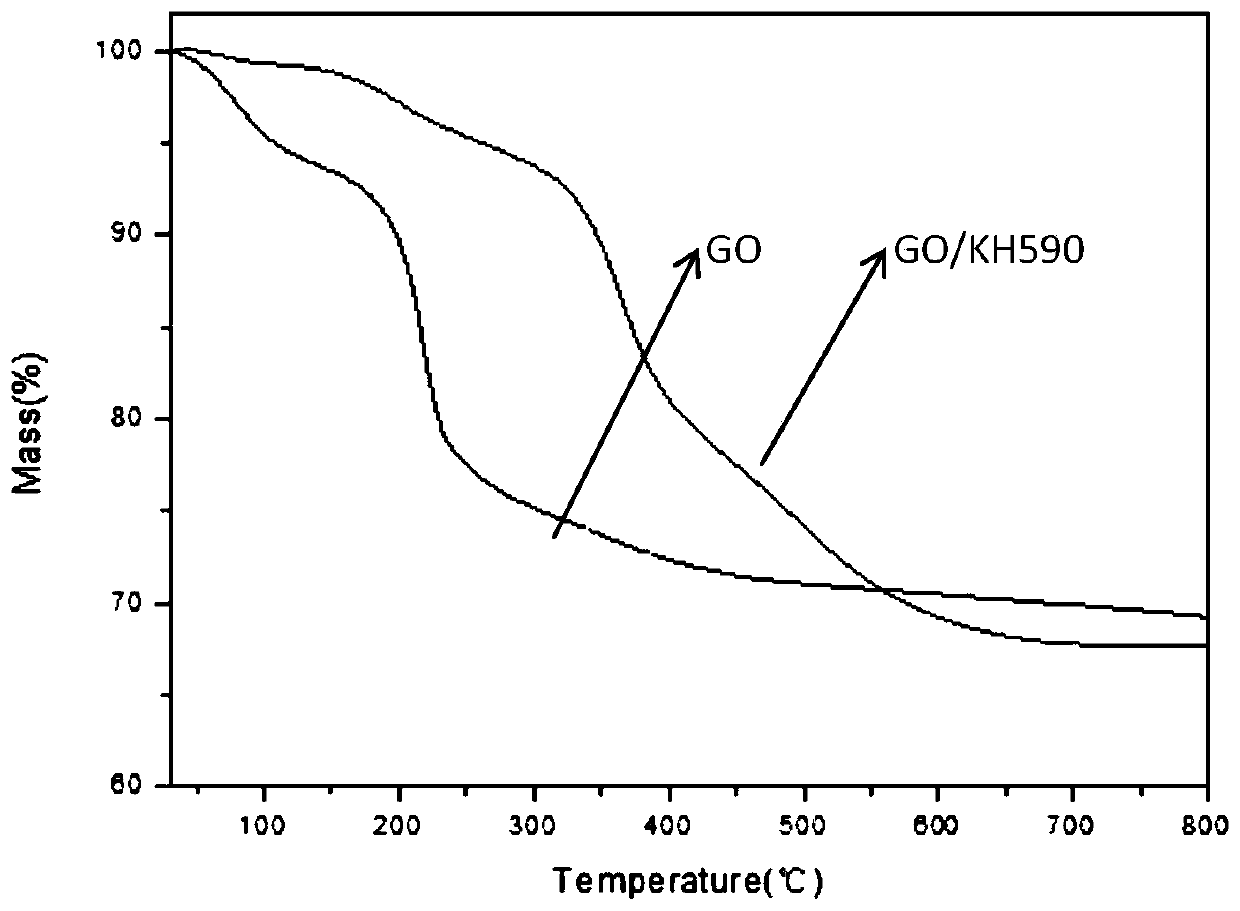

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

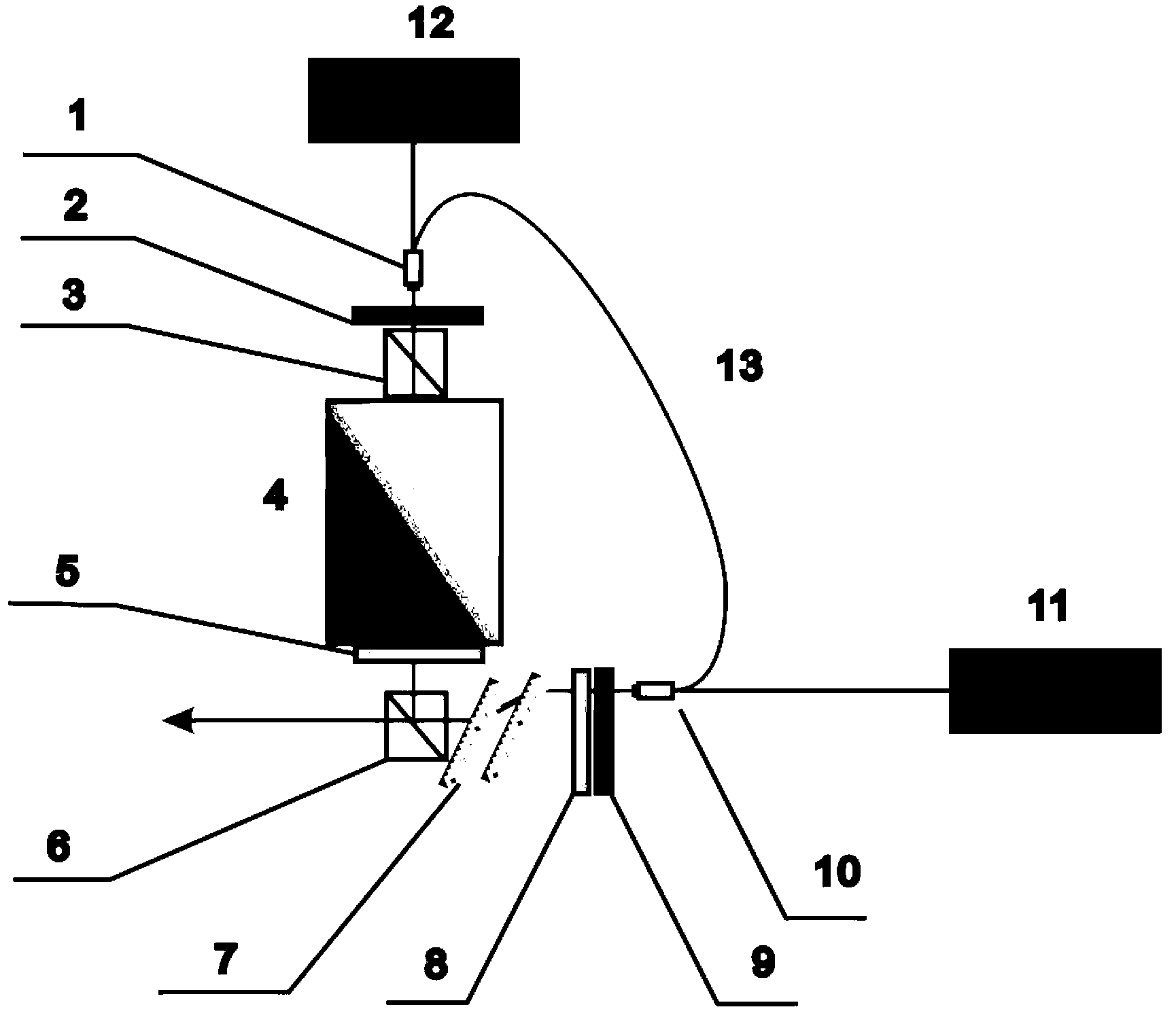

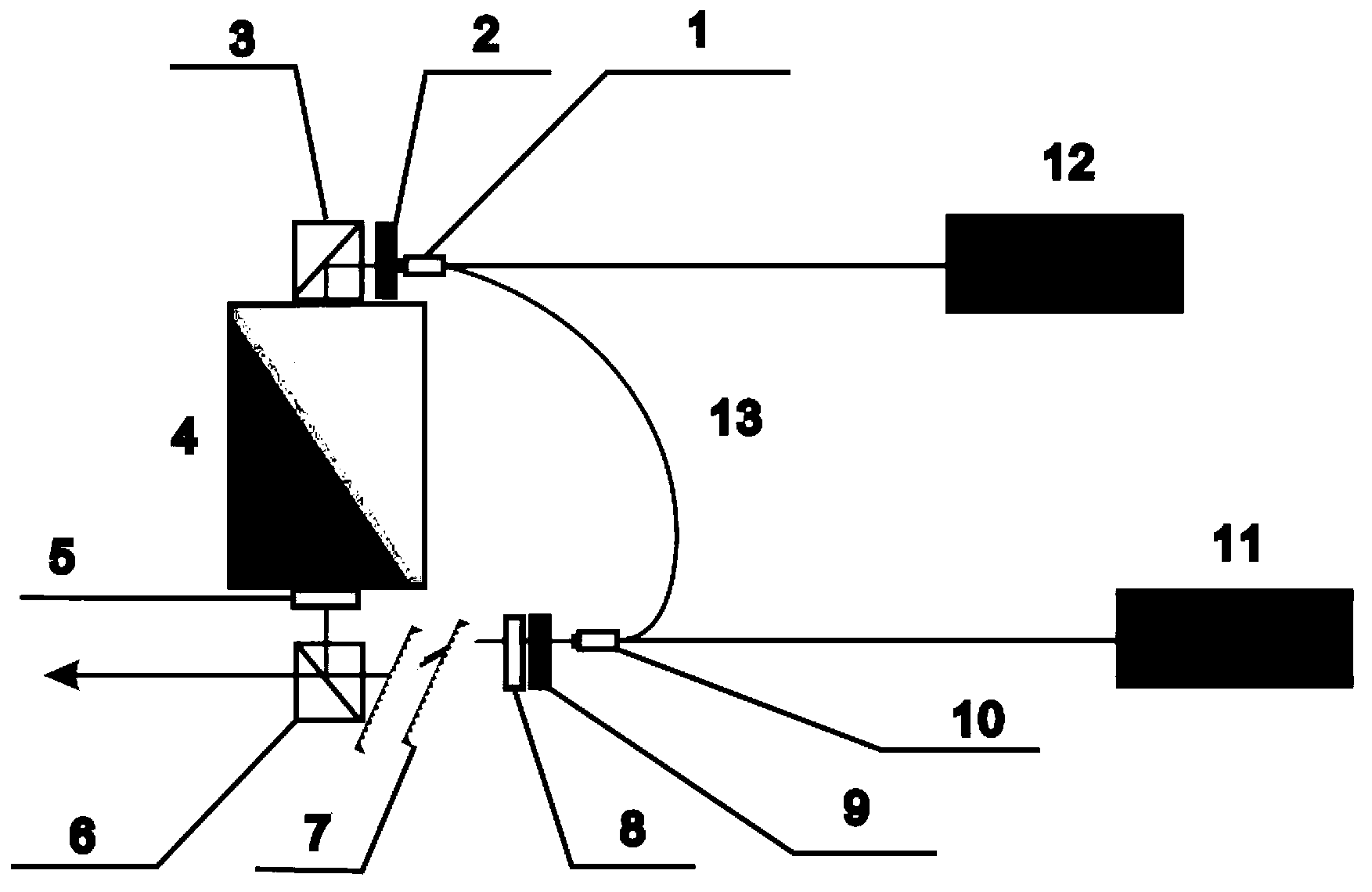

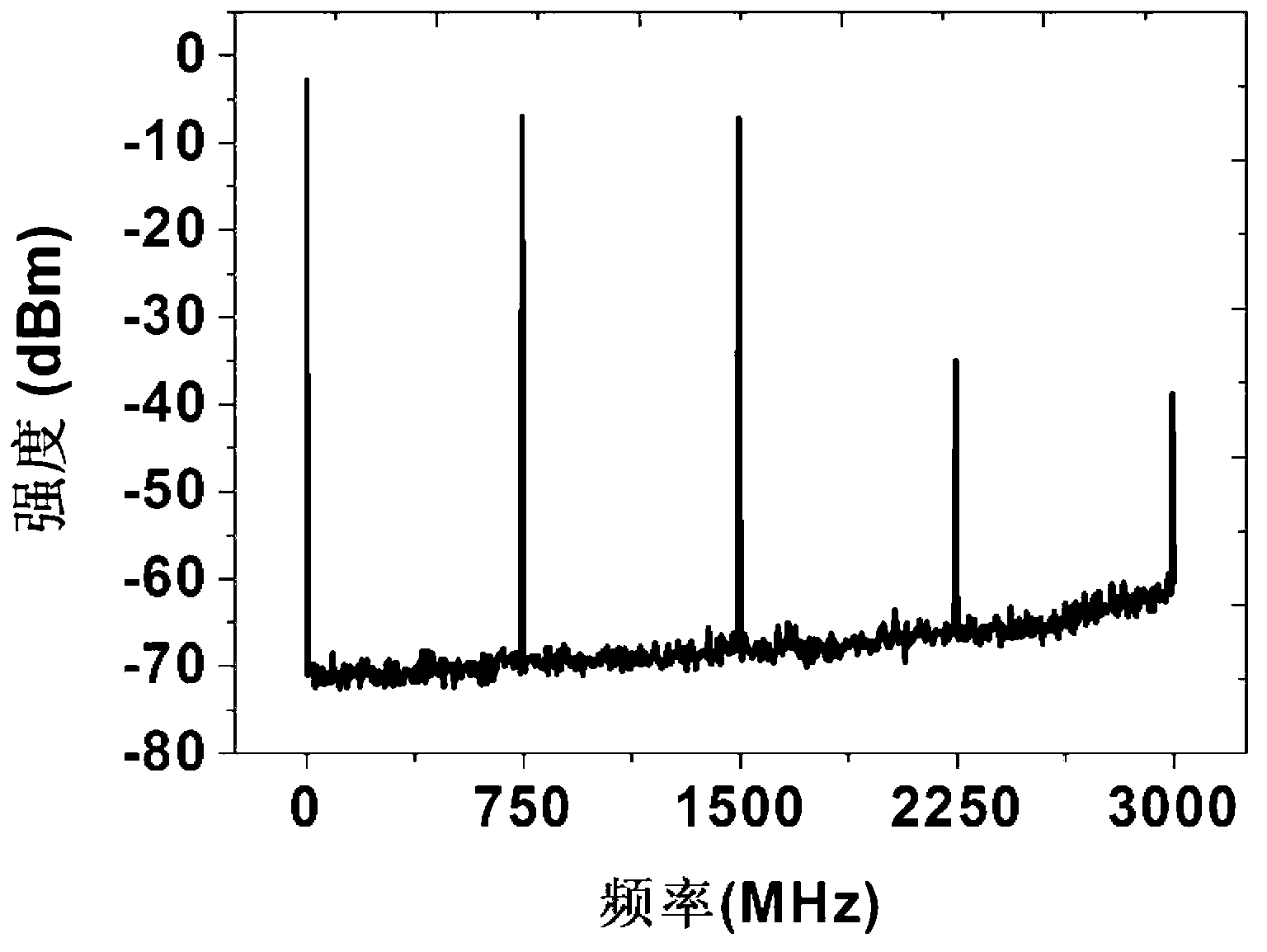

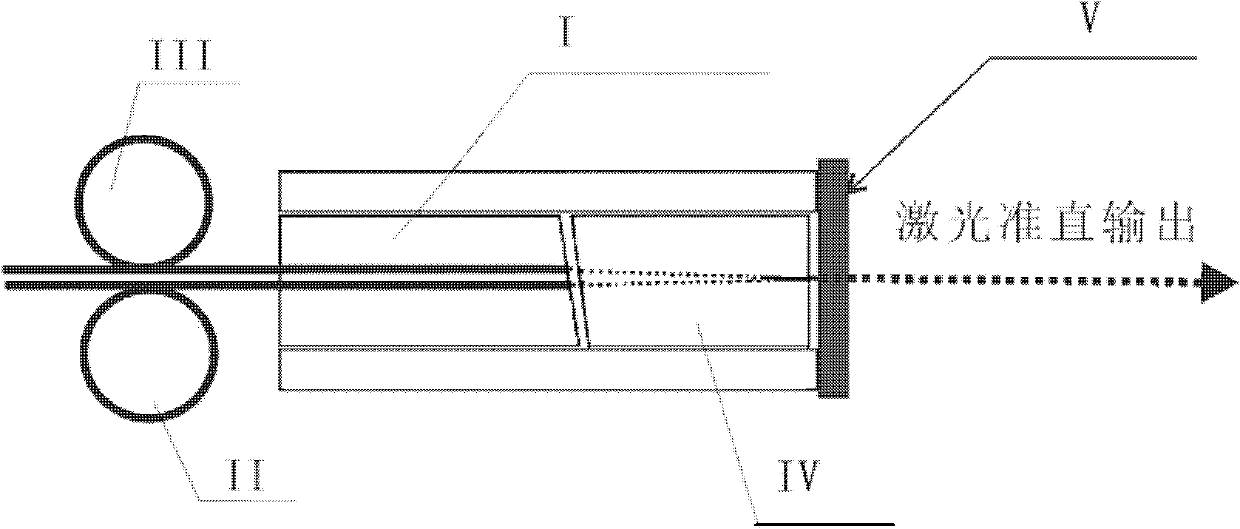

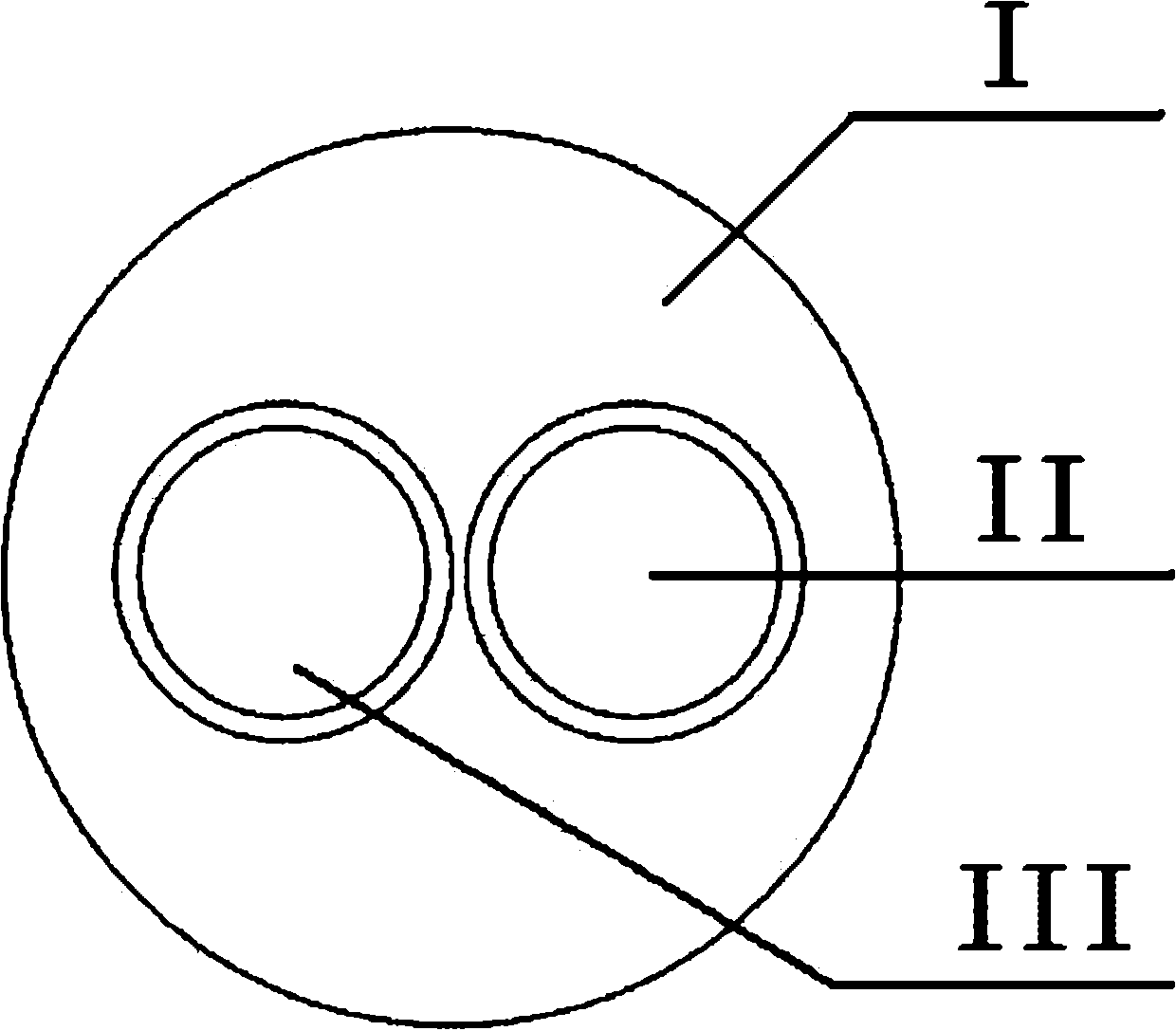

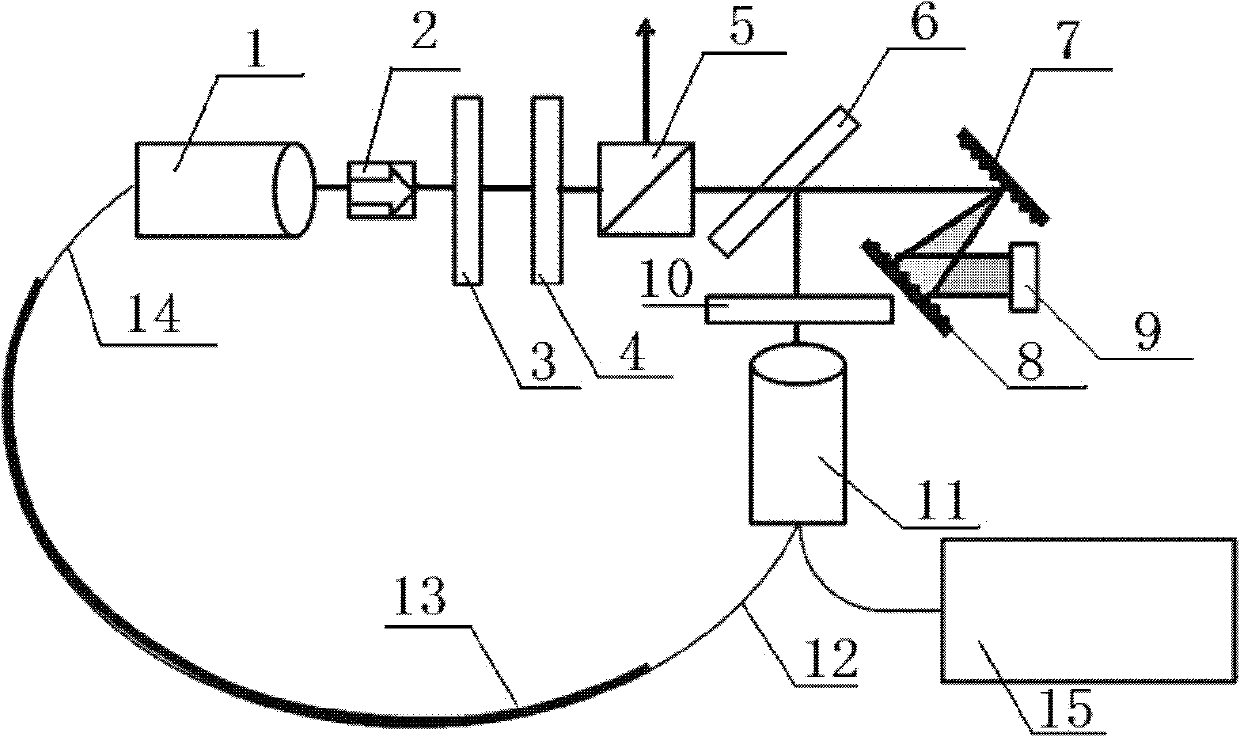

Ring cavity mode locking fiber laser

InactiveCN103022863AShorten the lengthReduce free spaceActive medium shape and constructionMode locked fiber laserGrating

The invention discloses a ring cavity mode locking fiber laser capable of generating high-repeating-frequency laser. The ring cavity mode locking fiber laser comprises an optoisolator, a polarization control component, a first wavelength division multiplexing collimator (1) and a second wavelength division multiplexing collimator (10). Simultaneously, a structure that the optoisolator made of a film magneto-optic material and light pass through a grating pair in unidirectional mode is adopted, the length of the optical fiber is greatly reduced, a laser system is simplified, coupling power and coupling efficiency are improved, repeating frequency, namely frequency interval, is improved, and resolution of the ring cavity mode locking fiber laser used as a frequency comb of a light source is improved.

