Patents

Literature

154 results about "Sulfallate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic, amber oil that is slightly soluble in water and soluble in most organic solvents. Sulfallate products are no longer used in the United States. Therefore, the potential for human exposure is low. When heated to decomposition, sulfallate emits toxic fumes of hydrochloric acid, nitrogen, and sulfur oxides. It is reasonably anticipated to be a human carcinogen. (NCI05)

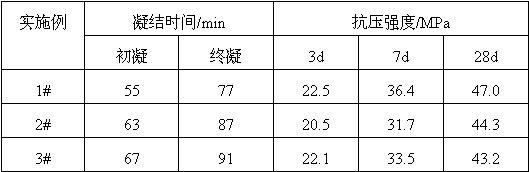

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

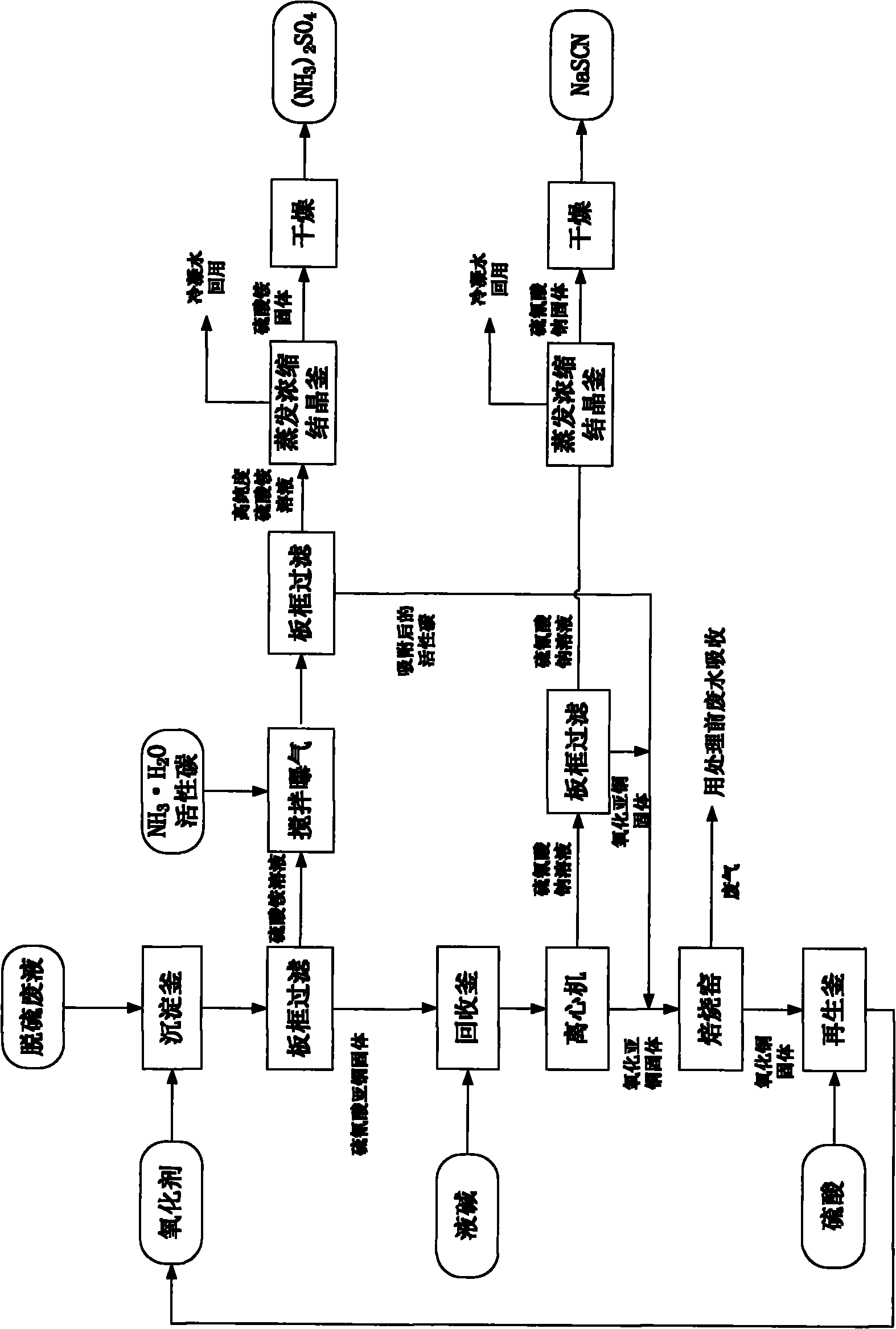

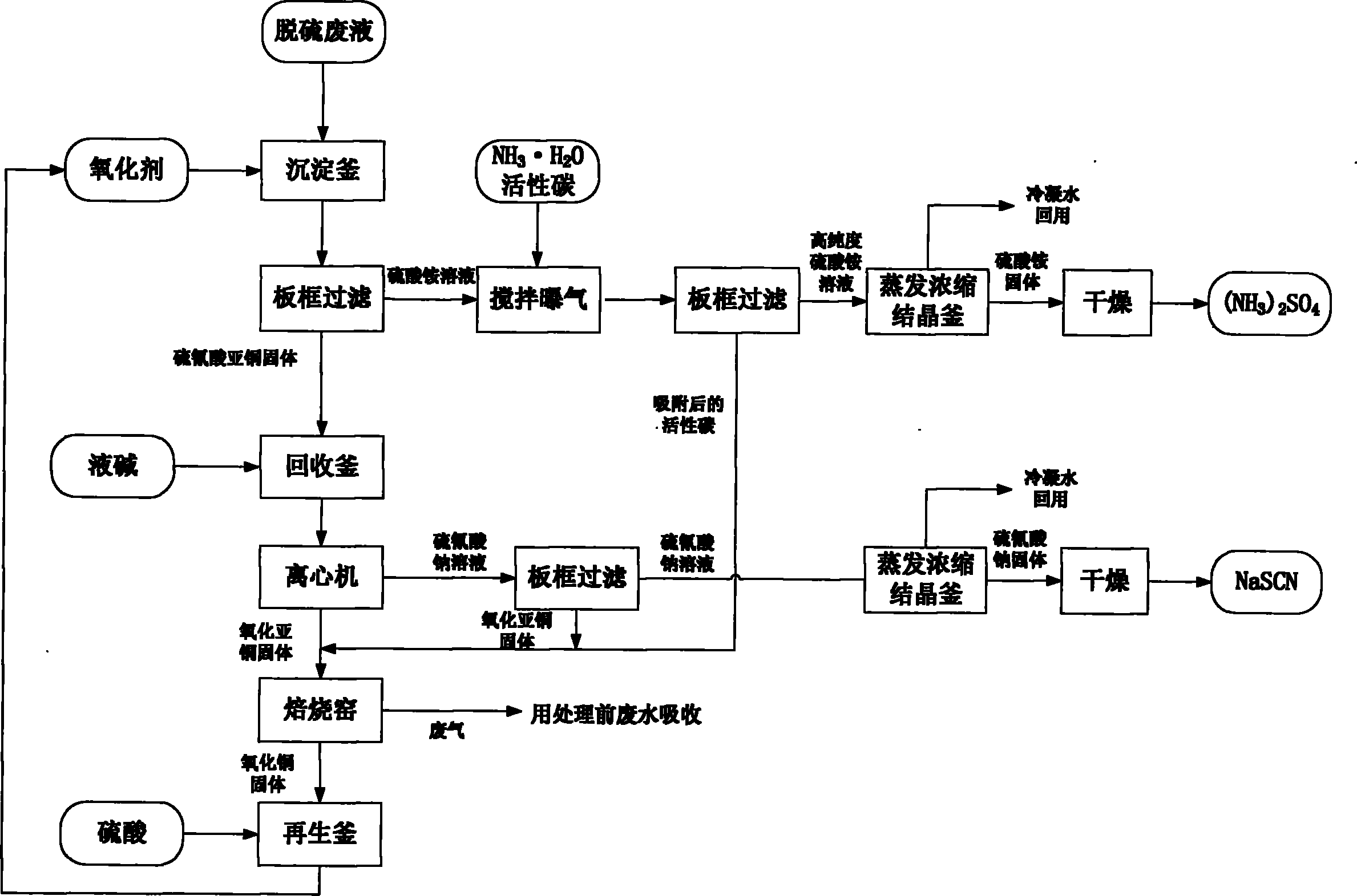

Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

ActiveCN101985359AReduce consumptionReduce lossesThiocyanic acidSulfate preparationActivated carbonSulfate

The invention relates to a method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in a coking plant, which comprises the following steps of: preparing saturated solution of copper sulfate, mixing the saturated solution with desulfuration waste liquor, and heating and stirring; performing solid-liquid separation to obtain a solid and sulfate liquid; adding aqueous alkali into the solid, heating at the temperature of between 50 and 98 DEG C, and stirring and reacting for 10 to 120 minutes; performing solid-liquid separation on slurry obtained by heating; concentrating the obtained liquid, and freezing for crystallizing and drying to obtain a high-purity thiocyanate product; calcining the obtained solid, adding solution of sulfuric acid, and stirring to produce the copper sulfate for circular use; adding activated carbon into the sulfate liquid, and aerating and oxidizing to purify sulfate; and concentrating the sulfate, and crystallizing and drying to obtain a high-purity sulfate product. The method solves the problem of pollution of the desulfuration waste liquor to the environment, and simultaneously, pollutants can become value products through the production of the high-purity thiocyanate product and the high-purity sulfate product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

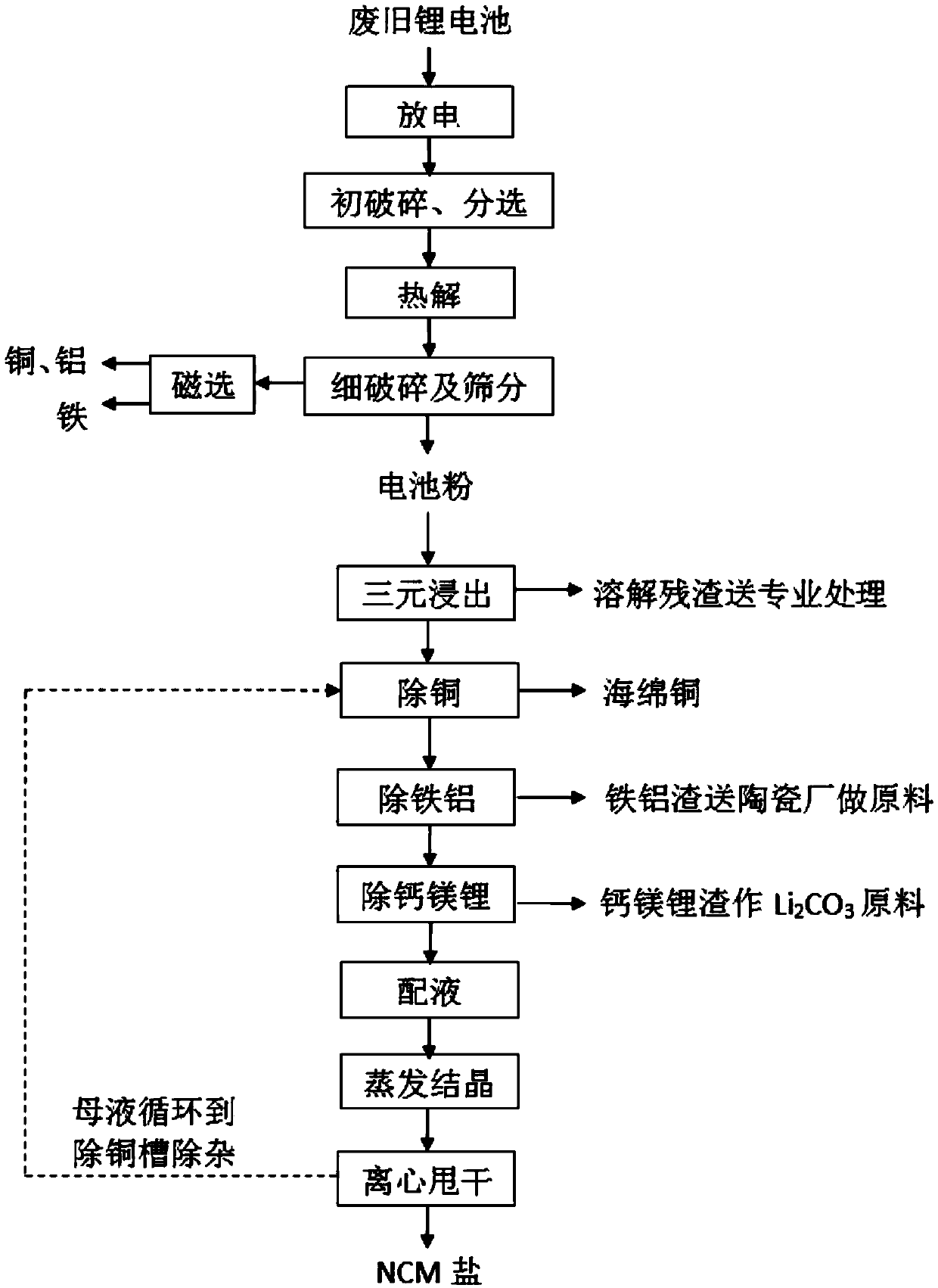

Method for recycling spent lithium-ion batteries to manufacture NCM salt

ActiveCN107768763AAchieve recyclingAchieving zero emissionsWaste accumulators reclaimingBattery recyclingPotassiumManganese

The invention provides a method for recycling spent lithium-ion batteries to manufacture NCM salt (a sulfate mixture containing nickel, cobalt and manganese). The process comprises the steps of crushing, pyrolyzing, sorting, leaching, purifying, dosing and crystalizing. The method provided by the invention has the beneficial effects that on one hand, no soluble alkali metal ions (such as potassiumand sodium) is carried in the whole production process, so that water recycling can be realized, wastewater zero discharging is realized, and a lot of water resources are saved; on the other end, after a purification liquid is dosed, a certain proportion of NCM salt is obtained by utilizing a crystalizing principle, so that an extraction process is avoided in the process, and the generation of alot of wastewater and waste gas is avoided. In addition, the NCM slat provided by the invention can be used as a raw material for producing a precursor, and according to a proportion requirement of the precursor material, bits of nickel sulfate, cobaltous sulfate and manganese sulfate are used for adjusting so as to accomplish the preparation before precursor synthesis, so that the process is simplified, and meanwhile, the production efficiency is improved.

