Environment-friendly continuous transformation method for shale gas well after hydraulic fracturing

An environmentally friendly technology for shale gas wells, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve the problems of gas well production decline, reduce processing costs, improve mass transfer capacity, and strengthen gas supply capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purpose and beneficial effects of the present invention, an embodiment of the present invention will be further described in conjunction with the accompanying drawings.

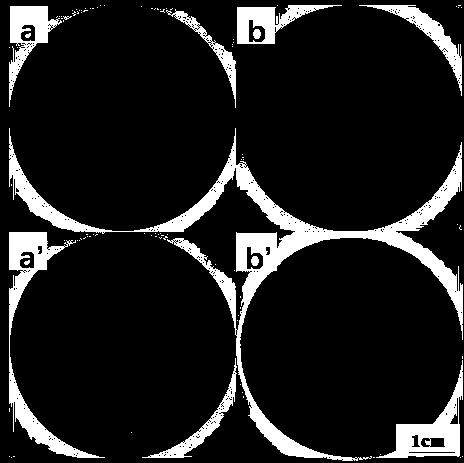

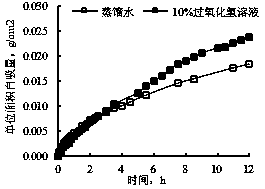

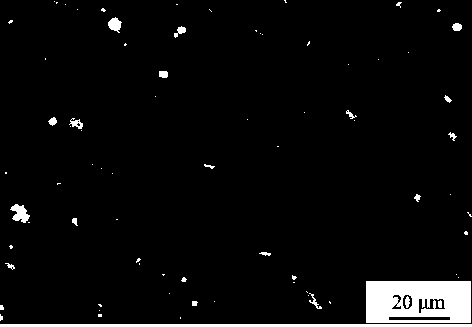

[0028] In order to verify the reliability of the present invention, using distilled water as a reference, carried out shale self-absorption 10% hydrogen peroxide solution, and shale-hydrogen peroxide solution interaction experiments, and used field emission electron microscope pictures to reveal the pores of shale before and after treatment Structural changes. The specific operation steps are as follows:

[0029] (1) Select the organic-rich shale of the Longmaxi Formation, drill parallel bedding at the same position of the same rock block, and select two shale pillar samples (2.5×5cm); at the same time, prepare two shale cubic samples (0.5× 0.5×0.5cm) a surface was polished with argon ions, and then the surface structure was observed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com