Owner:PEKING UNIV

Heddle with reduced play

InactiveUS20050087252A1Reduce end weightReduce the total massHealdsOther shedding mechanismReduced sizeEngineering

A heddle (14) of the invention is distinguished by end eyelets (15, 16) of reduced size, with which heddle support rails (6, 7) of reduced cross section are associated. The axial play of the heddles on the heddle support rails (6, 7) is limited to from 0.5 mm to 1.5 mm. The lateral play is in the range of 0.2 mm to 0.5 mm. This system formed of heddle support rails and heddles is especially suitable for particularly rigid heddle shafts for power looms with an extremely high operating speed.

Owner:GROZ BECKERT KG

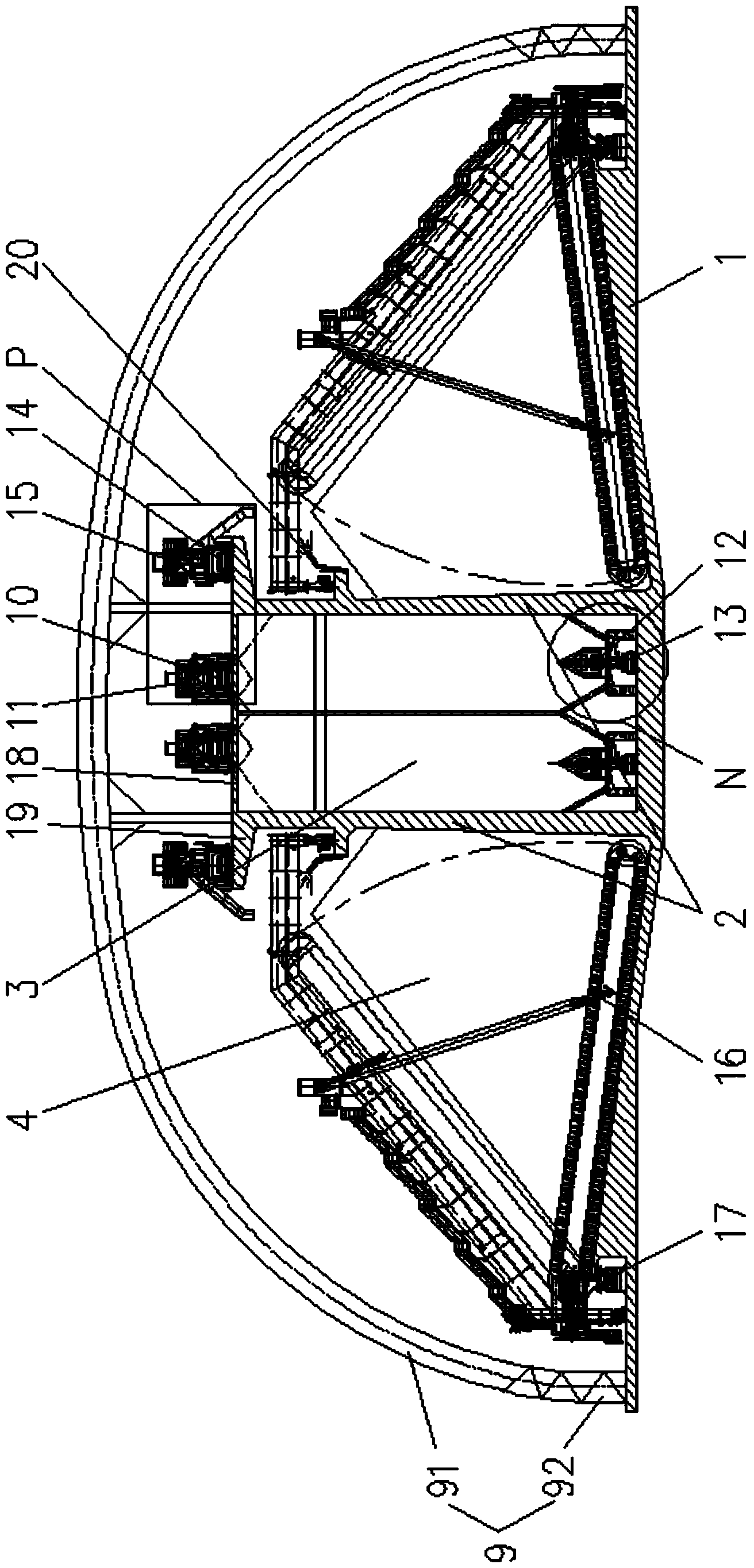

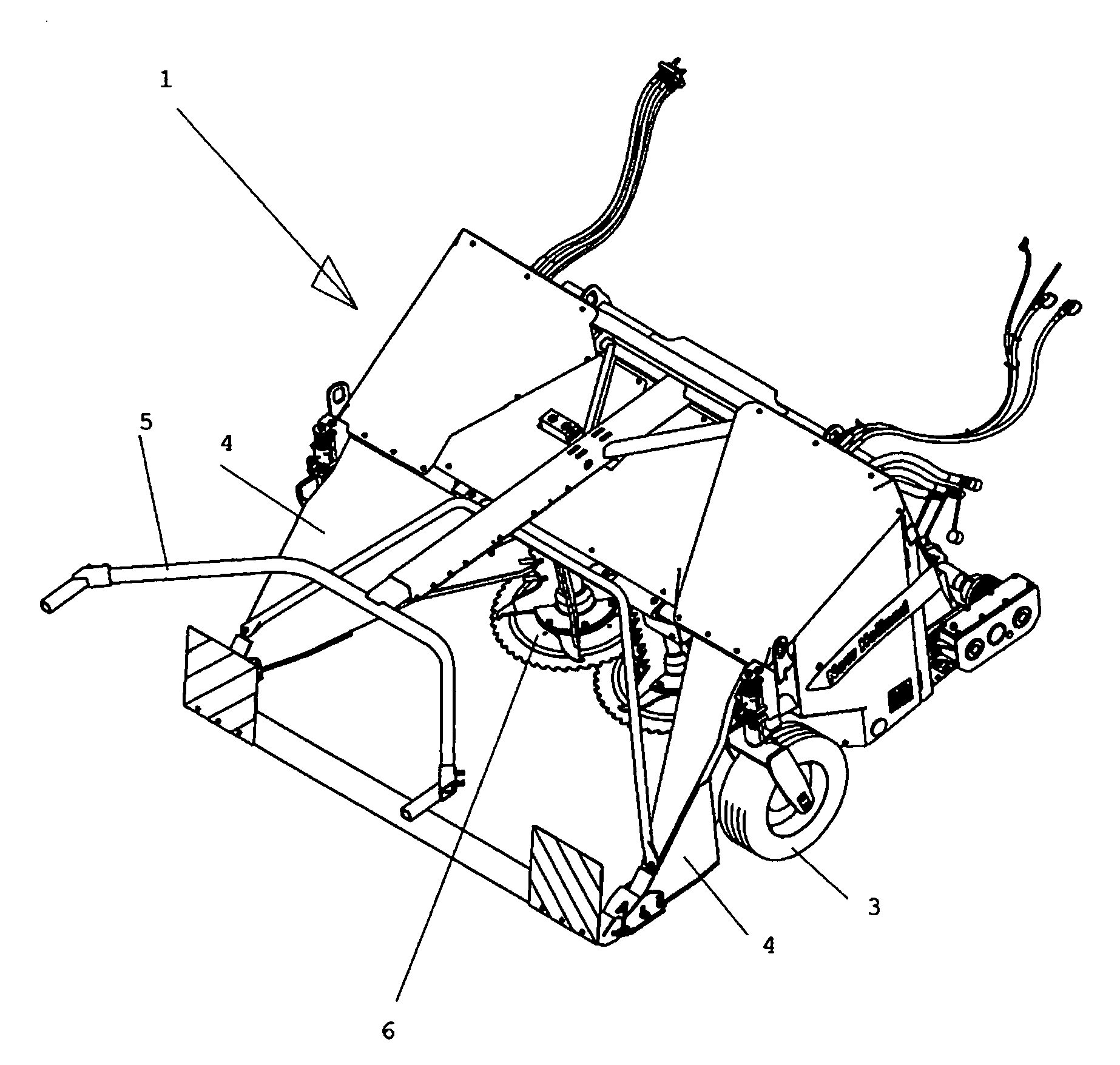

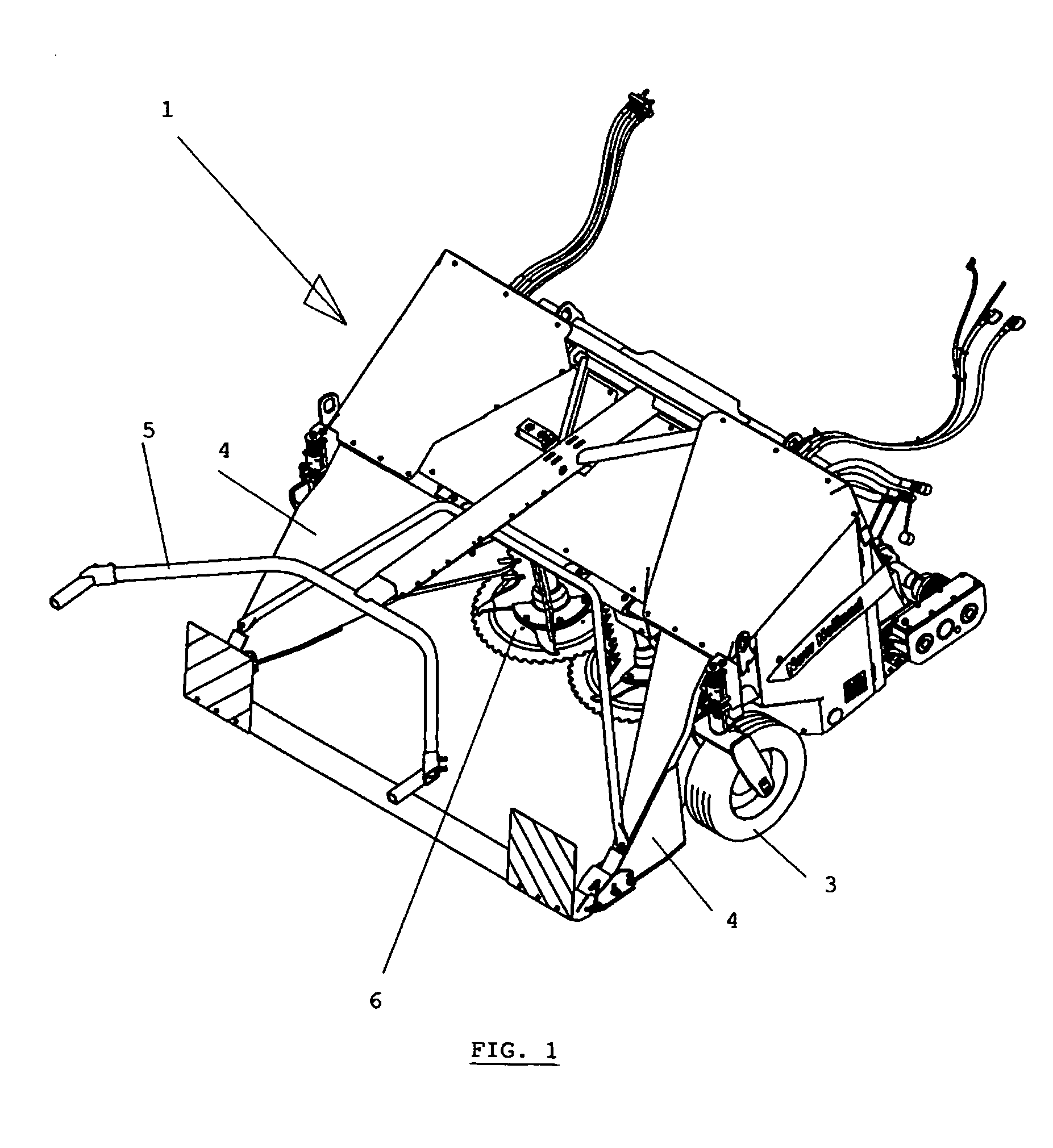

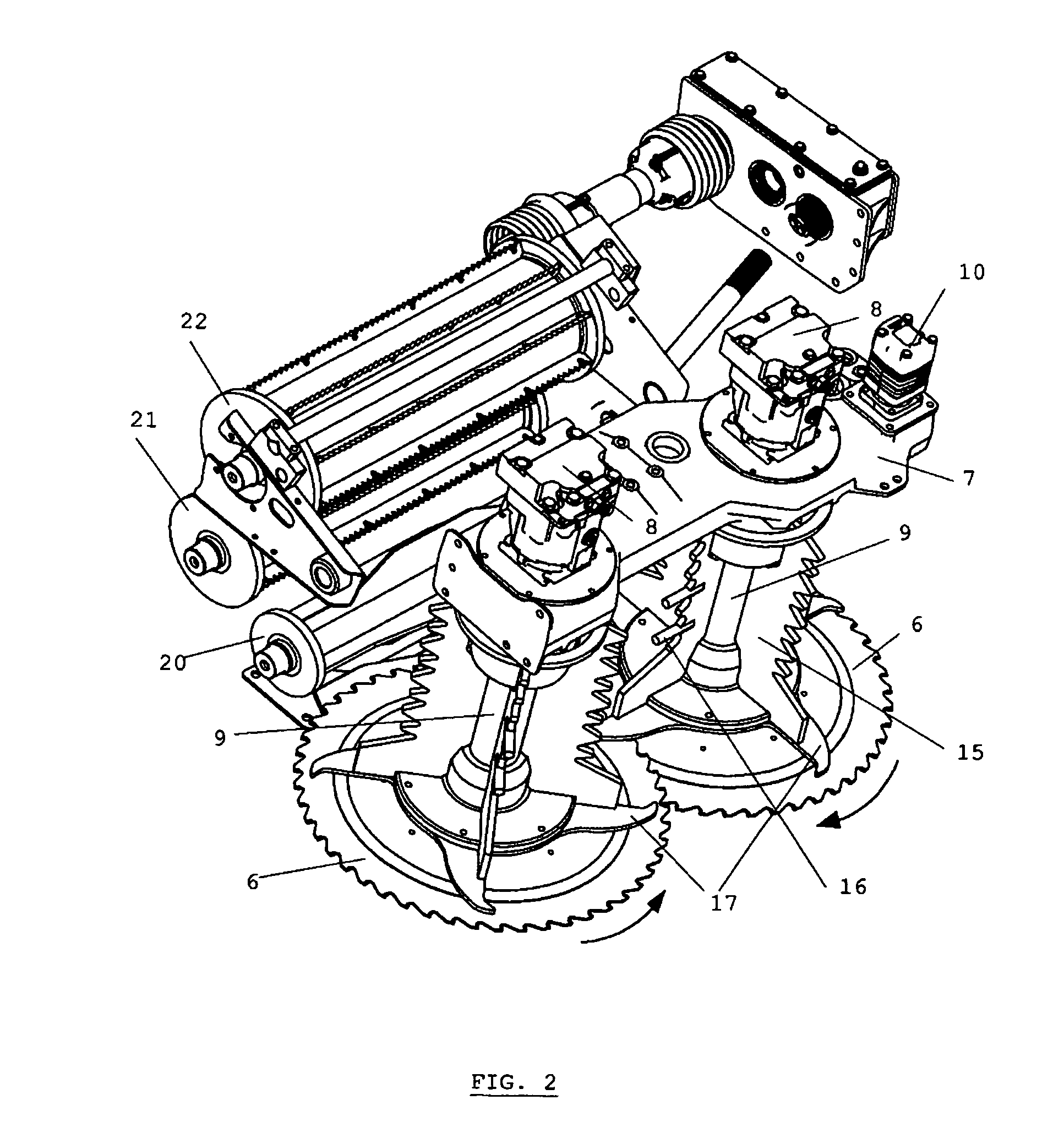

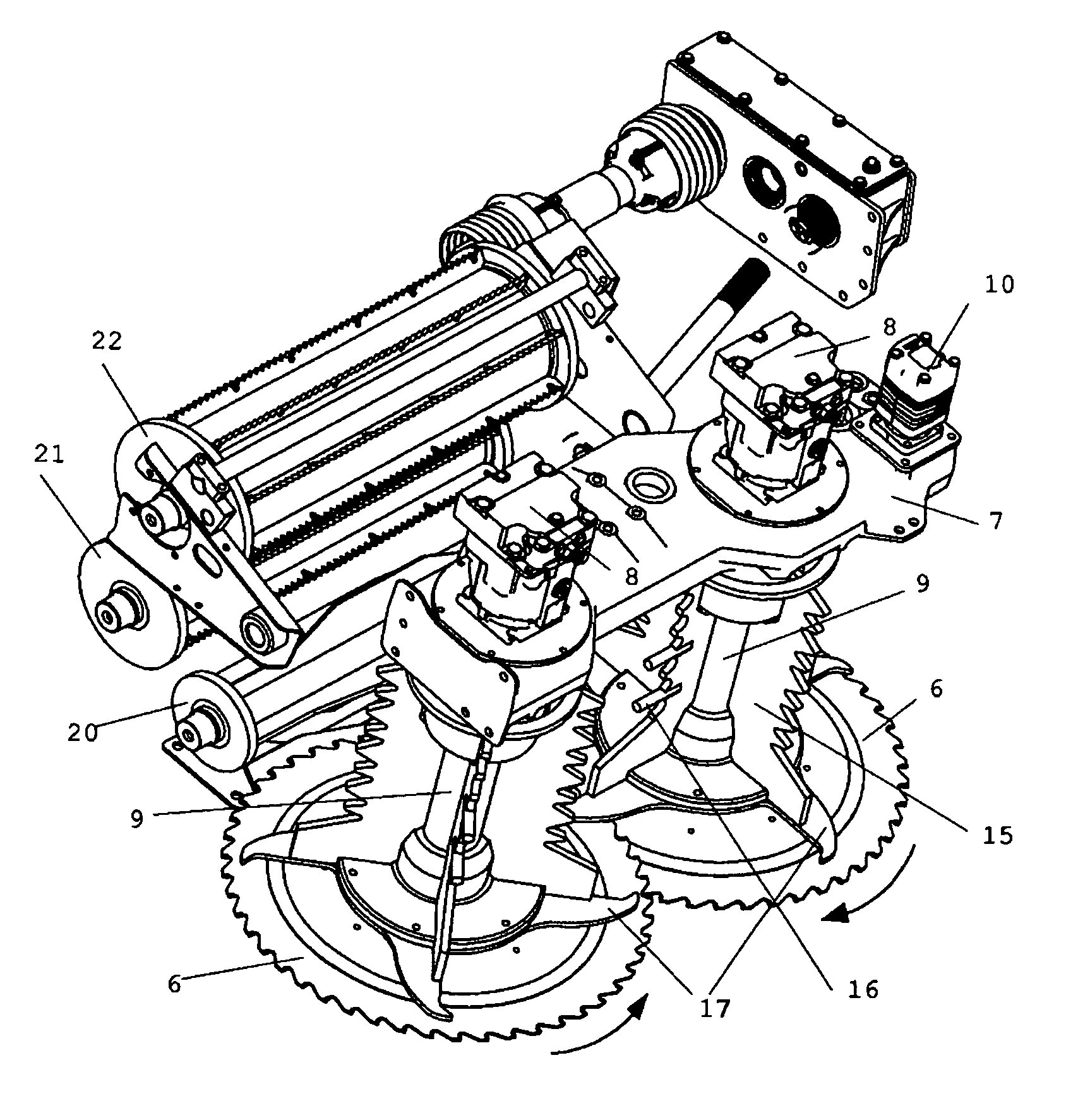

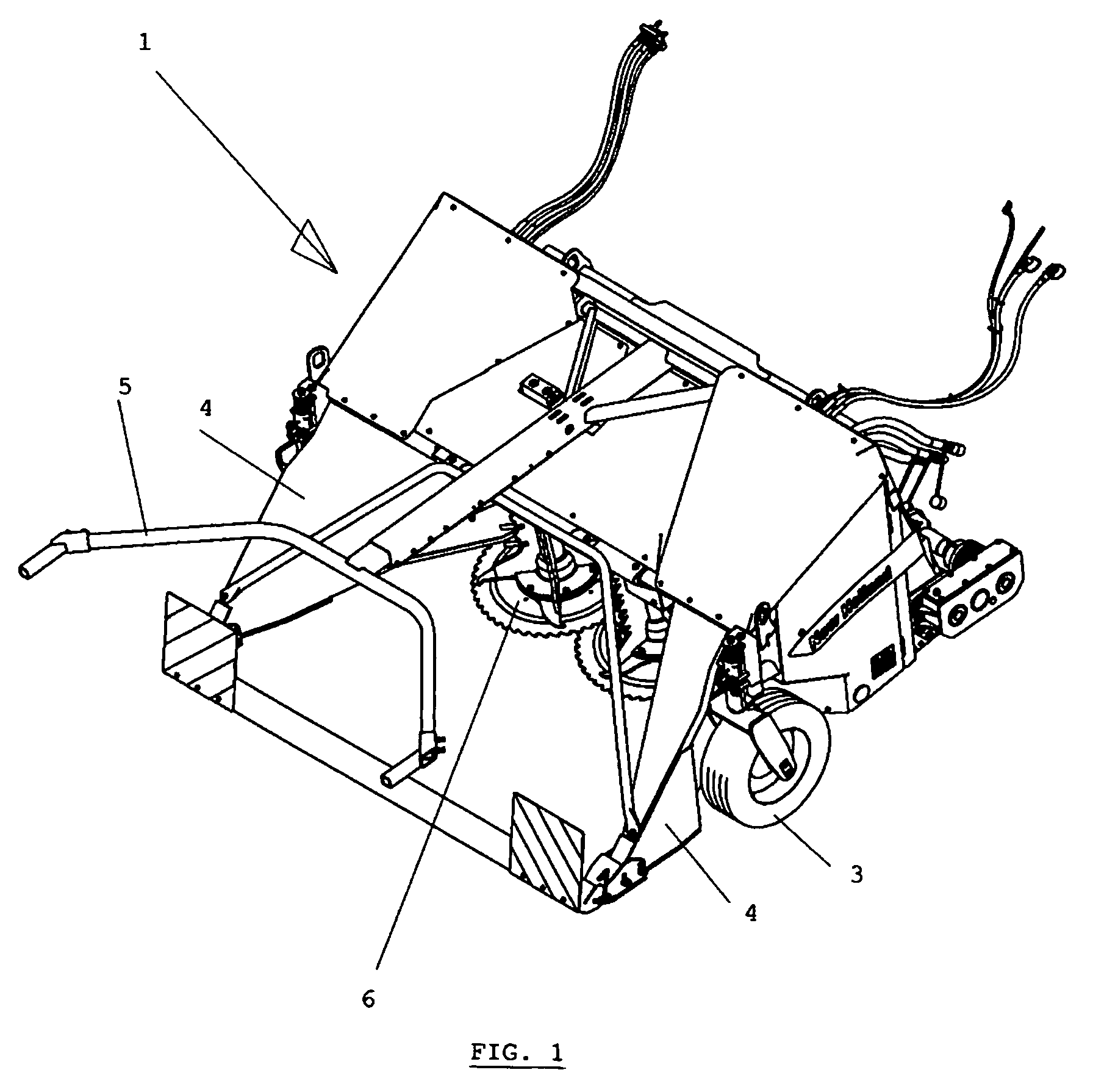