Owner:湖北碧拓新材料科技有限公司

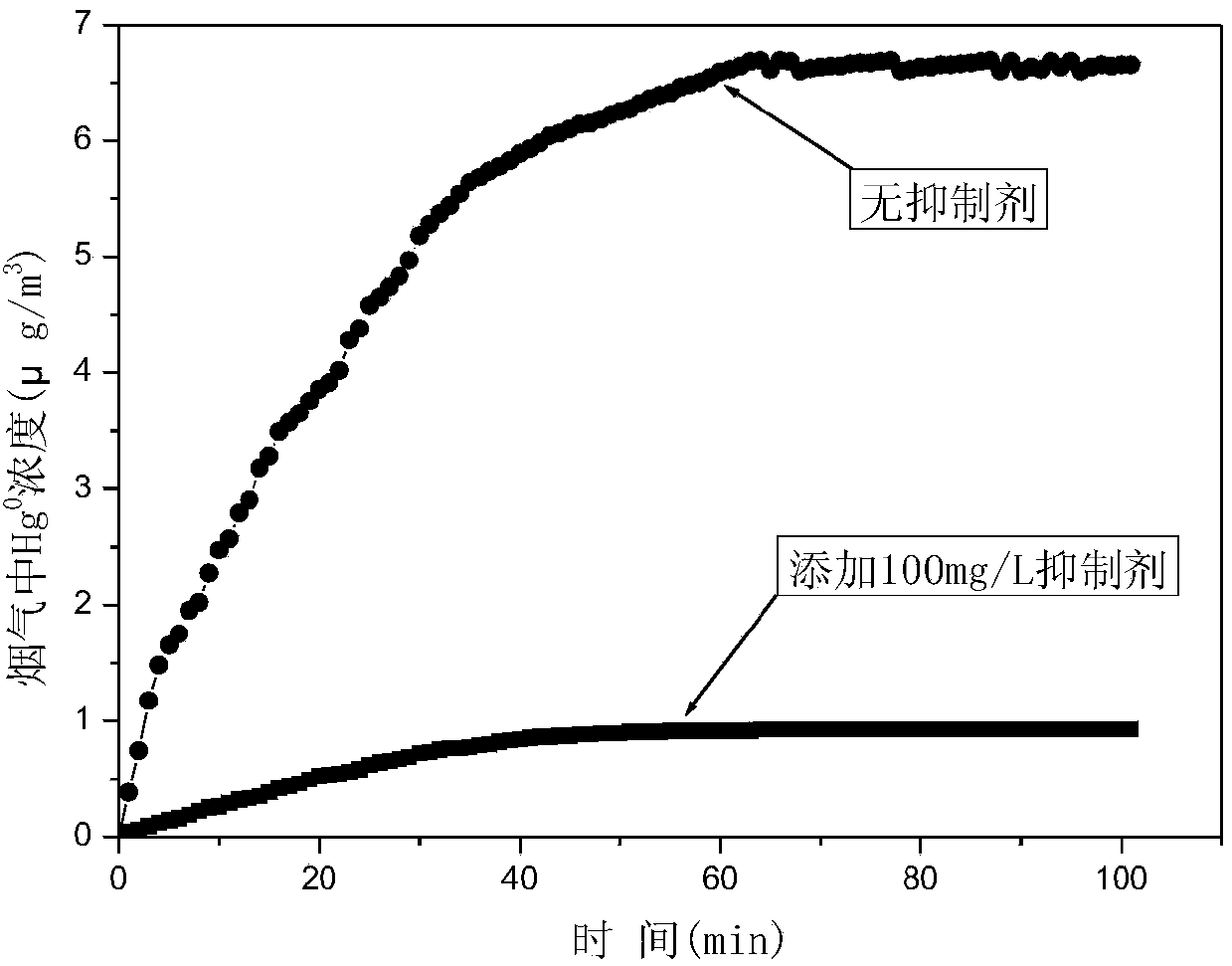

Mercury re-releasing inhibitor in wet flue gas desulfurization slurry and application method thereof

InactiveCN103736387AAvoid wastingEffective combinationDispersed particle separationSlurryMercury pollution

The invention discloses the technical field of flue gas demercuration method, and in particular to a mercury re-releasing inhibitor in wet flue gas desulfurization slurry and application method thereof. The inhibitor disclosed by the invention comprises the following components by weight percent: 25 to 45 percent of thiosulfate and 55 to 75 percent of sodium sulfide. The additive is added into the desulfurization slurry to inhibit the release of mercury; the adding amount of the additive is 100ml / L to 600mg / L. The inhibitor can react with Hg<2+> in the slurry well by utilizing the synergistic effect of thiosulfate and sodium sulfide to form stable HgS sediment; the sediment and desulfurization gypsum enter a solid phase together and are separated and removed. Meanwhile, the inhibitor disclosed by the invention is suitable for being added under the operating conditions of a wet desulfurization system, so that the waste of the additive is reduced. By the inhibitor, the re-release of the mercury in the limestone-gypsum wet flue gas desulfurization slurry can be inhibited effectively, the demercuration efficiency of a limestone-gypsum wet flue gas desulfurization system can be improved, and the problem of mercury pollution caused by coal-fired flue gas emissions can be solved effectively.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

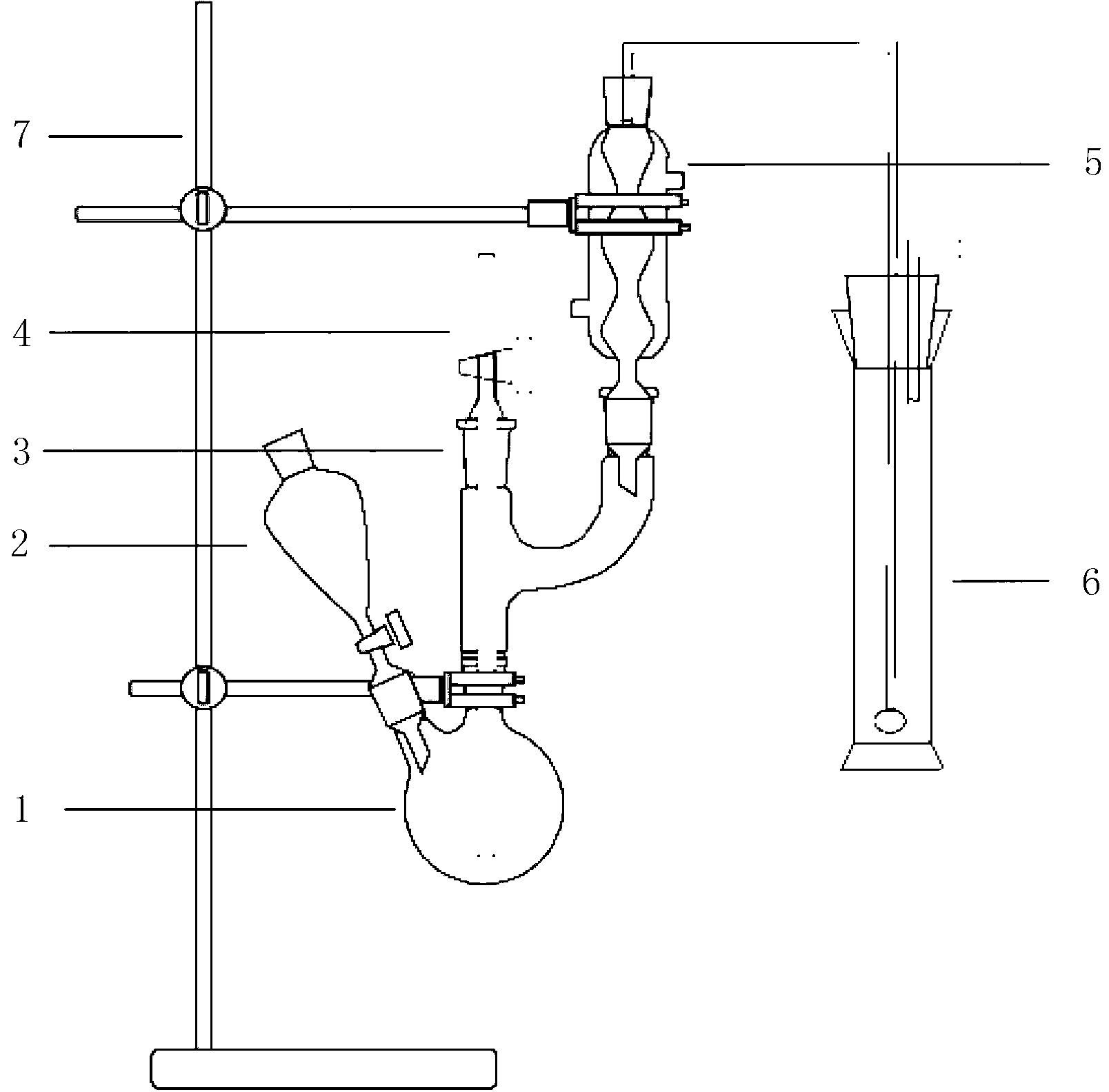

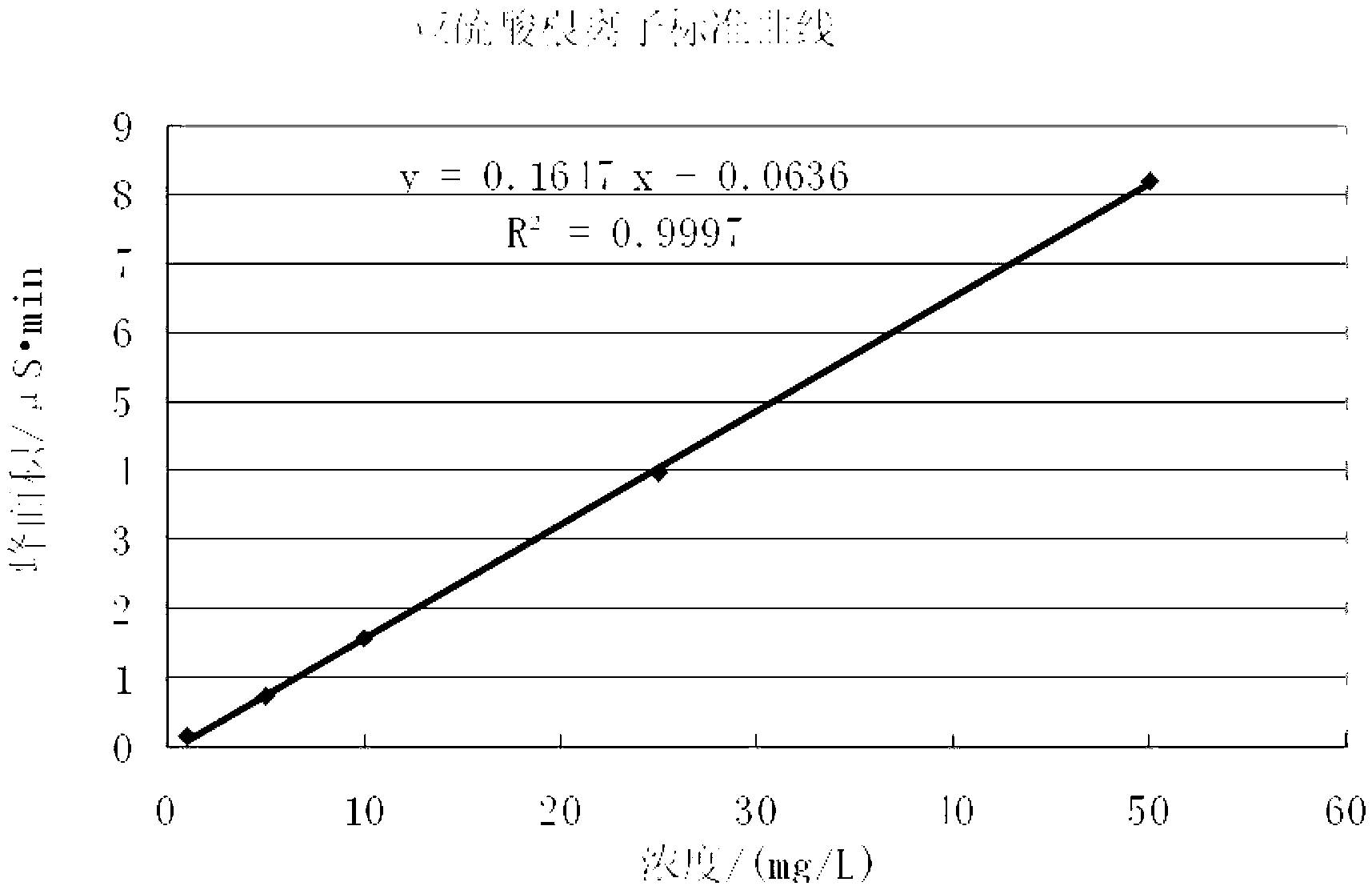

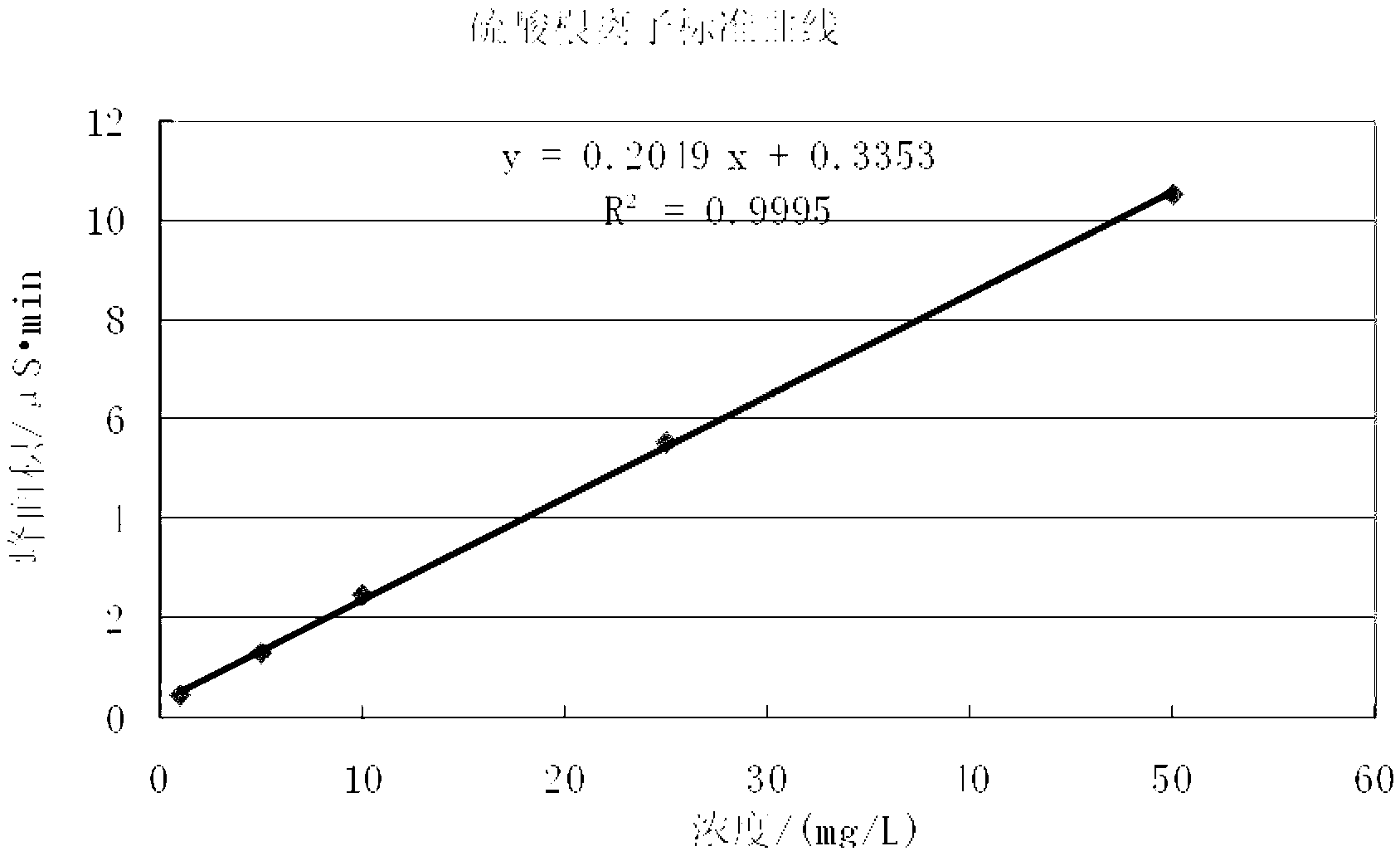

Sulphates content testing method in flue gas desulfurization system

InactiveCN101509909AImprove accuracy and reliabilityReliable methodChemical analysis using titrationChemical analysis using precipitationSulphate IonSulfite

The invention provides a test method of the sulphate content in a flue gas desulfurization system, relating to the technical field of a test method of the sulphate content in a desulphurization system. The test method is characterized in that two samples to be tested are taken simultaneously, wherein one sample is used for determining the sulphite content, and the other sample is used for determining the total content of the sulphite and sulphate; and the sulphate content is calculated by the difference between the total content of the sulphite and sulphate and the sulphite content. The test method has the positive effects that the method is accurate, thus greatly improving the accuracy and the reliability of analysis results of the sulphate in the desulphurization system, and providing reliable analysis results for the operation of the desulphurization system. As the sulphite content in the desulphurization system is an indispensable project to be tested in the conventional analysis, thus not increasing the workload when determining the sulphate content. As the test can be completed only by using an analytical instrument in a conventional laboratory, and a determining project and a determining instrument do not need to be increased, the test method is a very practical analysis method.

