Patents

Literature

43 results about "Hydraulic fracturing proppants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A proppant is a solid material, typically sand, treated sand or man-made ceramic materials, designed to keep an induced hydraulic fracture open, during or following a fracturing treatment. It is added to a fracking fluid which may vary in composition depending on the type of fracturing used, and can be gel, foam or slickwater–based. In addition, there may be unconventional fracking fluids. Fluids make tradeoffs in such material properties as viscosity, where more viscous fluids can carry more concentrated proppant; the energy or pressure demands to maintain a certain flux pump rate (flow velocity) that will conduct the proppant appropriately; pH, various rheological factors, among others. In addition, fluids may be used in low-volume well stimulation of high-permeability sandstone wells (20k to 80k gallons per well) to the high-volume operations such as shale gas and tight gas that use millions of gallons of water per well.

Coating and/or treating hydraulic fracturing proppants to improve wettability, proppant lubrication, and/or to reduce damage by fracturing fluids and reservoir fluids

InactiveUS20050244641A1Reduce conductivityEfficient arrangementSynthetic resin layered productsCellulosic plastic layered productsFracturing fluidCompound (substance)

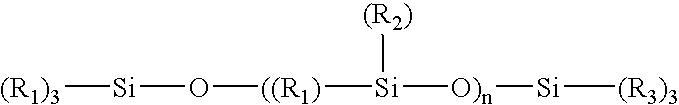

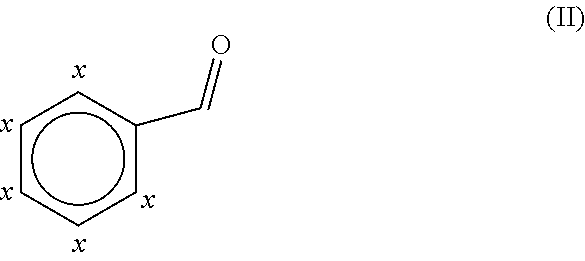

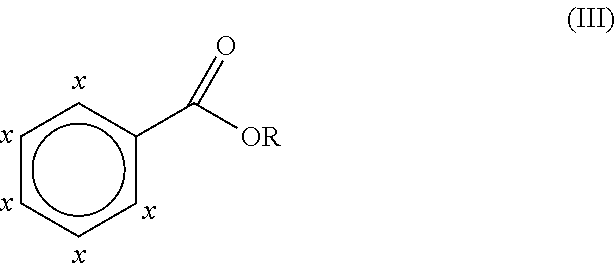

Surface modified oil and gas well hydraulic fracturing proppants for improving wettability, altering chemical reactivity, altering surface topography, imparting lubricity or controlling relative permeability to flow of fluids of such proppants. The use and preparation of such coated proppants in hydraulic fracturing of subterranean formations is also described.

Owner:CARBO CERAMICS

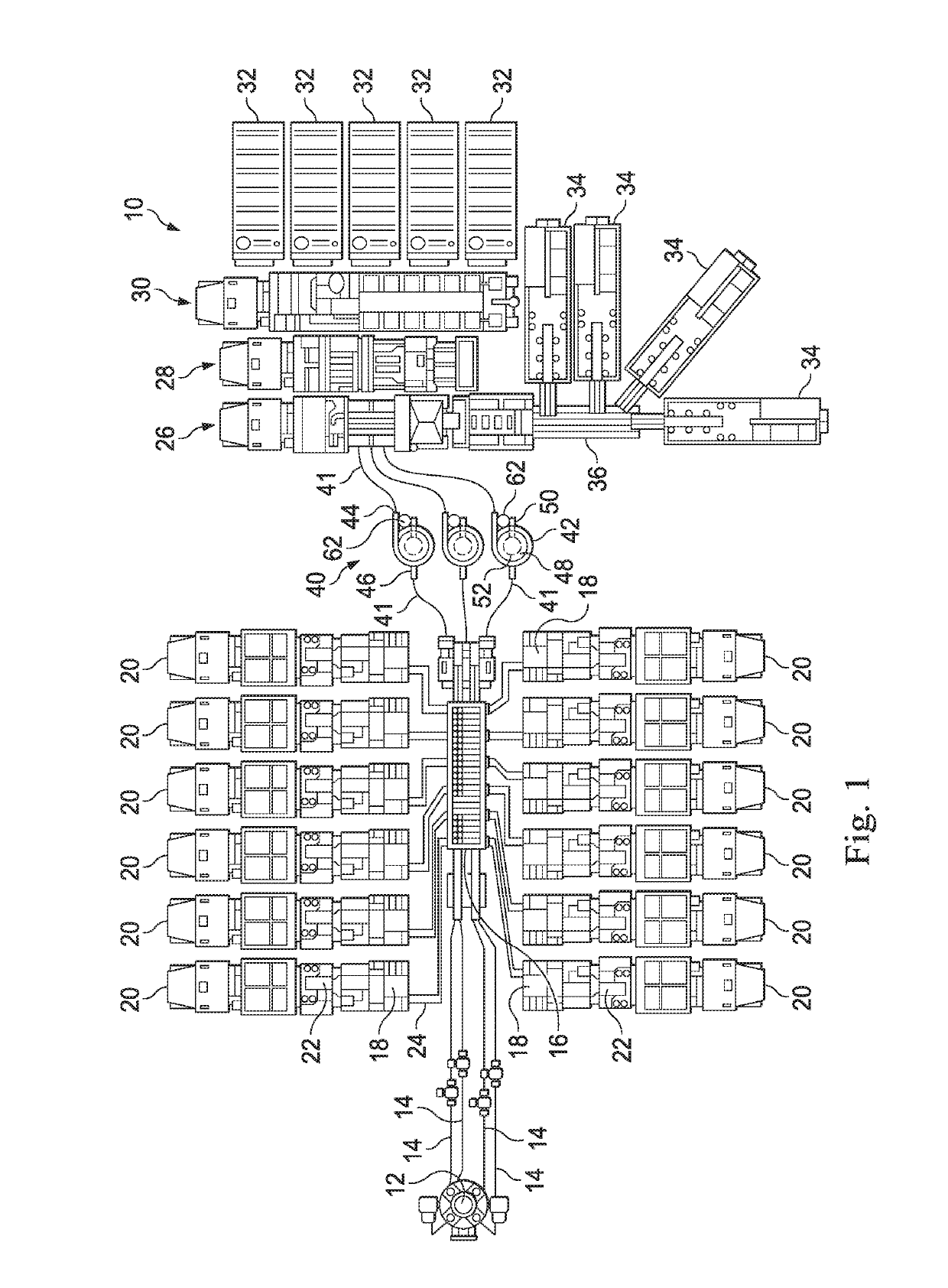

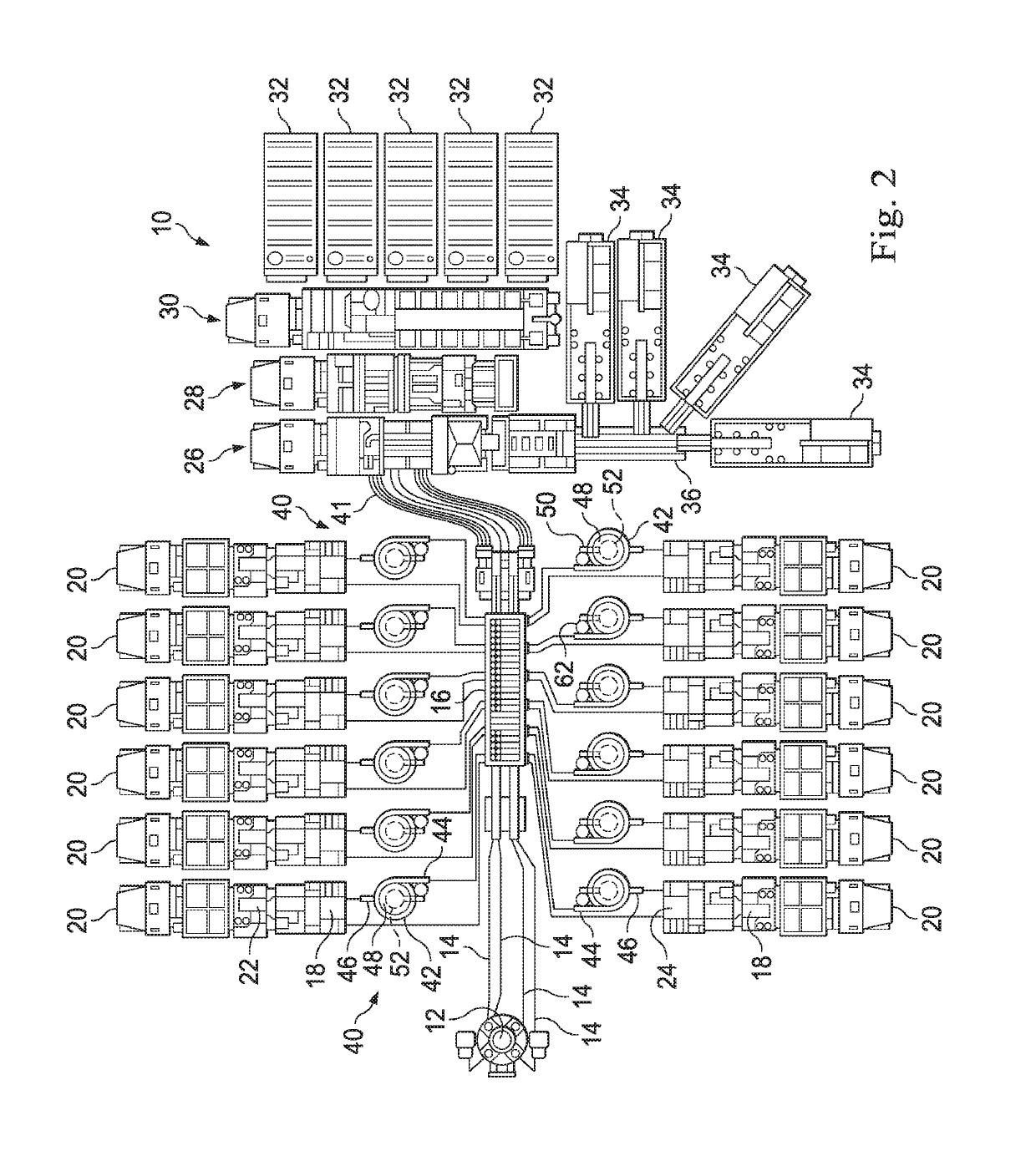

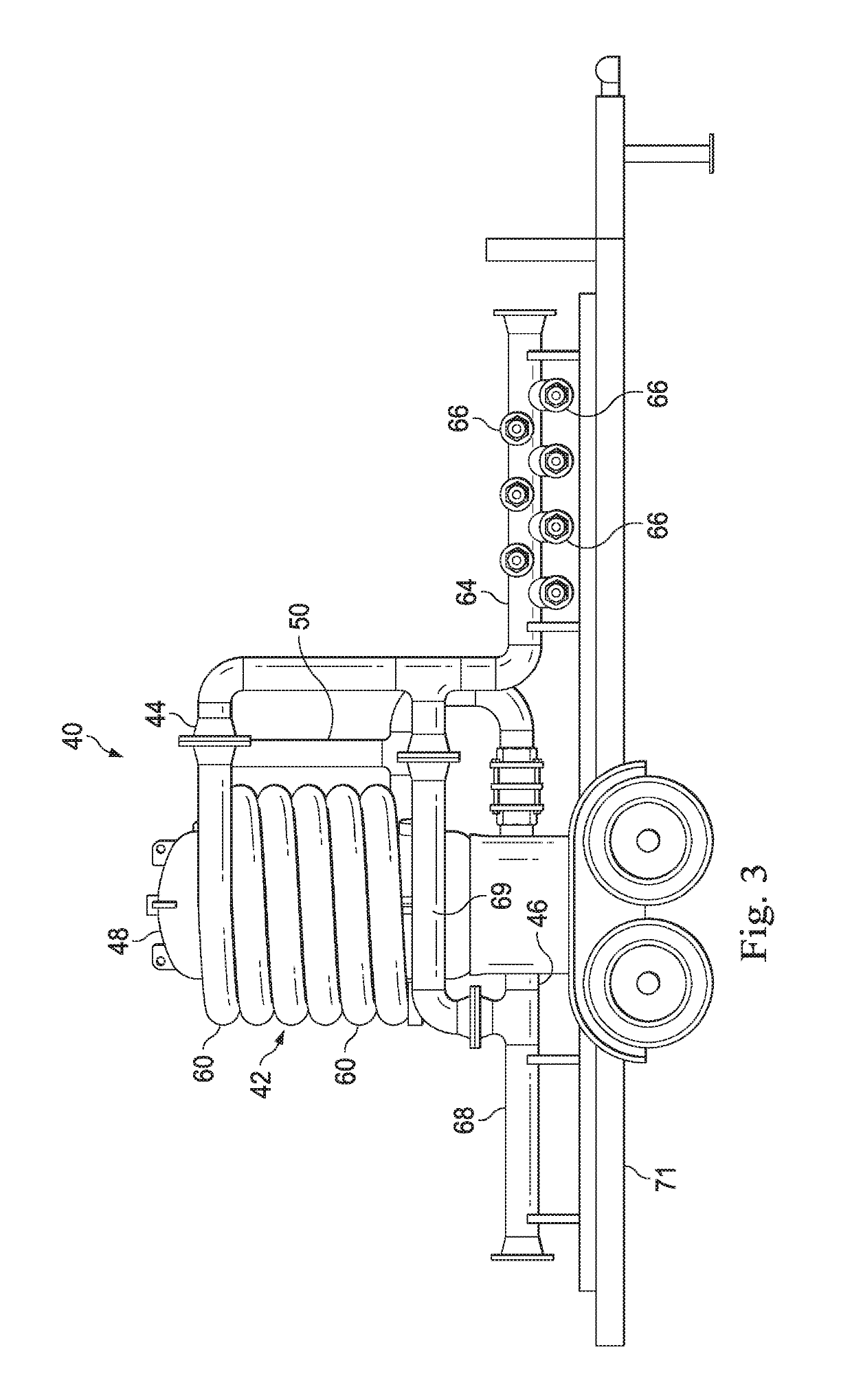

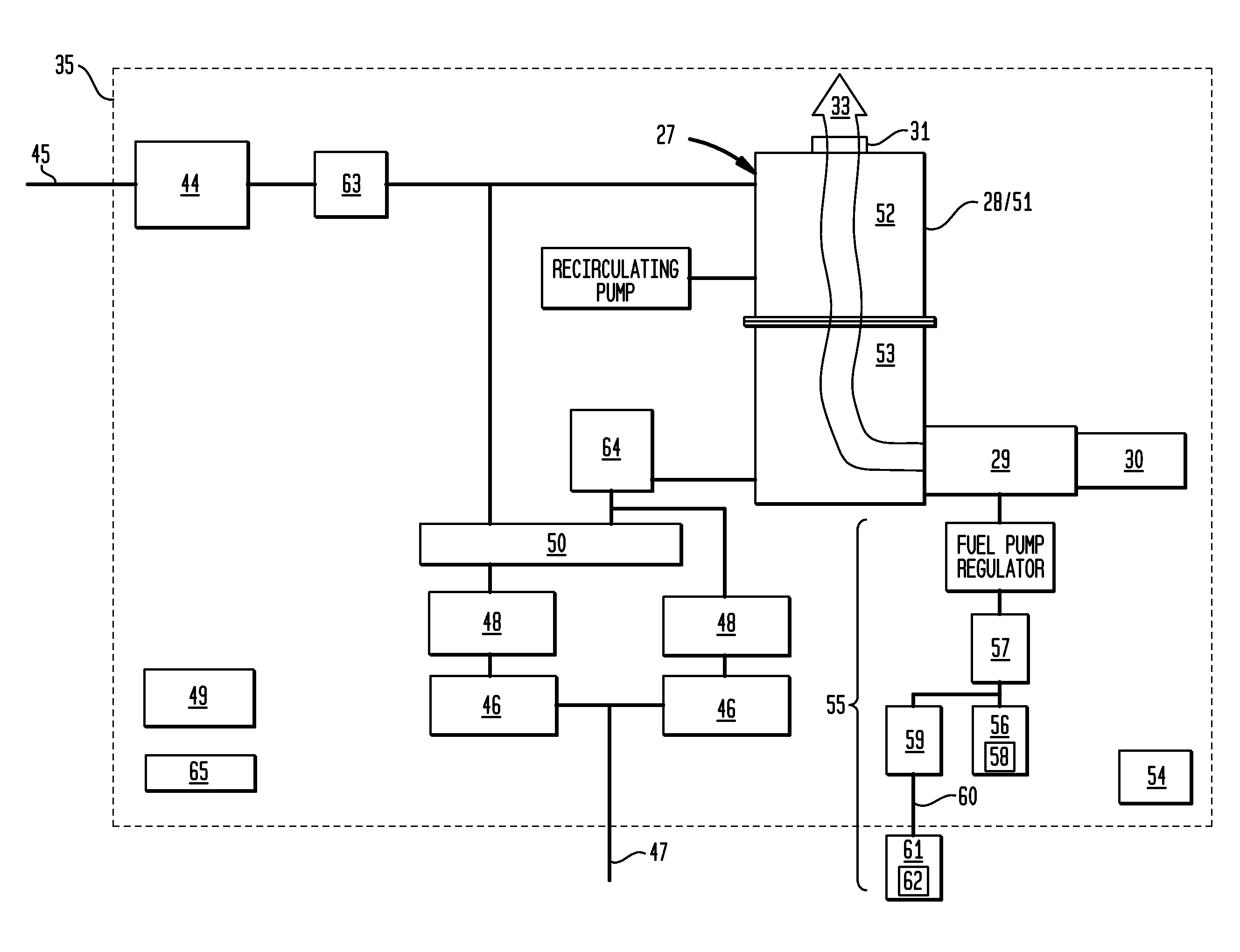

Apparatus and method for treatment of hydraulic fracturing fluid during hydraulic fracturing

A hydraulic fracturing system utilizes a multi-phase separation apparatus to separate gas entrained in hydraulic fracturing fluids during the blending process prior to introduction of hydraulic fracturing fluid into high pressure fracturing pumps by directing hydraulic fracturing fluids from a blender through a plurality of loops and thereafter, directing a portion of the separated fluid into a vortex cluster system.

