Pleated filtering core

A pleated filtration and filter core technology, which is applied in filtration separation, dispersed particle filtration, fixed filter element filters, etc., can solve the problems of affecting filtration effect and waste, and achieve the effect of strong filtration effect, material saving and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

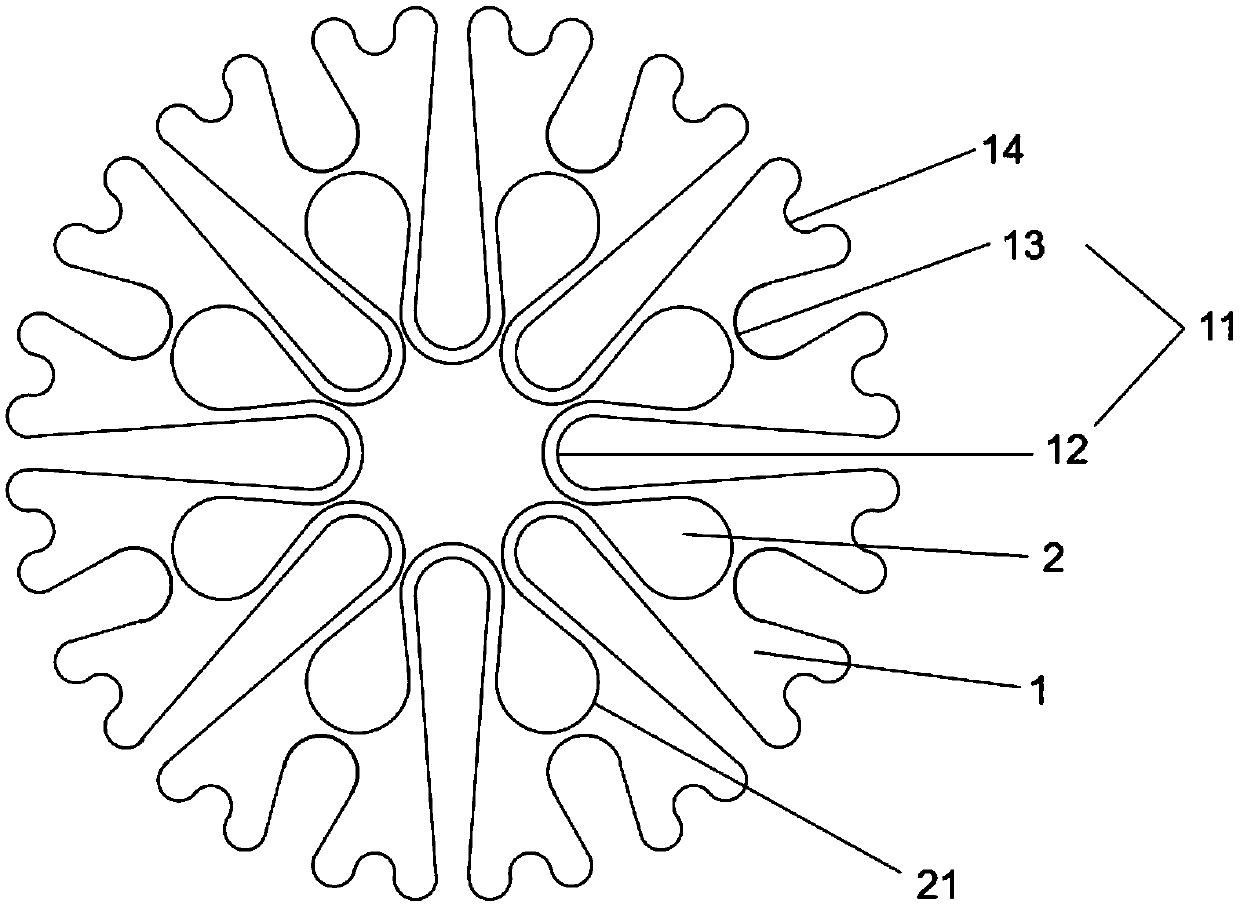

[0016] like figure 1 , The pleated filter core of this embodiment can be made of paper, chemical fiber, metal and other materials.

[0017] The outer cylinder 1 includes a plurality of outer pleats 11 distributed in the circumferential direction and extending longitudinally. The outer pleats 11 are evenly distributed around the circumference of the outer cylinder 1. The outer pleats 11 are bow-shaped pleats. The outer pleats 11 include large pleats 12 and small pleats 13 arranged at intervals , the large folds 12 have equal arc lengths, and the small folds 13 have equal arc lengths, the large folds 12 and the adjacent small folds 13 partially overlap each other, and the arc length ratio of the overlap is 8:5. Another branch pleat 14 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com