A method for determining the content of alkali metal sulfate in Portland cement and clinker

An alkali metal sulfate and Portland cement technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of low accuracy and lack of accuracy, achieve high test accuracy, reduce adverse effects, and solve the time-consuming and accurate test. low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of method (alcohol dissolution method) of the alkali metal sulfate content in measuring portland cement and clinker, comprises the following steps:

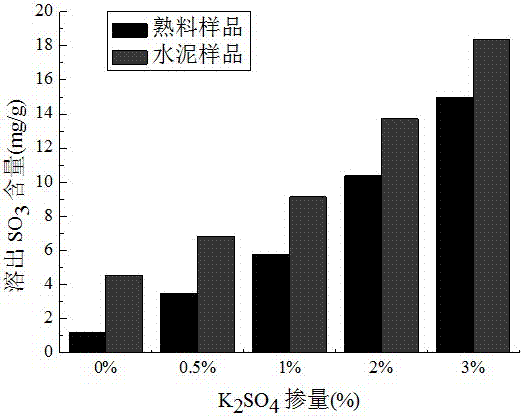

[0025] 1) Prepare 50% (v / v) ethanol extract and add 0.5%, 1%, 2% and 3% analytically pure K 2 SO 4 Cement or clinker samples; wherein, the 50% (v / v) ethanol extract is prepared from analytical pure anhydrous ethanol and deionized water at a volume ratio of 1:1.

[0026] 2) Weigh 1g of the above-mentioned cement or clinker samples into a beaker, add 100 mL of the ethanol extract prepared above to dissolve, place on a magnetic stirrer for mechanical stirring, and quickly vacuum filter the mixture after 2 minutes. Take the filtrate in a 300 mL beaker.

[0027] 3) Use a pipette to draw 50 mL of the filtrate into a beaker, place it on a heating plate and heat until the ethanol is completely evaporated. In this step, the heating until the ethanol is completely volatilized is judged by the sense of smell t...

Embodiment 2

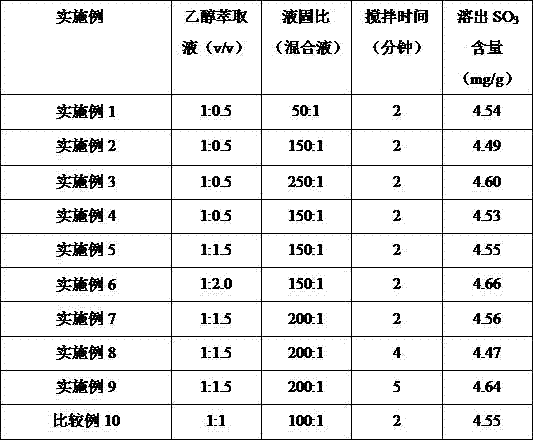

[0034] Embodiment 2: For the same cement sample (the cement sample used in the above-mentioned embodiment 1 without internal admixture), two of the three variables of ethanol extract concentration, liquid-solid ratio, and stirring time were fixed respectively, and the analytical purity was controlled. The volume ratio of water ethanol to deionized water is 1:0.5~1:2.0, the liquid-solid ratio is 50:1~250:1, and the stirring time is changed within 2~5 minutes. The following examples are carried out to measure the test results. And calculate the dissolved SO 3 The content (mg / g), the results are shown in Table 1:

[0035] Table 1 Test results under different conditions

[0036]

[0037] As can be seen from the final result of the above table, adopt the numerical value in the ethanol extract concentration of the inventive method, liquid-solid ratio and stirring time change value range, all can accurately and effectively measure the alkali metal sulfate content in the cement, mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com