Owner:HEBEI ELECTRIC POWER RES INST

Method for continuously detecting content of sulfite and sulfide in building material and geological material

ActiveCN103063781AHigh sensitivityNo distractionComponent separationIon chromatographyPotassium hydroxide

The invention discloses a method for continuously detecting content of sulfite and sulfide in a building material and a geological material. The method comprises the following steps of: collecting a sample of the building material or the geological material, dissolving the sample together with hydrochloric acid and stannous chloride in a closed container, taking out released sulfur dioxide and hydrogen sulfide by using highly pure nitrogen or argon airflows, absorbing by using sodium hydroxide or potassium hydroxide solution, detecting the concentration of sulfite ions generated in the absorbed solution by using ion chromatography, thus obtaining the content of the sulfite through calculation; and oxidizing the absorbed solution by using hydrogen peroxide, wherein both the sulfite and the sulfide are oxidized into sulfate, detecting the concentration of sulfate ions by using the ion chromatography, and then obtaining the content of the sulfide by the measured concentration of the sulfate ions and the measured concentration of the sulfite ions through the calculation (subtraction method). The method plays an important role in detecting the content of the sulfite and that of the sulfide in the building material and the geological material, and the application prospect is brilliant.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

Bitumen mixture anti-stripping agent

InactiveCN103086628ASpeed up fusionEasy to integrateSolid waste managementAluminateAlkali activated slag

The invention discloses a bitumen mixture anti-stripping agent which consists of the following components in parts by weight: 30-50 parts of construction waste micropowder, 10-25 parts of alkali residue micropowder, 10-15 parts of coal gangue incinerator ash and 1-3 parts of additive, wherein the construction waste micropowder is formed by grinding construction waste (basically consisting of 20 percent of waste concrete and 80 percent of waste tiles) in which organic matters are removed; the coal gangue incinerator ash is coal gangue incinerator ash which is activated by keeping the temperature at 750-900 DEG C for 2.5-3 hours; and the additive is one or more of sulfoaluminate, silicate cement clinker and triethanolamine. Compared with like products in the prior art, the bitumen mixture anti-stripping agent has the advantages that the harm of chlorine salt and water to bitumen can be prevented, the anti-stripping agent is prevented from being decomposed due to heating, the environmental harm is avoided, and the price is low.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

SRR deodorant for treating sludge stink and deodoration method by using SRR deodorant

The invention discloses an SRR deodorant for treating sludge stink and a deodoration method by using the SRR deodorant. The deodorant is prepared from a free radical source, an active stimulator, a balance stabilizer and a long-acting promoter, wherein the free radical source is a mixture of a halogen free radical source, an SR free radical source and a hydroxyl free radical source; the deodorant can be used for sludge deodoration, and due to addition of the halogen free radical source in the deodorant, the problem that humic amine stink is difficultly solved by separated use of the SR free radical source and the hydrogen peroxide free radical source. High oxidation potentials such as SR free radical, hydroxyl free radical and halogen free radical produced after the deodorant is dissolved and activated in water can decompose almost all rhodanides, sulfur-containing organic substances, humic amine and other non-biodegradable stink compounds and toxic organic substances in the sludge, and the non-biodegradable stink compounds and toxic organic substances can be thoroughly converted into harmless inorganic substances such as inorganic sulfates, carbon dioxide (CO2) and water (H2O), and the stink of the sludge treated by adopting the technology can be alleviated to last for two to three days.

Owner:成都安捷芮环保科技有限公司

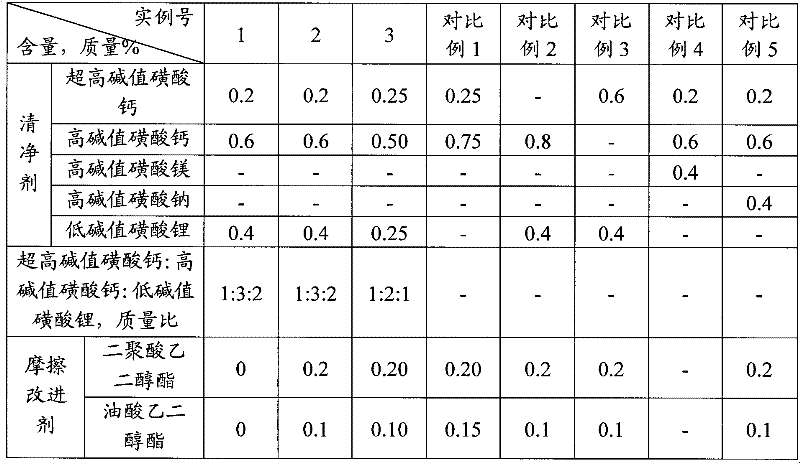

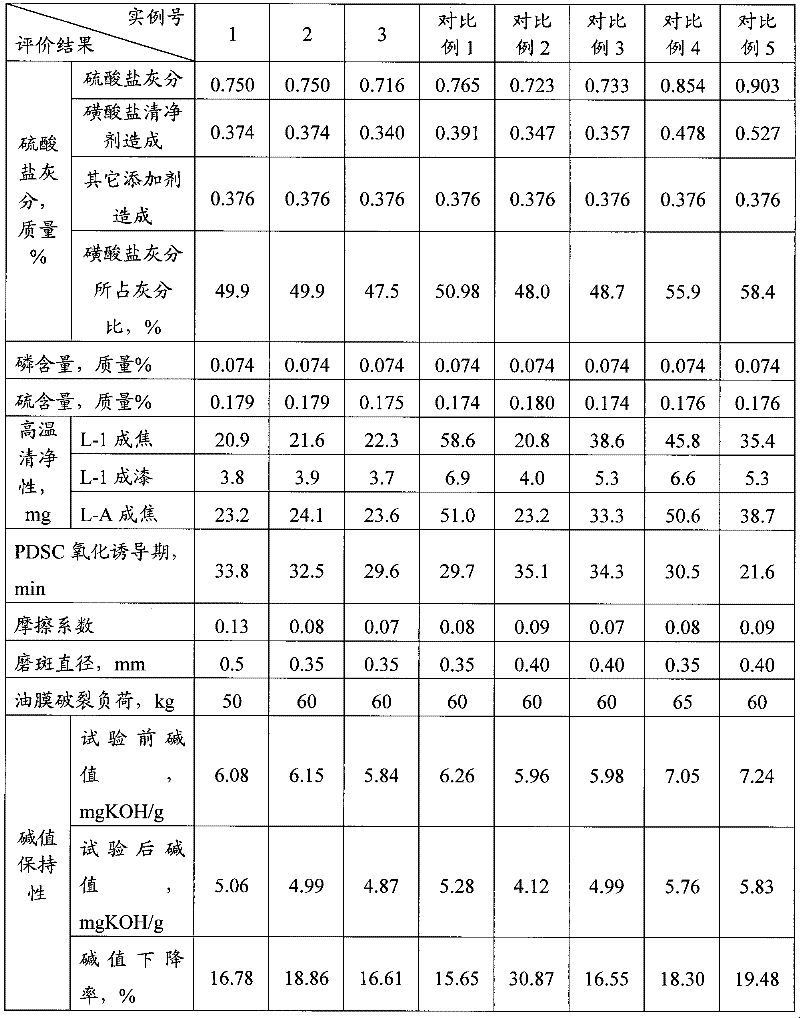

Lubricant composition for internal combustion engines

A lubricant composition for internal combustion engines is provided, which comprises a lubricant base oil and a sulfonate detergent, wherein the content of the sulfonate detergent is 0.8% to 1.5% (by weight) calculated on the basis of the composition; the sulfonate detergent comprises calcium sulfonate with a ultra-high base number more than 400 mg KOH / g, calcium sulfonate with a high base number of 300 to 350 mg KOH / g and lithium sulfonate with a base number less than 150 mg KOH / g. The lubricant composition has low contents of S, P and sulfuric ash, the additives used have a low cost and are easily available, and the economical efficiency is better. The lubricant composition can not only meet the requirements for normal operation of engines but also meet the requirements for normal operation of automobile exhaust gas recirculation (EGR) systems.

Owner:CHINA PETROLEUM & CHEM CORP +1

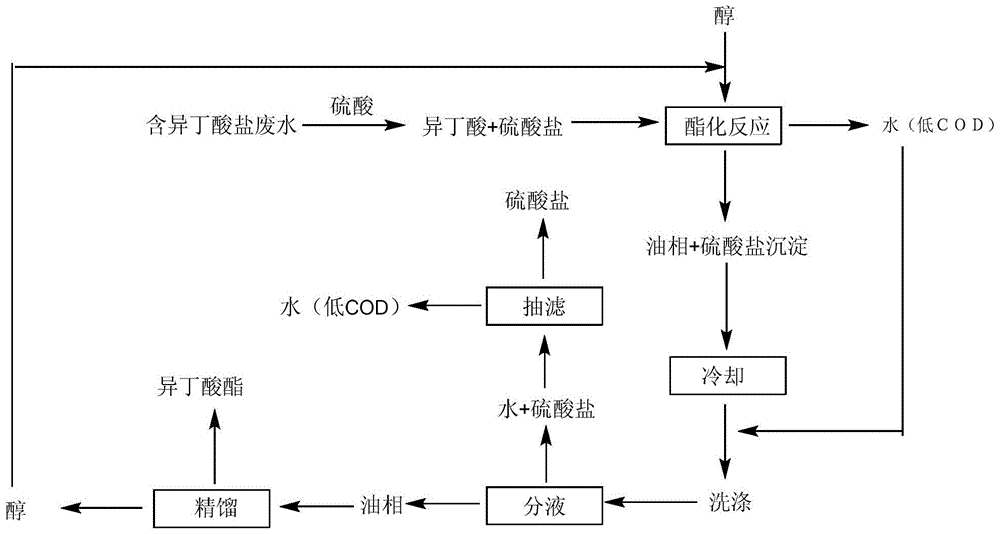

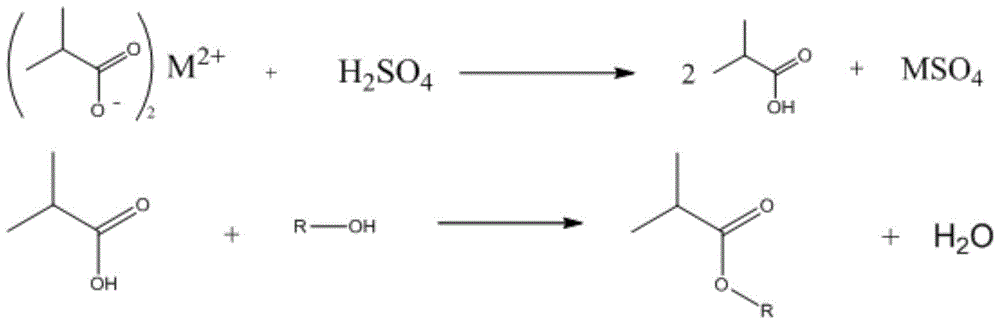

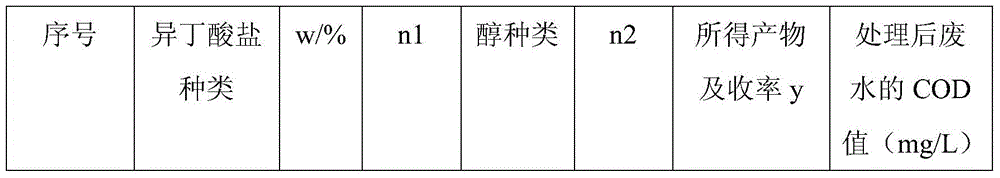

Method for treating isobutyrate-containing wastewater by alcohol etherification

ActiveCN105712874AReduce solubilityEasy to separateOrganic compound preparationWater contaminantsAlcoholSulfate

The invention discloses a method for treating isobutyrate-containing wastewater by alcohol etherification, comprising the following steps: 1), acidifying isobutyrate-containing wastewater with concentrated sulfuric acid, adding alcohol, subjecting a reaction system to etherification under reflux condition so as to generate isobutyrate, and stopping reacting until no water is generated in the reaction system; 2), cooling reaction liquid obtained in step 1) to room temperature, re-adding water separated from the reaction system and obtained in step 1), into the cooled reaction liquid, and stirring and standing to obtain oil phase and water phase; subjecting the water phase to solid-liquid separation to obtain low-COD wastewater and sulfate; 3), rectifying the oil phase obtained in step 2); collecting an alcohol fraction and an isobutyrate fraction. The wastewater treated by the method has low COD value.

Owner:宁波永顺精细化工有限公司

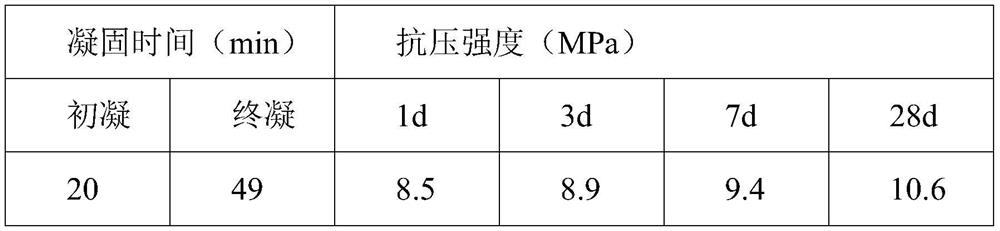

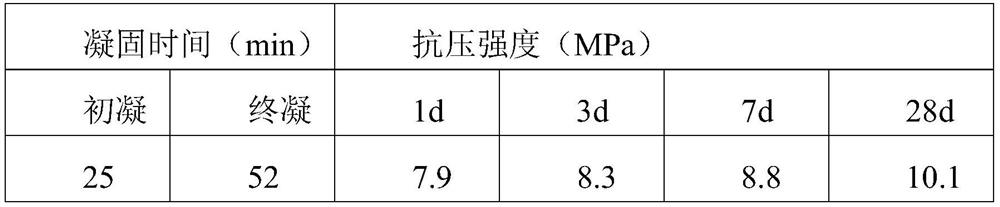

Low-cost quick-setting expansible hole-sealing material applied to coal mine

The invention discloses a low-cost quick-setting expansible hole-sealing material applied to coal mine. The low-cost quick-setting expansible hole-sealing material applied to the coal mine is prepared from the following raw materials: 30-50 parts of coal gasification fine ash, 25-35 parts of sulpho aluminate cement, 0.04-0.15 part of citric acid, 5-10 parts of quick lime, 20-25 parts of gypsum and 2-3 parts of sodium hydroxide. The low-cost quick-setting expansible hole-sealing material applied to coal mine has the advantages that a large amount of coal gasification fine ash which is industrial solid waste (the waste of coal chemical industry) is added into the raw materials, and the waste is utilized and is changed into wealth; the cost of the hole-sealing material is greatly reduced to 600 RMB per ton under the condition that the strength and expansion rate meet the requirements. The hole-sealing material is innocuous, unpoisonous and pollution-free, can be used for sealing holes in gas drainage of the coal mine and can also be used for sealing holes, opening sealing and blocking leakage air during post-grouting and reinforcing of walls of coal mine laneways; the large amount of the coal gasification fine ash is added into the raw materials, so that the hole-sealing material has obvious environmental protection significance; an important thinking is provided for clean production in the coal chemical industry.

Owner:HENAN INST OF ENG

Hypochlorite denture compositions and methods of use

ActiveUS20110027194A1Minimizes and eliminates formation of residueDissolve fastInorganic/elemental detergent compounding agentsCosmetic preparationsDicarbonateAlkaline earth metal

A solid composition including calcium and / or magnesium hypochlorite, a builder (e.g., one or more of carbonate, bicarbonate, sesquicarbonate), an acid, a water-soluble polymer, at least one anionic surfactant, and optionally, a hydrotrope. The composition does not include any potassium hypochlorite, sodium hypochlorite, lithium hypochlorite, N-halogenated compounds, peroxides, persulfates, hydantoins, isocyanurates, or carboxylic acids that also have hydroxyl, amino, amido, imino, or imido groups. Upon dissolution of the composition in water, the calcium and / or magnesium hypochlorite and acid react to form hypochlorous acid. The use of hypochlorous acid, rather than direct use of an alkaline or alkaline earth hypochlorite results in a composition that is typically acidic rather than basic, and that results in improved cleaning. The composition is particularly suited for cleaning and disinfecting dentures.

Owner:THE CLOROX CO

Saline soil curing agent and technical applications thereof

InactiveCN101289850AImprove structural strengthImprove structural stabilityOrganic fertilisersSoil conditioning compositionsAluminateNatural mineral

The invention provides a saline soil curing agent and a method for applying the same in engineering. The mixture ratio of raw materials of the curing agent in portion by weight is: 17-22 portions of silicate, 20-30 portions of aluminate, 18-22 portions of ferrous aluminate, 10-15 portions of sulphate, 8-13 portions of silicon dioxide, 15- 20 portions of sulpho-aluminate, 3-7 portions of chloride and 2-4 portions of oxide. The saline soil curing agent is formed by mixing a plurality of natural mineral materials and inorganic substances. The production process of the curing agent is simple mechanical mixture, and the production cost is low. Powder solids which meet granularity requirements and are very extensive in source are adopted as the raw materials. Products of the invention are off-white powder solids, have the fineness degree over 200 mesh, are scentless and nontoxic, and have the shelf life of 18 months under dry conditions.

