Patents

Literature

93results about "Rare earth metal sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

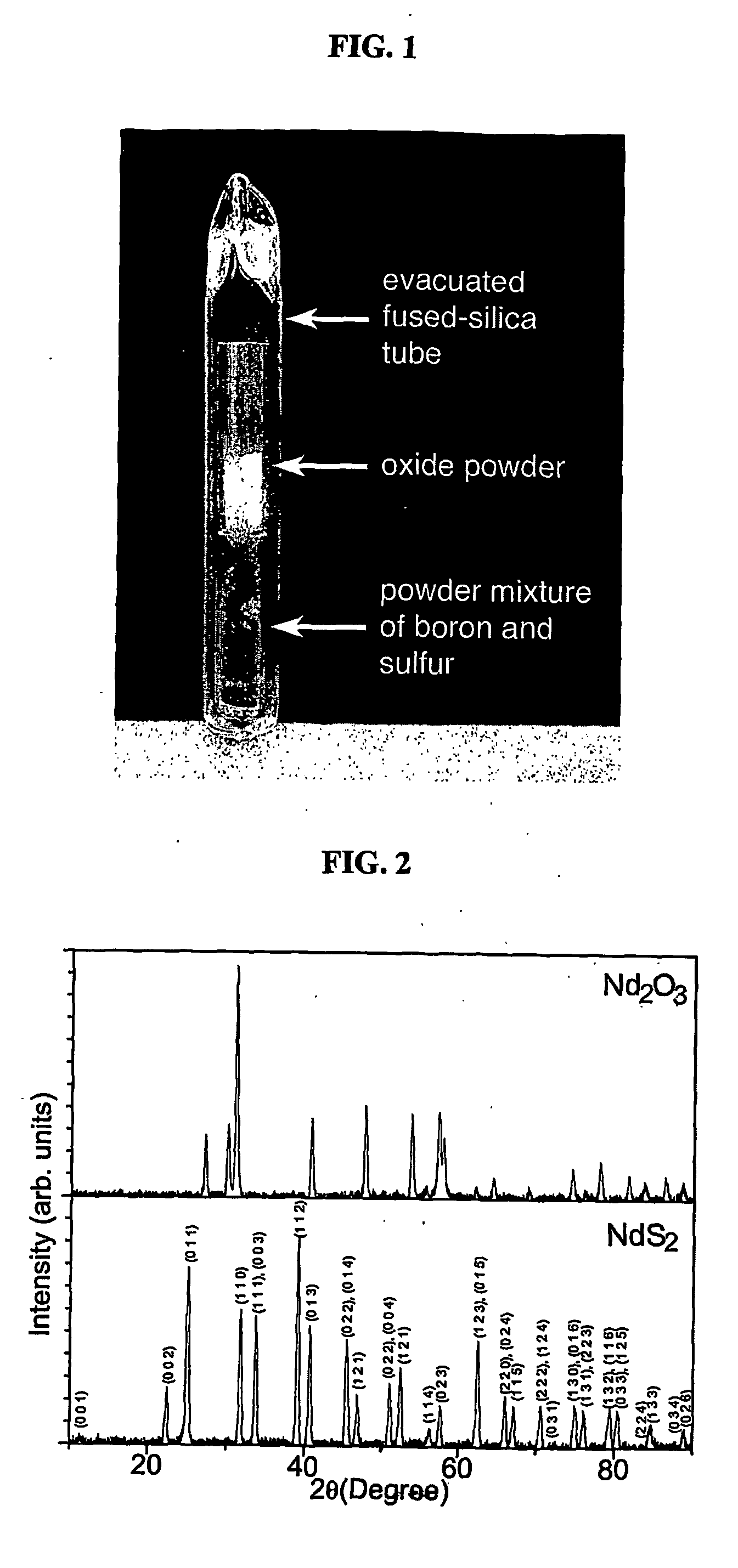

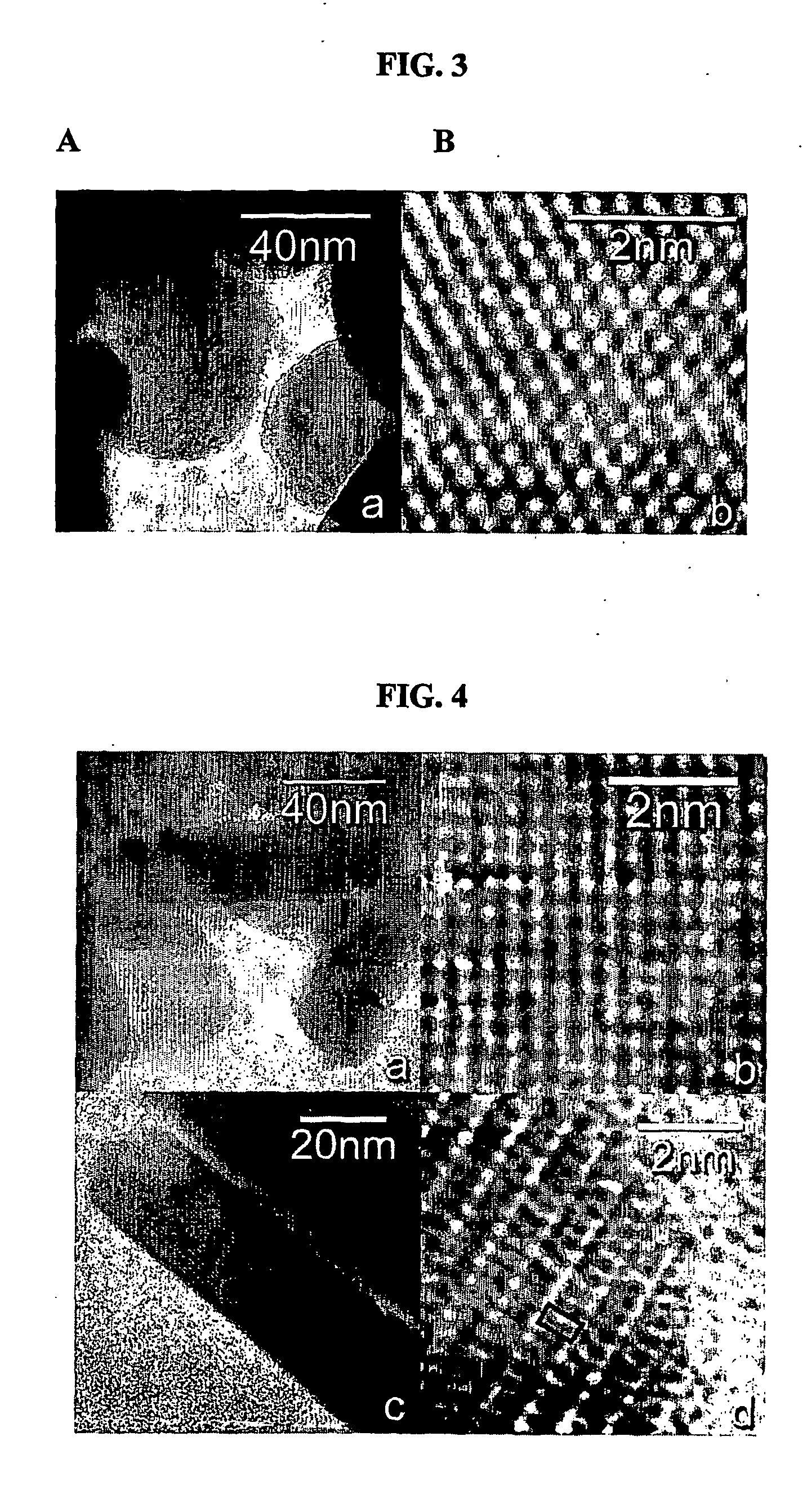

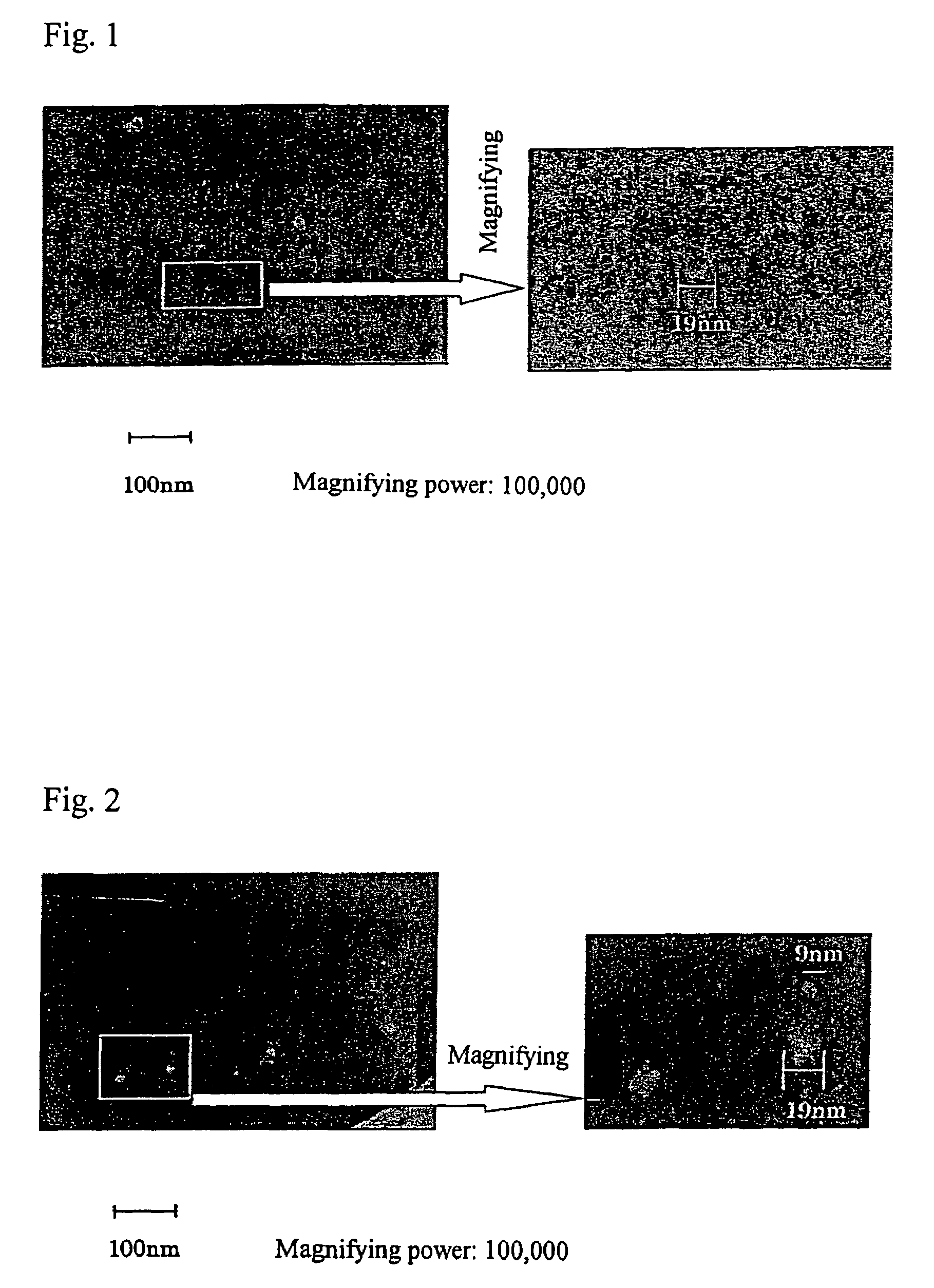

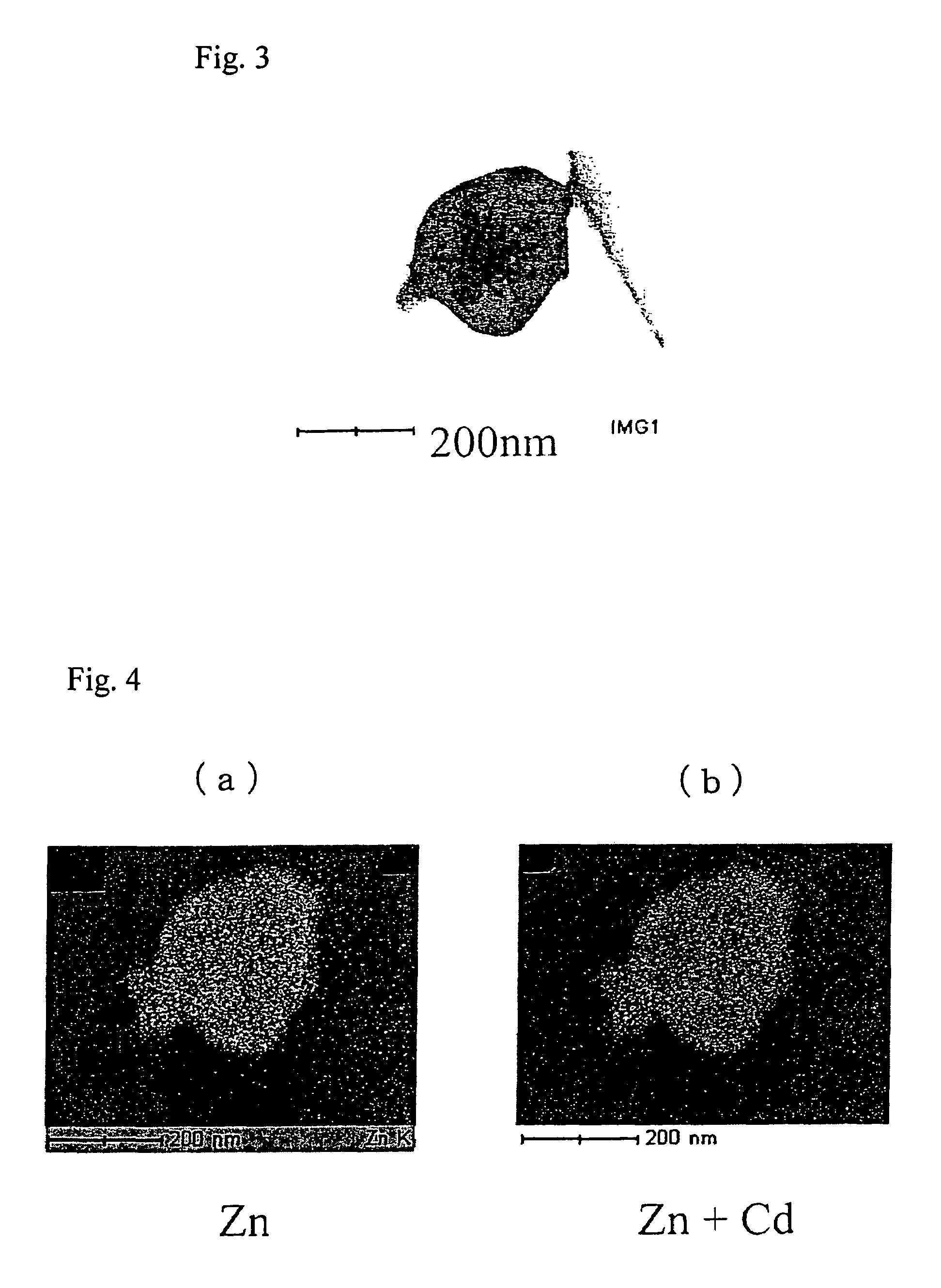

Process for the production of ultrafine particles

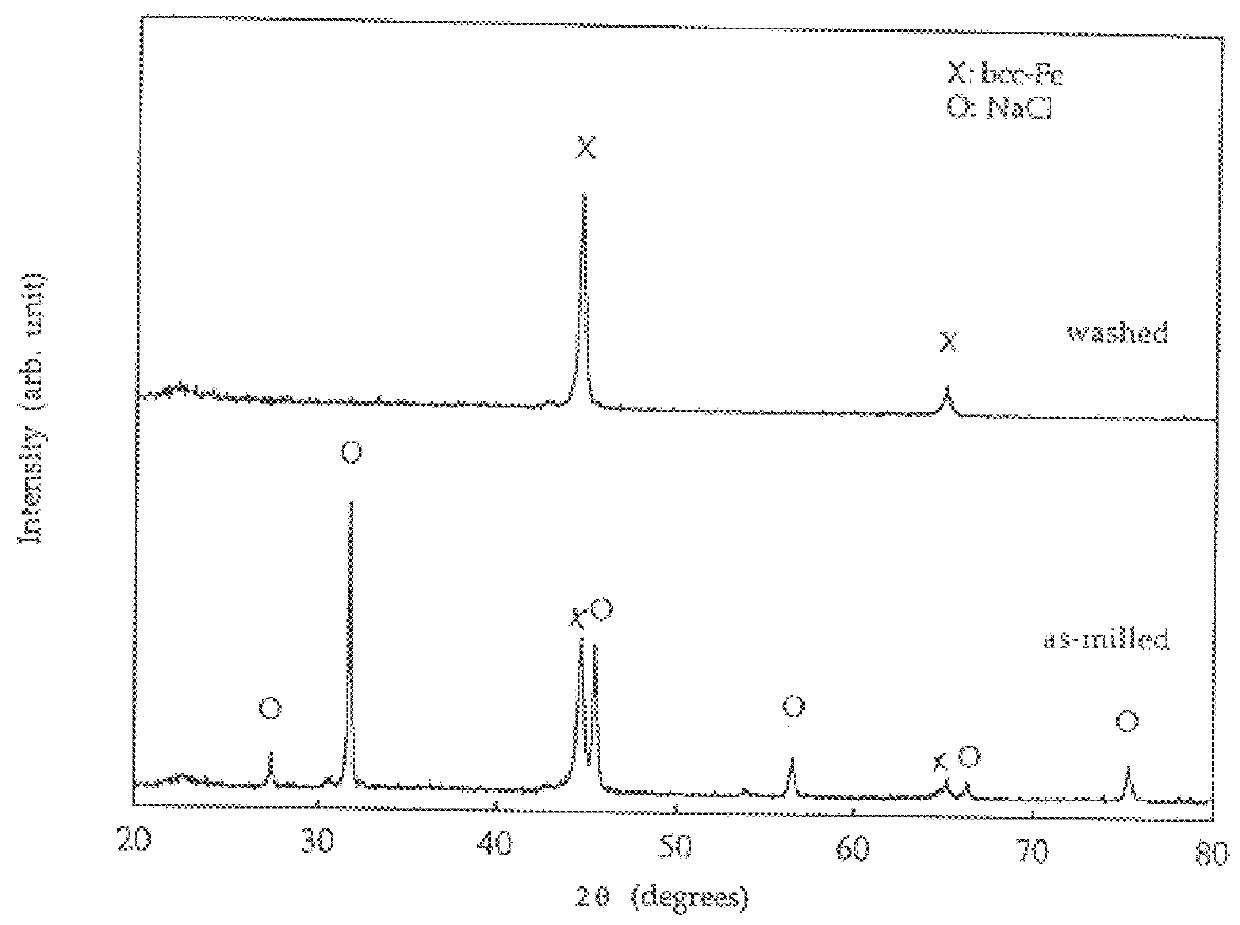

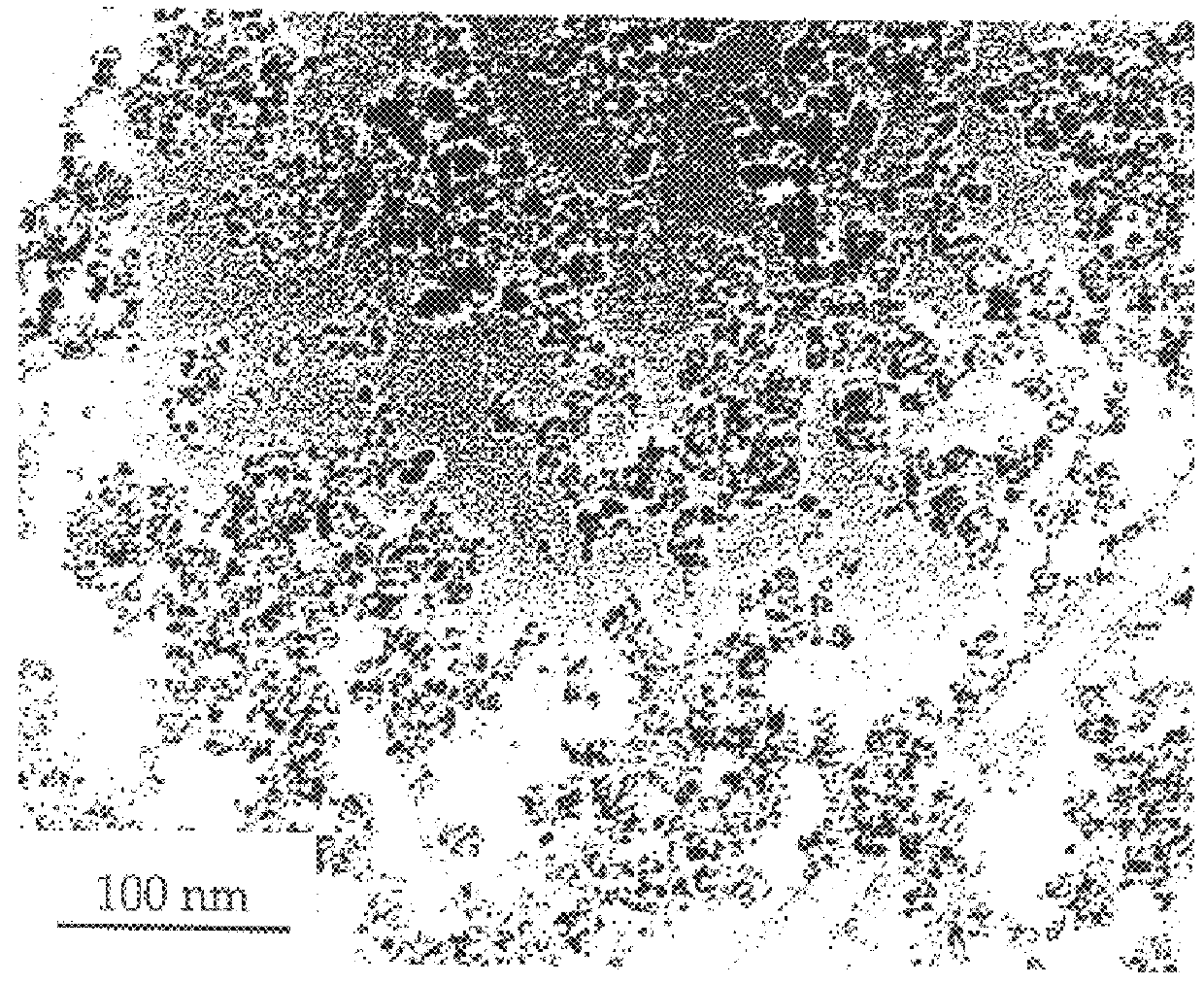

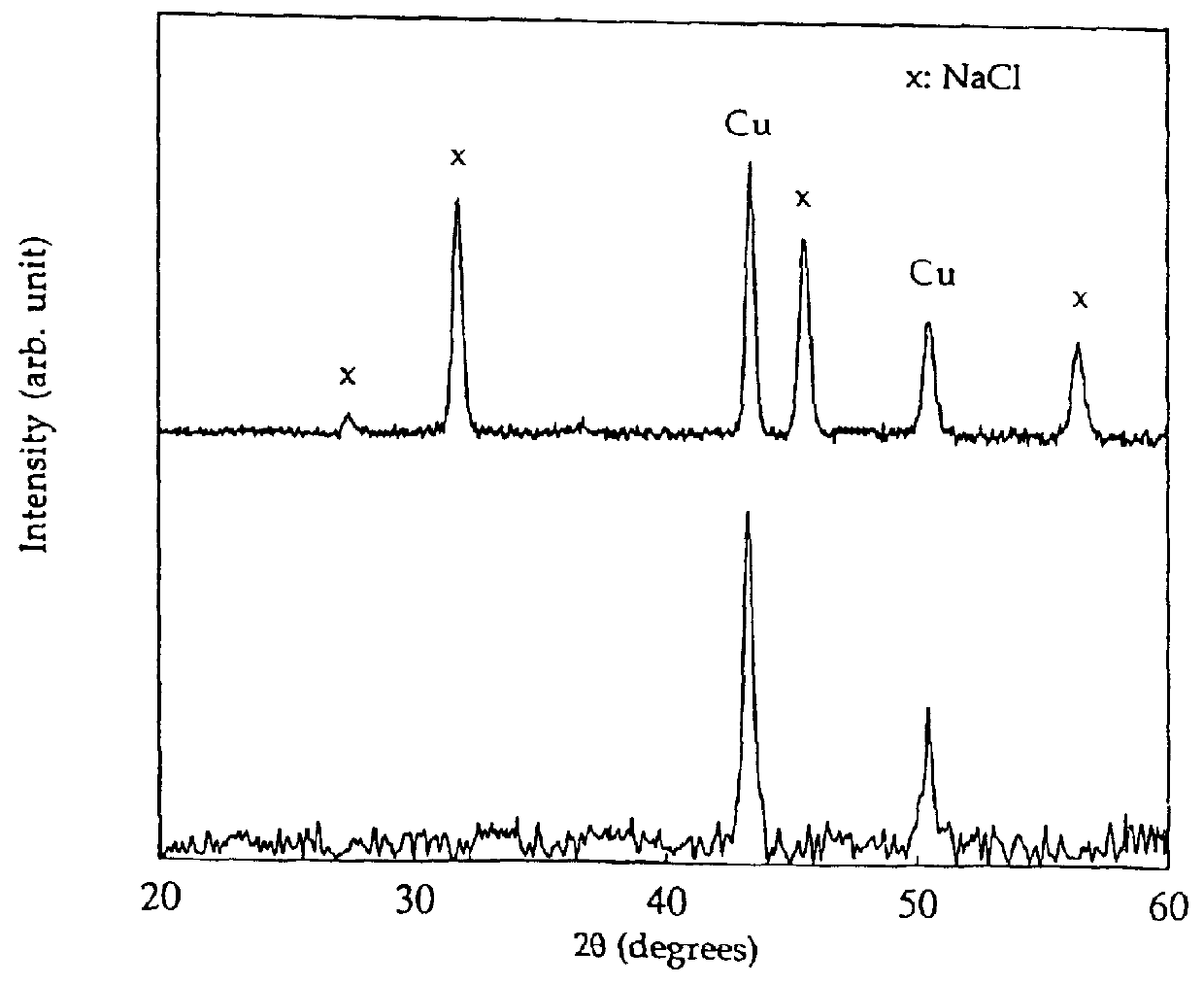

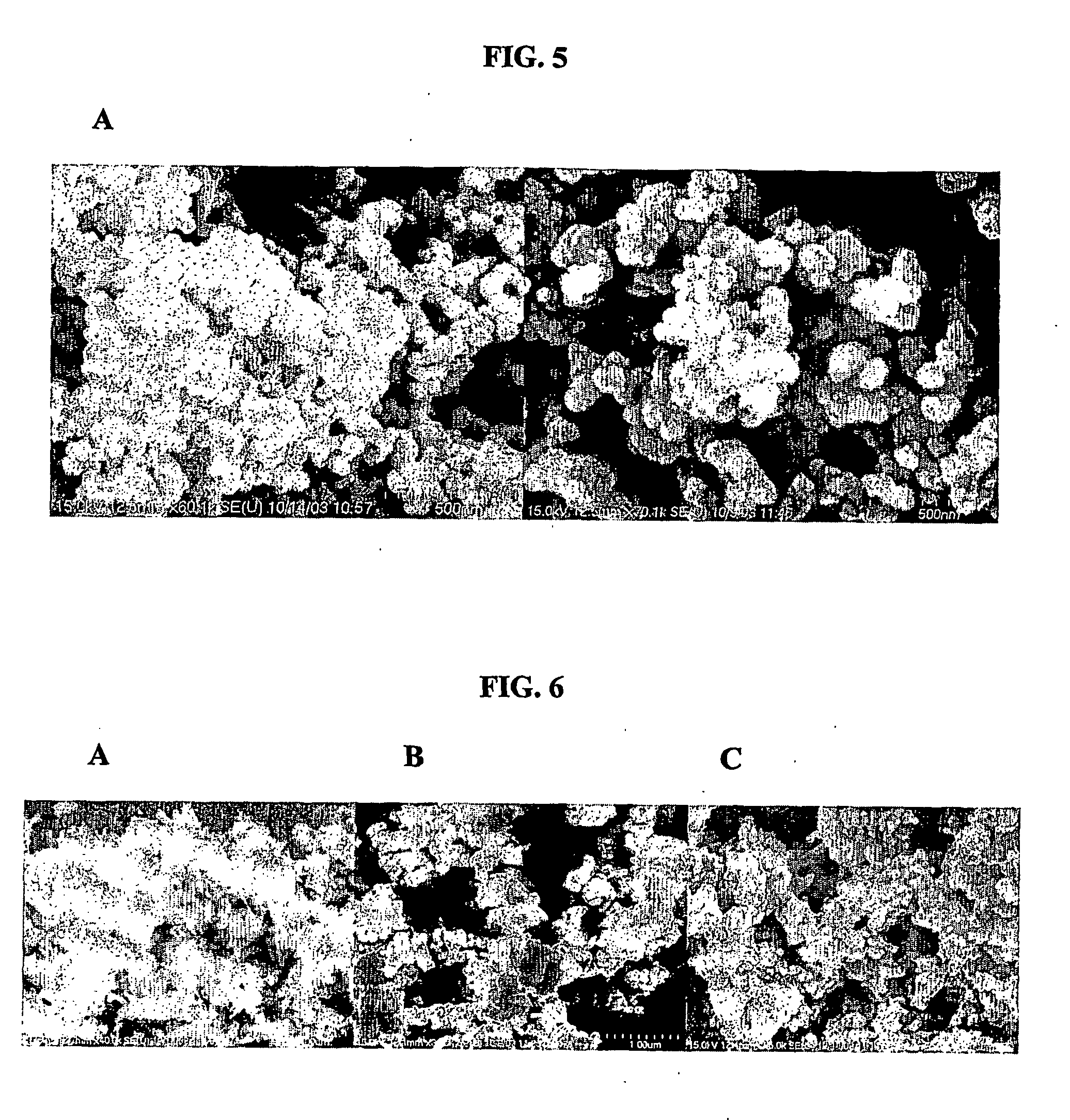

A new, cost effective process for the production of ultrafine particles which is based on mechanically activated chemical reaction of a metal compound with a suitable reagent. The process involves subjecting a mixture of a metal compound and a suitable reagent to mechanical activation to increase the chemical reactivity of the reactants and / or reaction kinetics such that a chemical reaction can occur which produces a solid nano-phase substance. Concomitantly, a by-product phase is also formed. This by-product phase is removed so that the solid nano-phase substance is left behind in the form of ultrafine particles. During mechanical activation a composite structure is formed which consists of an intimate mixture of nano-sized grains of the nano-phase substance and the reaction by-product phase. The step of removing the by-product phase, following mechanical activation, may involve subjecting the composite structure to a suitable solvent which dissolves the by-product phase, while not reacting with the solid nano-phase substance. The process according to the invention may be used to form ultrafine metal powders as well as ultrafine ceramic powders. Advantages of the process include a significant degree of control over the size and size distribution of the ultrafine particles, and over the nature of interfaces created between the solid nano-phase substance and the reaction by-product phase.