Owner:CH INT EQUIP LTD +1

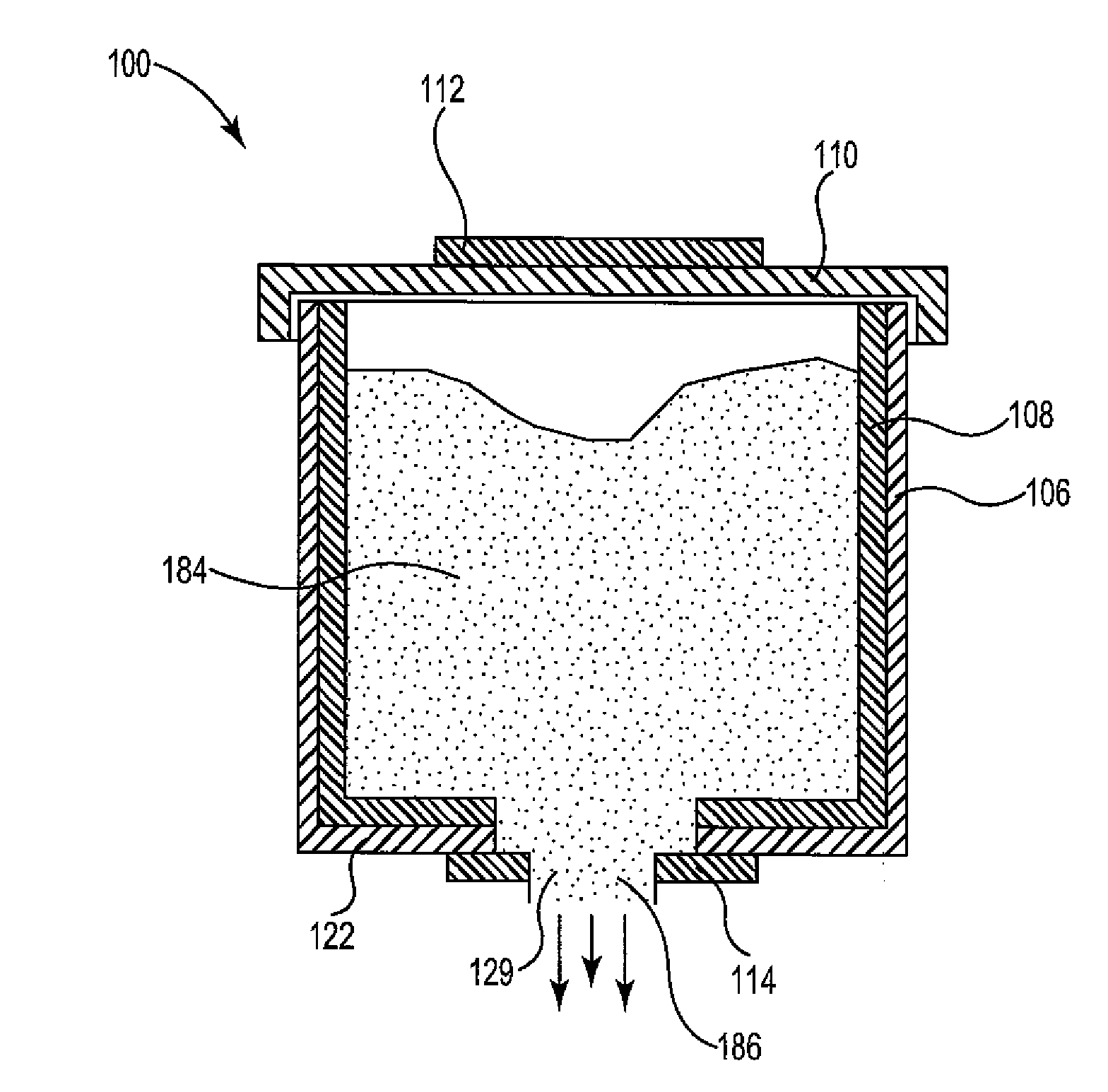

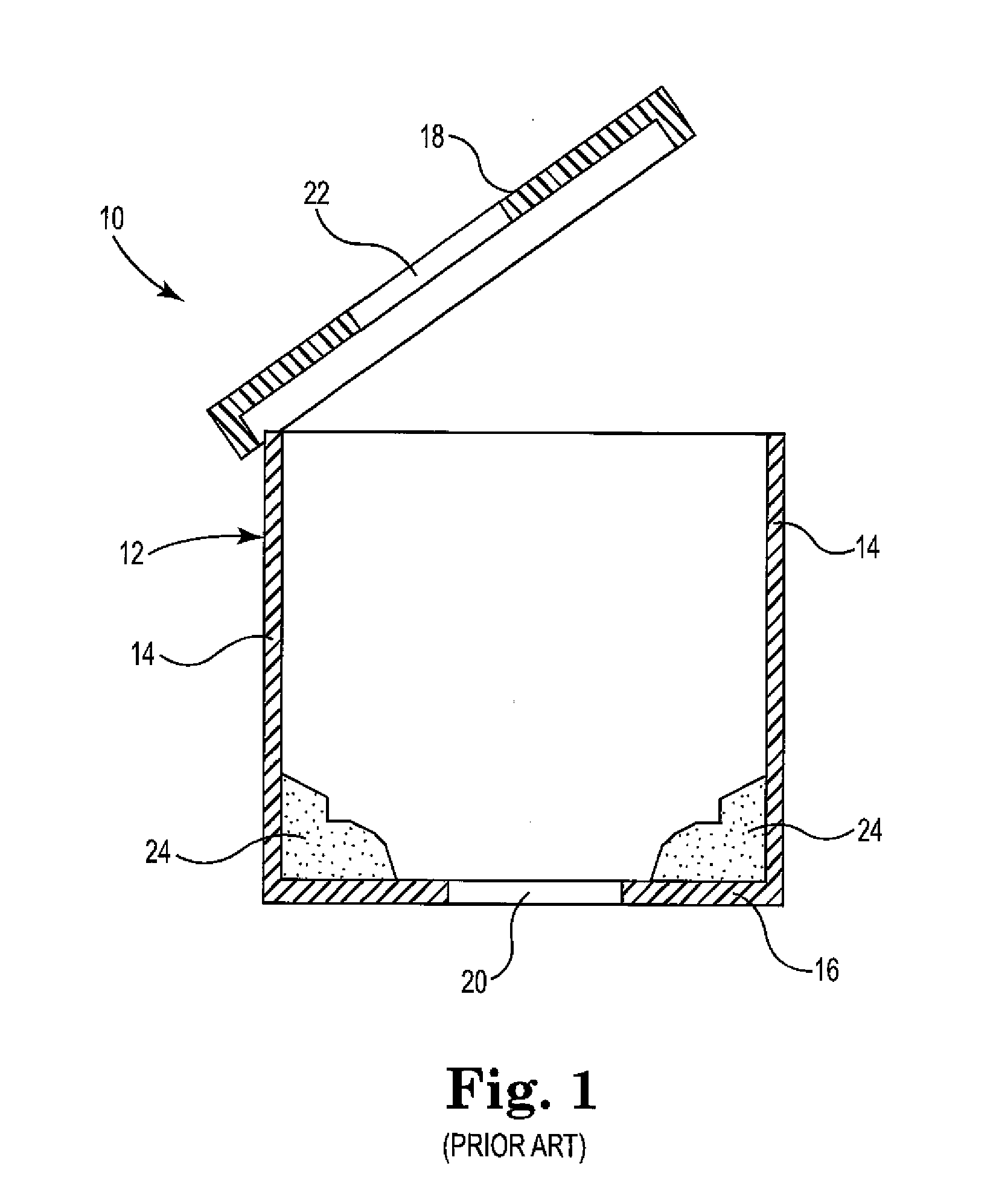

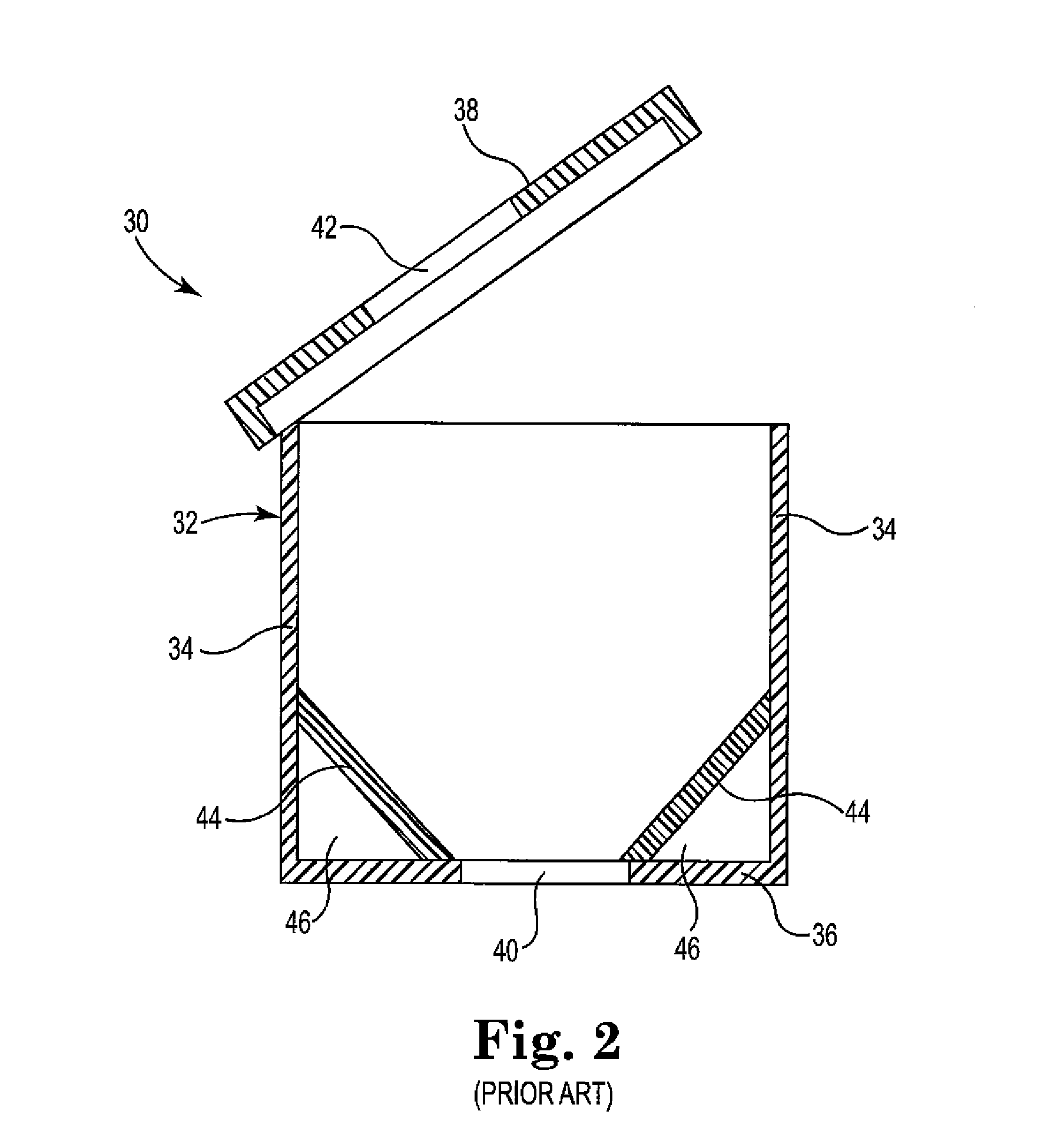

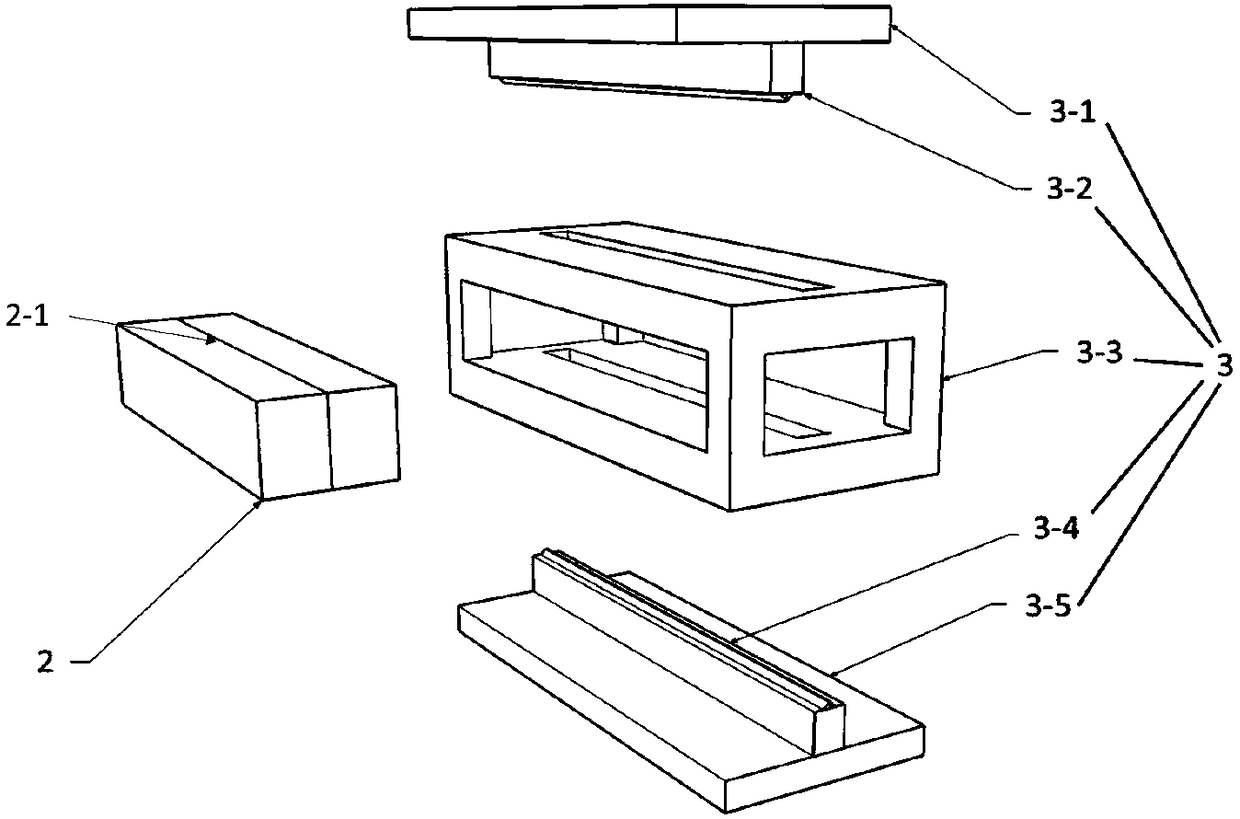

Container system for hydraulic fracturing proppants

InactiveUS20150086307A1Large storage capacityIncrease storage capacityLoadersLarge containersEngineeringHydraulic fracturing proppants

Described herein is an improved container for storing, shipping, and dispensing proppant materials used in hydraulic fracturing operations. The container systems incorporate stretchable hopper structures in the container. The hopper expands and contracts responsive to the amount of proppant material held in the container. When the container is filled with a sufficient amount of proppant, the hopper stretches to expand the storage volume. When the sufficient amount of proppant material is dispensed from the container, the hopper contracts to lift and dispense the container contents.

Owner:PROPPANT EXPRESS SOLUTIONS LLC

System to heat water for hydraulic fracturing

Generally, a system for hydraulic fracturing of a geologic formation. Specifically, a transportable heating apparatus and method for the production of heated water for use in hydraulic fracturing of a geologic formation.

Owner:H2O INFERNO

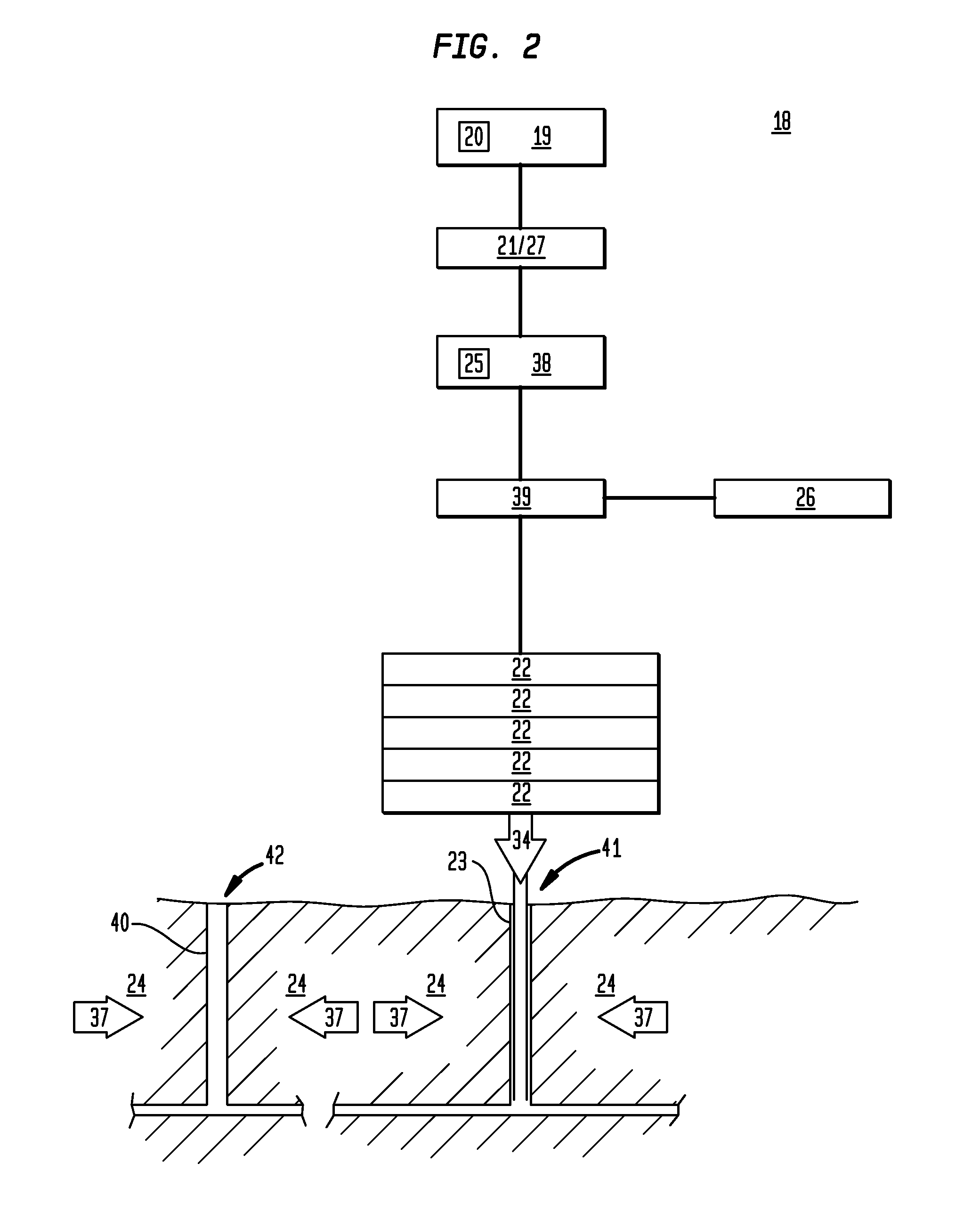

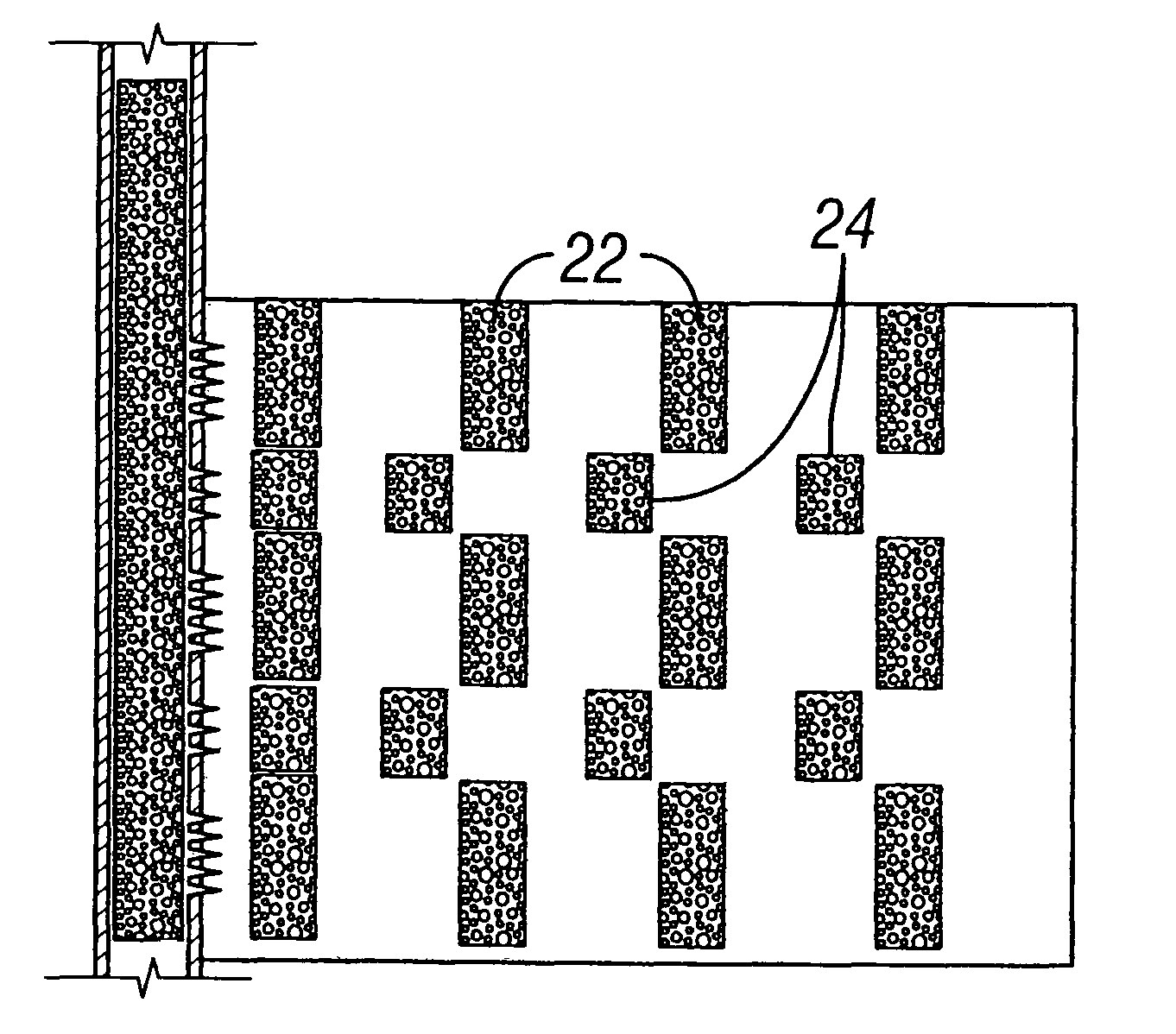

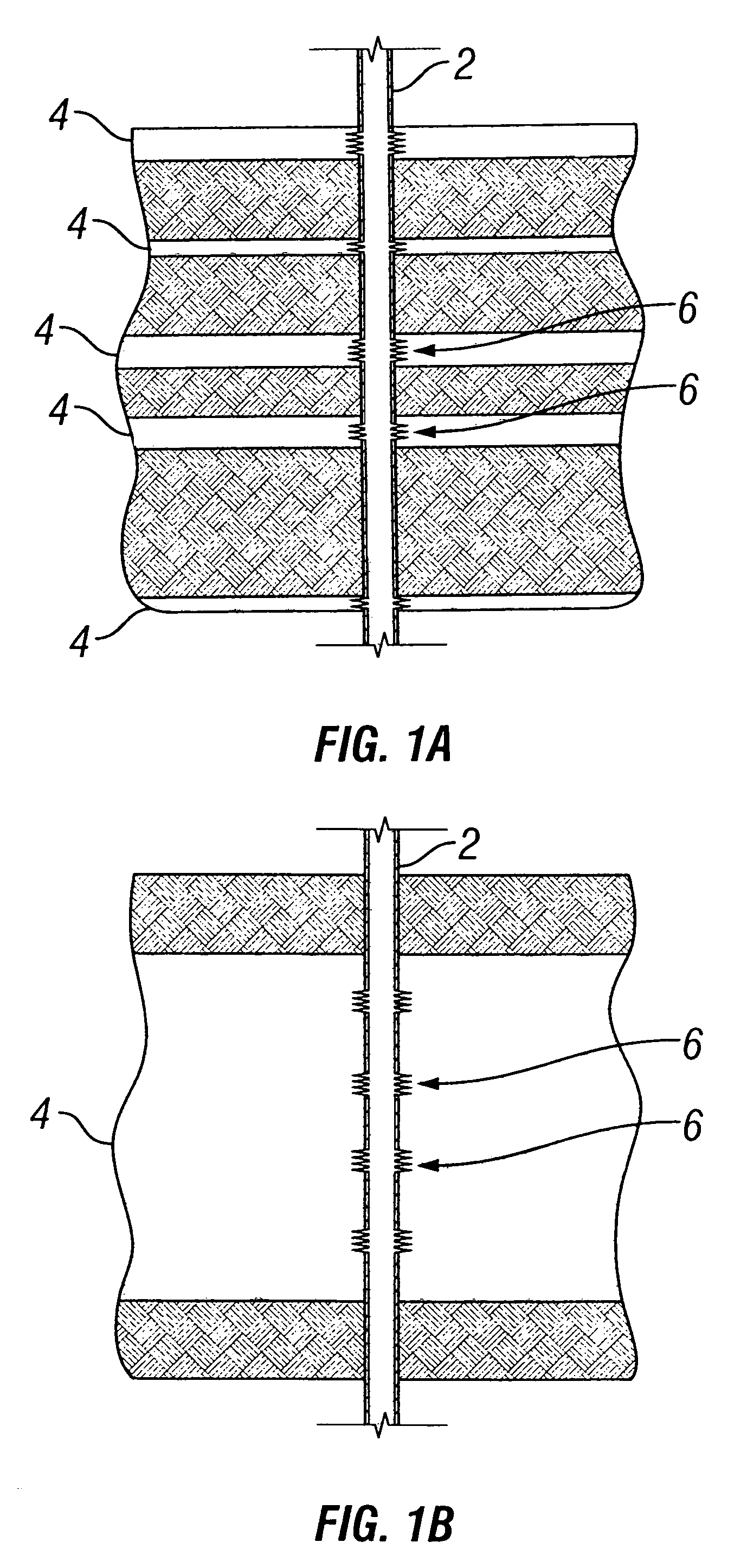

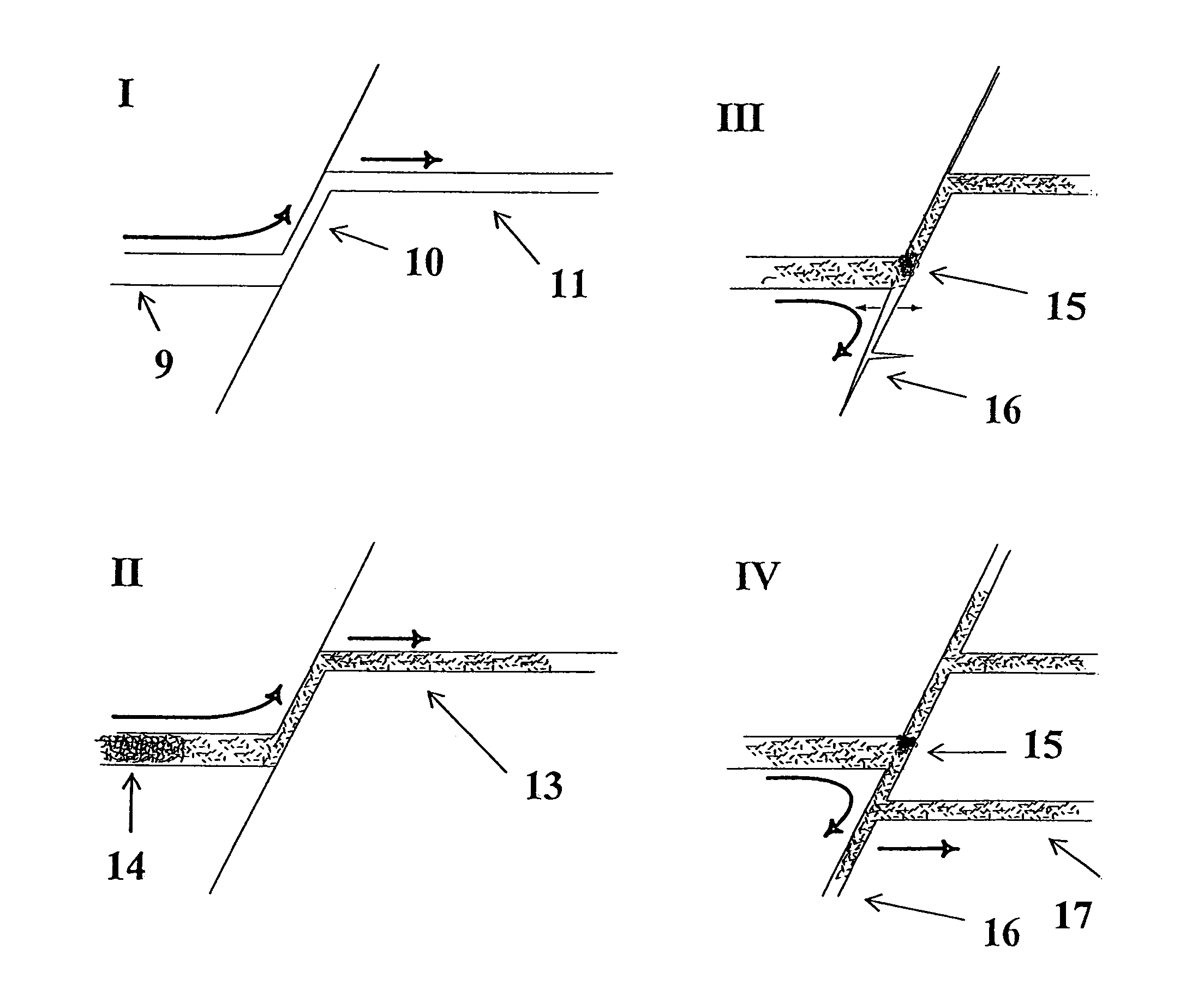

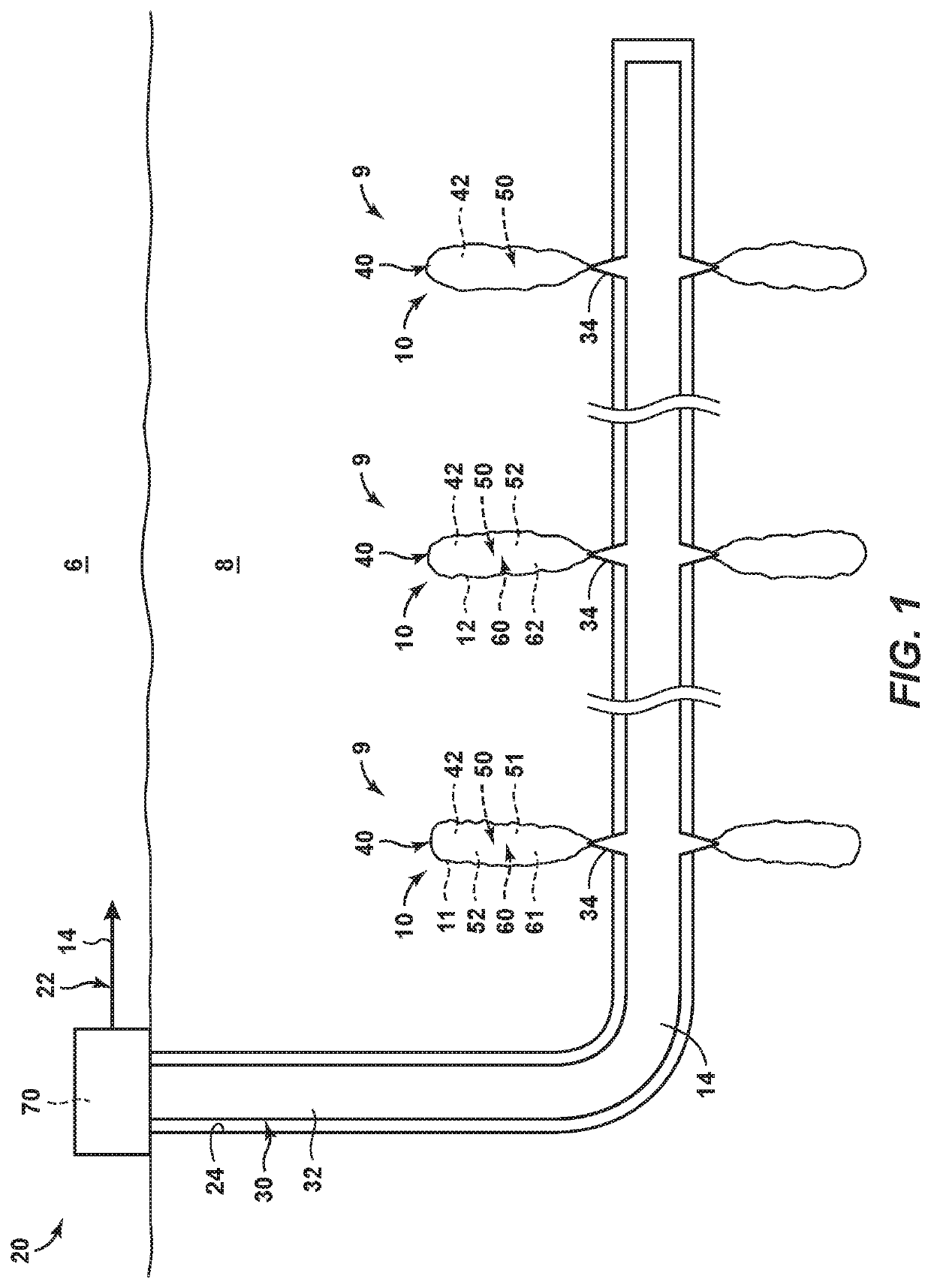

Perforation strategy for heterogeneous proppant placement in hydraulic fracturing