Owner:凌贤长 +1

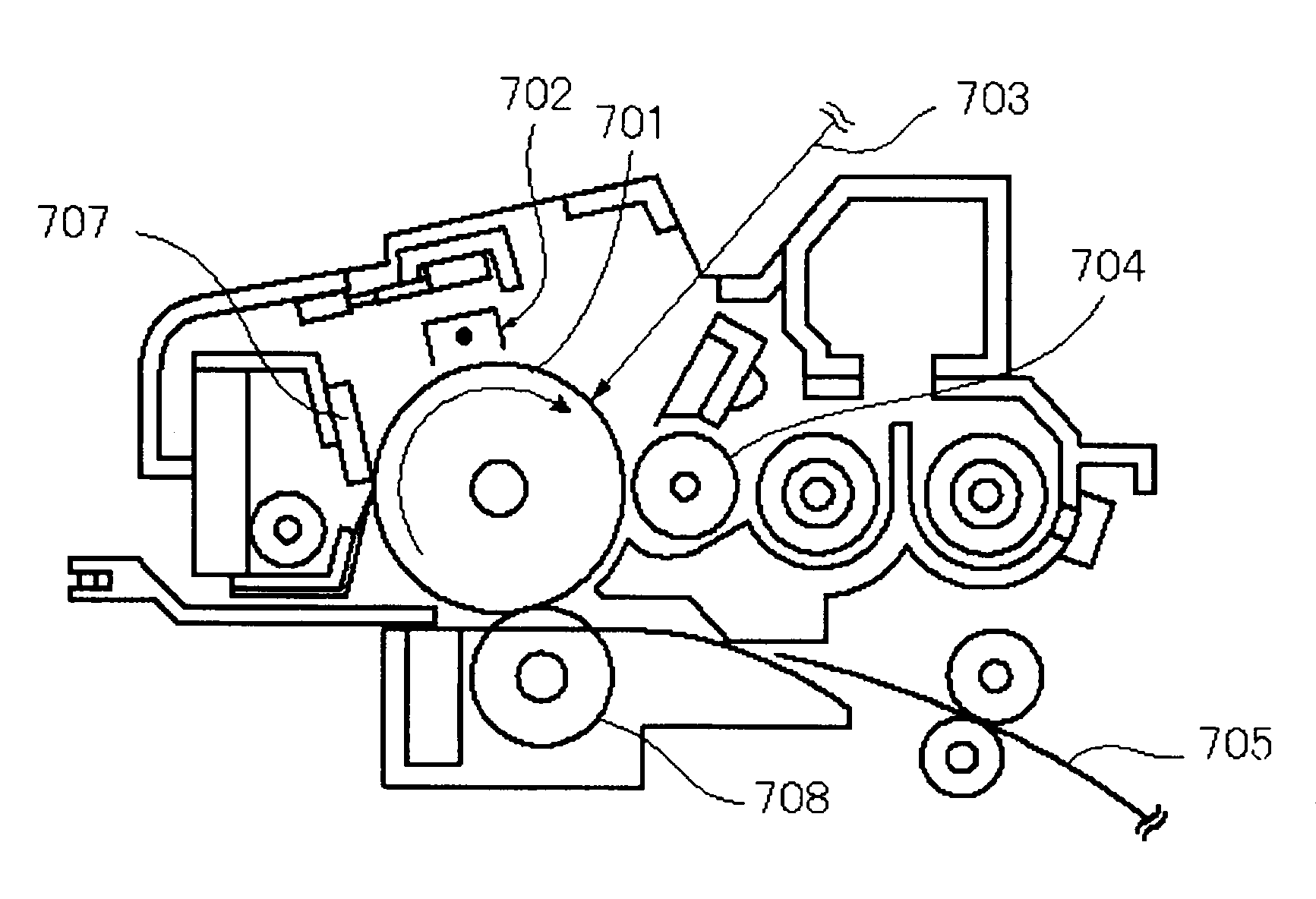

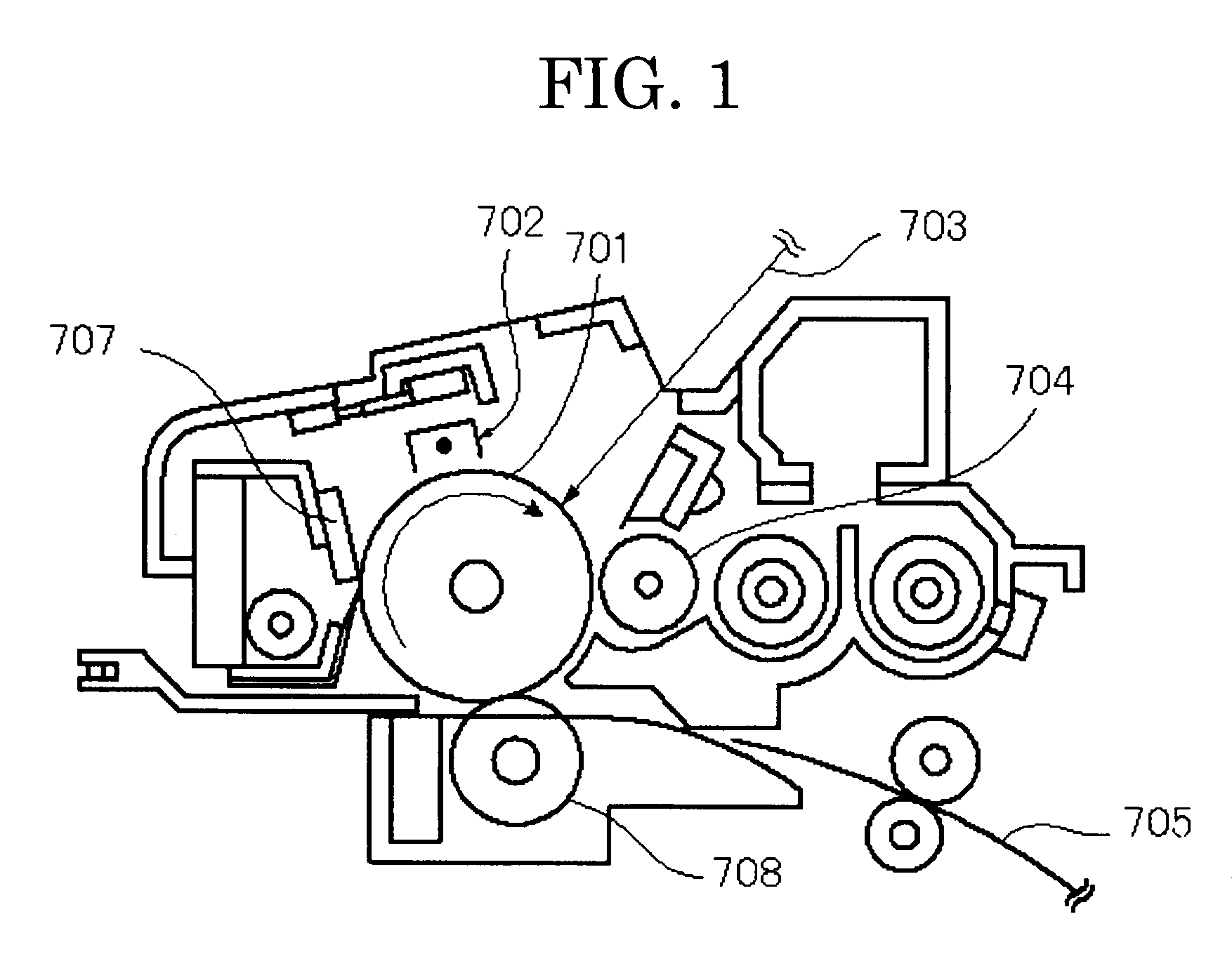

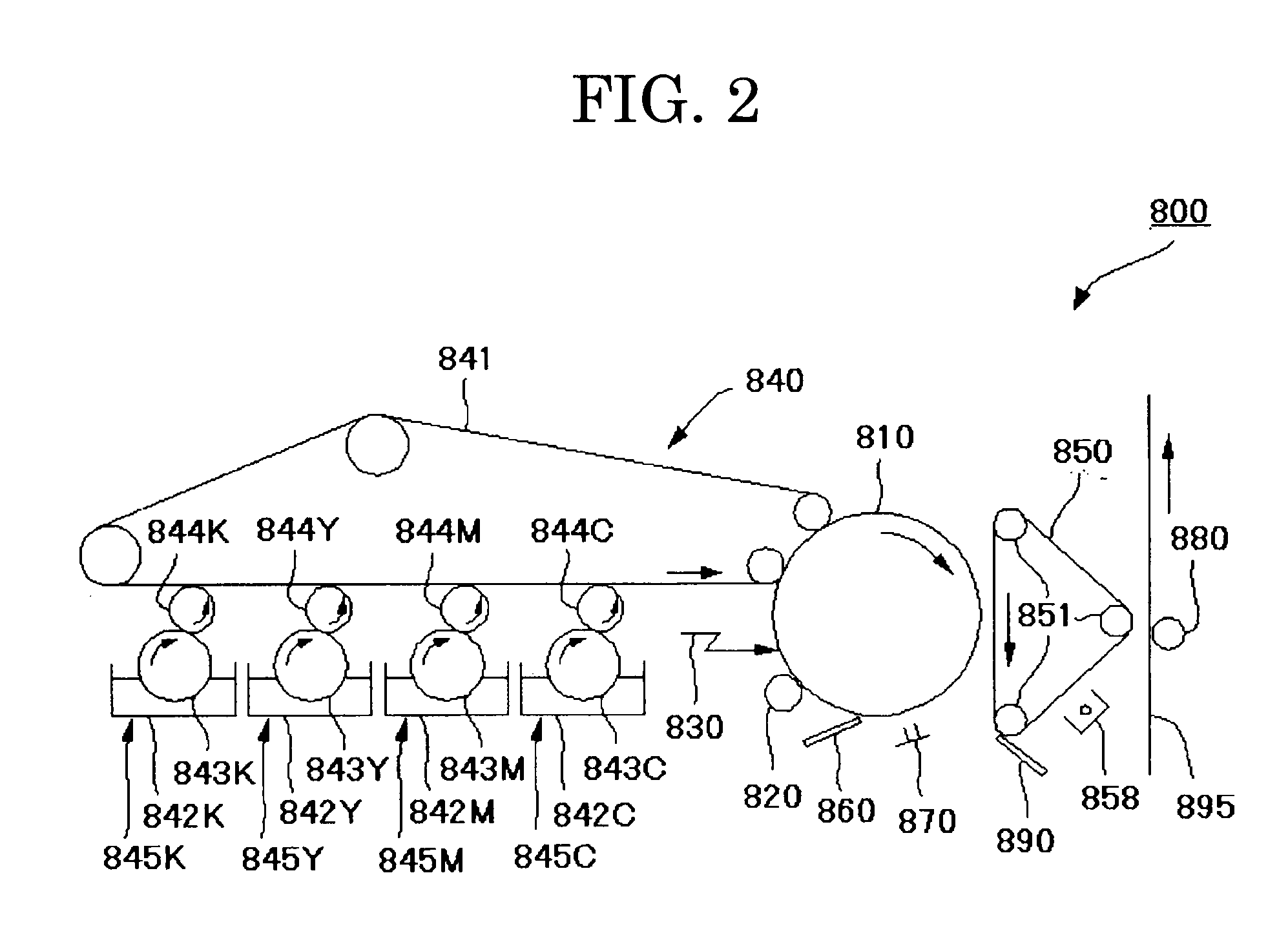

Toner for developing electrostatic charge image, image forming method and image forming apparatus

InactiveUS20090170019A1Good transferabilitySuperior in cleaning abilityElectrographic process apparatusDevelopersSulfateImage formation

To provide a toner for developing an electrostatic charge image, the toner containing at least a colorant obtained by reacting a polymer with a basic dye, wherein the polymer contains 10 mol % or more of a monomer unit having any one of a sulfonic acid group, a sulfonic acid salt group, a sulfuric acid group and a sulfuric acid salt group as a constitutional unit, and the toner is obtained by forming a toner composition liquid containing at least the colorant into oil droplets in an aqueous medium, and solidifying the oil droplets into solid particles.

Owner:RICOH KK

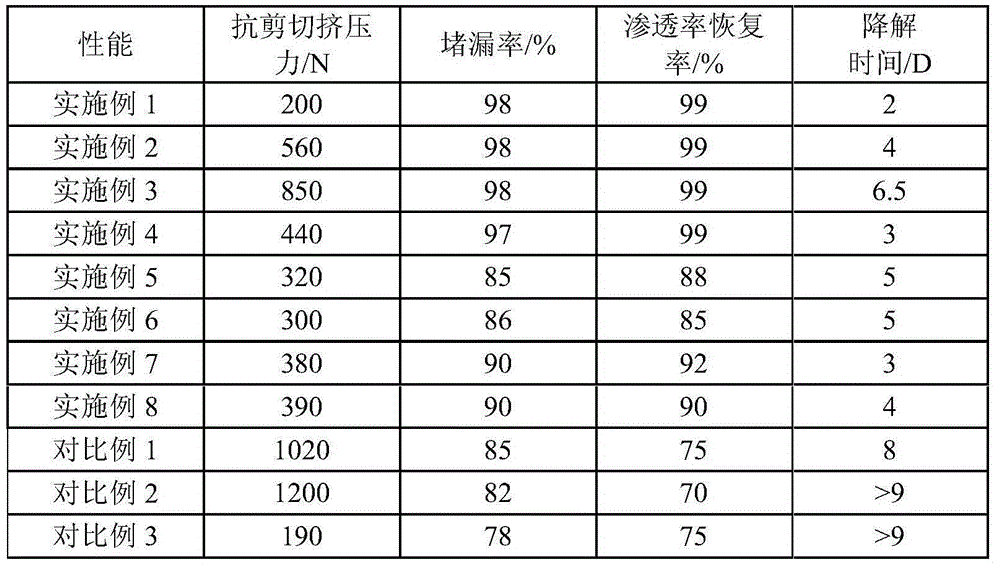

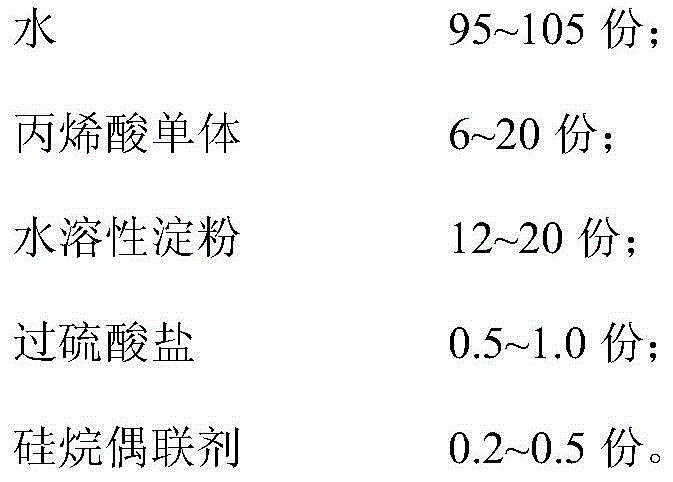

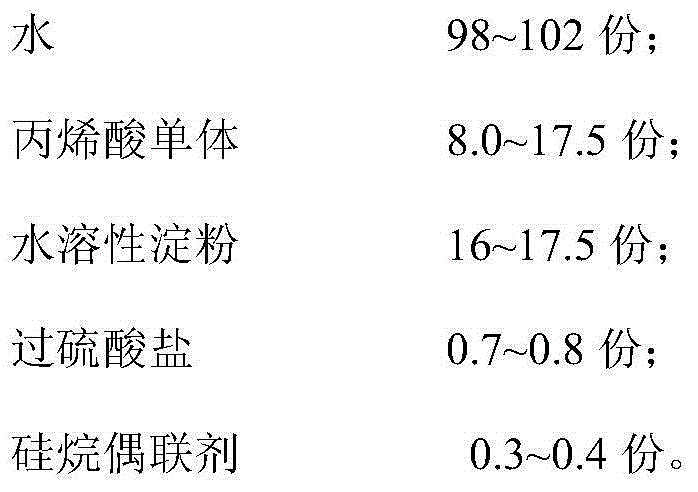

Self-degradable leaking-prevention and stoppage material and preparation method thereof, self-degradable leaking-prevention and stoppage product and application thereof

The invention provides a self-degradable leaking-prevention and stoppage material and a preparation method thereof, a self-degradable leaking-prevention and stoppage product and an application thereof. The self-degradable leaking-prevention and stoppage material comprises the following raw materials in mass by part: 95-105 parts of water, 6-20 parts of an acrylic acid monomer, 12-20 parts of water-soluble starch, 0.5-1.0 parts of persulfate, and 0.2-0.5 parts of a silane coupling agent. In the above raw materials, the acrylic acid monomer is taken as a polymeric monomer, sulfate is taken as an initiator for initiating polymerization of acrylic acid, a silane coupling agent is used for coupling water-soluble starch and the acrylic acid monomer, at the same time, by controlling the usage amount of the raw materials in the above ratio scope, synergism between raw materials is optimized, and the self-degradable leaking-prevention and stoppage material has excellent permeability restoration ratio and self-degradation performance.