Owner:WESTERN AUSTRALIA UNIV OF THE

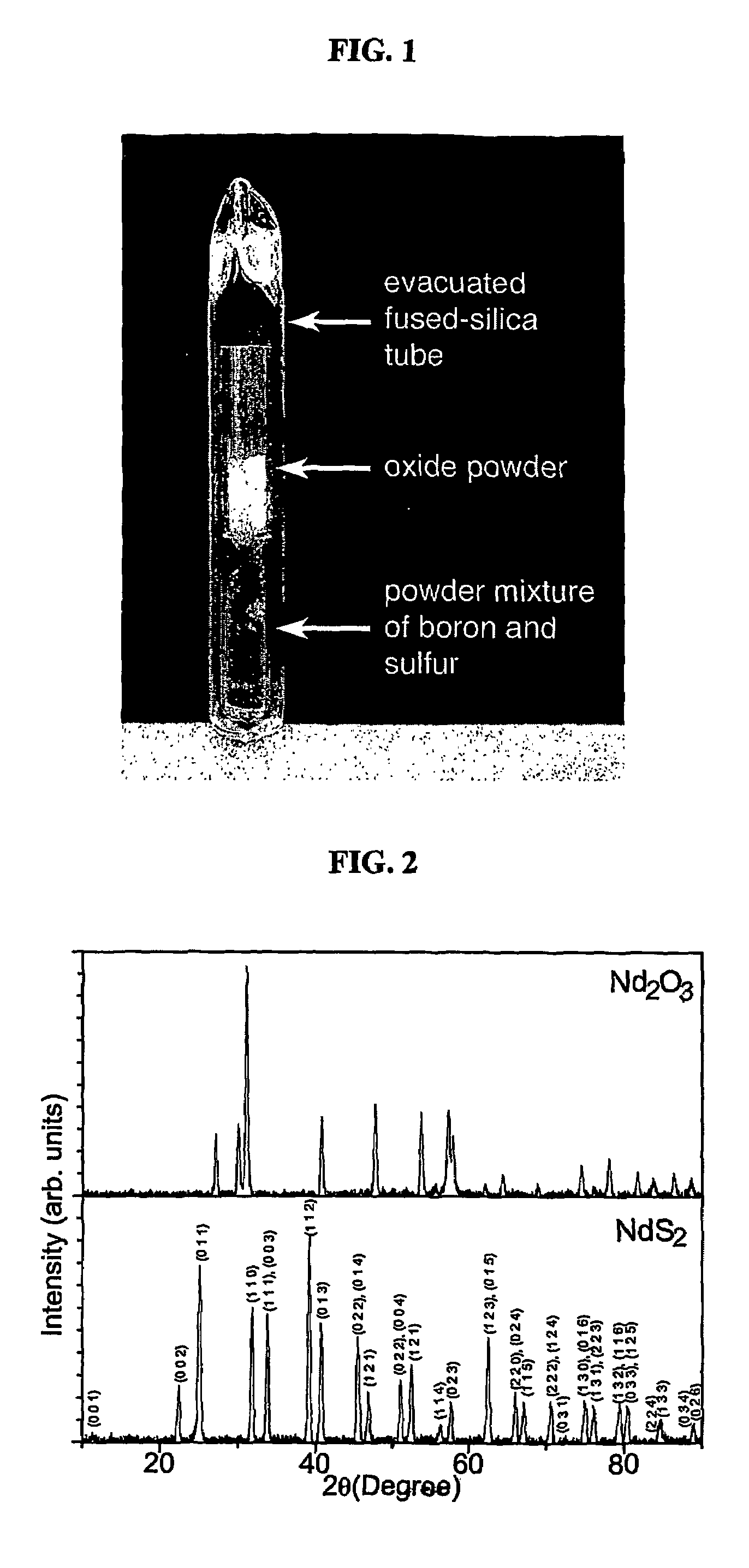

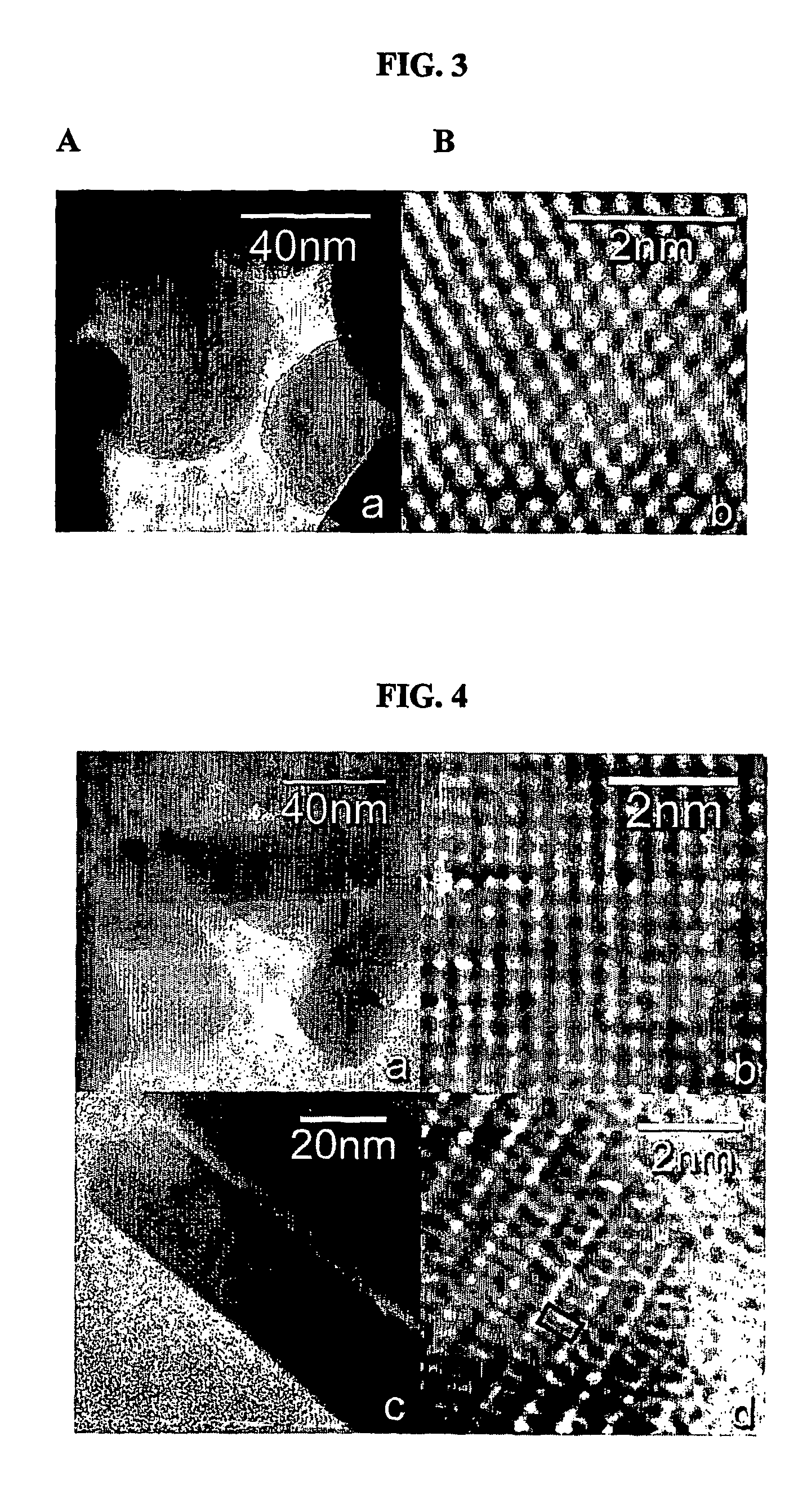

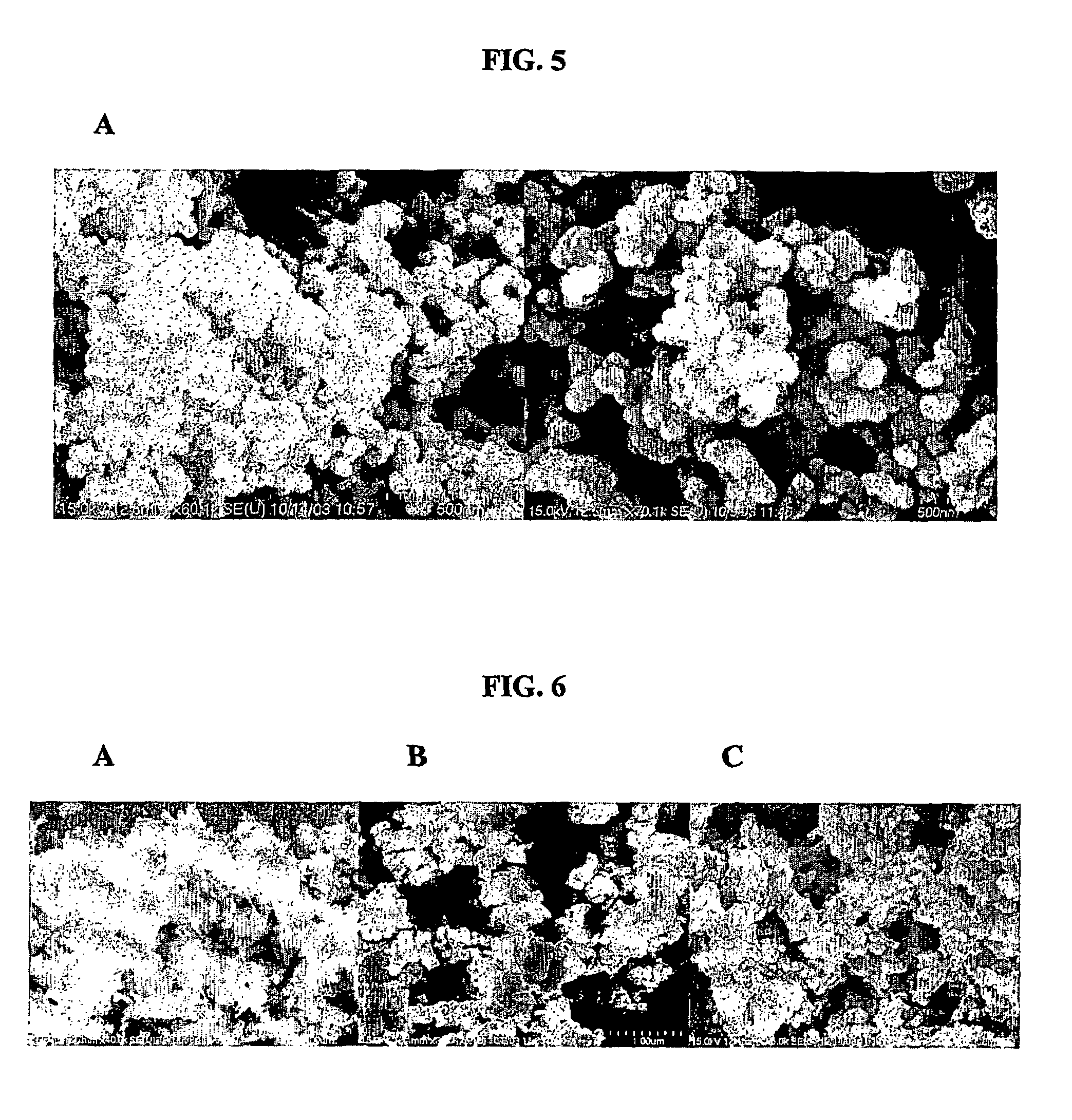

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Security pigments and the process of making thereof

InactiveUS20080274028A1Low costVerify authenticityMaterial nanotechnologyPigmenting treatmentRare earthPigment

Disclosed are methods for using color inconstancy pigments and / or dyes, such as rare earth doped color inconstancy pigments, in security applications including semi-overt and covert security application.