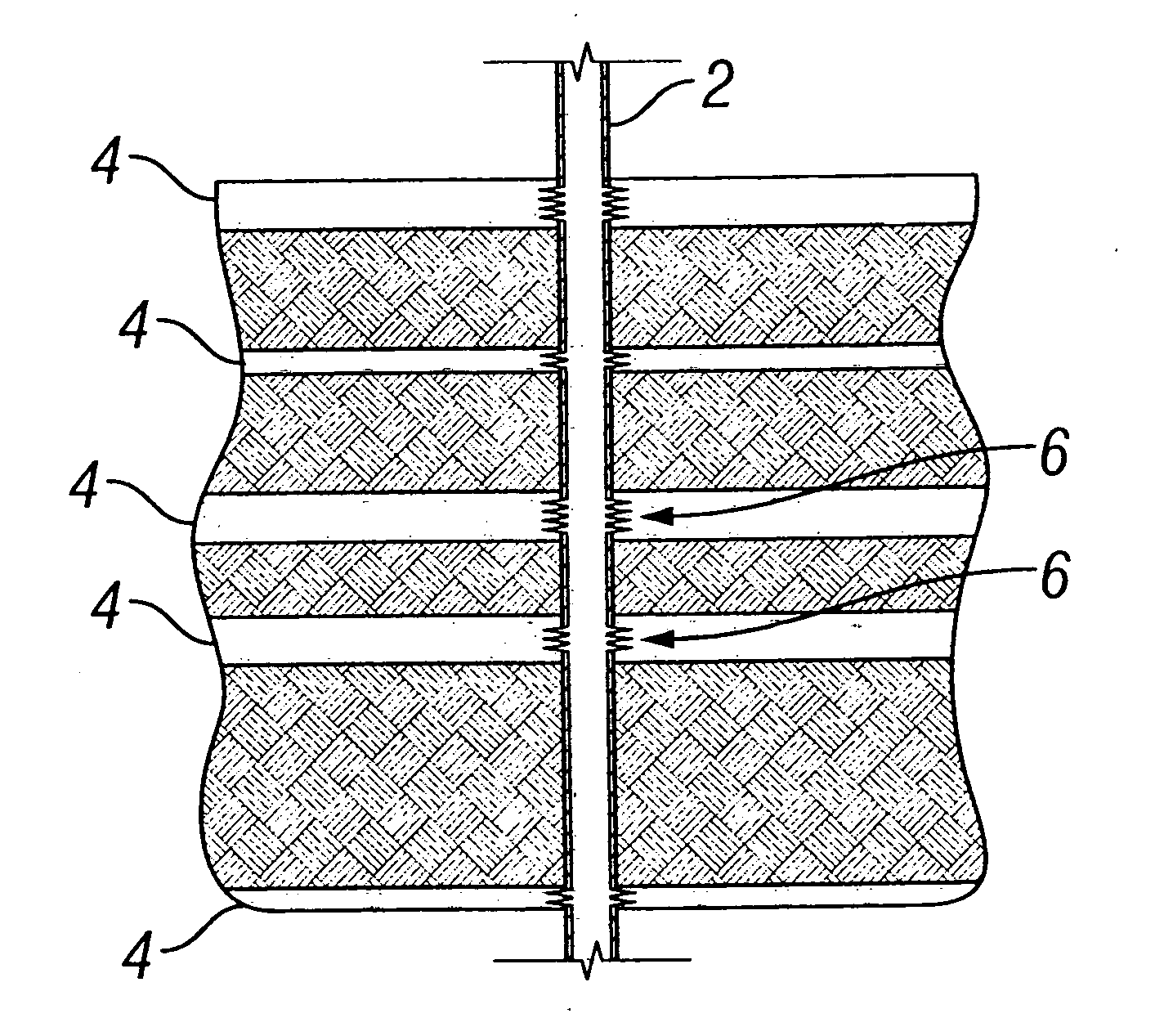

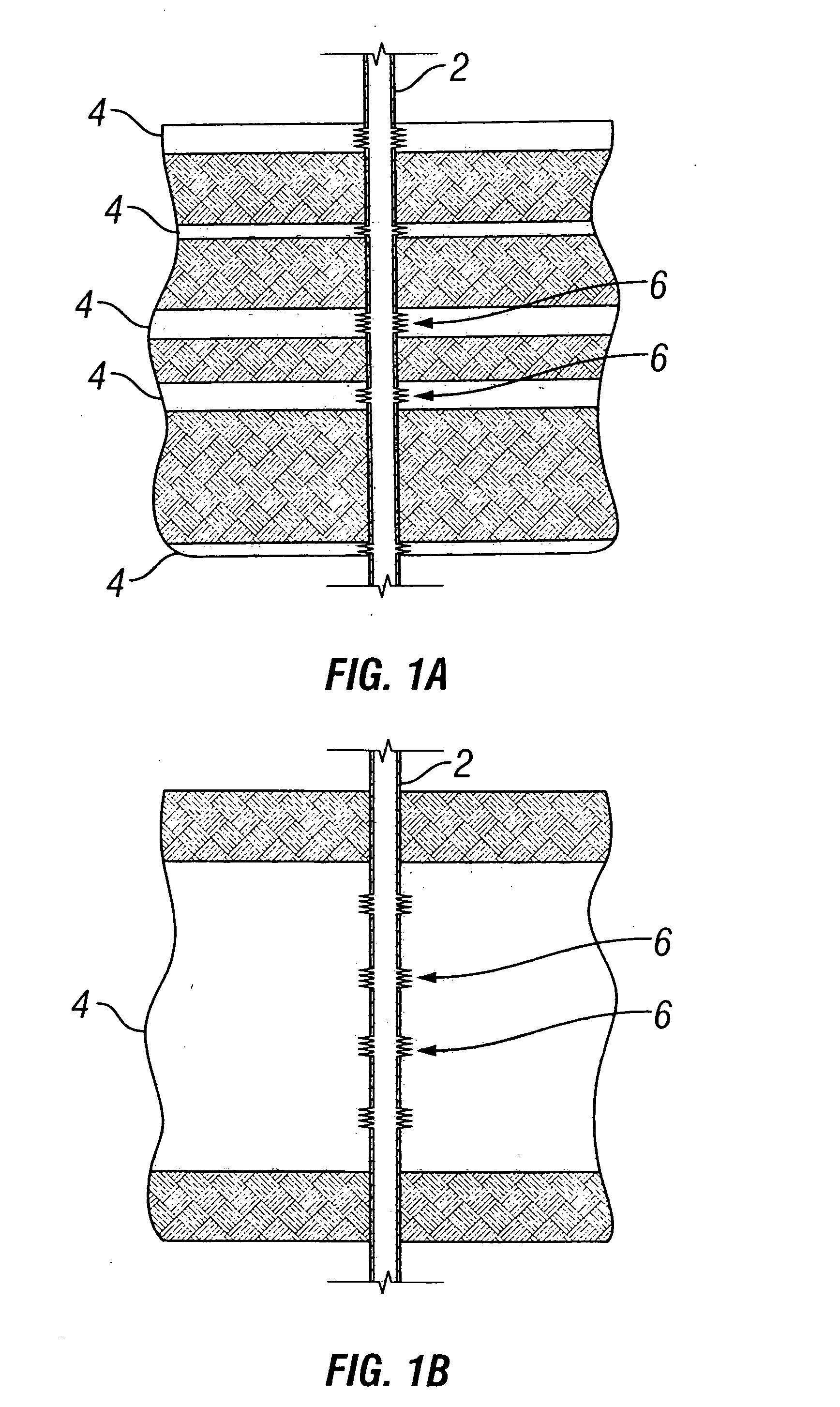

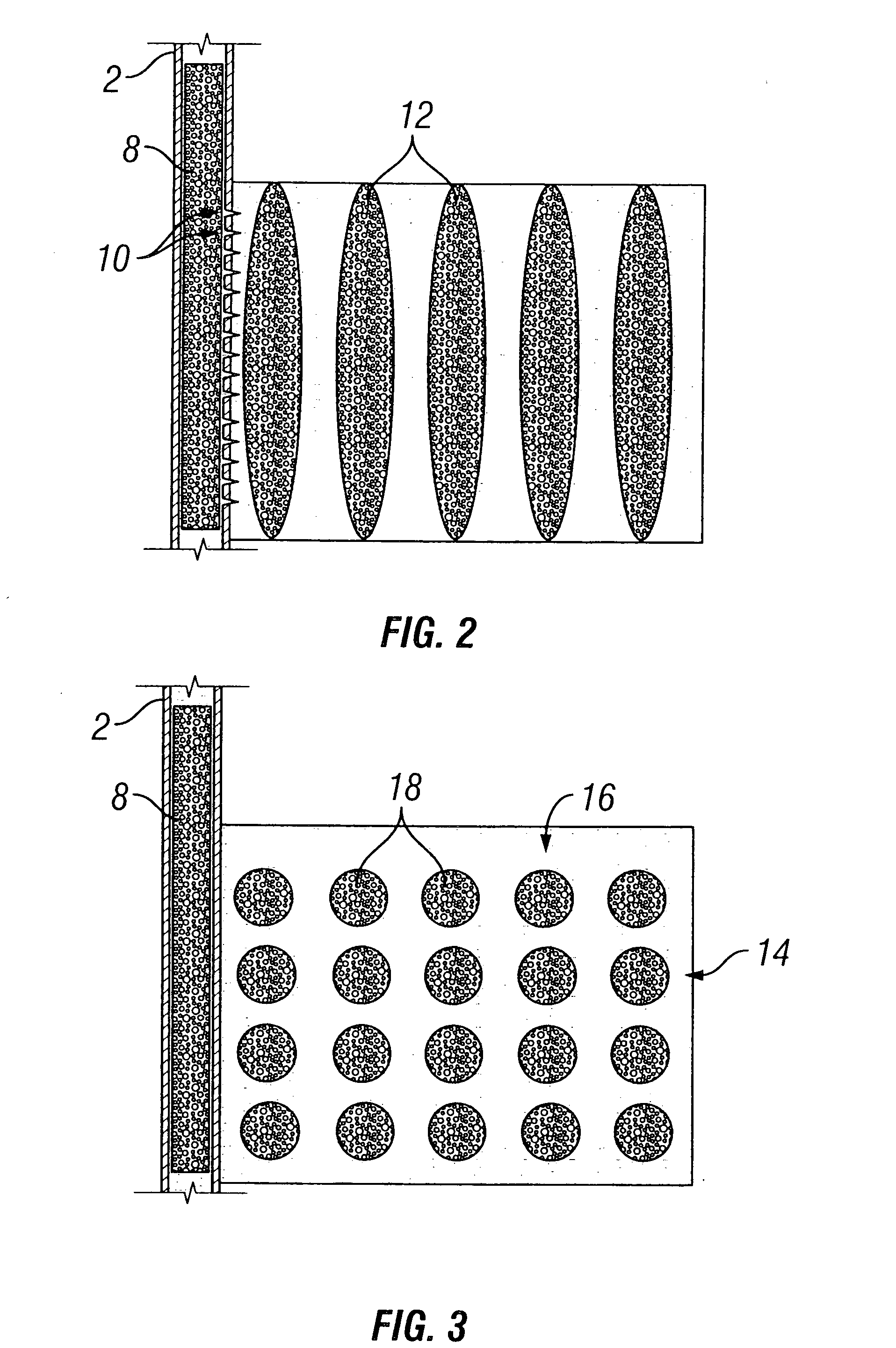

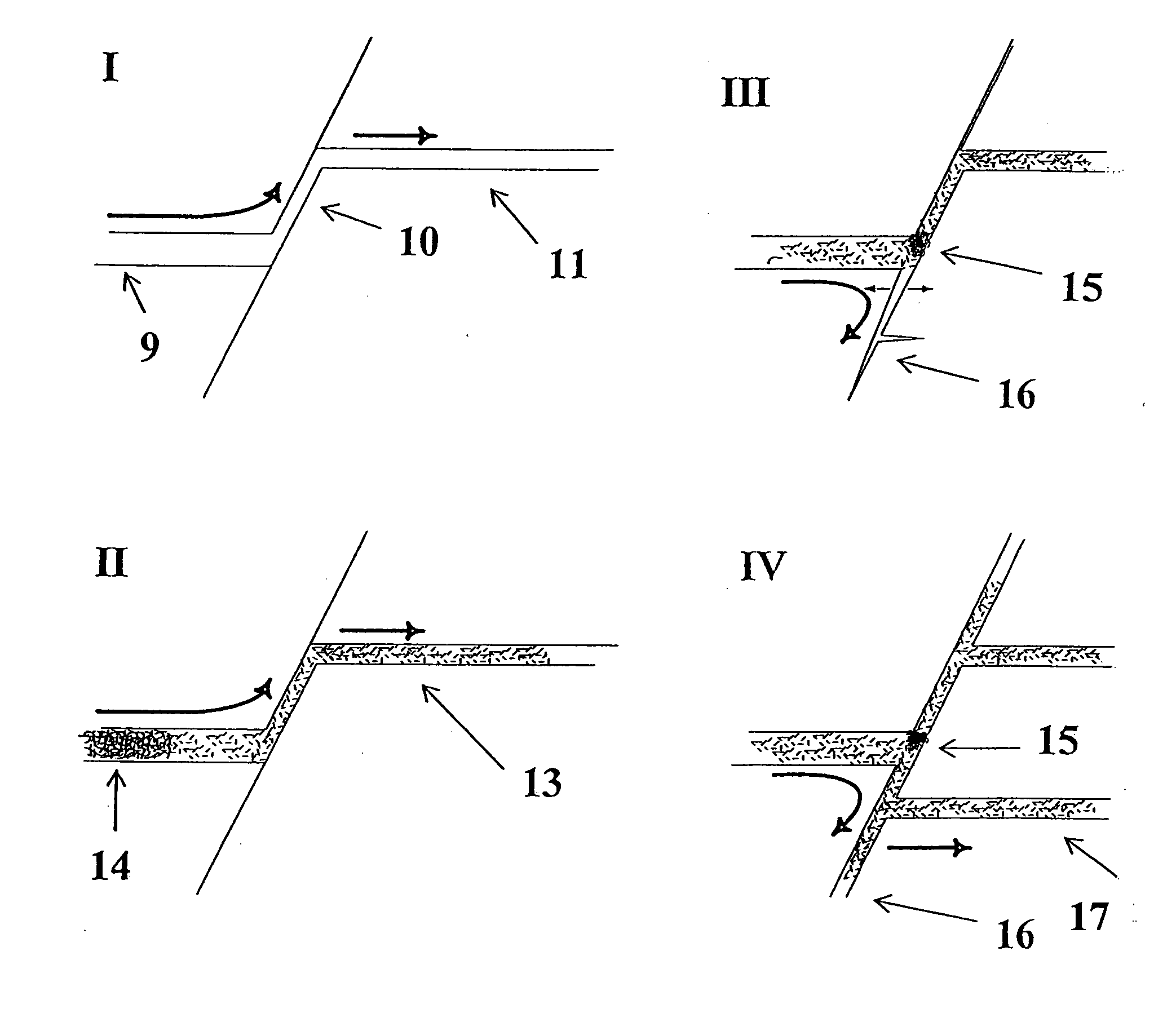

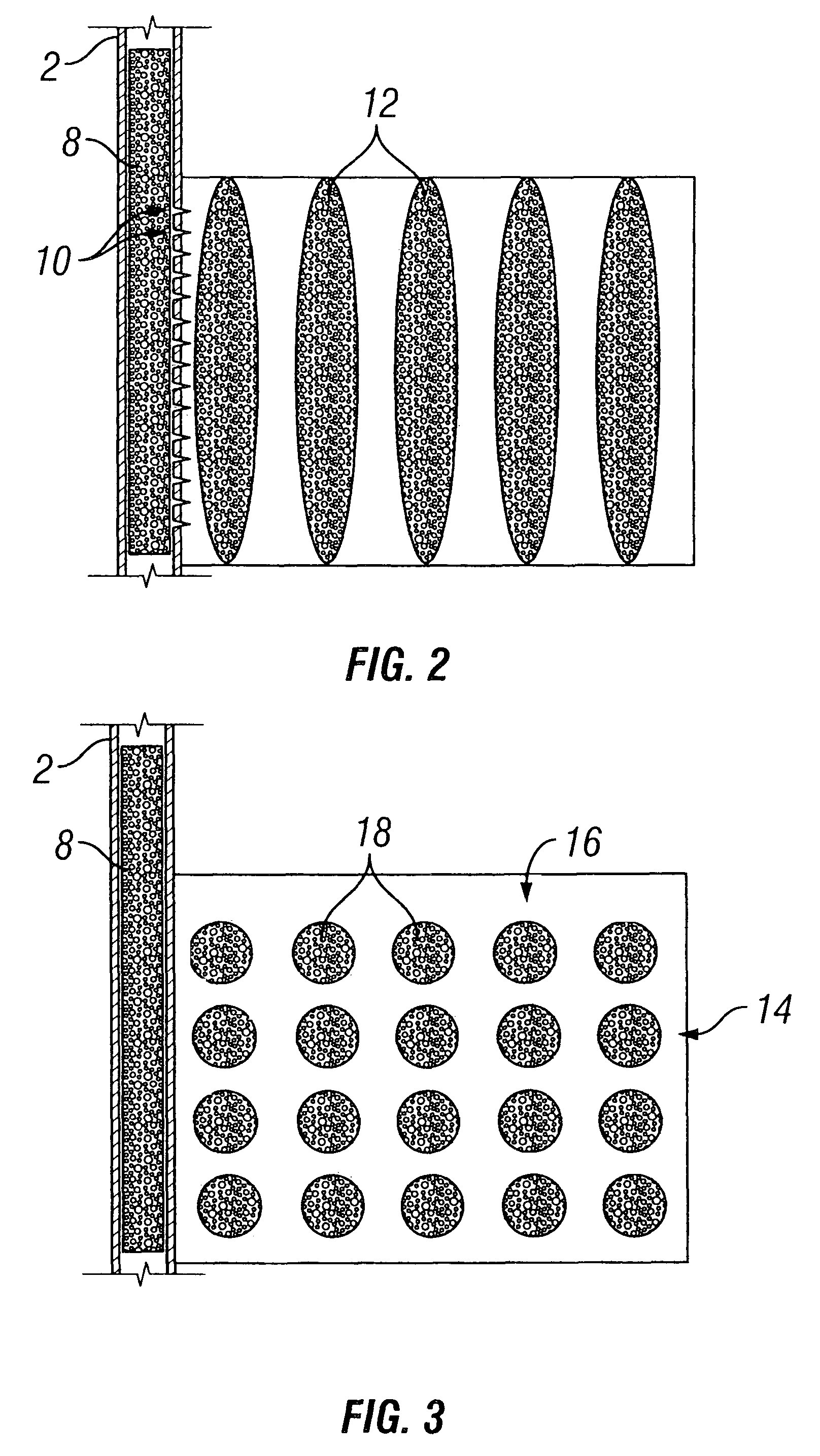

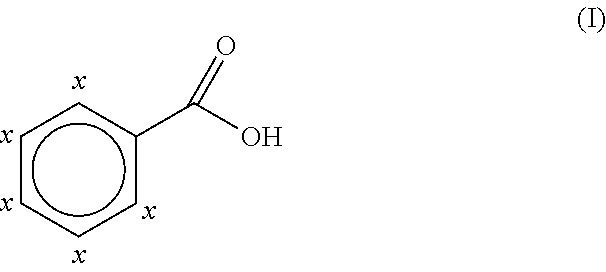

Hydraulic fracturing an individual reservoir fracturing layer of a subterranean formation to produce heterogeneous proppant placement is given in which pillars of proppant are placed such that the pillars do not extend the entire height of the fracture (for a vertical fracture) but are themselves interrupted by channels so that the channels between the pillars form pathways that lead to the wellbore. The method combines methods of introducing slugs of proppant-carrying and proppant-free fluids through multiple clusters of perforations within a single fracturing layer of rock, with methods of ensuring that the slugs exiting the individual clusters do not merge.