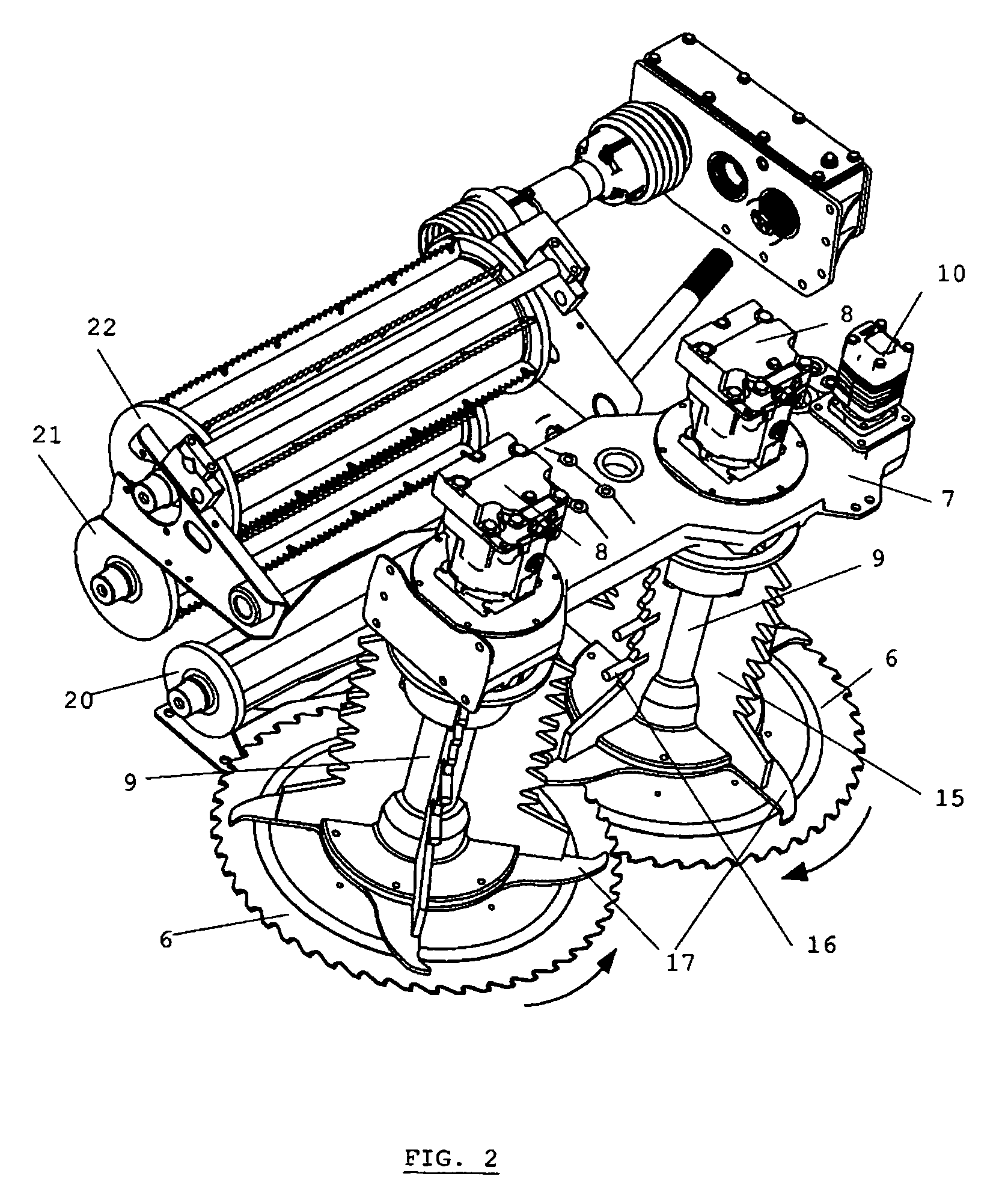

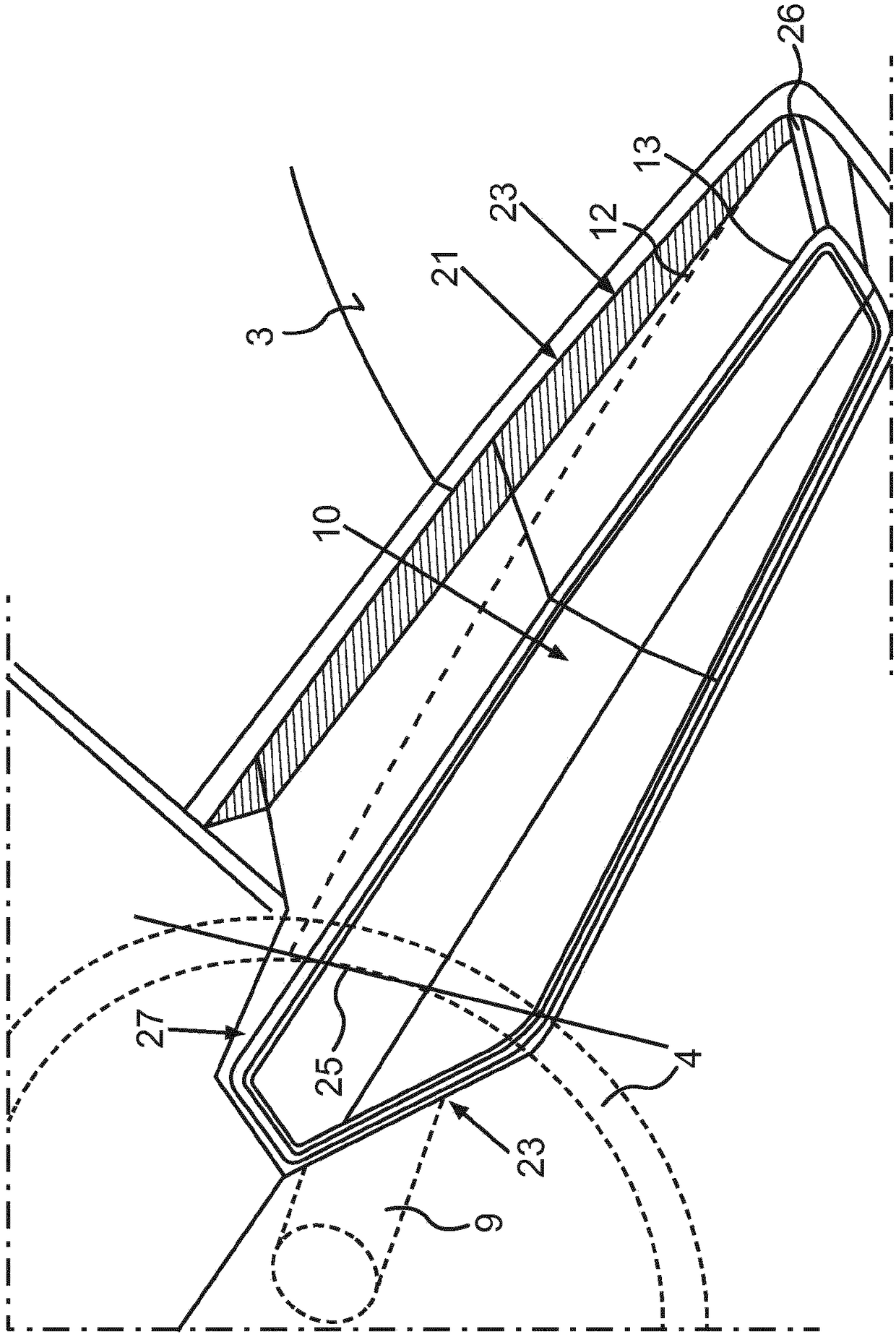

Header for a forage harvester

A coppice header for a forage harvester adapted to be mounted on and powered by a forage harvester. The header including at the front side two circular rotatable knives, a feeding drum being mounted above each knife, said drums being rotatable about the same rotation axis as the respective knives, wherein each feeding drum is equipped with one or more flat hook-shaped extensions adapted to grab the cut stems in the region immediately above the rotatable knives. The header may also be provided with a front feed roll placed behind the knives and two additional feed rolls placed behind the front feed roll, wherein the front feed roll is equipped with guiding blades along the length of the feed roll. The blades have a central protrusion, so that the blades are longer in a region around the middle of the blade than at the lateral ends of the blades.