Owner:SUN CHEM CORP

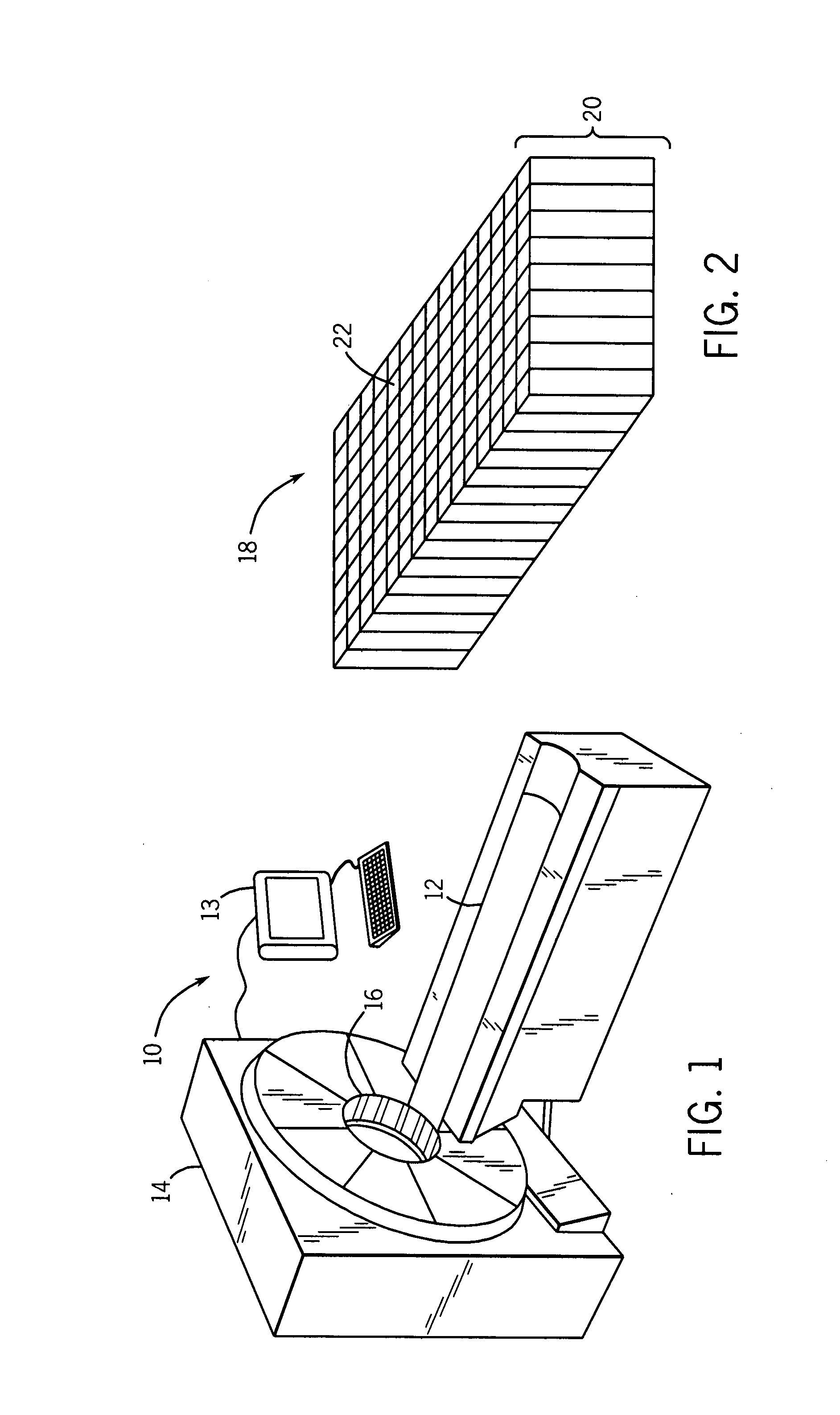

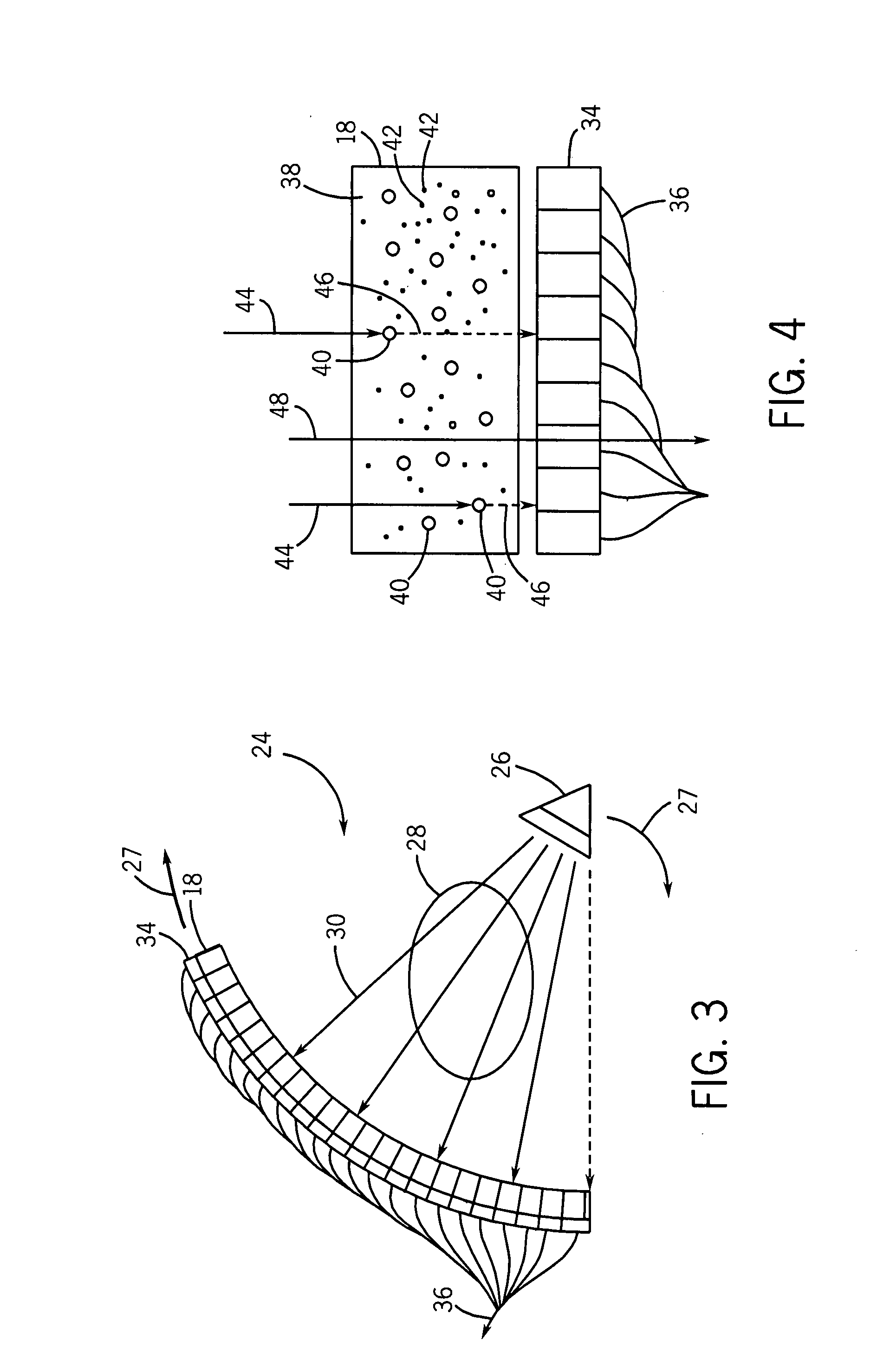

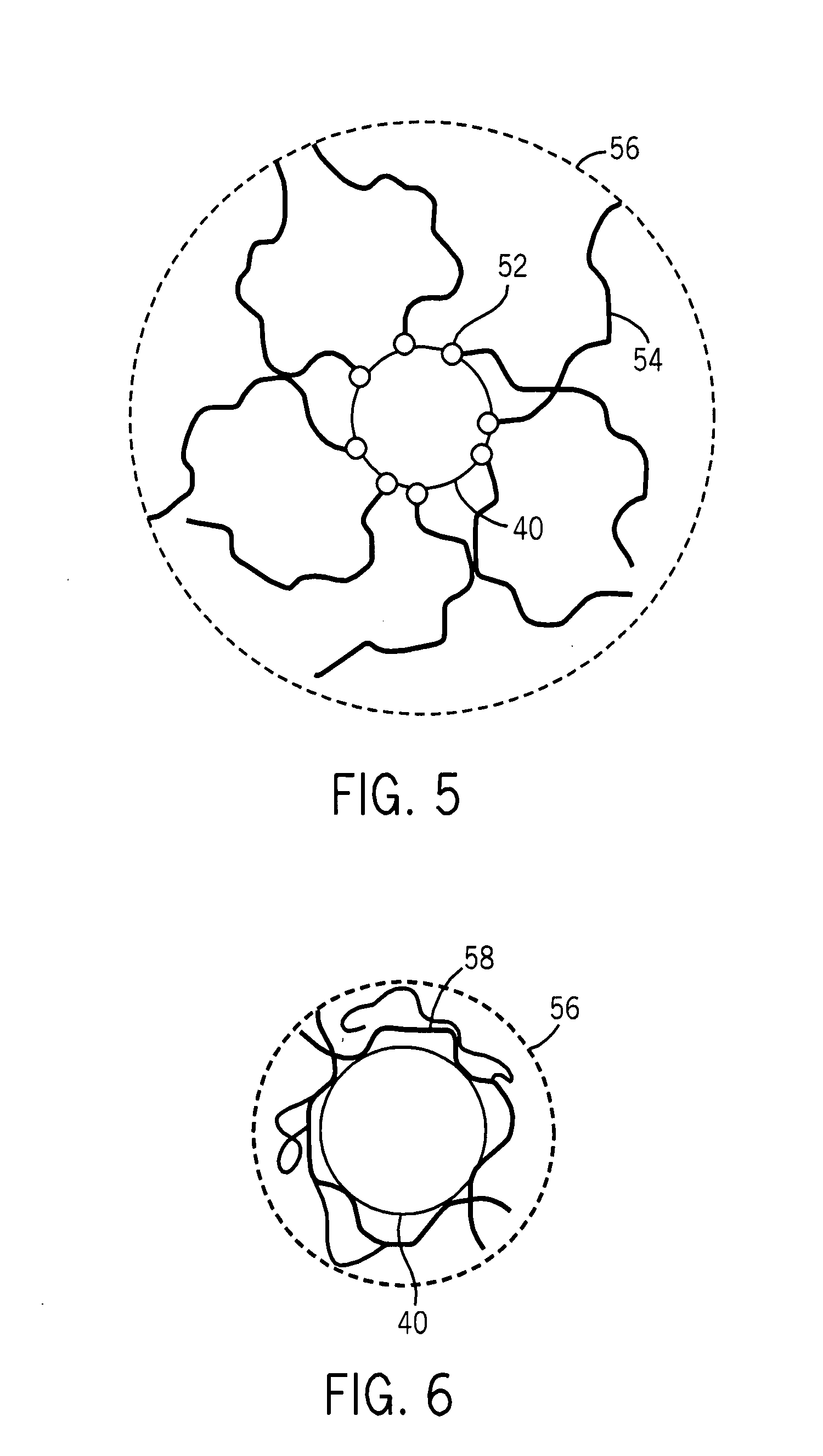

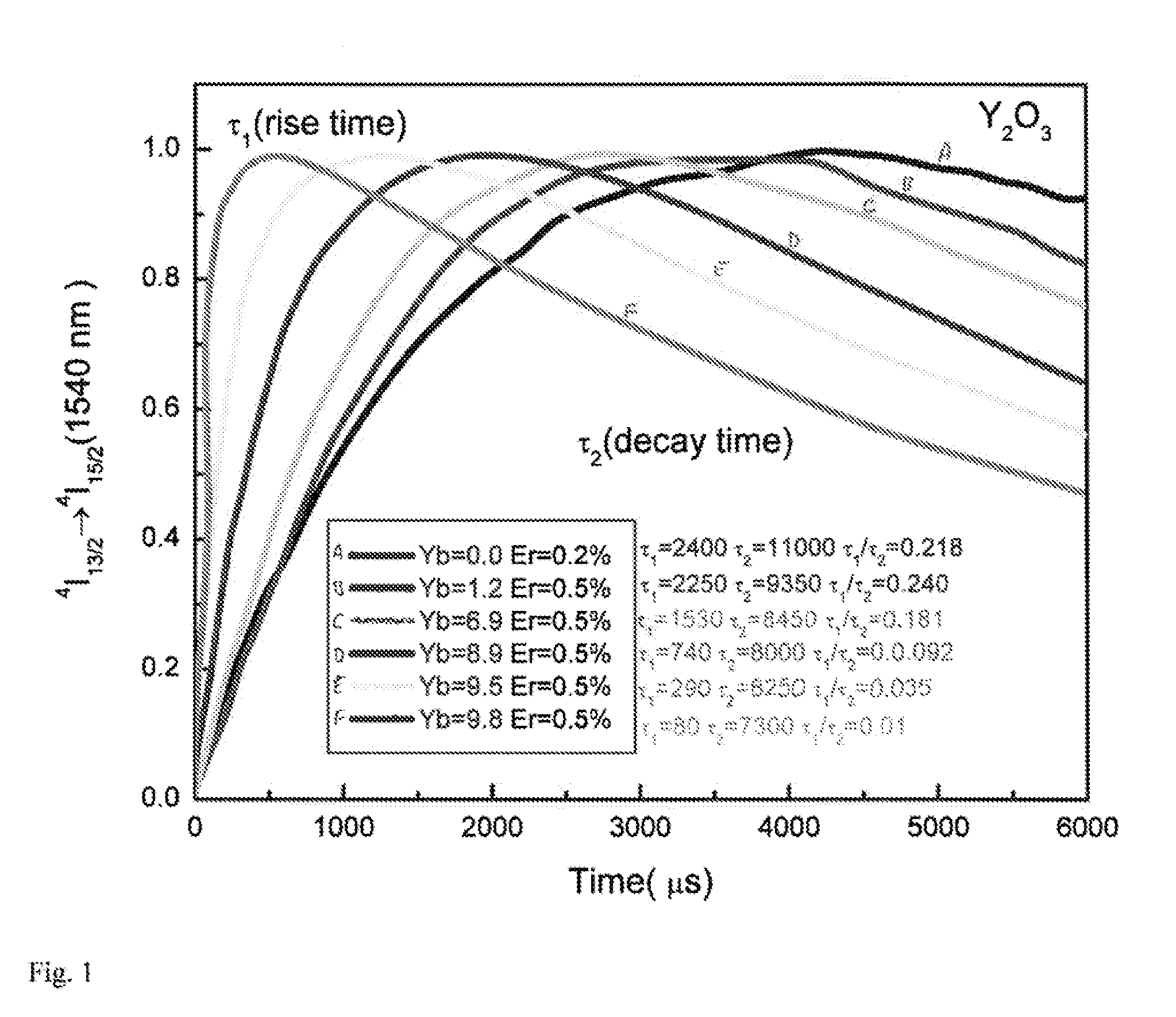

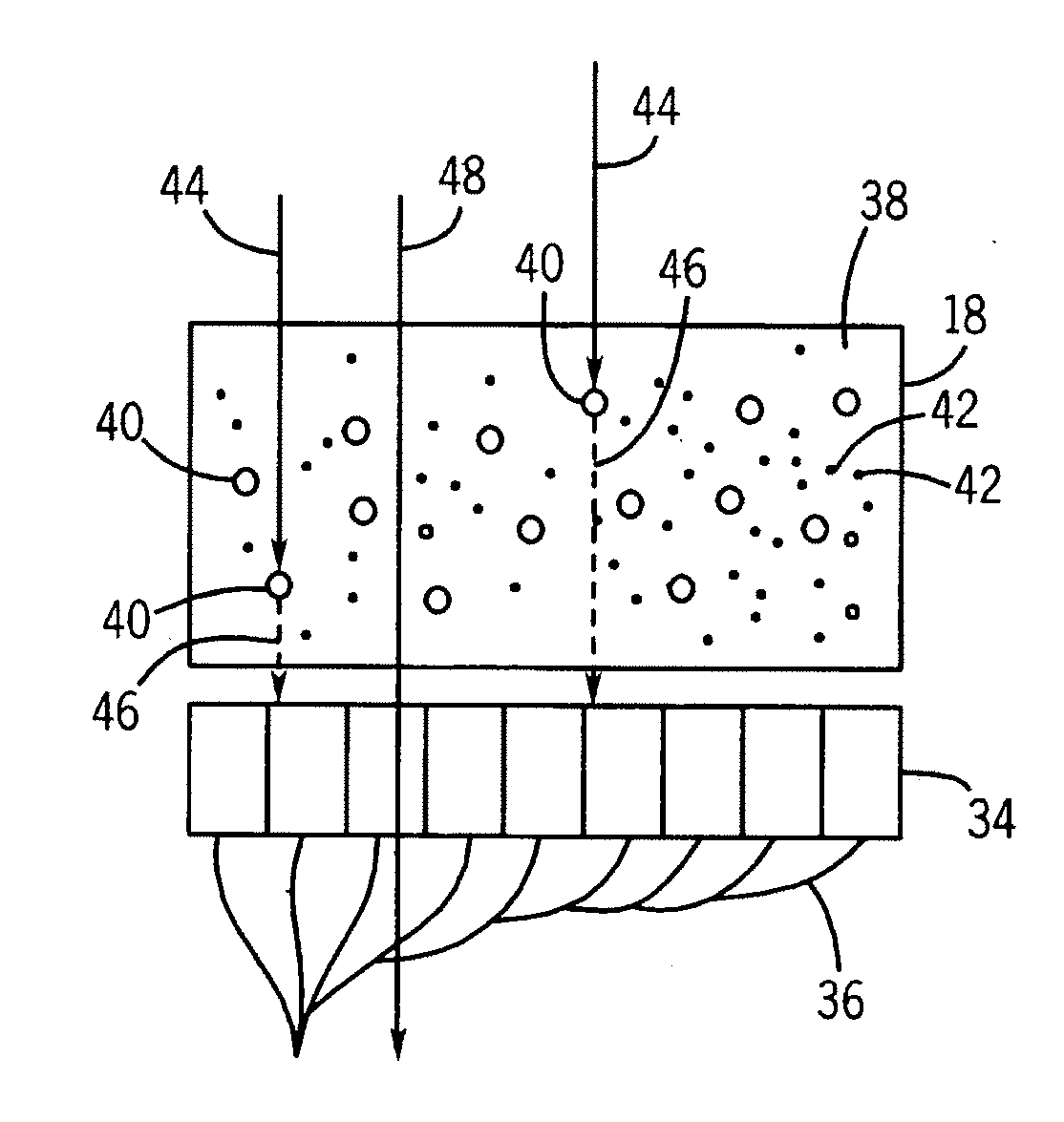

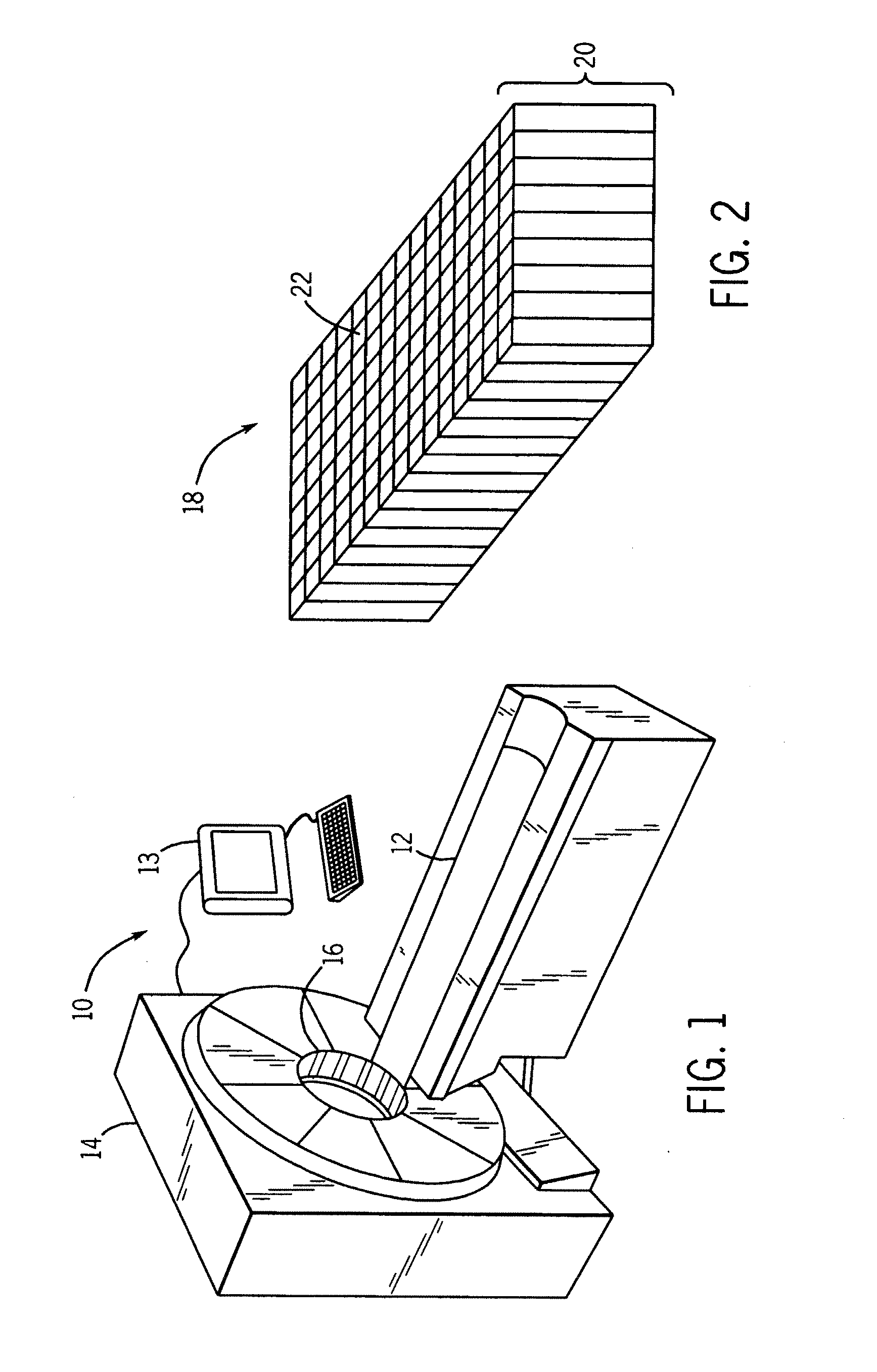

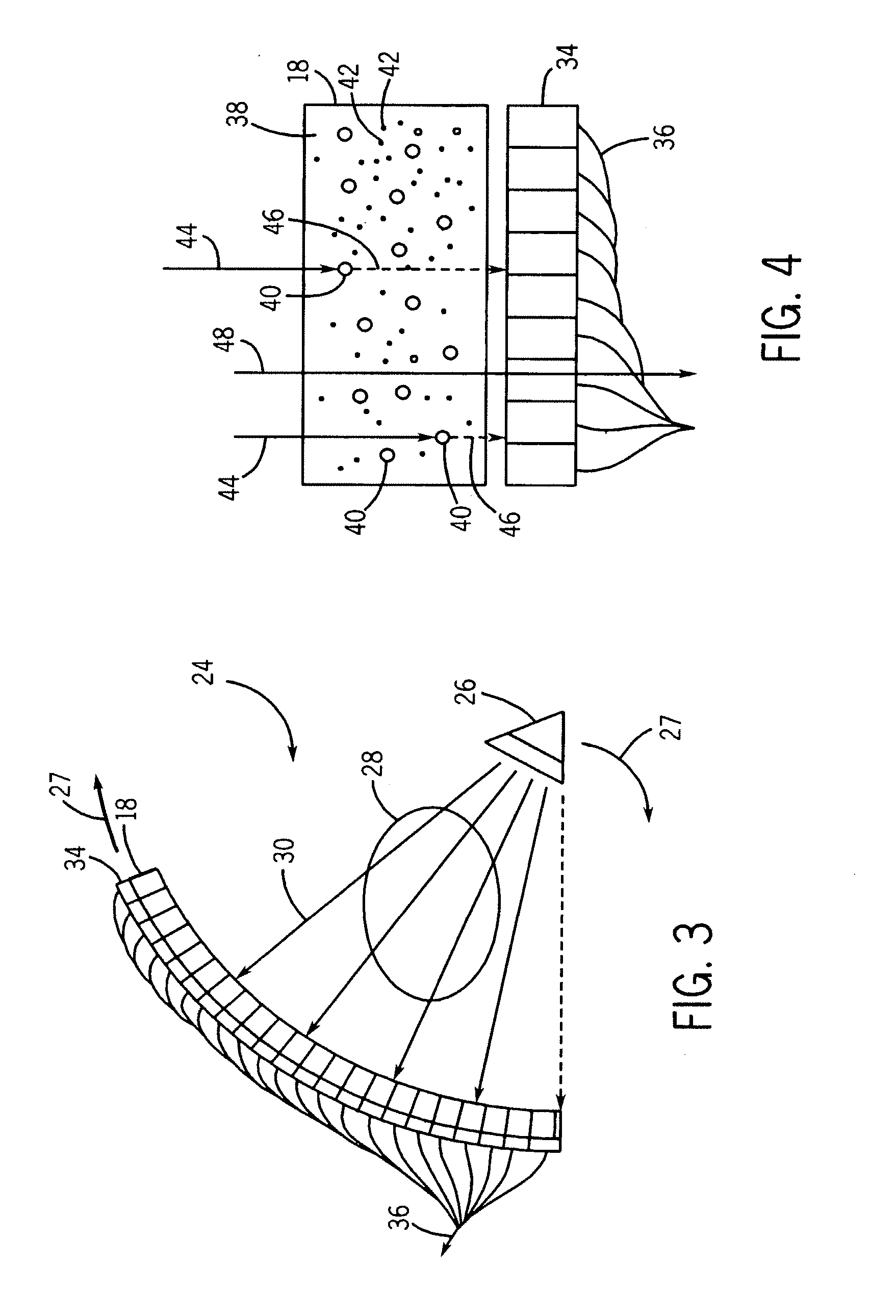

Nano-scale metal oxyhalide and oxysulfide scintillation materials and methods for making same

InactiveUS20080241041A1Rare earth metal oxides/hydroxidesMaterial nanotechnologyEmulsionNanoparticle

Crystalline scintillator materials comprising nano-scale particles of metal oxides, metal oxyhalides and metal oxysulfides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In one method, used to form oxyhalides and oxysulfides, metal salts are dissolved in water, and then precipitated out as fine particles using an aqueous base. After the particles are separated from the solution, they are annealed under a flow of a water saturated hydrogen anion gas, such as HCl or H2S, to form the crystalline scintillator particles. The other methods take advantage of the characteristics of microemulsion solutions to control droplet size, and, thus, the particle size of the final nano-particles. For example, in one method, a first micro-emulsion containing metal salts if formed. The first micro-emulsion is mixed with an aqueous base in a second micro-emulsion to form the final nano-scale particles.

Owner:GENERAL ELECTRIC CO

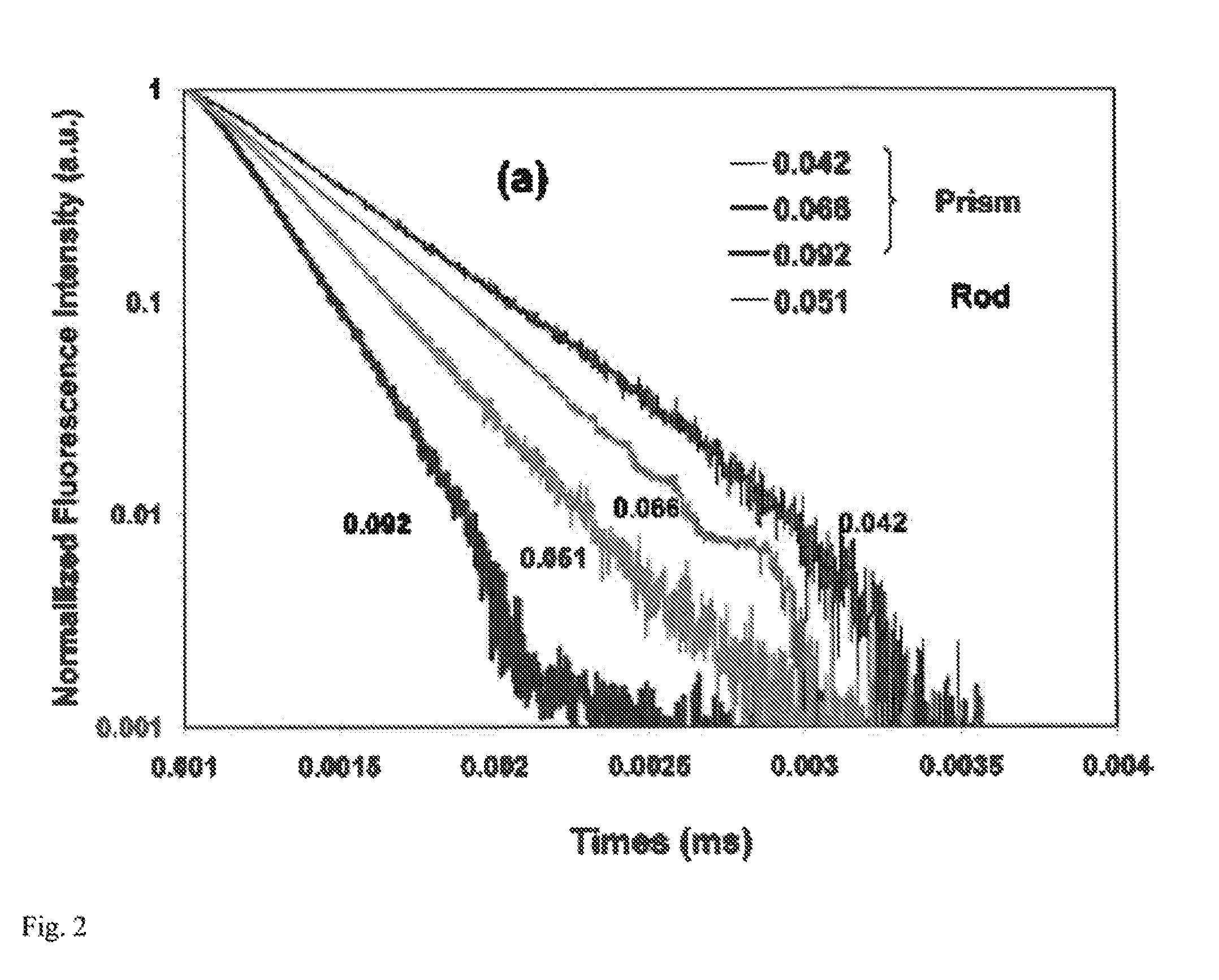

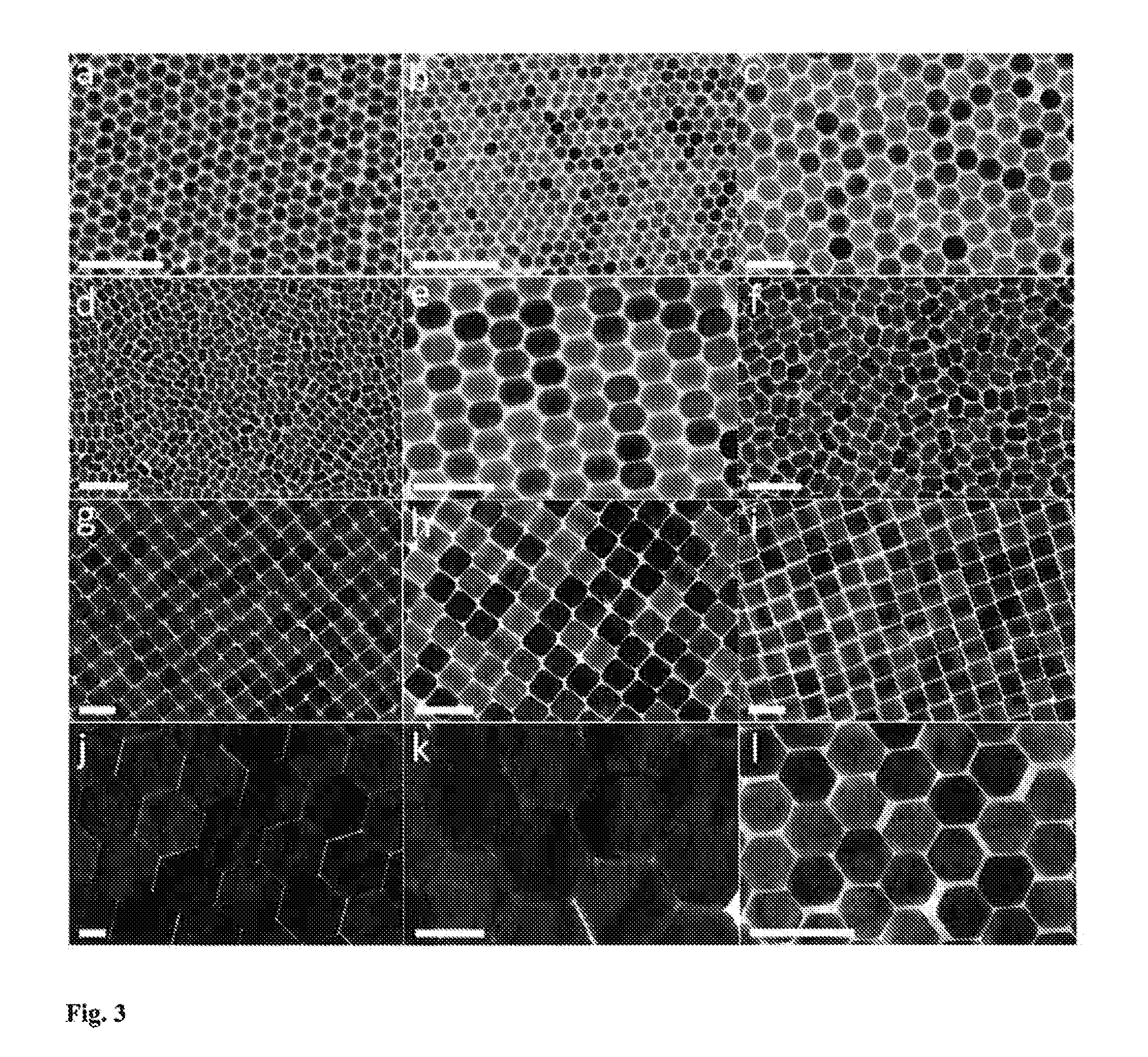

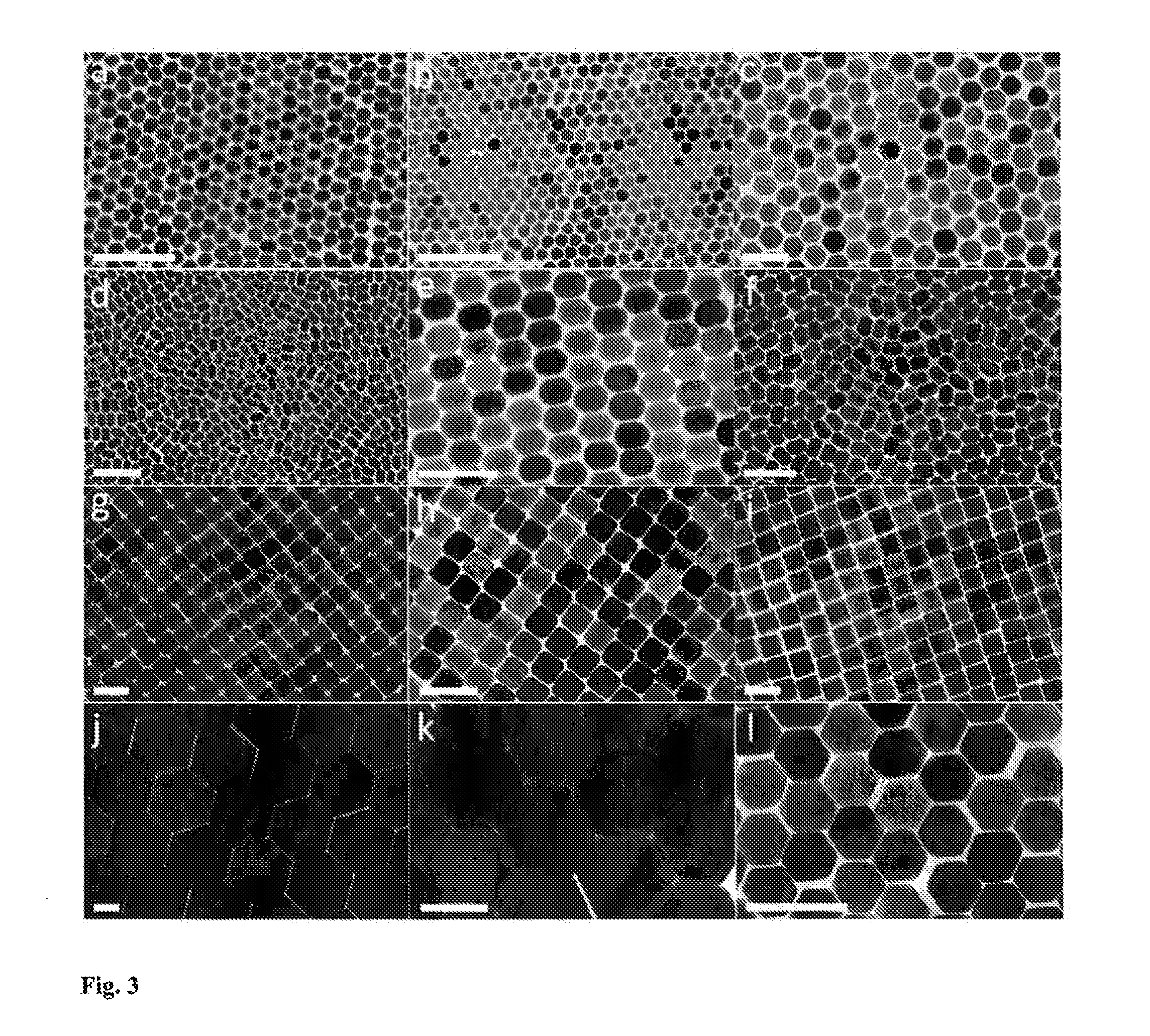

Morphologically and size uniform monodisperse particles and their shape-directed self-assembly

ActiveUS9181477B2Increase in sizeQuench reactionMaterial nanotechnologyFrom normal temperature solutionsRare earthLanthanide

Monodisperse particles having: a single pure crystalline phase of a rare earth-containing lattice, a uniform three-dimensional size, and a uniform polyhedral morphology are disclosed. Due to their uniform size and shape, the monodisperse particles self assemble into superlattices. The particles may be luminescent particles such as down-converting phosphor particles and up-converting phosphors. The monodisperse particles of the invention have a rare earth-containing lattice which in one embodiment may be an yttrium-containing lattice or in another may be a lanthanide-containing lattice. The monodisperse particles may have different optical properties based on their composition, their size, and / or their morphology (or shape). Also disclosed is a combination of at least two types of monodisperse particles, where each type is a plurality of monodisperse particles having a single pure crystalline phase of a rare earth-containing lattice, a uniform three-dimensional size, and a uniform polyhedral morphology; and where the types of monodisperse particles differ from one another by composition, by size, or by morphology. In a preferred embodiment, the types of monodisperse particles have the same composition but different morphologies. Methods of making and methods of using the monodisperse particles are disclosed.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