Owner:SCHLUMBERGER TECH CORP

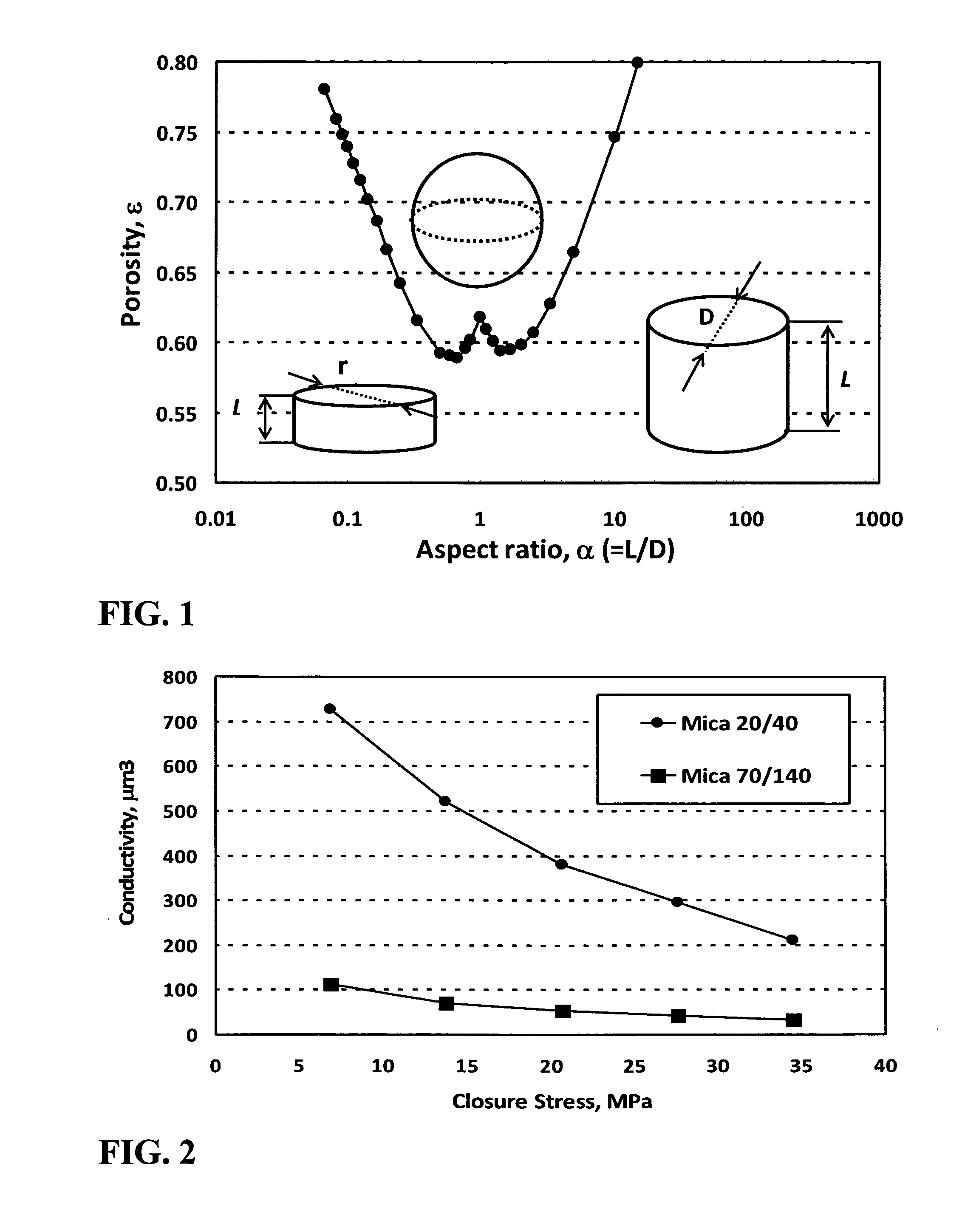

Hydraulic Fracturing Proppants

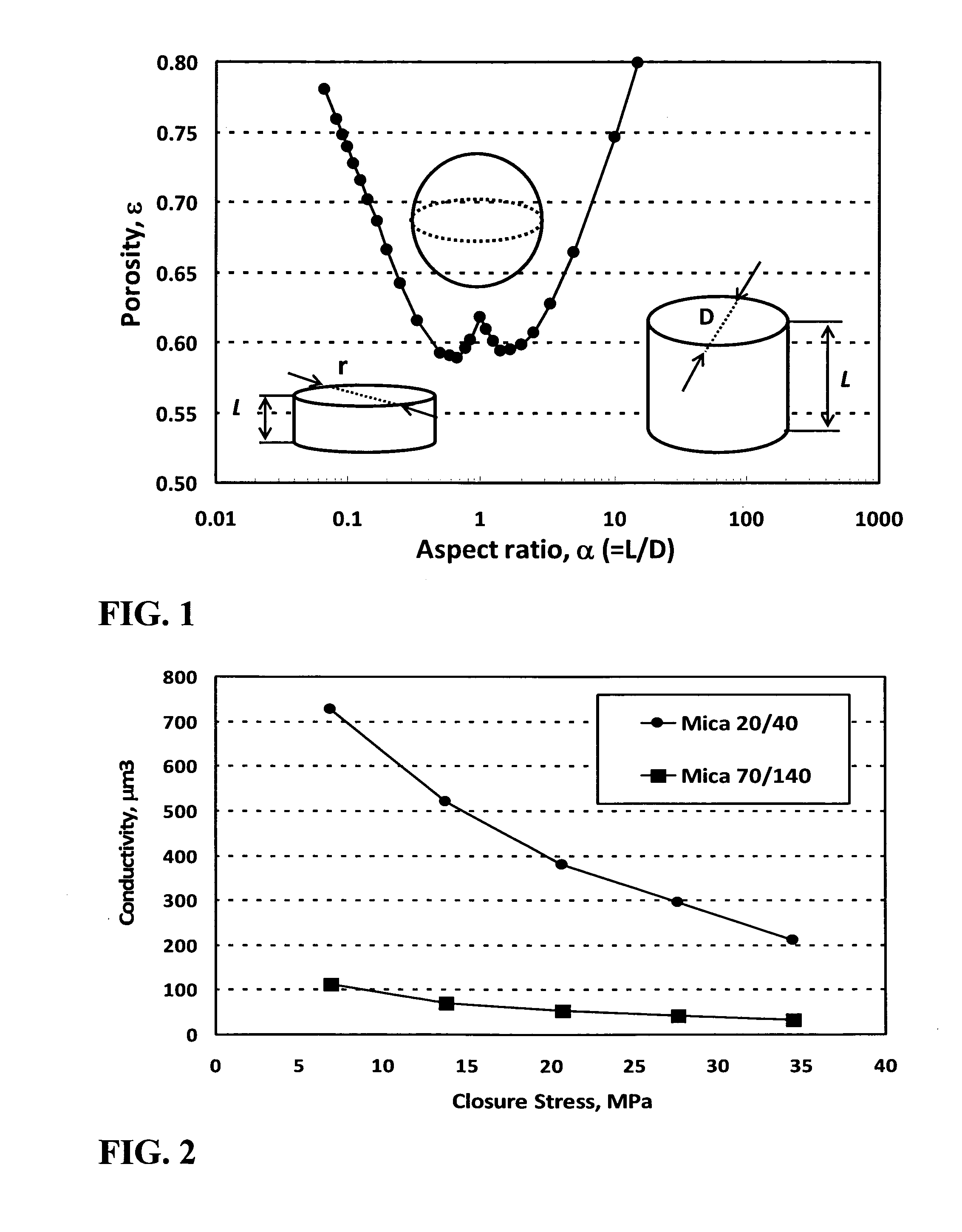

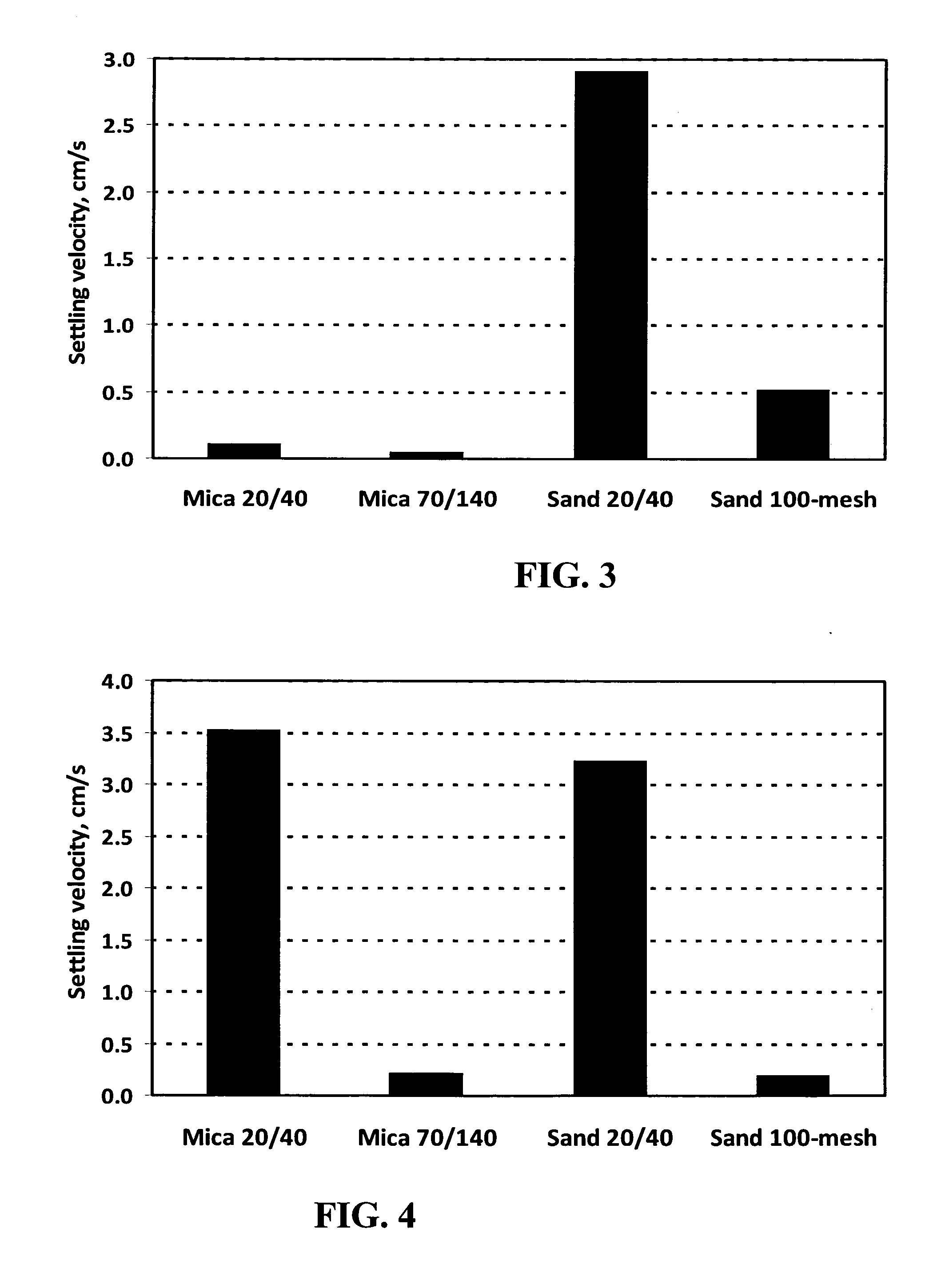

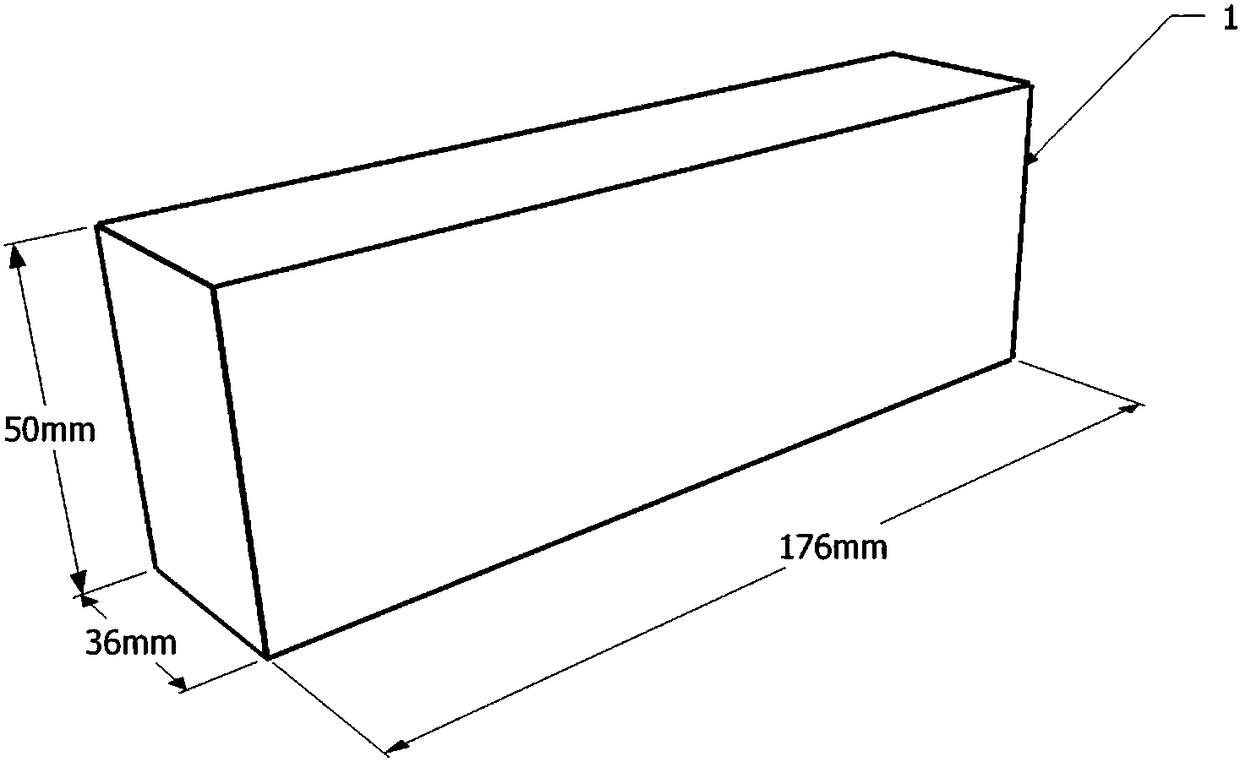

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

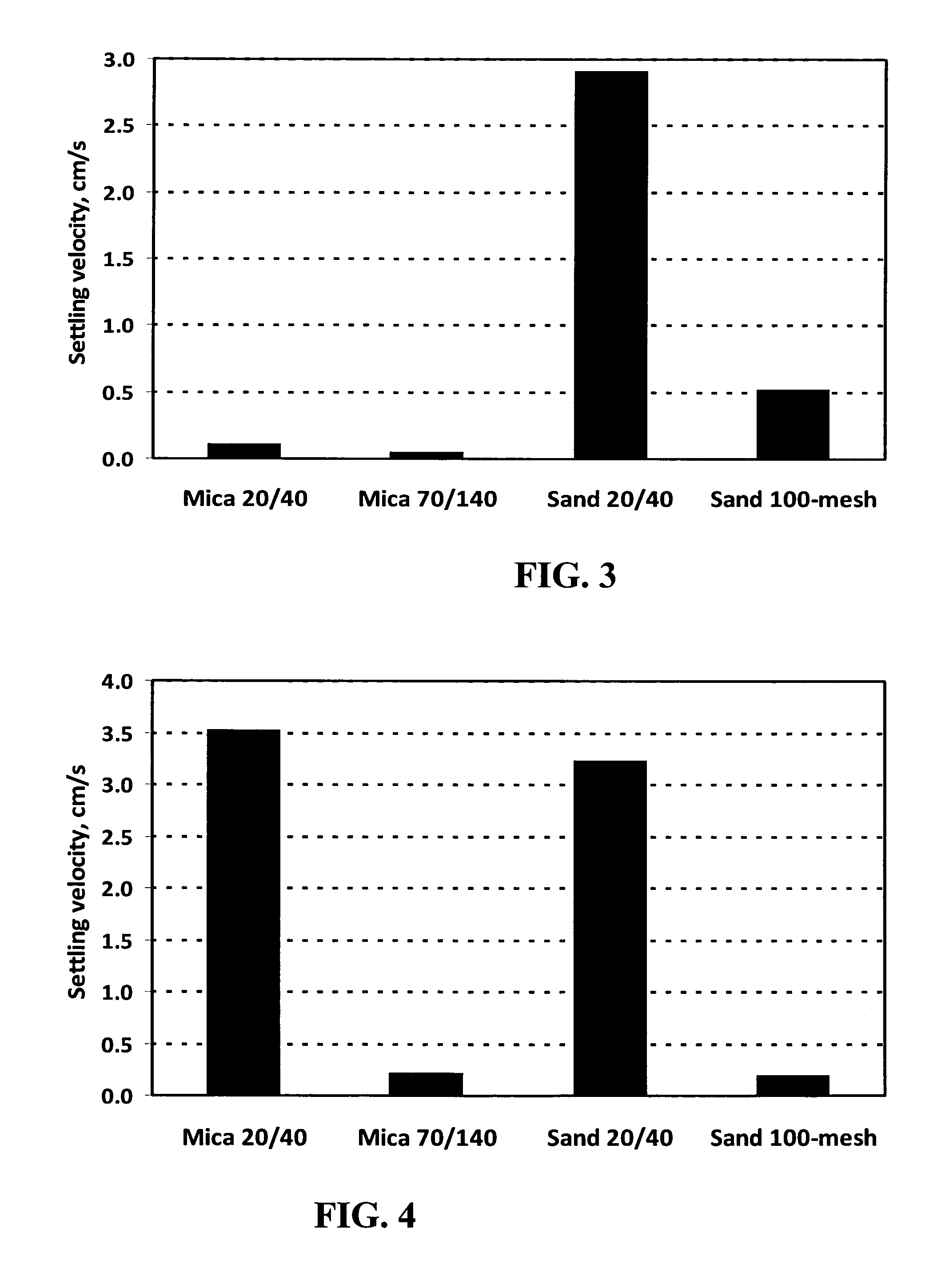

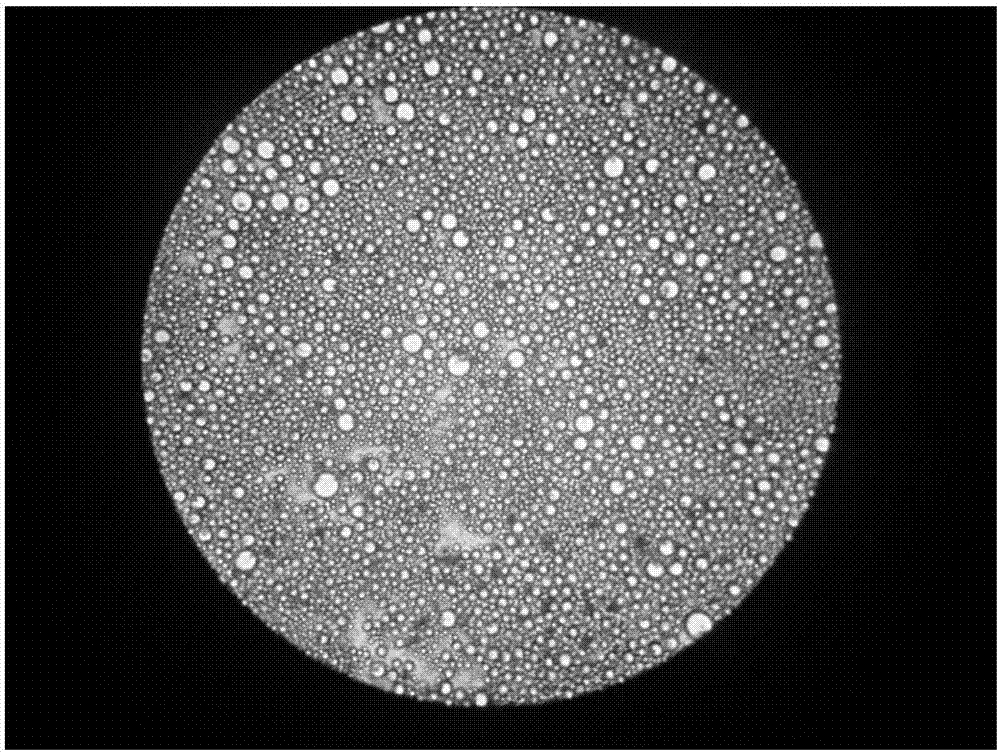

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

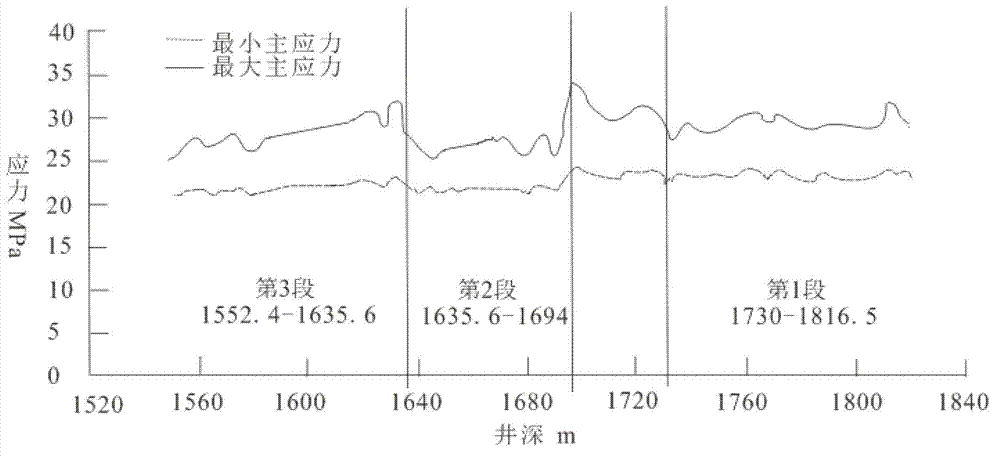

Optimizing method for parameters of hydraulic fracturing proppant for sandstone reservoir

The invention discloses an optimizing method for parameters of a hydraulic fracturing proppant for a sandstone reservoir. The optimizing method comprises the following steps: inputting wellbore data and the like of the sandstone reservoir to be fractured into oil and gas reservoir capacity simulating software, simulating and calculating the reservoir capacity under different fracture parameters todetermine the optimal fracture flow conductivity required by the production of the reservoir; splitting by adopting a real rock plate of a reservoir to form a fracture, acquiring surface rough topographic data of the fracture, then manufacturing a sample preparation mould which is consistent with that the surface rough topographic data, and manufacturing an artificial sandstone rock sample with real fracture surface topography; performing a propped fracture flow conductivity test under different proppant parameters by adopting the artificial sandstone rock sample, and performing comparison analysis on a test result with a simulated calculation result to obtain an optimal proppant parameter which is in accordance with the characteristics of the reservoir. According to the optimizing methodfor the parameters of the hydraulic fracturing proppant for the sandstone reservoir, proppant parameter optimization results can be acquired efficiently and accurately by performing the propped fracture flow conductivity test through adopting the artificial sandstone rock sample which can reflect hydraulic fracturing real fracture surface topography of the sandstone reservoir.

Owner:SOUTHWEST PETROLEUM UNIV

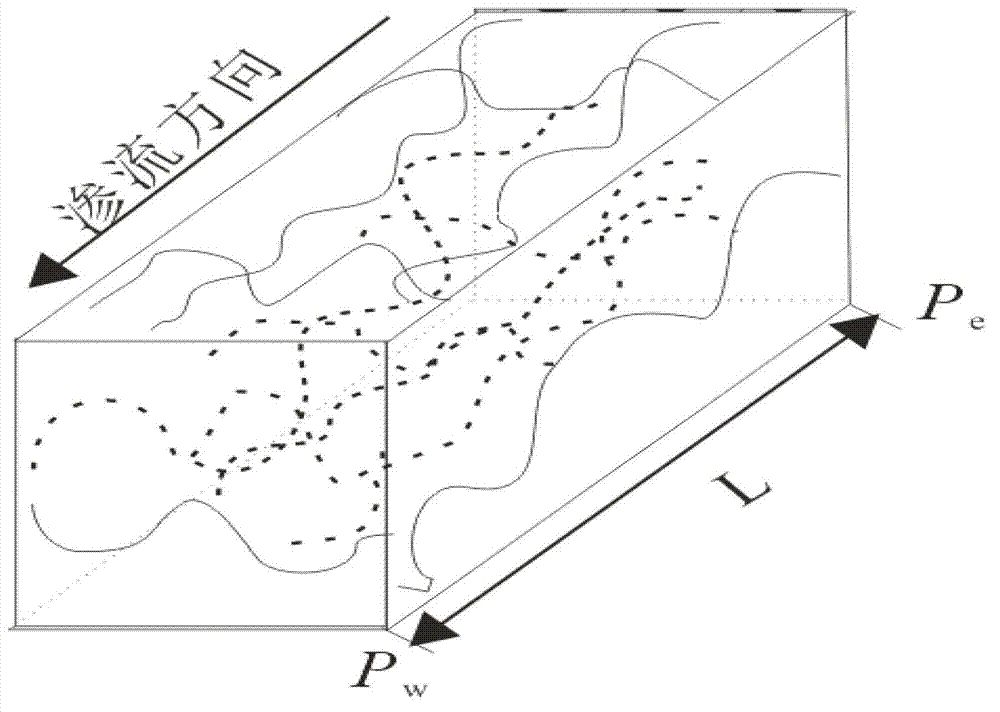

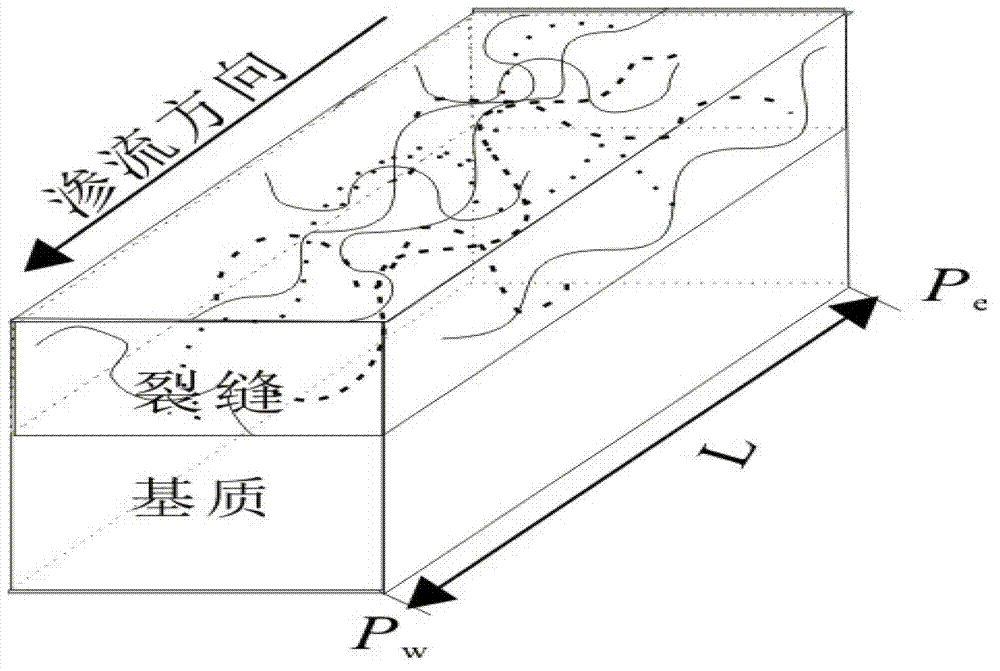

Determining method of amount of shale oil deposit hydrofracture propping agent

InactiveCN102865060AAvoid blindnessImprove the stimulation effect of fracturingFluid removalQuantitative modelEclipse

The invention relates to a determining method of amount of a shale oil deposit hydrofracture propping agent. The determining method mainly comprises the following steps of: (1) establishing a quantitative model of the relationship between a net jointing system and the amount of a propping agent based on an equivalent seepage principle; (2) preferably selecting quantity, volume and a permeability rate of a high-permeability zone by utilizing a universal Eclipse software for simulation of an oil deposit value based on reservoir liquid high-pressure property data, formation pressure data, rock data and a geologic model provided by a universal Petrel software for oil deposit geologic modeling; and (3) determining the amount of the propping agent for the shale oil deposit hydrofracture construction based on the model established in step (1) according to the quantity, the volume and the permeability rate of the high-permeability zone preferably selected in step (2). With the adoption of the determining method provided by the invention, shortcomings of the prior art can be overcome; blindness on the amount of the used sectional volume fracturing propping agent in a horizontal well of shale oil deposit can be effectively solved; fracturing and yield-increasing effects can be improved; and economic cost of fracturing can be saved.