Owner:PETROCHINA CO LTD

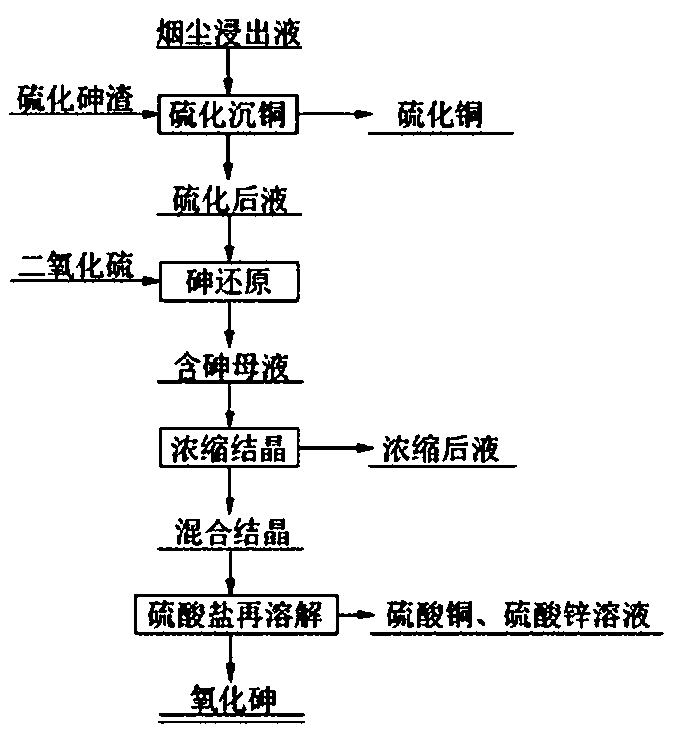

Comprehensive recovery method for arsenic in arsenic sulfide residues and smoke leaching liquid in copper smelting

InactiveCN108249480AHarmless maximizationMaximize resourcesZinc sulatesArsenic oxides/hydroxides/oxyacidsRecovery methodVulcanization

The invention provides a comprehensive recovery method for arsenic in arsenic sulfide residues and a smoke leaching liquid in copper smelting. The smoke leaching liquid and the arsenic sulfide residues are subjected to normal-pressure vulcanization copper precipitation treatment to obtain solid state copper sulphide and a vulcanized liquid; the vulcanized liquid is discharged into a reaction tankII, and sulfur dioxide is introduced into the reaction tank II to make the vulcanized liquid converted into an arsenic-containing mother liquid; the arsenic-containing mother liquid is discharged intoa reaction tank III, the arsenic-containing mother liquid is subjected to concentration and crystallization, and filtration is performed to obtain a sulfate mixed crystal and a concentrated liquid; the sulfate mixed crystal is added into a reaction tank IV, copper sulfate and zinc sulfate in the sulfate mixed crystal are dissolved into water, and filtration is performed to obtain arsenic oxide and a solution of the copper sulfate and the zinc sulfate. The method provided by the invention has the advantages that the process collocation is reasonable, parameters in each process are strictly controlled, the arsenic can be safely disposed, and valuable elements such as copper, lead and zinc are recycled and effectively utilized, the purposes of environmental protection, economy, energy conservation and a high resource utilization rate are achieved, and harmlessness and resource utilization maximization of the arsenic are realized.

Owner:DONGYING FANGYUAN NONFERROUS METALS +2

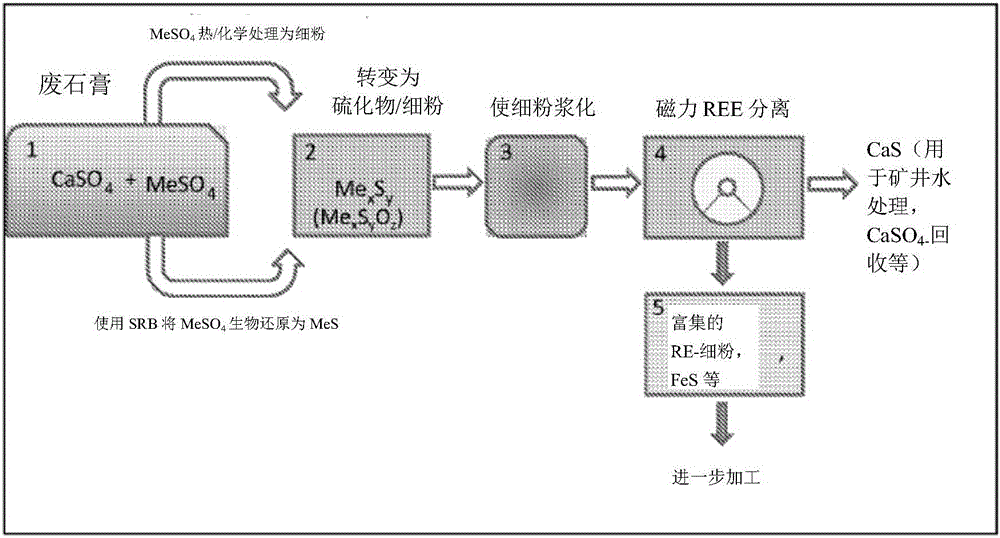

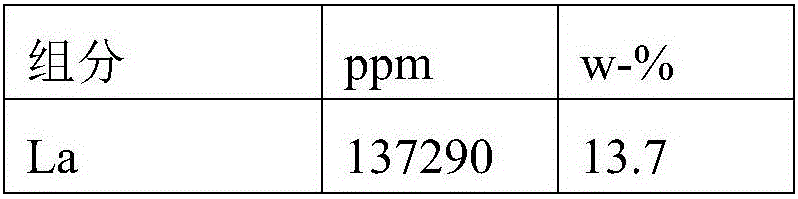

Method for recovering rare earth metals from waste sulphates

InactiveCN105765091ALow costHigh gradient magnetic separationRare earth metal sulfidesRare-earth elementMagnetic susceptibility

The present invention relates to a method for recovering rare earth metals from waste sulphate materials, such as waste gypsum, which is a known secondary resource of rare earth metals and widely present e.g. in areas, where industrial phosphate production takes place. The present invention combines sulphate reduction treatment, such as bioreduction with sulphate reducing bacteria, and magnetic separation, which is based on an exceptionally high magnetic susceptibility of rare earth compounds compared to e.g. calcium compounds in such reductively pretreated gypsum precipitate.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

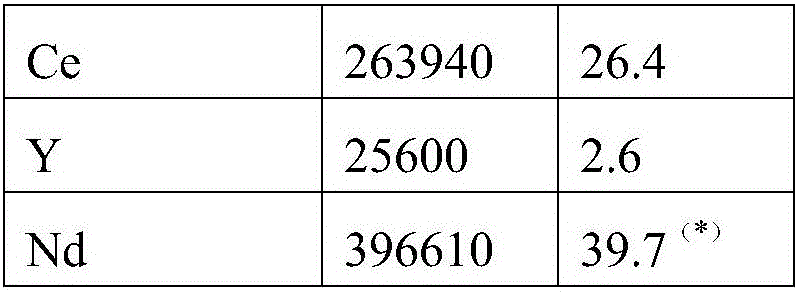

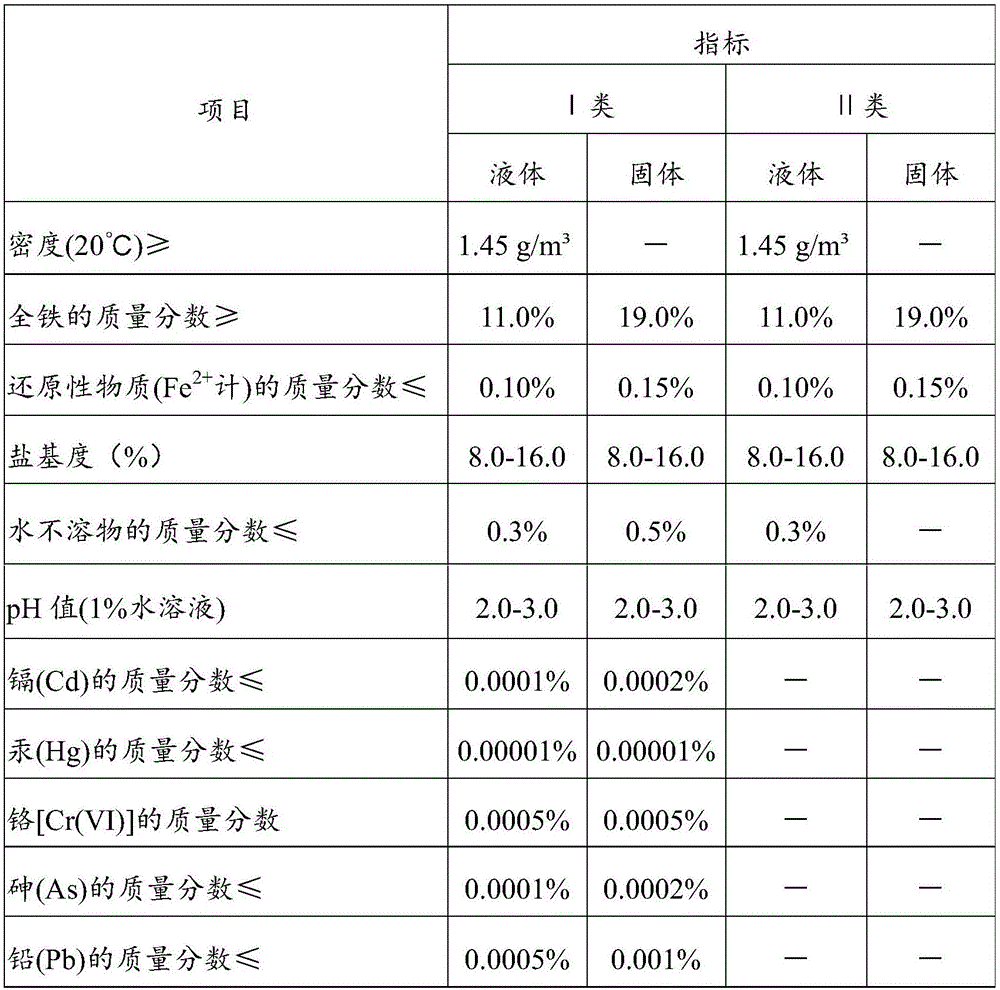

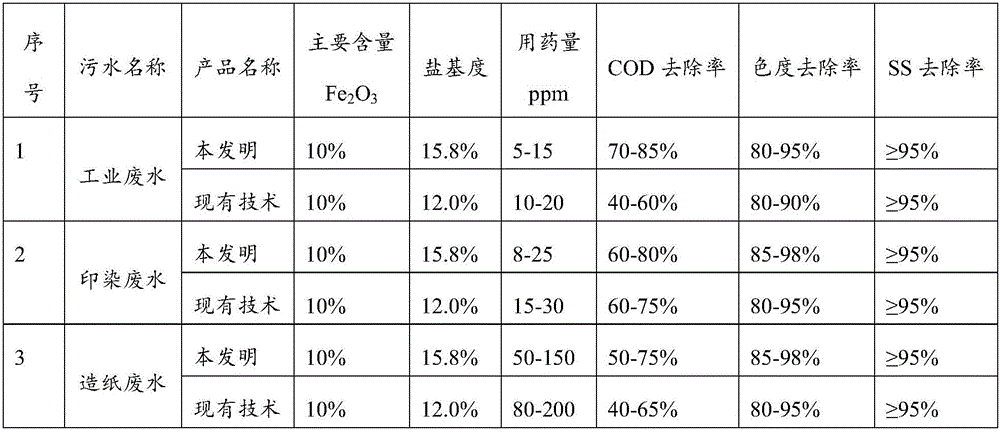

Polyferric sulfate and preparation method of polyferric sulfate

ActiveCN105692717AAdjust the reaction temperatureIncrease acidityIron sulfatesWater/sewage treatment by flocculation/precipitationRare earthIron(III) sulfate

The invention discloses polyferric sulfate as well as a preparation method and a preparation device of the polyferric sulfate. The preparation method comprises the following steps: conveying the following components into a mixing tank in percentage by weight: 40 percent to 50 percent of iron sulfate heptahydrate and 60 percent to 50 percent of titanium dioxide waste sulfuric acid, and blending the materials; adjusting the concentration range of the titanium dioxide waste sulfuric acid H2SO4 to be 21 percent to 23 percent to obtain mixed reaction materials; conveying the reaction materials into a reaction tower, and adding a sulfate composite rare-earth solution as a reaction cocatalyst when conveying the reaction materials into the reaction tower; controlling the temperature in the reaction tower to be 40 DEG C to 60 DEG C; after all the blended materials enter the reaction tower, adding a sodium nitrite solution as a reaction catalyst; continually introducing oxygen gas into the reaction tower so that the oxygen gas and the reaction materials make oxidization, hydrolysis and polymerization reactions under the action of the cocatalyst and the catalyst; after effectively converting Fe<2+> ions in the materials into Fe<3+> ions, obtaining liquid polyferric sulfate. With the adoption of the polyferric sulfate as well as the preparation method and the preparation device of the polyferric sulfate, the production efficiency can be greatly improved, environmental hazards are reduced, and a more prominent water purification and coagulation effect is realized.

Owner:广西继禹环保科技有限公司

Method for determining content of sulfite in wet desulphurization slurry

ActiveCN103149201AImprove accuracyImprove reliabilityMaterial analysis by observing effect on chemical indicatorSodium acetateSlurry

The invention relates to a method for determining the content of sulfite in a wet desulphurization slurry. The method comprises the following determination steps: 1, adding 50ml of an acetic acid-sodium acetate buffer solution having a pH value of 4.0-5.7 and 10.00ml of a 0.1mol / L iodine standard solution to a stopper possessed measuring flask; 2, adding a tested sample filtrate until the iodine solution becomes flavescent or tannish, and carrying to a laboratory under a dark condition; 3, adding 1ml of a 1% starch solution to make the tested sample become blue; 4, titrating the sample solution with a 0.1mol / L sodium hyposulfite standard solution until the blue color disappears, and recording the consumption amount of the sodium hyposulfite standard solution; carrying out a blank experiment; and 6, calculating to obtain the content of sulfite. The method which allows the buffer solution to be added in the sampling process has the advantages of avoiding of the oxidation in the sampling process, prevention of the interference of components comprising S2O3<2-> and the like in the test process, increase of the interference resistance of the slurry in the sampling and testing process, and improvement of the accuracy and the reliability of the test result.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