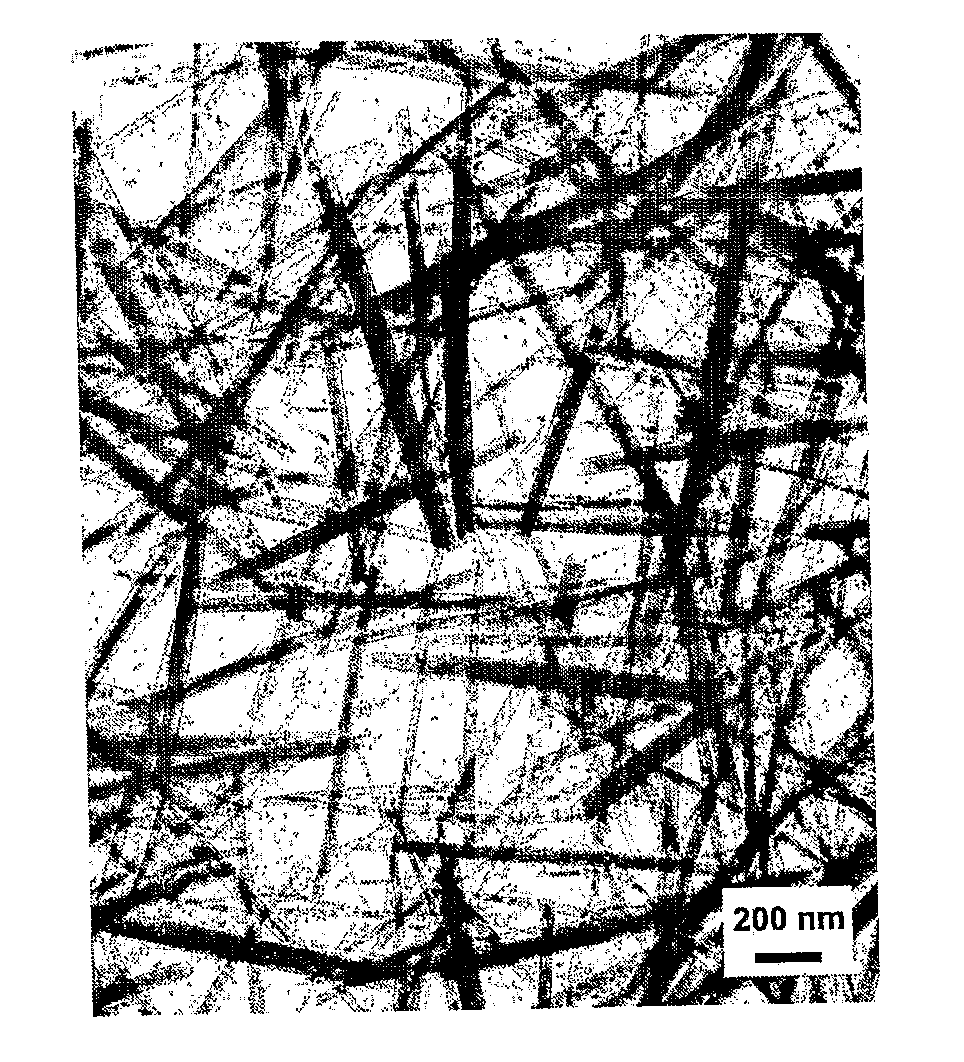

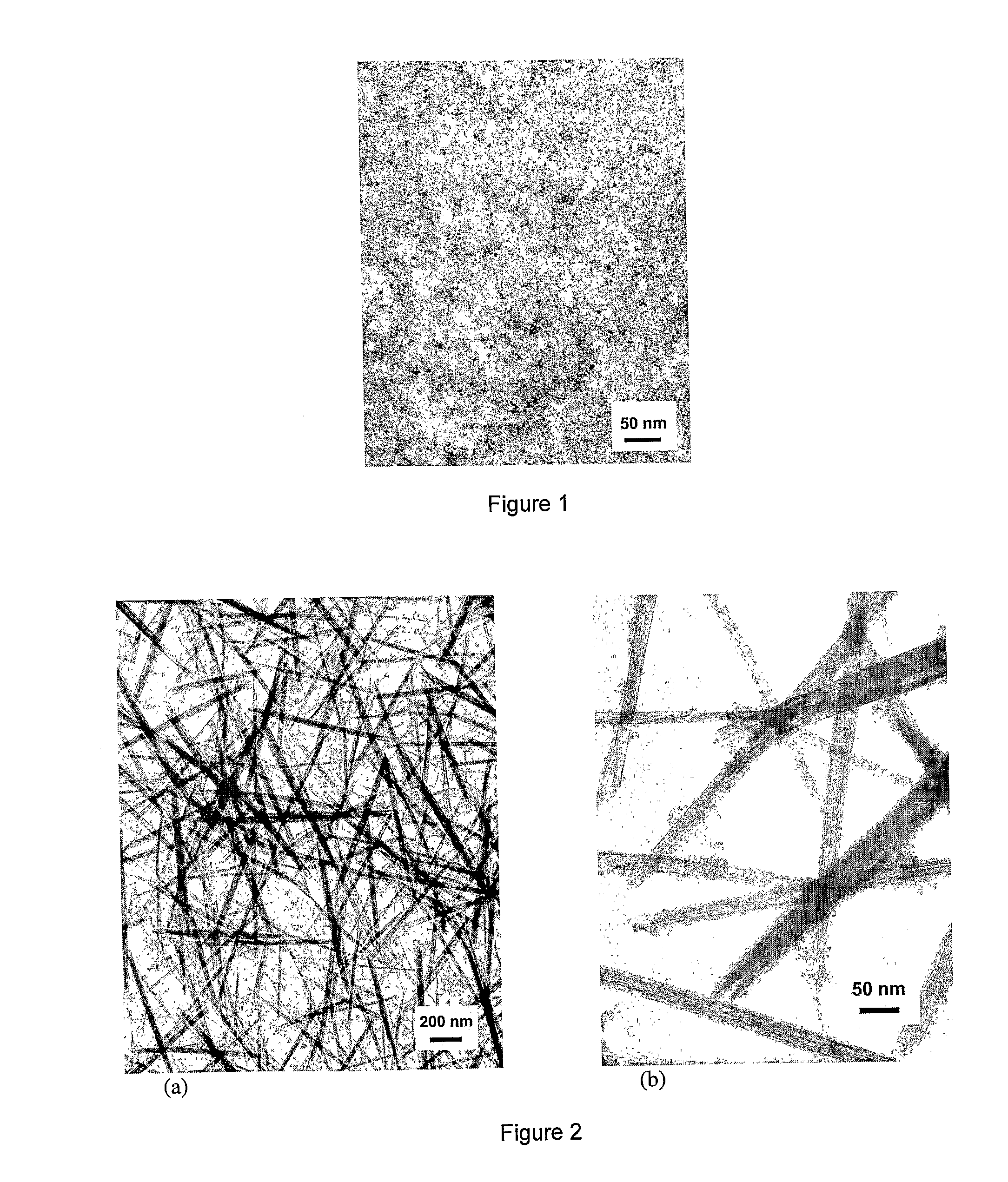

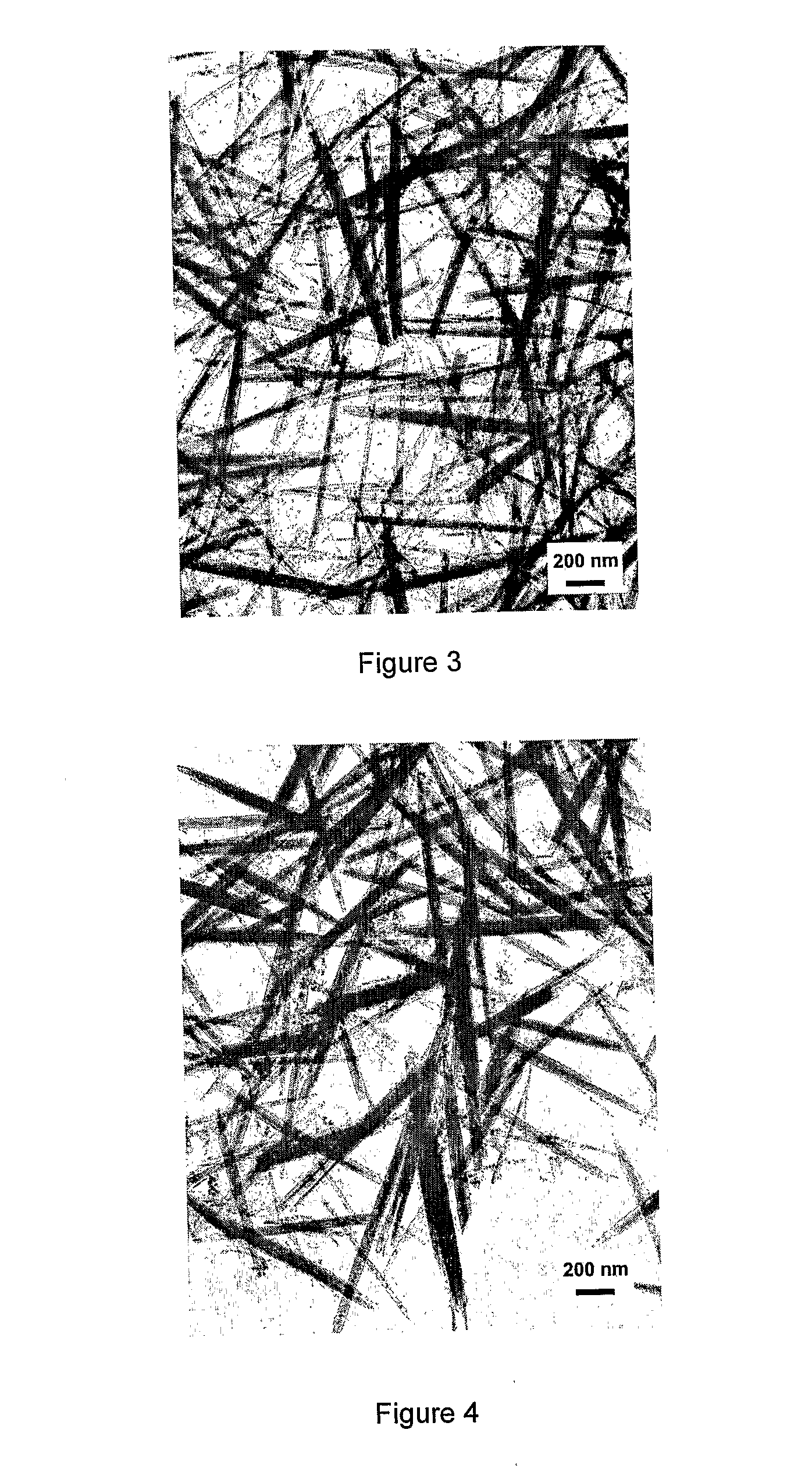

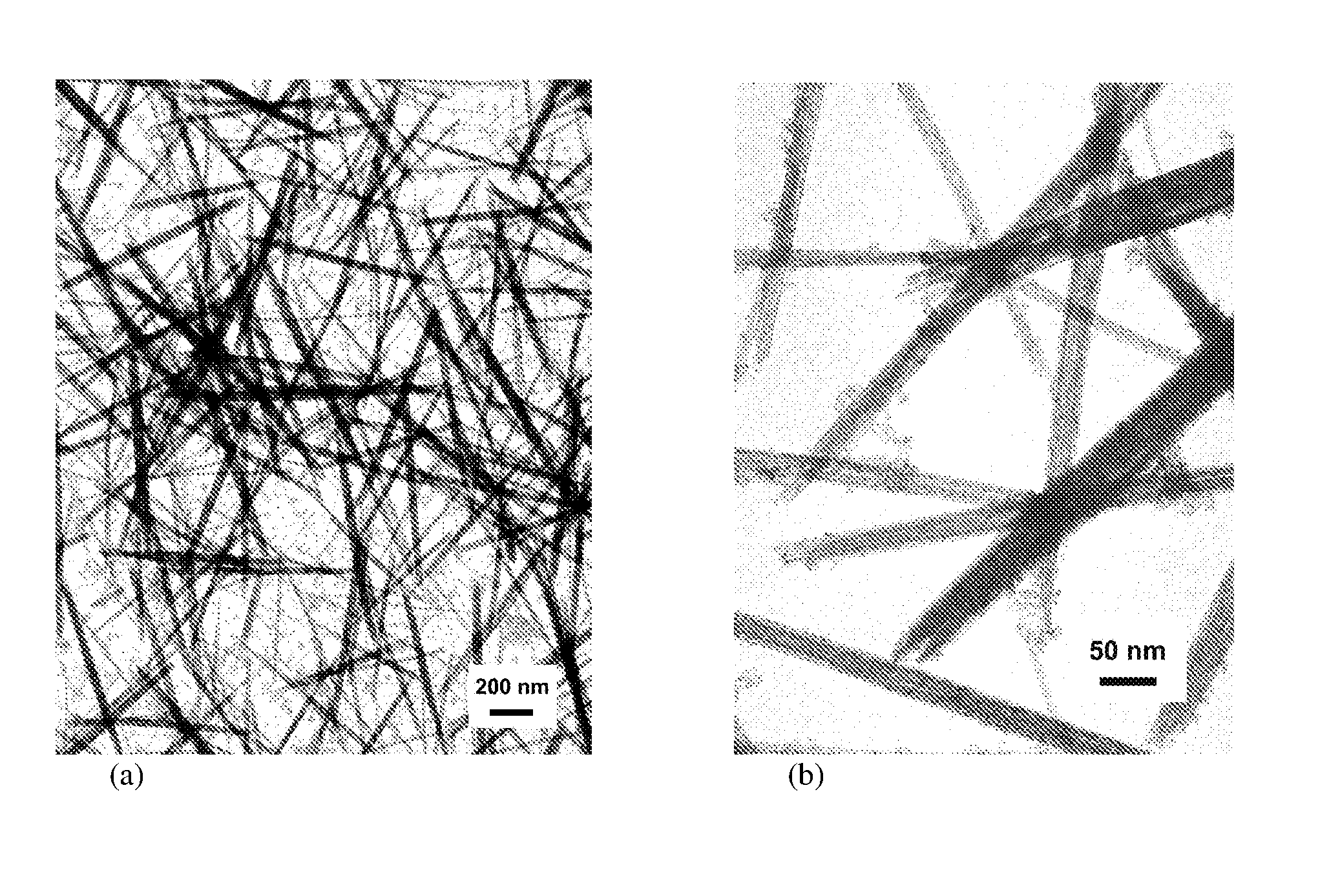

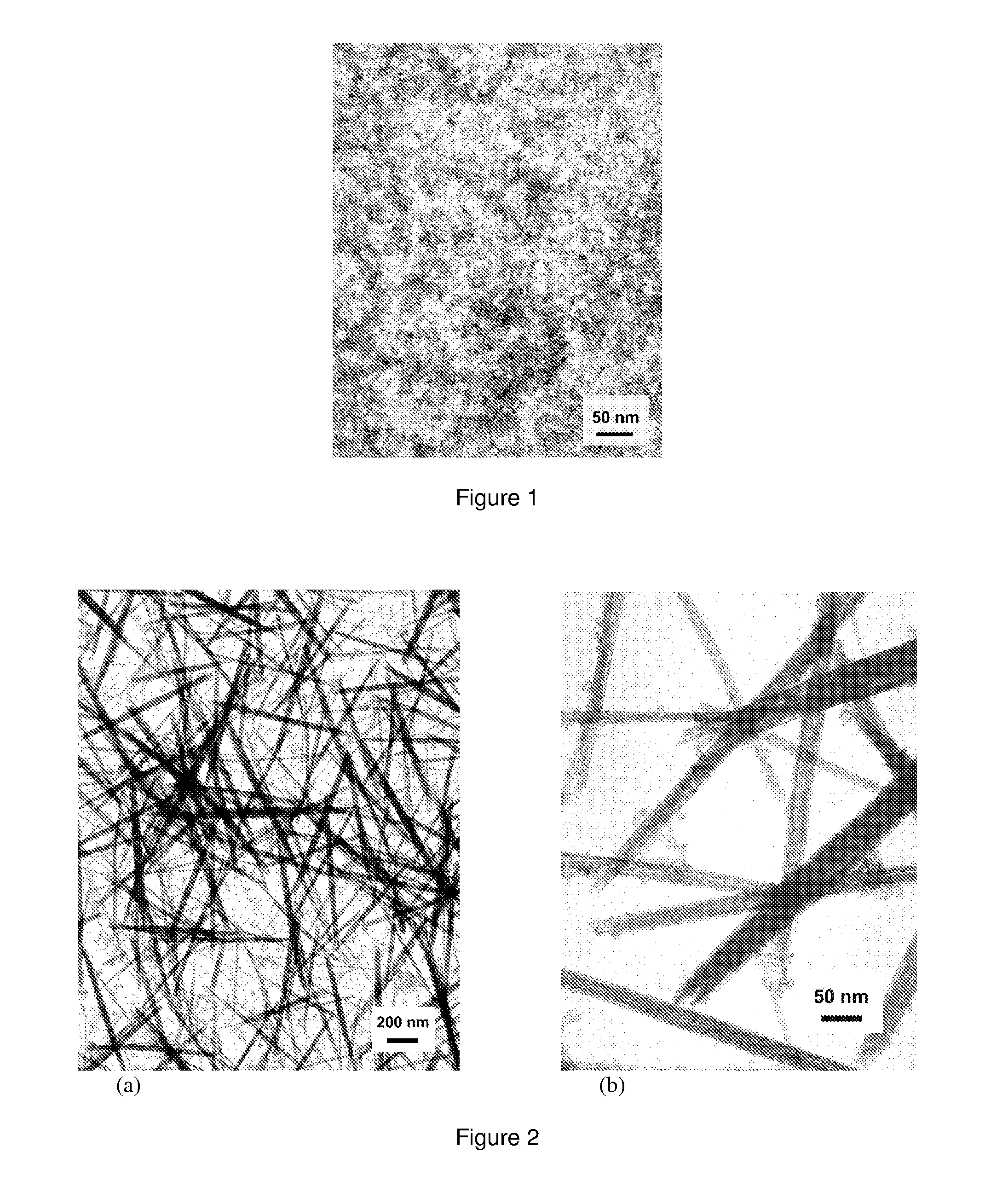

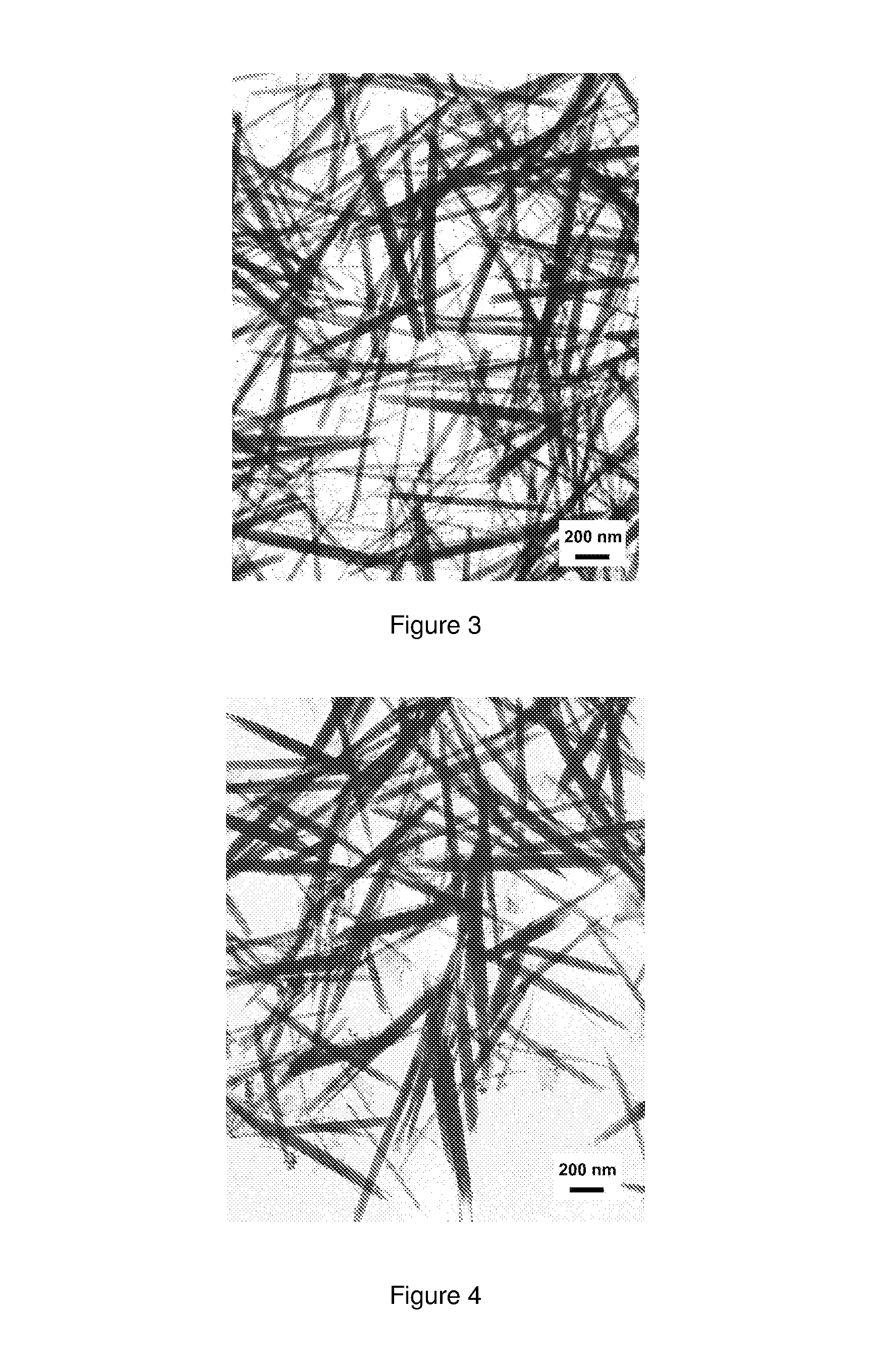

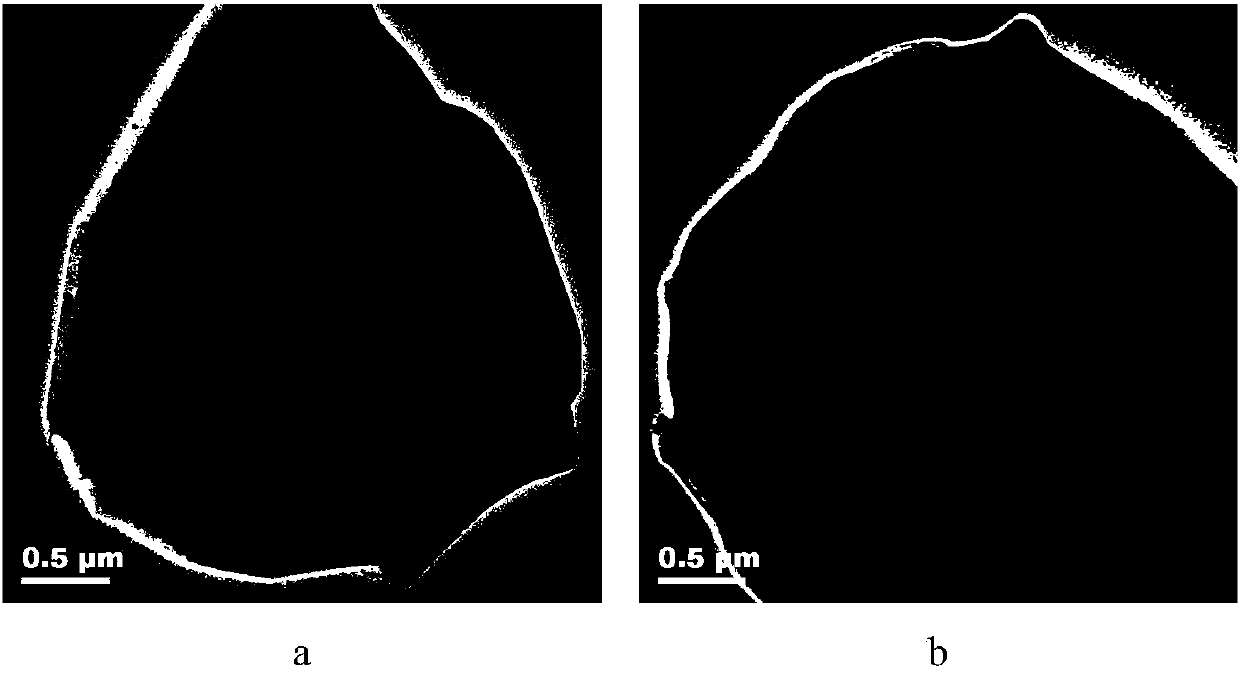

Rare Earth Nanorods

ActiveUS20080279744A1Reduce expenditureMaterial nanotechnologyPolycrystalline material growthNanoparticleRare earth

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

Rare earth nanorods

ActiveUS7943106B2Reduce expenditureMaterial nanotechnologyPolycrystalline material growthRare-earth elementAnisotropic growth

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

Method for improving the screen brightness of gadolinium oxysulfide x-ray phosphors

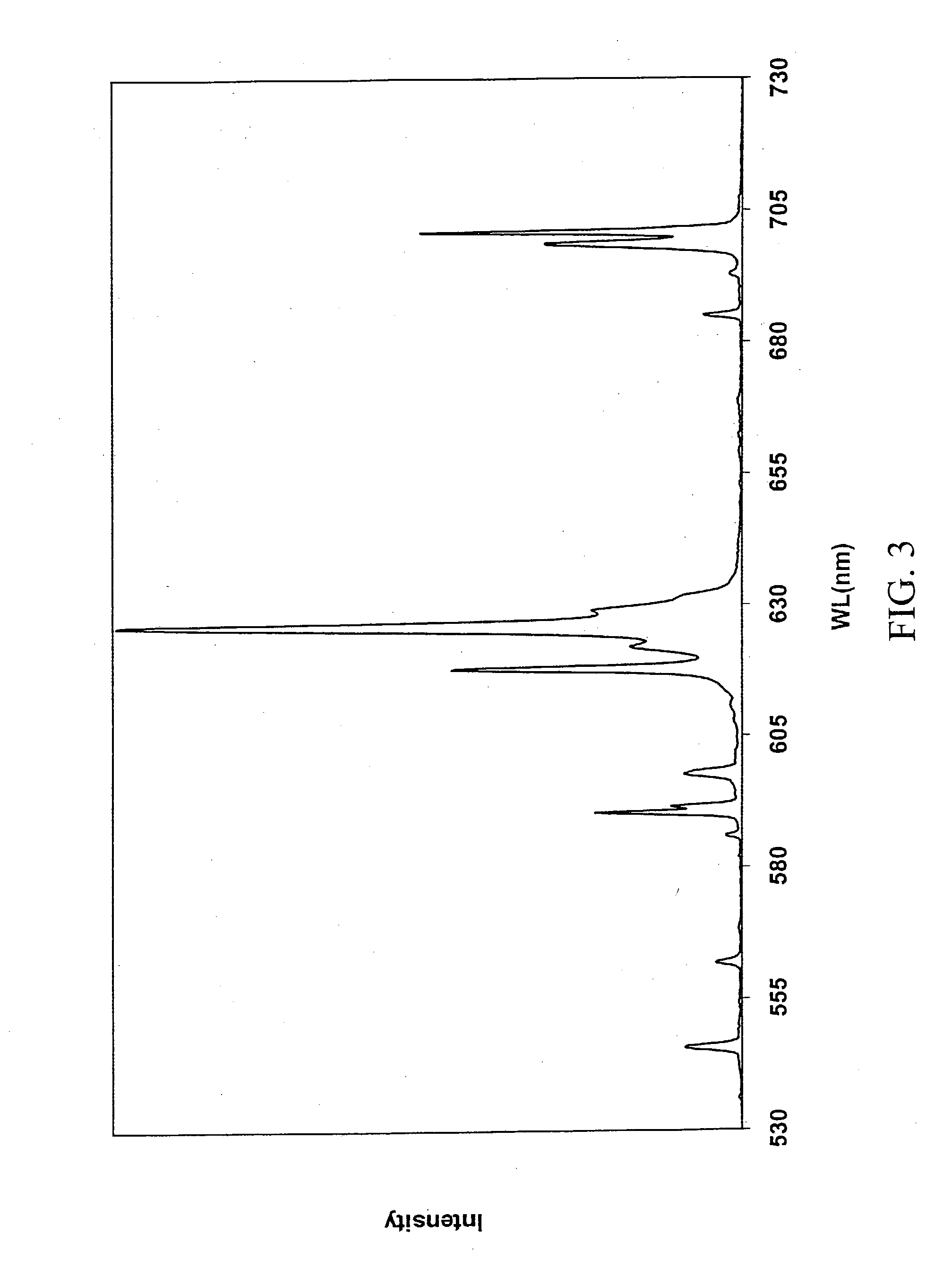

InactiveUS6103296AIncrease screen brightnessAmeliorates the damage caused by deagglomerationRare earth metal sulfidesBleaching apparatusPhysicsGadolinium oxysulfide

A method is provided for improving the x-ray screen brightness of gadolinium oxysulfide x-ray phosphors. The method applies annealing and acid washing steps in a specific order following deagglomeration of the phosphor in order to ameliorate the loss of brightness caused by the deagglomeration.

Owner:GLOBAL TUNGSTEN & POWDERS CORP

Morphologically and size uniform monodisperse particles and their shape-directed self-assembly

ActiveUS20130302358A1Increase in sizeQuench reactionMaterial nanotechnologyRare earth metal sulfidesOptical propertyPhosphor