Owner:BLUE LEAF I P INC

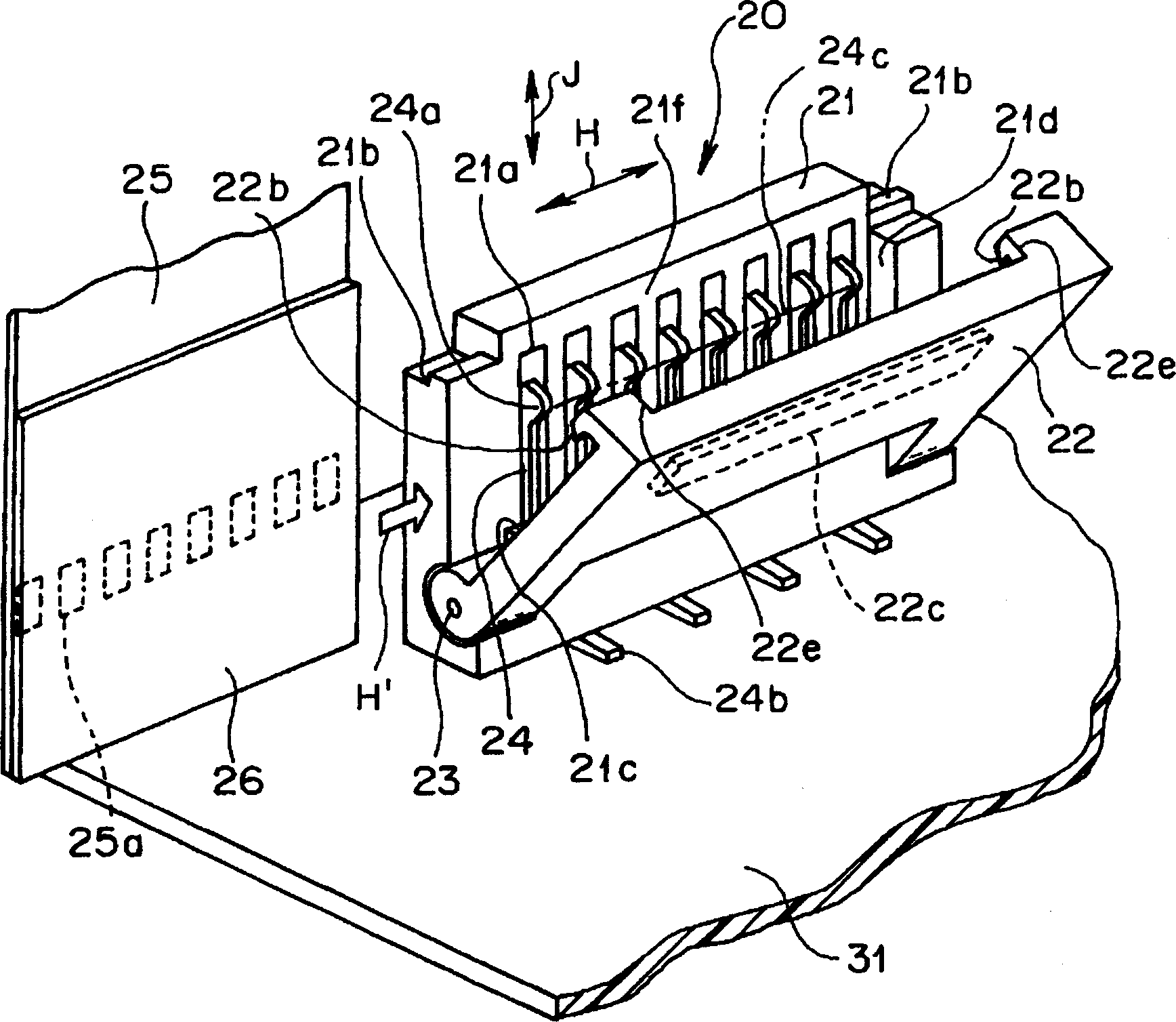

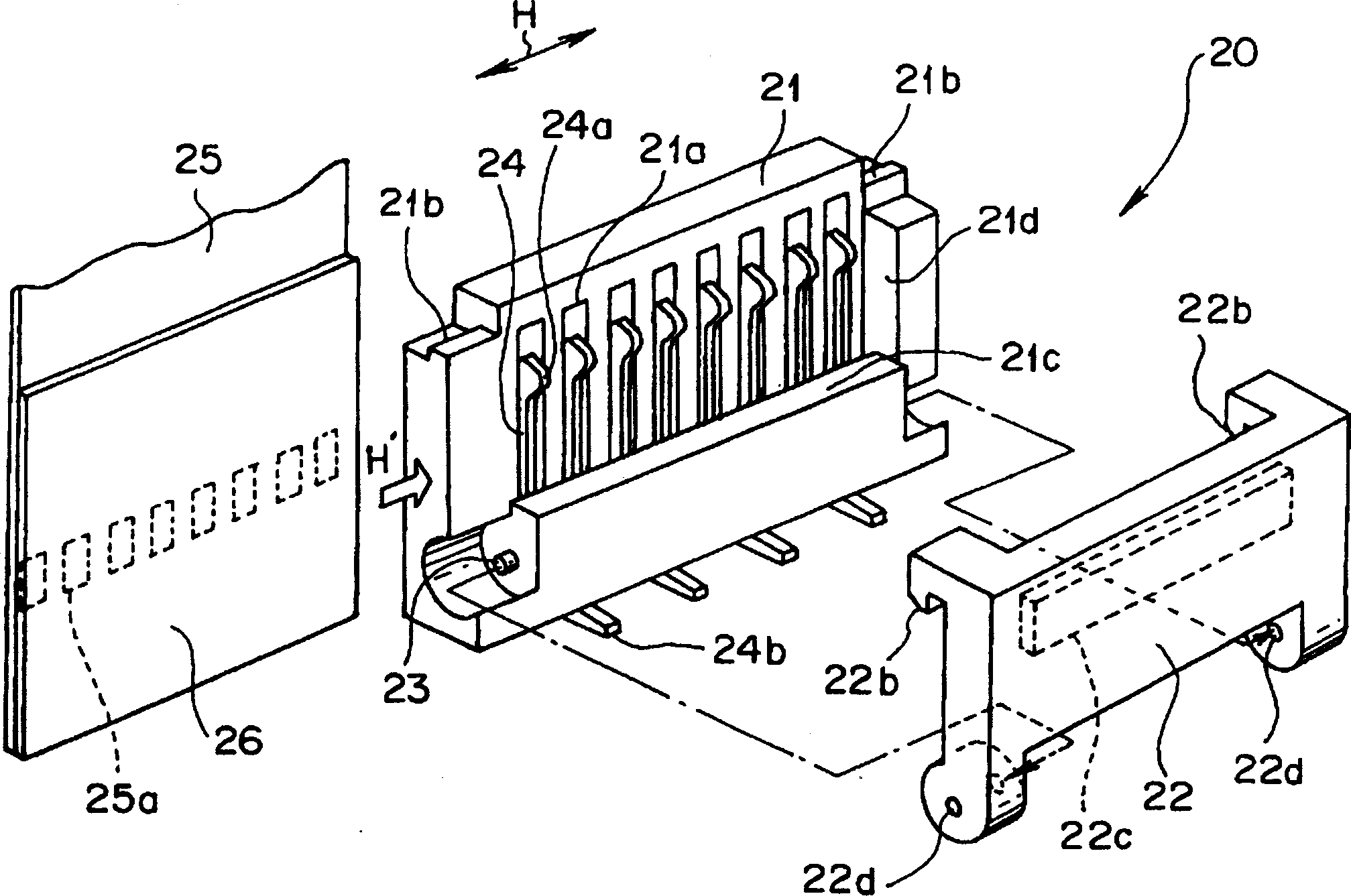

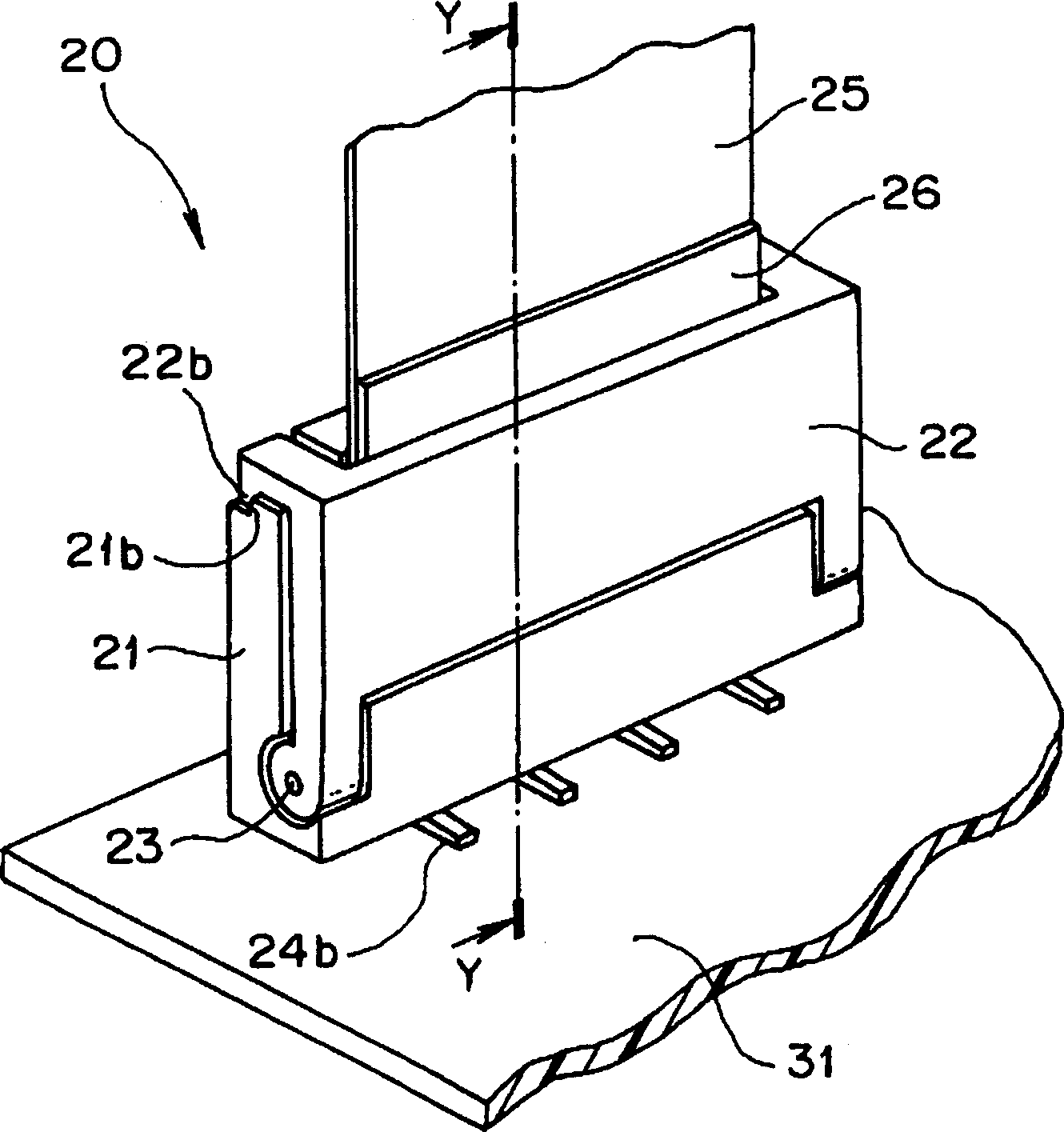

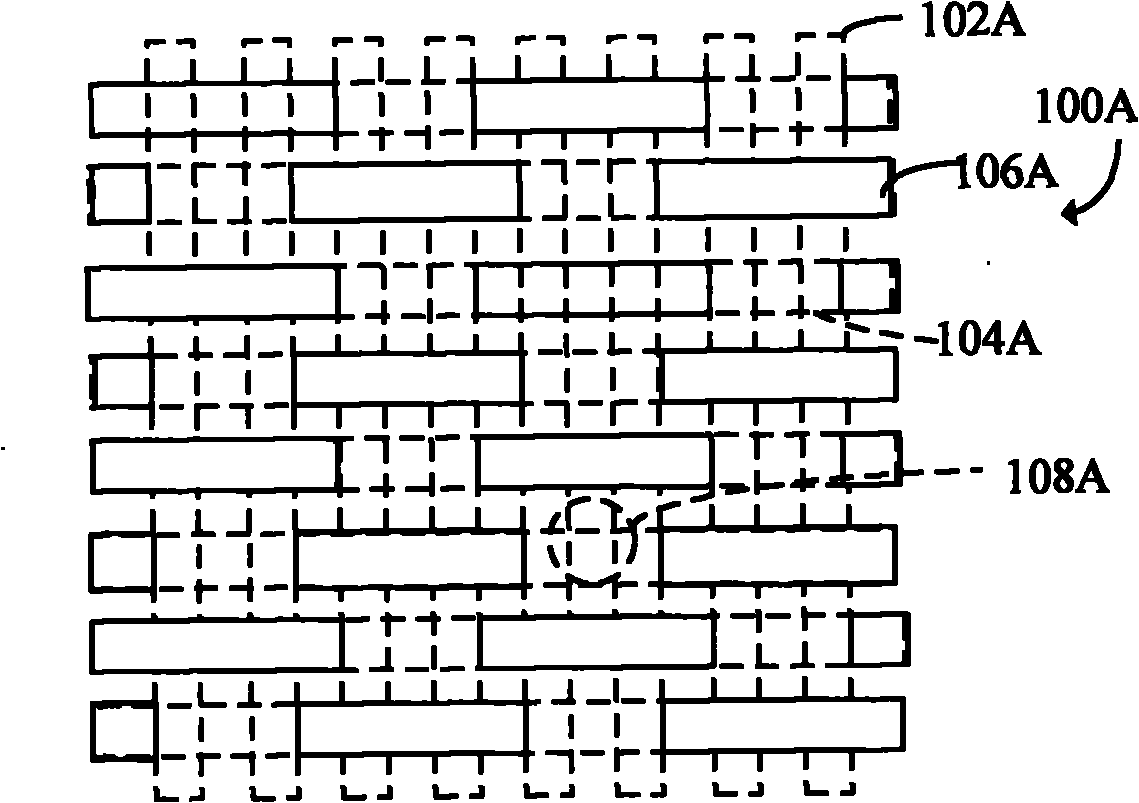

Connector for connecting flexible printed circuit tobard and flexible printed circuit board for connecting

InactiveCN1461073AReduce free spaceFirmly connectedCoupling device detailsEngineeringPrinted circuit board

The utility model provides a connector for flexible printed substrate connection, which can inhibit the rest space of the device used for connecting the flexible printed substrate for connection with the hard substrate to the minimum limit, and, make the connecting and separating operations more easy. The FPC connector 20 connected with the FPC used for connection (flexible printed substrate) 25 is provided with a connector body 21 and a locking component 22. The connector body 21 is provided with a connecting terminal plate 24 which is provided with a plurality of connecting parts 24a arranging 24c configuration along the directionof H. The locking component 22 is rotatably supported on the connector body 21. In the FPC25 used for connection, the connecting front end part is provided with a plurality of connecting patterns 25a, a reinforcing base plate 26 is stuck on the inner side. Corresponding to the FPC connector 20, the FPC25 used connection plugs in from the direction parallel to direction of H, and turns off the locking component 22, being set as the connection state.

Owner:OLYMPUS CORP

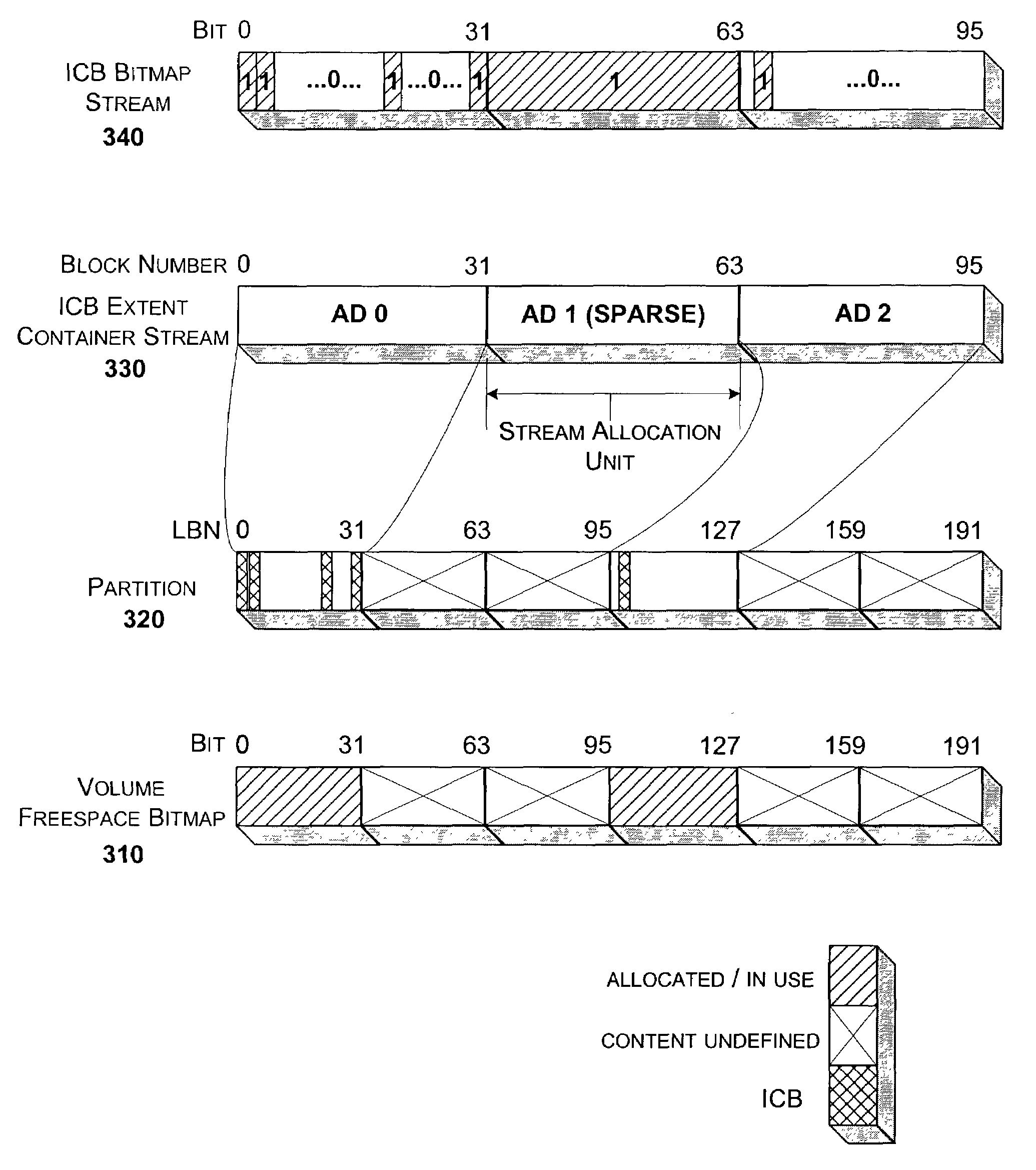

System and method for information control block tracking streams for universal disk format file systems

ActiveUS6981116B2Reduces free space fragmentationImproves general file system performanceTelevision system detailsInput/output to record carriersFile systemInformation control

A system and method for providing information control block (ICB) tracking streams for Universal Disk Format (UDF) file systems. The streams assist in tracking the location of the ICBs on the media, and promote clustering of ICBs. Both of these factors increase the speed of the UDF file system by greatly reducing the time to scan and locate files.

Owner:MICROSOFT TECH LICENSING LLC

Header for a forage harvester

A coppice header for a forage harvester adapted to be mounted on and powered by a forage harvester. The header including at the front side two circular rotatable knives, a feeding drum being mounted above each knife, said drums being rotatable about the same rotation axis as the respective knives, wherein each feeding drum is equipped with one or more flat hook-shaped extensions adapted to grab the cut stems in the region immediately above the rotatable knives. The header may also be provided with a front feed roll placed behind the knives and two additional feed rolls placed behind the front feed roll, wherein the front feed roll is equipped with guiding blades along the length of the feed roll. The blades have a central protrusion, so that the blades are longer in a region around the middle of the blade than at the lateral ends of the blades.

Owner:BLUE LEAF I P INC

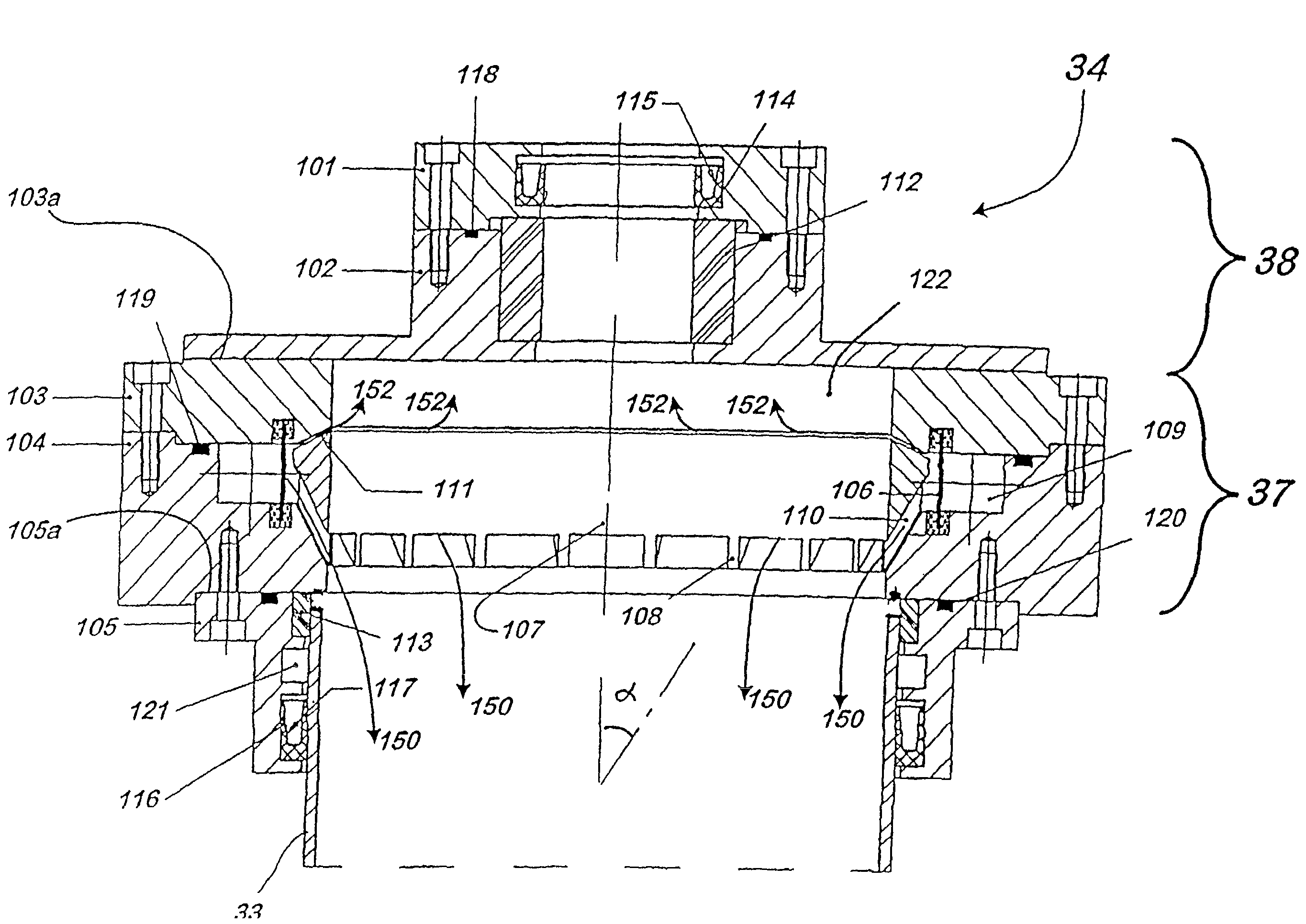

Method and induction furnace for drawing large diameter preforms to optical fibres

InactiveUS7814767B2Reduce free spaceTurbulence in the flow of conditioning gas may be prevented easierFurnaces without endless coreGlass furnace apparatusGraphiteMechanical engineering

An induction furnace capable of drawing large diameter preforms of up to 130 mm is described. The induction furnace has top and bottom chimneys surrounding the entire preform during operation of the furnace with an inert conditioning gas which is introduced into the top chimney and flows downward through the furnace body and bottom chimney without significant turbulence. A distributor ring inside the top chimney redirects flow from a circumferential direction to a downward direction. The top chimney also includes a resilient seal to releasably hold the top of the preform. The bottom chimney has a smoothly decreasing cross-sectional area preventing turbulence at the furnace exit. The furnace insulation is preferably a rigid self-supporting graphite cylinder. A method of drawing large diameter preforms either to an optical fiber or to a preform of smaller diameter using such a furnace is also described.

Owner:PIRELLI CAVI E SISTEMI SPA +1

Gear pump

ActiveCN102959245AAvoid stayingSmall volume flowRotary piston pumpsRotary piston liquid enginesGear pumpCoupling

A gear pump is described with a plurality of gear wheels which intermesh in order to deliver a pumping medium, are held rotatably in a pump case and deliver a pumping medium from a priming zone into a delivery pressure zone of the pump case. One of the gear wheels is driven by a pump shaft which protrudes with a coupling end out of the pump case. In order to seal the pump case, a shaft sealing ring is held around the circumference of the pump shaft, wherein, in order to avoid material deposits, the shaft sealing ring is assigned, according to the invention, an interior flushing chamber on the circumference of the pump shaft, the flushing chamber being connected to the delivery pressure zone of the pump case by a feed channel in the pump case.