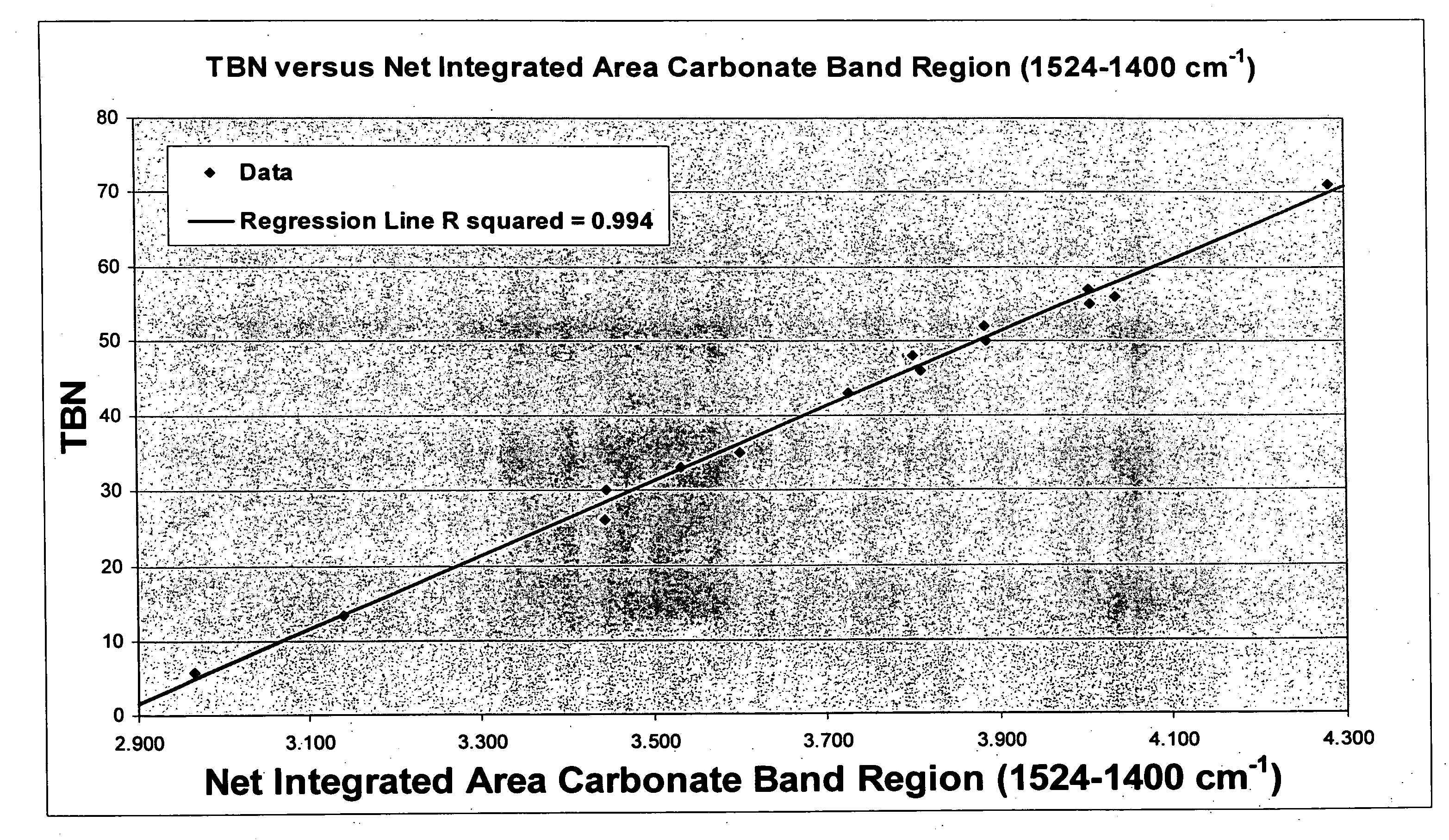

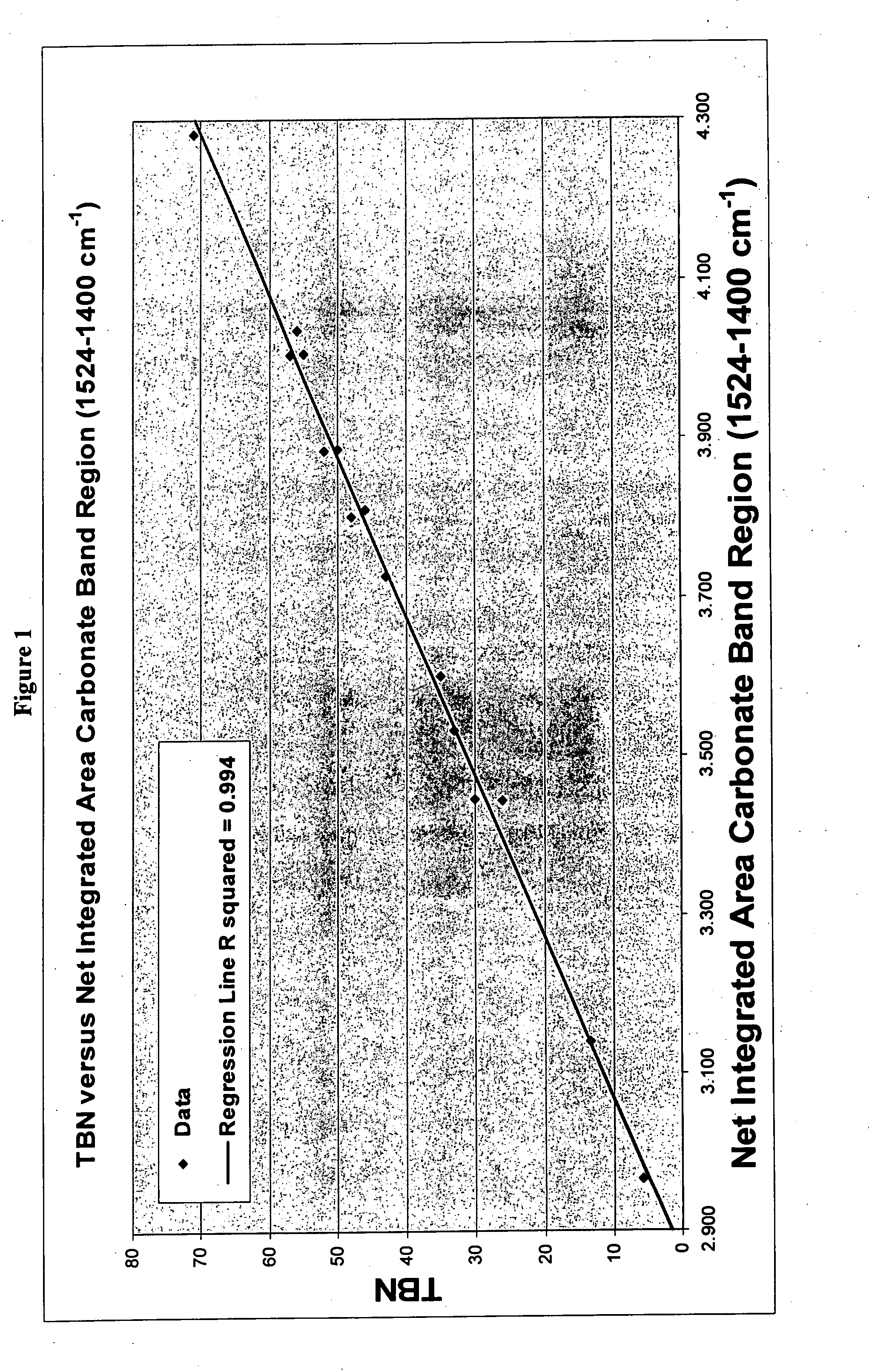

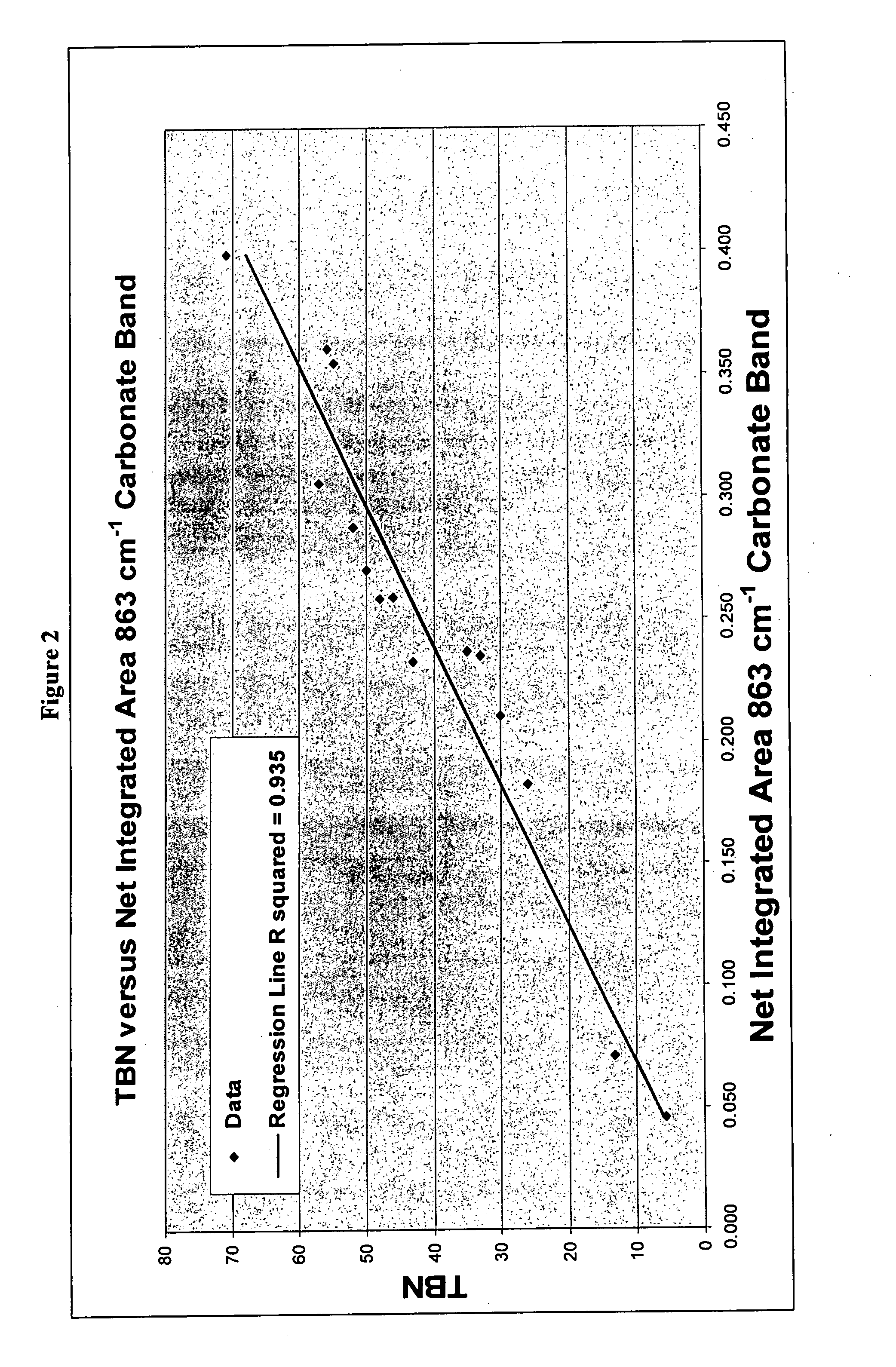

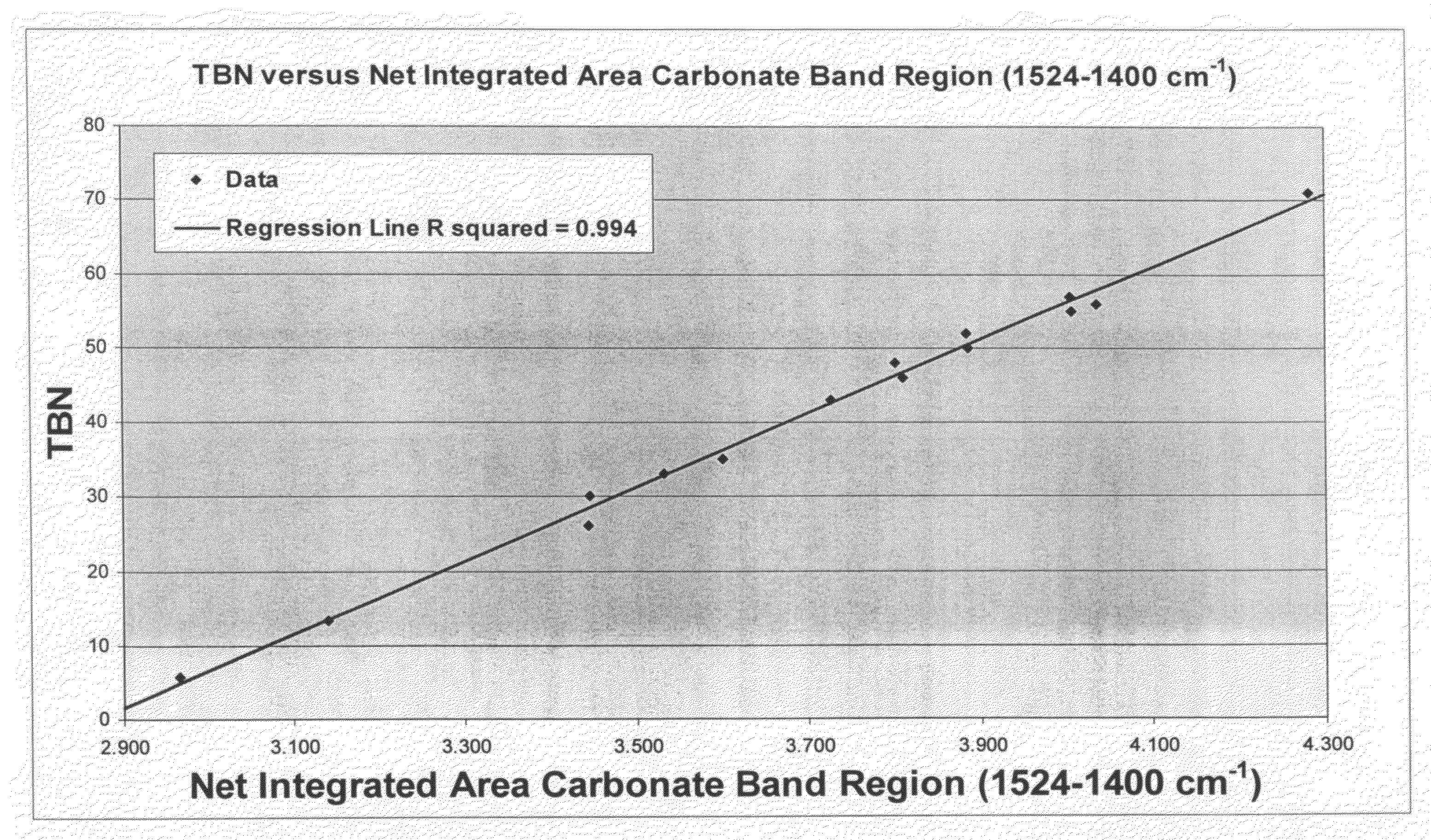

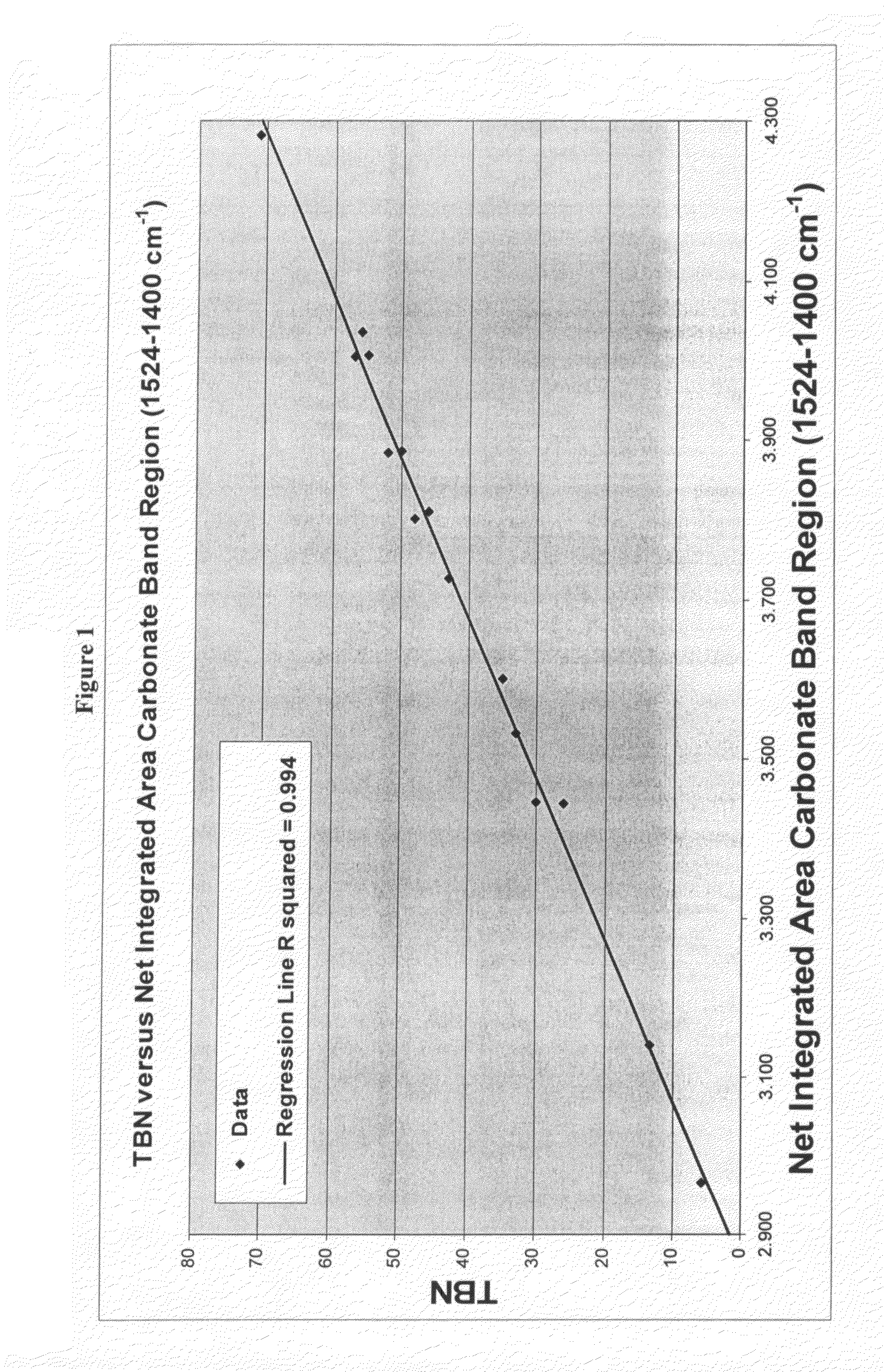

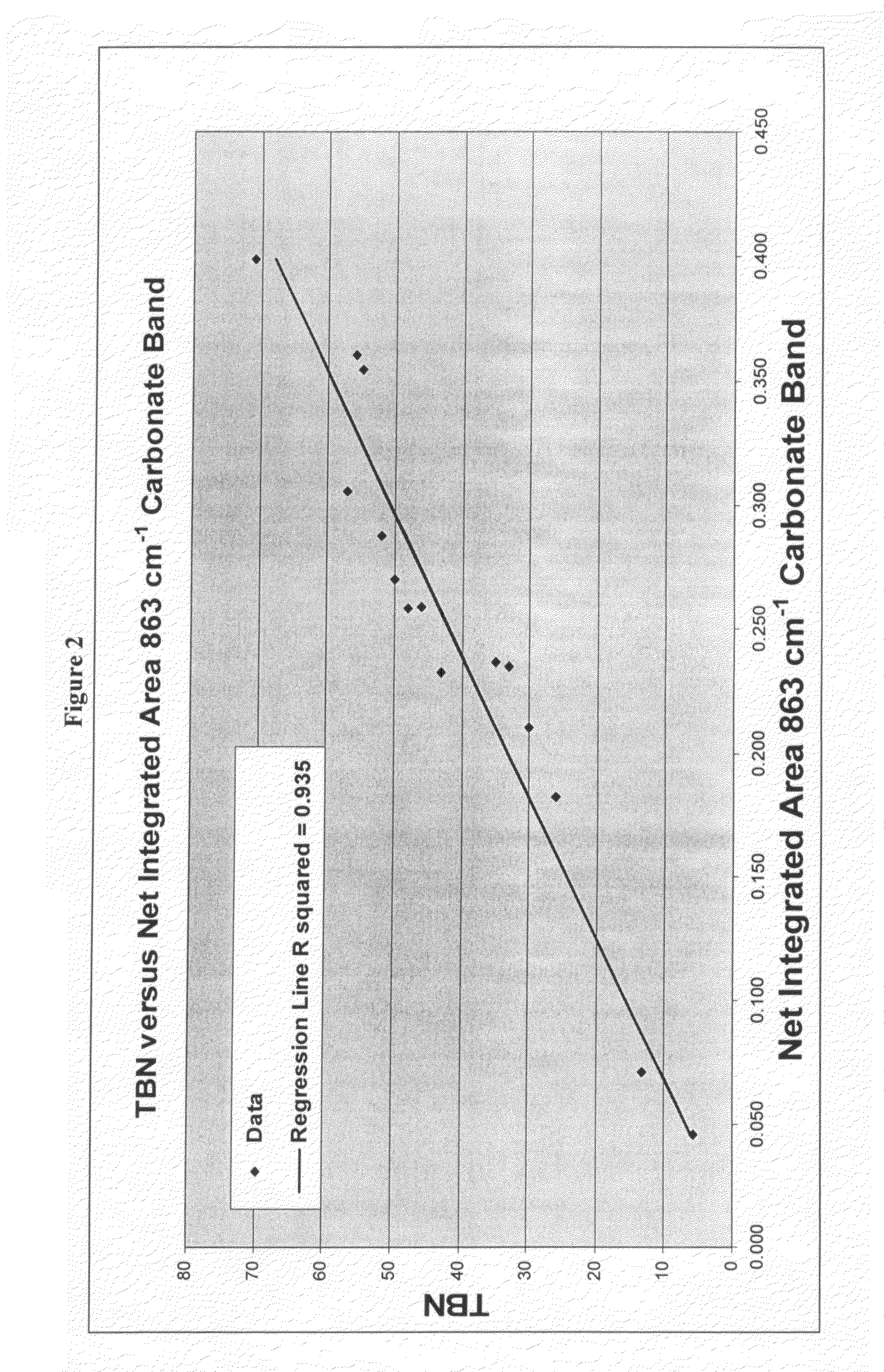

Infrared spectroscopy method for measuring the base number of overbased lubricants

The present invention provides a method for measuring a lubricant's total basicity by measuring one or more preselected infrared absorption bands of a lubricant and correlating the measured bands to the basicity. Preferably, the measured bands are due to carbonate or sulfate species in the lubricant.

Owner:EXXON RES & ENG CO

Preparation method for 2,4,6-trimethyl pyridine

ActiveCN102372667AIncrease concentrationThe recovery rate did not drop muchOrganic chemistrySulfatePyridine sulfate

The invention discloses a preparation method for 2,4,6-trimethyl pyridine. The method comprises the following steps of: adding raw materials of 2,4,6-trimethyl pyridine, an industrial ethanol solvent and concentrated sulfuric acid into a reactor, and reacting with stirring till crystals are formed in the reactor; filtering or performing suction filtering; washing the crystals including a part of impurities at high temperature after filtering; and recrystallizing the crystal lattice of 2,4,6-trimethyl pyridine sulfate including a part of impurities after filtering. The invention has the advantages: according to basic property of a pyridine-series compound, by performing vitriolization, crystallization in ethanol, recrystallization and alkaline hydrolysis and purifying 2,4,6-trimethyl pyridine from a crude 2,4,6-trimethyl pyridine fraction extracted by primary rectification, the concentration of refined 2,4,6-trimethyl pyridine can be increased to 97-98 percent, the recovering rate is not lowered greatly, and the concentration can be increased to over 99 percent in further recrystallization.

Owner:上海鼎素精细化工有限公司

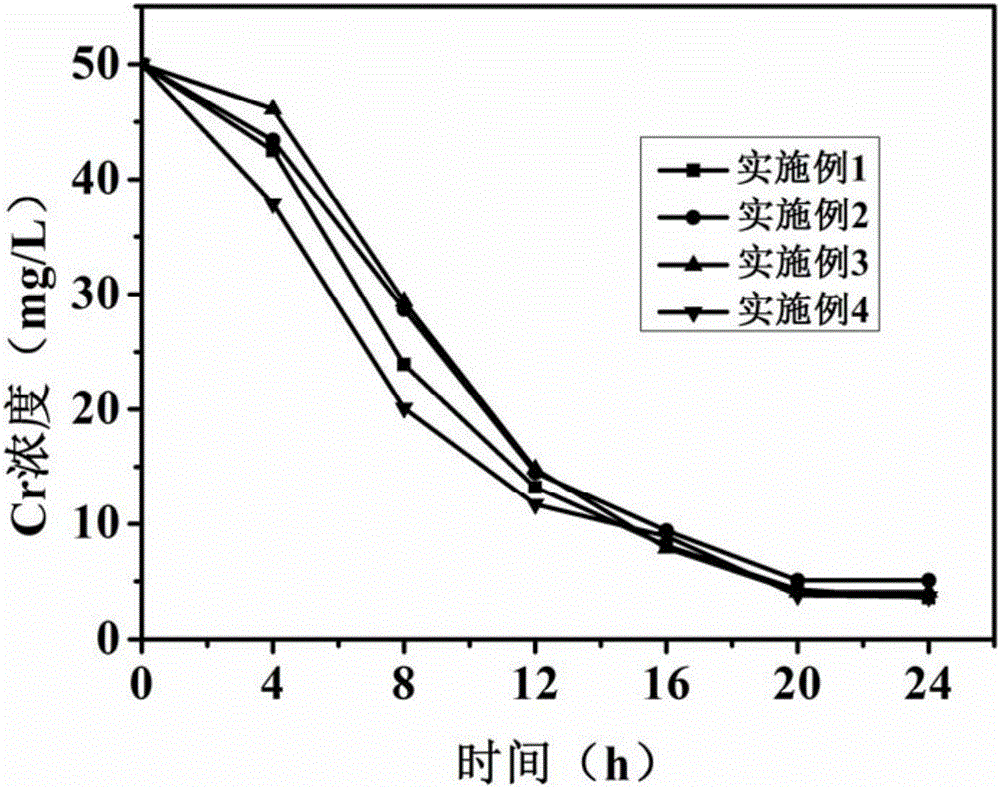

Method for synergically removing sulfate and Cr (VI) in wastewater through sponge iron and microorganisms

ActiveCN106115932AMaintain reducing activityEffective recoveryWater contaminantsBiological water/sewage treatmentSulfate-reducing bacteriaSTERILE SALINE SOLUTION

The invention discloses a method for synergically removing sulfate and Cr (VI) in wastewater through sponge iron and microorganisms. The method comprises the steps that under anaerobic conditions, a sponge iron solution A, a bacterial suspension B of sulfate reducing bacteria and a bacterial suspension C of sulfate reducing bacteria are mixed according to the volume ratio of 1 to 3 to 4, aging is performed for 30-60 minutes, sponge iron / microbial microspheres are repeatedly washed with deoxidized deionized water after the reaction finished and are soaked in a sterile saline solution to obtain a mixture of sponge iron and sulfate reducing bacteria / iron reducing bacteria; the mixture of sponge iron and sulfate reducing bacteria / iron reducing bacteria is mixed with sulfate and Cr (VI) in the wastewater, reaction is performed at room temperature for more than 24 hours, and meanwhile the sulphate and Cr (VI) in the wastewater are purified. The Cr (VI) metal removal rate of the method is above 89%, the required equipment is simple, reaction is completed at normal temperature and pressure, a product is a solid phase, a reaction system is a liquid phase, the product is easy to separate, and the method is used for large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Infrared spectroscopy method for measuring the base number of overbased lubricants

The present invention provides a method for measuring a lubricant's total basicity by measuring one or more preselected infrared absorption bands of a lubricant and correlating the measured bands to the basicity. Preferably, the measured bands are due to carbonate or sulfate species in the lubricant.

Owner:EXXON RES & ENG CO