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

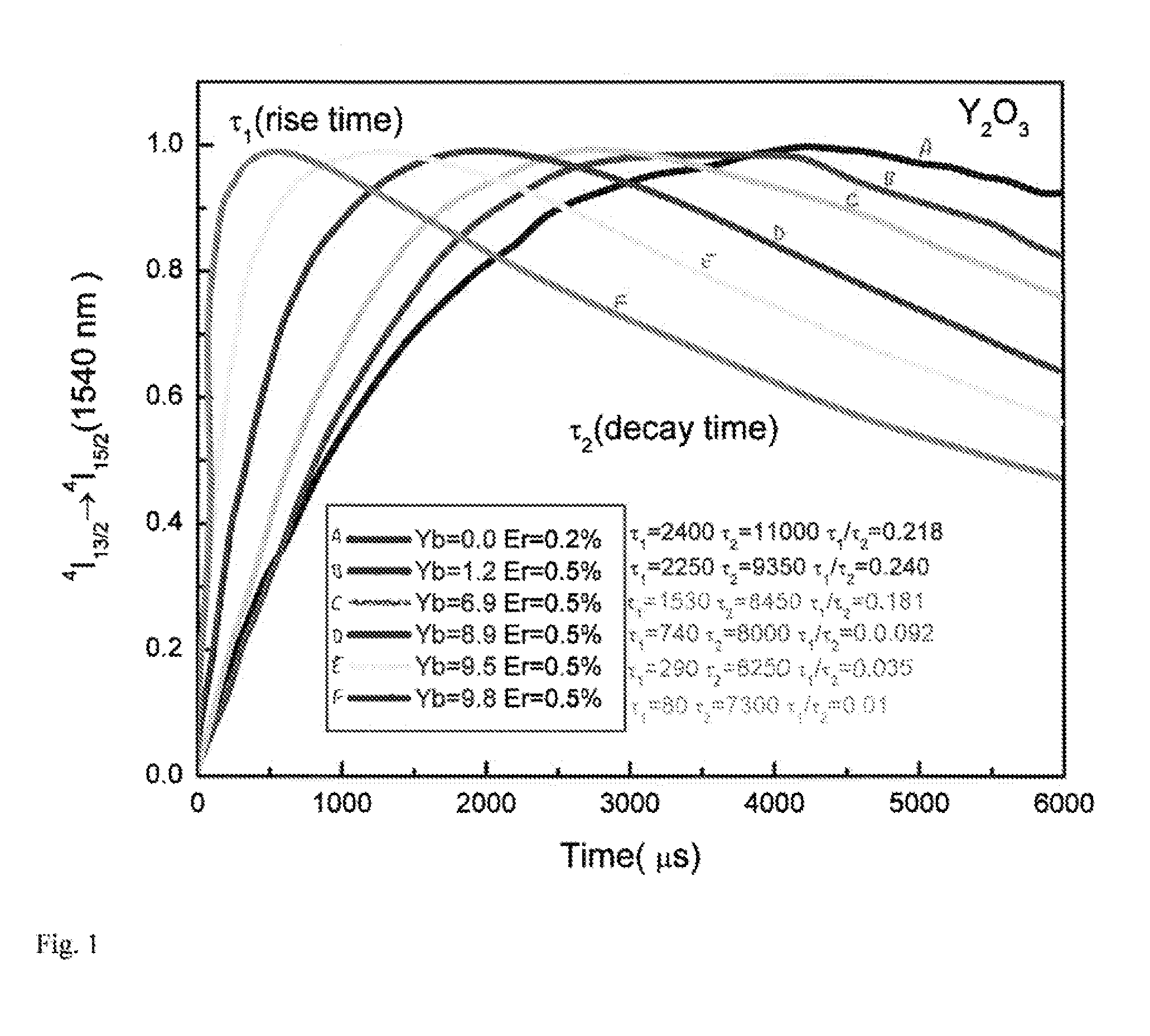

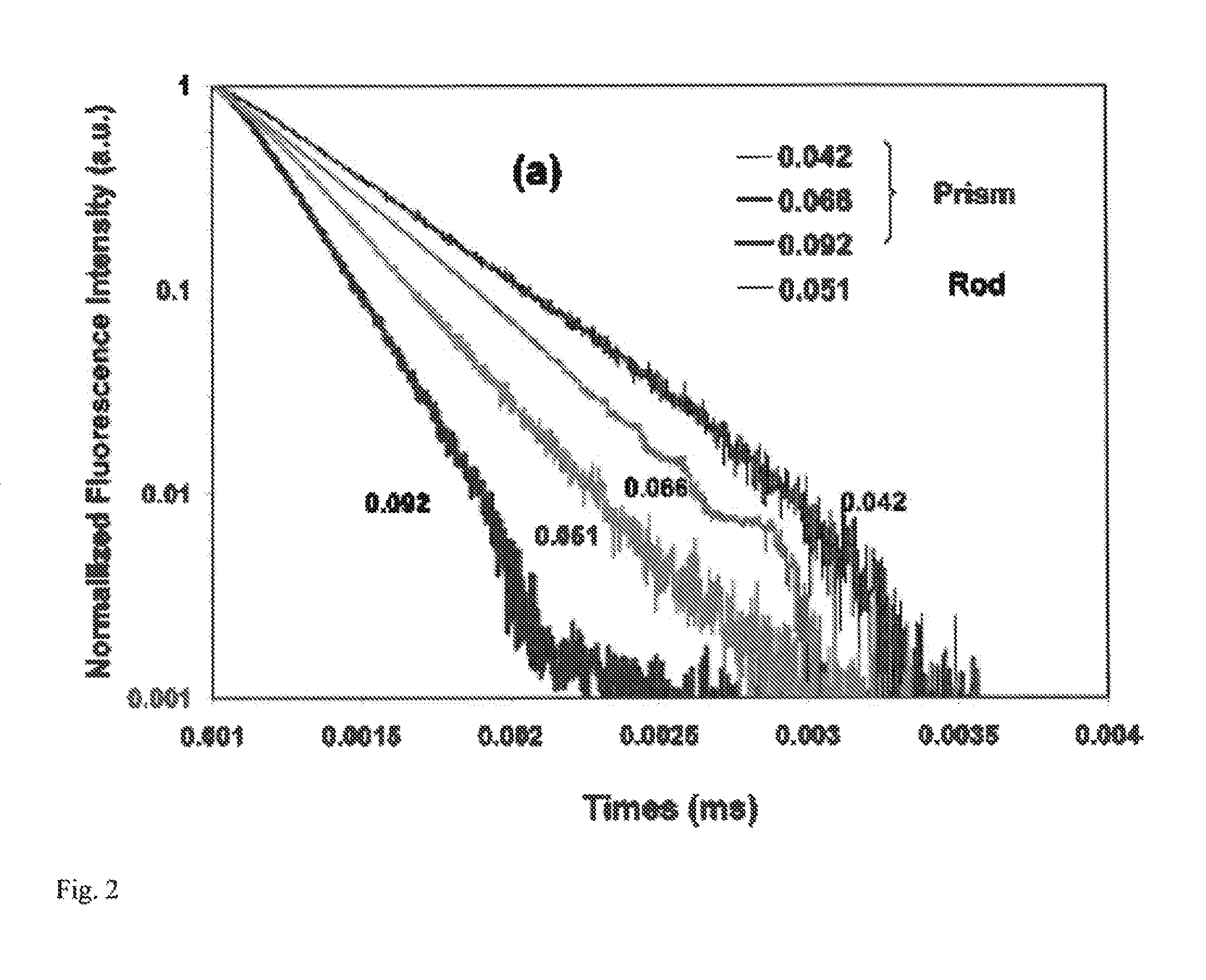

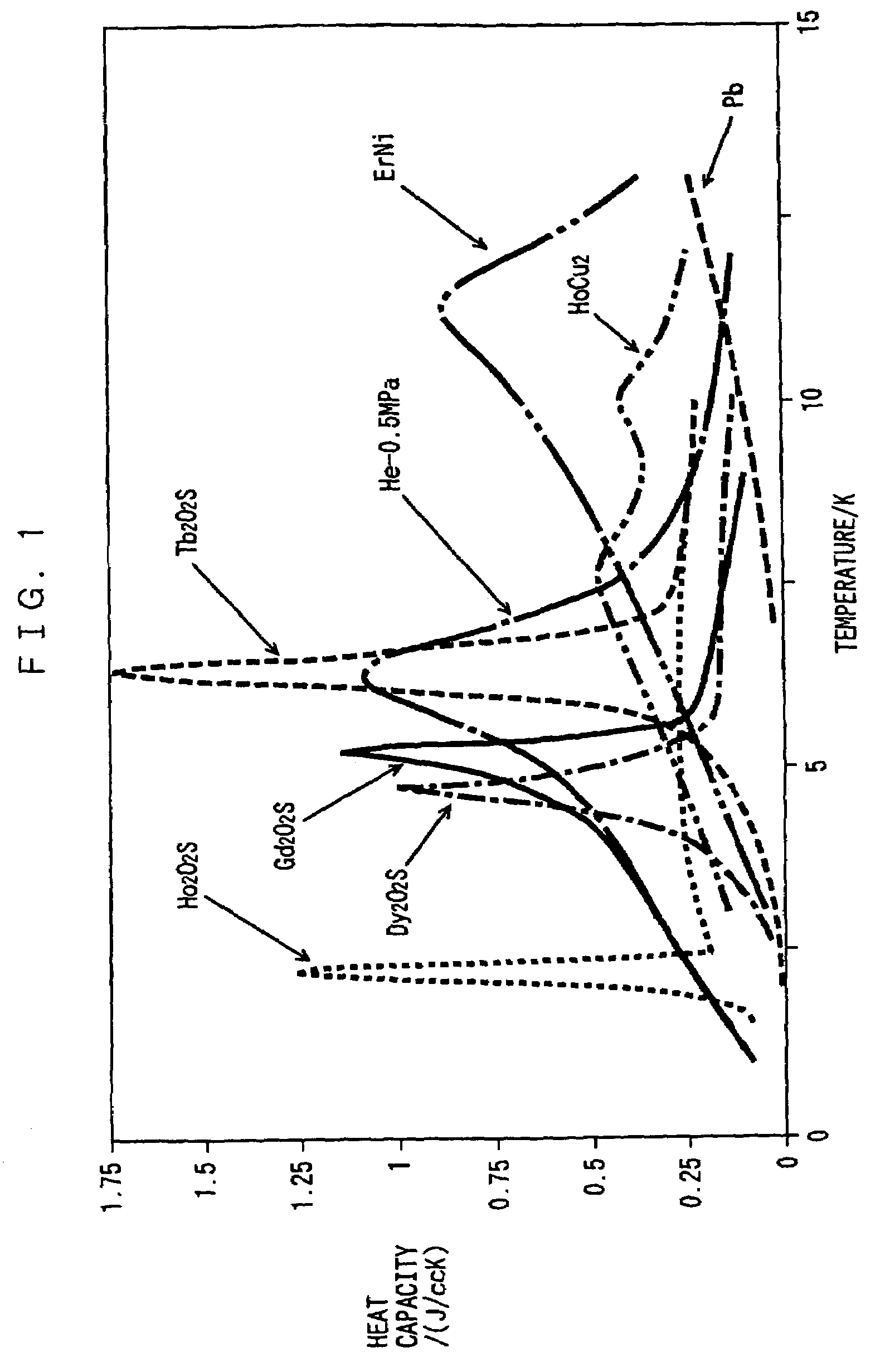

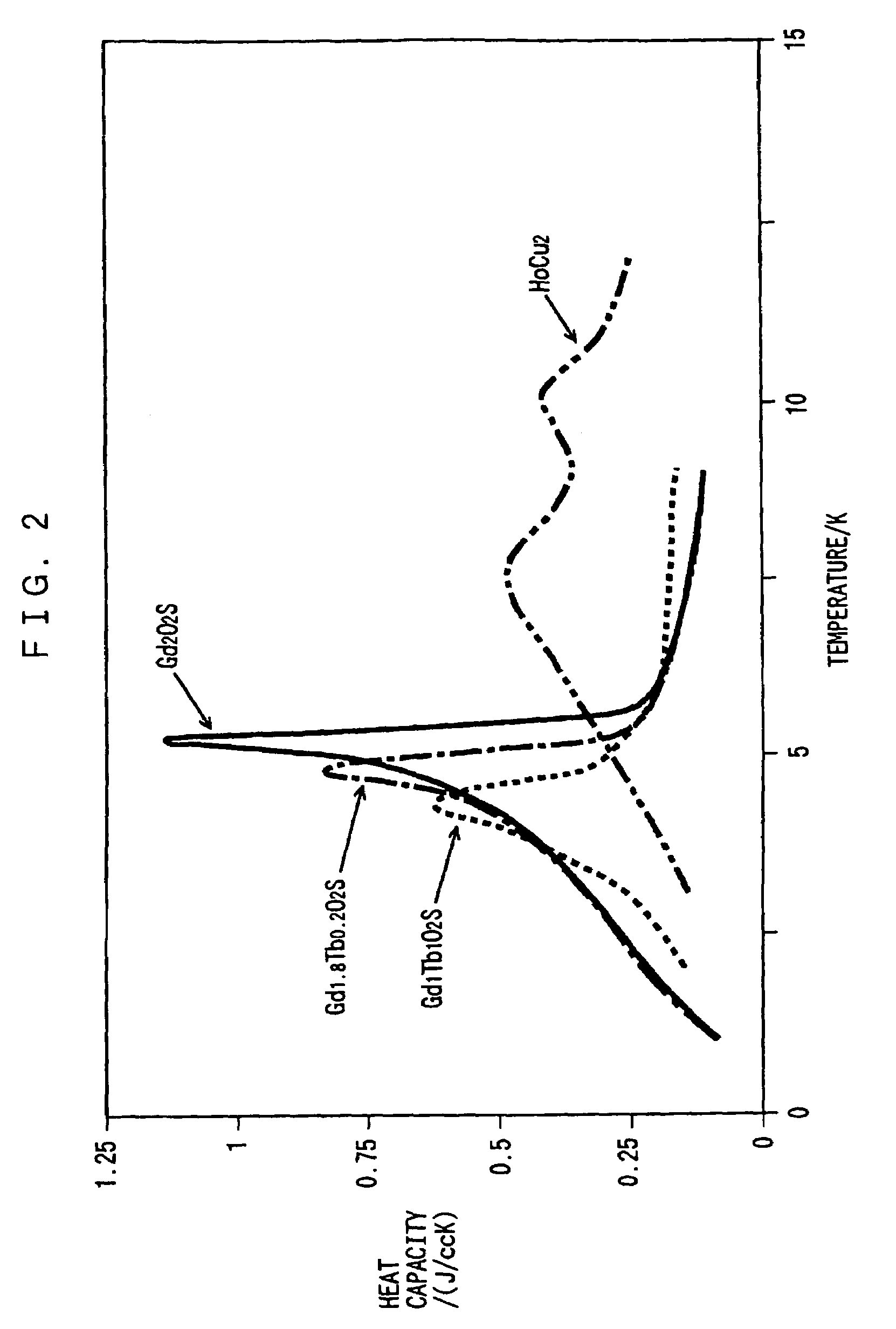

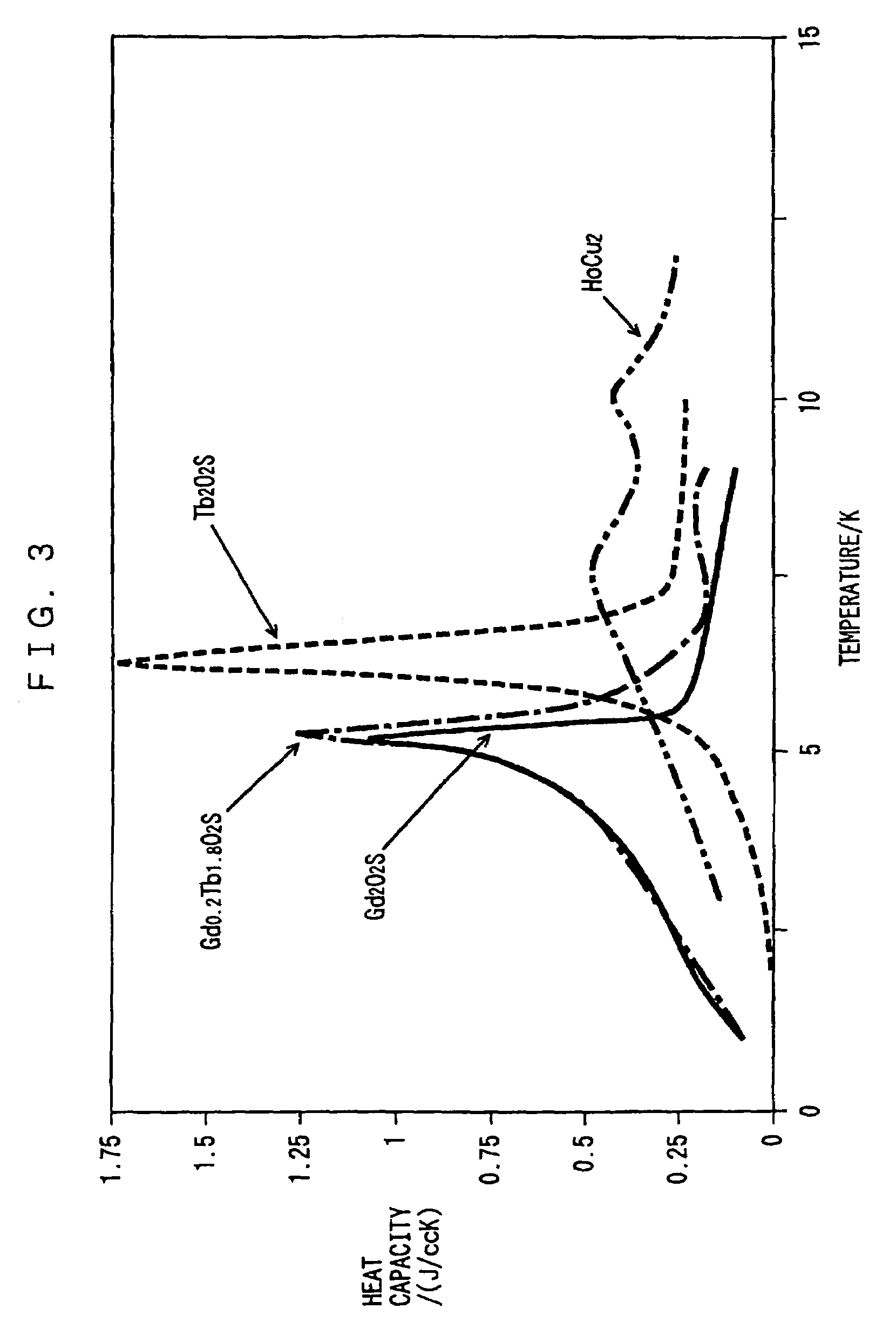

Rare earth metal oxysulfide regenerative material and regenerator

InactiveUS7226543B2Large heat capacityIncreased durabilityRare earth metal sulfidesOther chemical processesMischmetalSpherical granule

A rare earth metal oxysulfide represented by a general formula R2O2S (R denotes one kind or two or more kinds of rare earth elements to be selected from a group of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, as wells as Y) is formed into spherical granules. The mean particle size of the granules is 0.05–1 mm and their relative density is 96% or over. The granules are used as a regenerative material at the liquid helium temperature.

Owner:KONOSHIMA CHEMICAL CO LTD

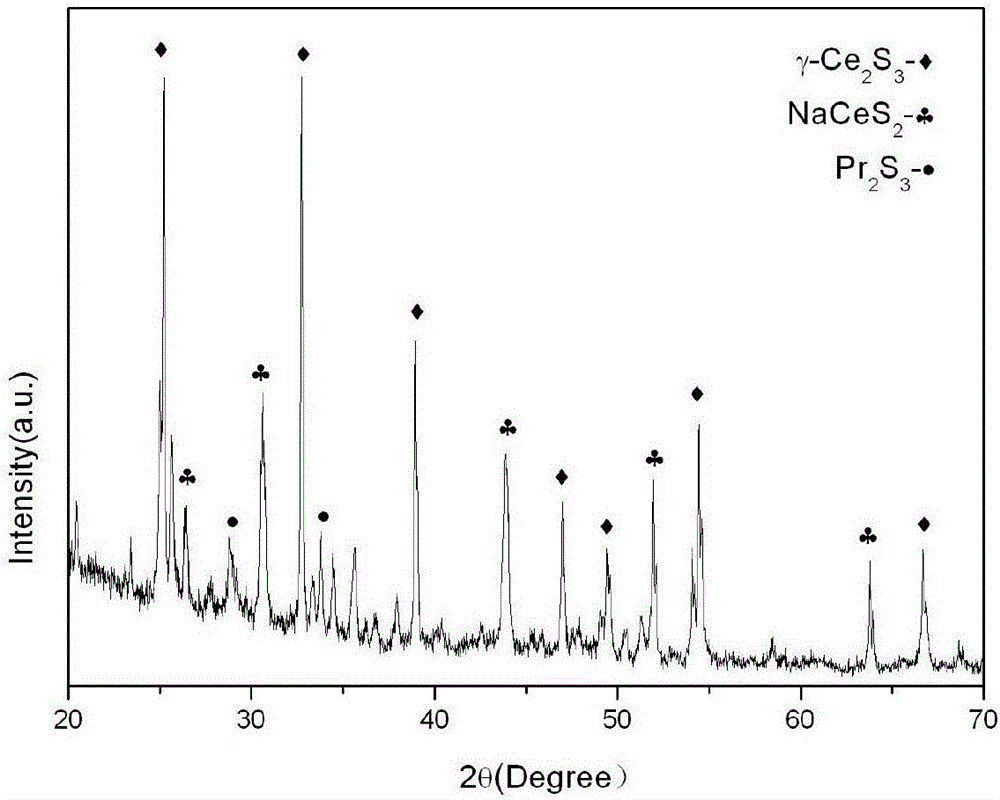

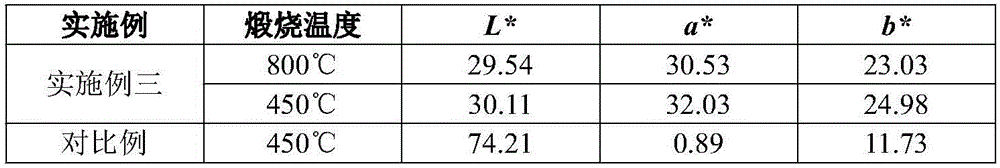

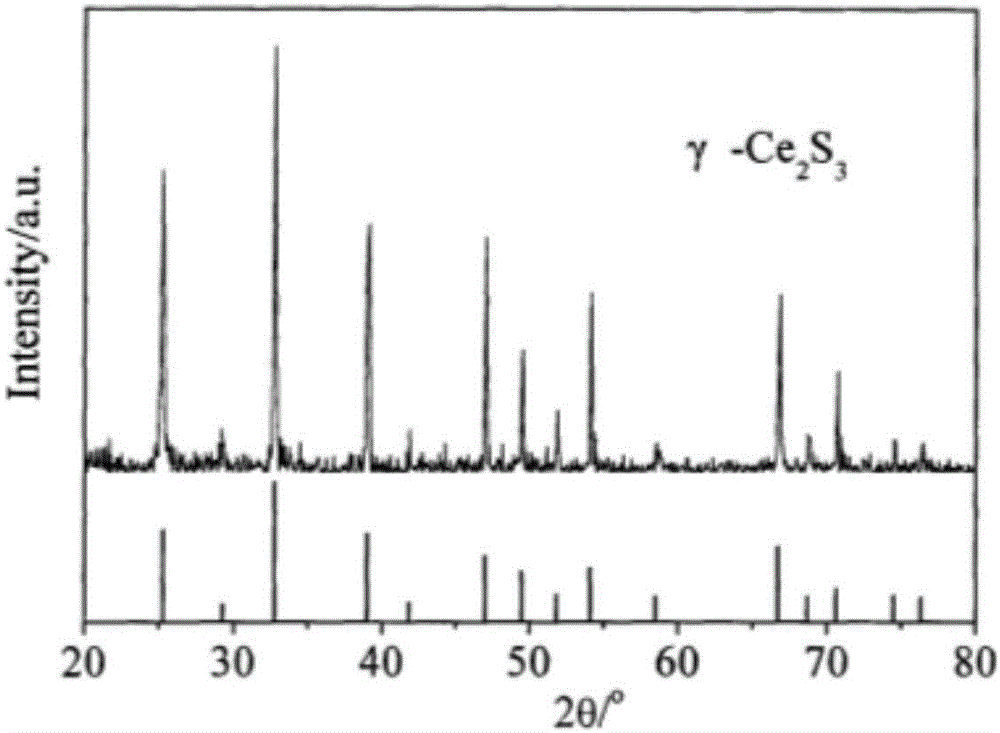

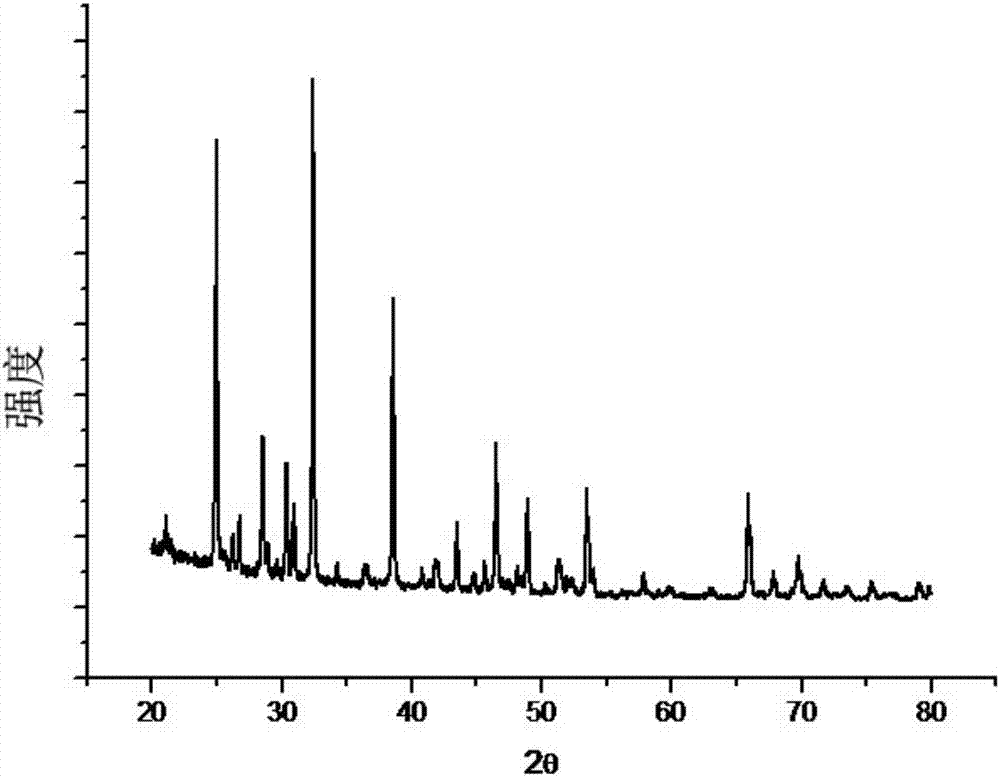

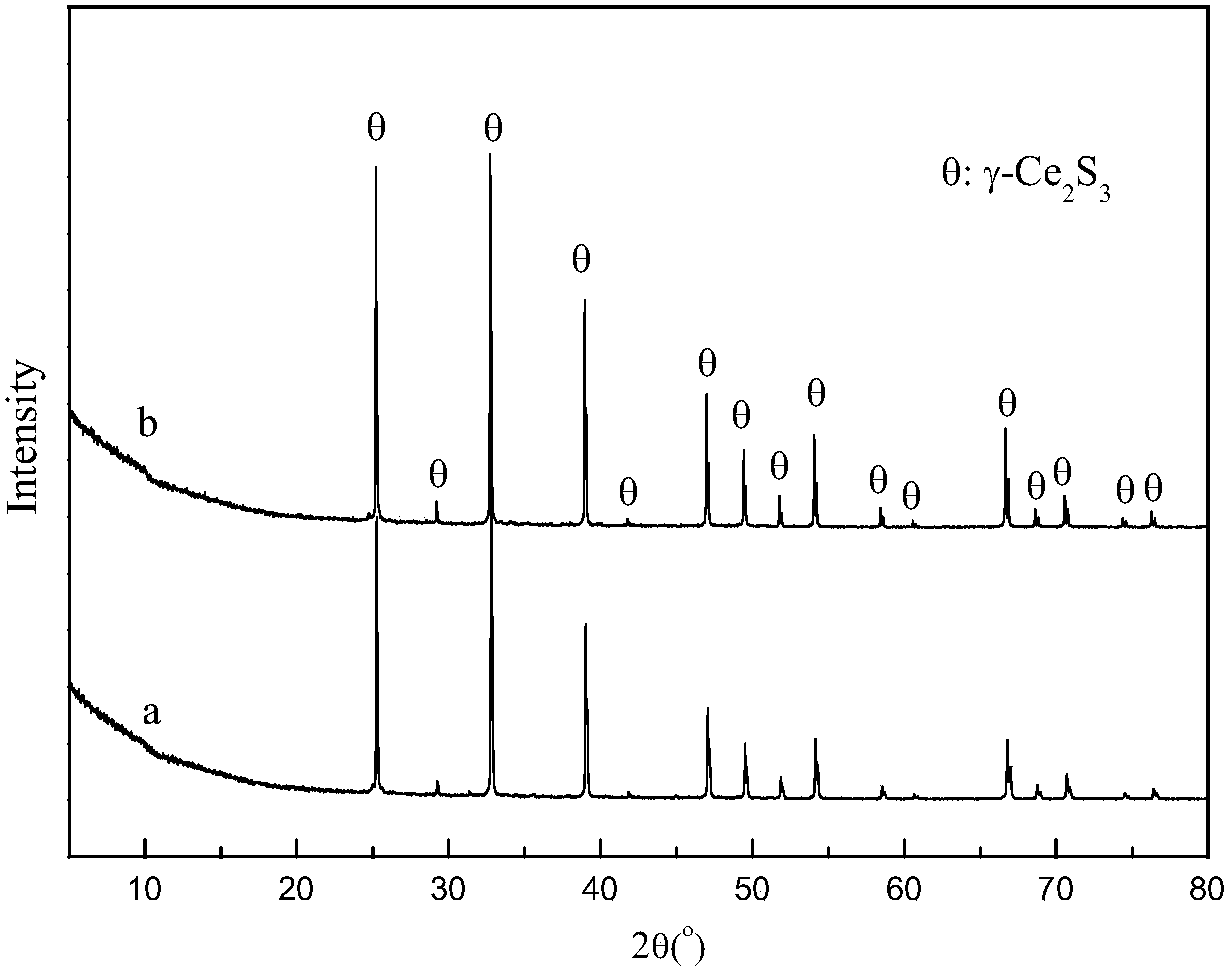

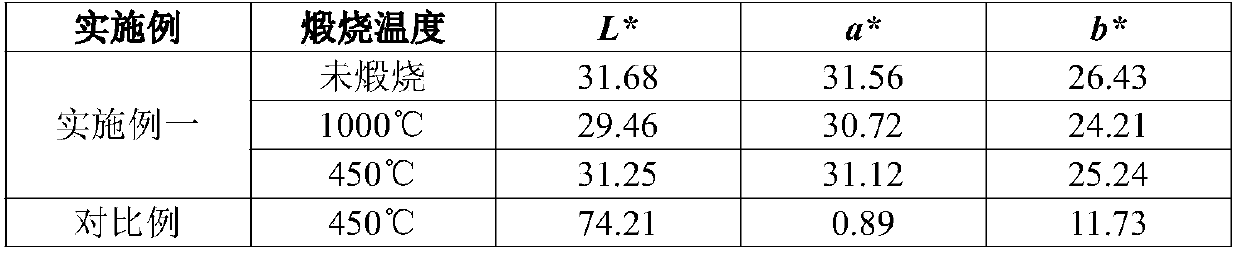

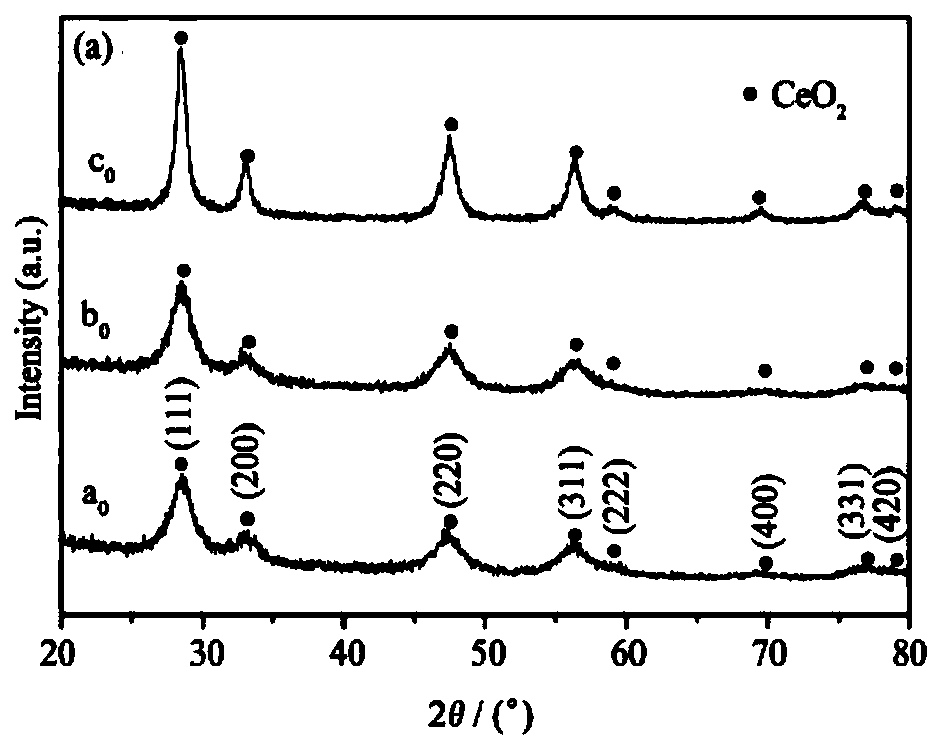

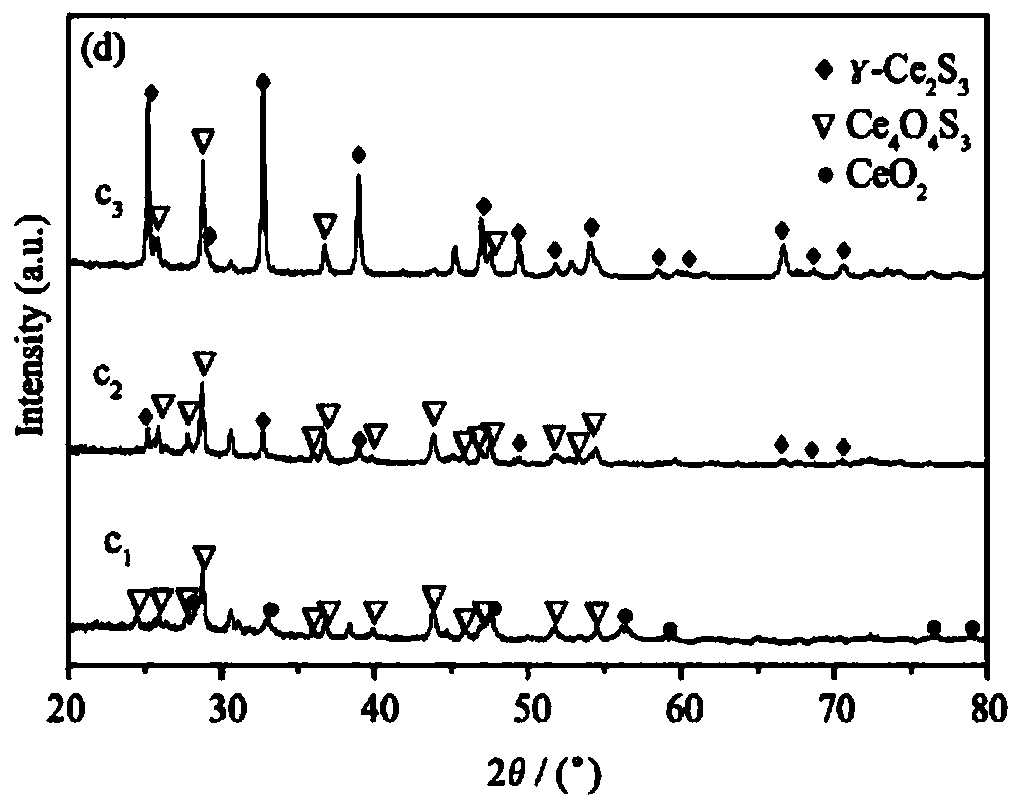

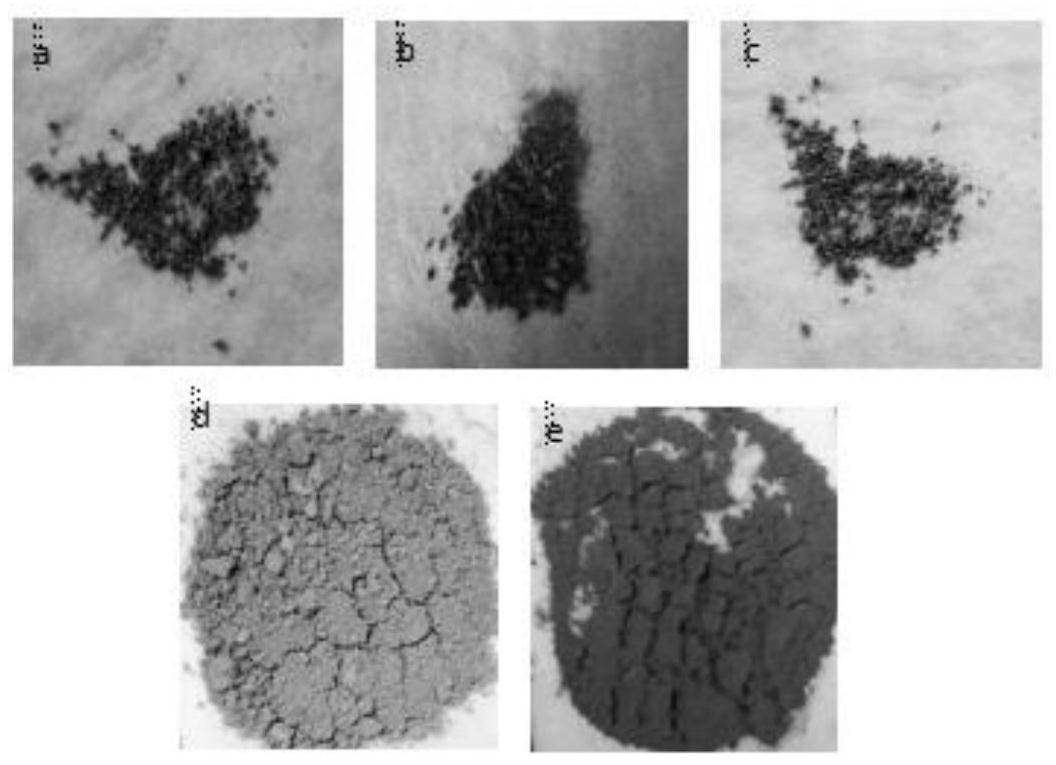

Method for preparing gamma-Ce2S3 red pigment by taking ion-doped CeO2 as precursor and vulcanizing

ActiveCN106830048AImprove high temperature stabilitySimple preparation processPigmenting treatmentRare earth metal sulfidesIonLiquid phase

The invention discloses a method for preparing gamma-Ce2S3 red pigment by taking ion-doped CeO2 as a precursor and vulcanizing. The method comprises the following steps: preparing an ion-doped CeO2 precursor suspension solution through a liquid-phase method; centrifuging the precursor suspension solution, washing with water, washing with alcohol and drying to prepare ion-doped CeO2 precursor powder; vulcanizing the precursor powder at high temperature to obtain the ion-doped stable gamma-Ce2S3 red pigment. Furthermore, the invention further discloses a product prepared by utilizing the preparation method. According to the method disclosed by the invention, doping ions are added so that gamma-Ce2S3 crystal lattices are effectively stabilized and the high-temperature stability of the doped pigment is greatly improved; the obtained pigment product still has a red appearance at the temperature of 800 DEG C so that the application field of the pigment is extremely expanded. The method has the advantages that a preparation process is simple, the high-temperature stability of the product is high, the industrial application value is very high and the industrial popularization and application are facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Nano-scale metal oxyhalide and oxysulfide scintillation materials and methods for making same

InactiveUS20110024685A1Rare earth metal oxides/hydroxidesMaterial nanotechnologyEmulsionMicroemulsion

Crystalline scintillator materials comprising nano-scale particles of metal oxides, metal oxyhalides and metal oxysulfides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In one method, used to form oxyhalides and oxysulfides, metal salts are dissolved in water, and then precipitated out as fine particles using an aqueous base. After the particles are separated from the solution, they are annealed under a flow of a water saturated hydrogen anion gas, such as HCl or H2S, to form the crystalline scintillator particles The other methods take advantage of the characteristics of microemulsion solutions to control droplet size, and, thus, the particle size of the final nano-particles. For example, in one method, a first micro-emulsion containing metal salts if formed. The first micro-emulsion is mixed with an aqueous base in a second micro-emulsion to form the final nano-scale particles.