Owner:SOUTHWEST PETROLEUM UNIV

Proppant for hydraulic fracturing of oil and gas wells

ActiveUS7954548B2Eliminating and decreasing “ flow-back ”Synthetic resin layered productsCellulosic plastic layered productsHydraulic fracturing proppantsOil well

The present invention relates to a proppant for the hydraulic fracturing of oil or gas wells, which consists of a mixture of from 10 to 95% by weight of a spherical proppant and from 5 to 90% by weight of an angular material, the percentages being based on the total weight of the mixture. The proppant obtained according to the present invention is useful for eliminating or decreasing the “flow-back” phenomenon in operations in oil or gas wells.

Owner:MINERACAO CURIMBABA

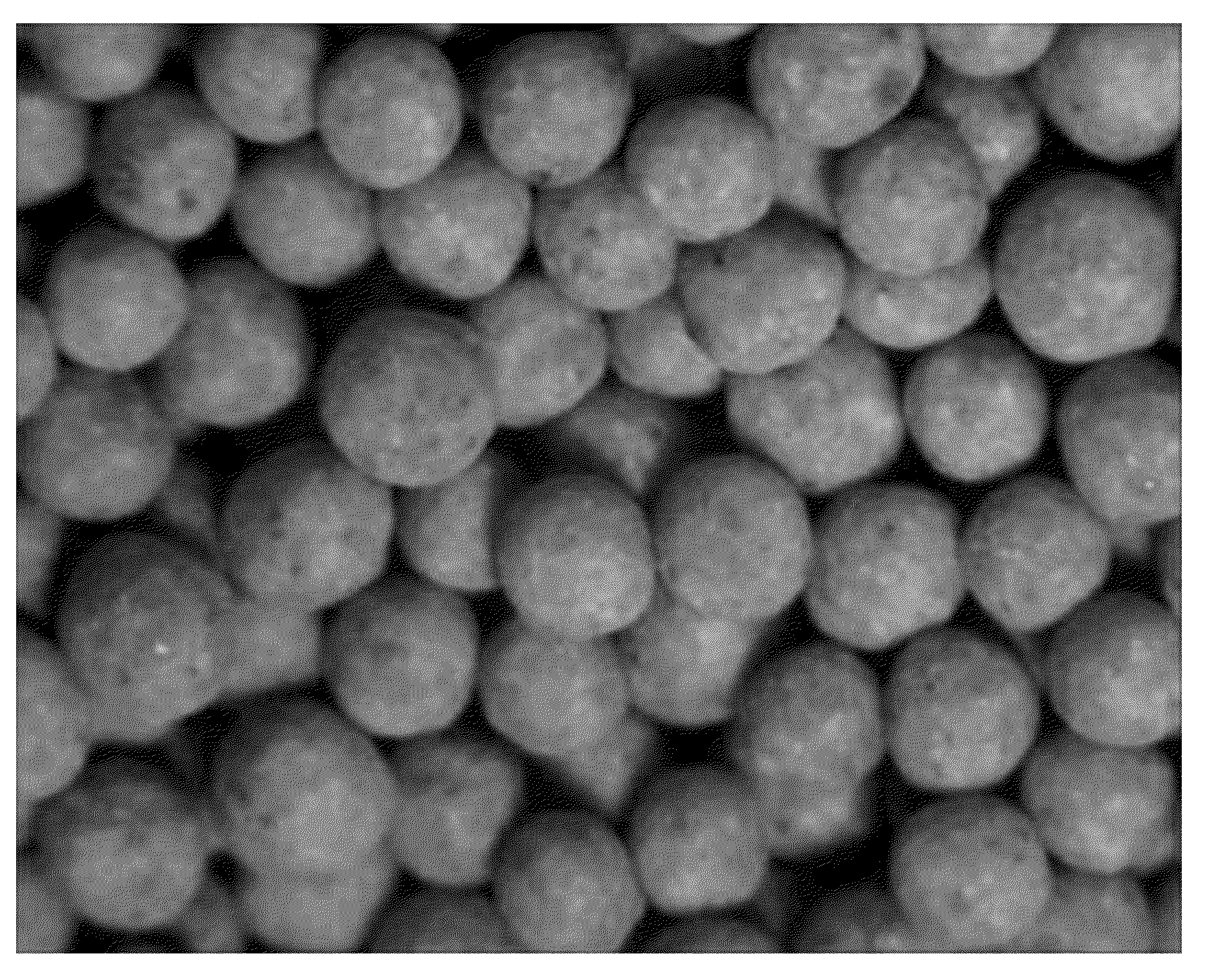

Hydraulic fracturing proppants and methods of use

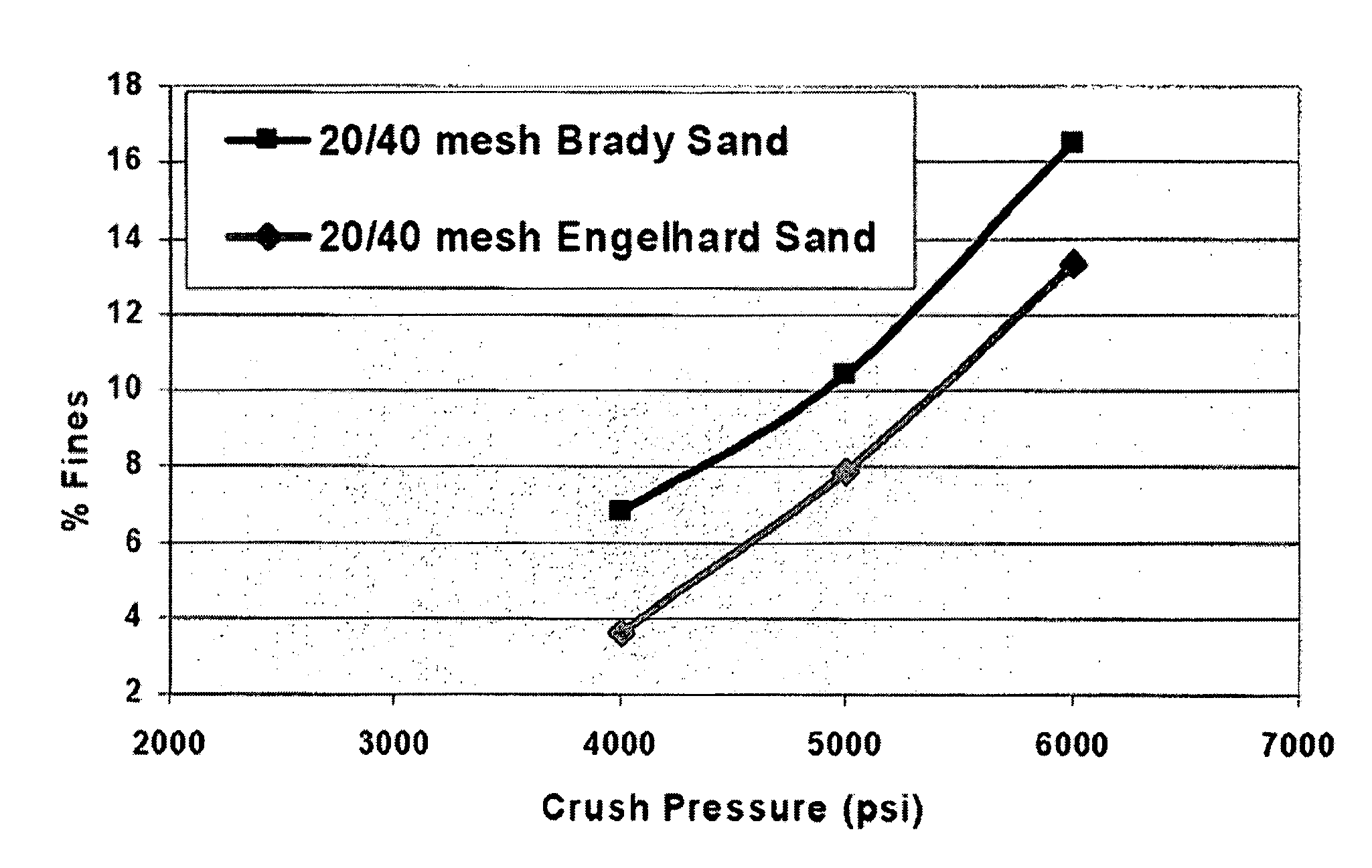

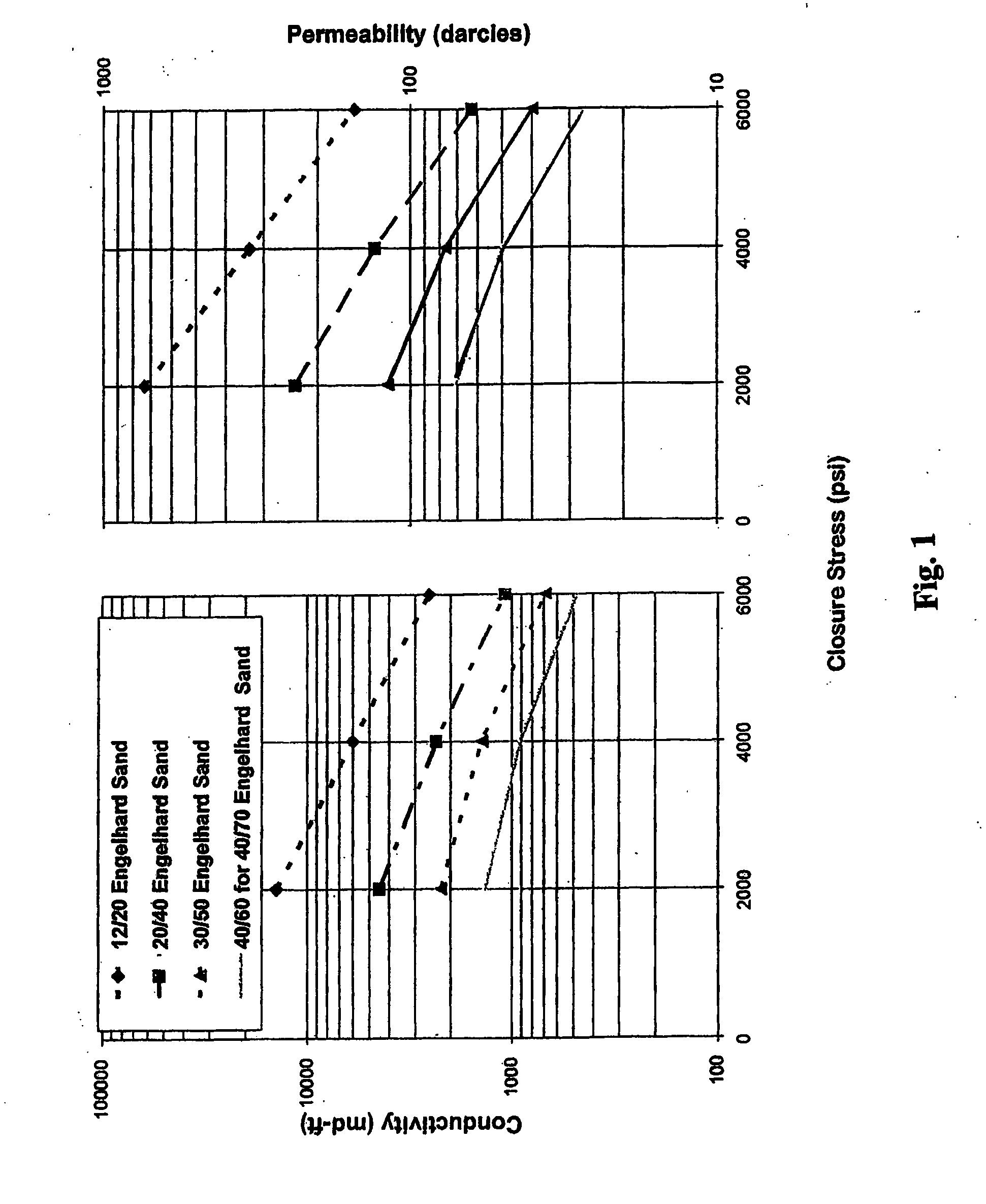

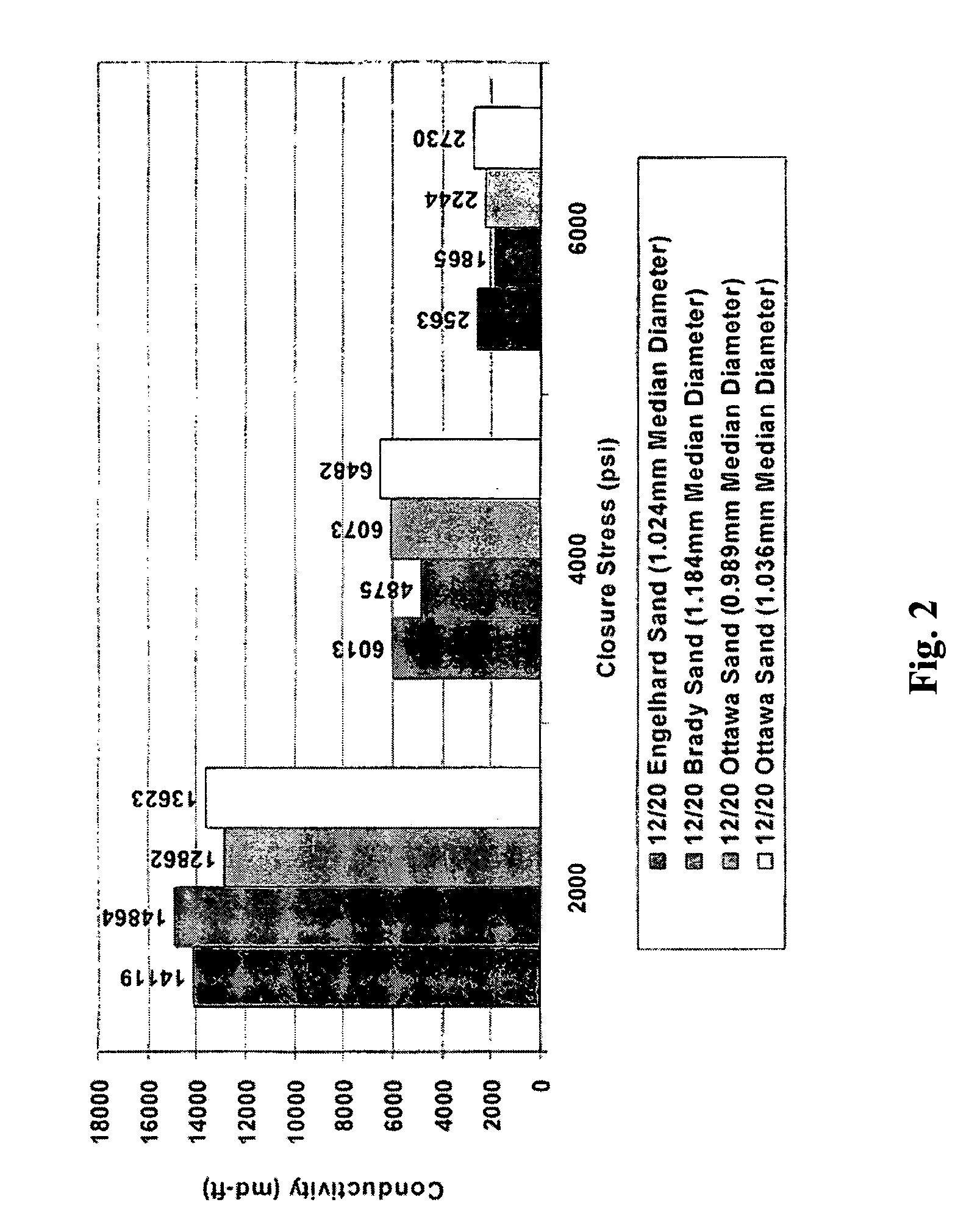

Hydraulic fracturing proppants for use in propping fractures in subterranean well bores comprising sand particles and methods for their manufacture are described. According to one or more embodiments, the proppants exhibit a narrow particle size distribution, crush resistance, sphericity, roundness and turbidity. Methods for propping open fractures during a hydraulic fracturing operation are also described.

Owner:ENGELHARD CORP

Environment-friendly continuous transformation method for shale gas well after hydraulic fracturing

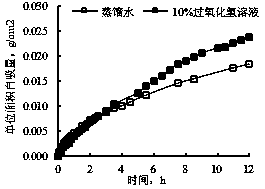

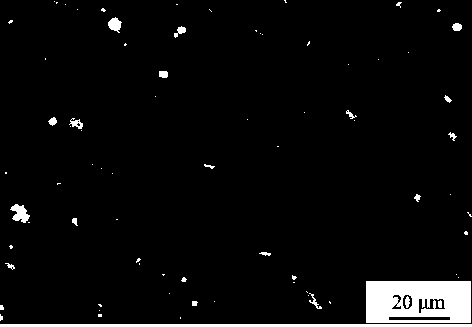

InactiveCN109751031AAchieving the purpose of long-term transformationFully play an active roleFluid removalDesorptionPyrite

The invention relates to an environment-friendly continuous transformation method for a shale gas well after hydraulic fracturing. Shale gas production undergoes a desorption-diffusion-seepage process, a complex seam net is formed through hydraulic fracturing, only the gas seepage capacity is improved, and gas desorption-diffusion is almost not influenced, so that the gas well post-fracturing exploitation initial-stage yield is decreased gradually and quickly. Meanwhile, the dosage of single well fracturing fluid is large, the flowback rate after fracturing is generally lower than 30%, and reservoir damage is induced by retained fracturing fluid. Due to the fact that the characteristic that organic matter and pyrite in shale are easy to decompose under the conditions of reduction environment deposition and oxidation, shale matrix is further transformed by adding an oxidizing agent into the fracturing fluid and inducing the shale pore crack dissolving and expanding effect through oxidative corrosion in combination with the characteristic that a large amount of fracturing fluid is retained, and gas desorption-diffusion capability is improved, the gas well hydraulic fracturing effectis enhanced, and the gas reservoir recovery rate is increased. The invention belongs to the technical field of petroleum and natural gas exploitation, and relates to an environment-friendly continuoustransformation method for a shale gas well after hydraulic fracturing.

Owner:SOUTHWEST PETROLEUM UNIV

Perforation strategy for heterogeneous proppant placement in hydraulic fracturing

Owner:SCHLUMBERGER TECH CORP

Method and composition for hydraulic fracturing and for tracing petroleum production

A method of hydraulic fracturing, and tracer composites for use in the fracturing procedure, for tracing the production of crude oil or other hydrocarbon liquid products from one or more fractured zones. The tracer composites preferably include an oil soluble tracer adsorbed onto a solid carrier material. A non-water soluble coating is preferable also included on the composite over the tracer compound.

Owner:SPECTRUM TRACER SERVICES

Spherical pellets containing common clay particulate material useful as a proppant in hydraulic fracturing of oil and gas wells

InactiveUS20130345100A1Low raw material costImprove stress resistanceFluid removalFlushingParticulatesMineral particles

A ceramic propping agent, in the form of a spherical pellet, and containing common mineral particulate. The desired propping agent is defined as a particulate ceramic made from raw materials which may be comprised of about: 10%-90% parts by weight of a naturally occurring mineral particulate, 30%-70% parts by weight aluminosilicate network modifier, 0.25-20% parts by weight strength enhancer, and at least one part, typically less than 10% by weight, binder. For use in oil and / or natural gas wells as a hydraulic fracturing proppant.

Owner:BROWNWOOD CLAY HLDG

Precursor compositions for ceramic proppants

InactiveUS20080073083A1Broad sinteringIncrease resistanceFluid removalDrilling compositionAlkali feldsparHydraulic fracturing proppants

A precursor composition for the production of granulated ceramic material to be used as hydraulic fracture proppant, comprises 20 to 55% pyroxene, and 15 to 50% olivine. The remaining component is quartz and / or feldspar. The precursor composition can be sintered in a broader temperature range. The resulting proppant material shows high mechanical strength and resistance to acids, and also higher stability under hydrothermal conditions than the prior art.

Owner:ILEM RES & DEV ESTAB

Precursor compositions for ceramic products

InactiveUS20090192059A1Broad sinteringIncrease resistanceCleaning apparatusFlushingAlkali feldsparHydraulic fracturing proppants