Owner:OERLIKON TEXTILE GMBH & CO KG

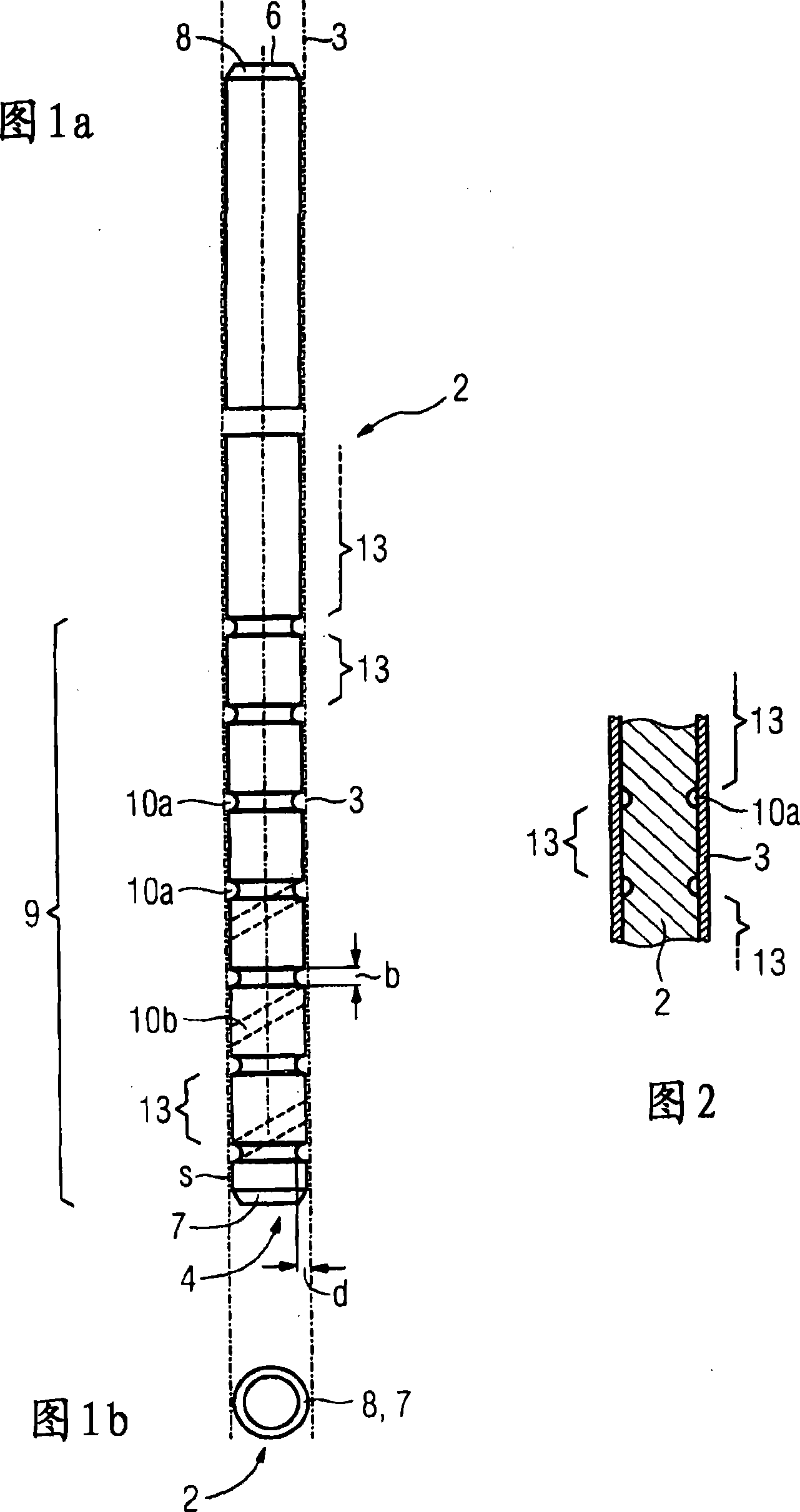

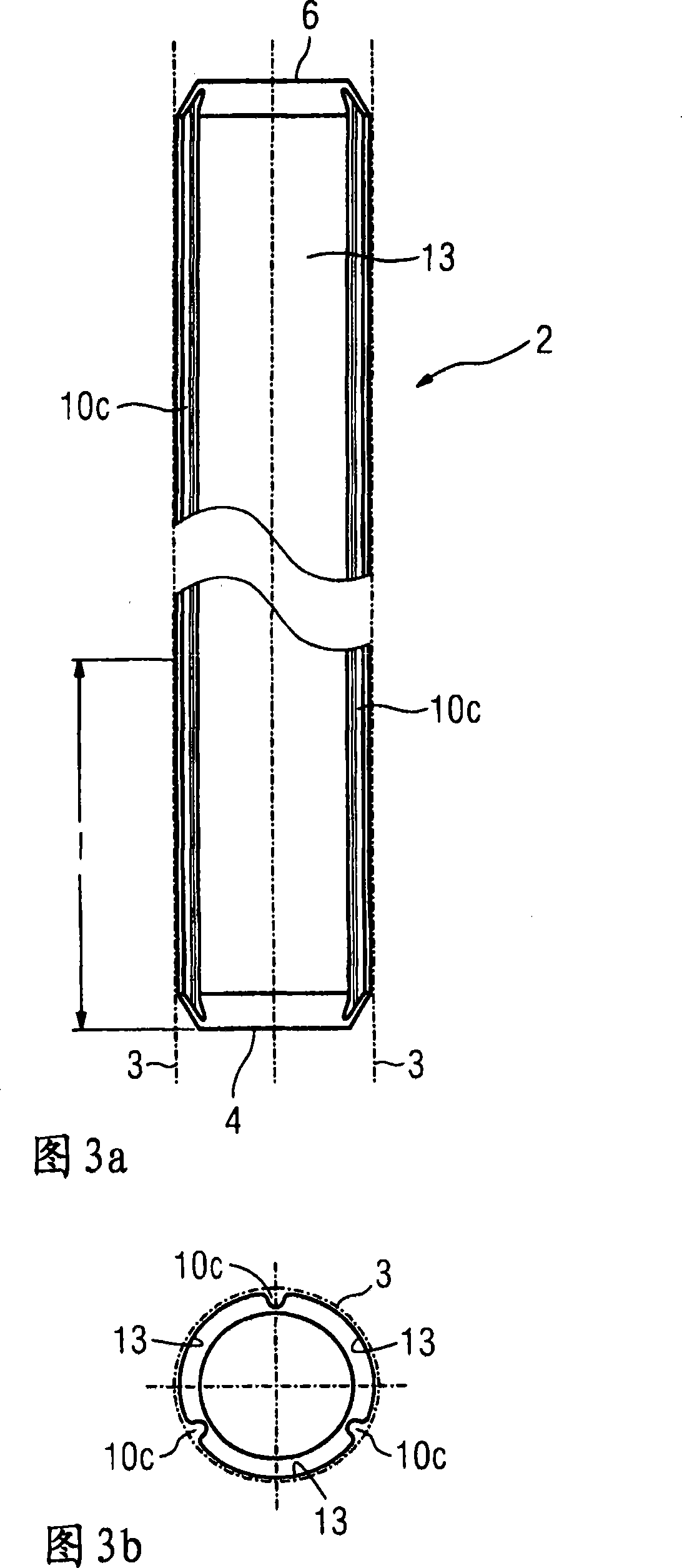

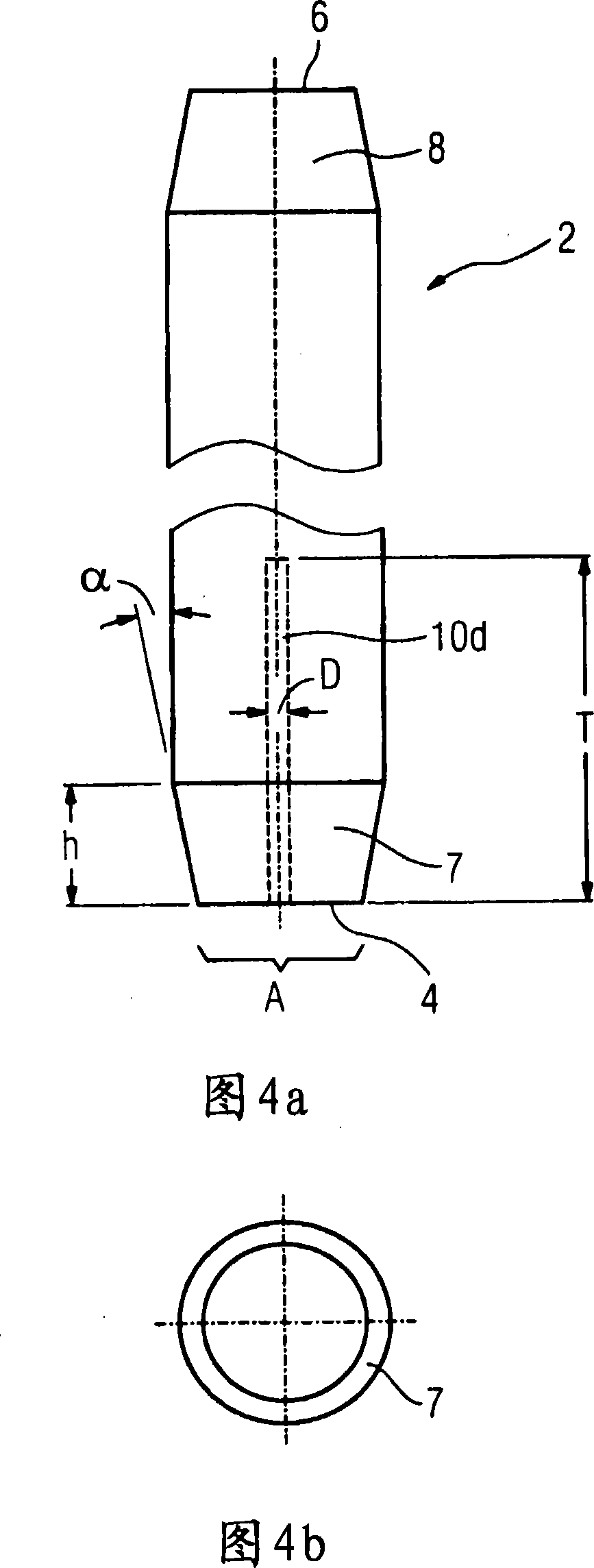

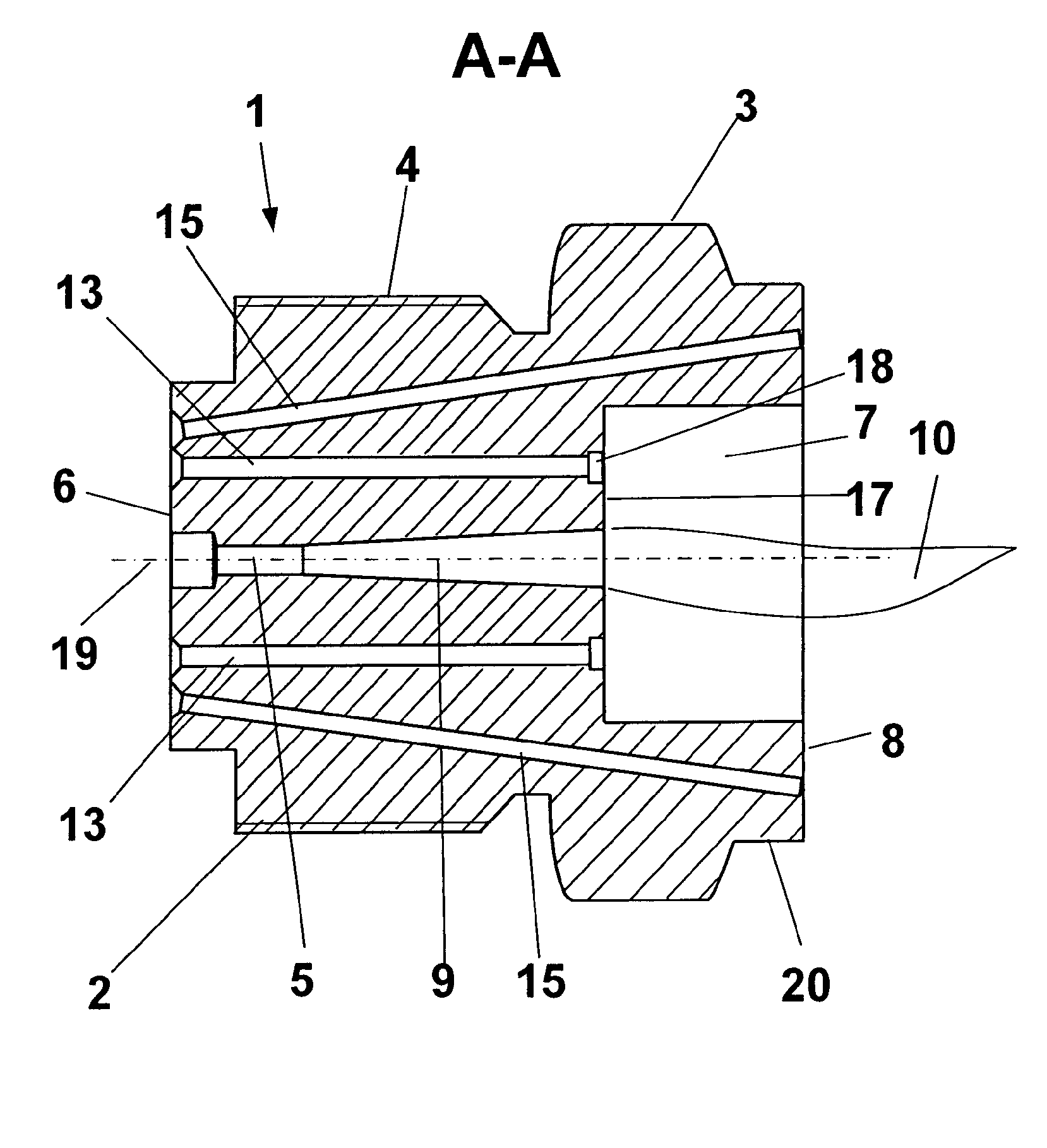

Control rod for a pressurized-water nuclear reactor

InactiveCN101228592AImprove performanceIncrease free spaceNuclear energy generationNuclear reaction controlNuclear reactorControl rod

The present invention relates to a control rod for a pressurized-water nuclear reactor which comprises an absorber rod (2) which is arranged in a casing tube (3) and, at least in a lower section (9), is provided with at least one recess (10a-d), thus making free space be arranged when encircling the casing tube (3) of the absorber rod (2). This measure reduces the problems associated with an expansion in the volume of the absorber rod (2).

Owner:FRAMATOME GMBH

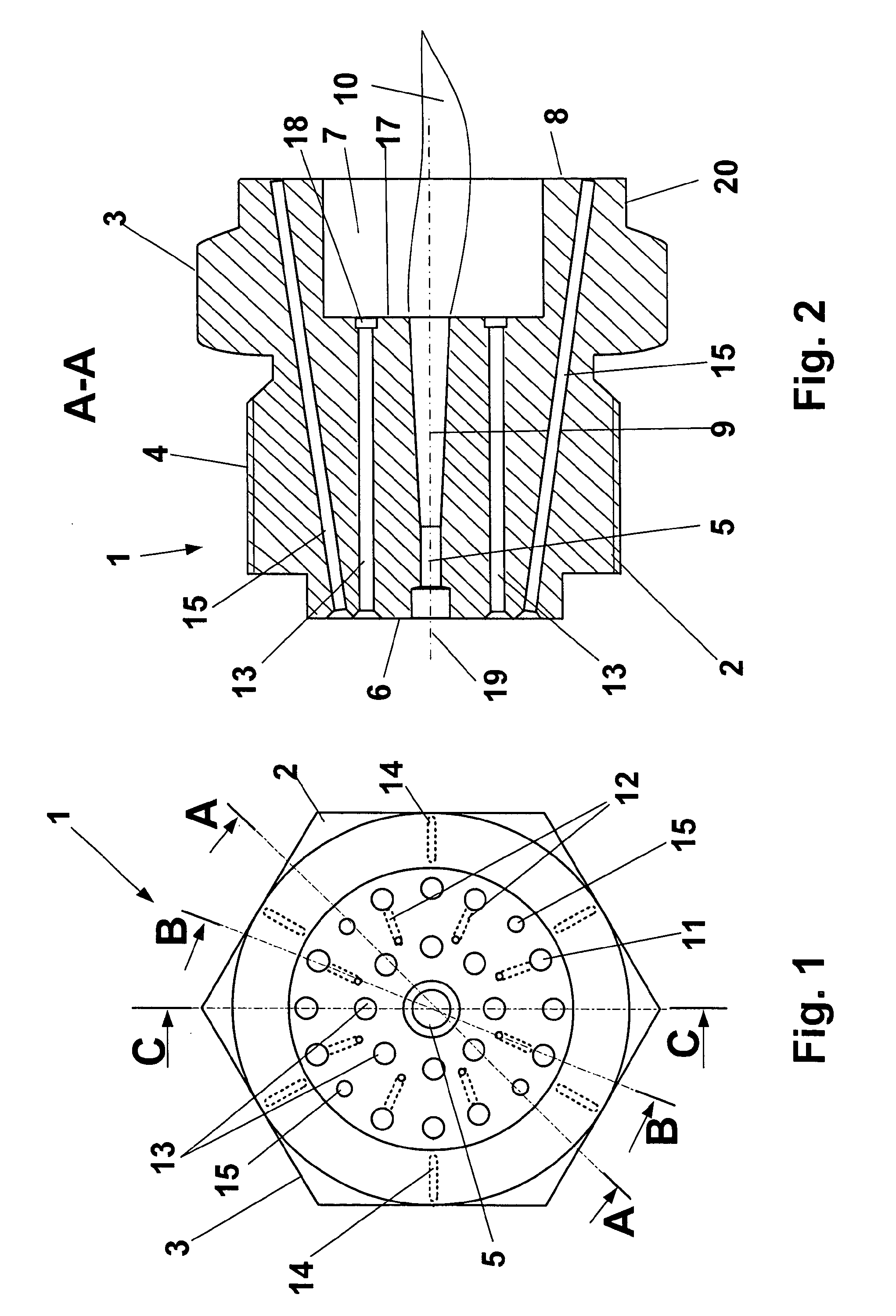

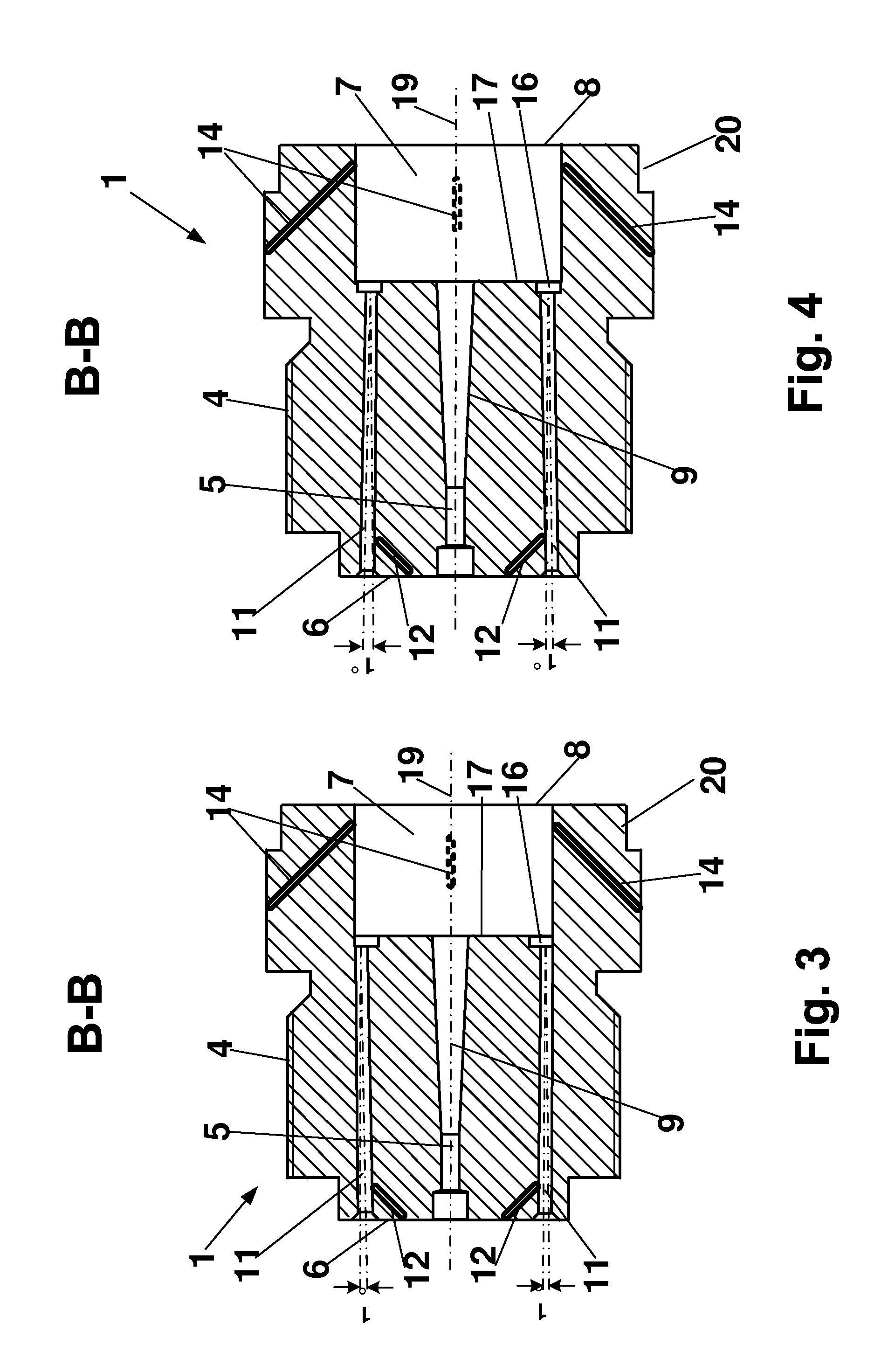

Nozzle for Cutting Steel Workpieces and Workpieces Made of Iron Alloys

InactiveUS20130038001A1Process economyLess componentsGaseous fuel burnerGas flame welding apparatusEngineeringIron alloys

The invention relates to a nozzle (1) for cutting steel workpieces and workpieces made of iron alloys, comprising a nozzle body (2) having an axial hole (5) for the discharge of cutting oxygen and a cylindrical free space (7) at the outlet surface (8) of the nozzle (1), which outlet surface forms the cutting flame (10). The nozzle (1) further comprises a plurality of heating gas holes (13) and a plurality of heating oxygen holes (11), which are arranged in an outer or inner concentric circle around the axial hole (5). In addition, a number of cooling oxygen holes (15) arranged in at least one concentric circle around the axial hole (5) is provided. The cooling oxygen holes run from the inlet side (6) of the nozzle body (2) to the outlet surface (8) of the nozzle (1) and open outside of the pot-shaped cylindrical free space (7).