Owner:GENERAL ELECTRIC CO

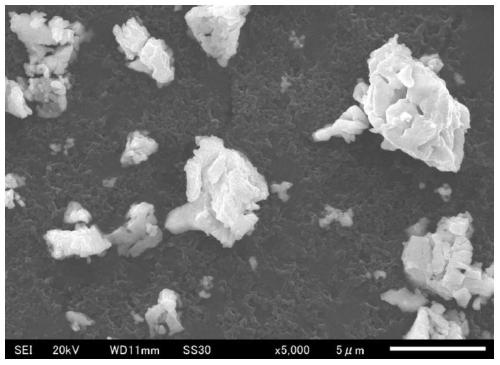

Method for preparing nano cerium sulfide by adopting liquid phase method

The invention relates to a method for preparing nano cerium sulfide by adopting a liquid phase method. The method comprises the following steps that a water-soluble trivalent cerium salt and a water-soluble sulfide reacts in a base solution to generate sol, and then filtration and drying are performed, wherein the base solution is prepared from mica powder and water; the obtained product and ammonium thiocyanate are uniformly mixed, and calcination is performed at the temperature of 800-1000 DEG C; then fluoridation treatment is performed by using an affiliative fluorinating agent. The prepared nano cerium sulfide (gamma-Ce2S3) product is bright in color and strong in tinting strength, the tinting strength can be up to 85% of the tinting strength of a cadmium red pigment and is greatly better than iron oxide red, molybdate red, manganese red and other inorganic red pigment. The covering power can be up to the level of the cadmium-based red pigment, the particle size is uniform, the dispersibility is good, and temperature resistance and corrosion resistance are good.

Owner:湖南科莱新材料有限公司

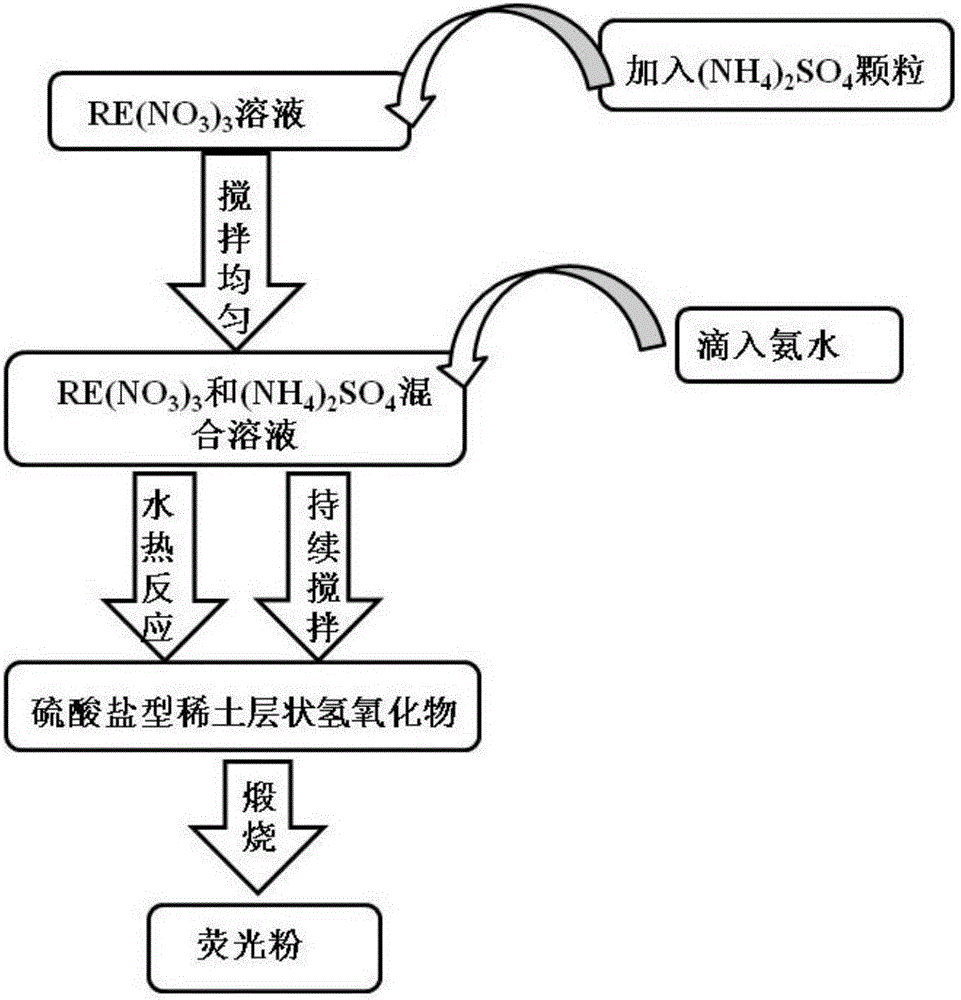

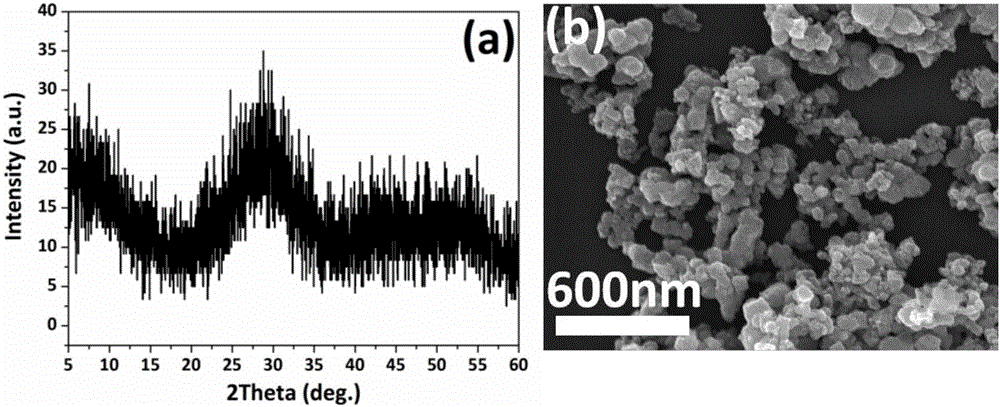

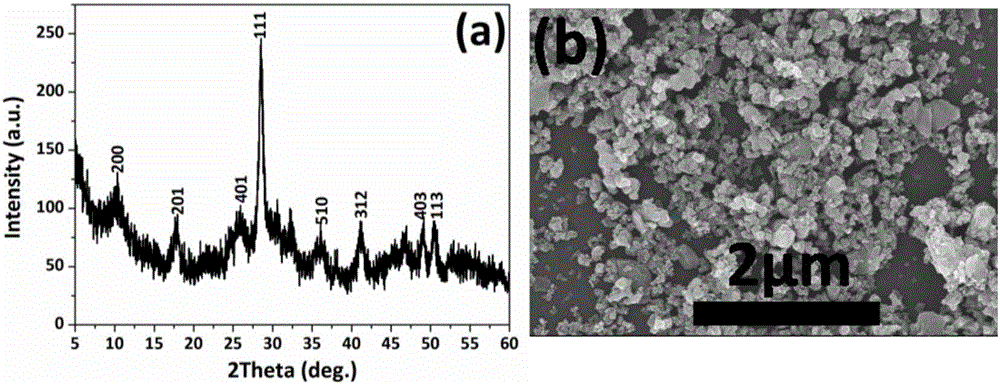

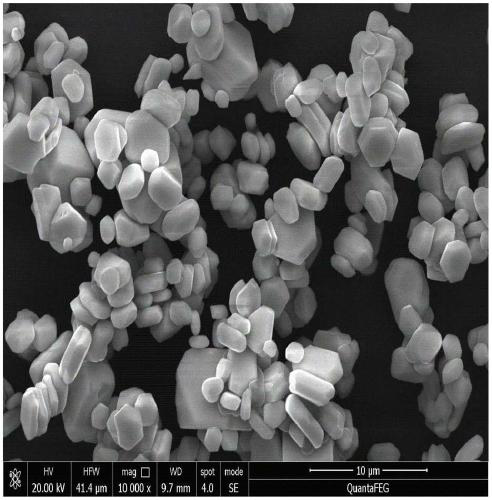

Preparing method of rare earth-doped gadolinium oxysulfide fluorescent powder

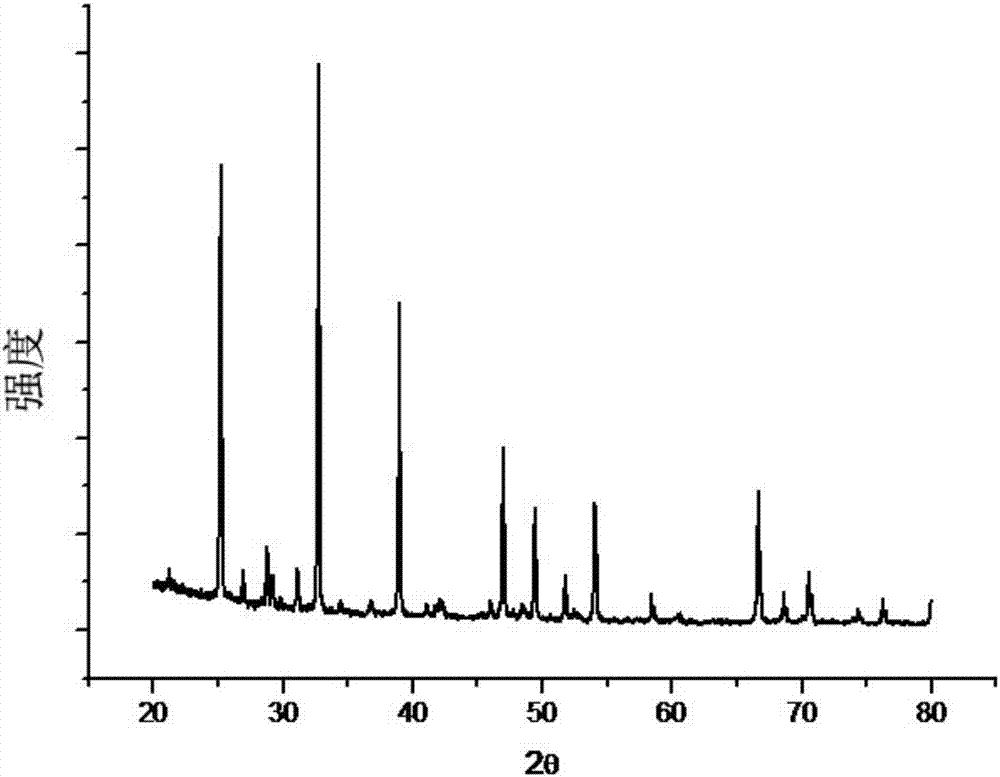

ActiveCN106544025AEffective adjustment of shapeSimple technical solutionRare earth metal sulfatesRare earth metal sulfidesGadolinium oxysulfideNitrate

The invention discloses a preparing method of rare earth-doped gadolinium oxysulfide fluorescent powder, and belongs to the technical field of materials. The preparing method comprises the first step of preparing a RE(NO3)3 solution, wherein the RE(NO3)3 solution is mixed liquid of Gd(NO3)3 and activating agent nitrate; the second step of dissolving ammonium sulfate into the RE(NO3)3 solution, continuously stirring the mixture and adding ammonium hydroxide into the mixture, and adjusting a pH value to obtain turbid liquid; the third step of conducting reaction on the turbid liquid at the temperature of minus 1-150 DEG C for 1-72 hours to obtain a reaction product; the fourth step of conducting centrifugal separation, cleaning and drying on the reaction product to obtain a white powder precursor; roasting the white powder precursor in reducing atmosphere to obtain (Gd,Tb)202S or (Gd,Pr)202S fluorescent powder. According to the technical scheme, the preparing method is simple and easy to operate, in the process of preparing (Gd,Tb)202S or (Gd,Pr)202S, sulfocompound which is harmful to the environment is not involved; in addition, (Gd,Tb)202S or (Gd,Pr)202S of various morphologies (nano-particles, agglomerated balls and standard hexagon micron sheet bars) can be obtained.

Owner:NORTHEASTERN UNIV

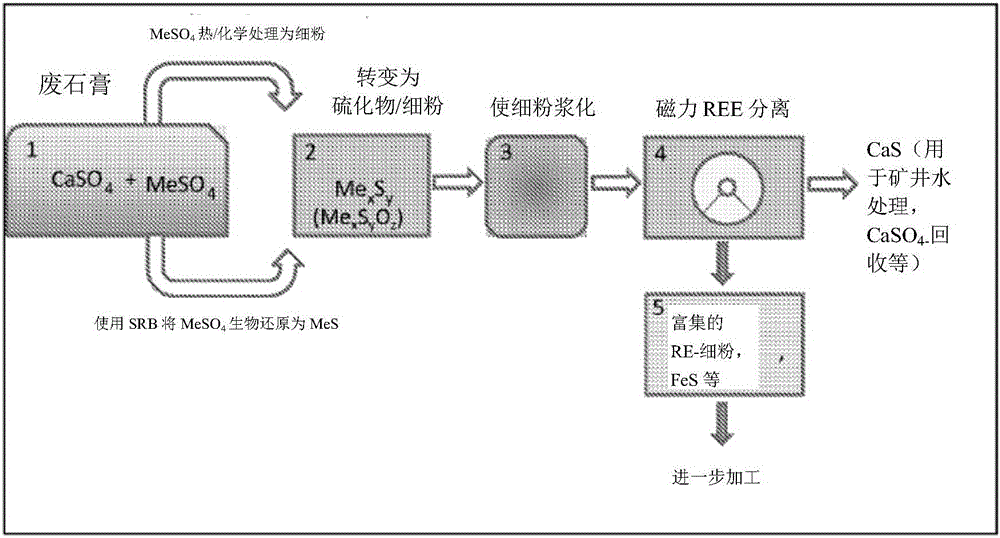

Method for recovering rare earth metals from waste sulphates

InactiveCN105765091ALow costHigh gradient magnetic separationRare earth metal sulfidesRare-earth elementMagnetic susceptibility

The present invention relates to a method for recovering rare earth metals from waste sulphate materials, such as waste gypsum, which is a known secondary resource of rare earth metals and widely present e.g. in areas, where industrial phosphate production takes place. The present invention combines sulphate reduction treatment, such as bioreduction with sulphate reducing bacteria, and magnetic separation, which is based on an exceptionally high magnetic susceptibility of rare earth compounds compared to e.g. calcium compounds in such reductively pretreated gypsum precipitate.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

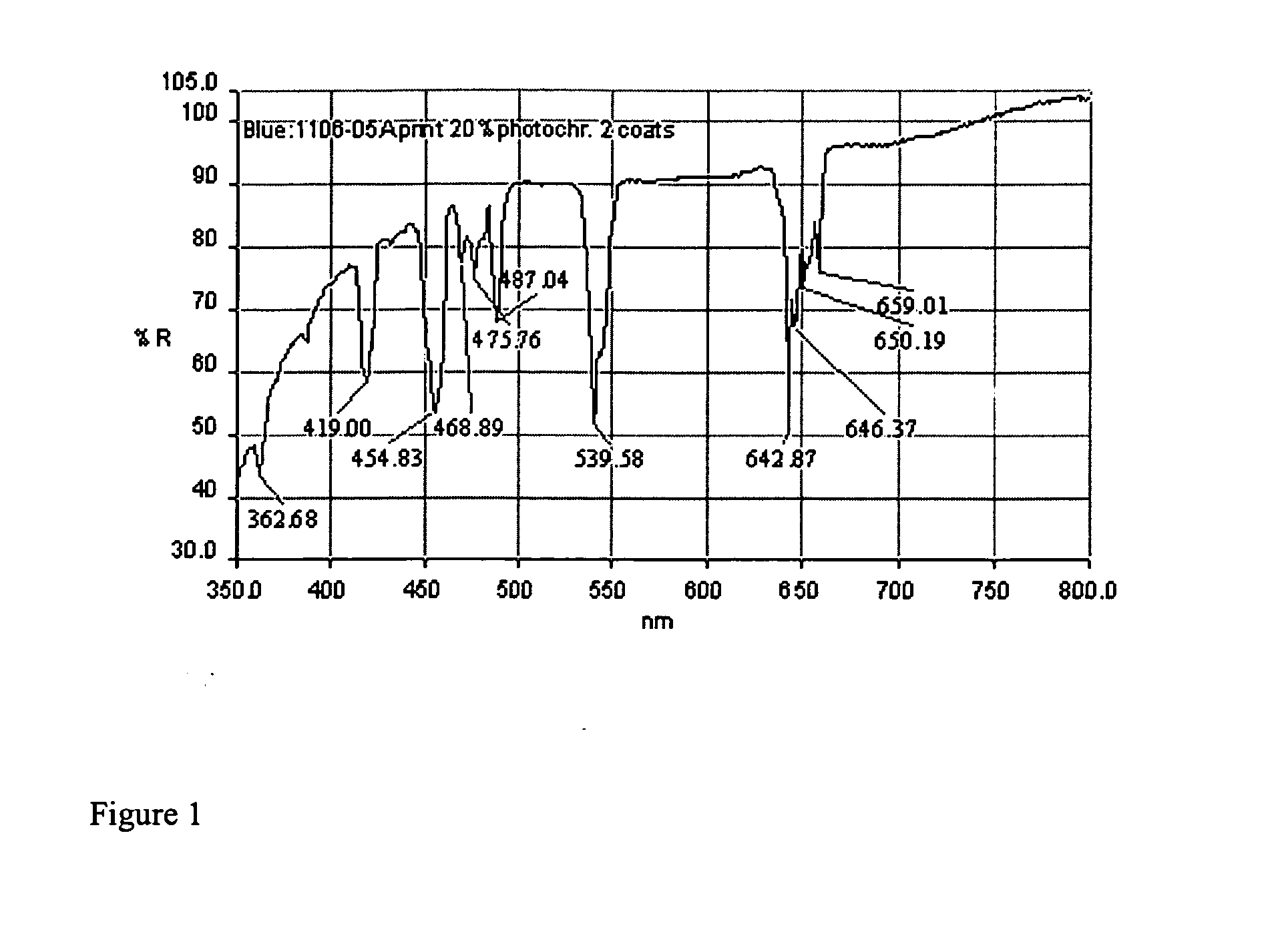

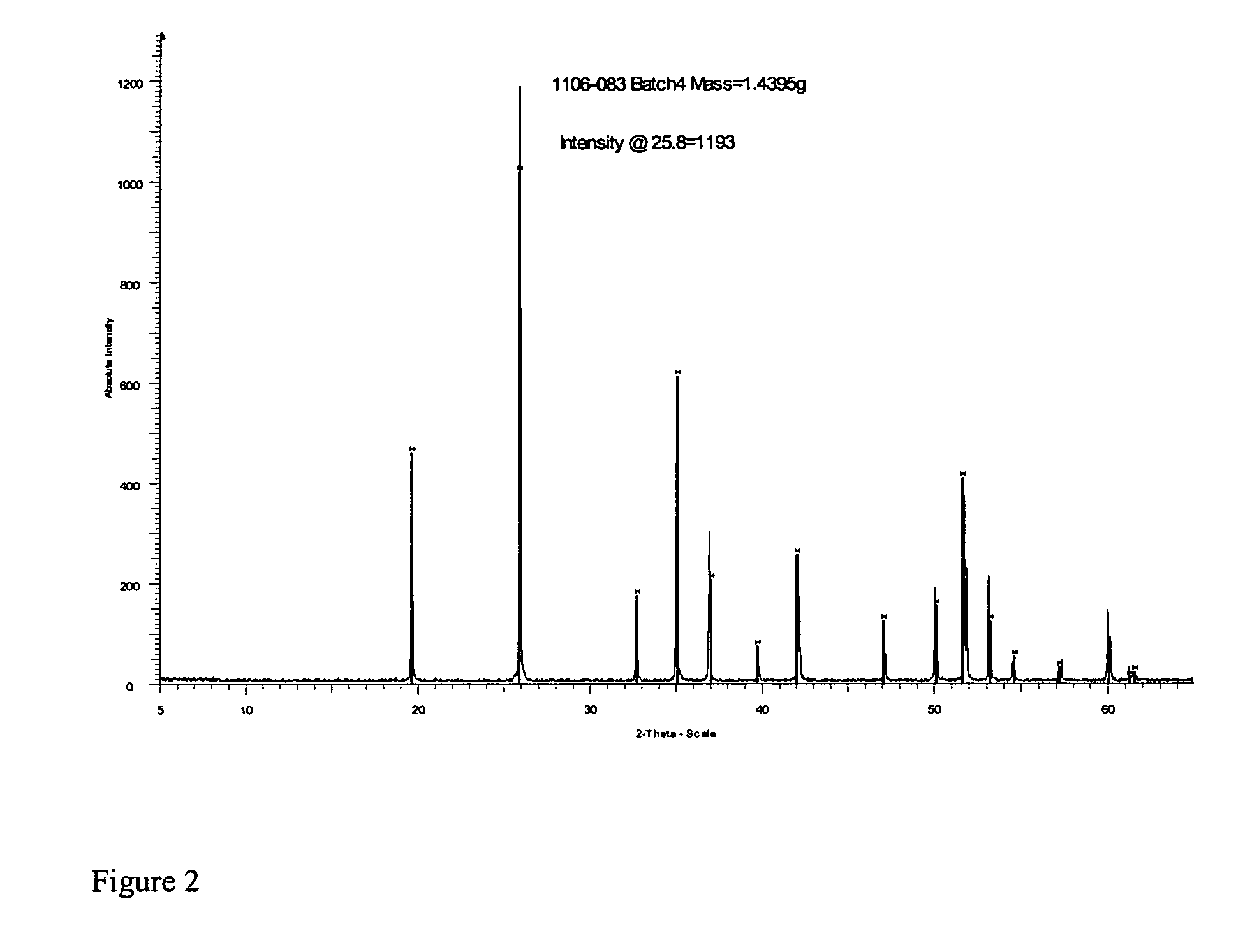

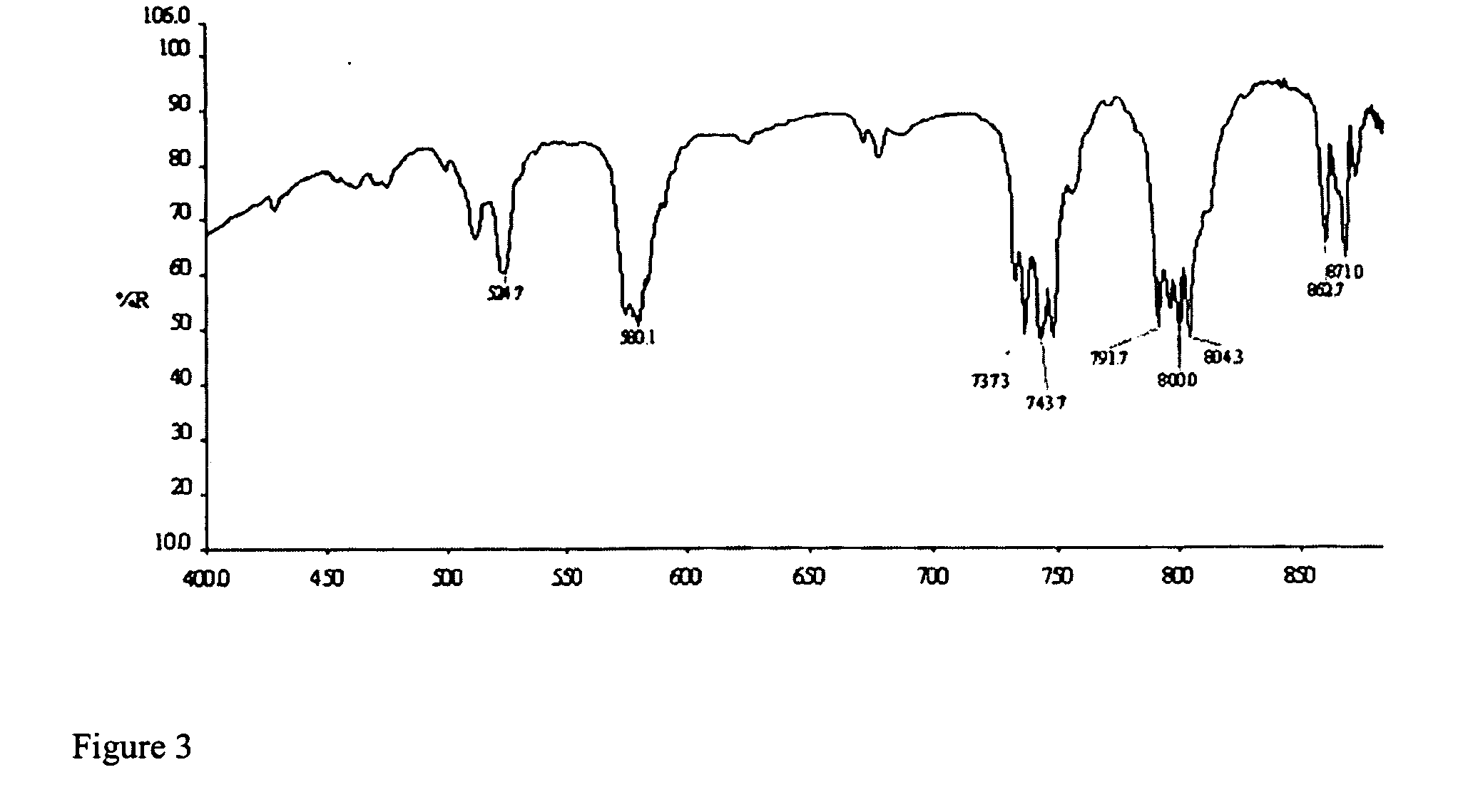

Novel methods for preparing rare-earth oxysulfide phosphors, and resulting materials

InactiveUS20030209694A1Reduce in quantityReduce energy costsRare earth metal sulfidesLuminescent compositionsPhosphorNitrate salts

The present invention provides new and useful methods for preparing rare-earth oxysulfide phosphors. Advantageously, in accordance with the methods of the subject invention, rare-earth oxysulfide phosphors can be prepared with lower reaction temperatures and fewer processing steps than methods currently in use. In a preferred embodiment, the process of the subject invention involves blending two different rare-earth nitrate salts and a sulfidizing agent. Then, the mixture is heated at relatively low temperatures until the rare-earth oxysulfide phosphor is produced.

Owner:FLORIDA UNIV OF A FLORIDA +1

Colorant and preparation method thereof

ActiveCN107151461AImprove vividnessOmit processingRare earth metal sulfidesInorganic pigment treatmentRare earthSulfide

The invention discloses a rare earth sulfide colorant and a preparation method thereof. The chemical formula of the rare earth sulfide colorant is RE2-2xS3-3x.2y[REPO4], wherein RE is one or more of La, Ce, Pr, Nd and Sm, and the ratio of y to x is 0.001-0.65. The invention further discloses application of a phosphorous compound to the improvement of color brightness of the rare earth sulfide colorant.