Owner:ILEM RES & DEV ESTAB

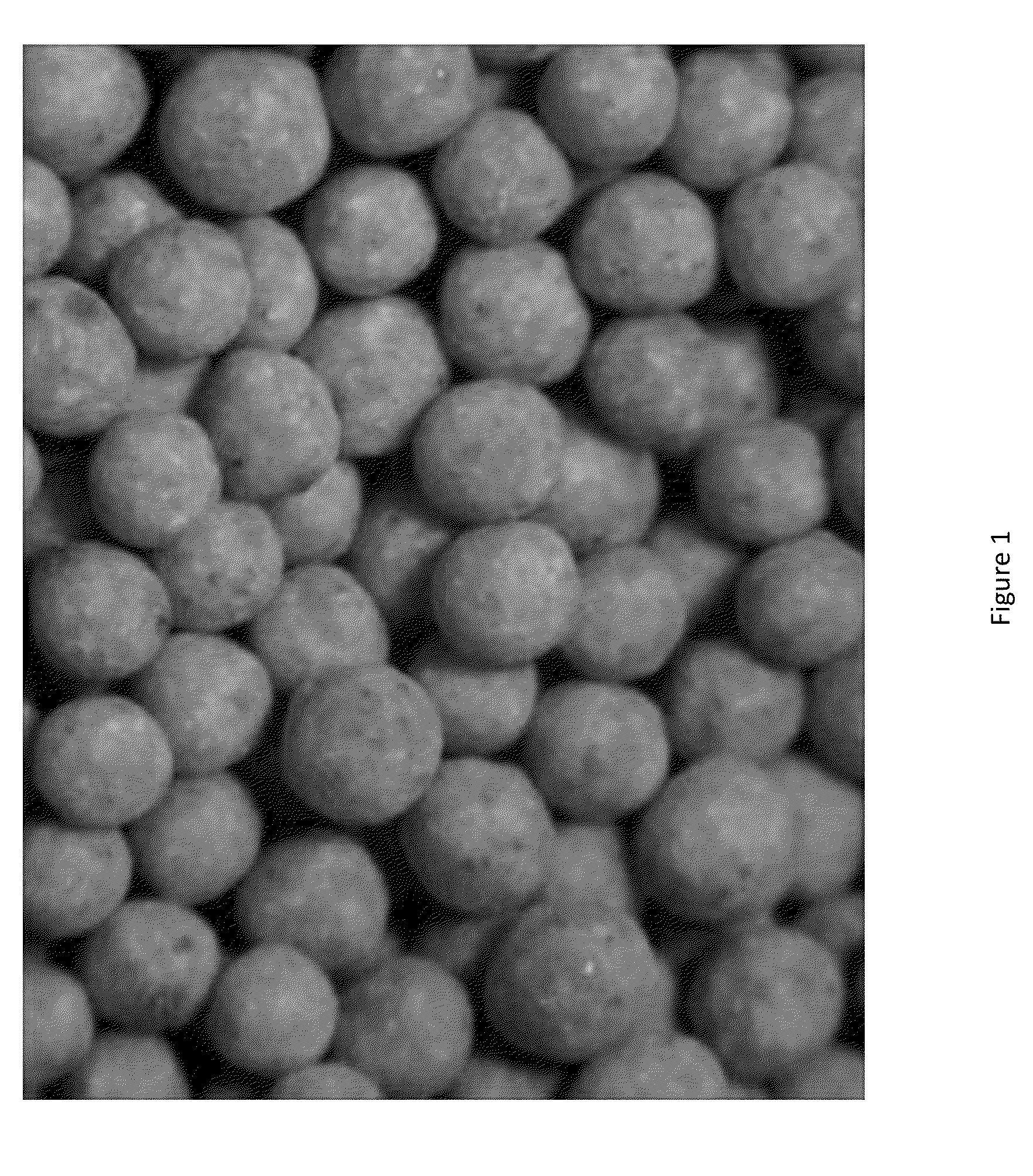

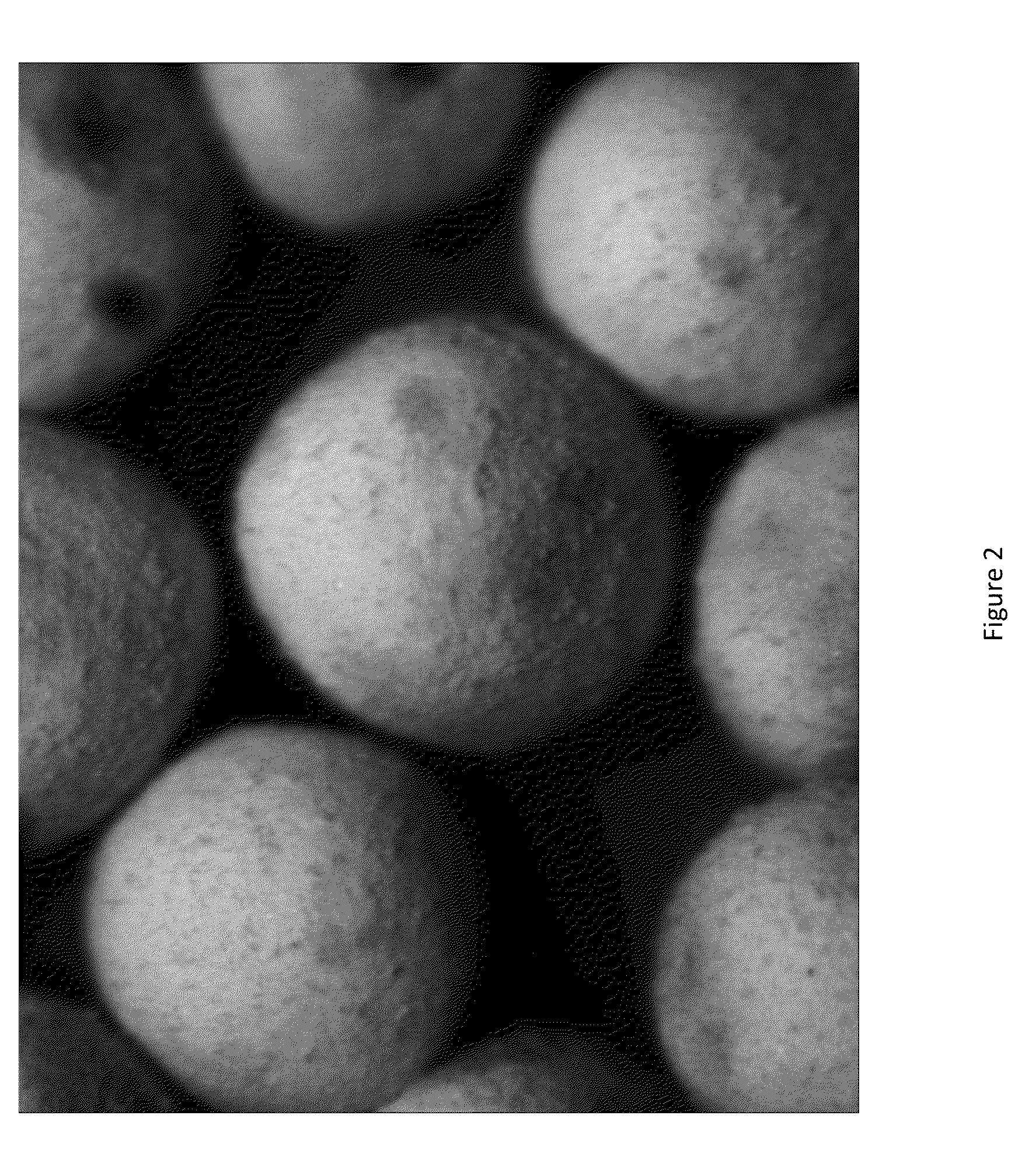

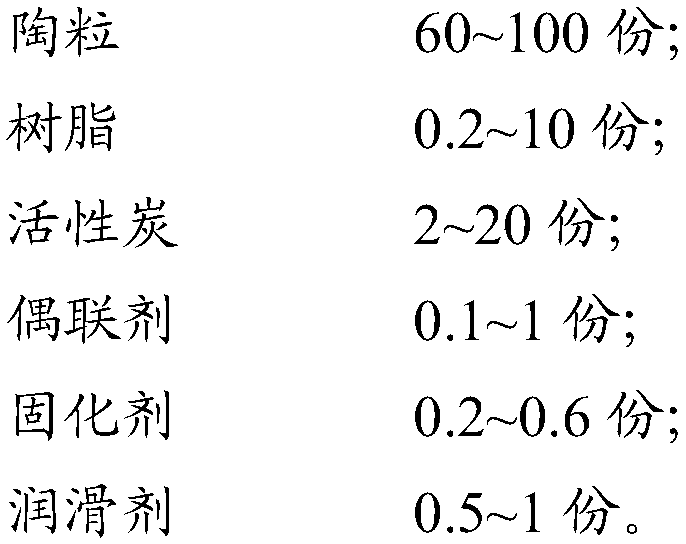

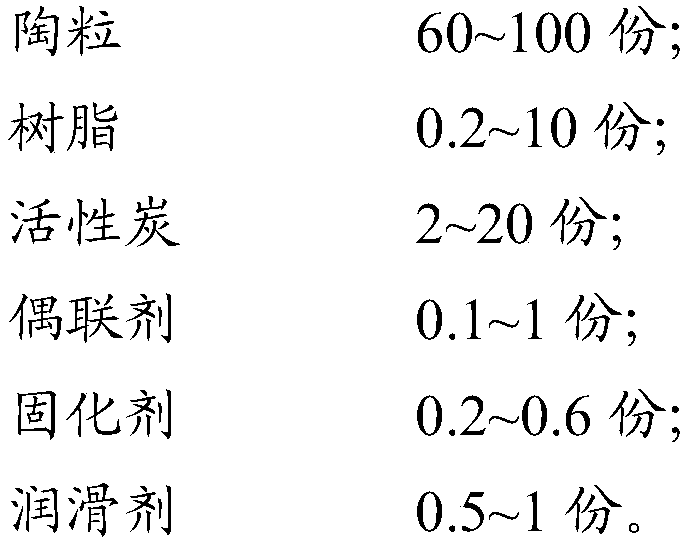

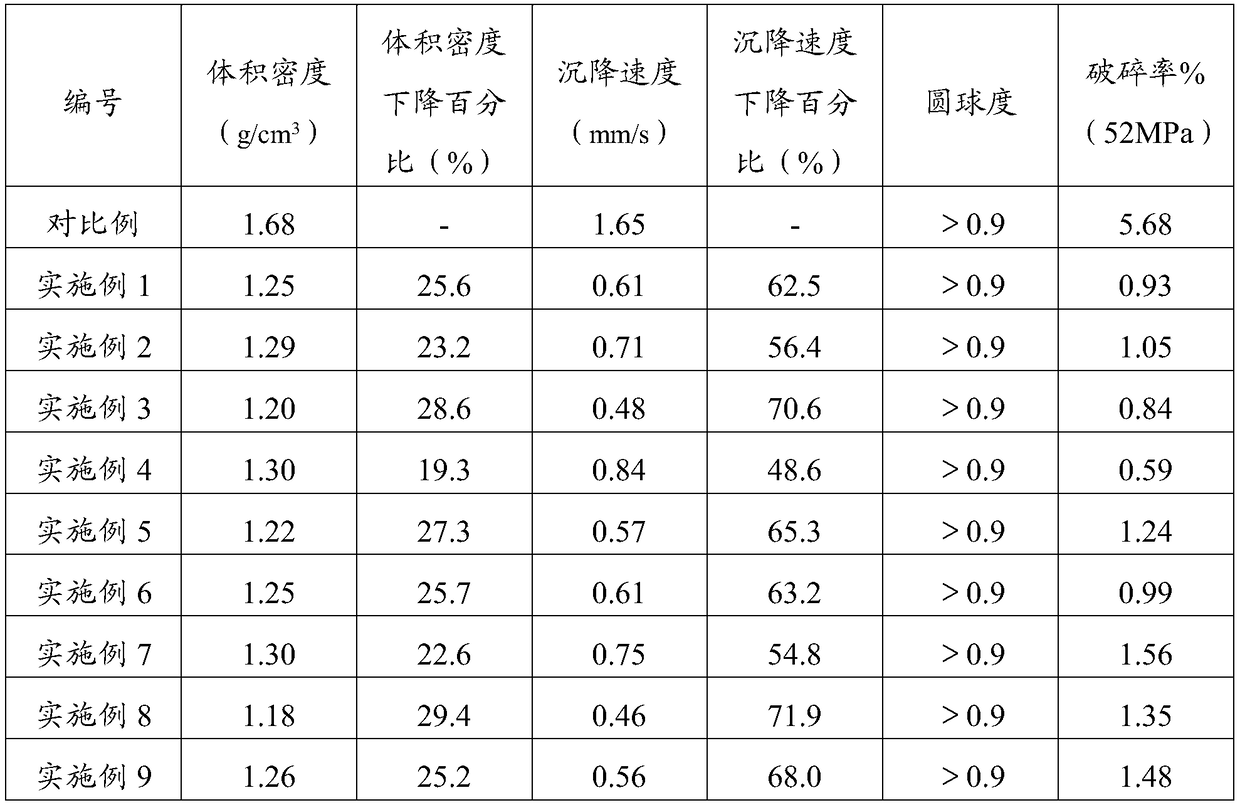

Low-density coated ceramsite proppant and preparation method thereof

InactiveCN109385263ARich in microporesCoated evenlyFluid removalDrilling compositionActivated carbonExpanded clay aggregate

The invention provides a low-density coated ceramsite proppant, and belongs to the technical field of hydraulic fracturing proppants. The low-density coated ceramsite proppant is prepared from the following raw materials in parts by weight: 60-100 parts of ceramsite, 0.2-10 parts of resin, 2-20 parts of activated carbon, 0.1-1 part of a coupling agent, 0.2-0.6 parts of a curing agent and 0.5-1 part of a lubricant. The activated carbon and resin are used as a film material and are applied to the surface of ceramsite under the action of the coupling agent by coating, and uniform coating and curing of the film material are achieved by cooperating with the curing agent and the lubricant; the activated carbon has rich micropores, and orifices of the activated carbon are closed by the resin material through mixing and curing with the resin. Thus, strength of the prepared coated ceramsite proppant can be ensured, certain gaps can be contained in the film material, and density is reduced; besides, the activated carbon has hydrophobic characteristic, and the hydrophobic surface of the activated carbon can reduce settling velocity of the activated carbon in fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

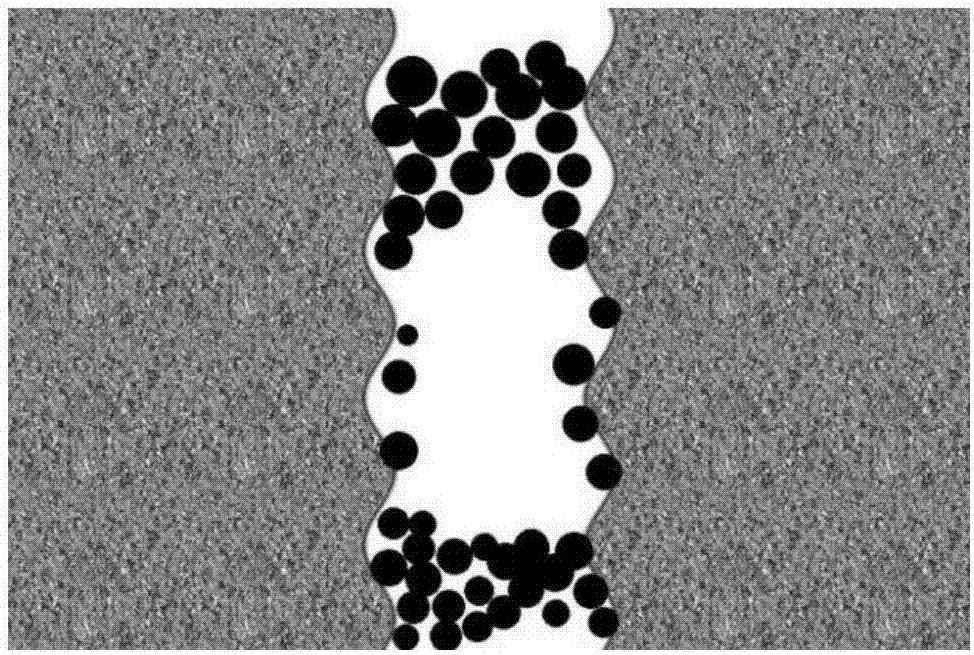

Methods of use of a salt solution of monovalent and divalent cations in hydraulic fracturing

The invention provides a method for fracturing a subterranean formation penetrated by a well bore, by formulating a fracturing fluid useful in hydrocarbon drilling having the properties of both a dispersing fracture solution and an aggregating fracture solution. In particular, the dispersing properties of the stabilizing fracture solution are able to act as a dispersing fracture fluid in the clay and earthen materials discharged from the pay zone, in the flow-back fluids during hydraulic fracturing. At the same time, aggregating properties of the stabilizing solution stabilizes the pay zone. This stabilization property allows the flow of hydrocarbon through the fractures for a significantly longer time than with prior art fluids.

Owner:CRILL DICK

Hydraulic fracturing proppants

ActiveUS8991494B2Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

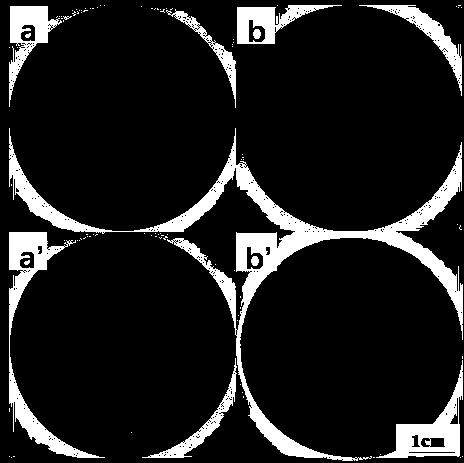

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

Pickering emulsion fracturing fluid as well as preparation method and application thereof

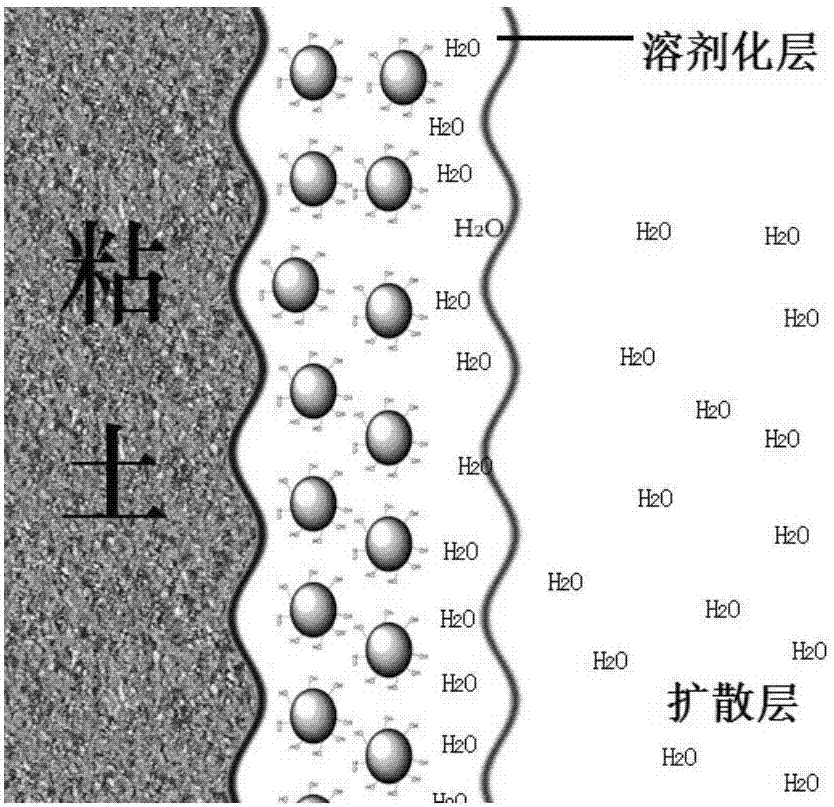

ActiveCN107880867AHigh viscosityReduce injection displacementFluid removalDrilling compositionPickering emulsionFracturing fluid

The invention relates to a Pickering emulsion fracturing fluid as well as a preparation method and application thereof. The Pickering emulsion fracturing fluid utilizes Pickering emulsion with stablesolid particles and realizes a dual technique of crack formation and placement of a propping agent at the same time, the defects that the traditional hydraulic fracturing propping agent is larger in particle size and can not enter tiny cracks in a remote well zone and settlement can be extremely easily caused are overcome, a link of injecting the propping agent is eliminated, and a hydraulic fracturing operation is simplified, so that cracks produced in a fracturing process are stabilized and propped up, and fracturing cost is reduced; and fracturing effect is greatly improved, and productioncapacity is greatly increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method and compositions for hydraulic fracturing and for tracing formation water

A method of hydraulic fracturing, and tracer composites for use in the fracturing procedure, for tracing the production of formation water from one or more fractured zones. The tracer composites preferably include a formation water tracer material adsorbed onto a solid carrier material.

Owner:SPECTRUM TRACER SERVICES

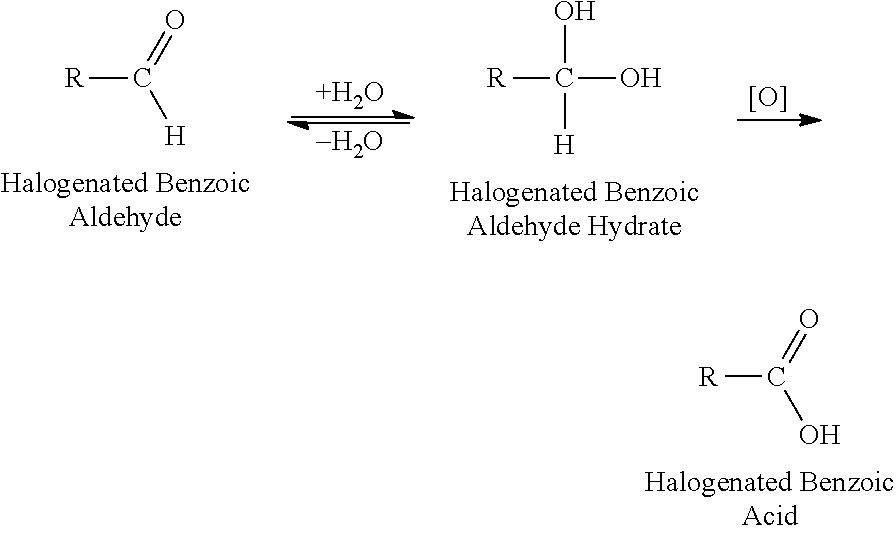

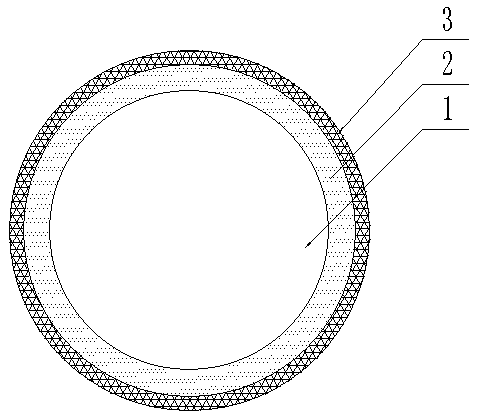

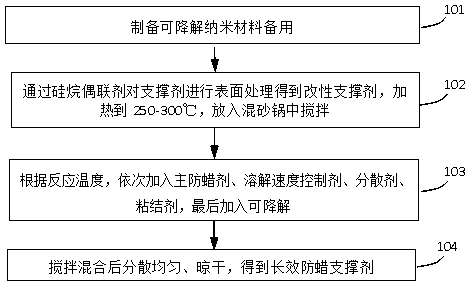

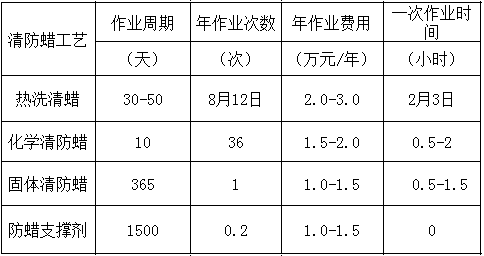

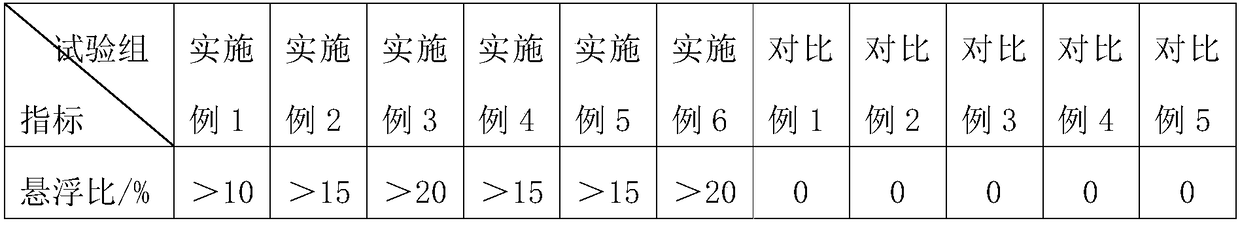

Hydraulic fracturing proppant as well as preparation method and application thereof

ActiveCN110982510AWax Resistant Organic UnifiedRelease long-lasting evenlyFluid removalDrilling compositionThermodynamicsHydraulic fracturing proppants

The invention discloses a hydraulic fracturing proppant and a preparation method and application thereof. The hydraulic fracturing proppant is composed of a modified proppant inner core, a solid paraffin control layer and a protective layer. The modified proppant inner core is ceramsite or quartz sand treated with a silane coupling agent; the solid paraffin control layer is composed of a main paraffin control agent, a dissolution rate control agent, a dispersing agent and a binding agent; and the main component of the protective layer is a degradable nano material. The proppant is added in theinitial stage of hydraulic fracturing sand adding and pumped to the deep part of an oil layer, and after the protective layer is dissolved in oil under the formation temperature condition, a paraffincontrol component is slowly released under the action of a dissolution rate control agent. The paraffin control component enters the deep part of the oil layer, so that the influence of seasons is avoided, the long-acting uniform release of the paraffin control component is realized, and the hydraulic fracturing proppant has the advantages of high paraffin control efficiency, long acting time, nolimitation of seasonal environment, simple construction operation, safety in use and easiness in popularization.