Owner:FUR AUTOGENMASCH UND GERATE MBH

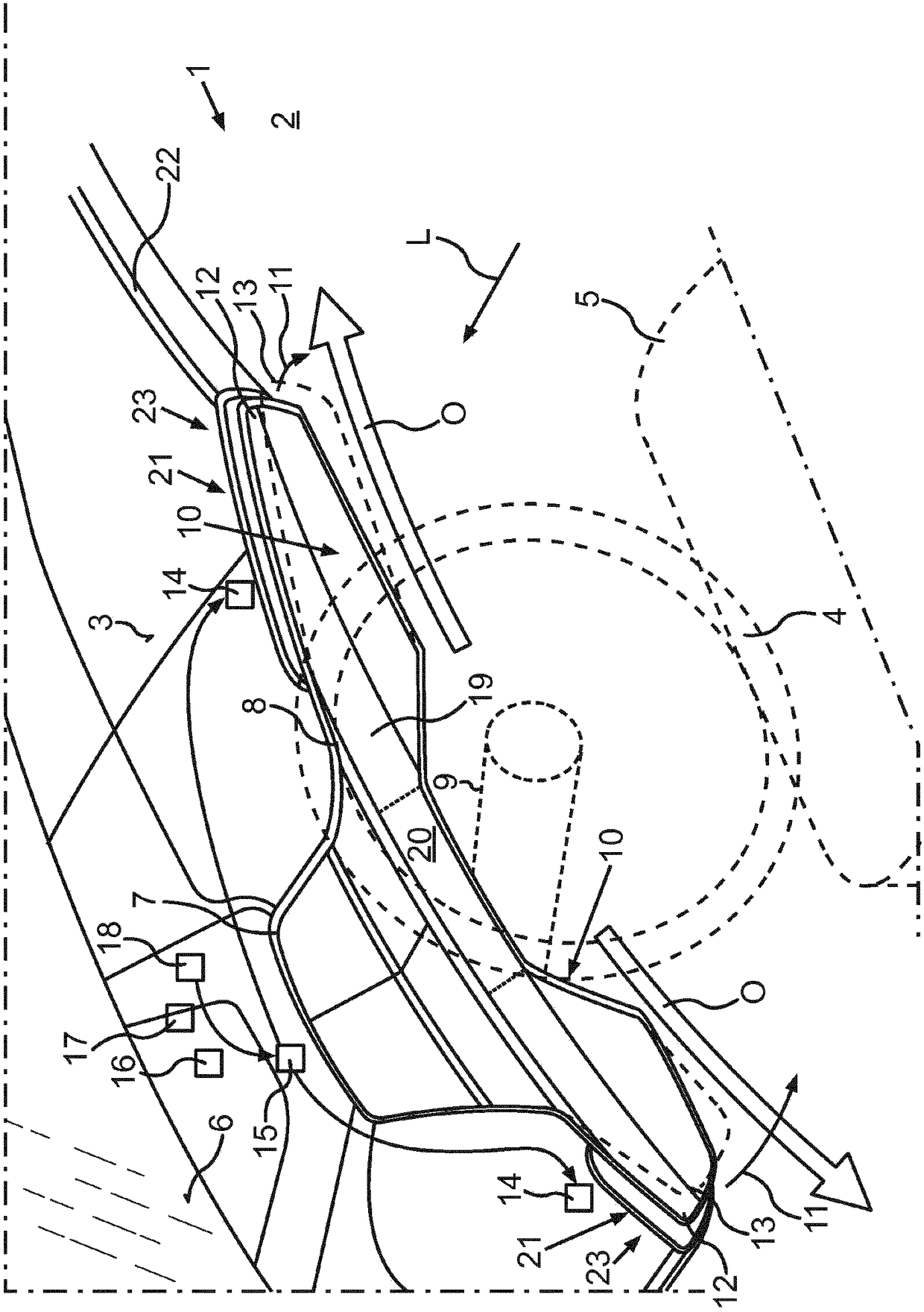

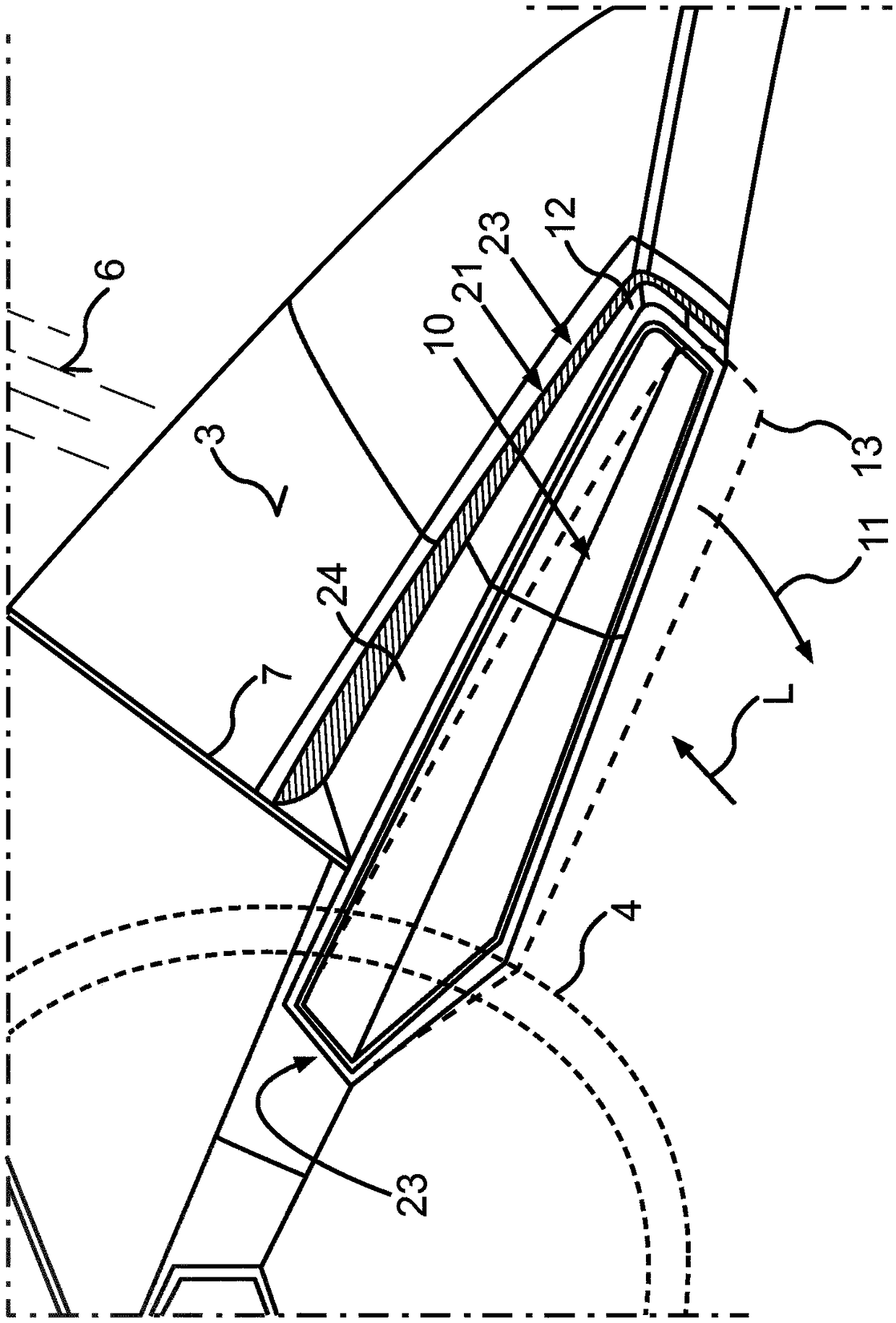

Motor vehicle with a control panel module

ActiveCN108430832AReduce free spaceEfficient use ofDashboard fitting arrangementsVehicle heating/cooling devicesSteering columnComputer module

The invention relates to a motor vehicle (1) having a control panel module (8) which is arranged between a steering handle (4) and a windscreen (6) and has at least one operator control element (10),wherein each operator control element (10) is in each case arranged on one side next to a steering column (9) of the steering handle (4). The invention makes provision for the at least one operator control element (10) to be arranged in each case rotatably about an axis of rotation (34) and / or movably at least along a longitudinal direction (L) of the motor vehicle (1) with respect to a driver's seat (5), and for an actuator device (14) of the control panel module (8) to be provided for respectively moving (11) the at least one operator control element (10), wherein a control device (15) of the control panel module (8) is designed in order, by activation of the actuator device (14), to move the at least one operator control element (10) in each case, depending on at least one enable signal(16), into an enable position (12) and, depending on at least one position signal (17), from the enable position (12) into a use position (13) corresponding in each case to the position signal (17).

Owner:AUDI AG

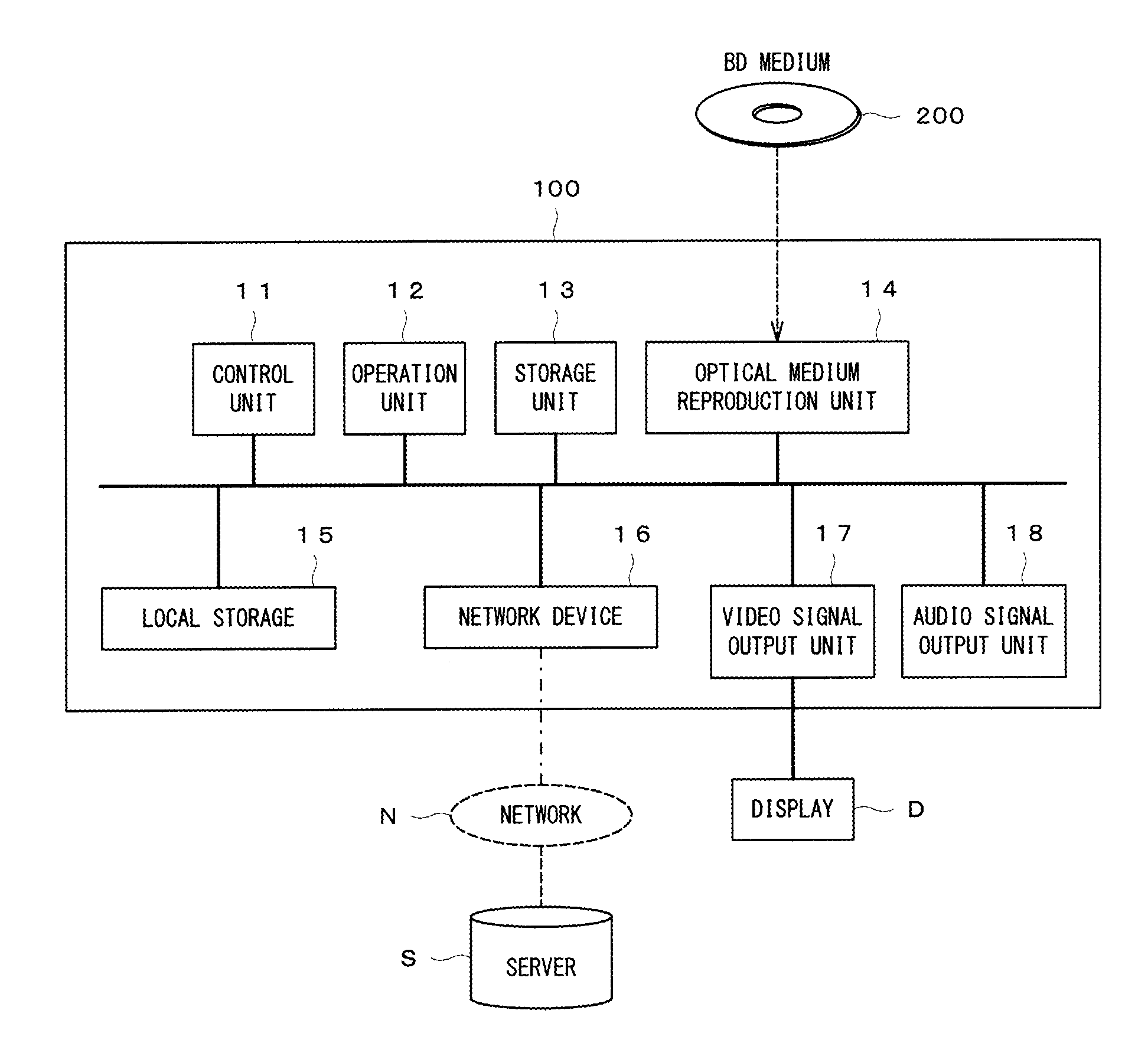

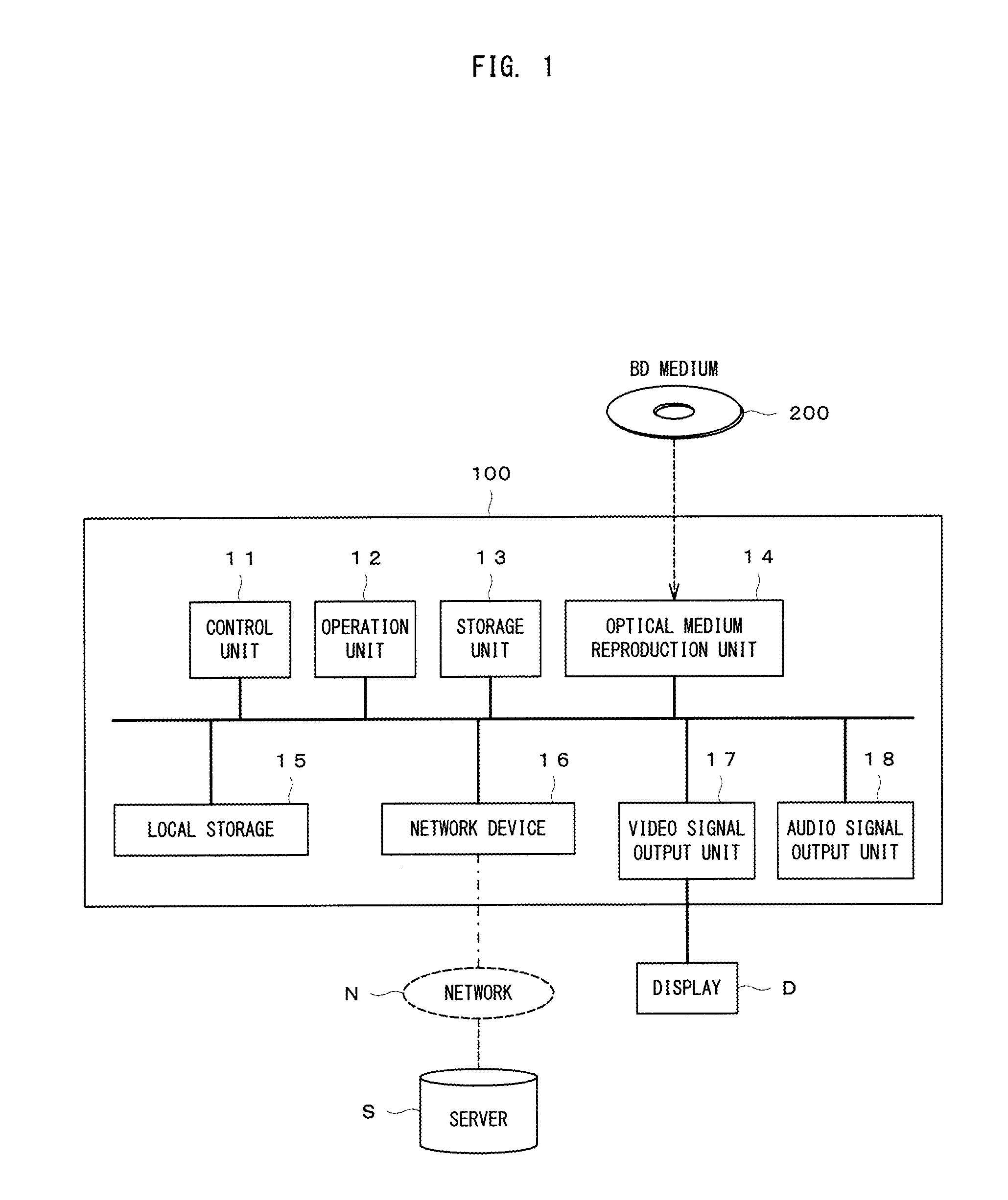

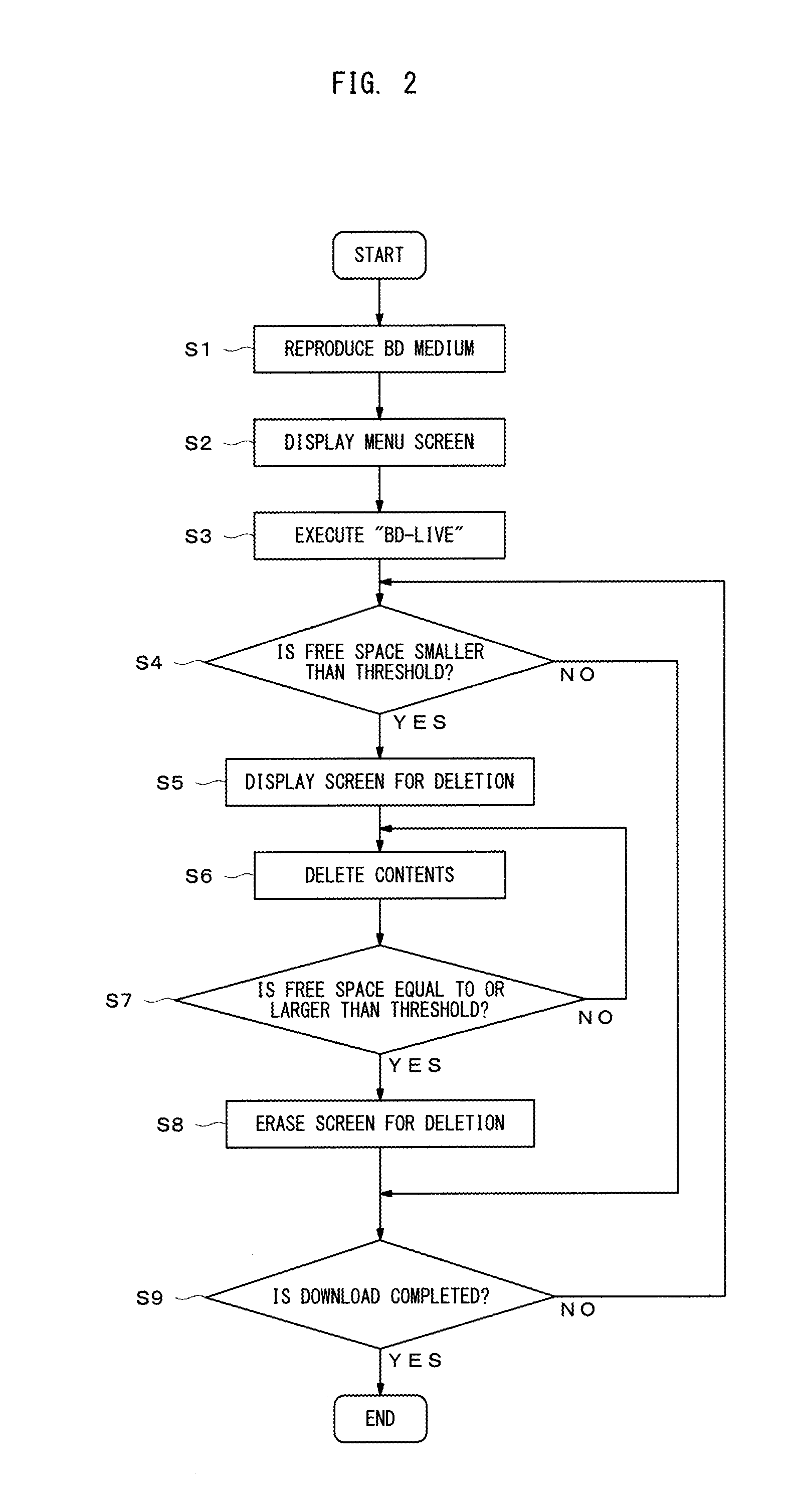

Information reproducing apparatus

InactiveUS20100296375A1Free space of storage for storingReduce free spaceElectronic editing digitised analogue information signalsFilamentary/web record carriersDisplay deviceComputer science

In a case where free space of a local storage becomes smaller than a predetermined threshold while additional contents are downloaded by executing a “BD-Live” function, a screen for deleting old contents is displayed on a display. When a user deletes the old contents and the free space of the local storage becomes equal to or larger than the threshold, the screen displayed on a display is automatically erased. By repeating the deletion of old contents until download of the additional contents is completed, the entire additional contents are completely acquired.

Owner:FUNAI ELECTRIC CO LTD

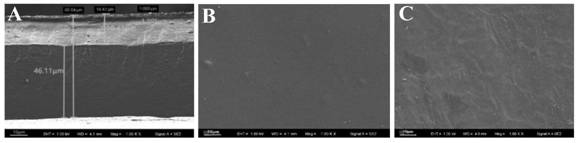

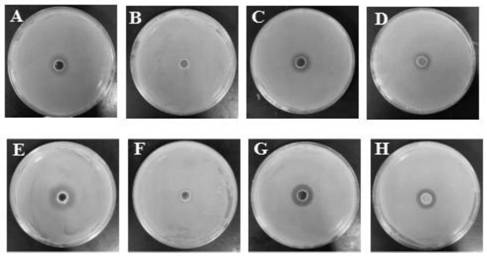

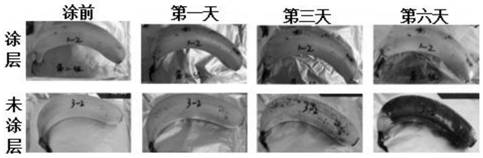

Degradable antibacterial composite preservative film as well as preparation method and application thereof

InactiveCN113383882AImprove water resistanceLow water vapor transmission rateFood ingredient as antioxidantFlexible coversAntioxidant capacityPolymer science

The invention belongs to the technical field of food packaging materials, and particularly relates to a degradable antibacterial composite preservative film as well as a preparation method and application thereof. The degradable antibacterial composite preservative film is prepared by sequentially casting a chitosan acetic acid solution, a tannic acid solution and a corn starch solution by adopting a layer-by-layer assembly casting method. The degradable antibacterial composite preservative film comprises a chitosan and tannic acid composite film with a phenol-amine network structure formed by covalent crosslinking of chitosan and tannic acid, and a corn starch film bonded with the chitosan and tannic acid composite film through hydrogen bonds. The degradable antibacterial composite preservative film prepared by the preparation method disclosed by the invention has very strong antibacterial ability and antioxidant ability.

