Storage device for storage yard and closed storage yard

A storage yard, closed technology, applied in the field of bulk material storage and transportation facilities, can solve the problems of poor variety adaptability, high engineering investment, low utilization rate of closed space, etc., to improve space utilization rate and low operating cost. , Improve the effect of storage capacity and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

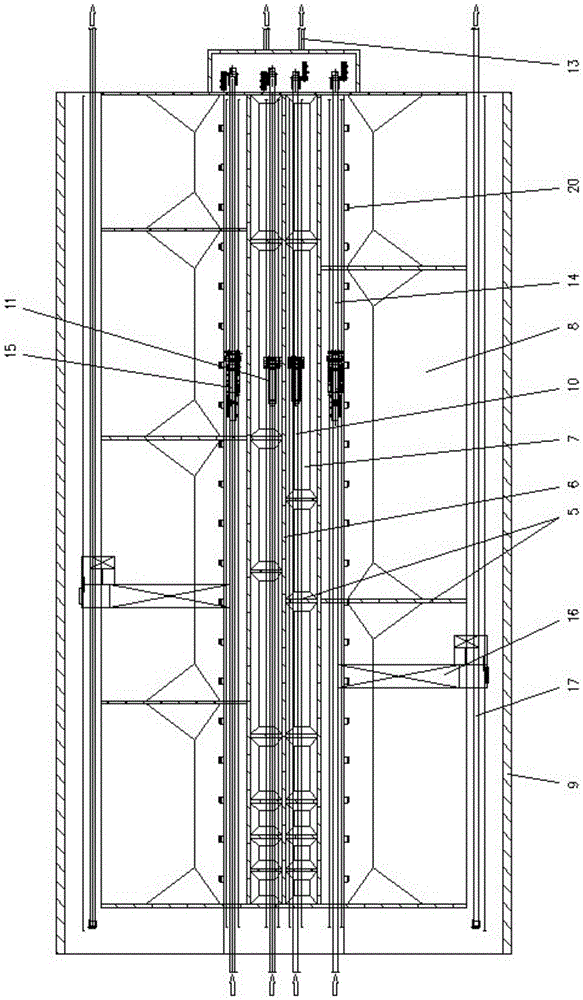

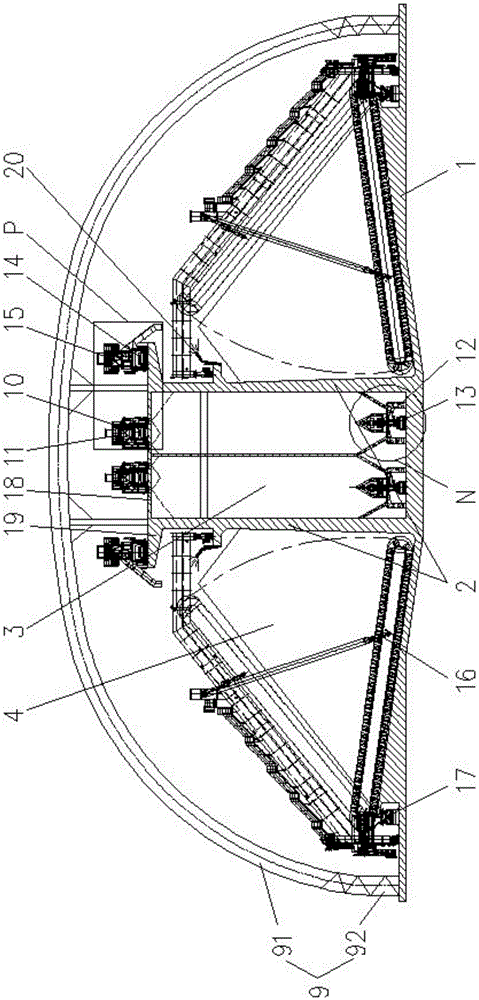

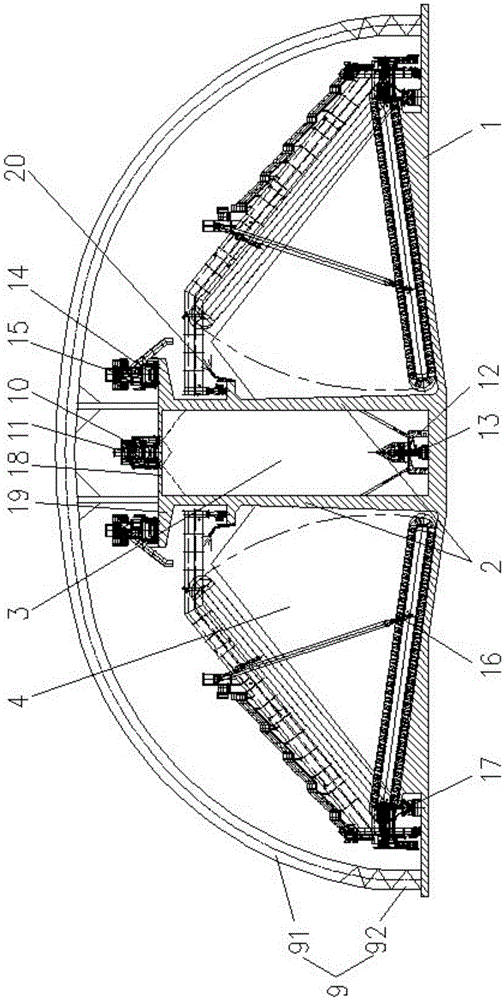

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] like figure 1 and figure 2 As shown, the material storage device of the storage yard in this embodiment includes a storage material bearing base plate 1, and the storage material bearing base plate 1 is provided with two retaining walls 2, and a storage bin 3 is formed between the two retaining walls 2, On both sides of the storage bin 3 in the longitudinal direction, there are storage compartments 4 composed of a storage base plate 1 and a retaining wall 2 . Certainly in concrete implementation, also can only be provided with material storage compartment 4 on one side of storage bin 3 as required (such as Figure 5 shown).

[0037] In the material storage device of the storage yard in this embodiment, the material stored in the storage bin 3 can be higher than the material in the storage grid 4 on both sides, which can eliminate the V-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com