Owner:PETROCHINA CO LTD

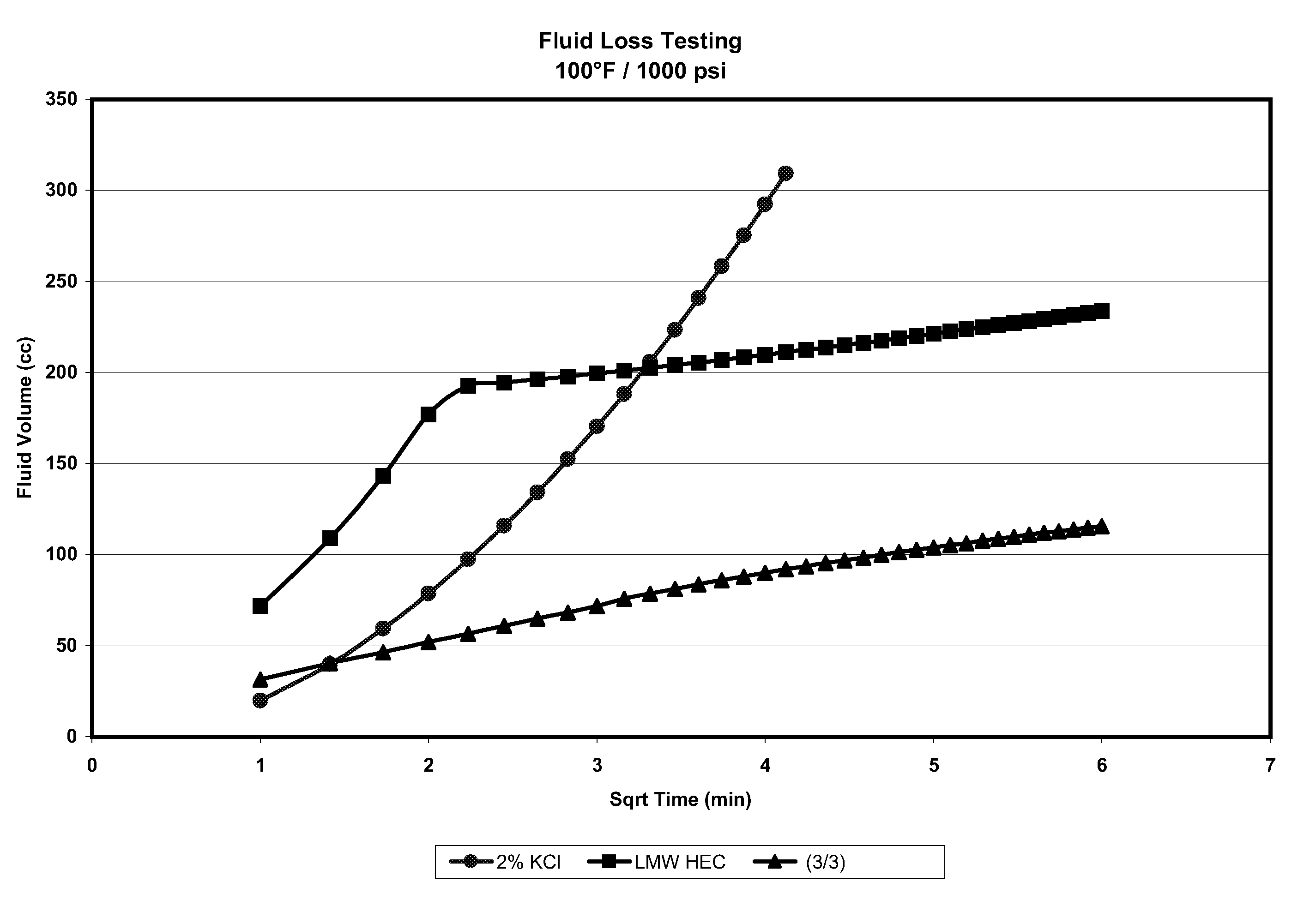

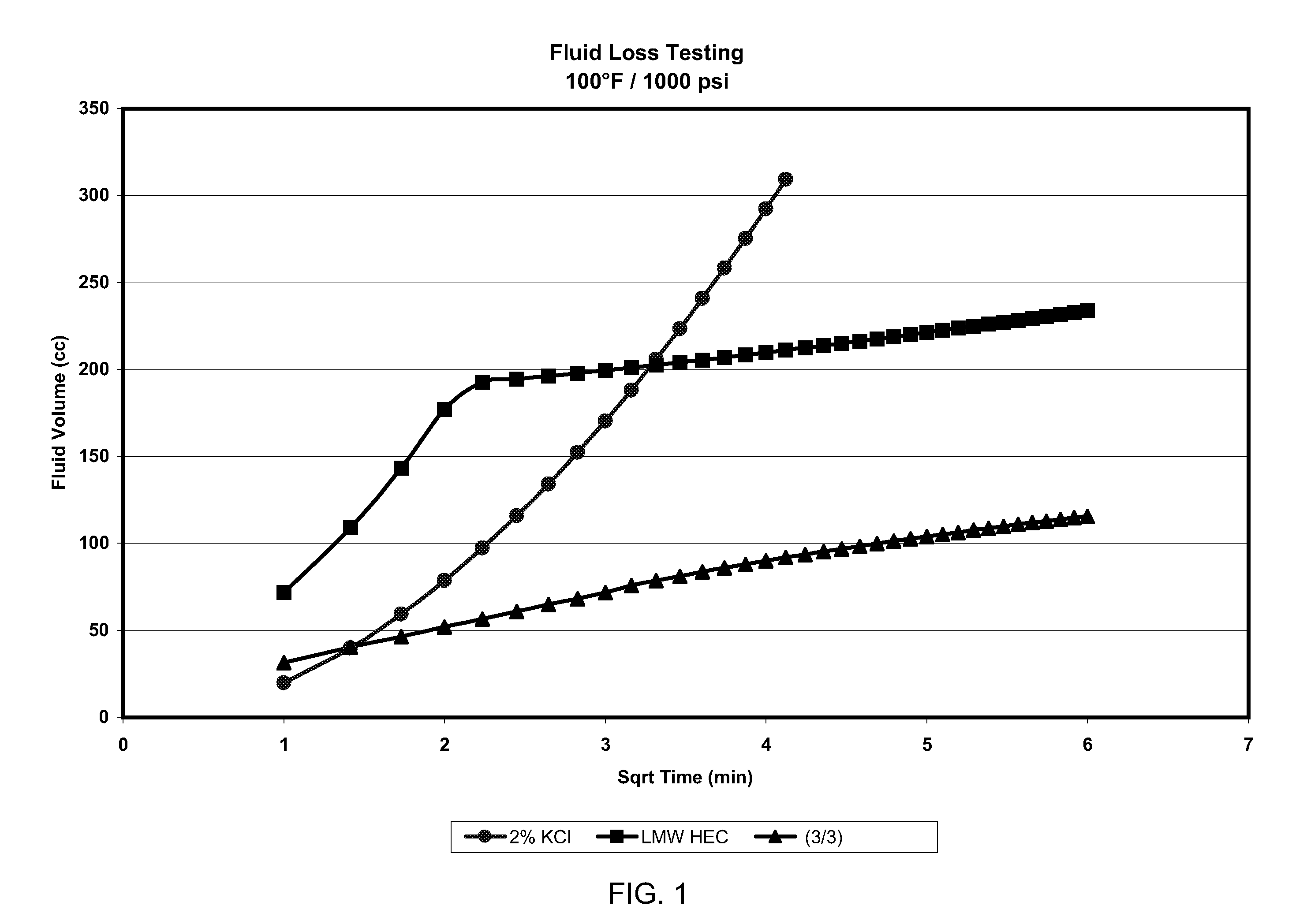

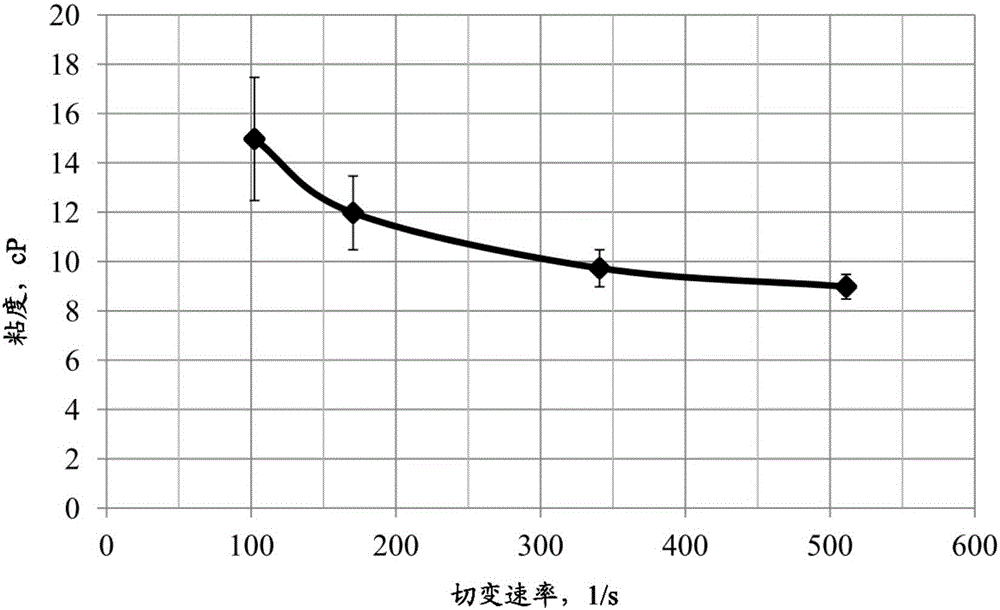

Method for reducing fluid loss during hydraulic fracturing or sand control treatment

A low viscosity fluid for reducing fluid loss in a relatively low permeability formation has a viscosity of less that 10 CP and contains a low molecular weight viscosifying agent The aqueous medium may be fresh water, salt water, brine or slickwater. The invention has particular applicability when an ultra lightweight (ULW) proppant or sand control particulate is employed. The fluid may be used in reservoirs having a relative permeability less than 10 mD.

Owner:BAKER HUGHES INC

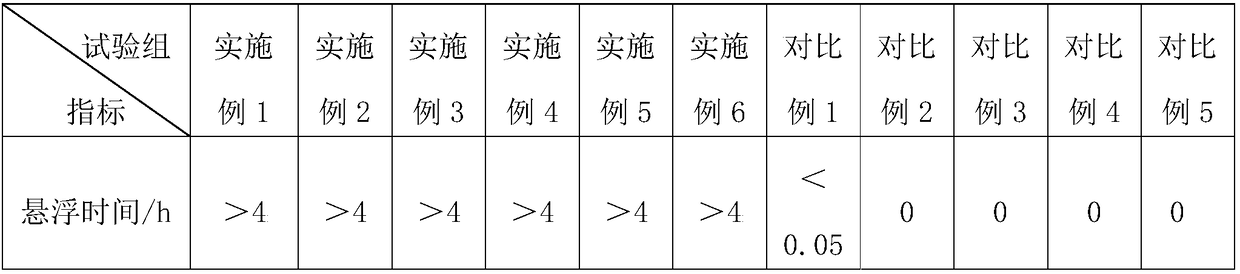

Method for preparing self-suspended hydraulic fracturing proppant

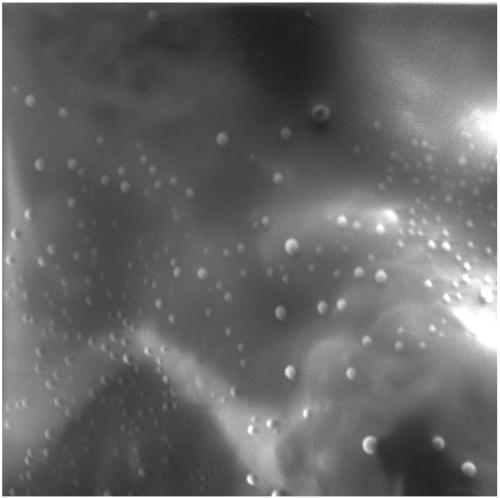

InactiveCN109233794AGood suspensionRelative density is smallFluid removalDrilling compositionSquare MillimeterPolymer science

The invention belongs to the field of compositions for enhancing the fracturing effect, and particularly discloses a method for preparing a self-suspended hydraulic fracturing proppant. Bulges havinga diameter of 100-500nm exist on the surface of the self-suspended hydraulic fracturing proppant, and about 4*10<7> bulges exist in each square millimeter. The preparation method comprises the following steps: (1) preparing the following raw materials: aggregates, resin, a curing agent, a catalyst and amine additives; (2) heating the aggregates to 80-90 DEG C, adding the resin and catalyst, and mixing and stirring; (3) adding the amine additives when the temperature is reduced to 70-80 DEG C, and stirring and mixing; and (4) adding the curing agent when the temperature is reduced to 65-75 DEGC, mixing and stirring, and removing from the pot when the temperature is reduced to 40-50 DEG C to prepare the self-suspended hydraulic fracturing proppant. The fracturing proppant prepared by usingthe method has good suspending performance, and can be easily carried into a well.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

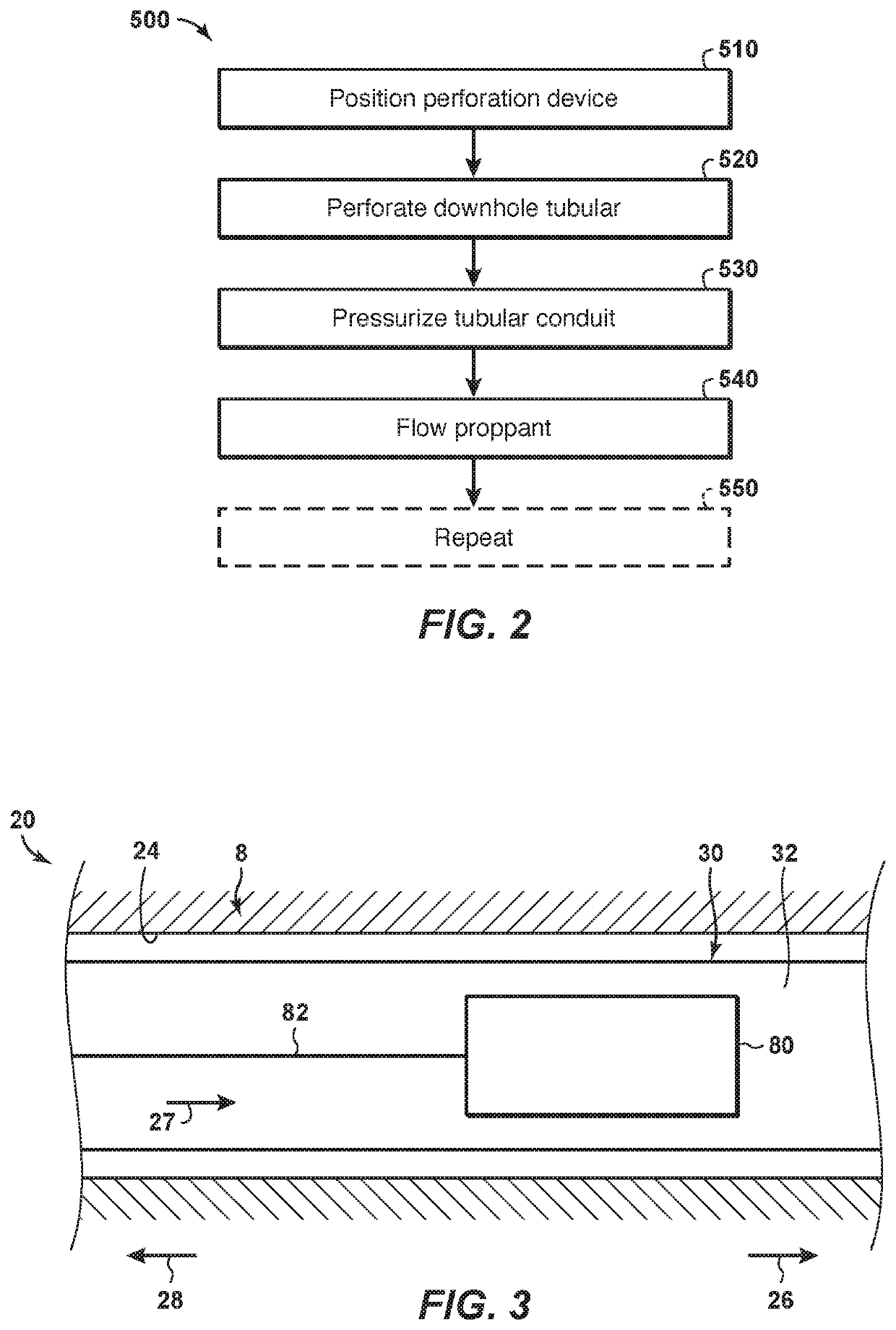

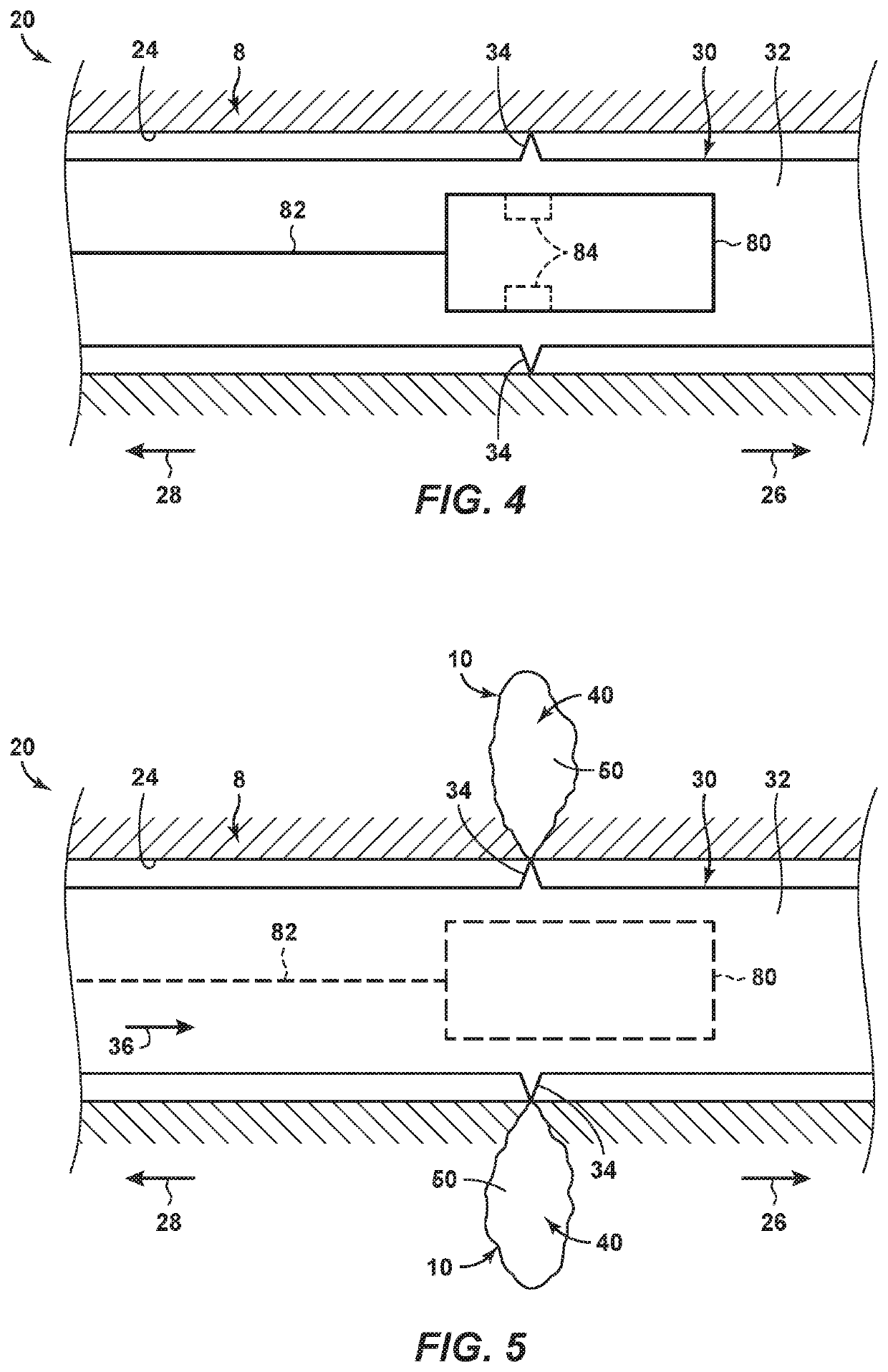

Granular Crosslinked Polyethylene as a Hydraulic Fracturing Proppant

Hydrocarbon wells including crosslinked polymer granules as a proppant, methods of forming the hydrocarbon wells, and methods of operating the hydrocarbon wells. The hydrocarbon wells include a wellbore that extends within a subsurface region and a downhole tubular that extends within the wellbore and defines a tubular conduit. The hydrocarbon wells also include a plurality of perforations formed within the downhole tubular and a plurality of fractures formed within the subsurface region. The hydrocarbon wells further include the proppant positioned within the plurality of fractures. The proppant includes a plurality of crosslinked polymer granules, and each crosslinked polymer granule has a characteristic dimension of at least 100 micrometers and at most 2 millimeters.

Owner:EXXONMOBIL UPSTREAM RES CO

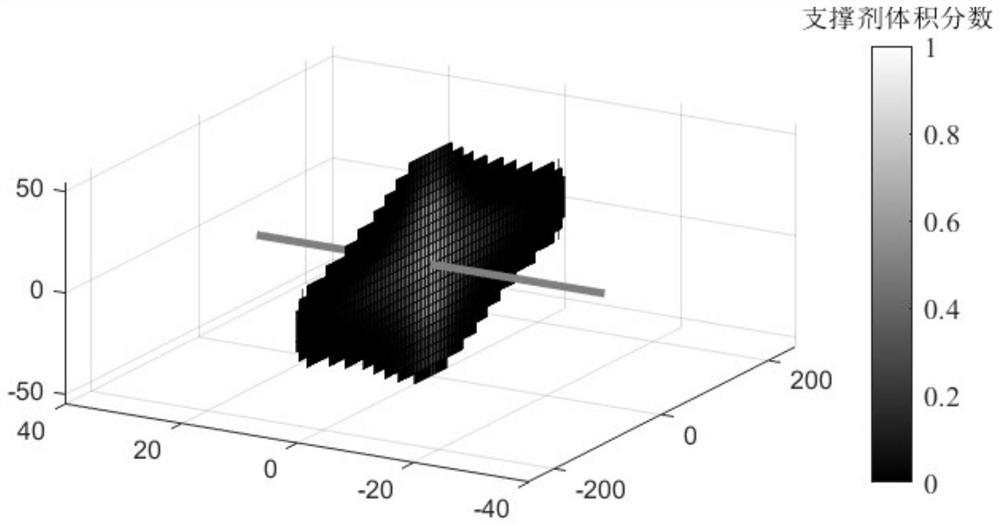

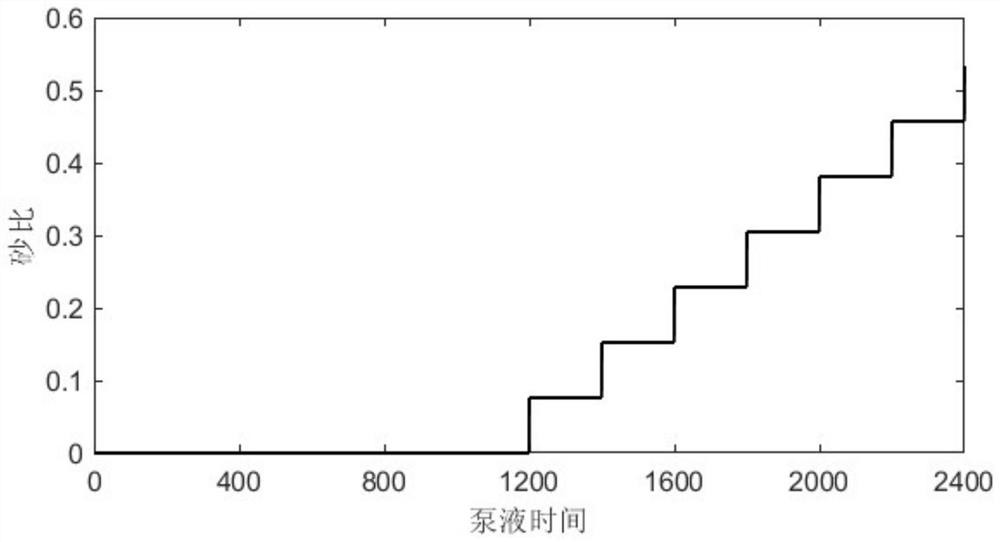

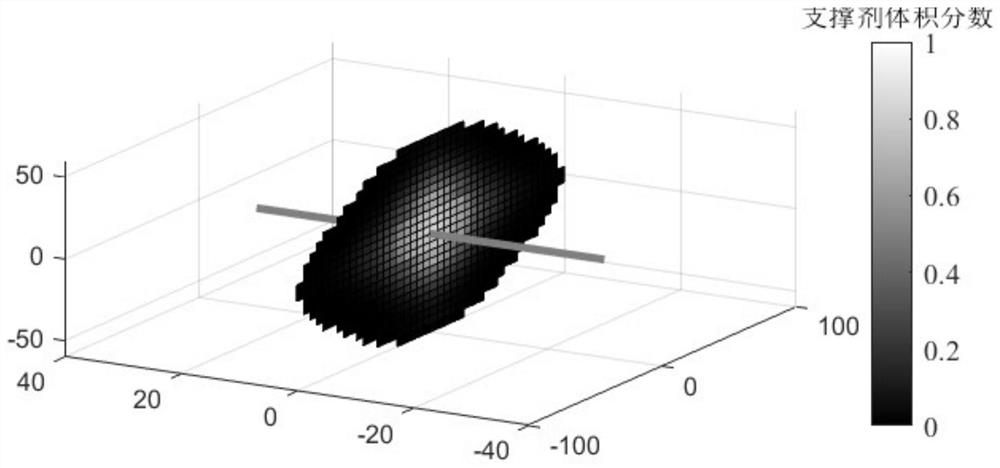

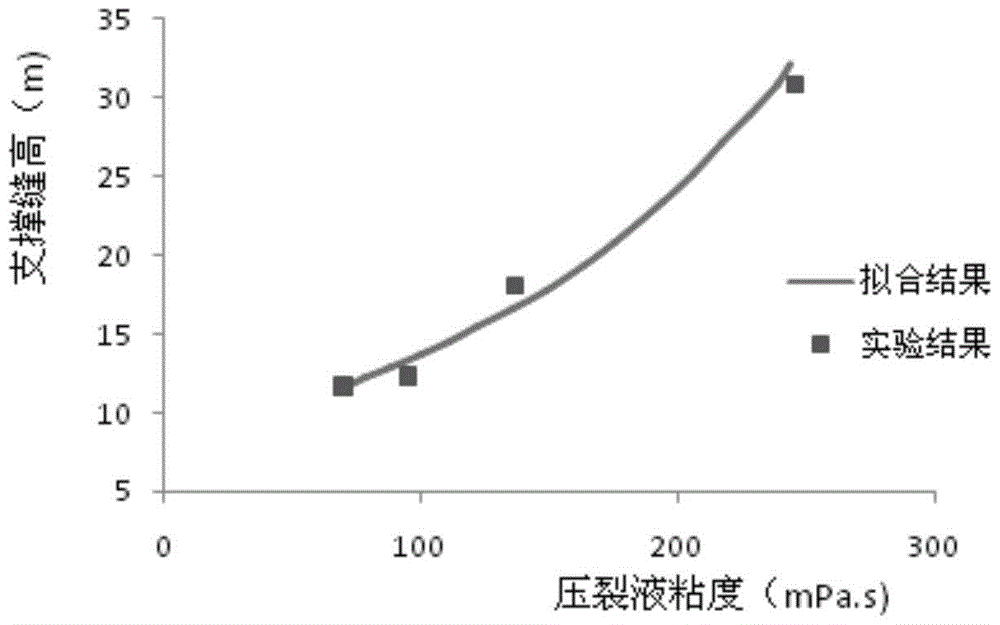

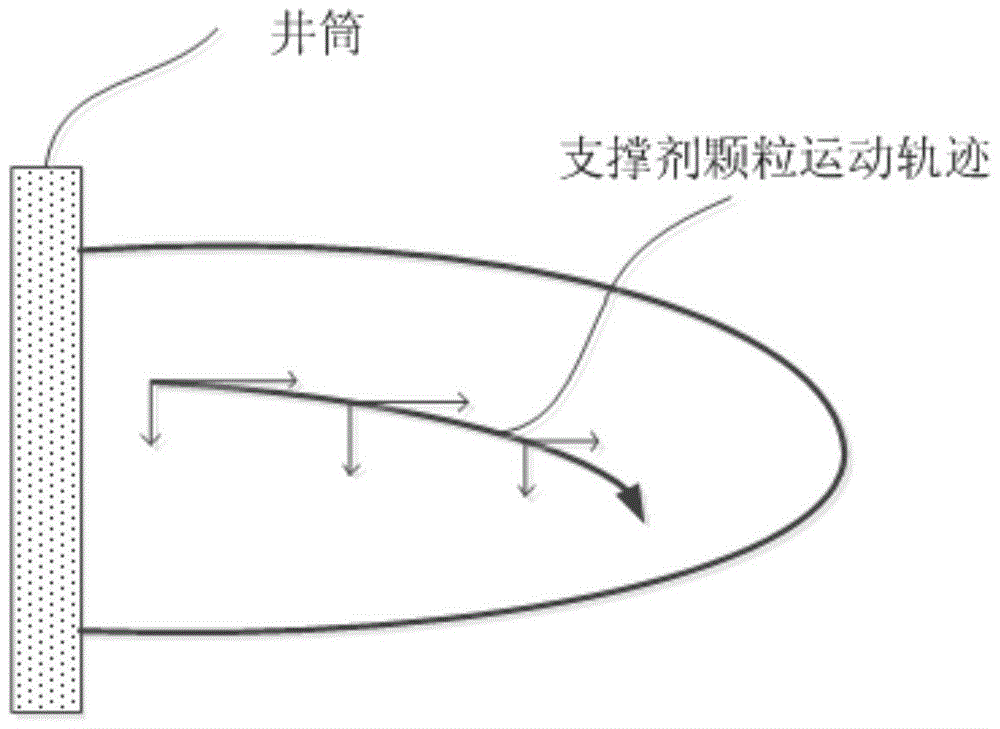

Optimization method for efficiently laying propping agents in hydraulic fracturing operation