Owner:QINGDAO AGRI UNIV

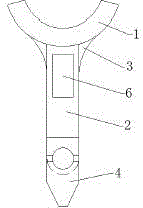

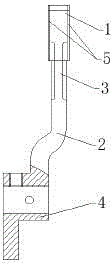

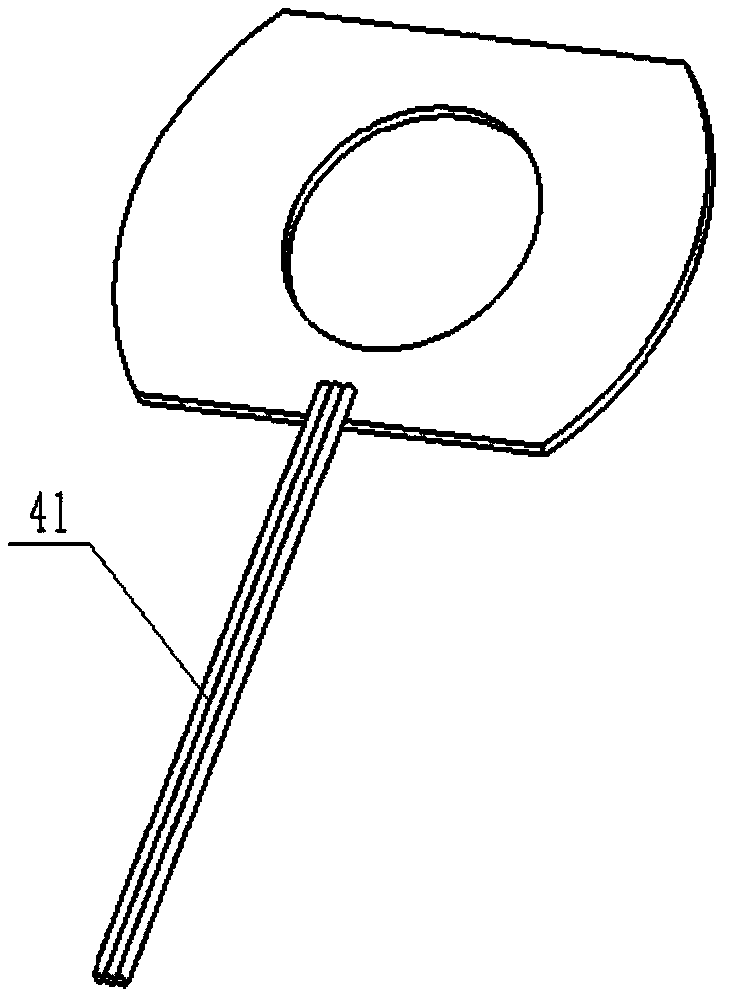

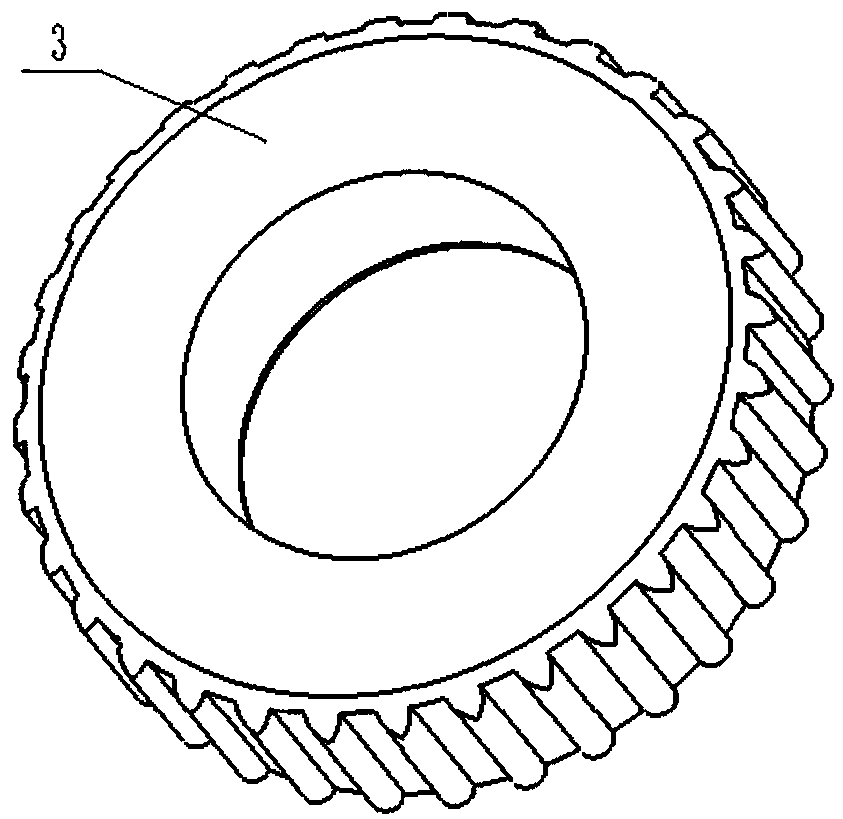

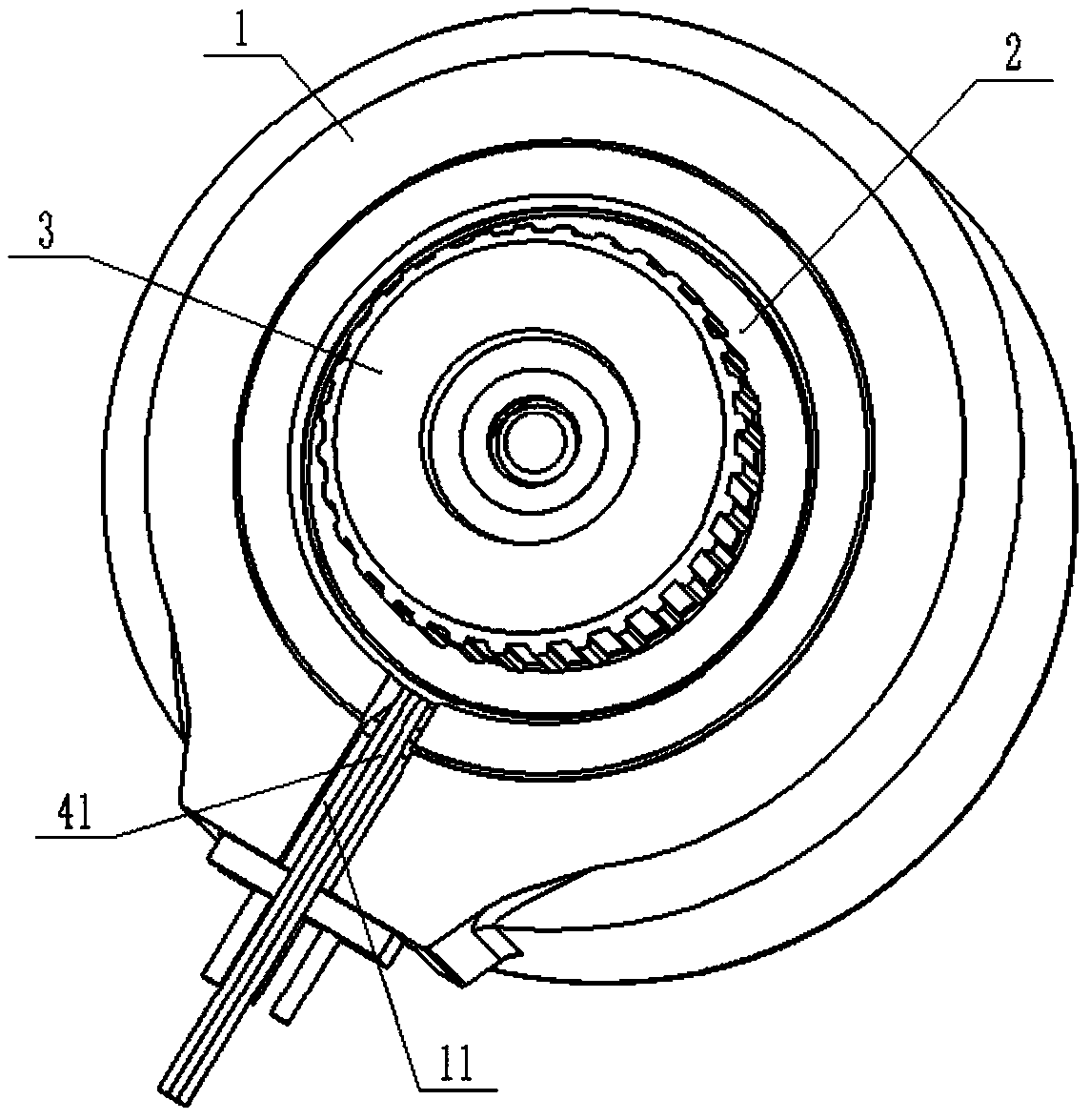

Light and practical transmission shifting fork

InactiveCN104455399AReduce free spaceCompact structureControlled membersGearing controlEngineeringRelative weight

The invention belongs to the field of mechanical parts and particularly relates to a transmission shifting fork. The transmission shifting fork comprises a fork surface, a connecting rod, connecting rod reinforcing ribs and a shifting fork sleeve, wherein the fork surface is connected with the connecting rod in parallel, the connecting rod reinforcing ribs are arranged at the joints between the fork surface and the connecting rod and located on the two sides of the connecting rod, the connecting rod is of a Z-like folding arc shape, the height of the Z-like folding arcs on the same side of the connecting rod ranges from 20 mm to 22 mm, the front face and the rear face of the connecting rod are both provided with grooves, the connecting rod is connected with the shifting fork sleeve in parallel, and the bottom faces of the joints between the connecting rod and the shifting fork sleeve are located on the same plane. A transmission provided with the transmission shifting fork can be compact in structure and low in relative weight, and the transmission shifting fork is simple in structure, low in cost, easy to produce in a large-scale and batch mode and long in service life.

Owner:SHANGHAI QISHAN INSTR TECH

Plastic package motor with sealing property

The invention relates to the technical field of plastic package motors, in particular to a plastic package motor with sealing property. A seal ring sleeves a power line and is arranged in a line slot;a bump for compressing the seal ring into the line slot is arranged at the bottom of a shock-proof rubber ring; the seal ring sleeves the power line and is located in the line slot; a bottom plate with the bump is arranged at the bottom of the shock-proof rubber ring; the bump at the bottom of the shock-proof rubber ring is compressed on the seal ring located in the line slot, so that the line slot, the seal ring sleeving the power line and the bump are mutually extruded, the spare space in the line slot is reduced and a gap in the line slot is reduced, thereby preventing external microorganisms and impurities from entering the inside of the plastic package motor and solving the problem that the gap is formed in the matched part among a traditional power line, a plastic package stator andan end cover and the external microorganisms and impurities can enter the inside of the plastic package stator from the gap to cause locking of the motor.

Owner:合肥市通得力电气制造有限公司

Optical fiber wavelength division multiplexing device and annular cavity optical fiber laser containing same

InactiveCN102169210AShorten the lengthSimple systemCoupling light guidesActive medium shape and constructionImage resolutionInstability

The invention discloses an optical fiber wavelength division multiplexing device and an annular cavity optical fiber laser containing same. The optical fiber wavelength division multiplexing device comprises a double-tail fiber collimating lens, wherein a fiber wavelength division multiplexing membrane is fixed on one end face of the double-tail fiber collimating lens or a membrane which can be used for realizing the wavelength division multiplexing is plated on one end face of the double-tail fiber collimating lens. By using the optical fiber wavelength division multiplexing device and the annular cavity optical fiber laser containing the same provided by the invention, the loss and instability caused by the space coupling can be avoided while the optical fiber length of the optical fiber laser is reduced and the repetition rate is increased, thereby increasing the resolution ratio when used as the frequency comb of a light source.

Owner:PEKING UNIV

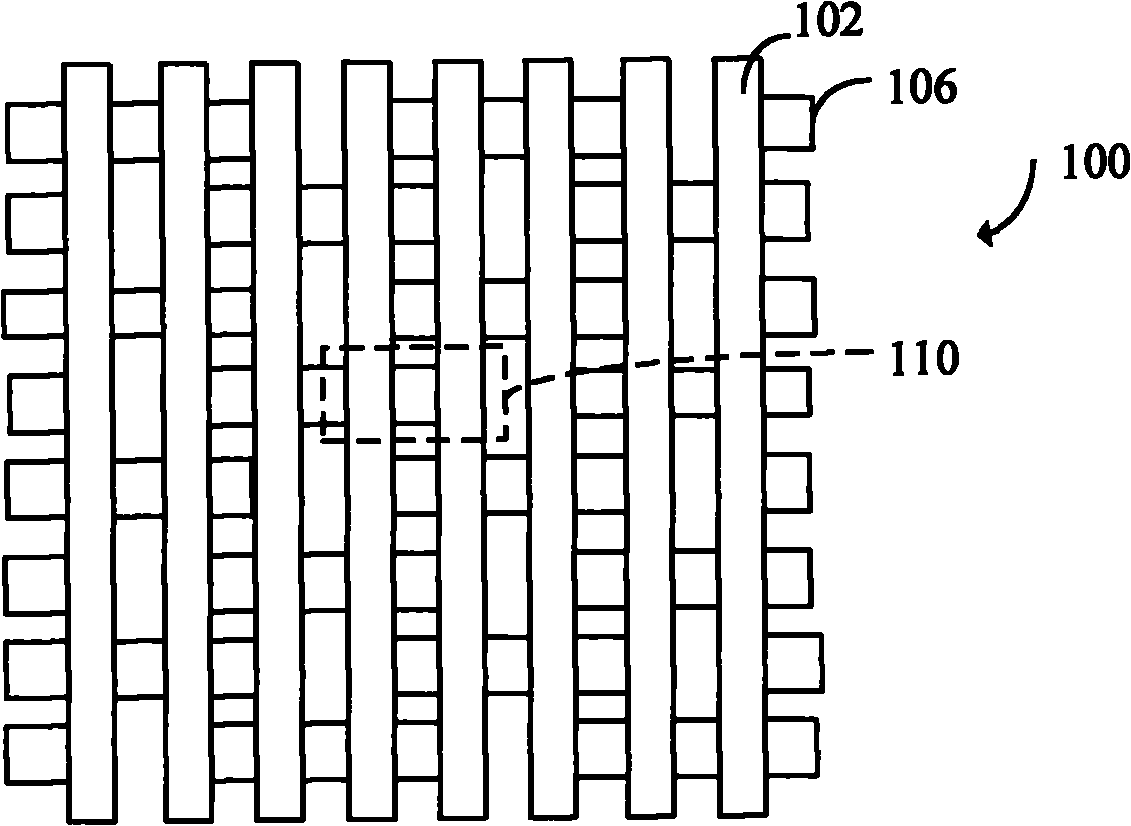

Dynamic random access memory (DRAM)

InactiveCN102054526AEfficient use ofReduce free spaceSolid-state devicesDigital storageLow noiseSignal-to-noise ratio (imaging)

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Storage device for storage yard and closed storage yard

ActiveCN103640832BIncrease storage capacityImprove space utilizationStorage devicesLoading/unloadingEngineeringYard

Owner:CISDI ENG CO LTD

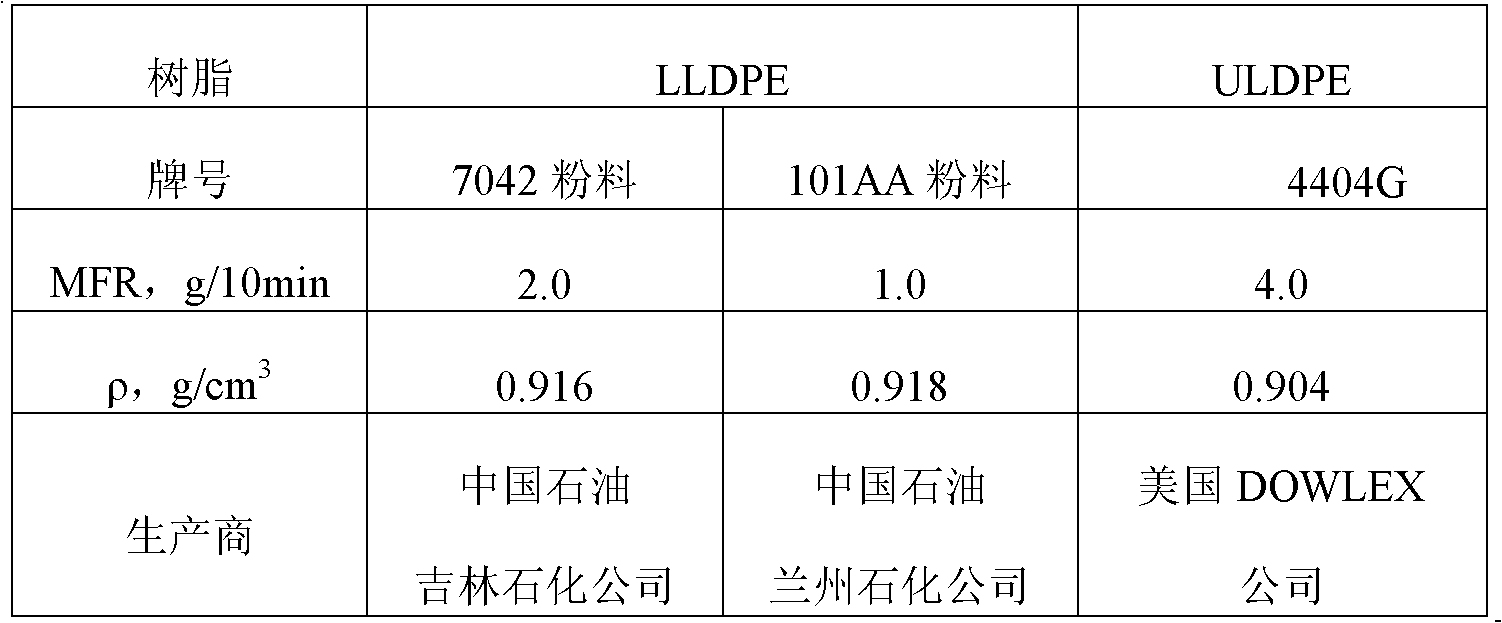

Polyethylene resin composition for greenhouse film and preparation method thereof

ActiveCN103160015ABig free spaceIncrease elasticityGreenhouse cultivationCross-linkLinear low-density polyethylene

The invention provides a linear low-density polyethylene resin composition for a greenhouse film and a preparation method thereof. The composition comprises, on the basis of 100 wt% of LLDPE, 100% of LLDPE, 0.05 to 0.3% of a complex cross-linking agent and 5 to 20% of a ULDPE graft, wherein the ULDPE graft is a graft copolymer prepared by grafting a styrene (St) monomer to a ULDPE main chain under action of an initiator. A broad-width greenhouse film (with a thickness of no less than 80 mu m and a width of no less than 8 m) produced with the composition as a raw material has high tearing strength and excellent weatherability, can withstand 7-grade to 8-grade sandstorms, has no natural damage even when a greenhouse shed has been constructed from the greenhouse film for more than 900 days and is especially applicable to laying in western regions with frequent sandstorms and long sunshine duration.

Owner:PETROCHINA CO LTD

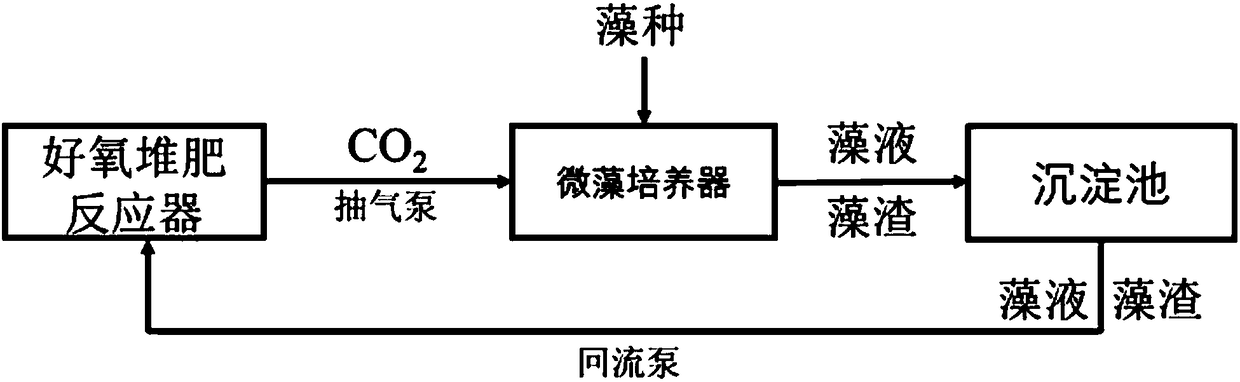

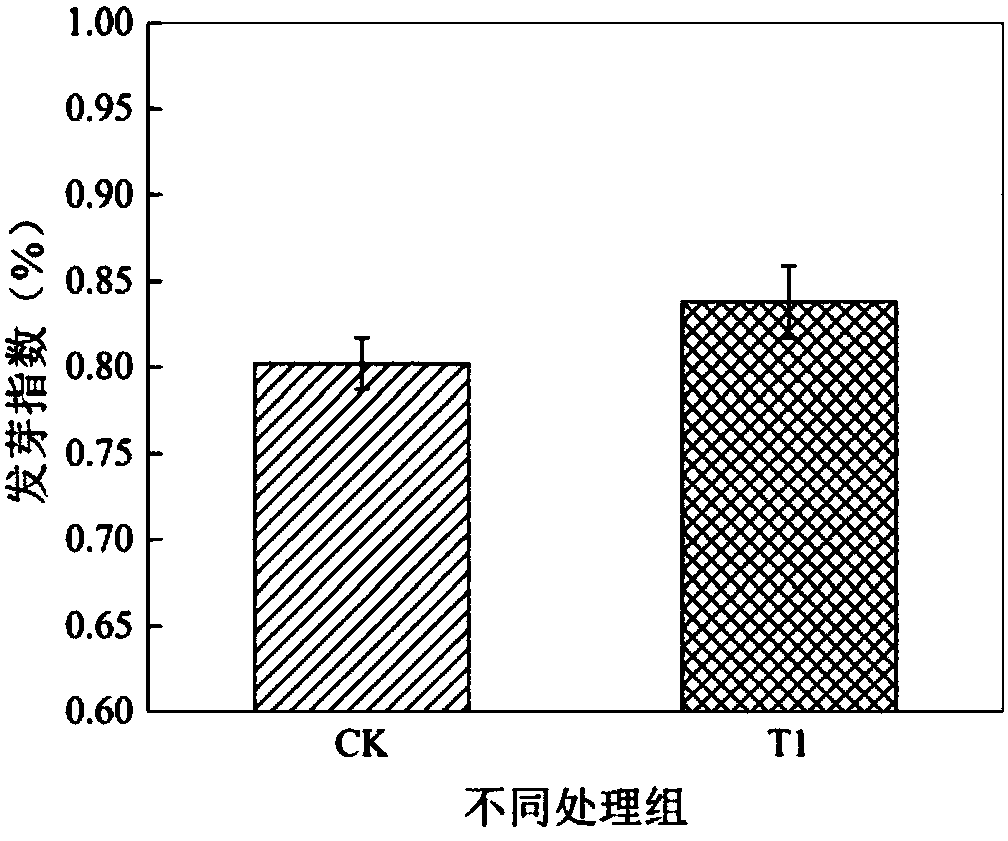

Method for absorbing CO2 in compost by microalgae and recycling microalgae

InactiveCN108440033ALow raw material costLow costProductsBio-organic fraction processingWater contentGreenhouse gas

The invention discloses a method for absorbing CO2 in compost by microalgae and recycling the microalgae, relates to a method for absorbing the CO2 in the compost by the microalgae and recycling the microalgae in the compost, belongs to the field of environment-friendly compost, and aims to solve the technical problem that greenhouse gas CO2 produced by the compost causes climate warming. The method comprises the following steps: 1, inflating the CO2 gas produced by an aerobic composting reactor into a microalgae incubator through a gas pump, culturing the microalgae under a closed light irradiation condition, mixing algae liquid and algae residues with a conditioning agent after a microalgae growth cycle, then enabling a mixture to return back into the compost in the aerobic composting reactor through a reflux pump till the C / N ratio of the compost is 20:1 to 25:1 and the water content is about 60%; 2, repeating the step 1. By the method, release of the greenhouse gas CO2 in the composting process is reduced, secondary pollution is not caused, manpower and material resources are greatly saved, energy is saved, environment friendliness is achieved, and economic benefits are improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