Owner:包头中科世纪科技有限责任公司

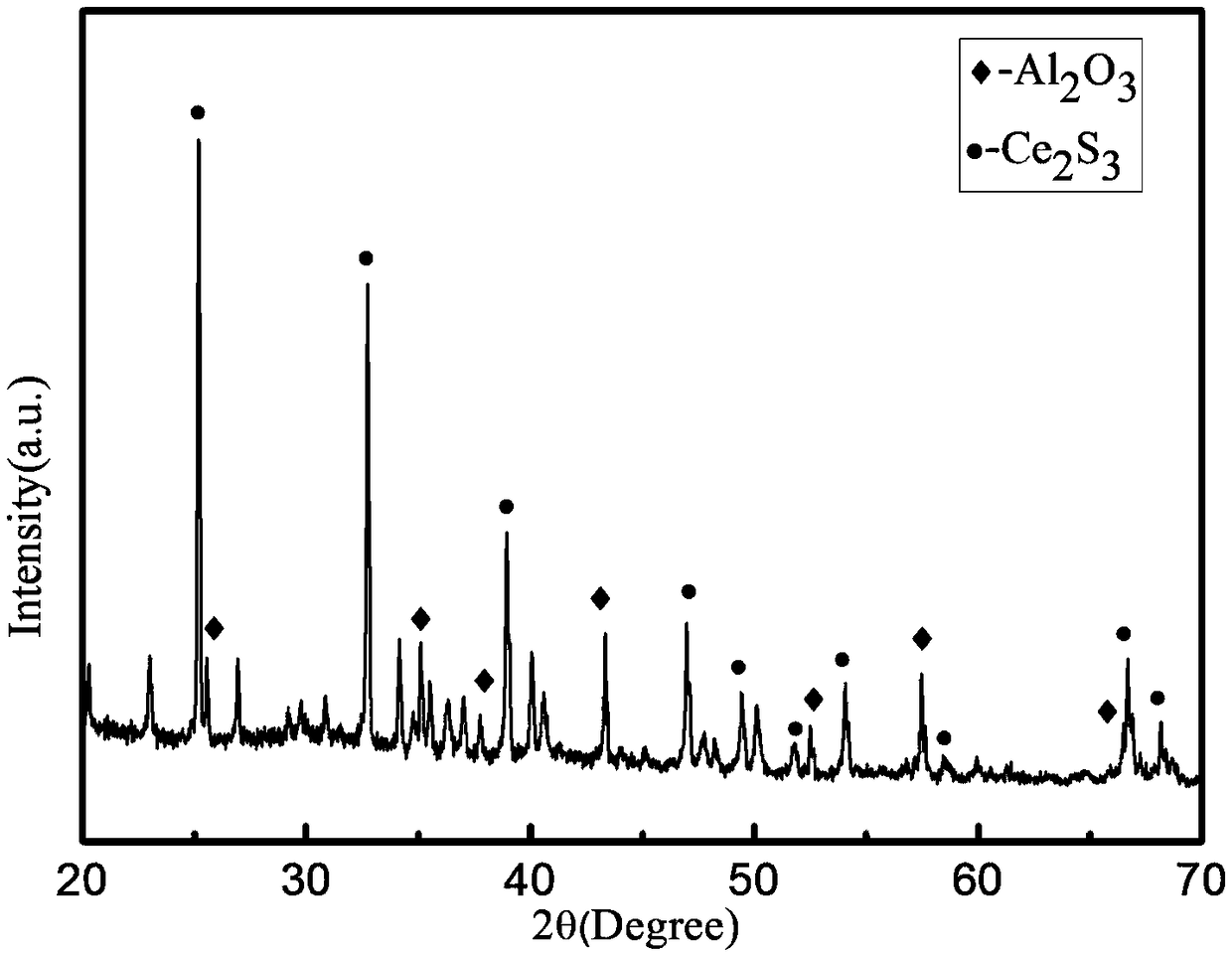

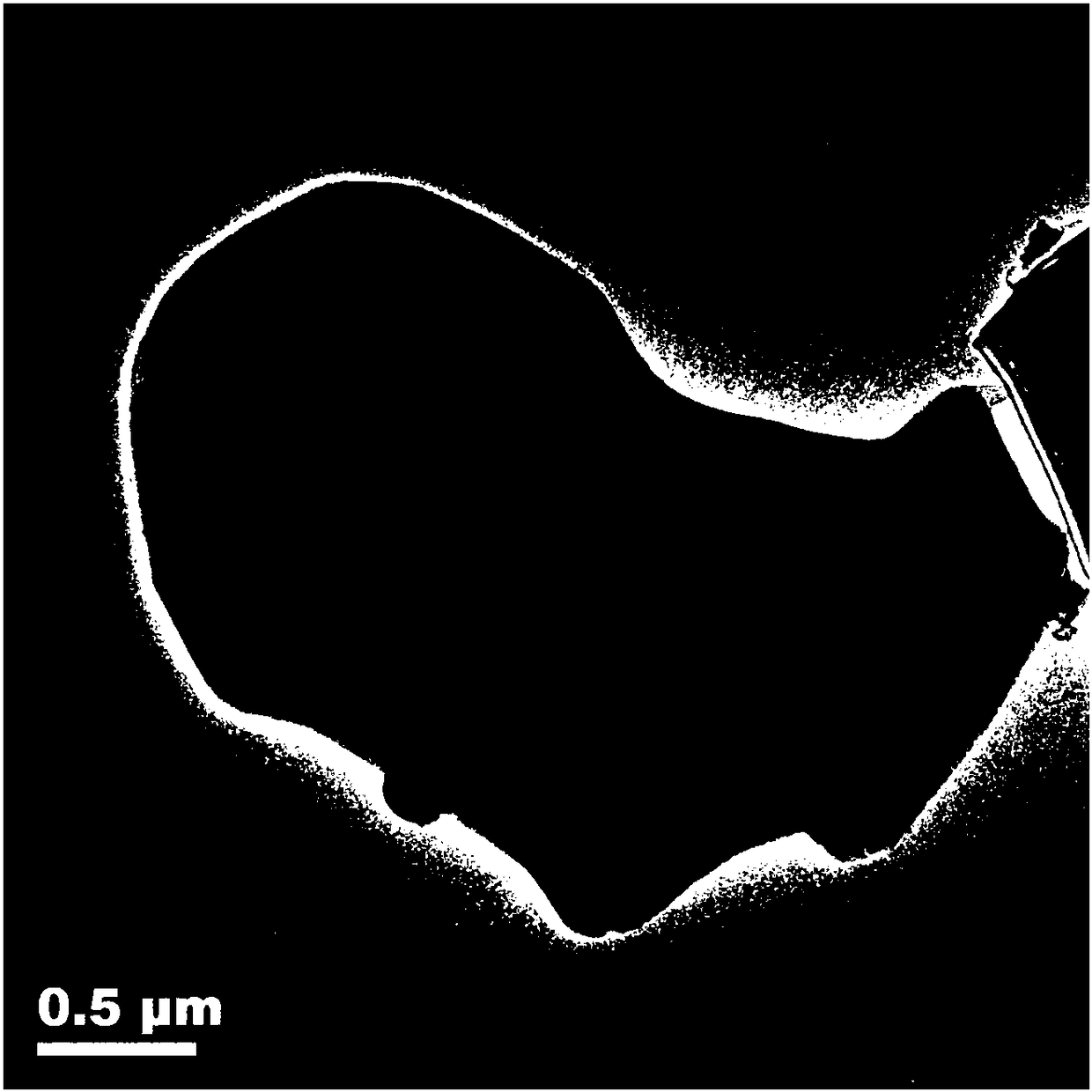

Magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment and preparation method thereof

ActiveCN108033477AImprove high temperature stabilityImprove corrosion resistanceRare earth metal sulfidesMangesium aluminatesVulcanizationSpinel

The invention discloses magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment. The magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment comprises a gamma-Ce2S3 color body servingas an inner core as well as a magnesium aluminum spinel shell wrapping the color body inner core. In addition, the invention also discloses a preparation method of the wrapping type gamma-Ce2S3 red pigment. The preparation method comprises the following steps: preparing a CeO2 precursor which is jointly wrapped by aluminum hydroxide and magnesium hydroxide by a liquid phase method and then performing high-temperature vulcanization treatment further through vulcanization atmosphere and inert atmosphere to prepare the magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment. Through wrapping by the magnesium aluminum spinel, the gamma-Ce2S3 is effectively stabilized, the high-temperature stability of the wrapped and modified pigment is greatly improved and the application field is greatly expanded; furthermore, the process is simple, the reaction is easy to control, the preparation process and the product performance are more stable and reliable, so that industrialized popularization and application are facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Process method of rare earth oxysulfide by using alkali chloride

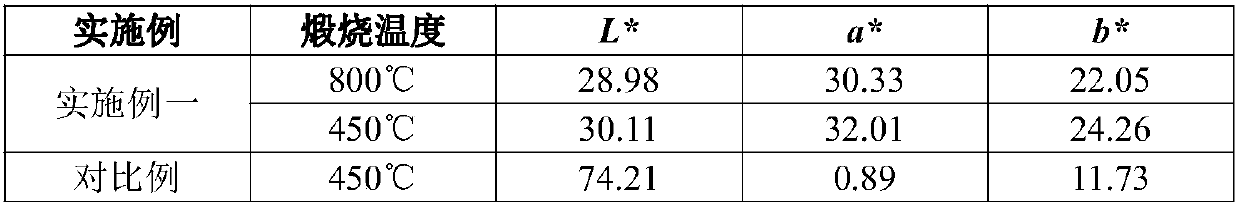

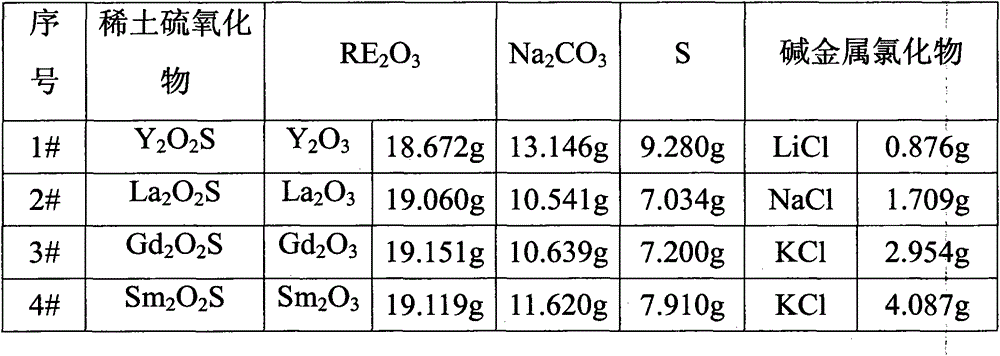

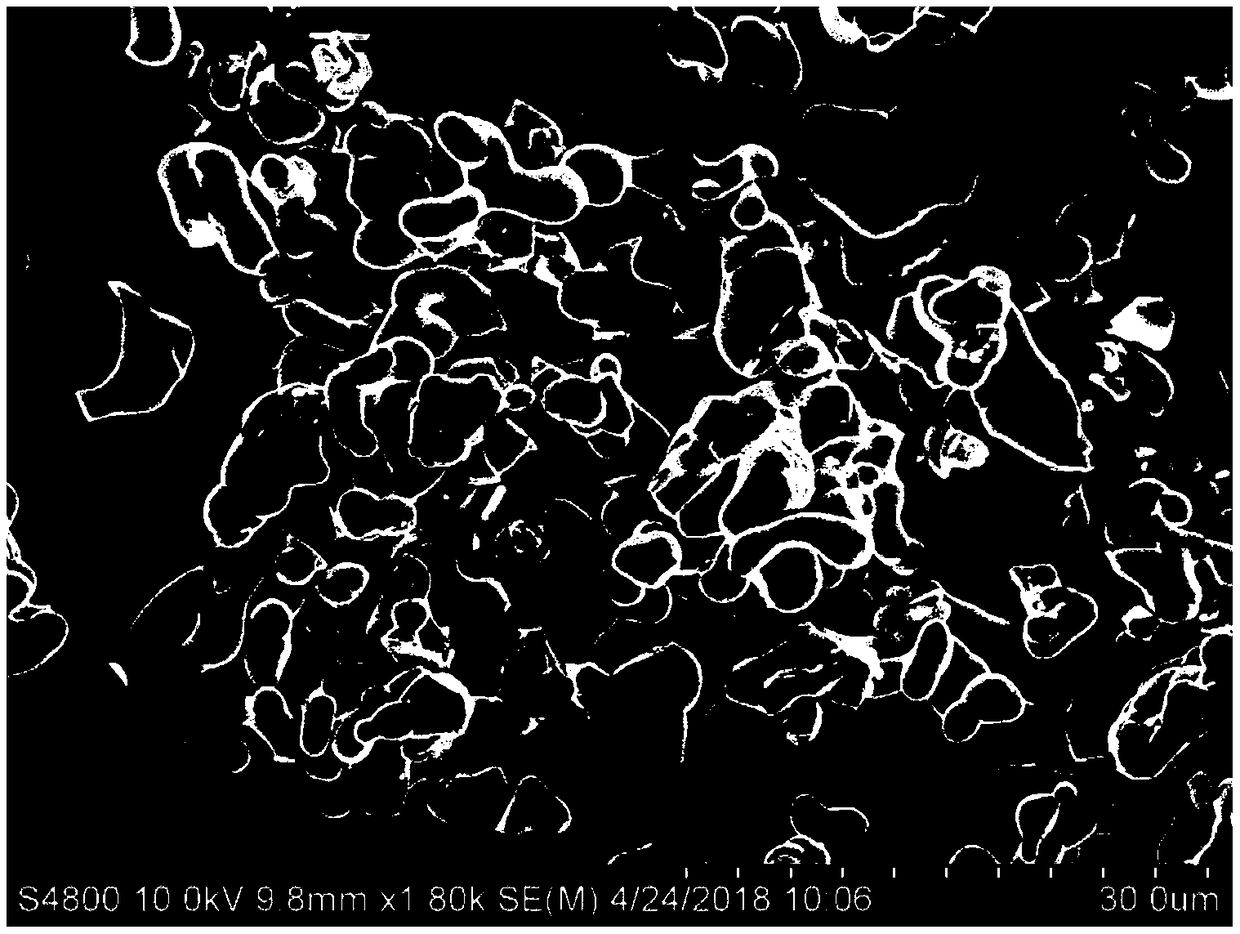

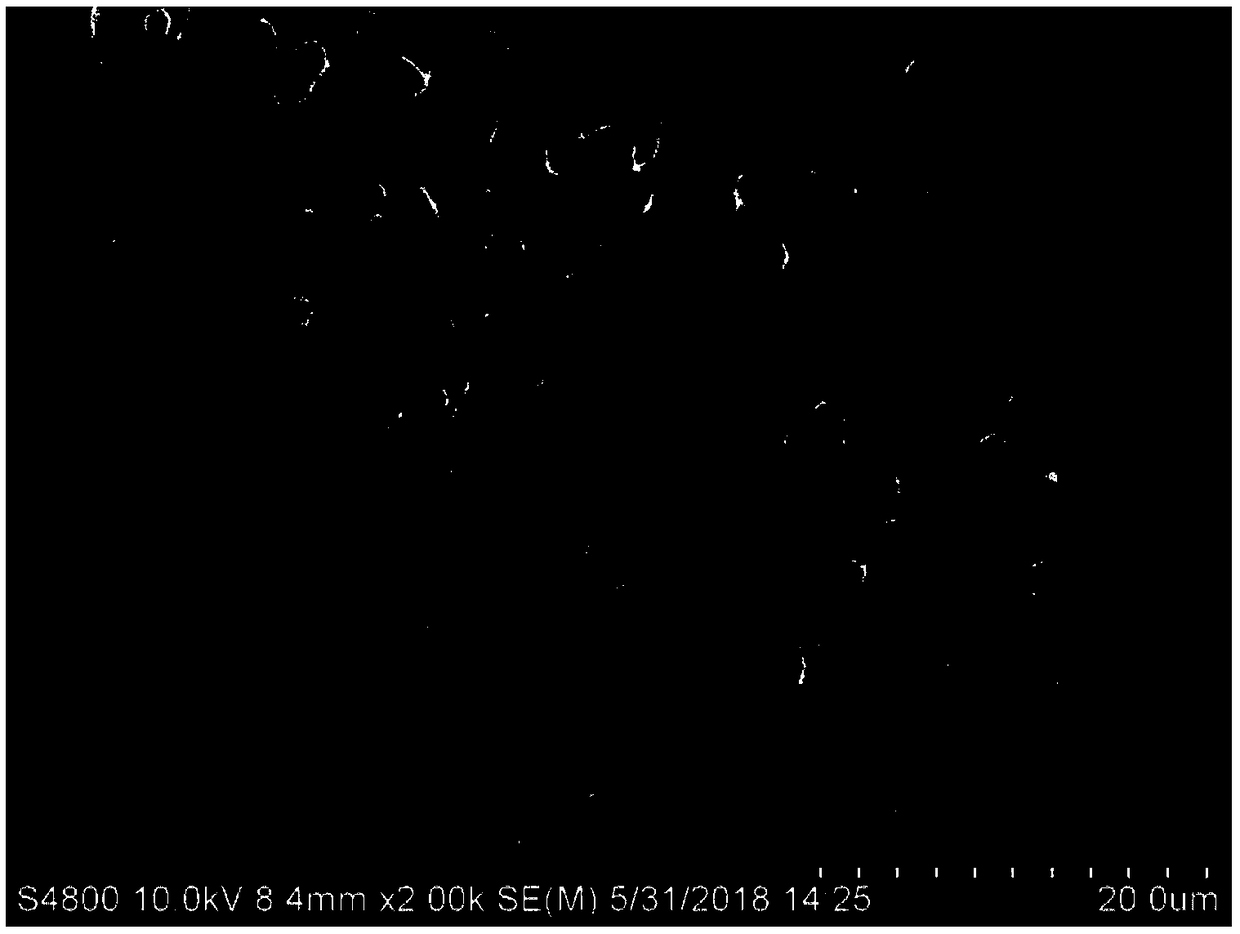

ActiveCN104310454AReduce particle distribution rangeGood light absorption propertiesRare earth metal sulfidesRare-earth elementFiltration

The invention discloses a process method of rare earth oxysulfide by using an alkali chloride. The method comprises the following steps: (1) weighing required materials RE2O2S (wherein RE is one of rare earth elements Y, La, Gd and Sm), Na2CO3, sublimed sulfur and alkali chloride AMCl (wherein AM is one of alkali metal elements Li, Na or K) according to a stoichiometric ratio and uniformly mixing the weighed materials; (2) putting the uniformly mixed materials into inner and outer crucibles, and filling high-temperature powder in the gap between the two crucibles and compacting, where each of the two crucibles has a cover; (3) raising the temperature of the crucibles with the mixed material to 1100-1250 DEG C in a gradient way, sintering for 3-5 hours and then cooling to room temperature along with a furnace; (4) washing the sintered product with hot water, stirring, and carrying out suction filtration; and (5) drying the washed product into a constant-temperature blowing drying box to obtain the rare earth oxysulfide. By taking RE2O3, Na2CO3, sublimed sulfur and alkali chloride AMCl as raw materials, the rare earth oxysulfide is prepared by using a sulfur melting method. The preparation method of the rare earth oxysulfide is simple and easy to operate and the rare earth oxysulfide can be used in the fields of light-emitting materials and photoabsorption materials and the like.

Owner:南通捷事达新材料有限公司

Preparation method of rare earth sulfide and/or rare earth oxysulfide colouring agent

ActiveCN108726556AImprove performanceHigh yieldPigmenting treatmentRare earth metal sulfidesMicrometerRare earth

The invention relates to a preparation method of a rare earth sulfide and / or rare earth oxysulfide colouring agent. The preparation method comprises following steps: a rare earth compound, sulphur, analkali metal compound, an organic auxiliary agent, and a borate are taken as raw materials, and are subjected to drying; the dried raw materials are mixed fully, and are introduced into a die for pressing moulding so as to obtain a powder cake for calcining, and the rare earth sulfide and / or rare earth oxysulfide colouring agent is obtained at last. The product performance of the rare earth sulfide and / or rare earth oxysulfide colouring agent is stable; the yield is high; the lightness is high; the color degree is stable; the particle size is small; the homogeneity is high; the hardness and the stability of the powder cake are improved; transportation, moving, and storage are convenient; the hardness of the powder cake processed through calcining is higher, it is convenient to take the powder cake from a porcelain jar; automatic filling, automatic sampling, impurity removing, and crushing are convenient to realize, and the particle size of particles obtained through crushing is about0.5 to 5 micrometers.

Owner:BAOTOU RARE EARTH RES & DEV CENT CHINESE ACADEMY OF SCI

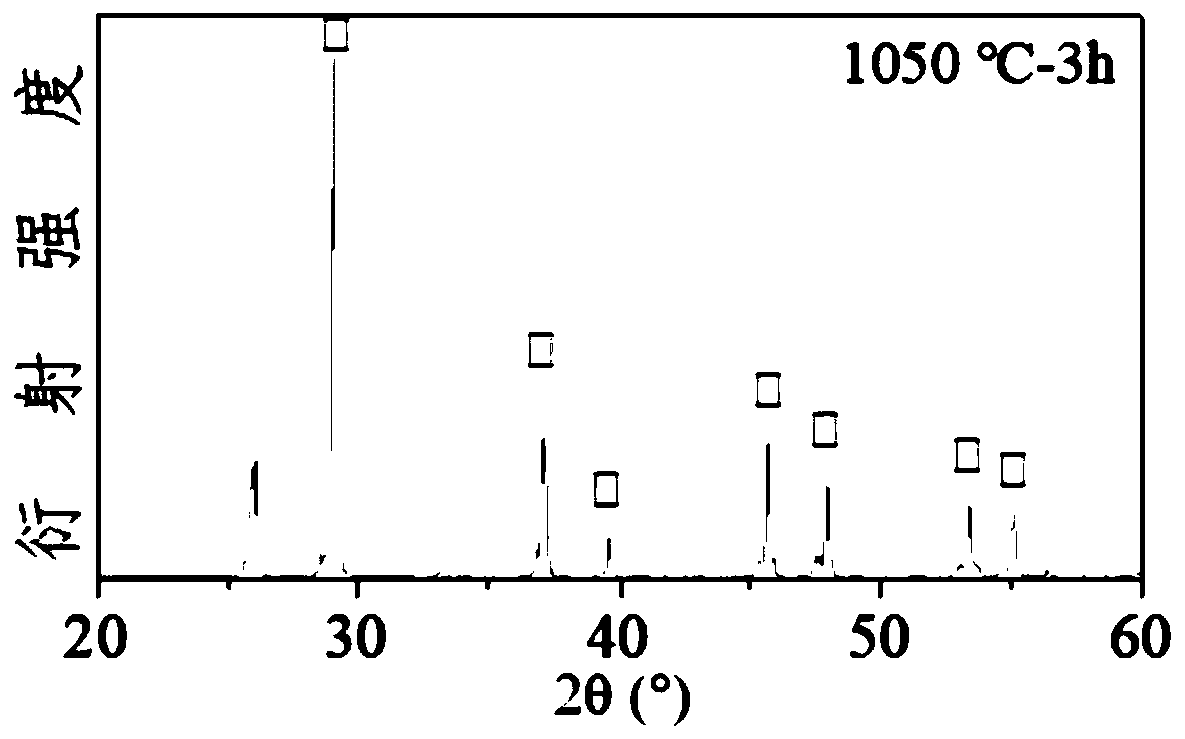

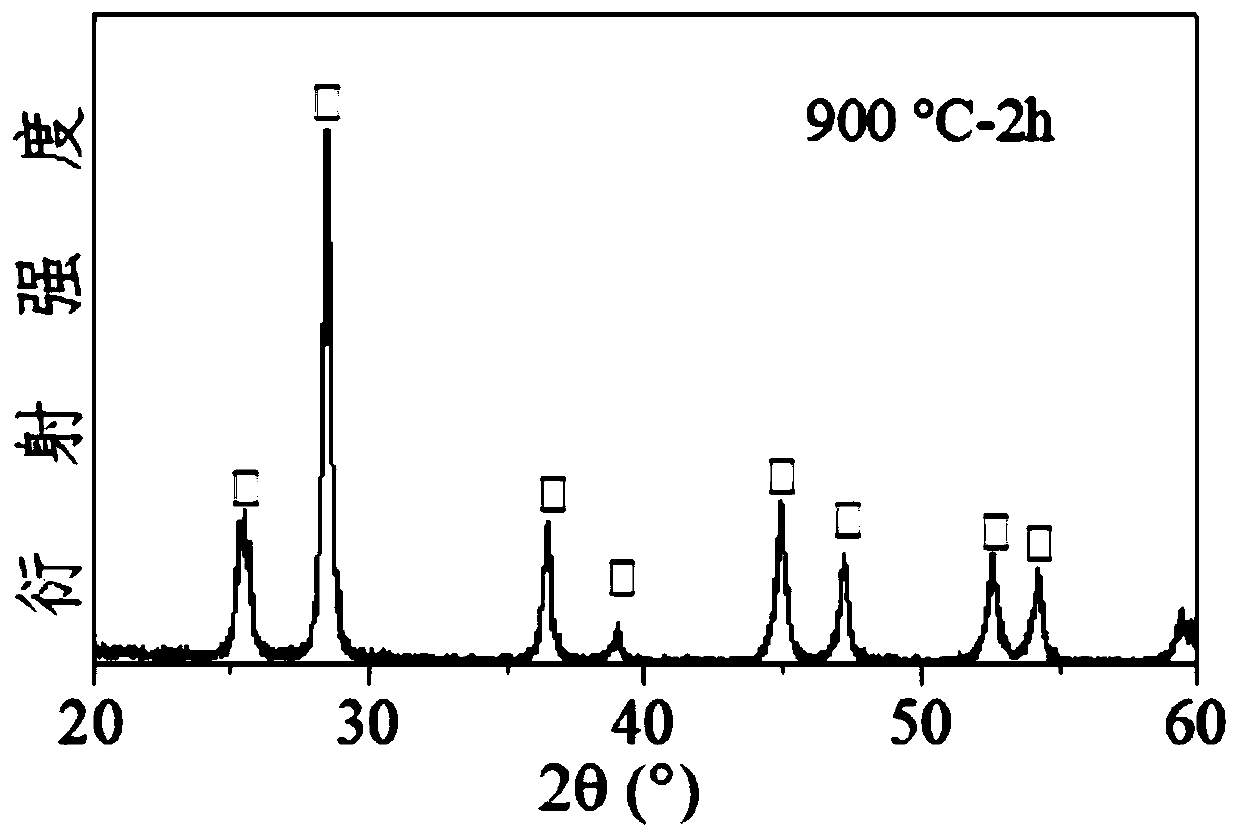

Method for synthesizing high-stability gamma-Pr2S3 powder

The invention relates to a method for synthesizing high-stability gamma-Pr2S3 powder. By virtue of the method, high-purity gamma-Pr2S3 powder with a cubic structure within a temperature range from the room temperature to 1340 DEG C and stable thermodynamics performance at a relatively low preparation temperature and a relative short temperature maintenance time can be obtained. The problems that the vulcanizing temperature is high, the time is long, the cost is high, or the product stability is low, the purity is low, and carbon pollution and sulfur oxide impurities are easily produced in the prior art are solved. Gamma-phase Pr2S3 belongs to a stable phase at a temperature higher than 1340 DEG C, so that praseodymium sulfide powder prepared by virtue of the method can stably preserve a gamma-phase structure in a whole temperature range. Meanwhile, the method is simple in process, low in cost and applicable to the large-scale preparation of high-stability high-purity gamma-phase praseodymium sulfide, and has wide application prospects.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