ActiveCN112761609AComprehensive optimization resultsConsider practicalitySurveyVolume measurement apparatus/methodsFracturing fluidStructural engineering

The invention discloses an optimization method for efficiently laying propping agents in hydraulic fracturing operation. The optimization method comprises the following steps that 1, a rock deformation control equation and a fracturing fluid flowing and propping agent migration material balance equation in the fracturing process are constructed; 2, a model used for representing the pumping volume fraction of the propping agents is constructed; 3, parameters are given, and the corresponding fracture geometric dimension and propping agent volume concentration distribution are obtained through calculation; 4, the laying efficiency of each group of propping agents is calculated; 5, the average propping agent laying efficiency of each group is calculated; 6, optimization parameters are selected; and 7, the propping agent pumping volume fraction changing along with time is calculated; and the result is substituted into the model in the step 1 for calculation, the calculated propping agent laying efficiency after fracturing is obtained, and whether the optimization parameters are optimal or not is verified. The optimization method has the advantages that the hydraulic fracturing propping agent laying effect can be improved, and the oil and gas productivity can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

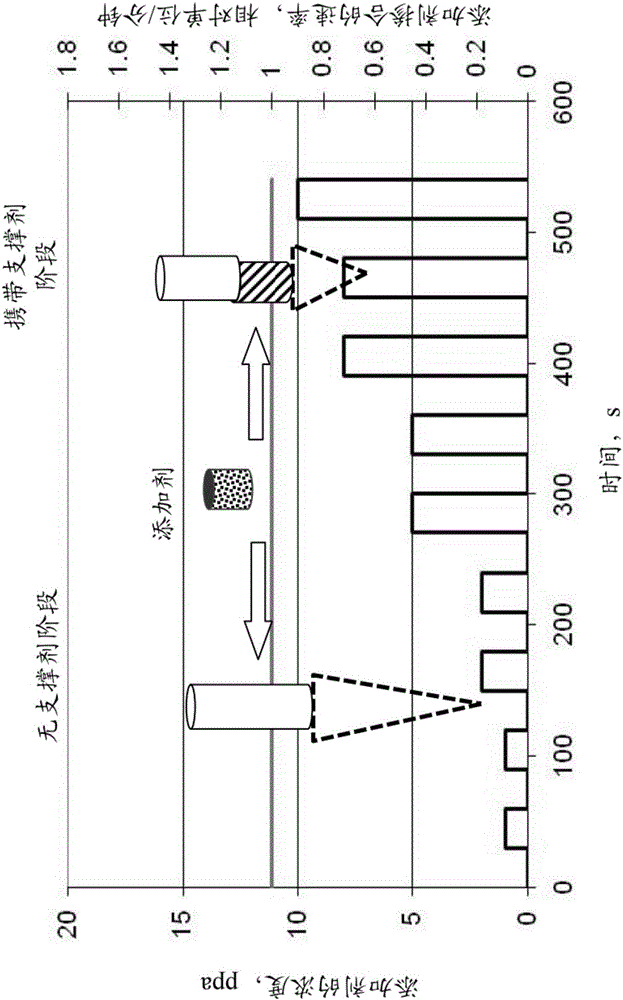

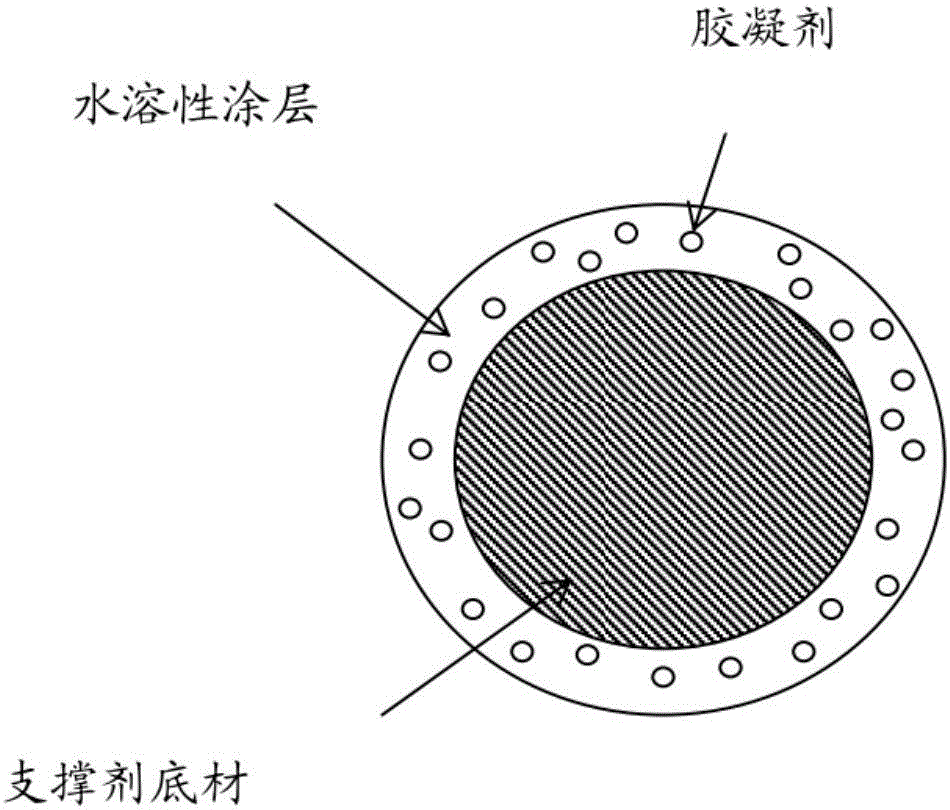

Propping agent and method for placing same in a hydraulic fracture

InactiveCN106661442AImprove filling efficiencyFluid removalDrilling compositionFracturing fluidWater soluble

The invention discloses a propping agent and a method for placing the same in a hydraulic fracture. The invention relates to the extraction of fluids from underground formations by means of hydraulic fracturing. The technical aim consists in improving the non-uniform placement of a propping agent. The propping agent consists of a material in the form of particles having a base, an outer water-soluble coating and a gelling agent, said gelling agent being immersed in the water-soluble coating in such a way that it is released from the base of a particle when the water-soluble coating is dissolved or destroyed upon introduction of the propping agent into portions of a hydraulic fracturing fluid. A method for the heterogeneous placement of a propping agent in a hydraulic fracture includes pumping alternating portions of hydraulic fracturing fluid, said portions containing and not containing the aforementioned particles, into a layer which is to undergo fracturing, under a pressure which exceeds a hydraulic fracturing pressure, through a plurality of clusters of perforations in a wellbore in the layer to be fractured, where the portions of hydraulic fracturing fluid containing the particles act as supports after the hydraulic fracture closes.

Owner:PRAD RES & DEV LTD

Spherical pellets containing common clay particulate material useful as a proppant in hydraulic fracturing of oil and gas wells

InactiveUS8772207B2High compressive strengthImprove stress resistanceFluid removalFlushingParticulatesMineral particles

A ceramic propping agent, in the form of a spherical pellet, and containing common mineral particulate. The desired propping agent is defined as a particulate ceramic made from raw materials which may be comprised of about: 10%-90% parts by weight of a naturally occurring mineral particulate, 30%-70% parts by weight aluminosilicate network modifier, 0.25-20% parts by weight strength enhancer, and at least one part, typically less than 10% by weight, binder. For use in oil and / or natural gas wells as a hydraulic fracturing proppant.

Owner:BROWNWOOD CLAY HLDG

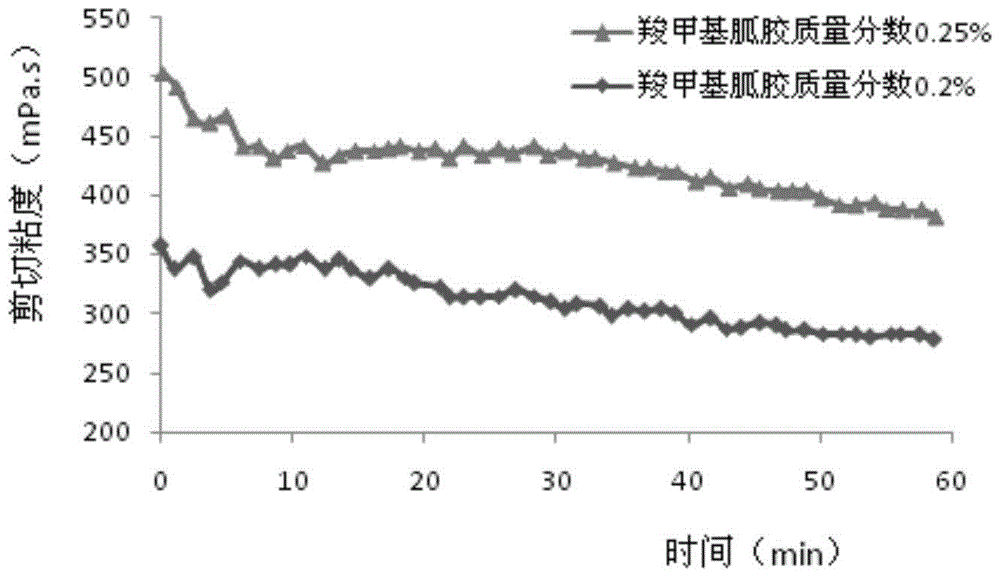

A method for hydraulic fracturing of coalbed methane

ActiveCN104088616BEfficient miningReduced fracturing costsFluid removalDrilling compositionCarboxymethyl guar gumFracturing fluid

The invention relates to a hydraulic fracturing method for coal bed gas. Active water fracturing fluid is used as the front fluid and the displacement fluid, and carboxymethyl guaridine fracturing fluid is used as the sand-carrying fluid; four kinds of quartz sands with different particle size ranges are selected as the proppant 100-70 mesh silt sand and 70-40 mesh fine sand are used as proppant in the pre-fluid, and 40-20 mesh medium sand and 20-14 mesh coarse sand are used as proppant in the sand-carrying liquid; the proppant selection is different The ratio of the amount of sand added to the particle size sand; the concentration of the clay stabilizer KCl in the active water fracturing fluid and the carboxymethyl guar gum fracturing fluid is based on the natural gamma ray log expressed in API units of the logging data of the fracturing target interval Intensity GR averages are determined. The invention greatly improves the effect of coal bed methane recovery increase, effectively prevents swelling and at the same time reduces the configuration cost of fracturing fluid to the greatest extent.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

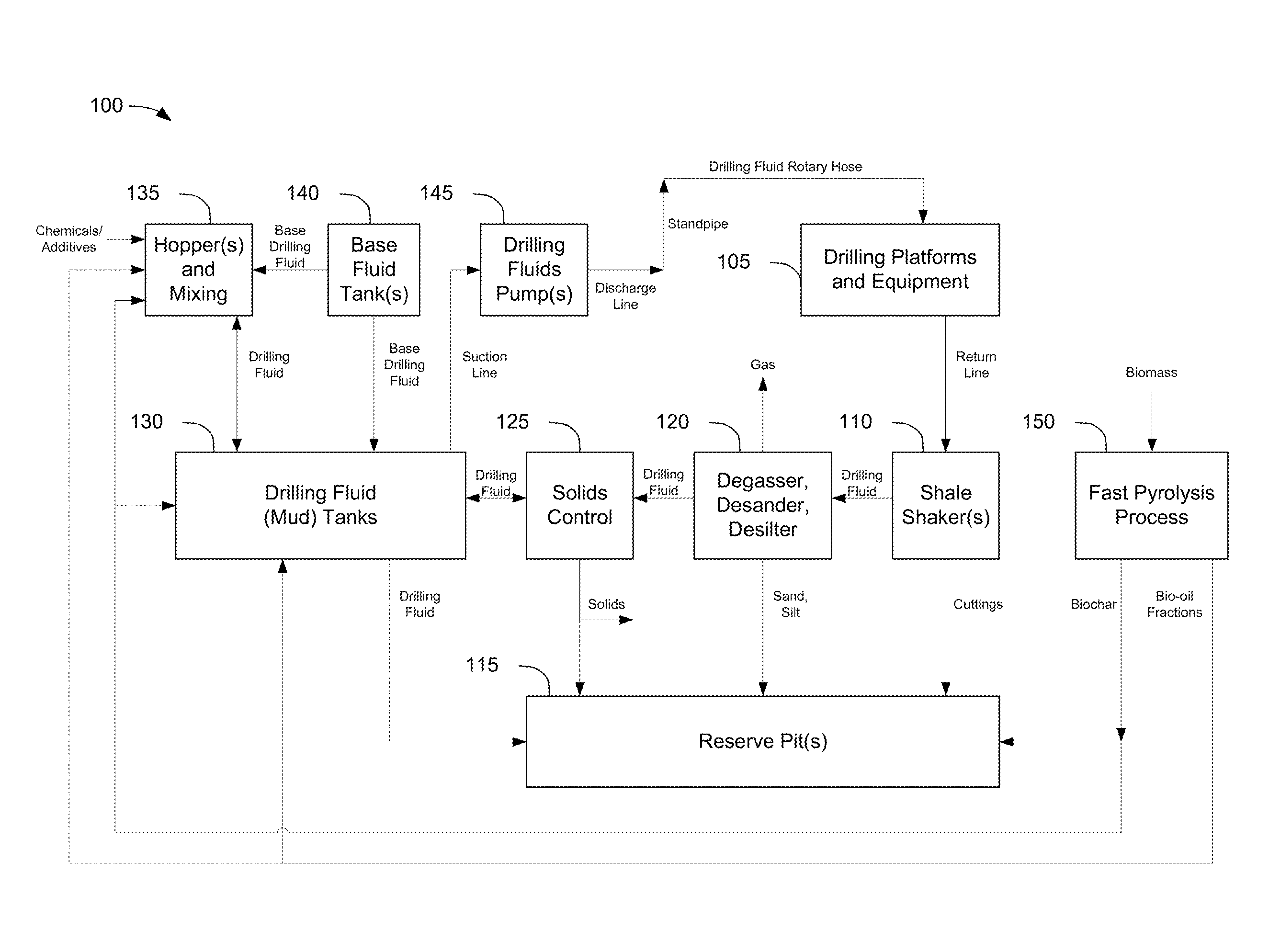

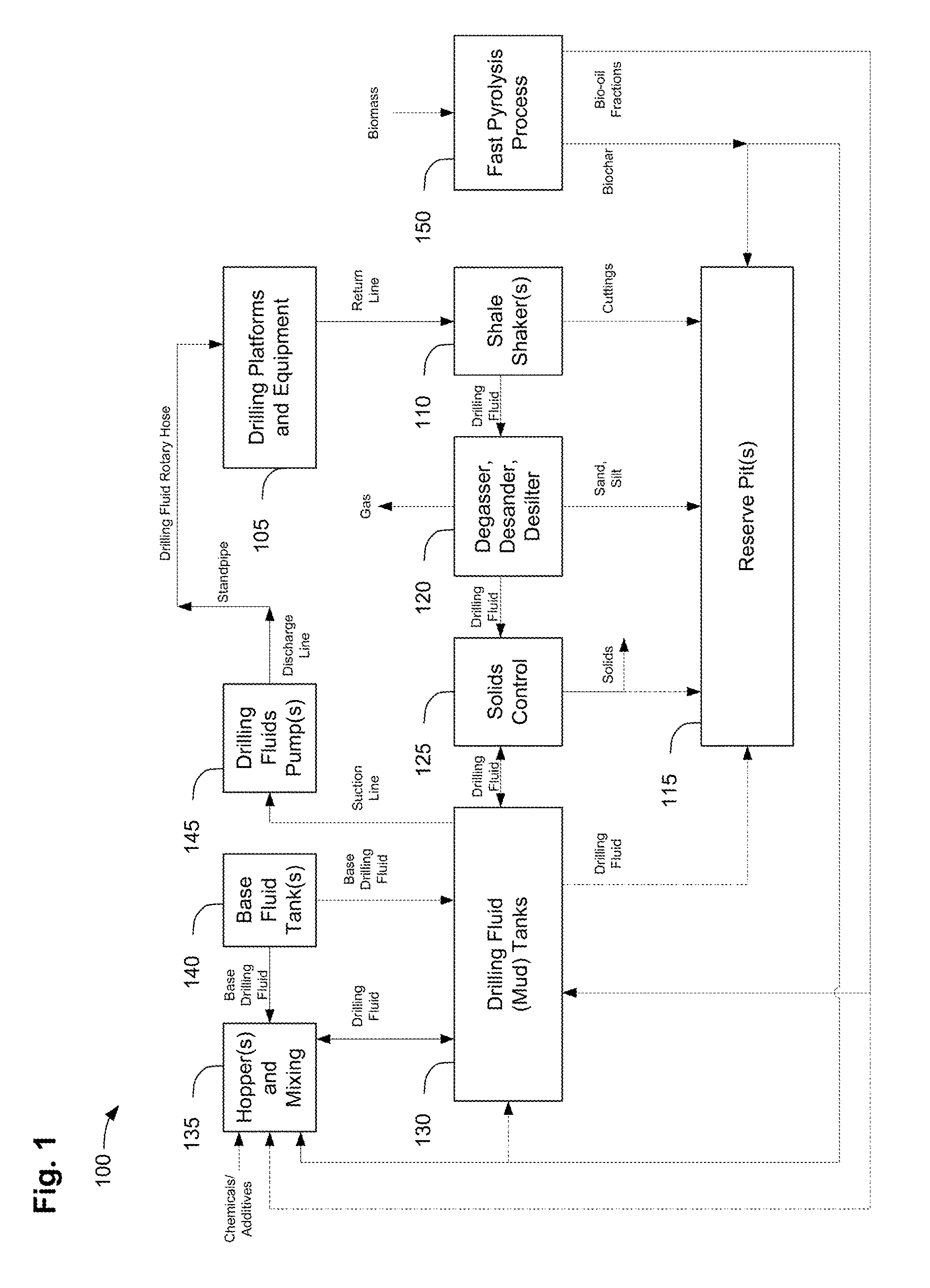

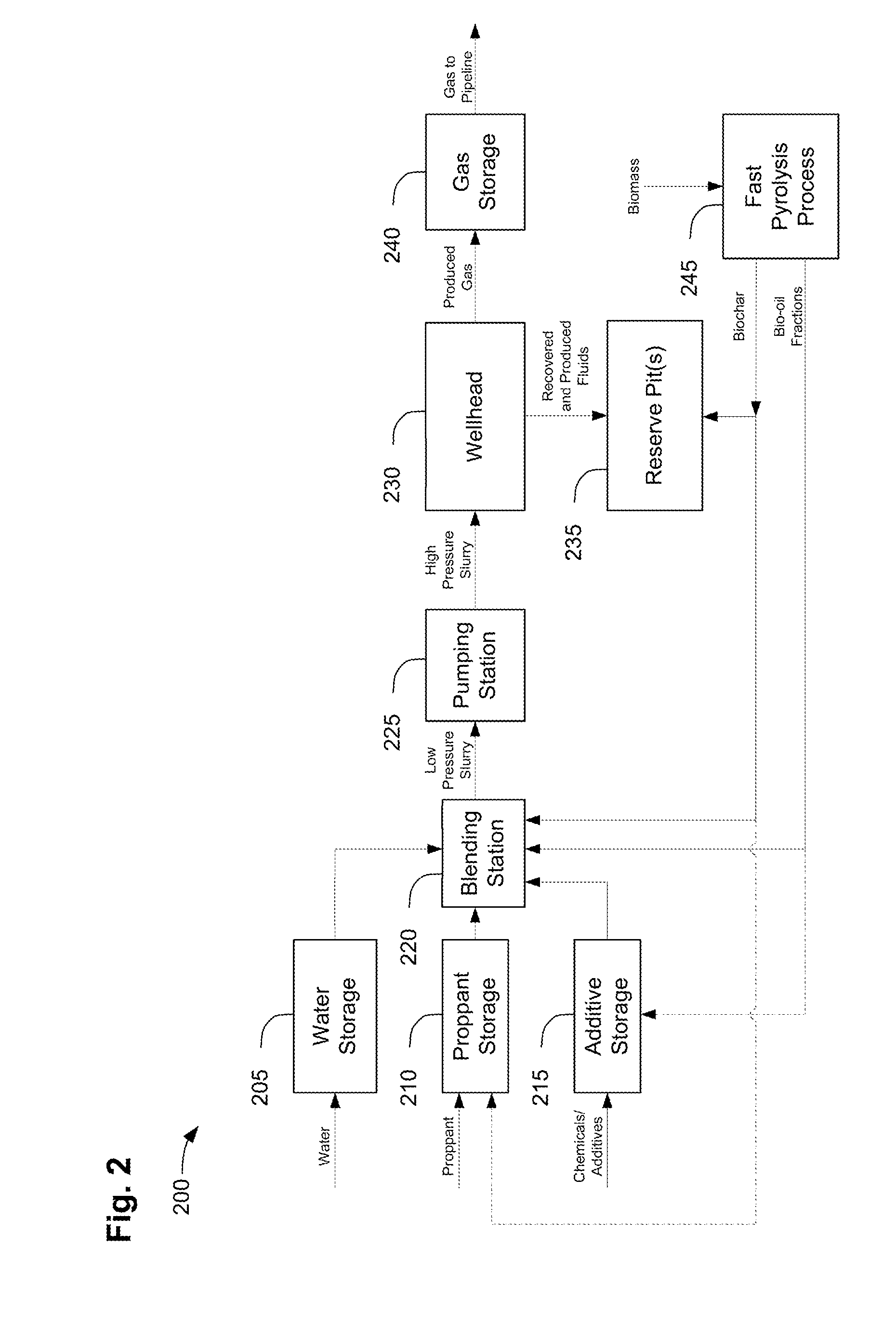

Compositions, methods, apparatus, and systems for incorporating bio-derived materials in drilling and hydraulic fracturing

ActiveUS9546315B2Improved propertyImprove the environmentFluid removalFlushingWater useFracturing fluid

The present invention provides compositions, methods, apparatus, and systems to minimize environmental impact, water use, and overall cost of drilling and hydraulic fracturing for crude oil and natural gas. Some variations of the invention provide a fracturing-fluid additive composition comprising a water-soluble portion of a biomass-pyrolysis liquid. In some embodiments, the fracturing-fluid additive composition is substantially biodegradable and is not toxic. Some variations provide improved proppants for oil or gas well fracturing. Other variations of this invention relate to drilling-fluid additive compositions, and methods of using these compositions. This invention can significantly improve the environmental, economic, and social sustainability associated with drilling and fracturing for production of oil and gas.

Owner:AVELLO BIOENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com