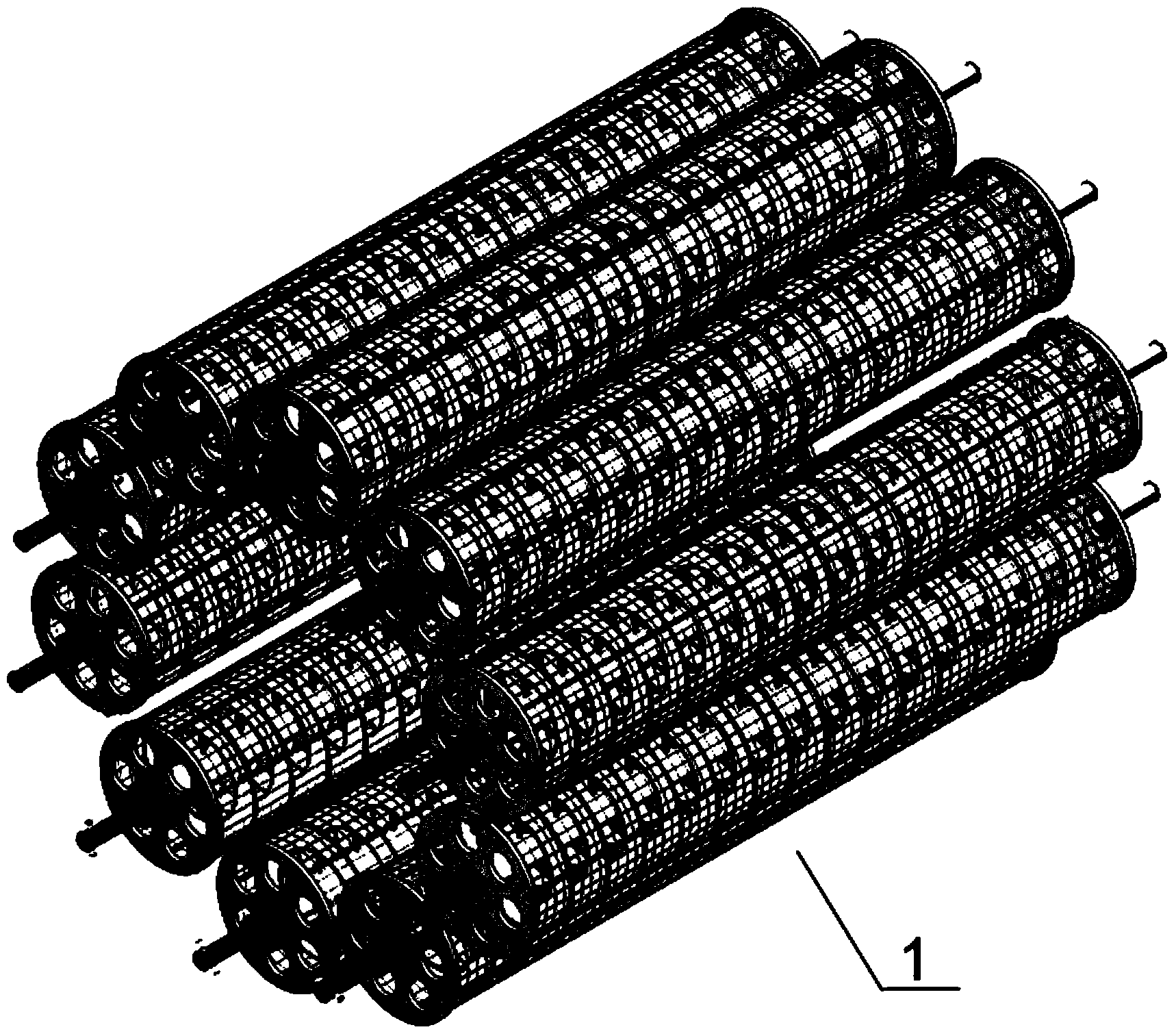

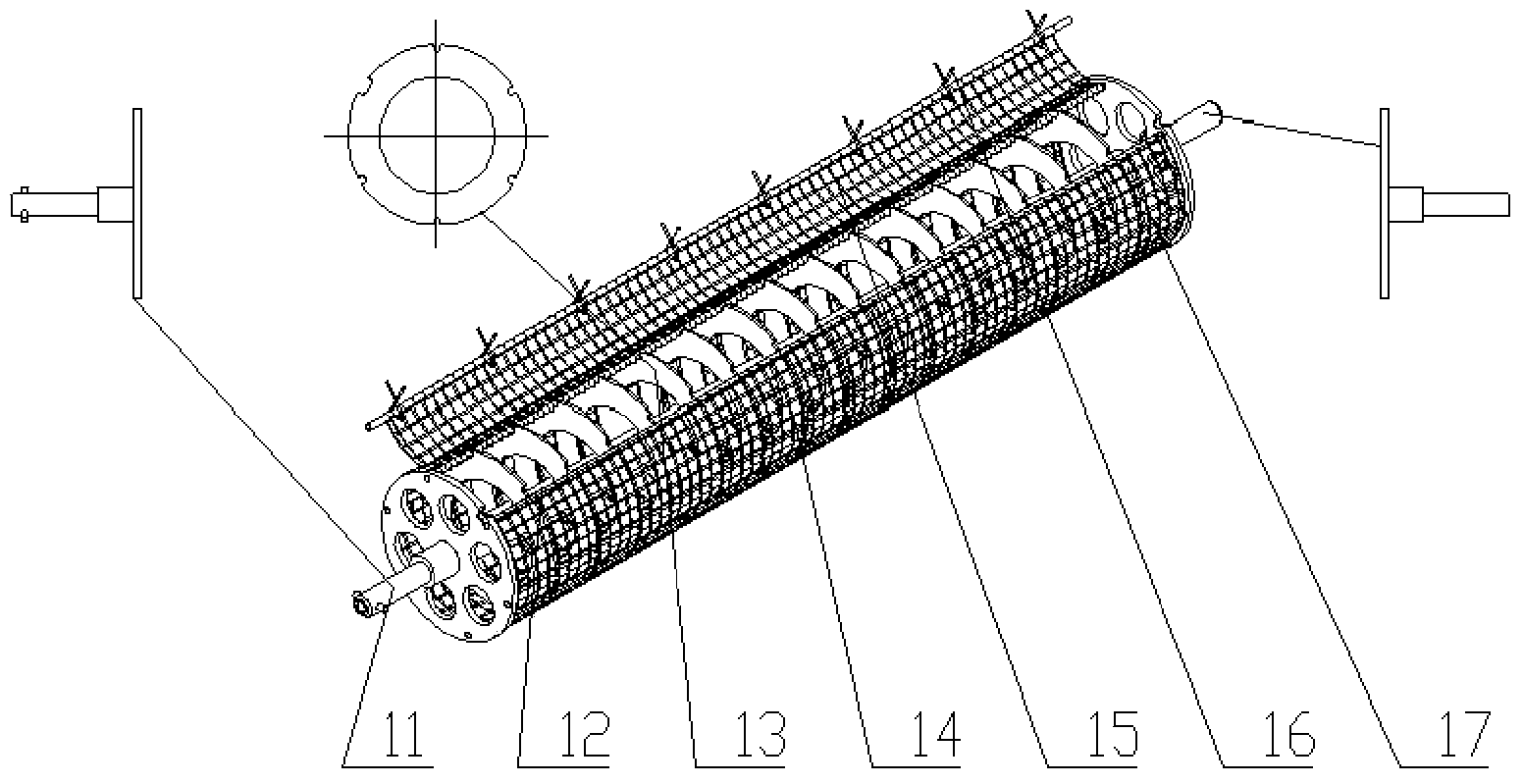

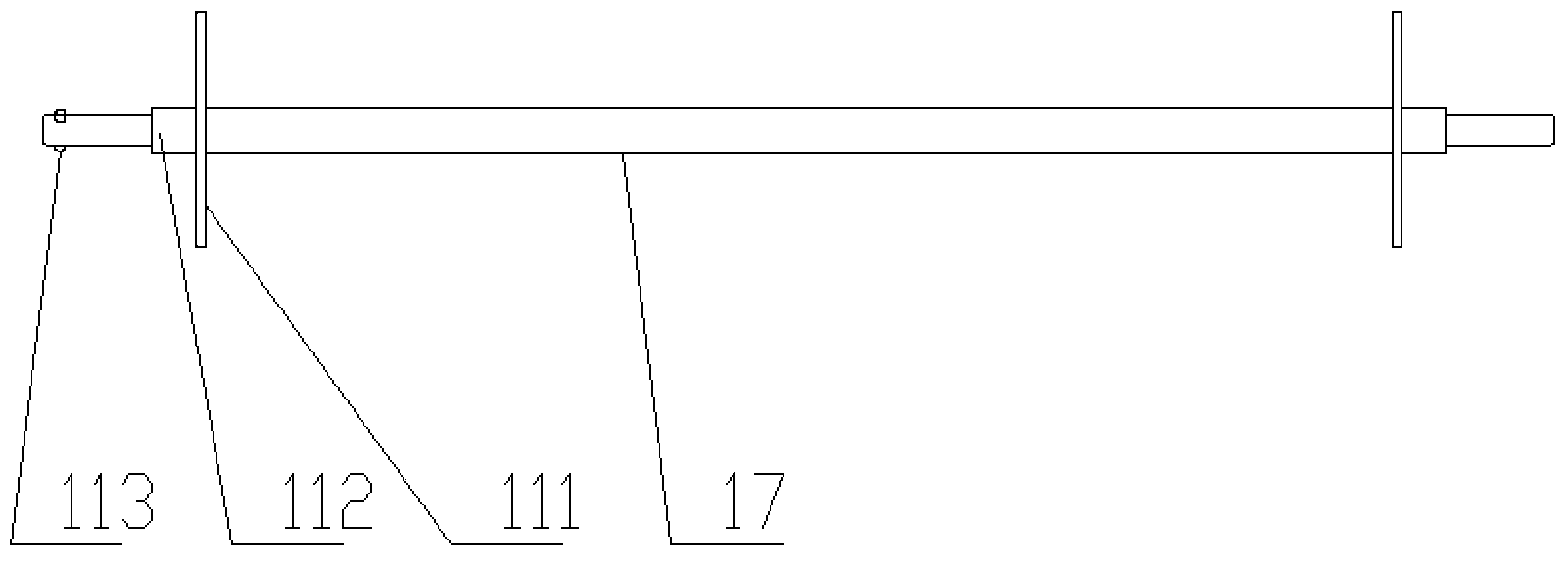

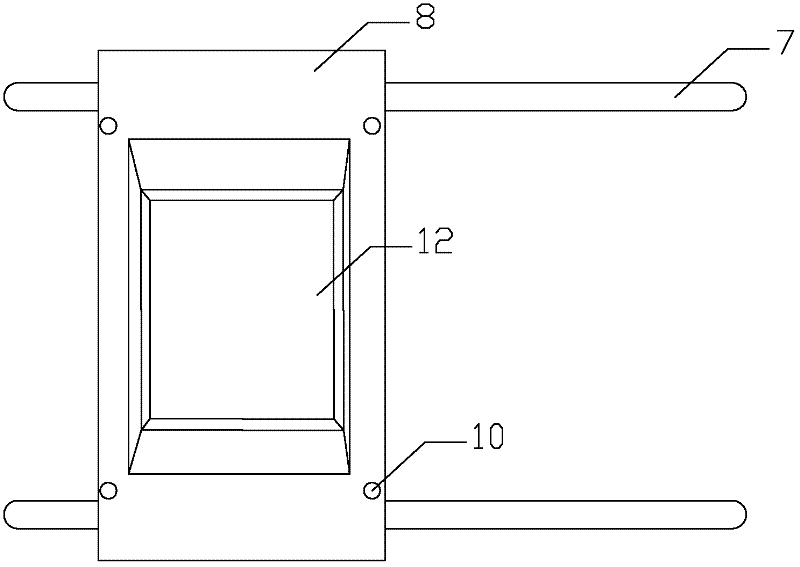

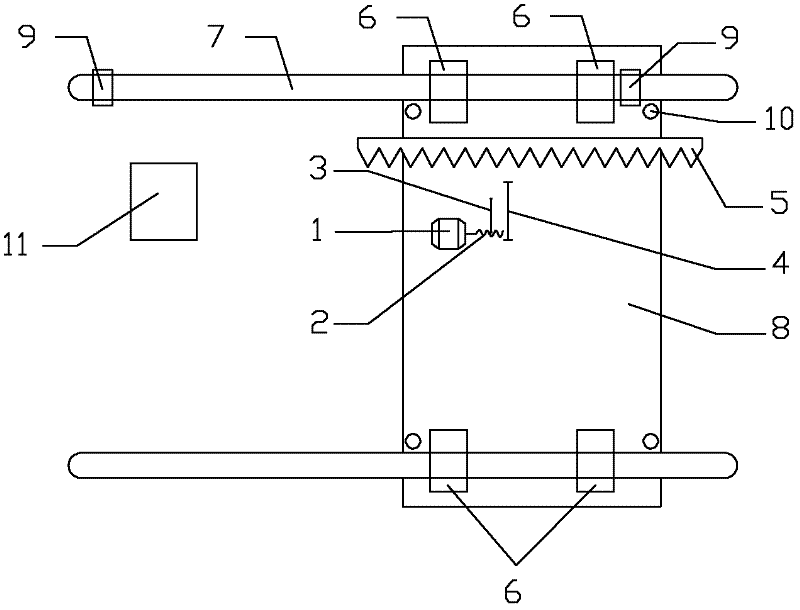

Metal mesh cage film-plating clamping device

InactiveCN104164656AReduce free spaceAvoid collision damageVacuum evaporation coatingSputtering coatingMetal meshMechanical engineering

The invention relates to a metal mesh cage film-plating clamping device, and belongs to the technical field of a vacuum film-plating device. The device is a planetary cylinder-type clamp composed of multiple mesh cages or multiple groups of mesh cages which are arranged side by side along a circumferential direction, each one of the mesh cages is cylindrical or multi-prismatic-type cylindrical, each one of the mesh cages is installed on a horizontal-rotation planetary rotating stand mechanism or on a horizontal-rotation planetary rotating stand mechanism with a two-process self-rotation mechanism by support shafts at two ends of the mesh cage, each one of the mesh cages realizes horizontal revolution once and horizontal autoroatation once or realizes horizontal revolution twice and horizontal autoroatation twice, the size and shape of the mesh cage match the shape and size of a workpiece to be plated with a film so that the workpiece can freely roll in the mesh cage under the gravity, and the length of the mesh cages matches the length of an uniform section of a film-plating zone of a film-plating machine. The metal mesh cage film-plating clamping device has the characteristics of workpiece assembling and unassembling operation convenience and no damage in workpiece film plating, and can be used for film plating processes on a lot of small and medium sized workpieces.

Owner:北京丹鹏表面技术研究中心

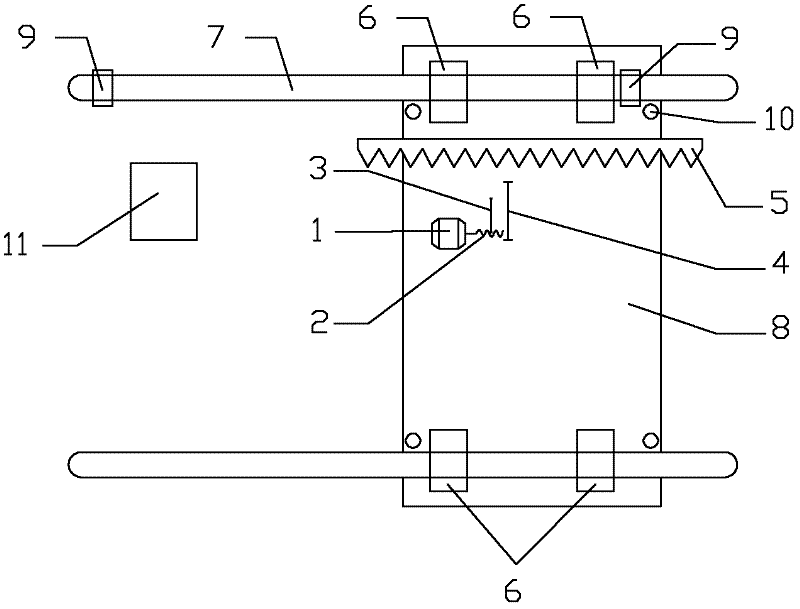

Safe parking system

The invention provides a safe parking system, which comprises guide rails, a parking plate, a traction device and travel switches, wherein the guide rails are arranged on the ground; the parking plate is arranged on the guide rails to move relatively to the guide rails and is used for parking vehicles; the traction device is connected with the parking plate to drive the parking plate to move; and the travel switches are arranged on two ends of the guide rails to space the parking plate. The area of a parking lot can be reasonably used to effectively reduce the spare area of the parking lot so as to alleviate the problem that parking is difficult. The phenomenon of parking scraping and colliding can be avoided, and loss is reduced.

Owner:方永强

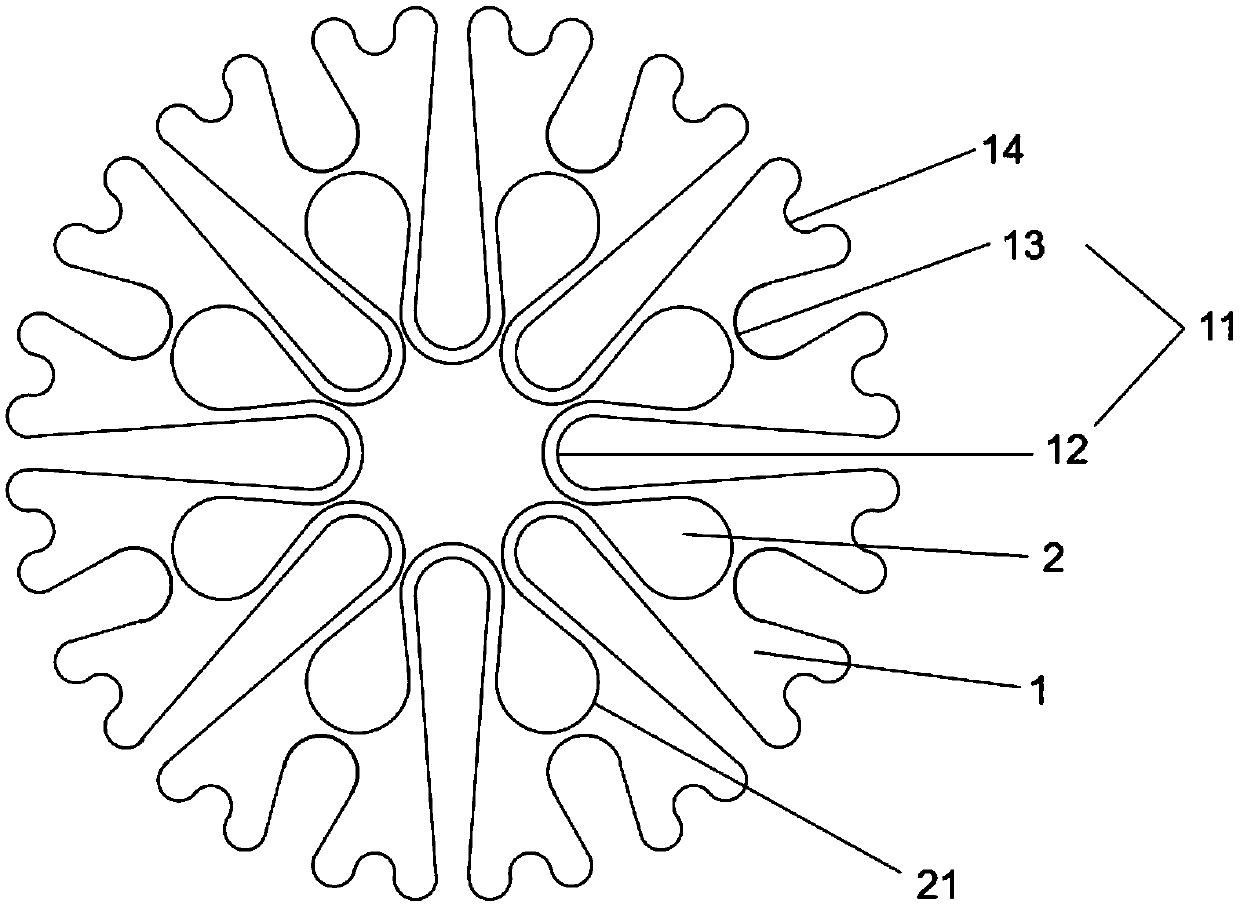

Pleated filtering core

PendingCN108671633AReduce free spaceLarge filter areaDispersed particle filtrationStationary filtering element filtersEngineeringFilter effect

The invention provides a pleated filtering core. The pleated filtering core is of a circular cylindrical shape, and is characterized by comprising an outer cylinder; the outer cylinder comprises a plurality of circumferentially distributed outer pleats extending longitudinally; the outer pleats are uniformly distributed around the circumference of the outer cylinder; the outer pleats are arch-shaped pleats; the outer pleats comprise large pleats and small pleats which are spaced apart; each of the large pleats has an equal arc length; each of the small pleats has an equal arc length; and the large pleats and the small pleats adjacent thereto are partially overlapped with each other. By adopting the pleated filtering core, the filtering area is greatly increased, the free space of the filtering core is reduced, the filtering effect is enhanced, and at the same time, the pleats are further stabilized, so that little possibility of displacement is ensured, the pleats of the filtering corecan be fully utilized, the material is saved and the cost is reduced.

Owner:DEQING GUONENG FILTER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com