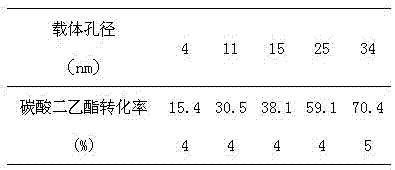

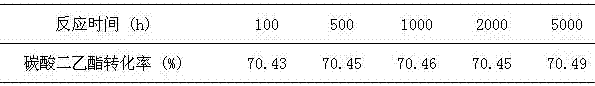

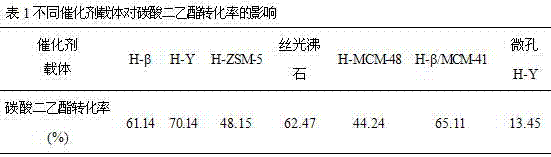

Method for preparing ethyl methyl carbonate from dimethyl carbonate and diethyl carbonate

InactiveCN107445836AGood dispersionHigh purityCatalyst carriersMolecular sieve catalystsDispersityCatalytic effect

The invention discloses a method for preparing ethyl methyl carbonate from dimethyl carbonate and diethyl carbonate, and relates to a method for preparing a chemical raw material. According to the method, alkaline or acidic and alkaline metal oxide is supported by adopting a coprecipitation manner, and a single solution or a mixed solution of metal nitrate, hydrochloride and sulfate is utilized as a source of an active ingredient, so that the catalytic activity of a catalyst is further improved; when the catalyst is 20%Cs-10%Al-7.5%La / Al2O3-SiO2, the air speed is 10h<-1> and the temperature is 200 DEG C, the conversion rate can reach 71.90 percent, and the catalyst can be stably reacted for 5,000h without a deactivation phenomenon; during tank reaction, the reacted catalyst can be reutilized after being simply treated, and can still keep with relatively high activity after being reutilized for multiple times; the metal oxide in the active center of the catalyst prepared by a precipitation method is smaller in crystalline granularity, higher in dispersity and larger in surface area, and the catalytic effect of the prepared catalyst is higher than that of a catalyst prepared by an impregnation method.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

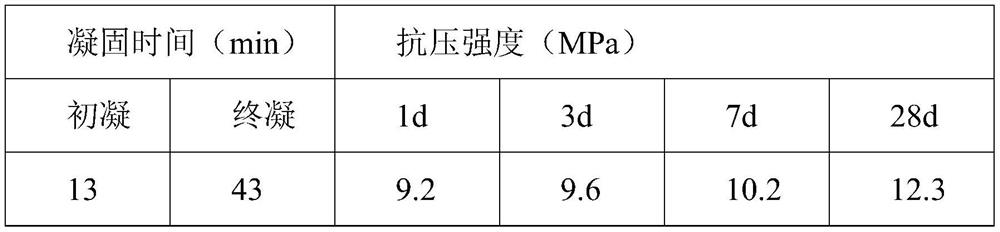

Mining high-water high-strength filling material and preparation method thereof

The invention discloses a mining high-water high-strength filling material and a preparation method thereof. The mining high-water high-strength filling material is prepared from, by mass, a componentA and a component B. The component A includes, by mass, 50-70 parts of sulphoaluminate cement, 5-10 parts of fly ash, 1-10 parts of sodium bentonite, 1-5 parts of retarder and 1-5 parts of suspendingagent; and the component B includes: 5-10 parts of gypsum powder, 2-5 parts of quick lime, 1-5 parts of kaolin, 5-30 parts of quartz powder and 1-10 parts of a composite additive; and the raw materials of the component A and the component B are mixed in proportion and uniformly stirred to obtain the mining high-water-content high-strength filling material. The prepared material has the advantagesthat the setting time can be adjusted from ten minutes to several hours, and the compressive strength is high.

Owner:渭南陕煤启辰科技有限公司

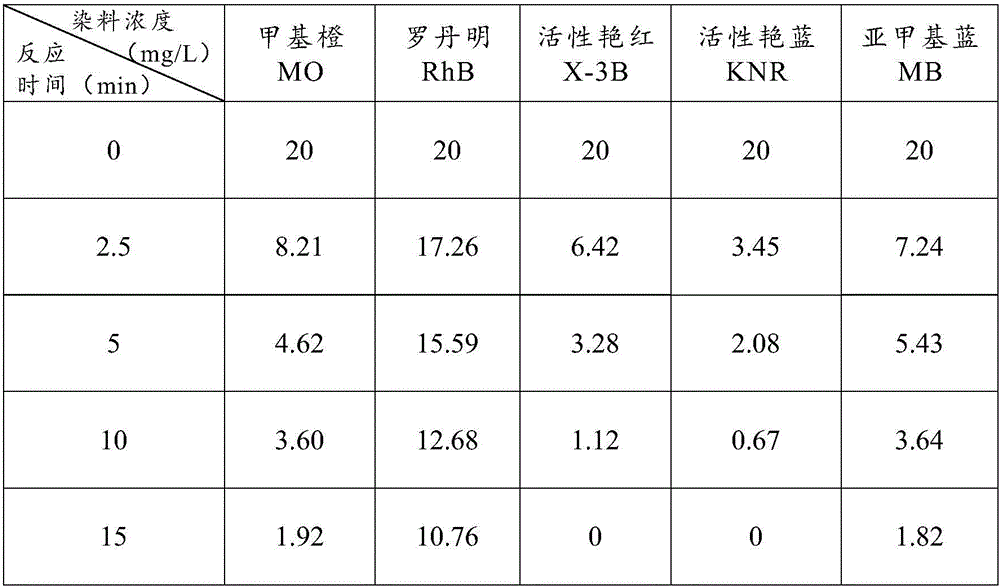

Application and method of degrading organic wastewater with Ce-OMS-2 catalyst

ActiveCN106630102AHigh catalytic activityGood effect on degrading pollutantsWater contaminantsWater/sewage treatment by oxidationSulfateWastewater

The invention discloses application and a method of degrading organic wastewater with a Ce-OMS-2 catalyst, and relates to the field of catalyzing and water treatment. The Ce-OMS-2 catalyst conducts degradation on the organic wastewater by activating persulfate. The method comprises the steps of adding persulfate and the Ce-OMS-2 catalyst to a wastewater solution, performing stirring and blending evenly and standing, converting nonbiodegradable organic pollutant into micromolecule pollution free matter, and achieving the purpose of degrading the organic wastewater. According to the application and the method of degrading the organic wastewater with the Ce-OMS-2 catalyst, the Ce-OMS-2 catalyst can steadily and efficiently catalyzes and activates persulfate to degrade the organic wastewater at ambient temperature and pressure, is wide in pH application rage, fast in degrading rate and low in reaction device requirement, can be applied repeatedly for many times, and has a large application prospect in the field of nonbiodegradable organic wastewater treatment.