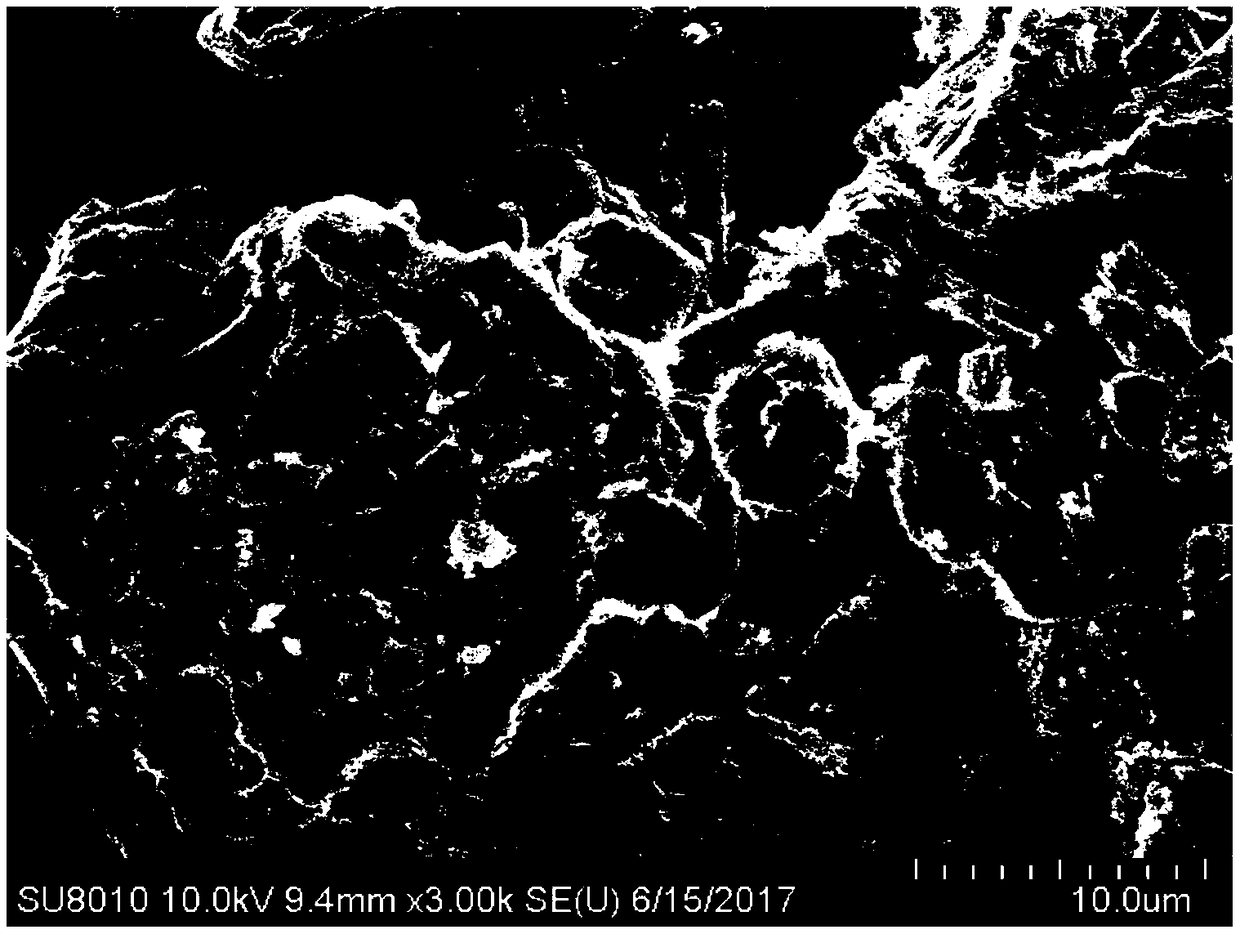

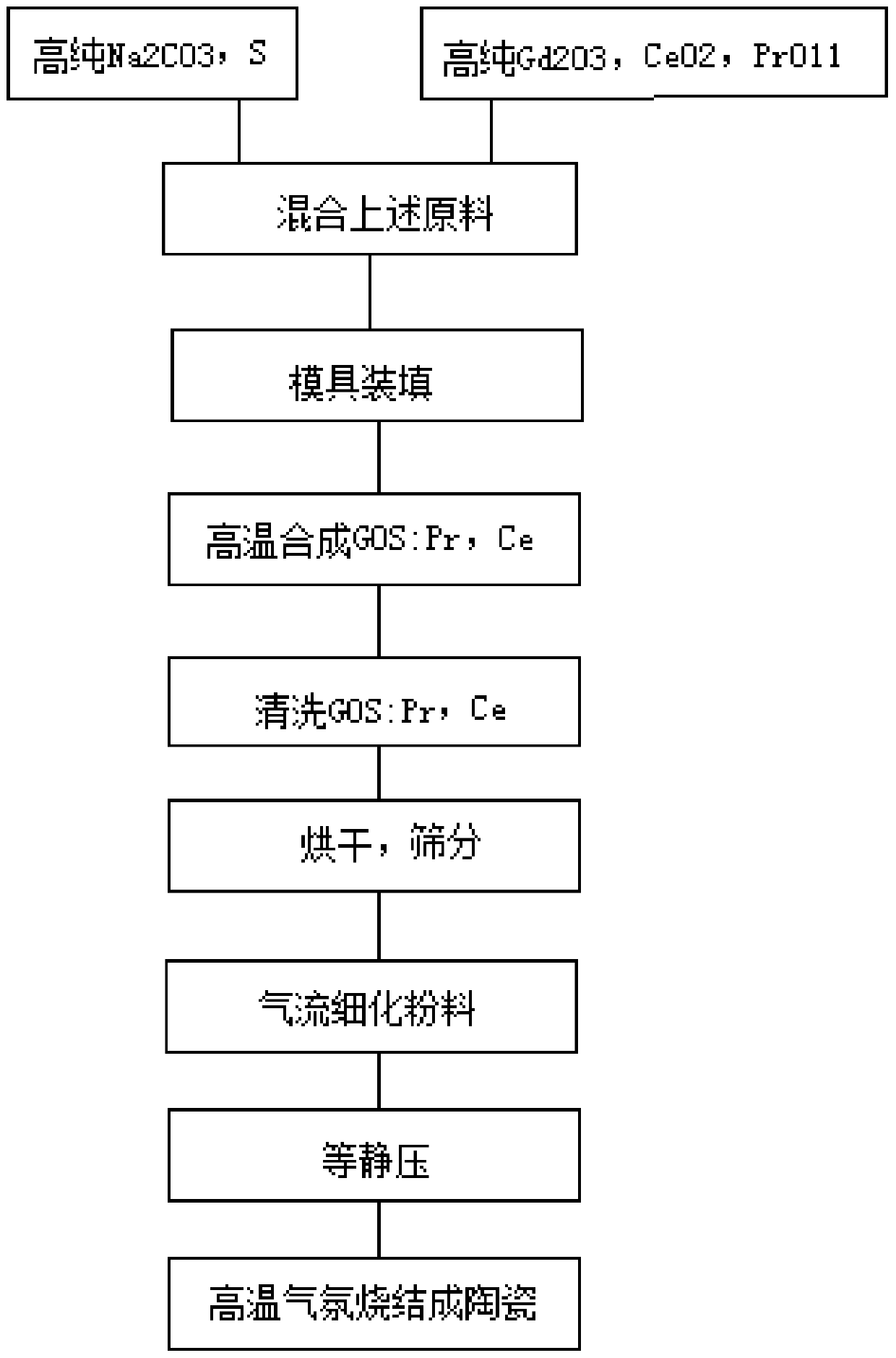

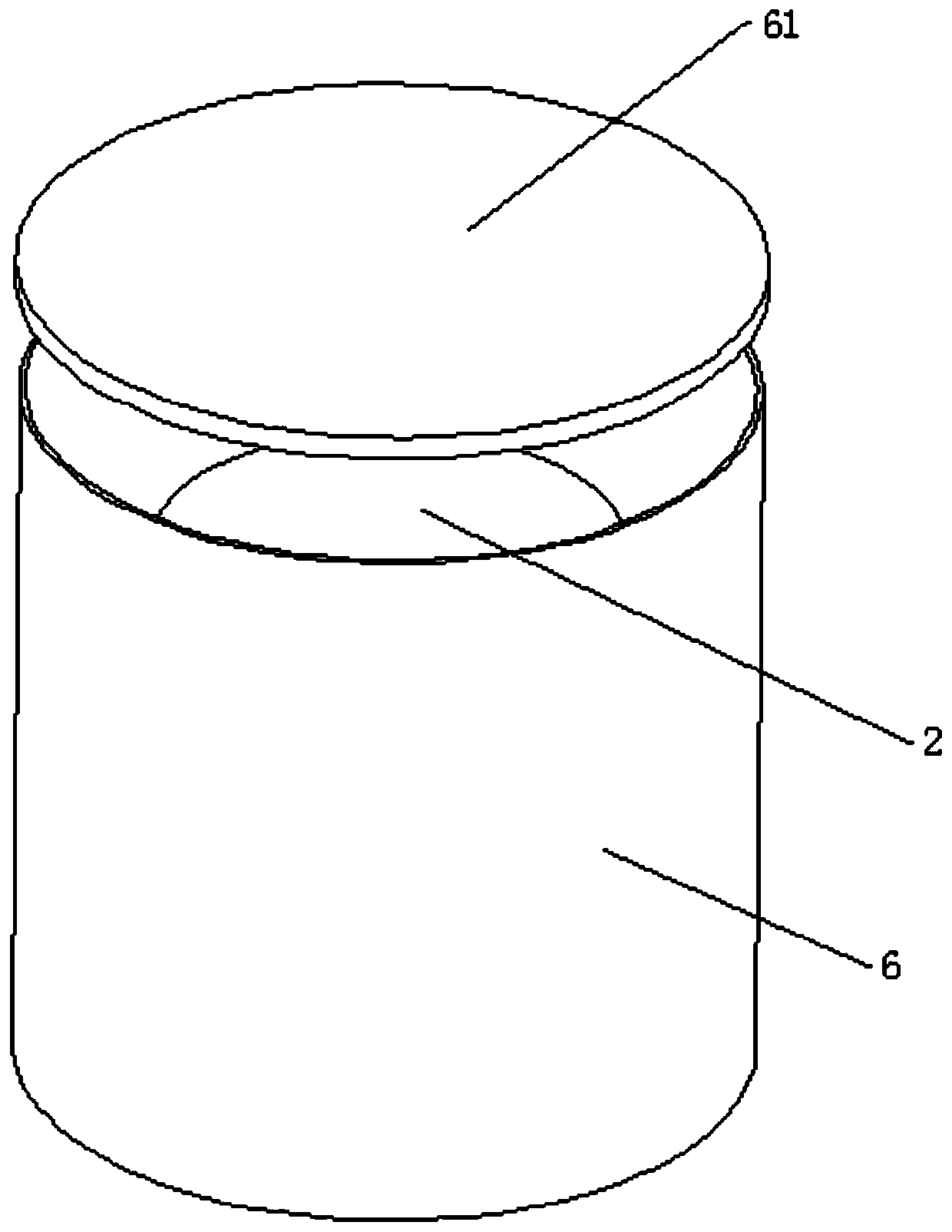

Gadolinium oxysulfide powder for X-ray detection and preparation method of scintillation ceramic

ActiveCN110282650AHigh purityEasy to manufactureRare earth metal sulfidesGadolinium oxysulfideSulfur

The invention discloses gadolinium oxysulfide powder for X-ray detection and a preparation method of scintillation ceramic. The method comprises the steps that high-purity gadolinium oxide, elemental sulfur, sodium carbonate and sodium carbonate powder are mixed to be raw materials, a mold for a special purpose is filled with the raw materials, the raw materials further include rare earth activated ions or rare earth oxide, and the raw materials are subjected to a high temperature reaction and washing to form Gd2O2S:Pr,Ce powder. Accordingly, an independent reduction reaction system is provided, the productivity is high, and the effect of uniform granulation is achieved.

Owner:江苏灵湾特种陶瓷科技有限公司

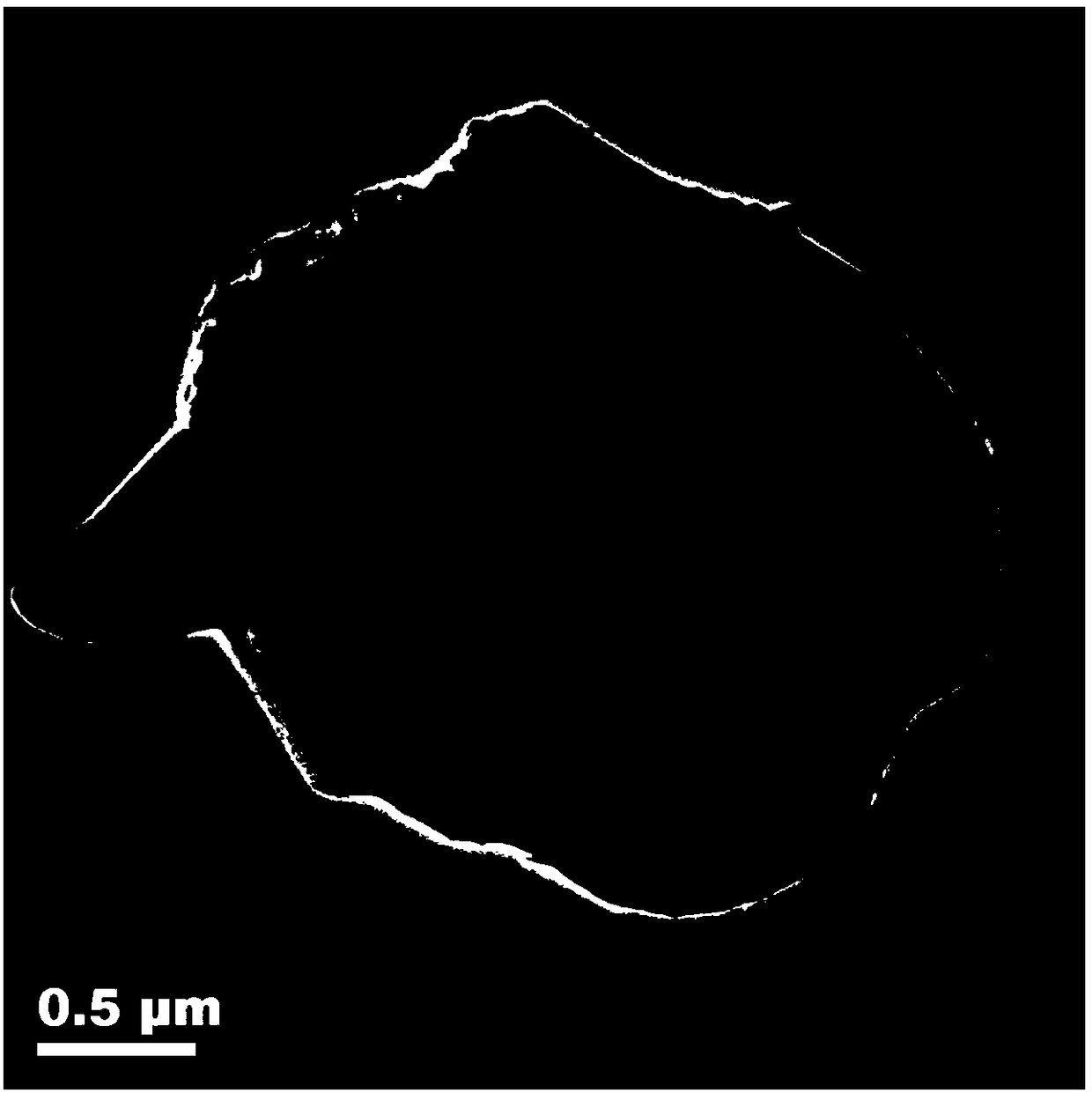

Preparation method of aluminum oxide coated gamma-Ce2S3 red pigment and product prepared by preparation method

ActiveCN108219536AImprove high temperature stabilityGuaranteed decentralizationRare earth metal sulfidesInorganic pigment treatmentVulcanizationHeat treated

The invention discloses a preparation method of an aluminum oxide coated gamma-Ce2S3 red pigment. The preparation method comprises the following steps: firstly, preparing an aluminum hydroxide coatedCeO2 precursor through a liquid-phase method; then carrying out vulcanization atmosphere and inert atmosphere high-temperature vulcanization heat treatment to obtain the aluminum oxide coated gamma-Ce2S3 red pigment. Furthermore, the invention further discloses a product prepared by the preparation method. According to the preparation method disclosed by the invention, gamma-Ce2S3 is effectively stabilized through coating aluminum oxide, so that the high-temperature stability of the coated modified pigment is greatly improved and an application field of the pigment is extremely expanded; the preparation method disclosed by the invention has the advantages that a technology is simple, reaction is easy to control, and a preparation process and product performance are more stable and reliable, so that industrialized popularization and application is facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Compound semiconductor particles and production process therefor

InactiveUS7407894B2Function increaseIncrease production capacityMaterial nanotechnologyRare earth metal sulfidesProduction rateLuminosity

There are provided: compound semiconductor particles that can display more excellent performance in functions peculiar to the compound semiconductor (e.g. luminosity and luminescence efficiency); and a production process for obtaining such compound semiconductor particles with economy, good productivity, and ease.Compound semiconductor particles, according to the present invention, are characterized by comprising body particles and a metal oxide, wherein the body particles have particle diameters of smaller than 1 μm and are covered with the metal oxide and include a compound semiconductor including an essential element combination of at least one element X selected from the group consisting of C, Si, Ge, Sn, Pb, N, P, As, Sb, S, Se, and Te and at least one metal element M that is not identical with the element X, and wherein the metal oxide is a metal oxide to which an acyloxyl group is bonded.

Owner:KOBAYASHI MASAKAZU +1

Zirconium silicate-coated low-valence ion co-doping gamma-Ce2S3 red pigment and preparation method thereof

ActiveCN107758720AImprove high temperature stabilityExtended temperature rangeRare earth metal sulfidesSilicon compoundsCrystal structurePhysical chemistry

The invention discloses a zirconium silicate-coated low-valence ion co-doping gamma-Ce2S3 red pigment which is composed of low-valence ion co-doping gamma-Ce2S3 red pigment powder and a zirconium silicate transparent shell coating the surface of the low-valence ion co-doping gamma-Ce2S3 red pigment powder, wherein in the low-valence ion co-doping gamma-Ce2S3 red pigment powder, the ion valence ofthe doping ion M is 2, and at least two doping ions exist according to a molar ratio of 2(1-x):3x between Ce<3+> and M(total), where x is greater than 0 and less than or equal to 0.1. The invention also discloses a preparation method of the gamma-Ce2S3 red pigment. According to the zirconium silicate-coated low-valence ion co-doping gamma-Ce2S3 red pigment disclosed by the invention, the gamma-Ce2S3 crystal structure is stabilized internally through a way of low-valence ion co-doping while the gamma-Ce2S3 is coated externally with zirconium silicate which is stable at high temperature, therebyremarkably improving the high-temperature stability of the gamma-Ce2S3 red pigment and significantly expanding the application field of the gamma-Ce2S3 red pigment. The preparation method disclosed by the invention has the advantages that the technology is simple and easy to operate, the influence factors are easy to control, the production cost is low and the promotion and application are facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Rare earth oxysulfide taken as lubricating oil additive, and preparation method thereof

ActiveCN110203960AGood effectImprove high temperature resistanceRare earth metal sulfidesAdditivesRare-earth elementOil additive

The invention provides a rare earth oxysulfide taken as a lubricating oil additive, and a preparation method thereof. The rare earth oxysulfide comprises a general formula Ln2O2S, wherein Ln is used for representing a rare earth element. The preparation method comprises following steps: 1, rare earth oxide Ln2O3 is weighed, and is introduced into a ball milling machine for ball milling, after ballmilling, rare earth sulfide Ln2S3 is weighed, and is added for continuous ball milling; 2, a slurry obtained in step is heated until complete evaporation of an organic solvent is realized, and sieving is carried out so as to obtain an initial mixture; 3, the initial mixture is introduced into a sintering furnace for sintering, and then grinding and sieving are carried out so as to obtain a singlephase rare earth oxysulfide Ln2O2S; and 4, the single phase rare earth oxysulfide Ln2O2S is added into an organic solvent, a surfactant is added, centrifugation, washing, and drying are carried out so as to obtain the rare earth oxysulfide taken as a lubricating oil additive. The Ln2O2S is convenient to prepare; bath production can be realized; the product is suitable for high temperature friction environment; and the friction coefficient is low.

Owner:NANYANG NORMAL UNIV

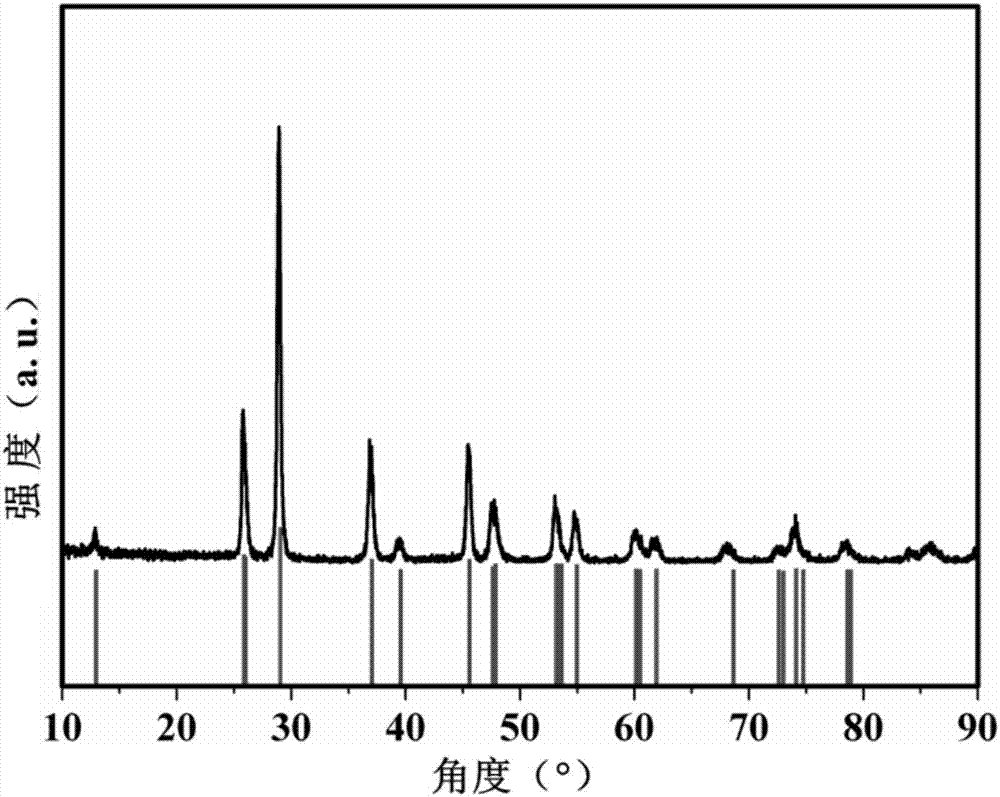

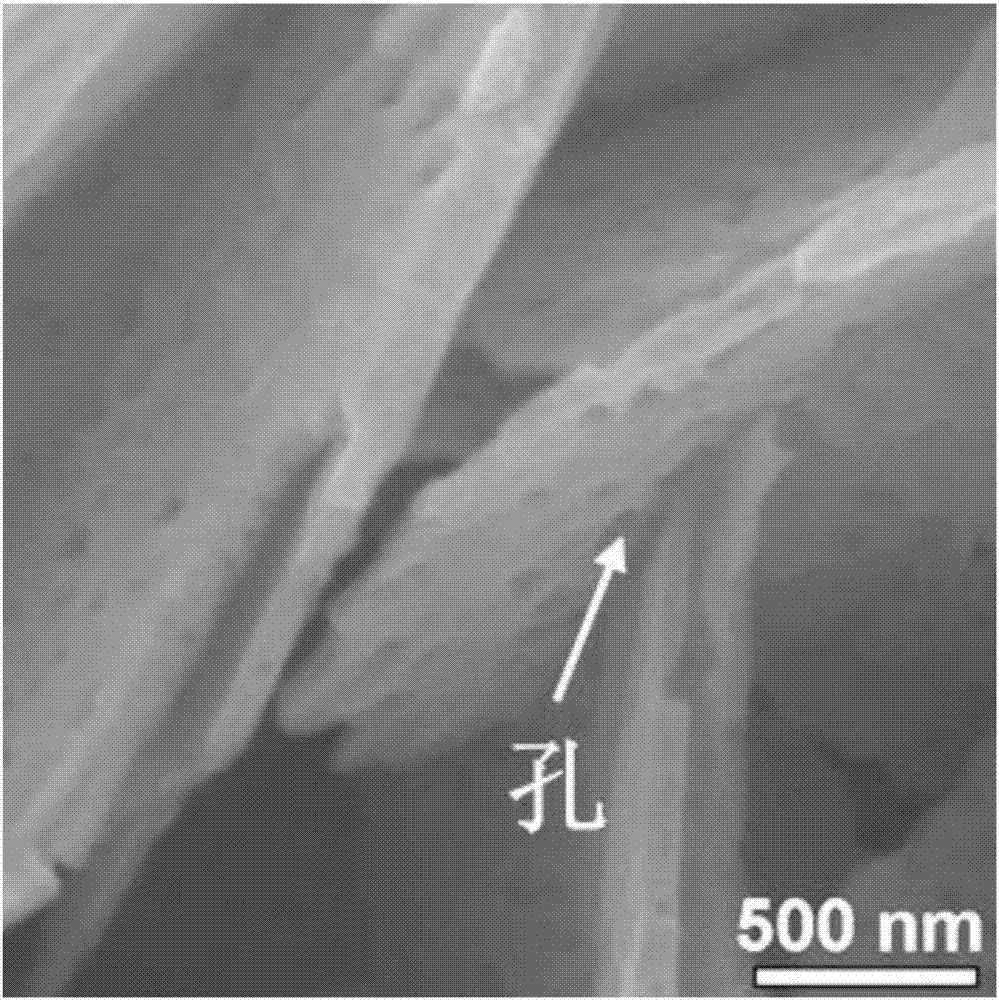

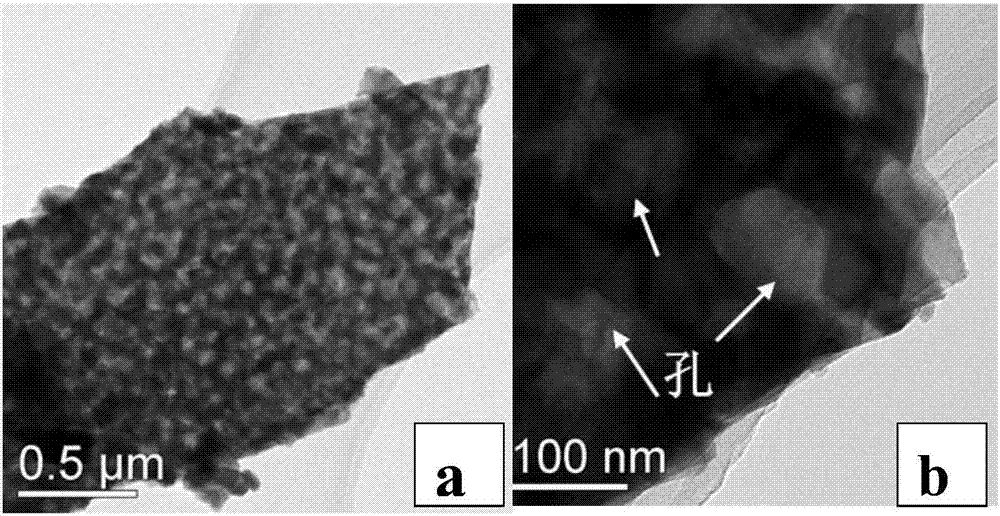

Preparation method of cerium oxysulfide porous nano-sheets

InactiveCN107416886AHigh specific surface areaSimple conditionsRare earth metal sulfidesNanotechnologyThioureaCerium

The invention discloses a preparation method of cerium oxysulfide porous nano-sheets. The preparation method includes the steps: (1) mixing thiourea group compounds and cerium salt solution, adding ethylene glycol amine into mixture of the thiourea group compounds and the cerium salt solution, and performing hydrothermal reaction and cooling; (2) filtering substances acquired after cooling of mixture in the step (1), cleaning and drying filter residues, performing hydrothermal reaction and cooling, and collecting samples to obtain the cerium oxysulfide porous nano-sheets. According to the method, cheap cerium salt, thiourea and the like serve as precursors, cerium oxysulfide is prepared by the aid of hydrothermal reaction and heat treatment, the prepared cerium oxysulfide is provided with pure-phase mono-crystal nano-sheets, the nano-sheets have mutually penetrated holes, so that the specific surface area of a cerium oxysulfide material is improved, and the preparation method is simple in reaction condition and device, simple, convenient, easy, economical and environmentally friendly and has great potential practical values.

Owner:GUANGXI UNIV

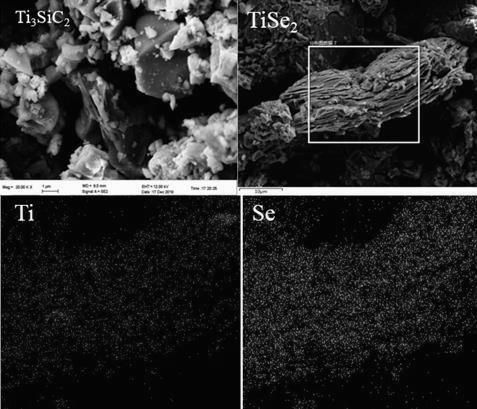

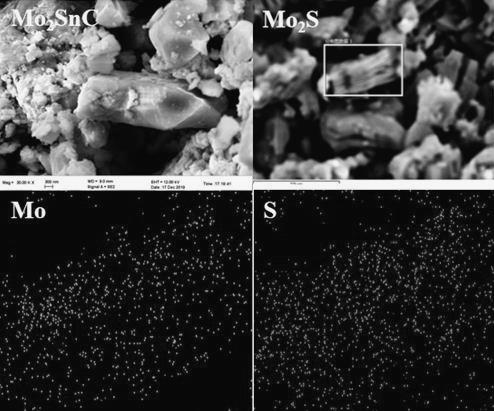

Preparation method for preparing two-dimensional layered transition metal sulfide

PendingCN111333040AEasy to getLow priceTitanium sulfidesRare earth metal sulfidesManufactured materialSulfide compound

The invention discloses a preparation method for preparing two-dimensional layered transition metal sulfide. The two-dimensional layered transition metal sulfide is mainly an MAX-phase ceramic powderraw material composed of the following elements. Wherein the M element is Ti, Nb, V, Y, Nb, Mo, Ta, W, Hf, Cr and Mn; wherein the element A is Al, Si, Ge, Sn, Ga and Sb; powder of max-phase ceramic ofwhich the X element is B, C, N and Si and powder of MAB-phase ceramic are used as raw materials; in the atmosphere containing H2S, H2Se and H2Te gas, the powder is heated for more than 5 hours withinthe temperature range of 500-1400 DEG C, and organ-shaped TMDCS powder can be obtained after the obtained powder is subjected to ball milling. According to the method, a CVD method and a mechanical stripping high-cost method for preparing the TMDCS are eliminated, an organ-shaped structure which cannot be obtained through the CVD method and the mechanical stripping method can be obtained, the cost is obviously reduced, and application and popularization of a two-dimensional TMDCS material are often facilitated.

Owner:苏州凯发新材料科技有限公司

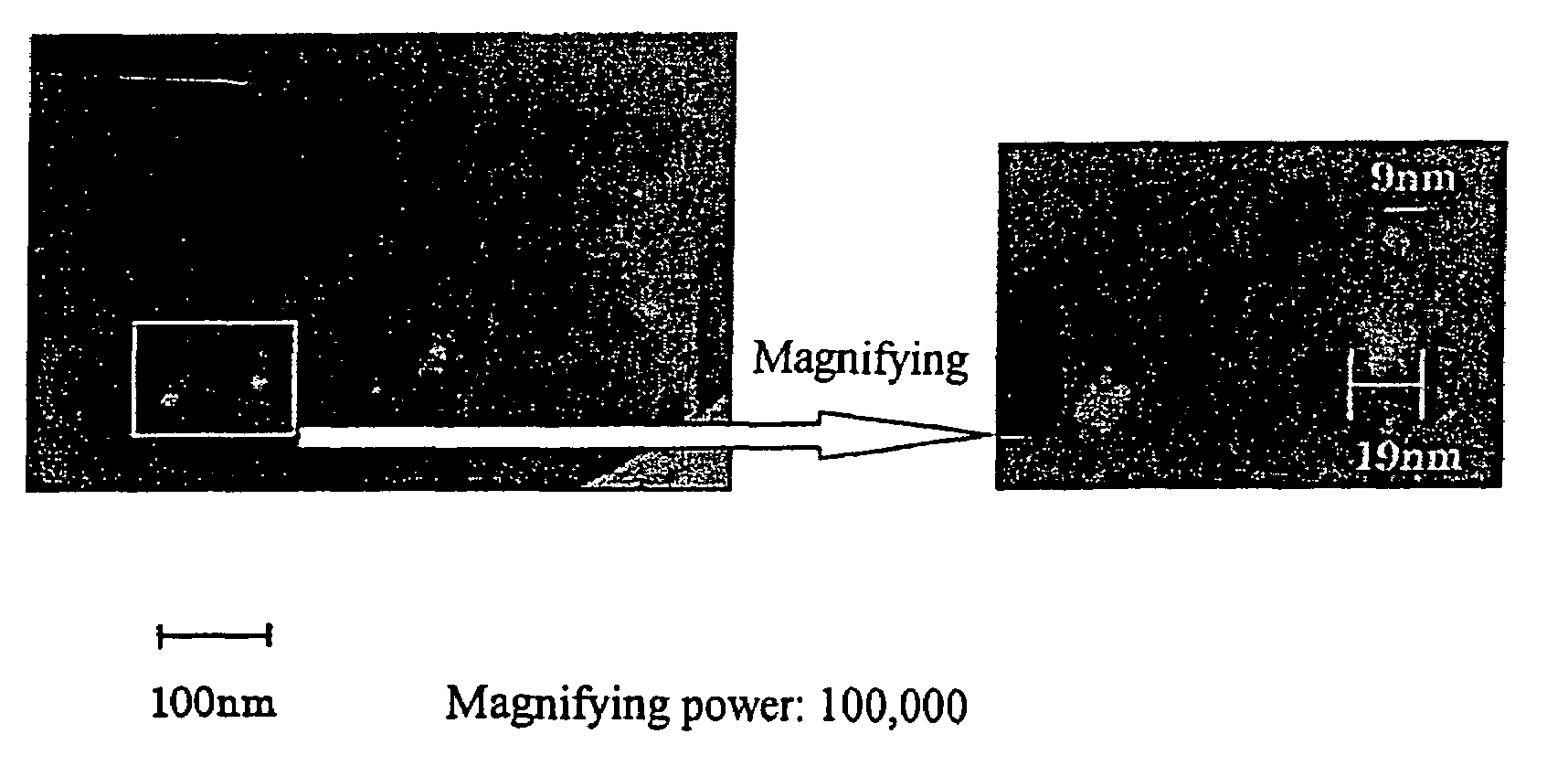

Preparation method of novel rare earth red pigment gamma-Ce2S3

ActiveCN111484065AHigh tinting strengthHigh glossRare earth metal sulfidesRare earth metal compounds preparation/treatmentPhotopigmentCombinatorial chemistry

The invention discloses a preparation method of a novel rare earth red pigment gamma-Ce2S3. The preparation method comprises the following steps: preparing modified CeO2 composite nano precursor powder and calcining and molding the red pigment gamma-Ce2S3. The preparation method of the modified CeO2 composite nano precursor powder comprises the following steps: preparing a CeCl3 solution and a Na2S solution, preparing a CeO2 precursor sample, preparing a CeO2 nano powder precursor and molding the modified CeO2 composite nano powder precursor. The calcining and forming process of the red pigment gamma-Ce2S3 comprises the following steps: calcining the modified composite nano-powder precursor and forming the red pigment gamma-Ce2S3. The red pigment gamma-Ce2S3 prepared by the preparation method disclosed by the invention has the advantages that the tinting strength, glossiness, purity and color intensity are obviously improved, meanwhile, the adhesive force is also obviously enhanced, the experiment result is stable through repeated experiments, and the preparation method is simple and reliable.

Owner:甘肃翔达新颜料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com