Owner:WUHAN TEXTILE UNIV

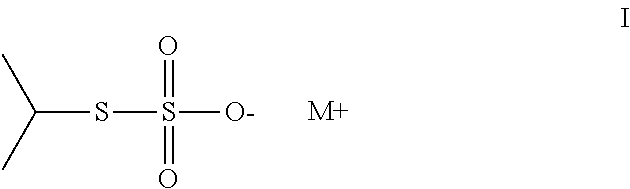

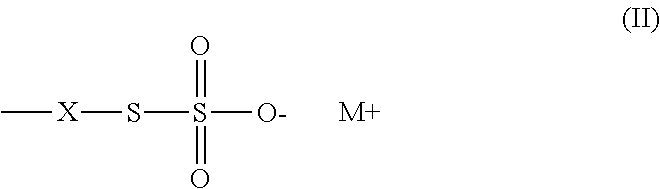

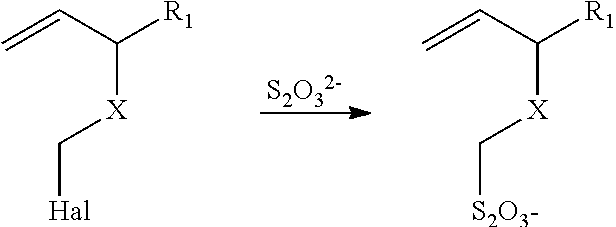

Method of sequestering metals using thiosulfate polymers

ActiveUS20140287366A1High bonding strengthLow costSemiconductor/solid-state device manufacturingPhotosensitive material processingPhotosensitizerBisulfide

A thiosulfate polymer composition includes an electron-accepting photosensitizer component, either as a separate compound or as an attachment to the thiosulfate polymer. The thiosulfate polymer composition can be applied to various articles, or used to form a predetermined polymeric pattern after photothermal reaction to form crosslinked disulfide bonds, removing non-crosslinked polymer, and reaction with a disulfide-reactive material. Such thiosulfate polymer compositions can also be used to sequestering metals.

Owner:EASTMAN KODAK CO

A detection reagent for detecting sulfate contents in a water body

InactiveCN103323409ALow priceEasy to carryColor/spectral properties measurementsPotassium hydroxideSurface water

The invention relates to a detection reagent for detecting sulfate contents in a water body. The detection reagent is prepared by steps of weighing barium chromate, calcium chloride, trichloroacetic acid, absolute ethyl alcohol, and polyvinylpyrrolidone according to a weight ratio of 2:1:4:10:20; dissolving the trichloroacetic acid into the absolute ethyl alcohol, adding the polyvinylpyrrolidone and mixing uniformly; allowing the mixture to stand and be exposed to air for 24h; grinding into powder after the ethyl alcohol is volatilized; and mixing with the barium chromate and the calcium chloride. When the detection reagent is used, after steps of adding 0.1-0.3 g of the detection reagent into 5-10 mL of a water sample, shaking and mixing for 3 min, adding 0.1g of potassium hydroxide and mixing uniformly, and filtrating, then the filtrate can be detected by the detection reagent by using a spectrophotometer or a colorimeter. The detection reagent provided by the invention has advantages of carry convenience, low price, and accurate and reliable results, and can be applied for on-site quantitative determination of sulfate concentrations for surface water, underground water, production water, domestic water, and the like.

Owner:TONGJI UNIV

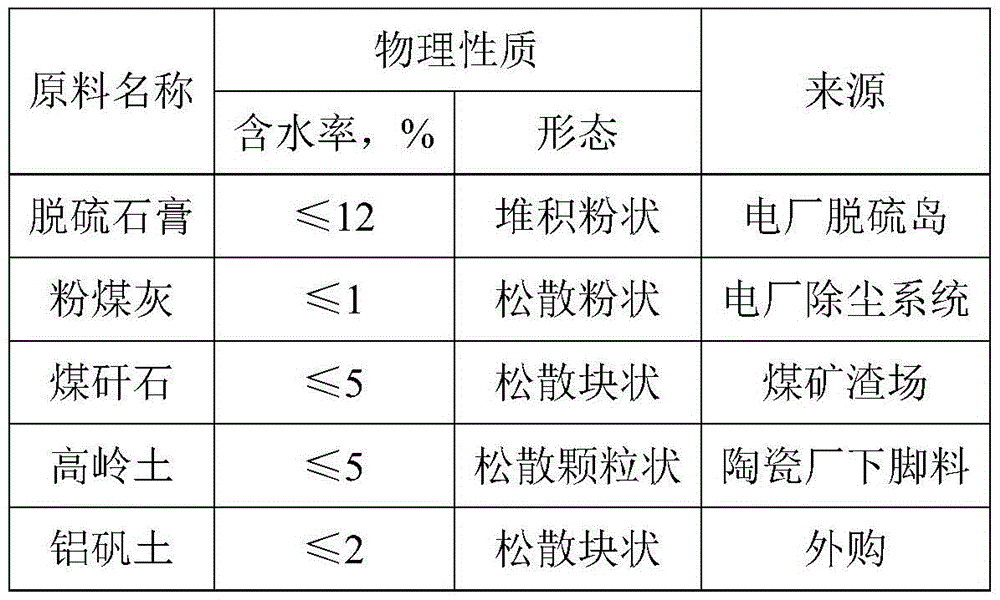

Sulphate aluminum cement clinker and preparation method thereof and sulphate aluminum cement

InactiveCN105621910ACarbon reductionCorrosion resistantClinker productionAluminatePulverized fuel ash

The invention discloses a sulphate aluminum cement clinker and a preparation method thereof. The sulphur aluminate cement clinker is prepared from, by weight, 20-25 parts of gypsum, 30-35 parts of pulverized fuel ash, 20-25 parts of kaolin, 5-10 parts of coal gangue, 10-15 parts of bauxite and an additive, wherein the additive is the mixture of potassium permanganate, manganese dioxide and barium sulfate, and the mass of the additive accounts for 0.02-0.05% of the total mass of the mixture of the gypsum, the pulverized fuel ash, the kaolin, the coal gangue and the bauxite. Compared with a sulphate aluminum cement clinker production process, the resource and energy consumption is low, the sintering temperature is low, and the recycling, reducing and harmless purposes of solid industrial waste residues are achieved.

Owner:HENAN JUNQIANG CEMENT CO LTD

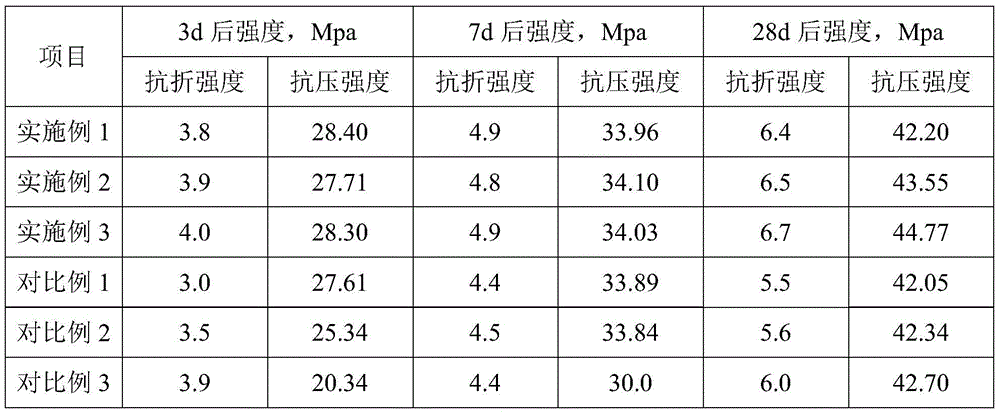

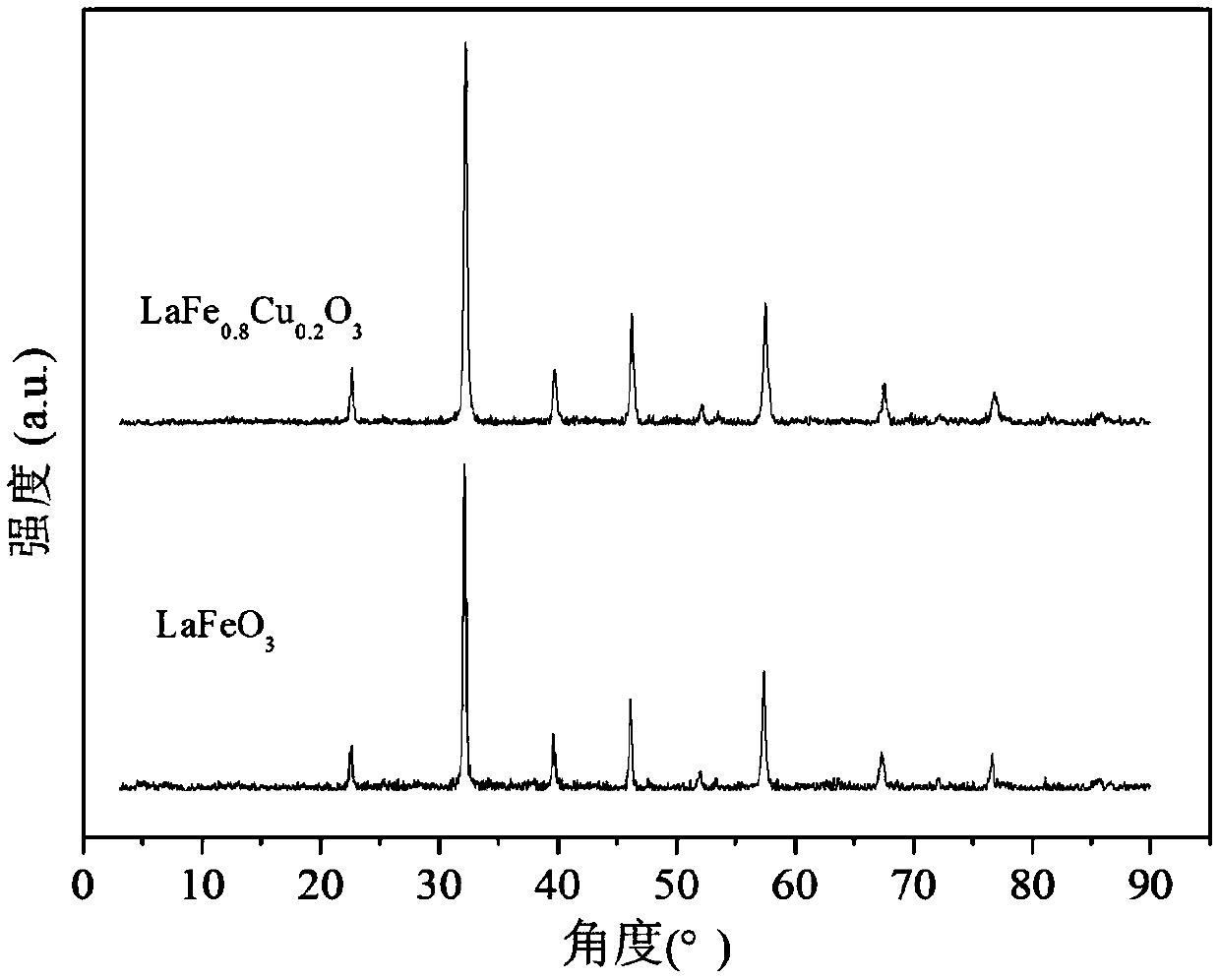

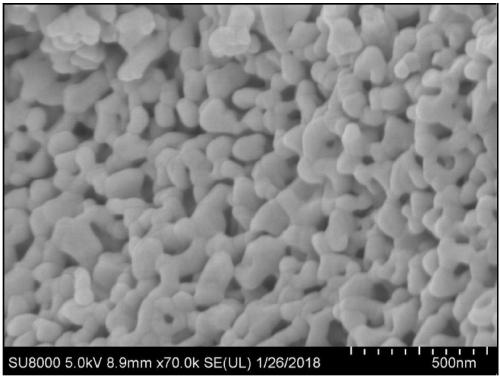

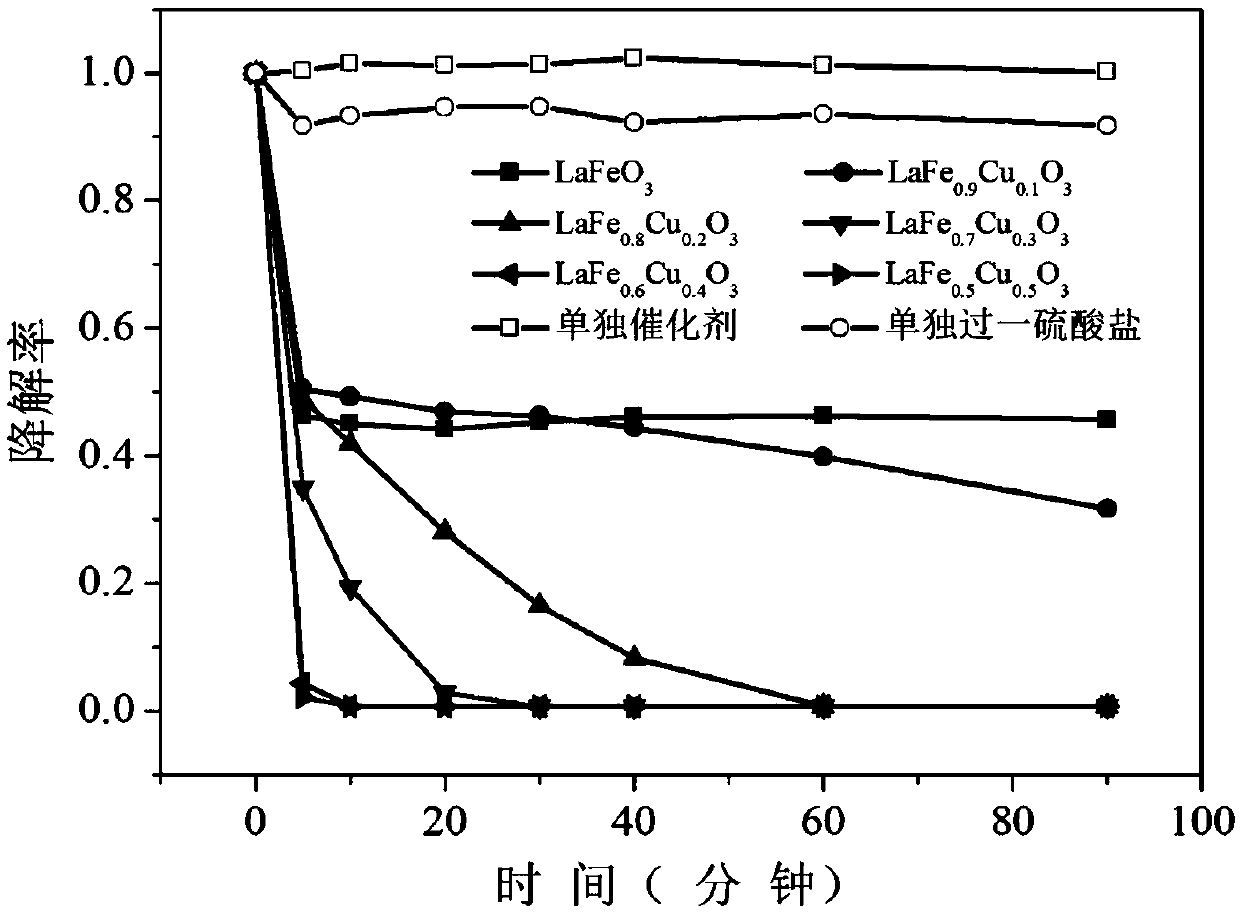

Method for treating residual atrazine in water body by LaFe(1-x)CuxO3

InactiveCN109095590AEasy to prepareEasy to operateWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsSulfate radicalsHomogeneous catalysis

The invention provides a method for treating residual atrazine in a water body by LaFe(1-x)CuxO3. The method comprises steps as follows: peroxymonosulfate is added to organic wastewater and mixed uniformly, then a LaFe(1-x)CuxO3 material is added and serves as a heterogeneous catalyst, all components are stirred, and atrazine pollutants are degraded accordingly; concentration of peroxymonosulfatein the organic wastewater is 0.25-1 mmol / L. According to the method, LaFe(1-x)CuxO3 is taken as the heterogeneous catalyst and is subjected to a reaction with to-be-treated atrazine in the coexistenceof both LaFe(1-x)CuxO3 and peroxymonosulfate, Fe(III) / Fe(II) and Cu(II) / Cu(I) in the LaFe(1-x)CuxO3 material are taken as main active components and subjected to a contact reaction with peroxymonosulfate, sulfate radicals with strong oxidizing property are produced, atrazine which is difficult to degrade in the water body is degraded by the sulfate radicals, and therefore, the water body is purified.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com